Oily wastewater treatment device and oily wastewater treatment method using same

A technology for wastewater treatment and wastewater, which is applied in the fields of permeation/dialysis water/sewage treatment, separation methods, chemical instruments and methods, etc. It can solve the problems of adverse environmental impact, increased treatment costs, and high water content of oily wastewater, so as to reduce treatment costs. , The effect of smooth wastewater treatment and improvement of concentration rate

Inactive Publication Date: 2019-02-05

AZTECH CORP

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, treatment methods such as evaporation or combustion in an incinerator have a problem of increased treatment costs due to the high water content of oily wastewater and the need for a large amount of energy for combustion.

In addition, when the recovered oil is incinerated, a large amount of carbon dioxide (CO 2 ), therefore, has the problem of adversely affecting the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0126] Hereinafter, the oily wastewater treatment device of the present invention will be further described based on examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

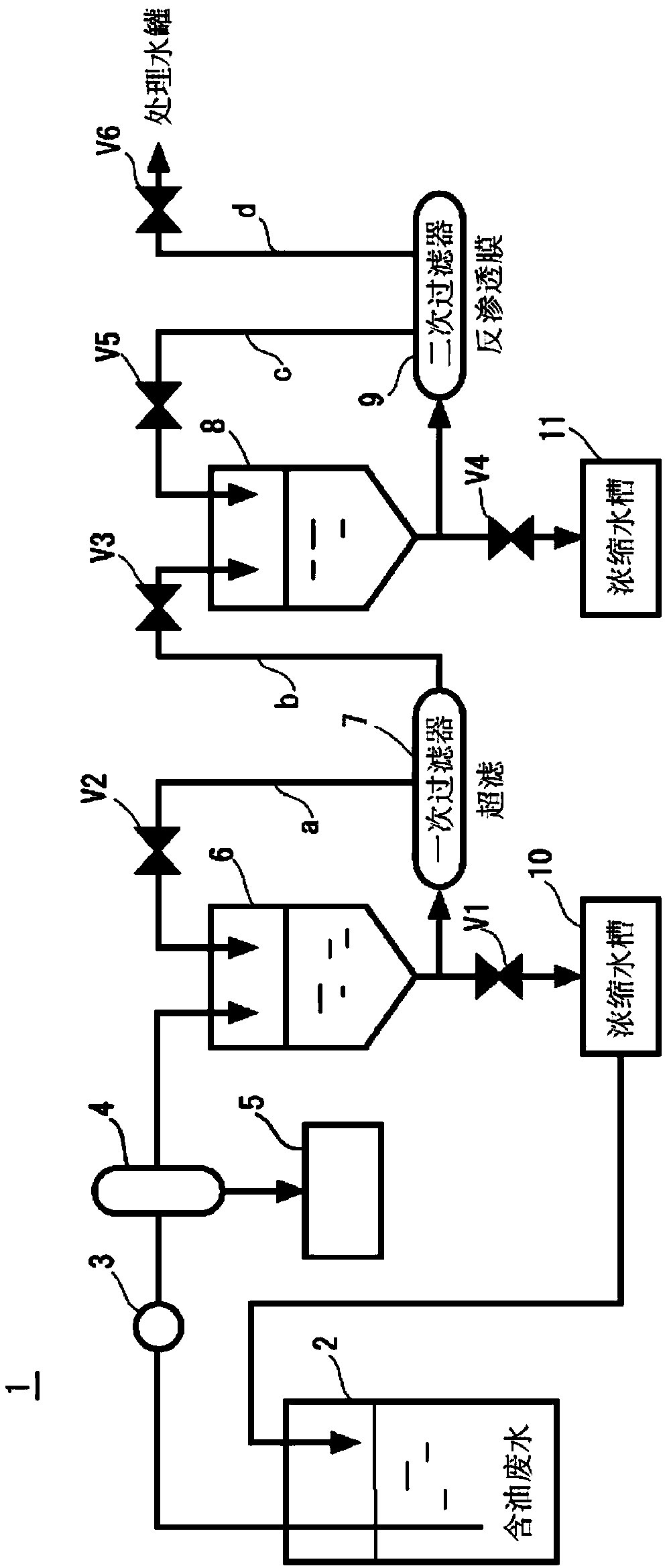

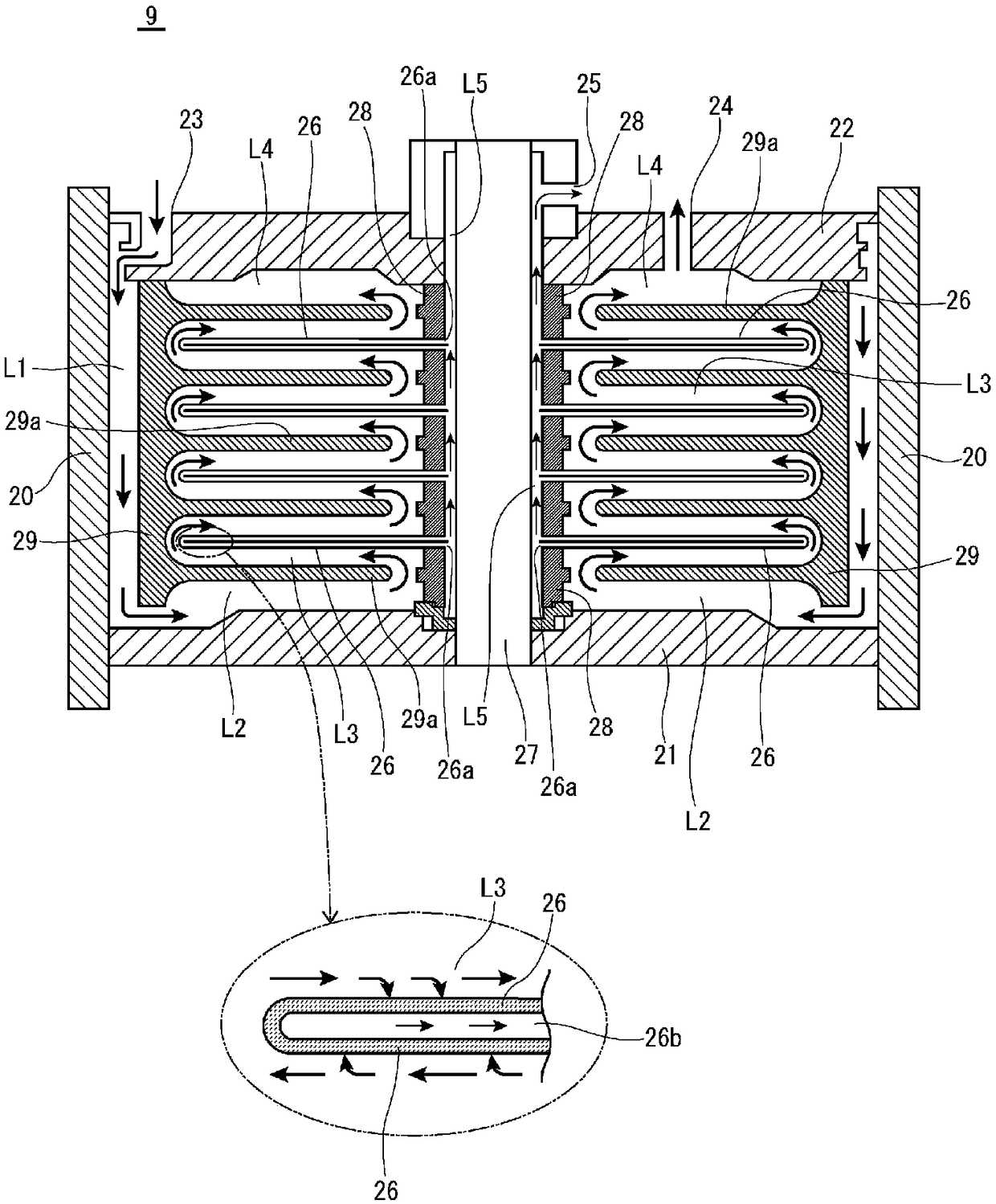

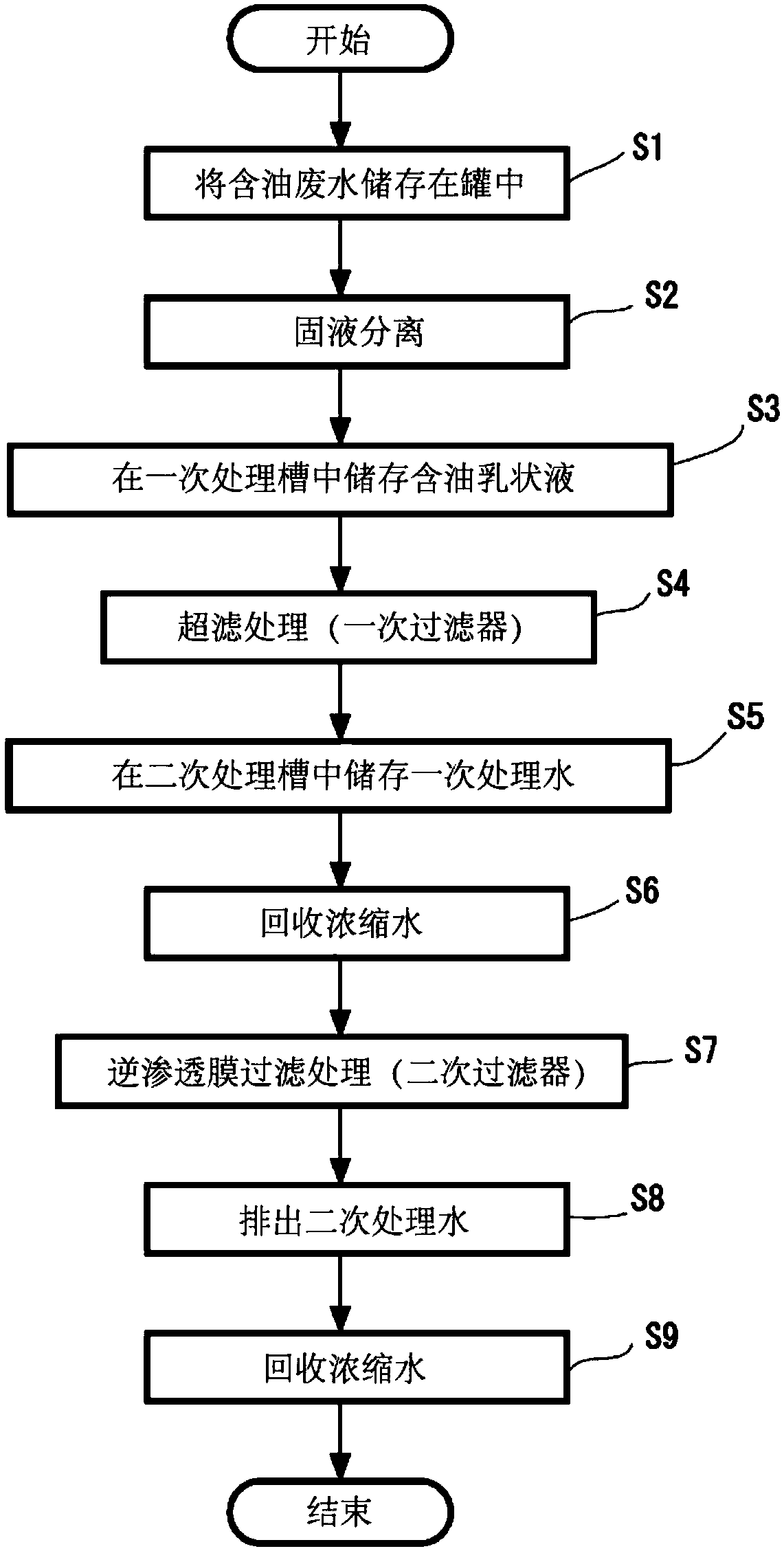

Provided are an oily wastewater treatment device that can process smoothly, can reduce costs for processing, and can perform wastewater treatment capable of purifying water to a level below the release standard value for public waters with little impact on the environment and an oily wastewater treatment method using same. An oily wastewater treatment device 1 comprises: a primary filter unit 7 that performs ultrafiltration on an oil-containing emulsion contained in oil-containing wastewater and that separates the oil-containing emulsion into an oil component and primary treated water; and a secondary filter unit 8 that performs a filtration treatment using a reverse osmosis membrane on the primary treated water separated by the first filter unit and that separates the primary treated water into low-molecular-weight impurities that were not removed by the primary filter unit and secondary treated water. The primary filter unit 7 is a filter having an ultrafiltration membrane filter structure of a tubular membrane type or a spiral membrane type, and the secondary filter unit 8 is a filter having a filter structure in which a plurality of disk-shaped reverse osmosis membranes is stacked.

Description

technical field [0001] The invention relates to an oily wastewater treatment device and an oily wastewater treatment method using the device, in particular to an oily wastewater treatment device capable of performing wastewater treatment with less adverse impact on the environment and an oily wastewater treatment method using the device. Background technique [0002] In the manufacturing process of automobile parts and the like, oils such as cutting oil are used to improve lubricity when performing metal processing. Usually, metal processing is performed while applying oil to the metal surface to be processed, but since the oil is easy to burn, there is a possibility of causing a fire. [0003] Therefore, water-soluble oil and water (oil for metal processing) has been used in recent years. The oil-water is a mixture of water and oil using a surfactant or the like as a medium. [0004] This water-soluble oil and water is difficult to dispose of after use, and as a disposal ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/44B01D17/00B01D61/02B01D61/08B01D61/14B01D61/16B01D61/18B01D61/58B01D63/06B01D63/08B01D63/10B01D69/02B01D71/34B01D71/36

CPCB01D17/00B01D61/02B01D61/08B01D61/14B01D61/16B01D61/18B01D61/58B01D63/06B01D63/08B01D63/10B01D69/02B01D71/34B01D71/36C02F1/44

Inventor 宫崎泰光

Owner AZTECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com