Micro-pore aerator

A technology of microporous aerator and aeration, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc. Realize the uniform and automatic opening of each annular filter, achieve good automatic cleaning effect, reduce production cost, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

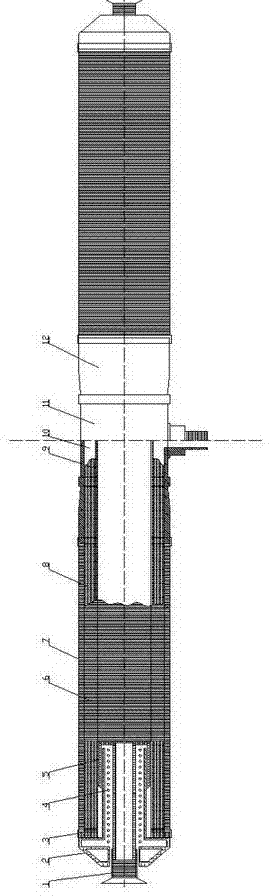

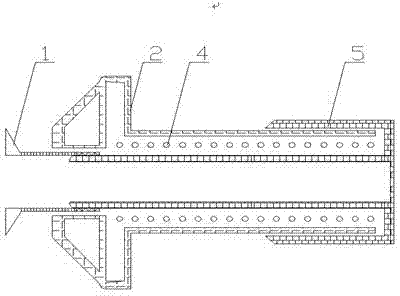

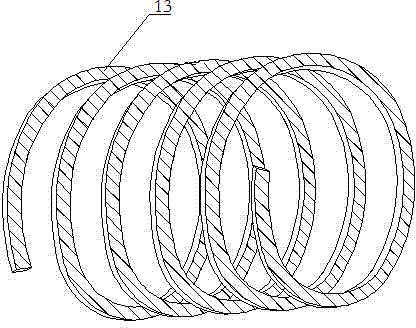

[0010] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The invention discloses a spiral membrane aerator, which comprises an aeration part, a pressure regulating system, a support part and a connection part, and the aeration part is installed on the support part. The aeration part is a rectangular strip with a certain thickness, which is wound according to a constant diameter to form a spiral diaphragm 7, and each circle is tightly fitted without gaps. A groove 13 on the spiral diaphragm is arranged on one side of the spiral diaphragm 7 . The supporting parts are hollow multi-peak tube 8 and peak tube bracket 9. The aeration part is installed on the multi-peak tube 8, and the spiral diaphragm 7 is supported by the multi-peak tube 8. The wave peaks form an air chamber, which can divide the gas into several part, distribute air evenly.

[0011] In this embodiment, there are two helical diaphrag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com