Magnetic-acoustic field synergistically enhanced sponge iron water deoxygenizing component

A technology of sponge iron and field synergy, which is applied in the fields of magnetic field/electric field water/sewage treatment, degassed water/sewage treatment, mechanical oscillation water/sewage treatment, etc., and can solve problems such as interruption of water discharge, slow process, and low dissolved oxygen content , achieve the effects of enhanced oxygen removal capacity, reduced oxygen removal cost, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

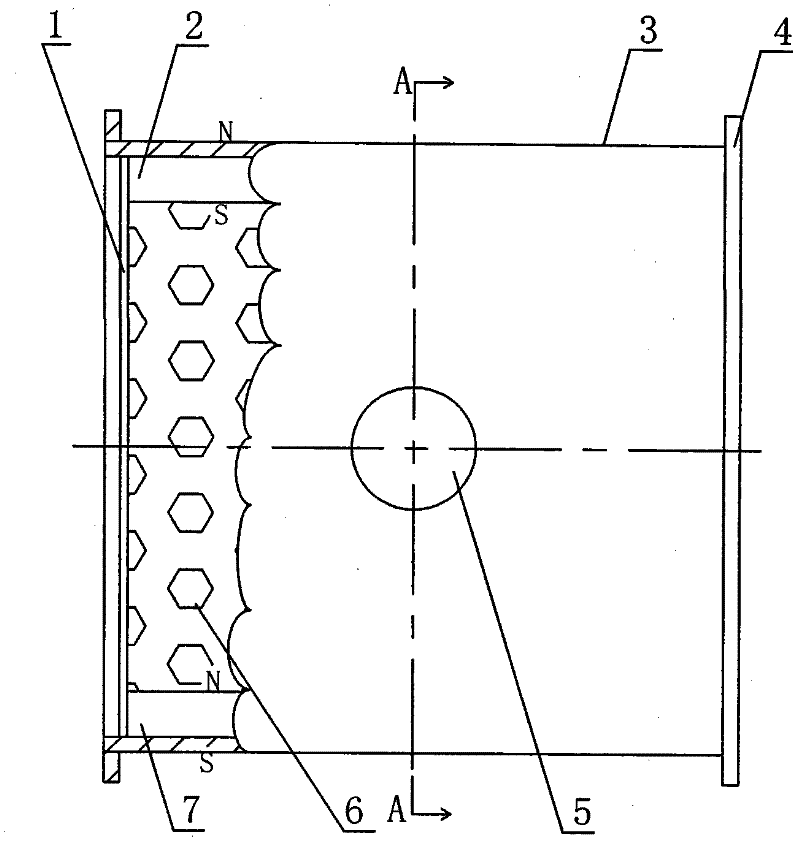

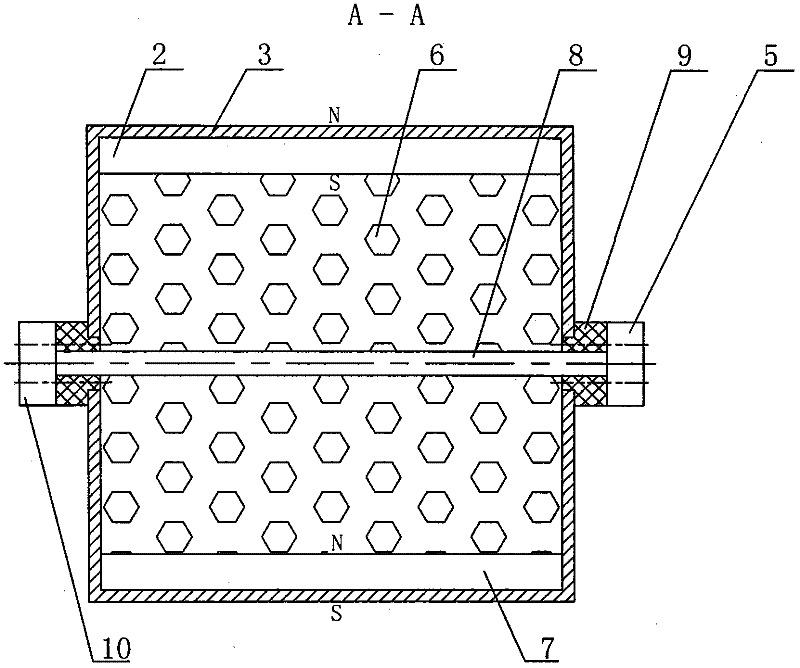

[0019] exist figure 1 , 2 Among them, the magneto-acoustic field synergistically strengthened sponge iron water body deoxygenation component consists of a filter screen 1, an upper permanent magnet 2, a housing 3, a flange 4, a front power ultrasonic transducer 5, sponge iron particles 6, and a lower permanent magnet. A magnet 7, a radial ultrasonic radiation tube 8, a rubber gasket 9, and a rear power ultrasonic transducer 10 are connected to form an upper permanent magnet 2, a lower permanent magnet 7, sponge iron particles 6, a radial ultrasonic radiation tube 8, and a front power ultrasonic transducer 10. The ultrasonic transducer 5 and the rear power ultrasonic transducer 10 are connected to form an oxygen removal unit.

[0020] The housing 3 of this embodiment is a tubular body with a rectangular cross section, and the left and right ends of the housing 3 are fixedly connected with a flange 4 with a threaded fastening connector, and the flange 4 is used to connect the p...

Embodiment 2

[0022] In Embodiment 1, flanges 4 are fixedly connected to the left and right ends of the housing 3 with threaded fasteners, and a deaeration unit is installed on the housing 3, and the permanent magnet 2 and the Sponge iron particles 6 are installed between the lower permanent magnets 7 and between the two filter screens 1, and the particle diameter of the sponge iron particles 6 is 3-7mm. Other components and the coupling relationship of the components are exactly the same as in Embodiment 1.

Embodiment 3

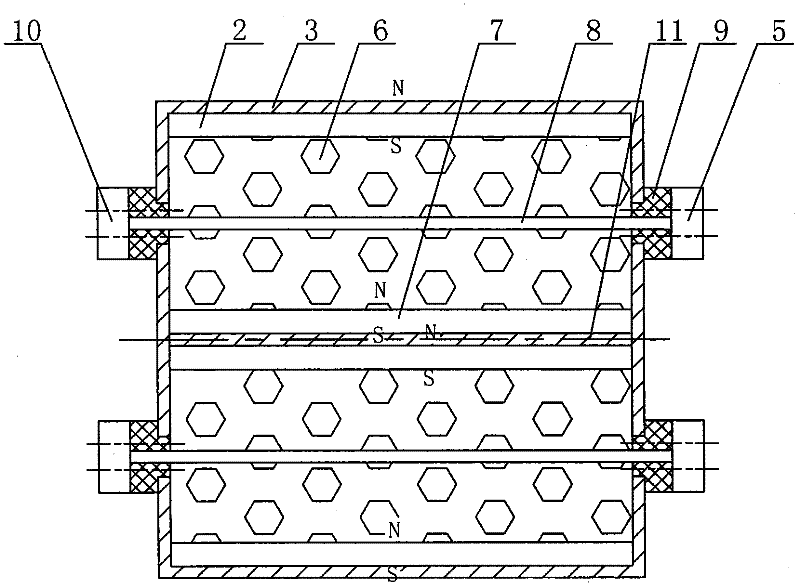

[0024] exist image 3 Among them, two deoxygenation units are installed on the housing 3, and the two deoxygenation units are installed on the housing 3 in parallel, and a partition is installed between the two deoxygenation units, and the partition is a non-magnetic partition. The parts used in the two deaeration units and the connection relationship of the parts are exactly the same as those of the deaeration unit in embodiment 1. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com