A food processor with good cleaning effect

A technology for food processors and cleaning effects, which is applied to utensils with integral electric heating devices, kitchen utensils, household utensils, etc., can solve problems such as poor sealing effect, sealing problems, and difficulty in heating, so as to avoid cracking or damage, Guaranteed airtightness and prevents breakage or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

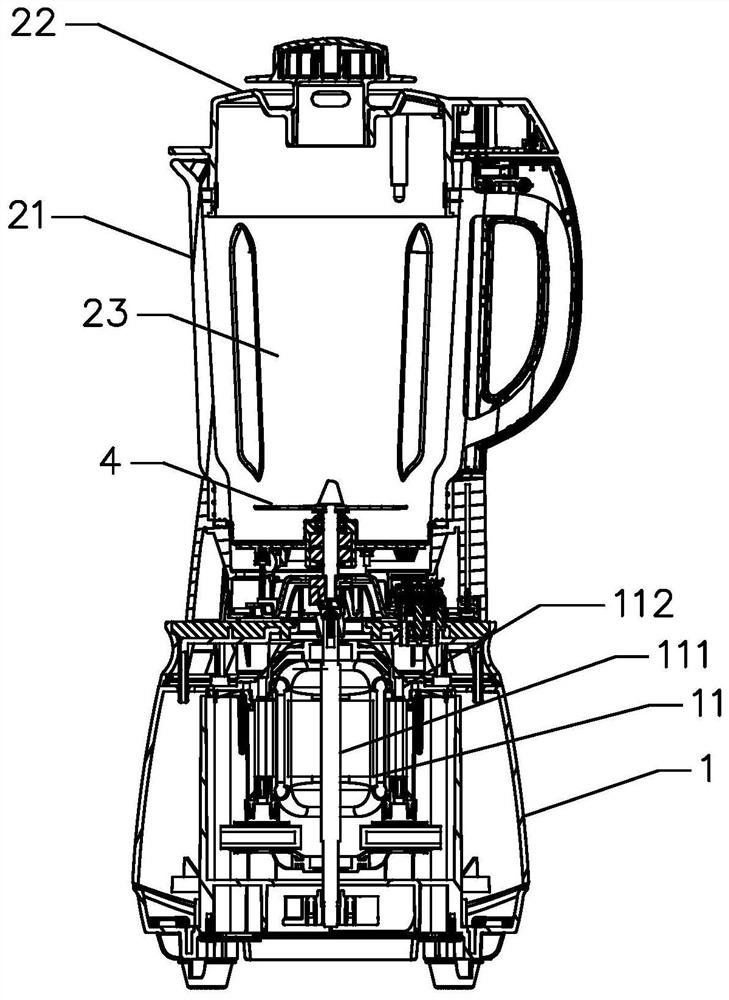

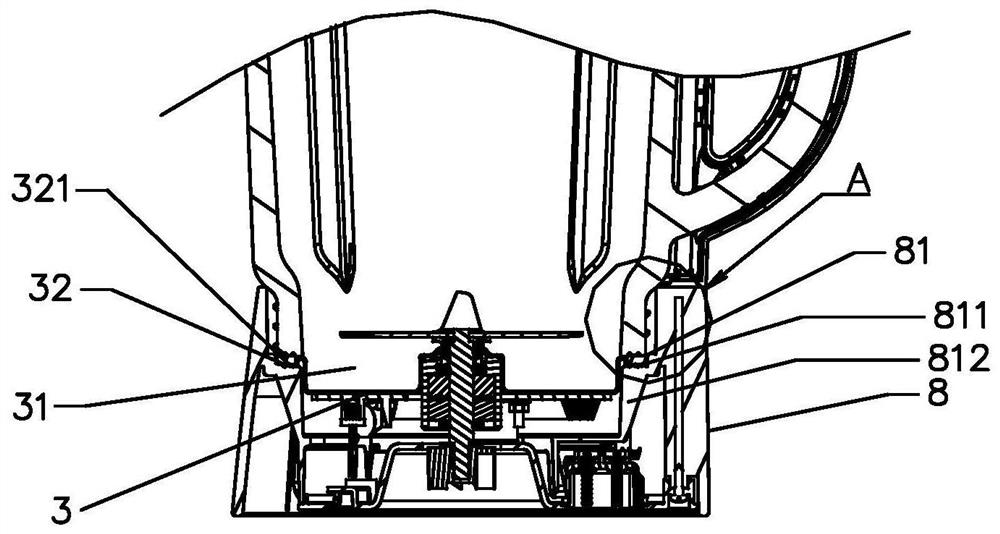

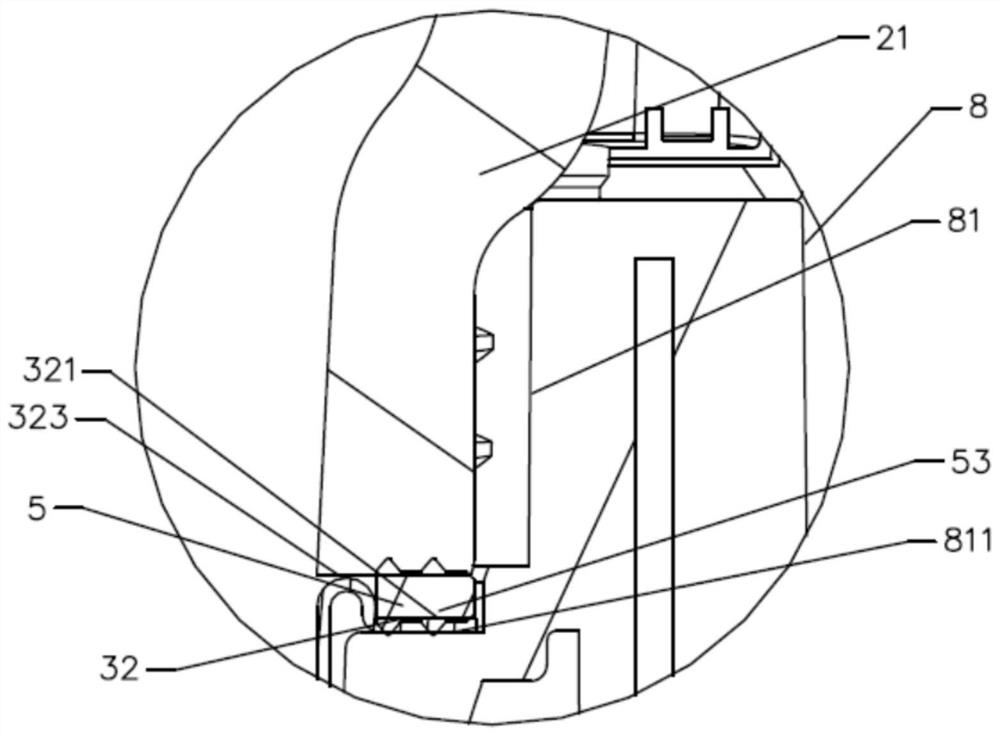

[0040] Such as Figures 1 to 4 As shown, the present invention provides a food processor with good crushing effect, comprising a body 1 with a built-in control panel, a motor 11, a crushing device 4, a crushing cup body and a crushing cup cover 22, the motor 11 is arranged in the body 1, The crushing cup body is placed on the body and is electrically connected to the control panel in the body through an electric coupler. The crushing cup body includes a glass body 21 with openings up and down, a metal plate 3 and a cup holder 8, and the metal plate 3 It is sealed and mounted on the lower opening of the glass body 21, the crushing cup cover is closed on the upper opening of the glass body, the crushing cup cover 22, the glass body 21 and the metal plate 3 are enclosed to form a pulping cavity 23, and the crushing knife 4 is set In the pulping chamber 23, the pulverizing device 4 is a pulverizing knife, the motor shaft 111 of the motor 11 is connected with the knife shaft throug...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that, if Figure 5 As shown, at the butt joint of the glass body 21 and the metal disc 3, the inner side wall of the metal disc 3 protrudes toward the center of the crushing cup body 2 relative to the inner side wall of the glass body 21, so that the metal disc and the glass body A relatively small step is formed between them. When the material and water in the metal plate are driven by the pulverizer and move, the material and the pulverizer are continuously collided and crushed, and the mixture of slurry and material is driven by the pulverizer. Downward and upward rotation movement, due to the existence of small steps, the movement route of the mixed liquid of material and slurry changes under its action, and the rotating liquid flow is more intense, so it is beneficial to the circulation of small particles that have not been crushed and crushed , the cycle speed and power are increased, so that more material...

Embodiment 3

[0058] The difference between this embodiment and Embodiment 1 is that, if Image 6 As shown, the heating device of the food processor is set 7 on the outer wall of the metal plate, the heating device is a bowl-shaped cast aluminum plate with a heating pipe on the side wall, the shape of the cast aluminum plate is consistent with the shape of the metal plate, The cast aluminum disc is welded on the outer wall of the metal disc. The depth H of the metal disc is 20 mm to 25 mm. The installation convenience of the heating device is guaranteed, the efficiency of heating and the effect of boiling are also guaranteed, and the problem of cleaning the inner wall of the metal plate at the side wall of the heating device 7 is also solved.

[0059] The structures and beneficial effects of other parts not described are the same as those in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com