Deoxidation energy conservation method by heating energy conservation technological improved apparatus of deoxidation device by heating

A technology for thermal deaeration and energy-saving transformation, which is applied in the field of thermal deaeration of boiler feed water and energy-saving thermal deaerators. The effect of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

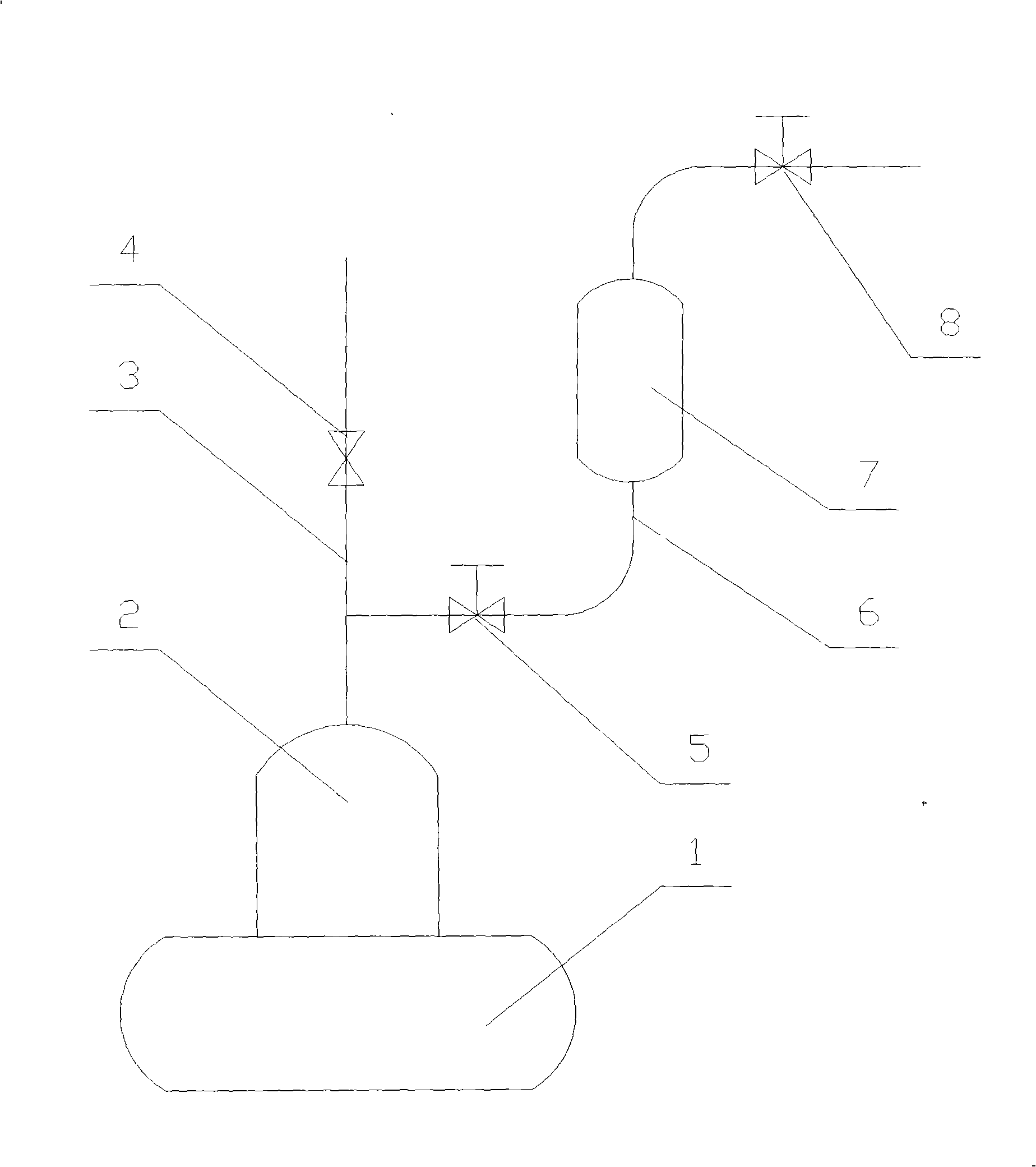

[0008] The main functions of the present invention are firstly to reduce the discharge of steam as much as possible while ensuring the effective discharge of oxygen, and secondly to form a stable pressure in the deaeration tower to increase the temperature in the deaeration tower and strengthen the deoxygenation effect.

[0009] Therefore, when implementing the method of the present invention, in addition to avoiding exceeding the maximum design pressure of the equipment for the control of the exhaust of the gas storage tank based on the pressure requirements in the deoxidation tower, it is also necessary to ensure a certain non-discharge time. The overall space formed by the gas storage tank forms a relatively stable layered distribution state of water, steam and gas, so that all or most of the space in the gas storage tank is dominated by gases such as oxygen, and the connecting pipe is closed when exhausting The connecting valve on the top, the material discharged outside is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com