A wiping method for solving blockage of smt stencil and tin blowing device thereof

A stencil and solder paste technology, applied in the direction of assembling printed circuits, printed circuits, and electrical components with electrical components, can solve problems such as poor soldering quality, and achieve the effect of enhancing the output of good products, excellent performance, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the present invention, the specific implementation manners of the present invention will be explained in detail below in conjunction with the accompanying drawings.

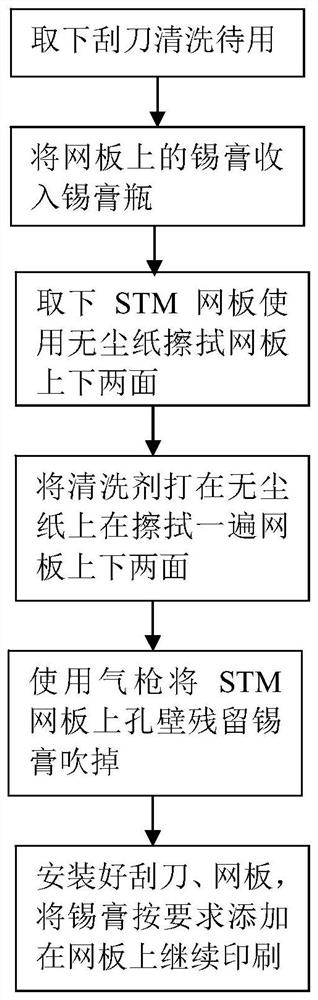

[0032] A kind of wiping method that solves SMT stencil blockage, its step comprises:

[0033] 1. The scraper moves to the front of the printing area to remove the SMT stencil;

[0034] 2. Put the solder paste on the SMT stencil into the solder paste bottle. The solder paste must be used up within the validity period of opening, otherwise it will be discarded;

[0035] 3. Use dust-free paper to wipe the upper and lower sides of the STM stencil;

[0036] 4. Apply the cleaning agent on the dust-free paper and wipe the upper and lower sides of the STM stencil again. When wiping, wipe back and forth in the horizontal and vertical directions. The wiping pressure is lower than the plastic deformation pressure of the STM stencil;

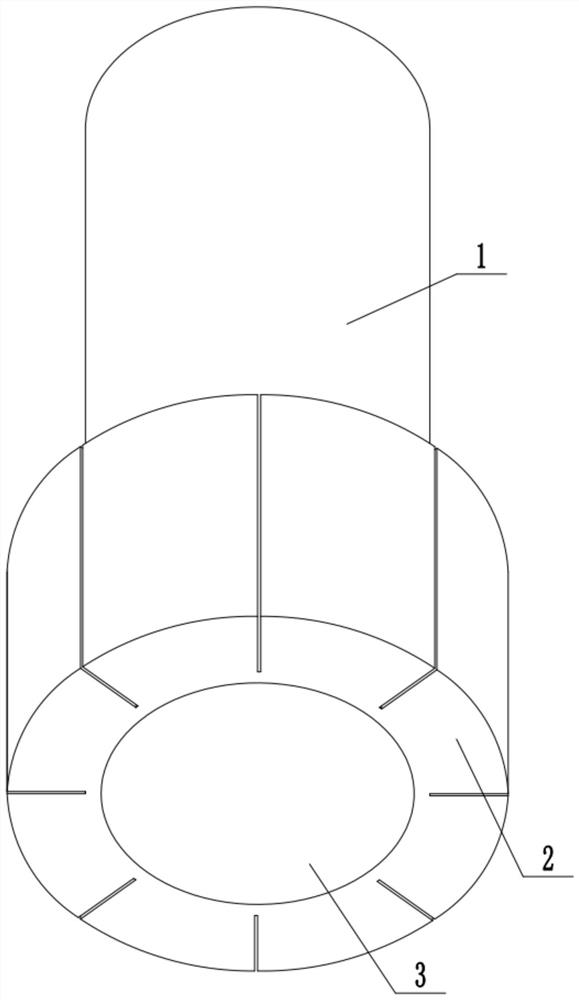

[0037] 5. Use a tin blowing device to blow off the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com