Patents

Literature

43results about How to "Low bending resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

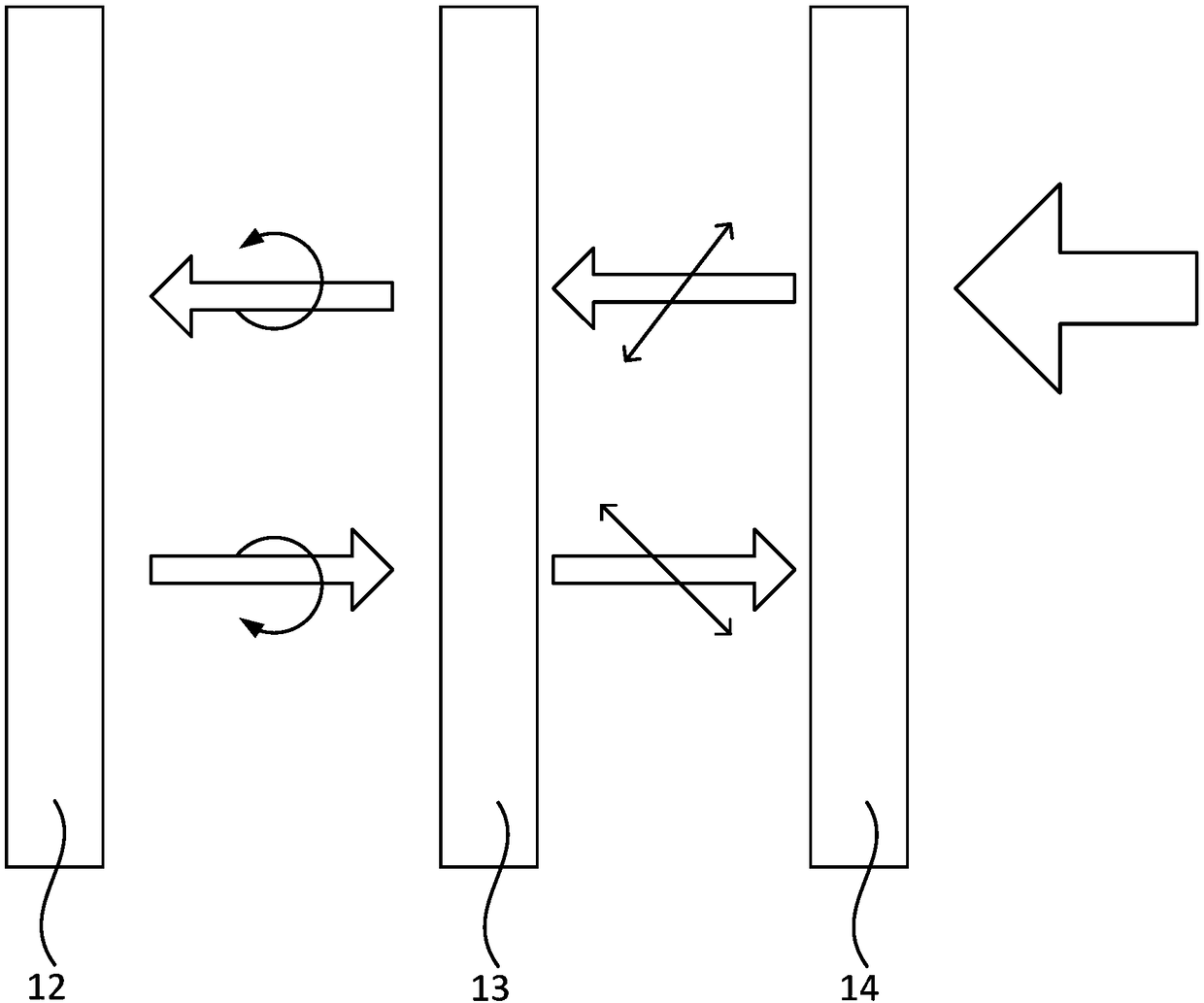

Patent Status

Application Year

Inventor

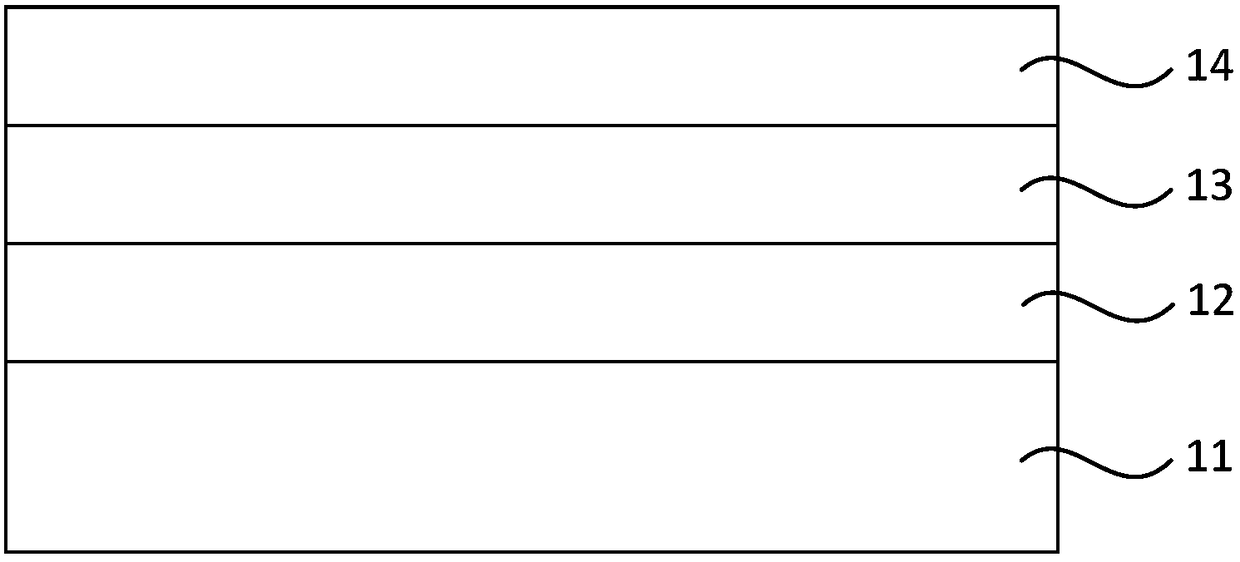

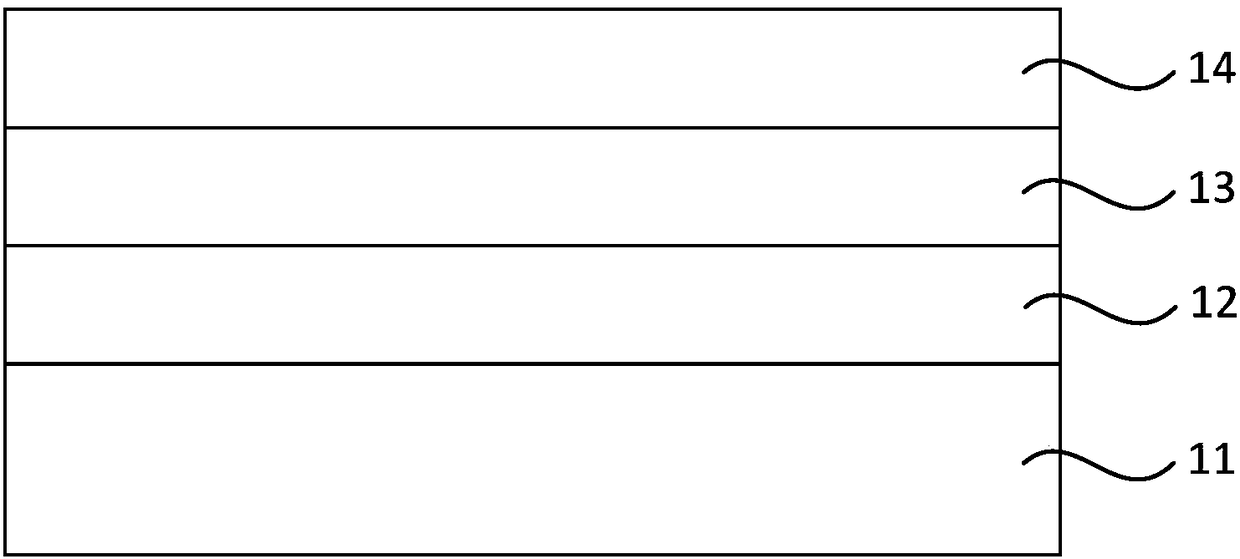

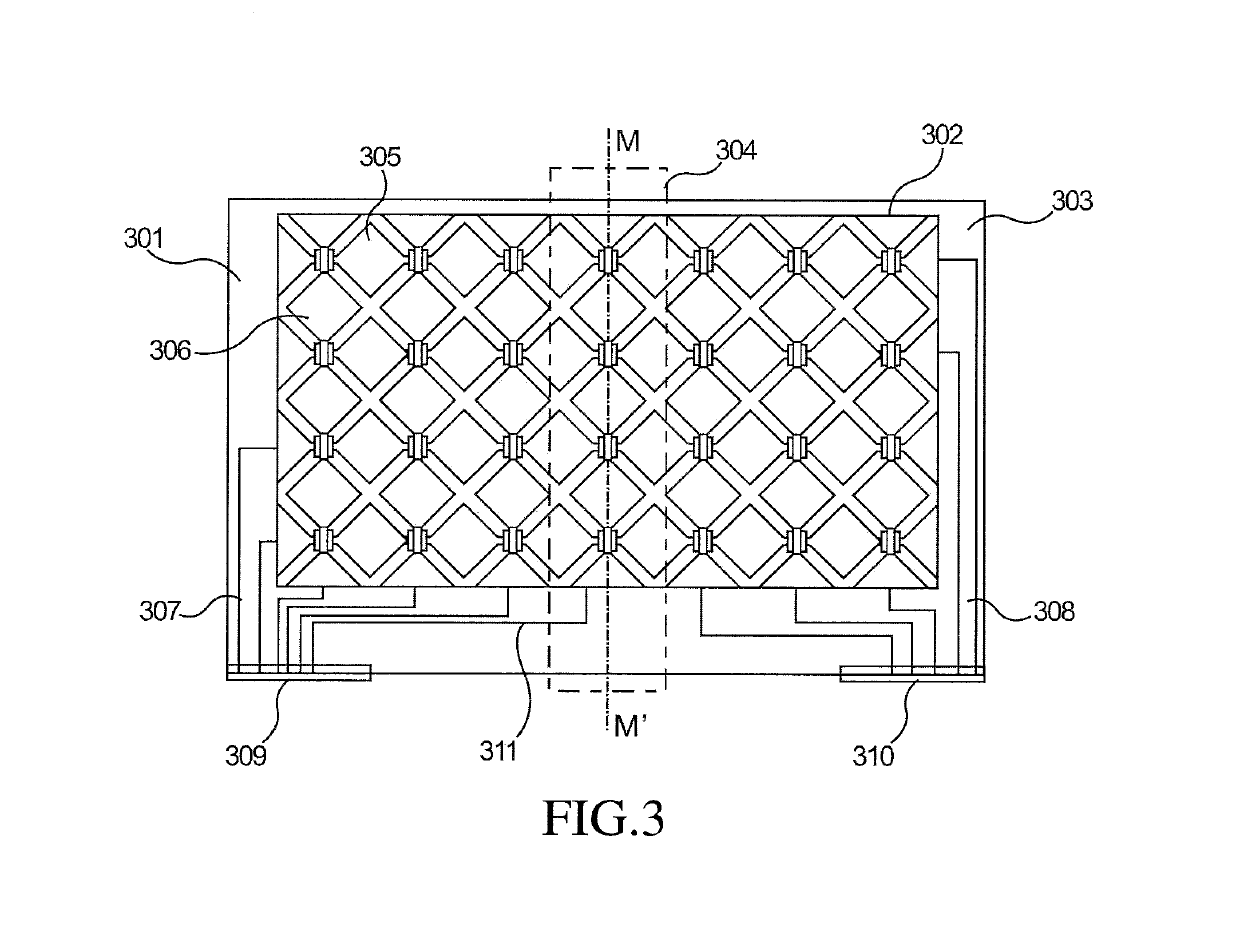

Display panel and display device

InactiveCN108666344AReduce thicknessLow bending resistanceSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceRefractive index

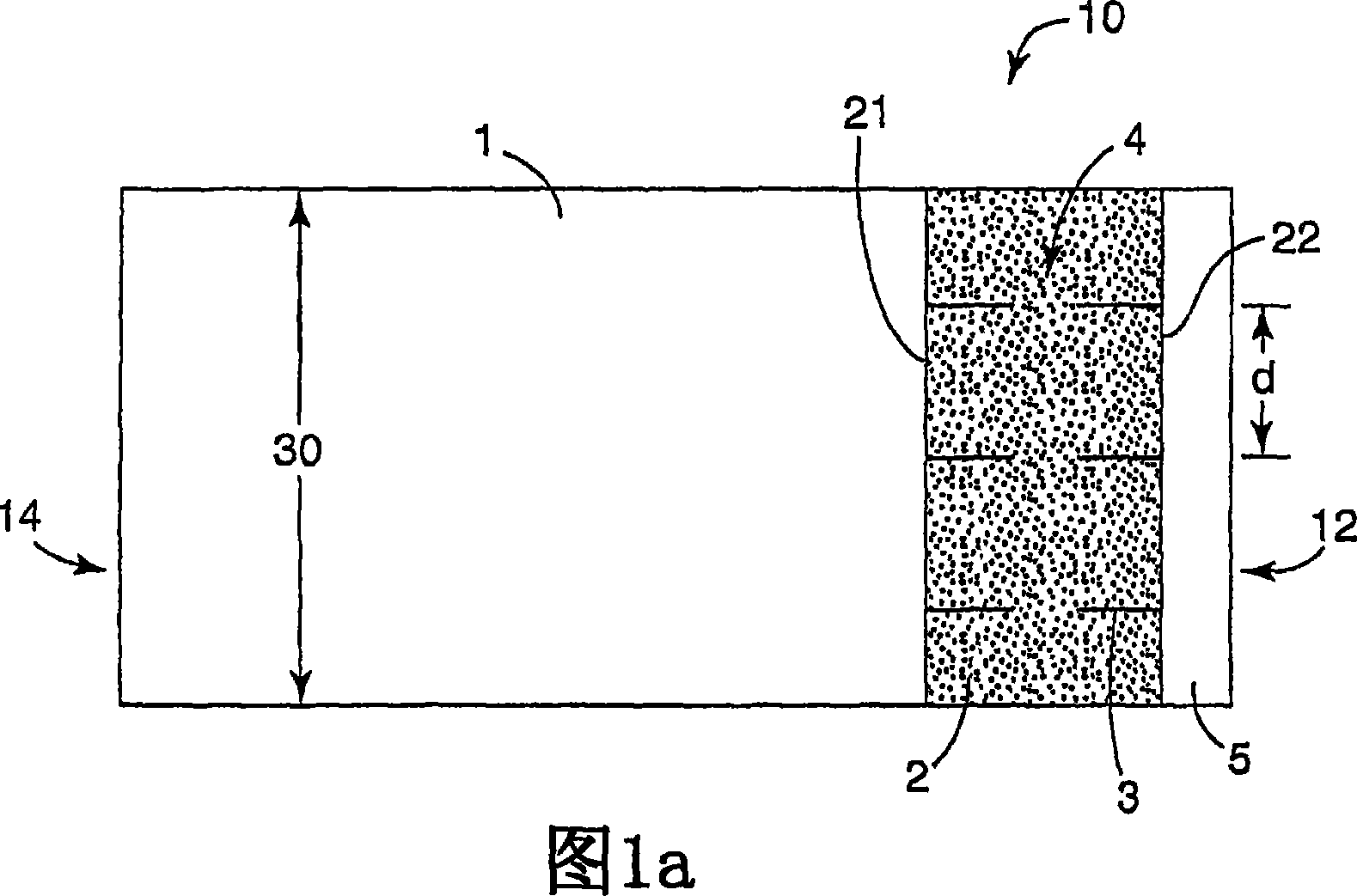

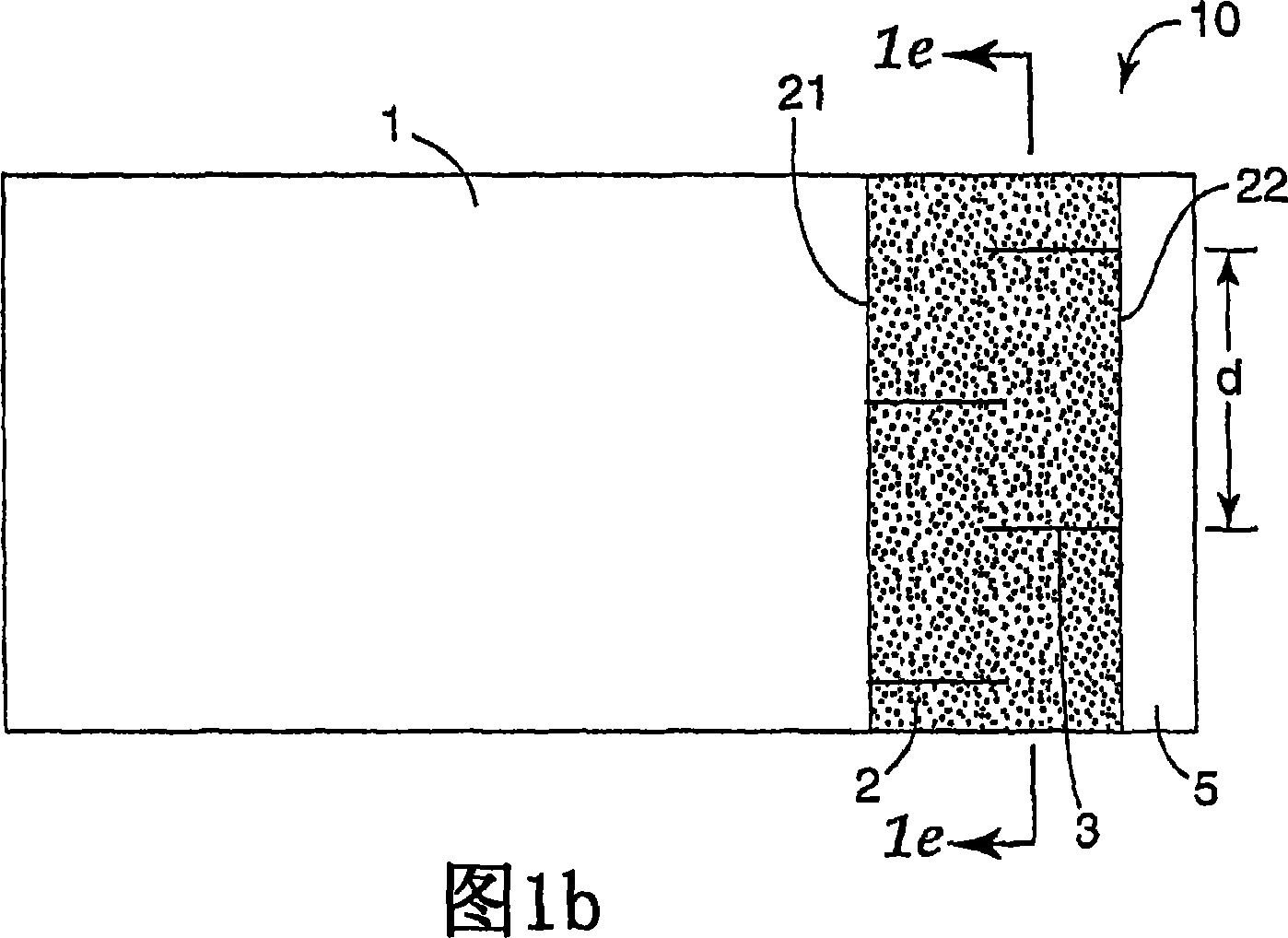

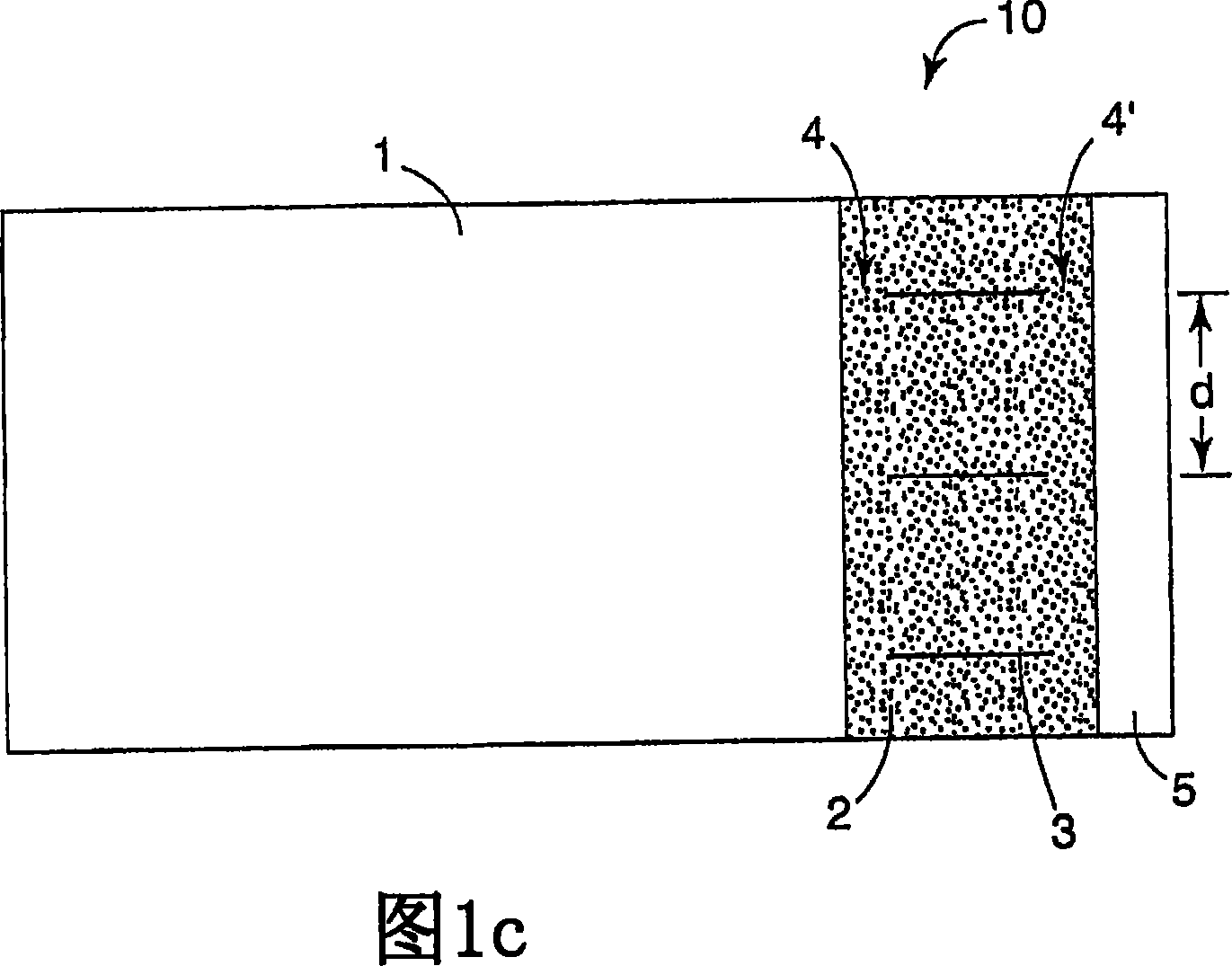

The embodiment of the invention discloses a display panel and a display device. The display panel comprises a substrate, an organic light emitting device disposed on the substrate, and a thin film package layer covering the organic light emitting device; wherein the thin film package layer includes a plurality of film layers stacked in a layer, and the refractive index of the plurality of film layers gradually increases in a direction close to the organic light emitting device. According to the embodiment of the invention, the display panel can solve the problems that the bending resistance ofthe display panel is low, and the display brightness and the luminous efficiency of the display panel are also low since the existing display panel including a polarizer which reduces the thickness of the display panel; and realize the purpose of improving the bending resistance, display brightness and luminous efficiency of the display panel under the premise of ensuring that the display panel has a relatively low reflectivity to external light.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

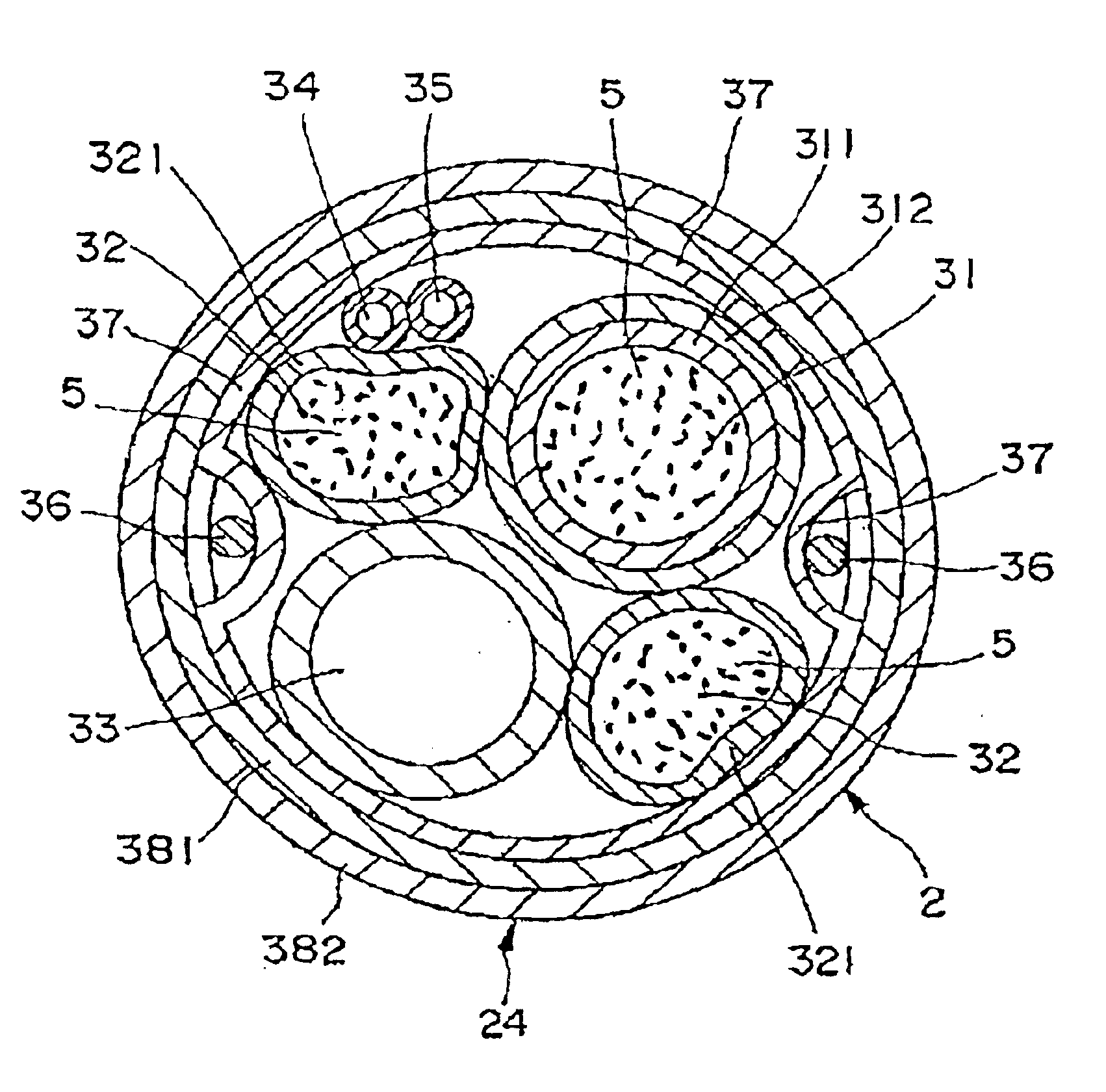

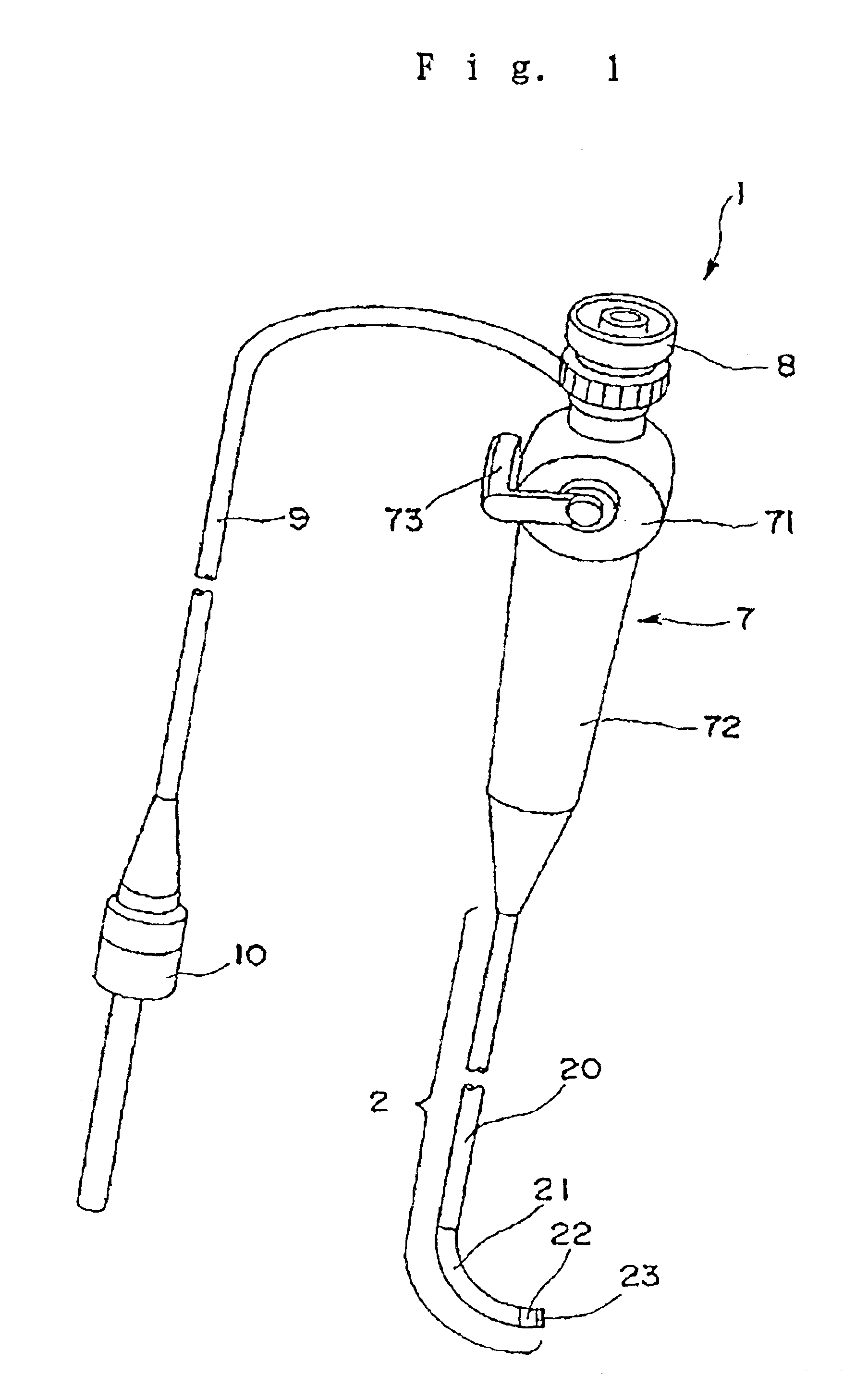

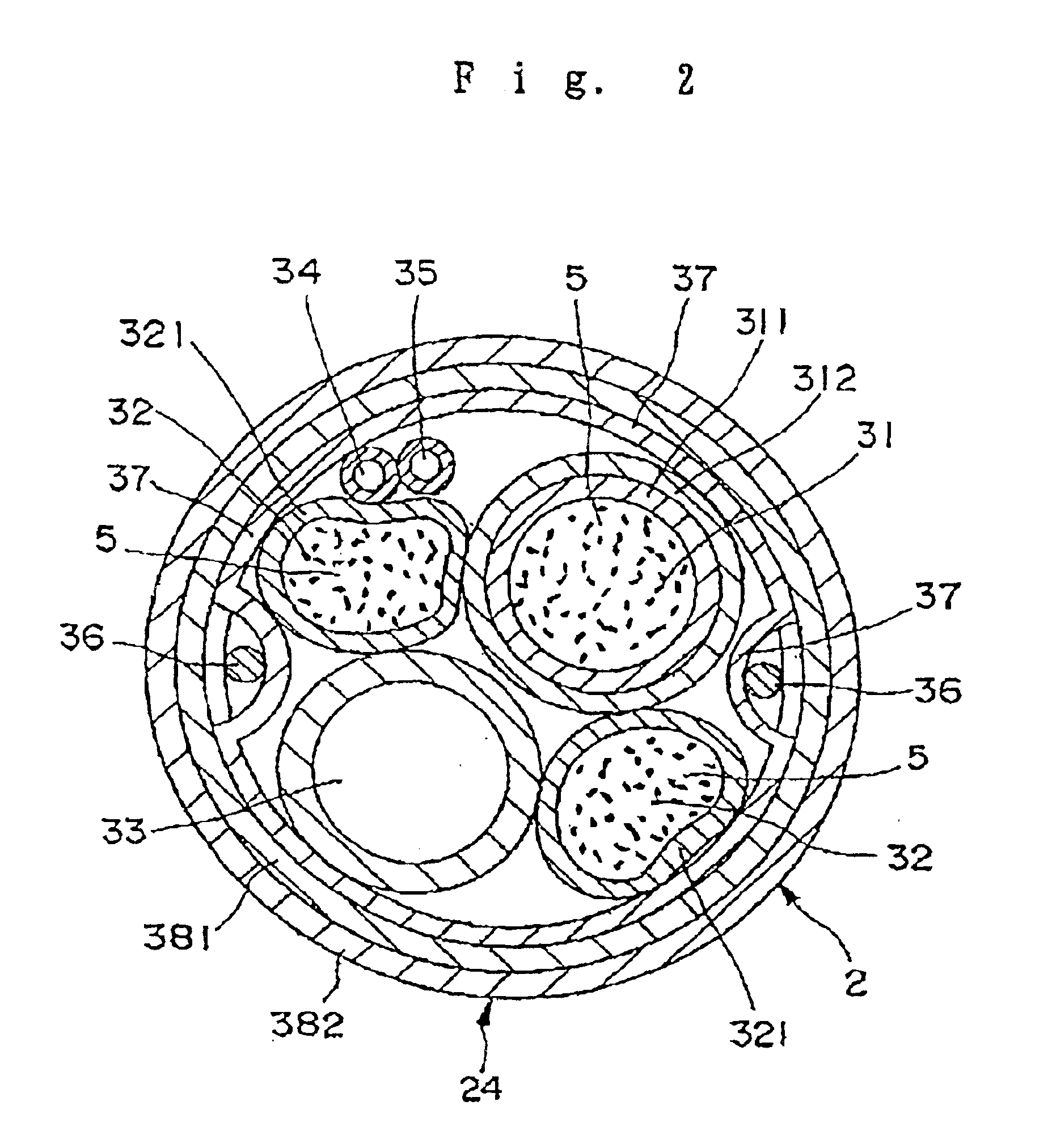

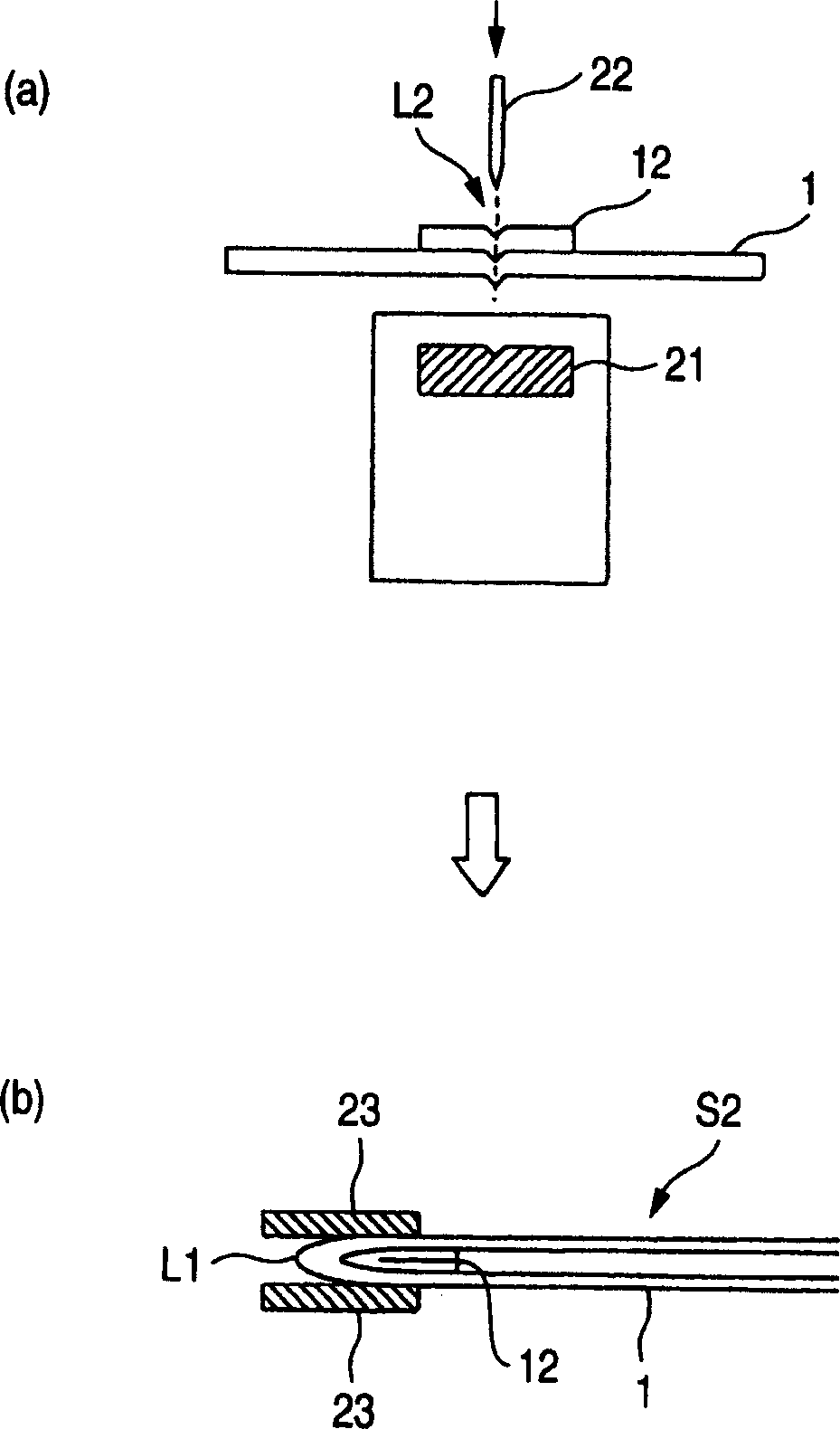

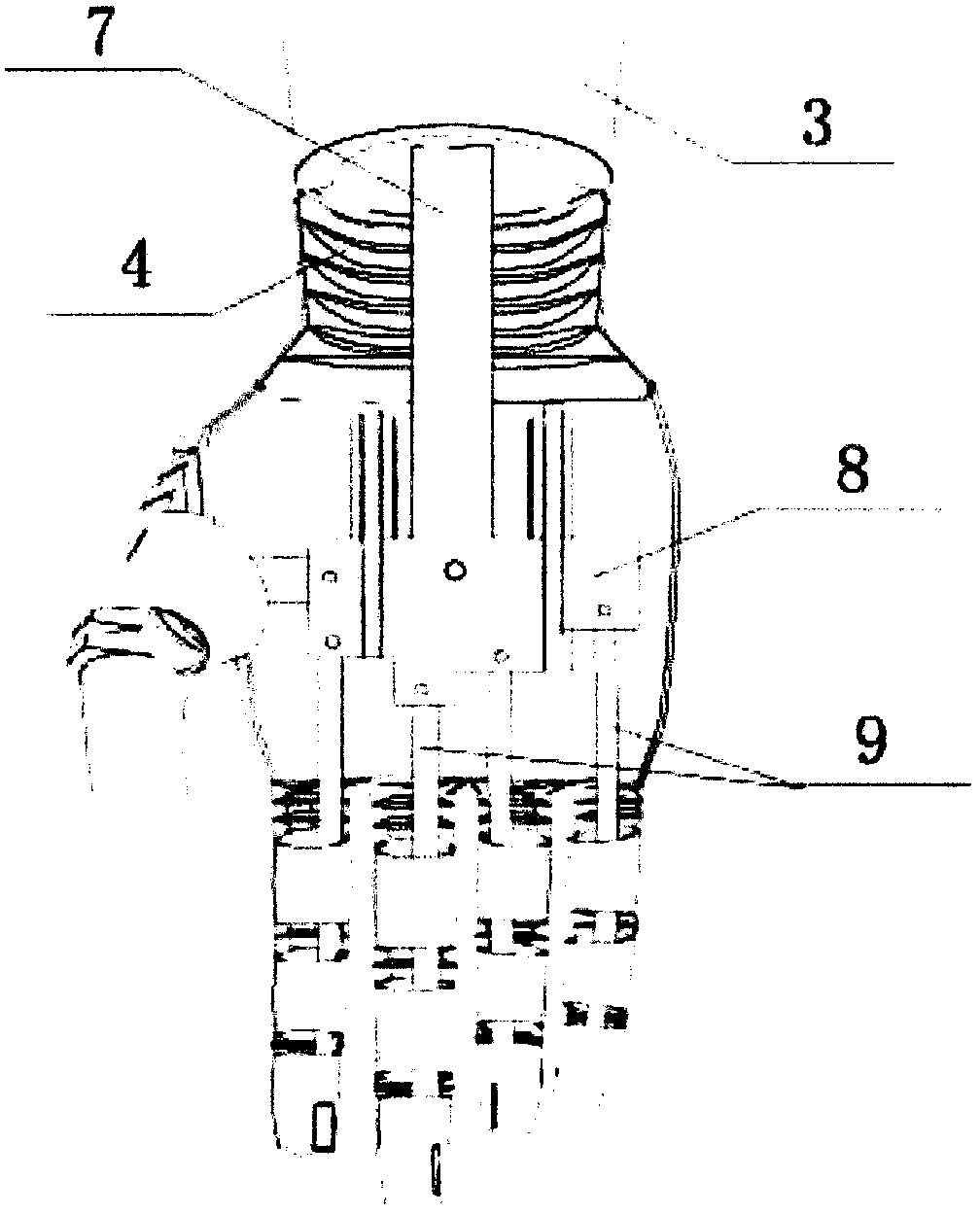

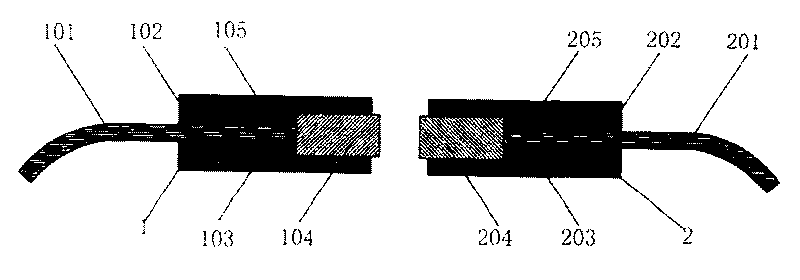

Endoscope having a lubricant

InactiveUS6923757B2Low bending resistanceHard can be damaged and brokenSurgeryEndoscopesTetrafluoroethyleneInterior space

An endoscope which has small bending resistance and is hard to be damaged or broken even when it is repeatedly used is disclosed. The endoscope includes a flexible insertion section 2 and an operation section 7 provided on the proximal end of the insertion section 2. The insertion section 2 has a sheath constructed from an outer layer 382 and the like, and elongated members such as an image guide 31 and light guides 32, 32 and the like are housed in lumens in the sheath. Further, each light guide 32 has an optical fiber bundle and a protective sheath 321 for protecting the optical fiber bundle. In the interior space of the protective sheath 321, a lubricant 5 containing a silicone oil and a solid lubricant is provided. The solid lubricant contains at least one of boron nitride, poly tetrafluoroethylene, and molybdenum disulfide. The solid lubricant is preferably formed into powder having an average grain size of 0.1 to 15 μm. By providing the lubricant 5 in the interior space of the lumen, bending resistance of the insertion section is reduced so that damage, breakage, or the like is hard to occur in the elongated members.

Owner:ASAHI KOGAKU KOGYO KK

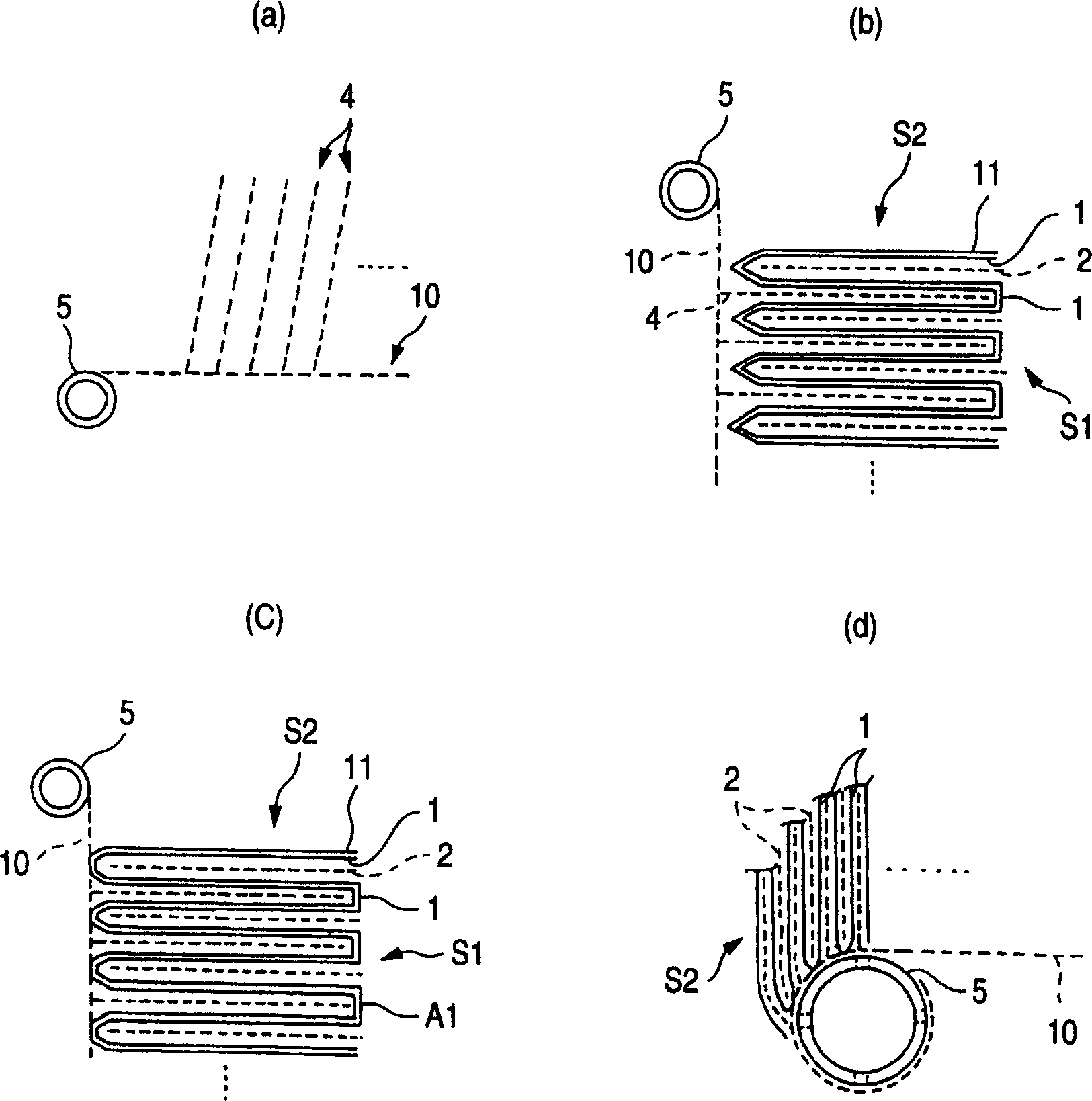

Method for producing spiral diaphragm pieces

InactiveCN1509803ALow bending resistanceAvoid damageSemi-permeable membranesConductor CoilPermeation

Owner:NITTO DENKO CORP

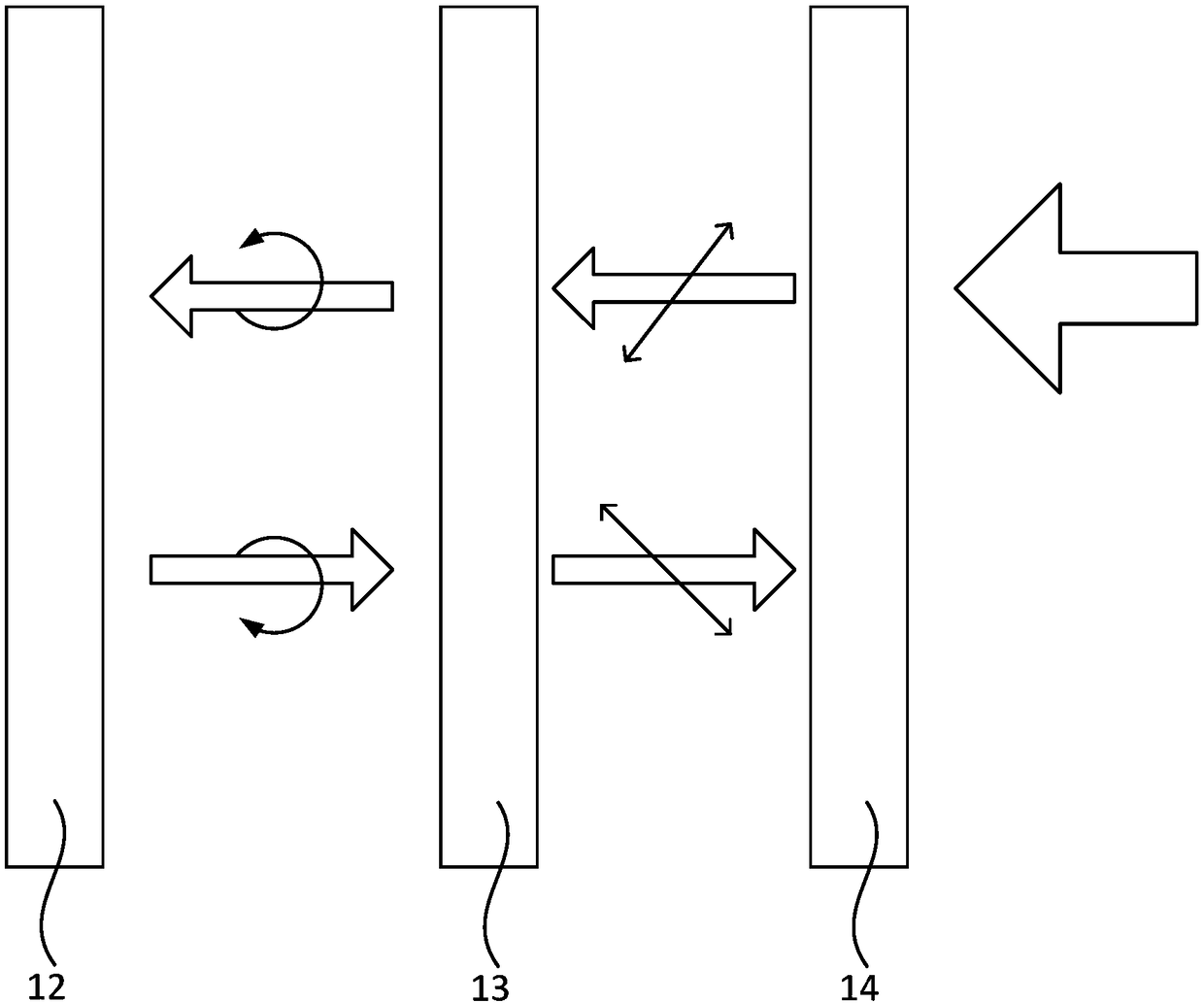

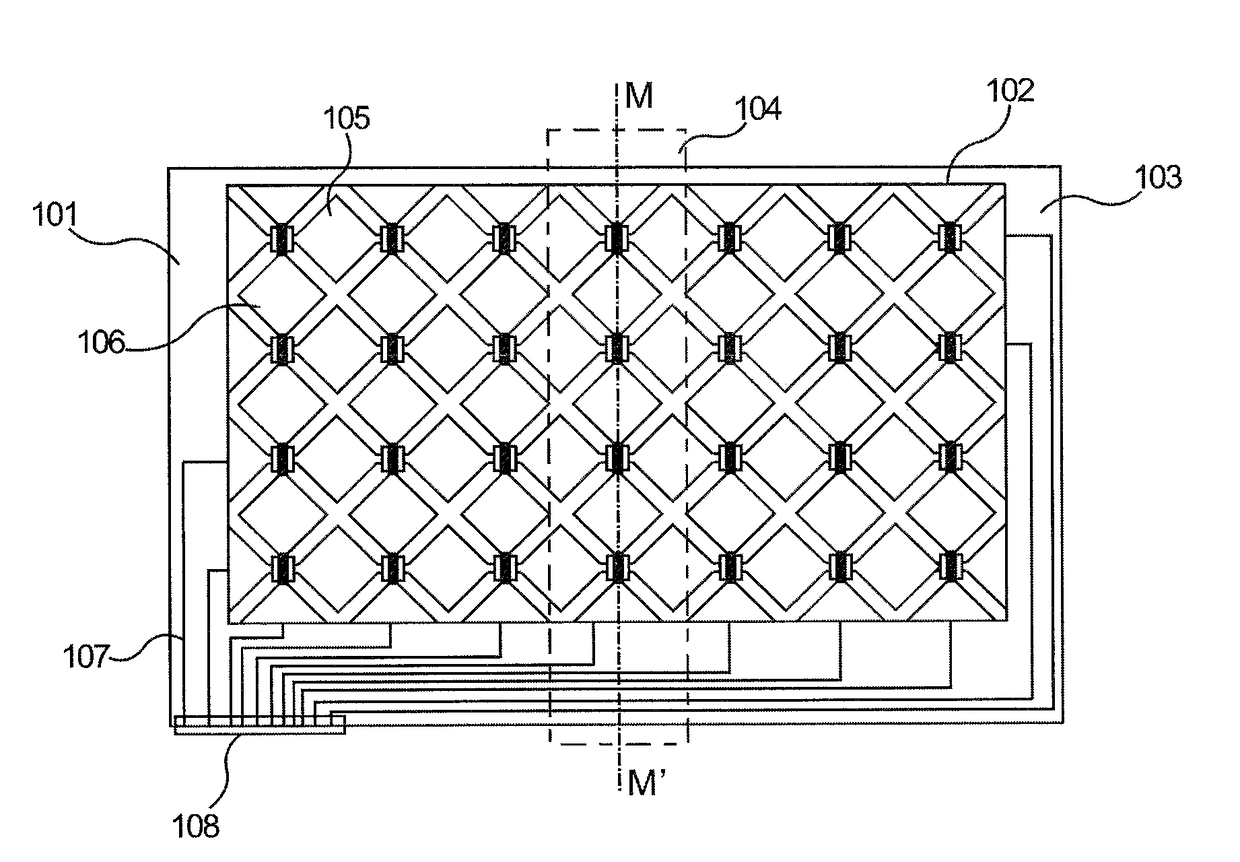

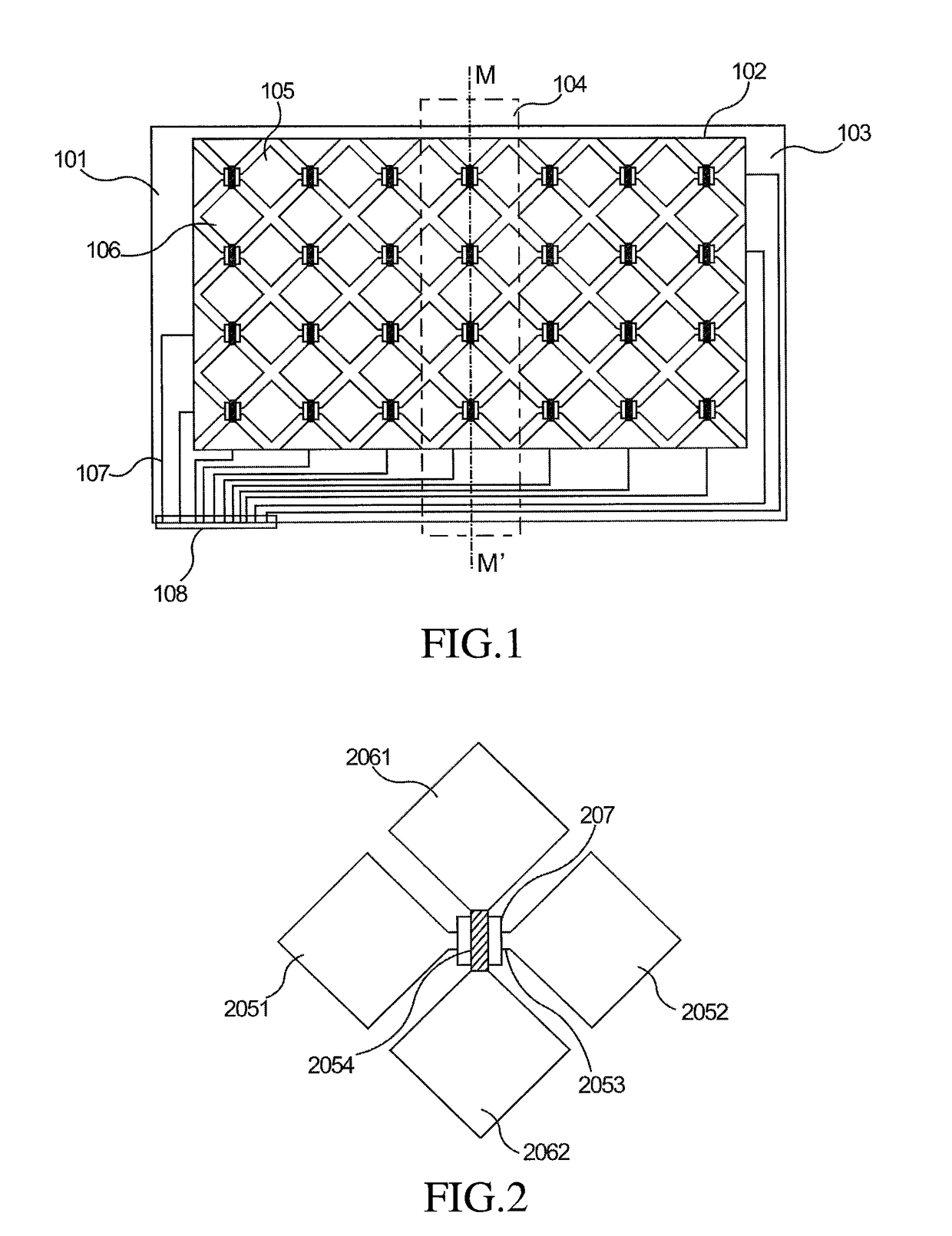

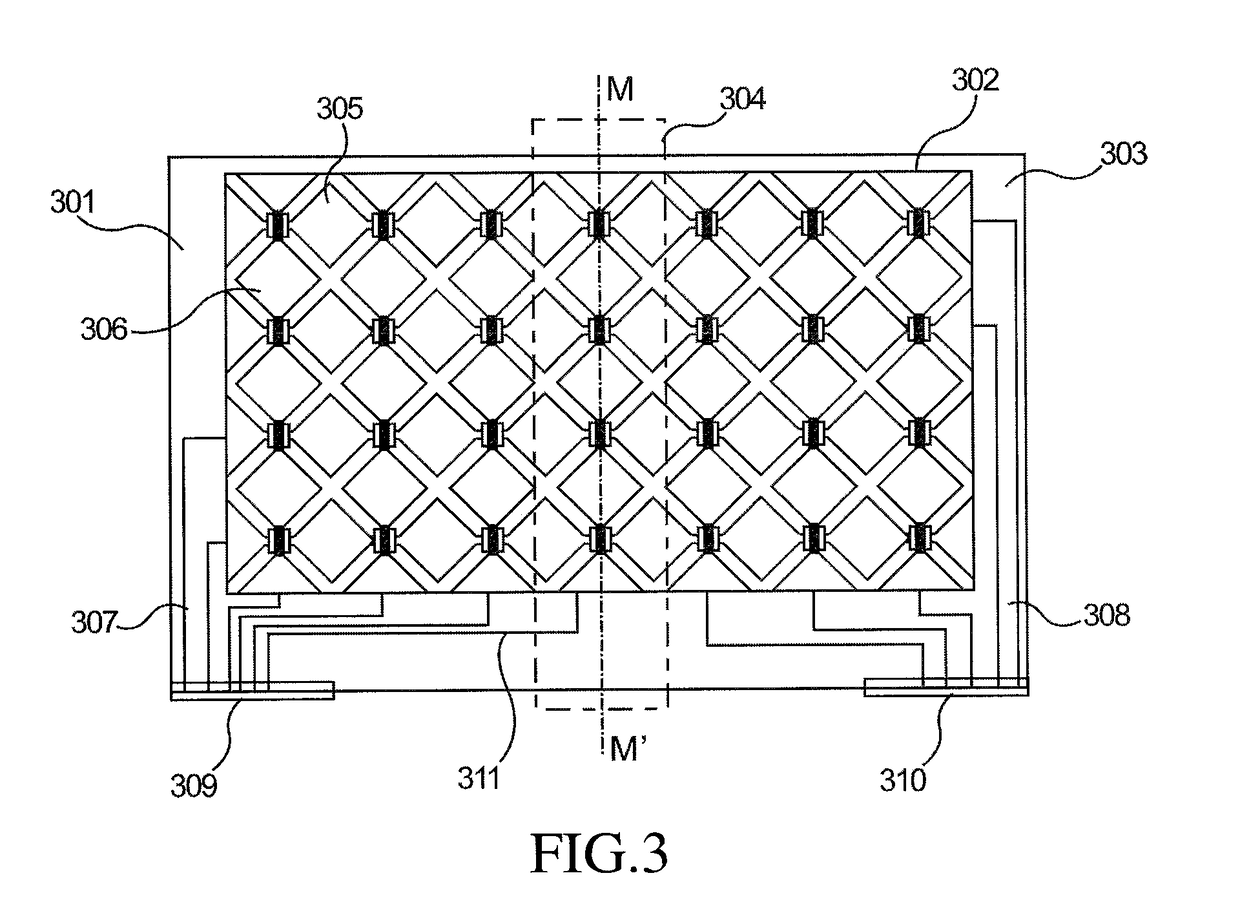

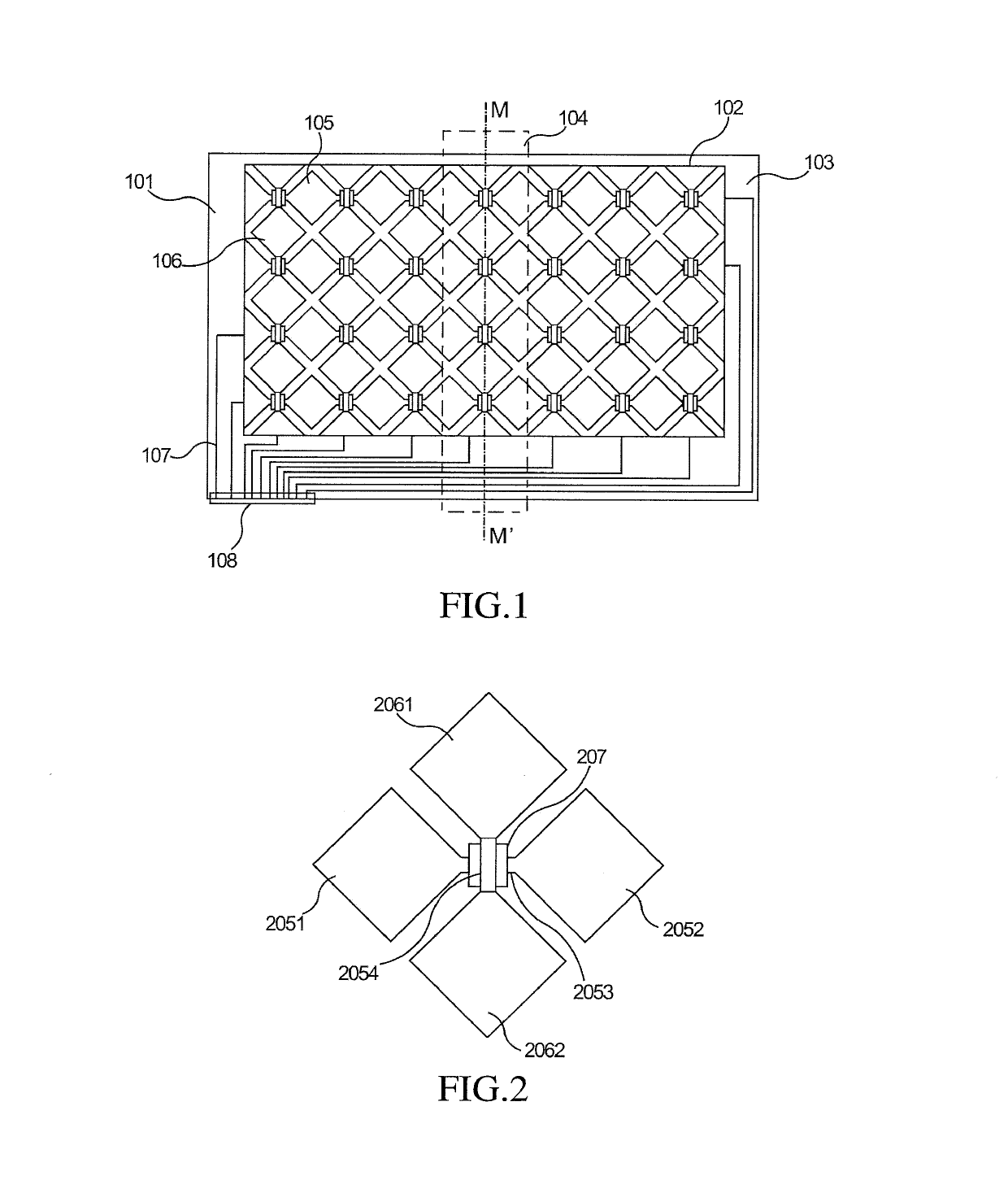

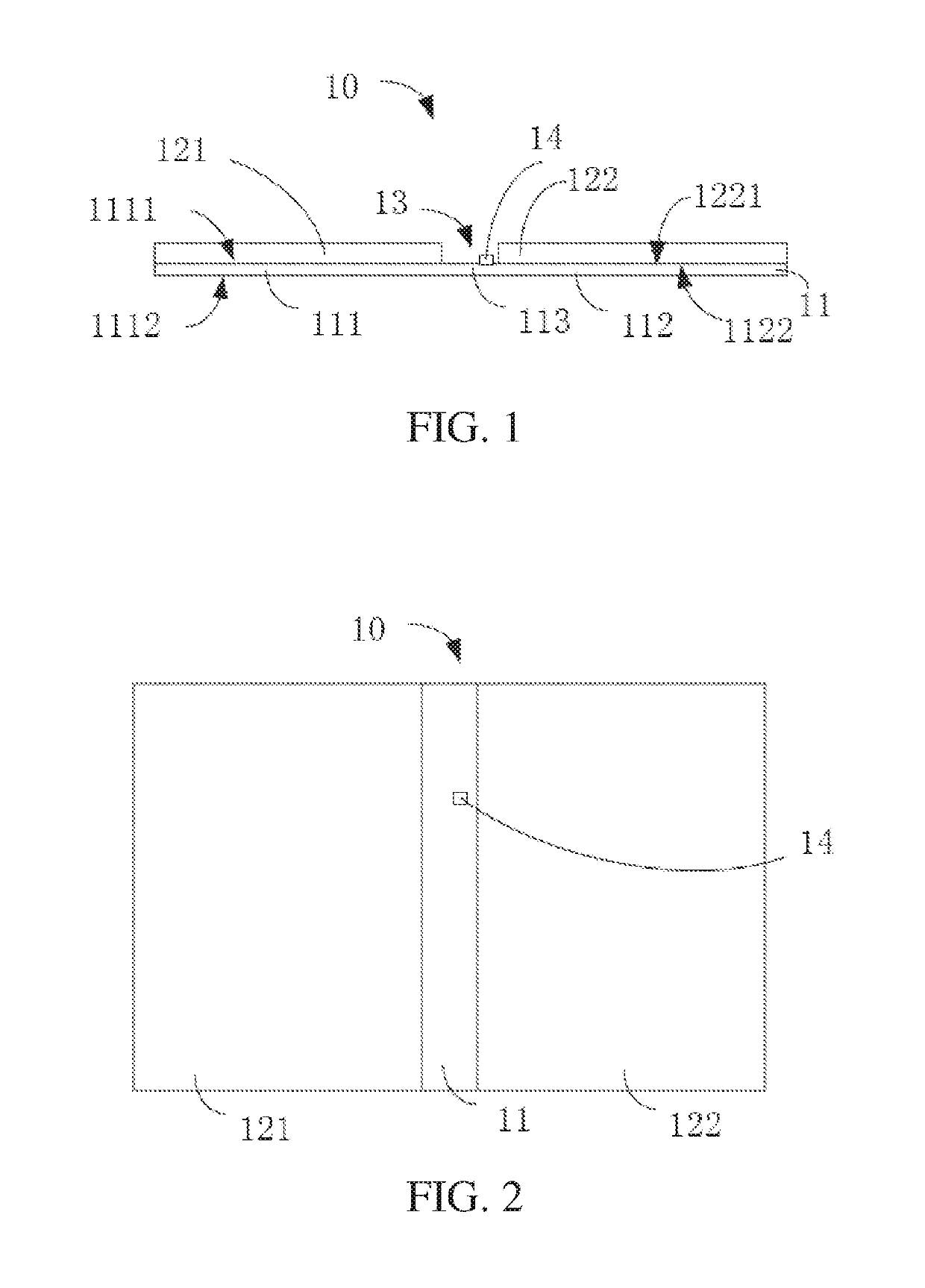

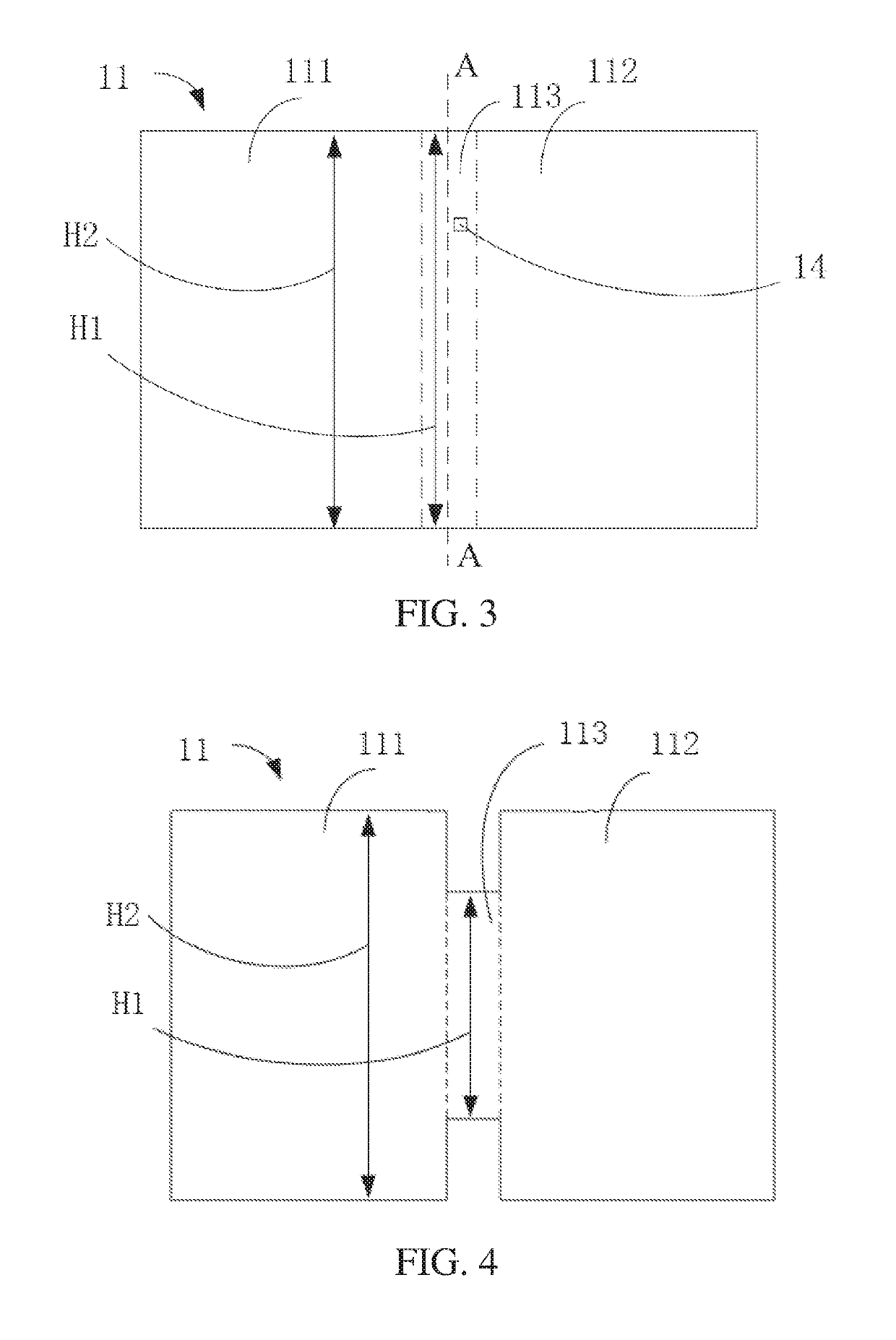

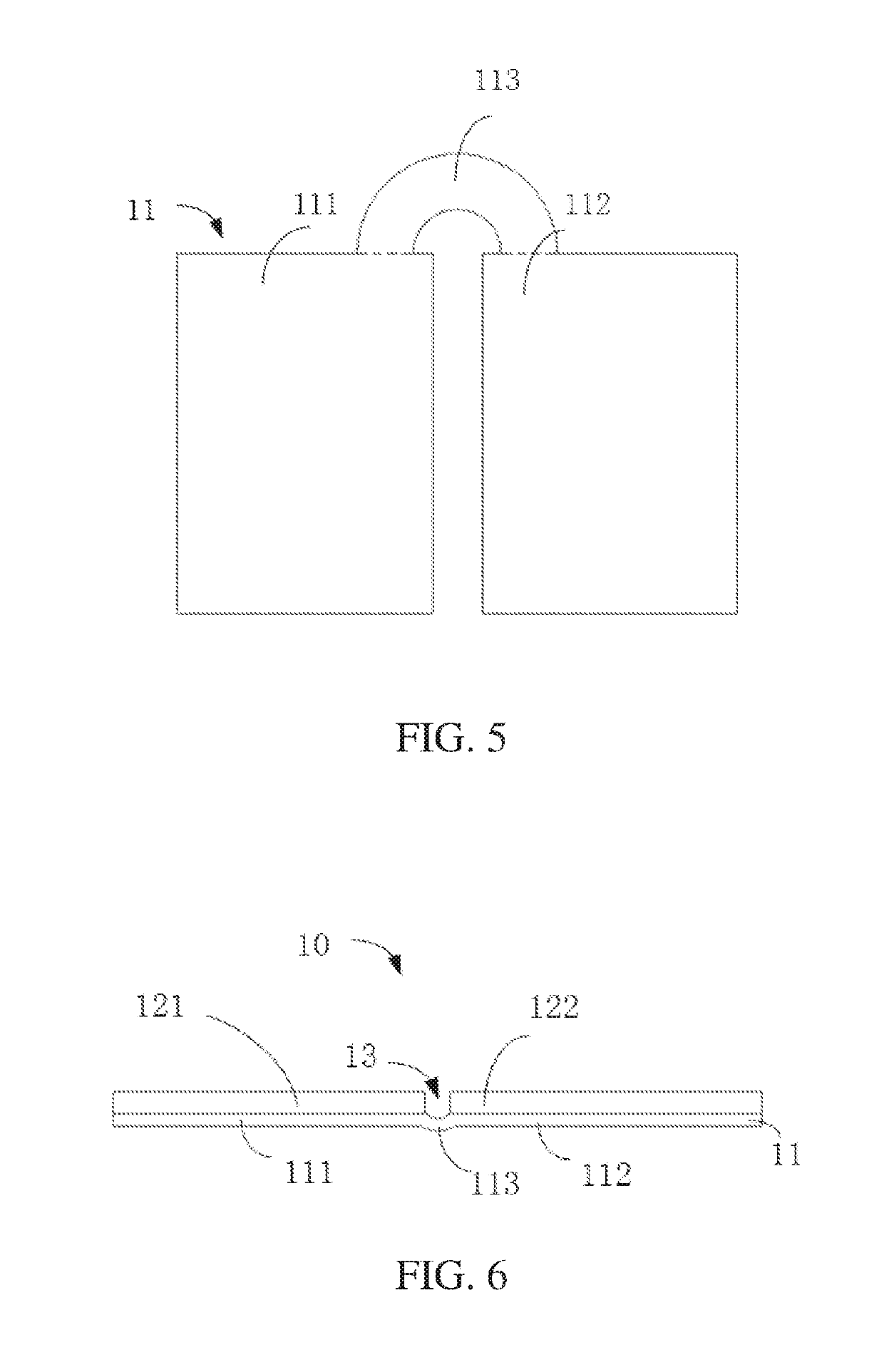

Foldable flexible touch screen and flexible touch display panel

ActiveUS20180329530A1Increased bending stressSolve the real problemInput/output processes for data processingEngineeringTouch function

A flexible touch screen fold along middle is provided. The flexible touch screen has a window region with a touch function, a folded section, and a non-window region for arranging leads. A part of the electrodes located at the folded section is made of transparent electrode material with a bending resistance. Because the electrodes of the folded section are made of the material with a bending resistance, the bending stress of the electrodes at the folded area of the flexible touch display panel can be improved, and the service life of the flexible touch display panel can be increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

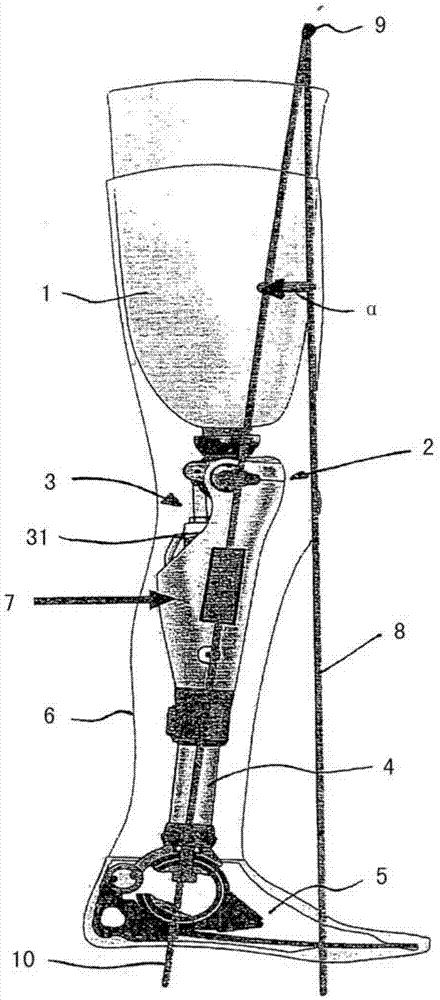

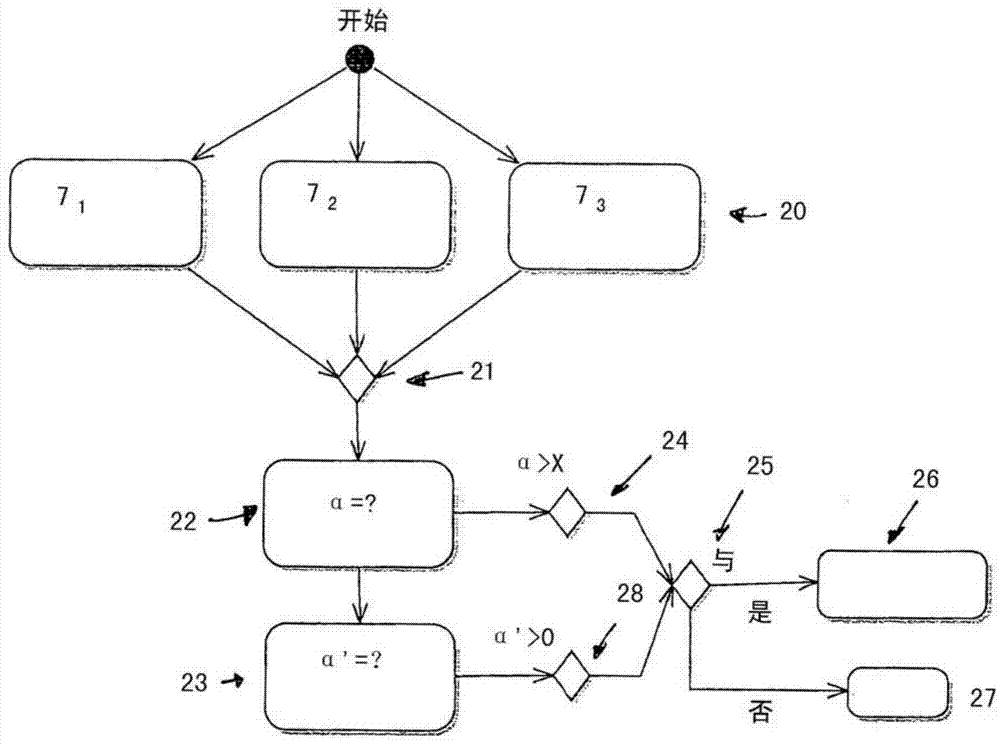

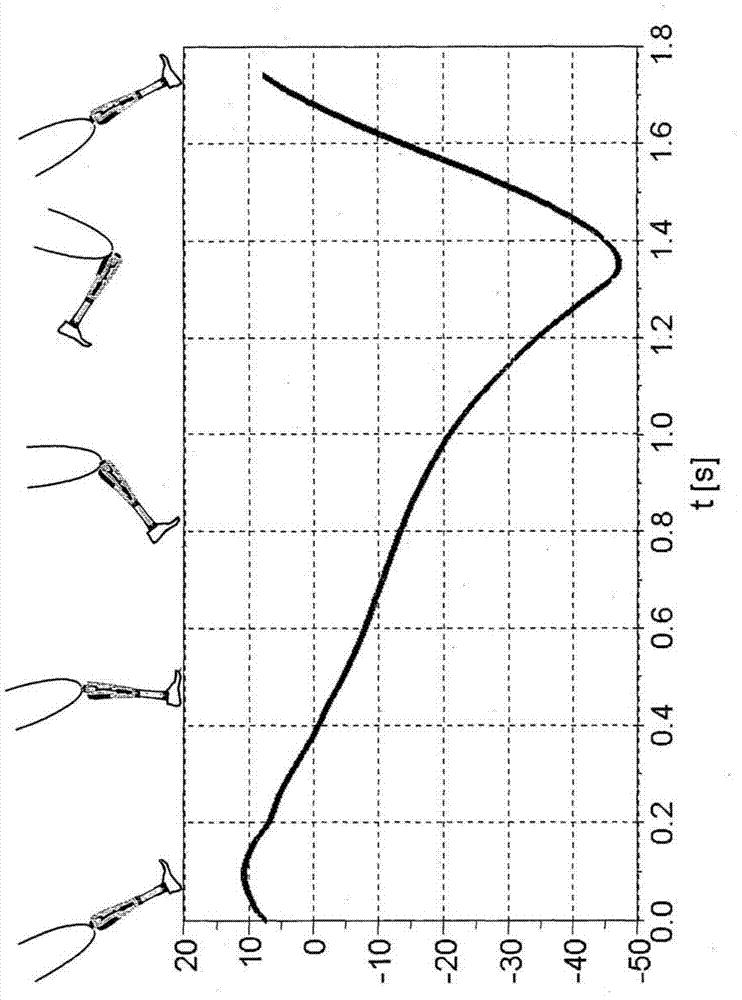

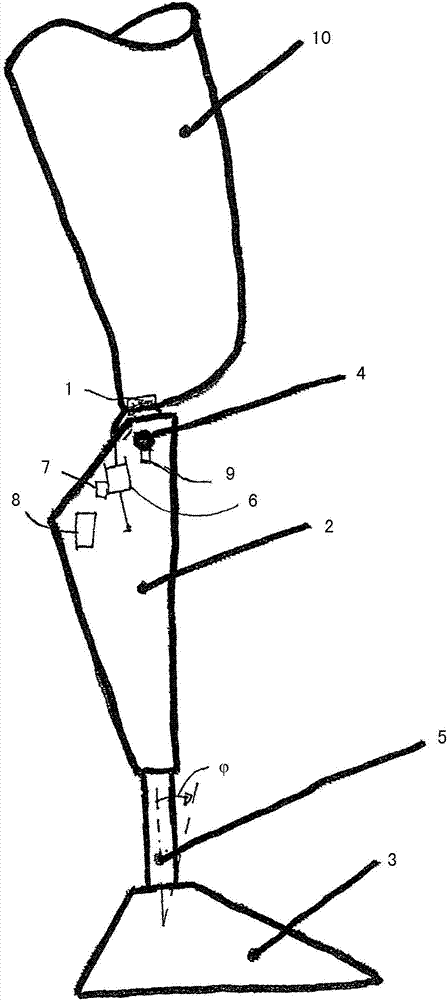

Method for controlling an artificial orthotic or prosthetic knee joint

ActiveCN104244872ALow bending resistanceCoordinated gaitArtificial legsPhysical medicine and rehabilitationKnee Joint

The invention relates to a method for controlling an artificial orthotic or prosthetic knee joint (2), on which a lower leg component (4, 5) is arranged and which is assigned a resistance device (3) having at least one actuator (31), by means of which the bending resistance is modified depending on sensor data that is determined during use of the orthotic or prosthetic knee joint by means of a sensor (7), wherein the absolute angle of the lower leg component (4, 5) is determined exclusively by means of at least one inertial sensor (7), the angle determined is compared with at least one threshold value, and the bending resistance is modified when the threshold value is reached.

Owner:OTTO BOCK HEALTHCARE IP GMBH & CO KG

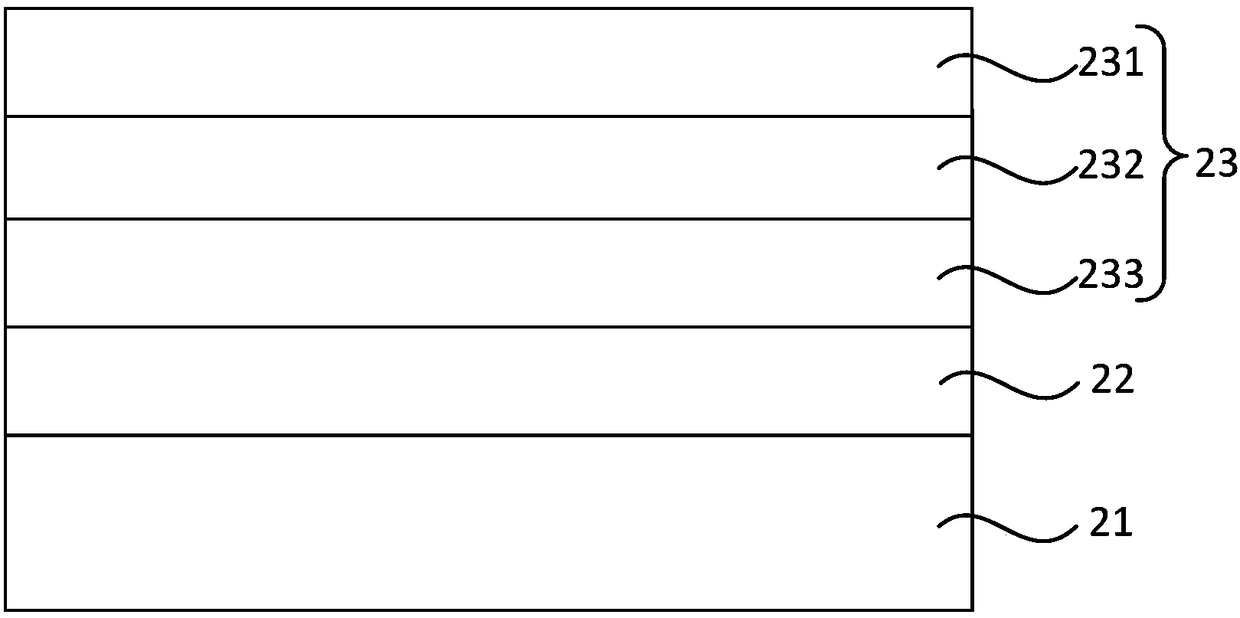

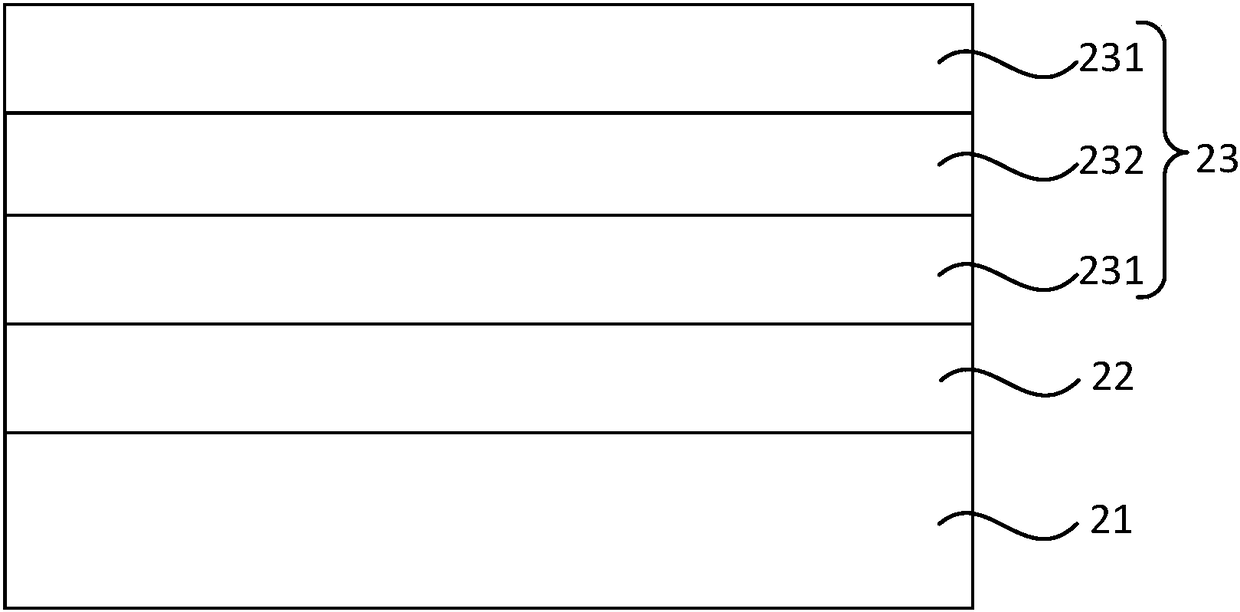

Display panel and display device

InactiveCN108666438ALow bending resistanceSolve the problem of low display brightnessSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceDisplay device

The embodiment of the invention discloses a display panel and a display device. The display panel comprises a substrate, an organic light-emitting device arranged on the substrate and an anti-reflection film arranged on the organic light-emitting device, wherein the anti-reflection film comprises N+1 first films and N second films alternately stacked and arranged, and N is a positive integer of greater than or equal to 1, wherein the refractive index of the first films is greater than that of the second films. Through the technical scheme, the problems that the bending resistance of the display panel is relatively low and the display brightness of the display panel is reduced caused by the fact that an existing display panel comprises a polaroid are solved, and the purposes of improving the bending resistance and the display brightness of the display panel are achieved under the premise of guaranteeing relatively low reflectivity of the display panel for external light.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

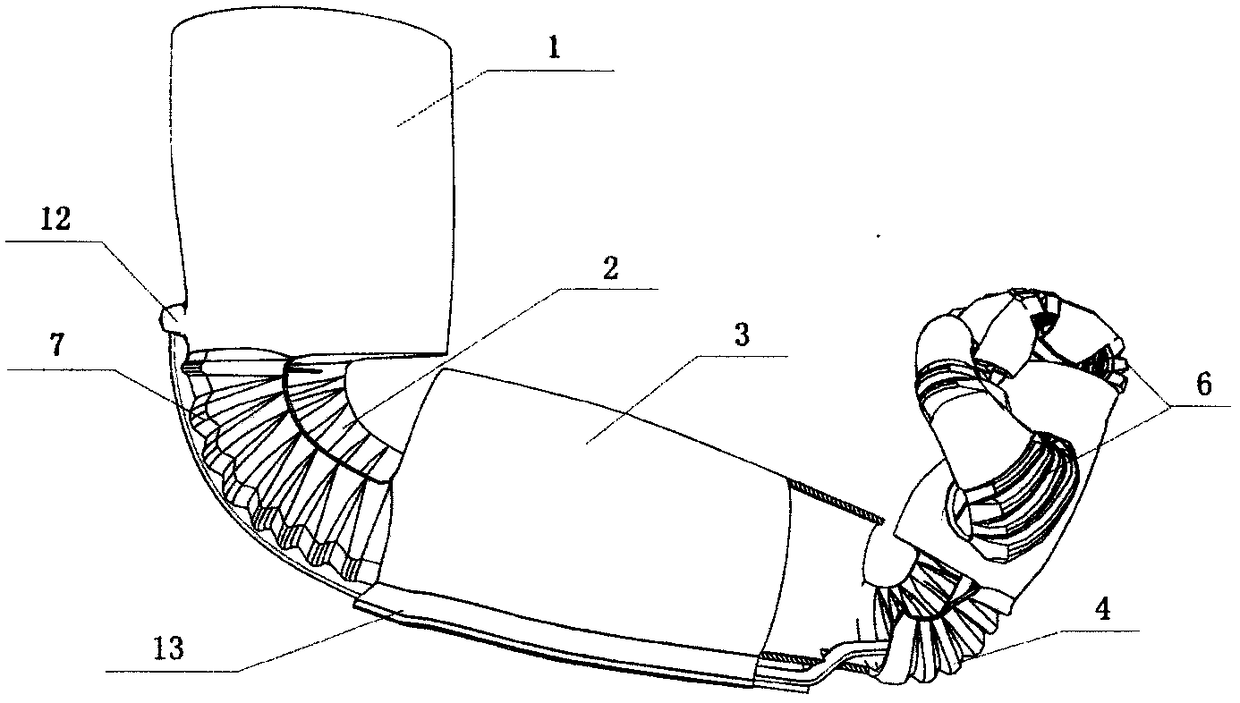

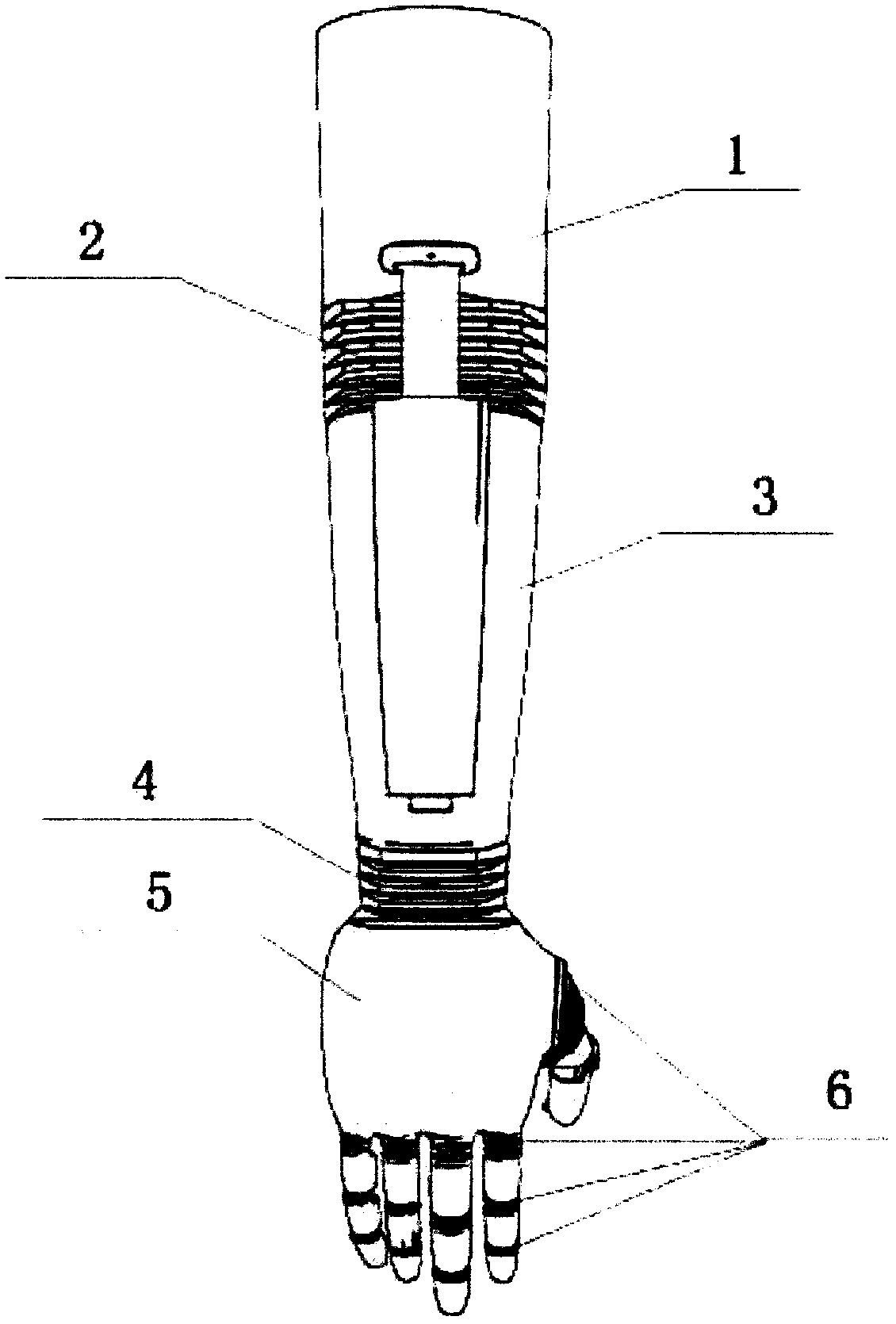

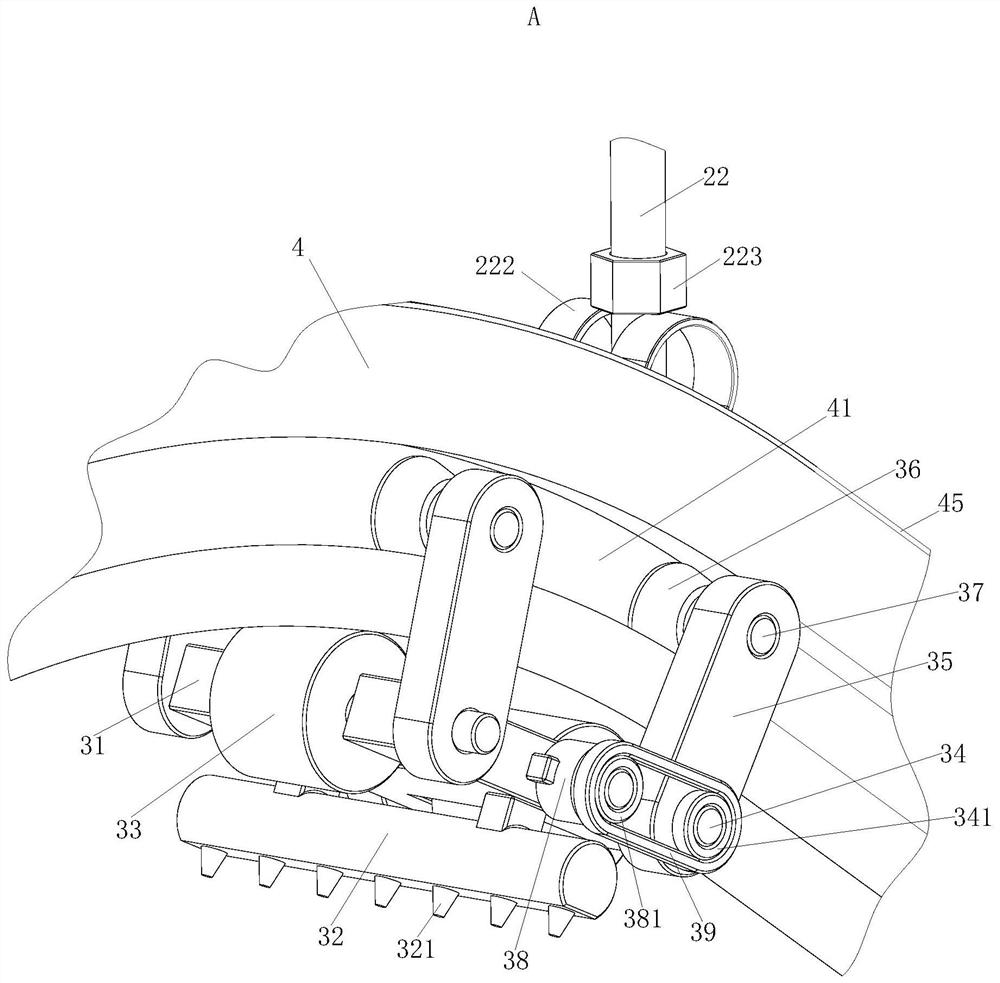

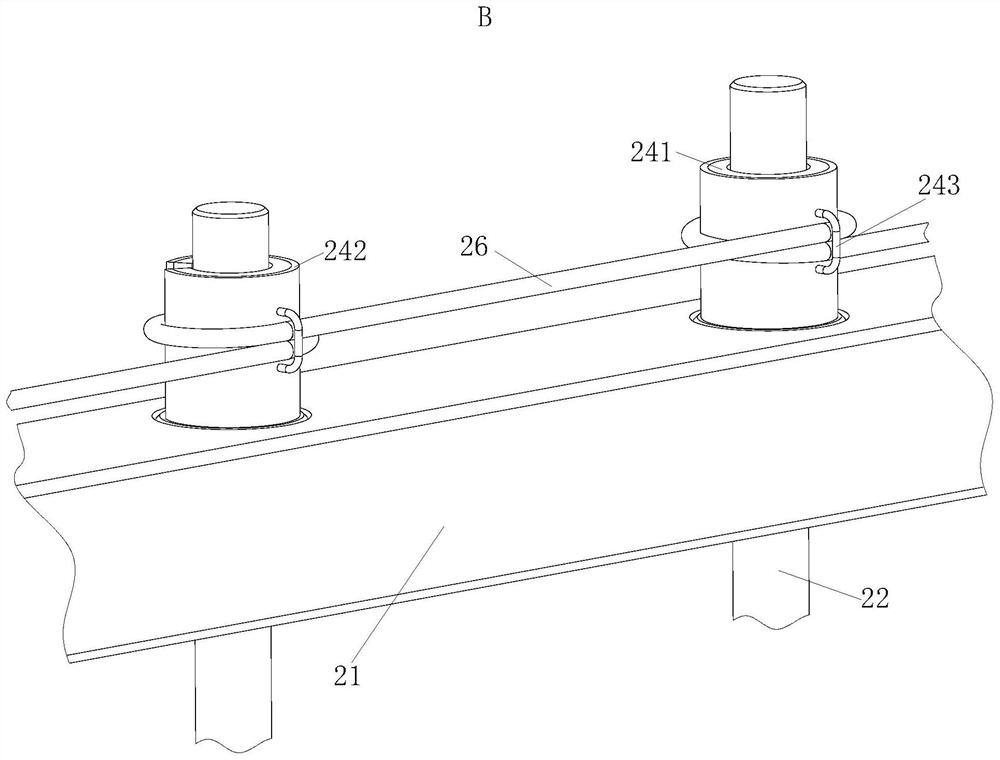

Printing prosthetic hand and manufacturing method thereof

PendingCN108186170AReduce weightLow bending resistanceAdditive manufacturing apparatusArtificial handsLittle fingerForearm cylinder

The invention relates to a printing prosthetic hand and a manufacturing method thereof, and belongs to the technical field of prosthetic hand designing and making. According to the technical scheme, the printing prosthetic hand is formed by a big arm cylinder, an elbow joint, a small forearm cylinder, a wrist joint, a palm, a thumb, an index finger, a middle finger, a ring finger and a little finger which are connected in sequence through integral one-time 3D printing, and a grasping and stretching system composed of stretching main sheet metal, a palm built-in module, finger stretching piecesheet metal and a fingertip prefabricated module which are connected in sequence is embedded into the prosthetic hand. The elbow joint, the wrist joint and all metacarpal joints and interphalangeal joints of the thumb, the index finger, the middle finger, the ring finger and the little finger are each of a folding type straight and curved telescopic joint structure, wherein the elbow joint and thewrist joint are each of a high-strength structure. For prosthetic hand making, a left or right prosthetic hand three-dimensional digital model file is built at first, and layer-by-layer three-dimensional continuous printing is conducted. The prosthetic hand is high in connection precision, low in weight, small in bend resistance and not prone to fatigue, assembling is not needed, the weight of the whole prosthetic hand can be lowered, and the cost can be lowered.

Owner:长春市漫思教育科技有限公司

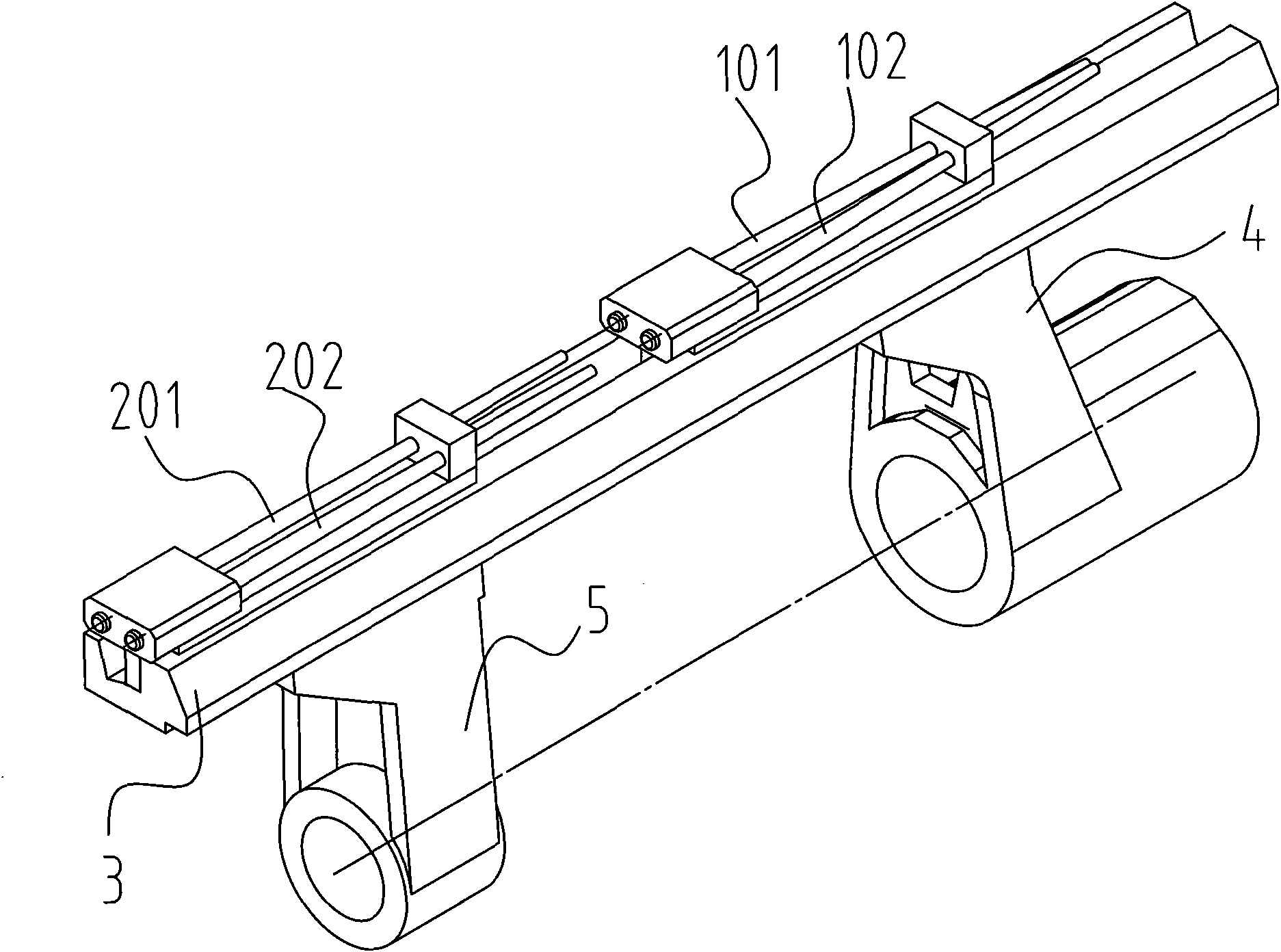

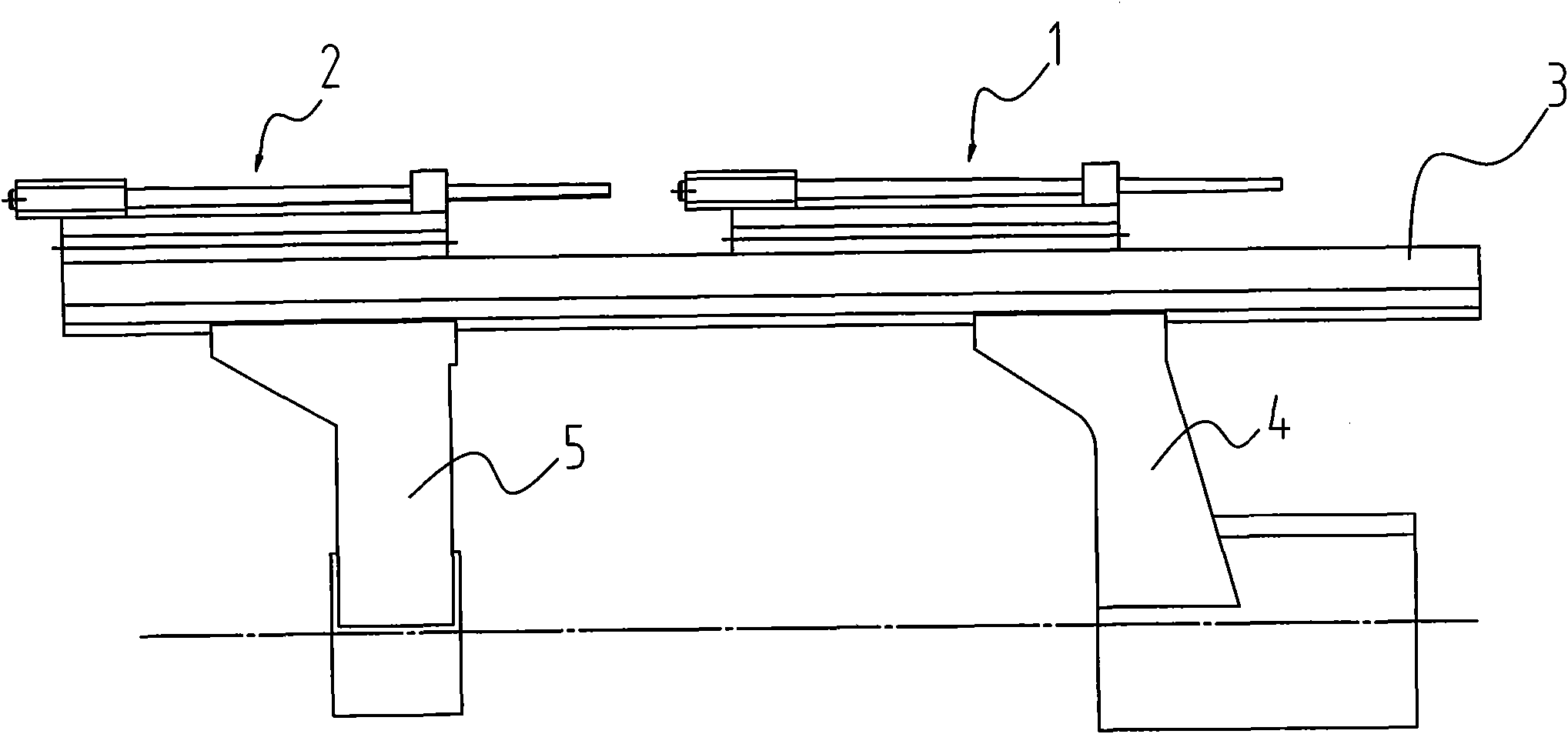

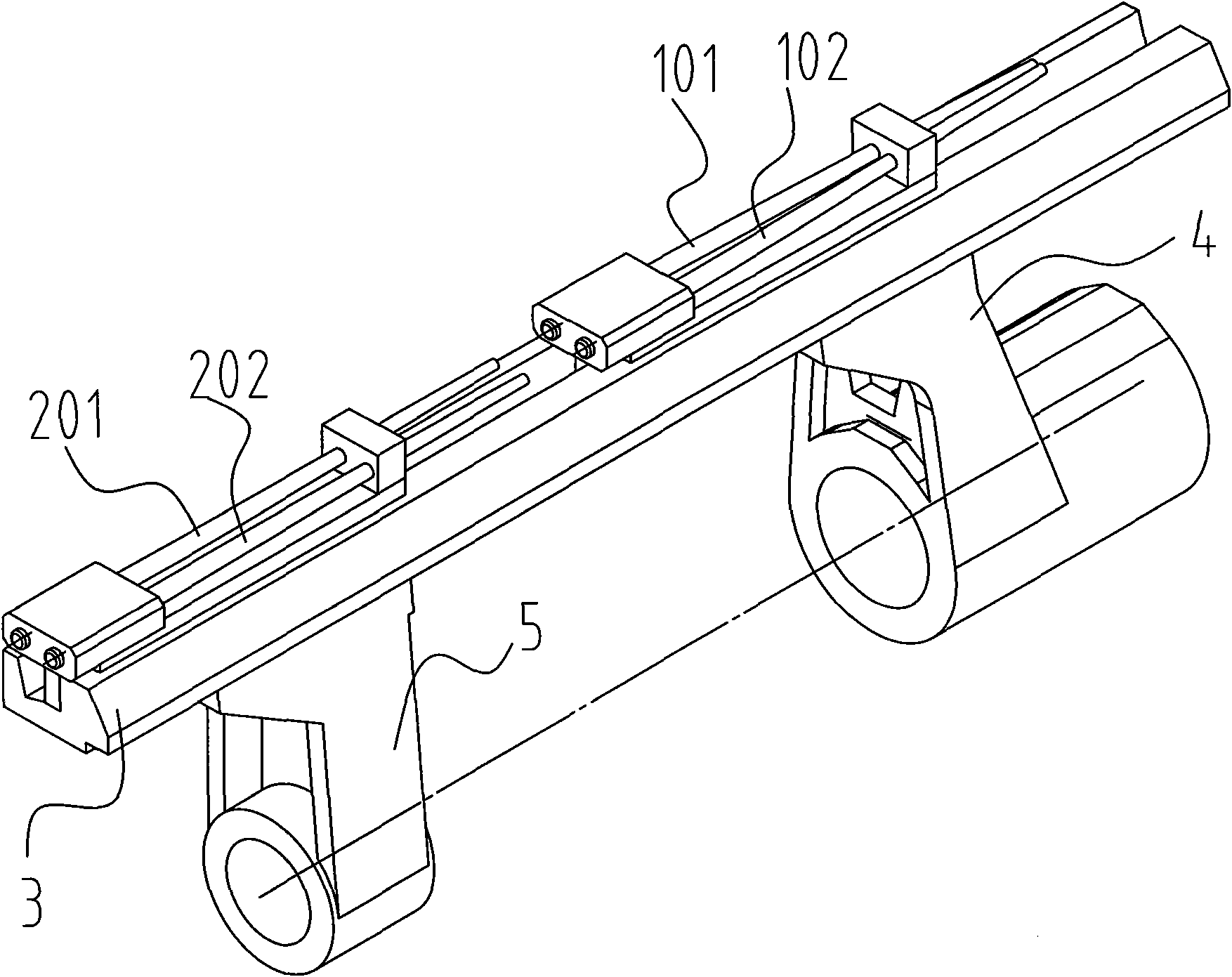

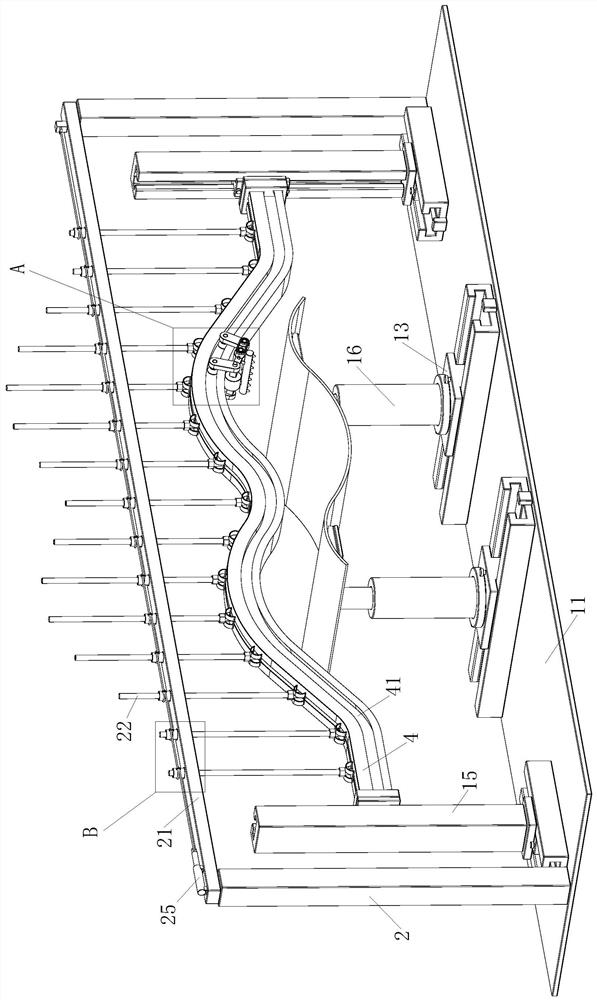

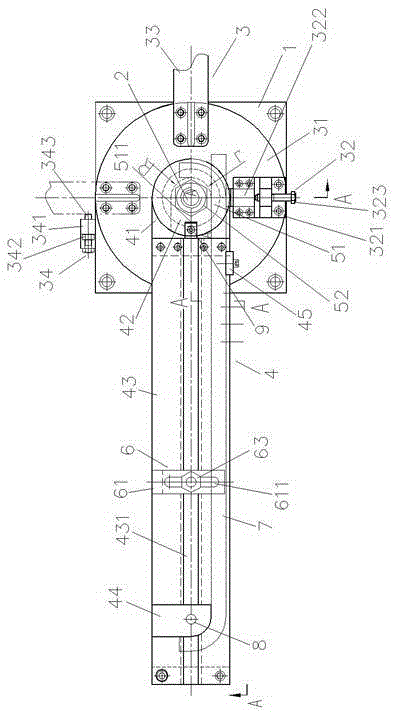

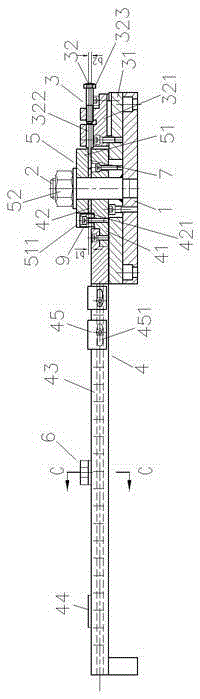

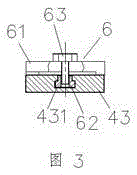

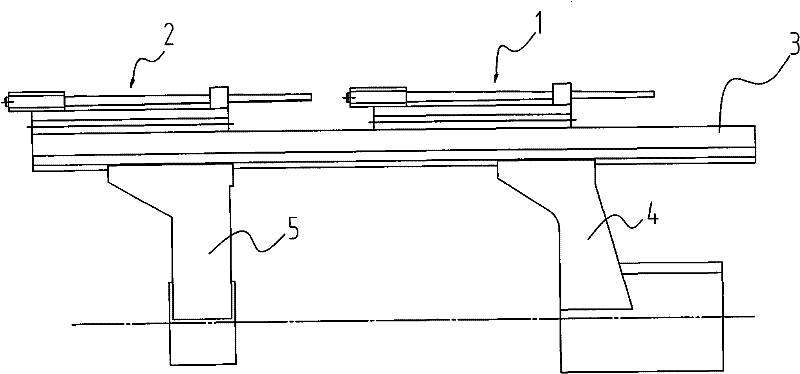

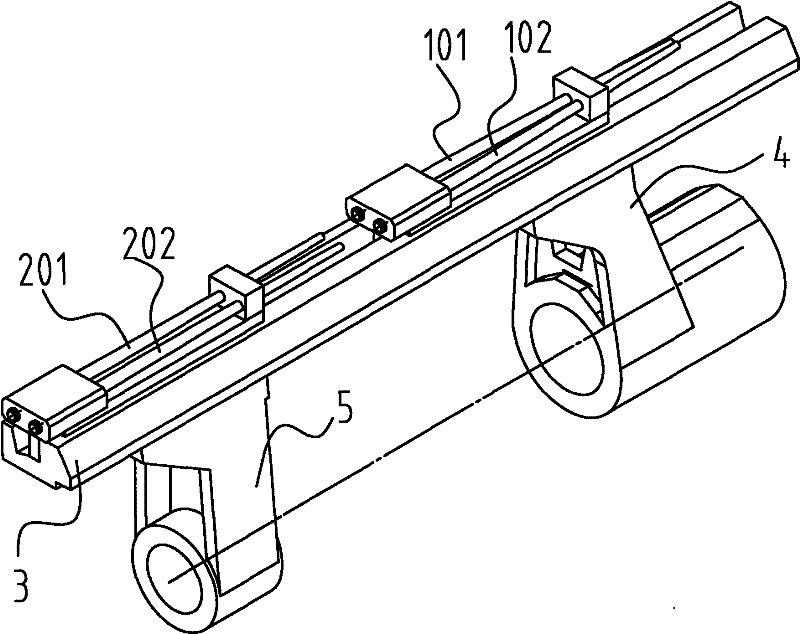

Double-swing main jet wefting insertion mechanism of jet loom

The invention discloses a double-swing main jet wefting insertion mechanism of a jet loom, comprising a fist-level main jet and a second-level main jet. The double-swing main jet wefting insertion mechanism of a jet loom is characterized in that the first-level main jet and the second-level main jet are arranged on the same buckle seat and synchronously swing with the buckle seat, the first-level main jet is arranged in front of the second-level main jet, and the nozzle of the second-level main jet is aligned with the nozzle of the first-level main jet one by one. In the invention, the fist-level main jet performs the main dragging action on weft yarn, the second-level main jet is the supplement of the fist-level main jet, and the second-level main jet and the first-level main jet are arranged on the same buckle seat and synchronously swing, which not only can obtain large enough traction to provide enough time for the weft yarn to fly but also can cause the weft yarn to fly along a straight line so as to reduce unnecessary bending resistance, and thus the weft yarn can smoothly fly. The invention lowers gas consumption, and can better improve wefting insertion rate to obtain the effect of energy saving and high efficiency. Meanwhile, the invention can better adapt to the requirements of high speed and wide width of jet looms.

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY

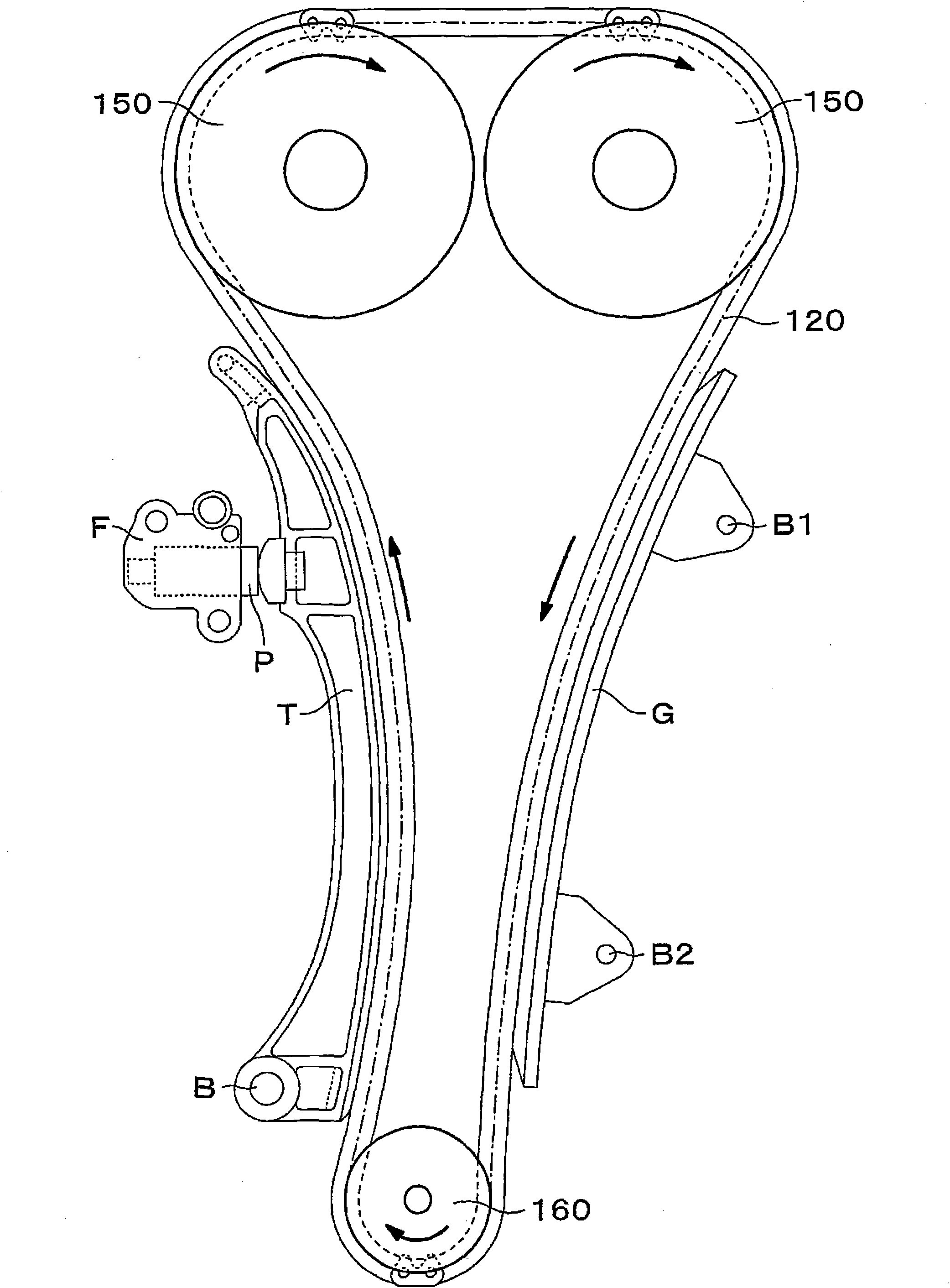

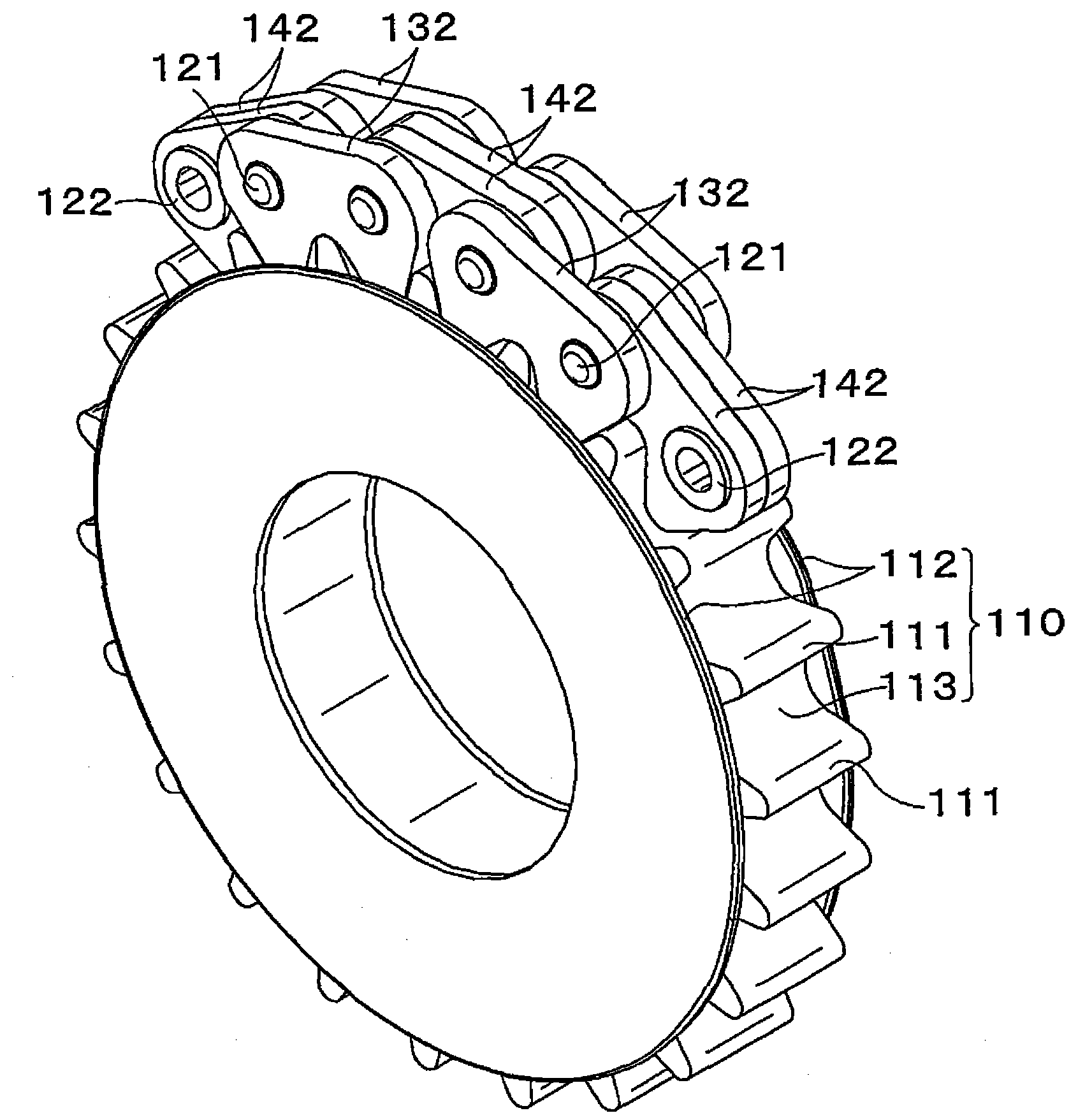

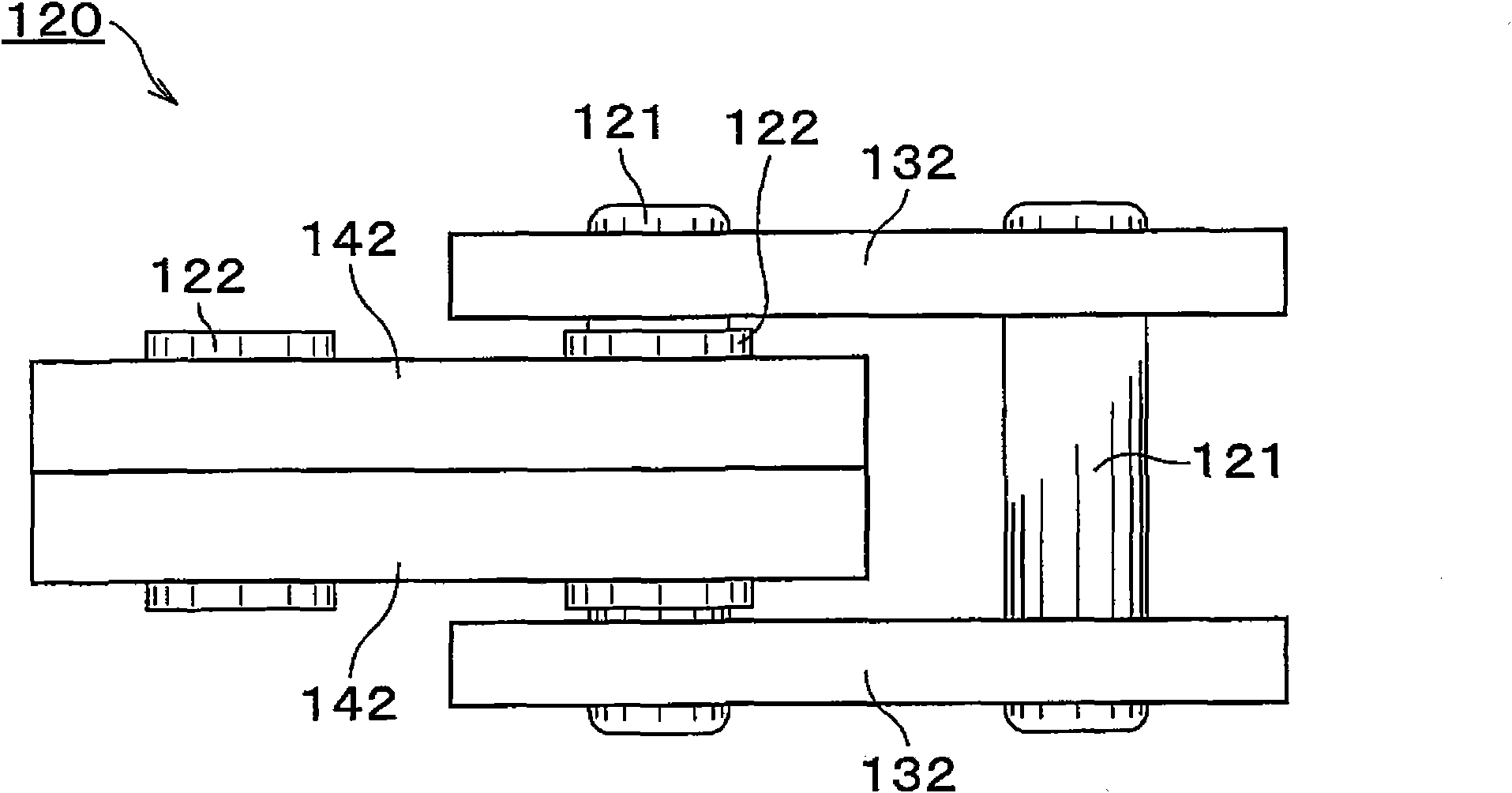

Silent chain transmission device

Owner:TSUBAKIMOTO CHAIN CO

Uniform spraying device for curved-surface plate

The invention belongs to the technical field of spraying equipment, and particularly relates to a uniform spraying device for a curved-surface plate. The uniform spraying device comprises a support part, a suspension part, a spraying mechanism and a rubber guide rail. According to the uniform spraying device for the curved-surface plate, a piston rod of a support cylinder drives the curved-surface plate to move upwards, so that a curved surface matched with the curved-surface plate is formed on the bottom surface of the rubber guide rail, after the matched curved surface is formed, a piston rod of a tensioning cylinder tensions a tension rope, a metal sheet is enabled to be attached to a rubber sheet, the rubber sheet is tightly attached to a hanger rod, the friction force between the rubber sheet and the hanger rod is increased, the hanger rod is locked, the lower end of the hanger rod is connected with the rubber guide rail, the bottom surface of the rubber guide rail is matched with the surface of the curved-surface plate accordingly, after the hanger rod is locked, the piston rod of the support cylinder drives the curved-surface plate to move downwards, the distance between the curved-surface plate and the spraying mechanism is the spraying distance, the vertical distances between the spraying mechanism and all the positions of the curved-surface plate are equal in the spraying process, then uniform spraying of the curved-surface plate is achieved, and the spraying quality is improved.

Owner:SHAOYANG VICTOR HYDRAULICS

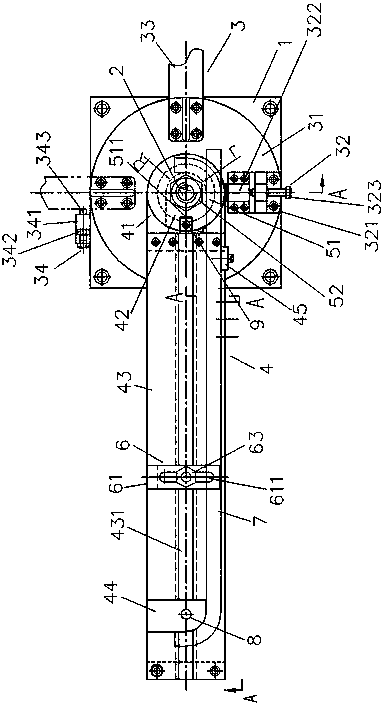

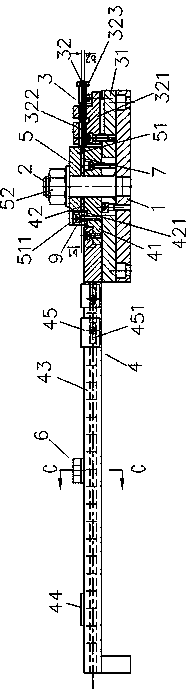

Copper bar bending device

The invention discloses a copper bar bending device. The copper bar bending device comprises a base plate, a main shaft, a copper bar bending mechanism, a copper bar locating mechanism, a locking mechanism and a copper bar pressing mechanism. The copper bar bending mechanism comprises a rotating disk, a wire pressing device, a handle and a handle limiting device, wherein the rotating disk is arranged on the main shaft in a sleeved mode, the wire pressing device and the handle are fixed to the radial outer side of the rotating disk, and the handle limiting device is fixed to the base plate. The copper bar locating mechanism comprises a backing plate, a core plate and a guide rail, wherein the backing plate and the core plate are sequentially arranged on the main shaft in a sleeved mode, a copper bar to be bent is longitudinally supported by the guide rail and one side of the backing plate, the inner side of one end of the copper bar to be bent abuts against one side of the core plate, and one end of the wire pressing device abuts against the outer side of one end of the copper bar to be bent. The copper bar pressing mechanism comprises an L-shaped pressing plate, a T-shaped nut and a pressing bolt. The locking mechanism comprises an upper pressing block and a locking nut. The copper bar bending device saves time and labor when operated, and is high in machining efficiency, low in cost, small in bending resistance in the bending process and suitable for single-piece or small-scale production.

Owner:ZHENJIANG ZHONGCHUAN XIANDAI GENERATING EQUIP CO LTD

Strip of male fastening means, patch cut therefrom, and fastening tape tab comprising such patch

InactiveCN101076269AReduce stiffnessImprove flexibilityAbsorbent padsLogisticsStructural engineeringMechanical engineering

The invention provides a patch of a male fastening means, in particular, a hook patch with decreased bending resistance. The patch according to the invention comprises a backing bearing a plurality of male fastening elements, in particular hook elements. The patch is integral and comprises a plurality of incisions. Said incisions do not extend across the whole width of the patch but preferably leave at least one intact bridge across the cross-direction of the patch. Furthermore, a fastening tape tab having a manufacturer's and user's end is provided, the fastening tape tab comprising a support layer bearing on its major surface of the user's end at least one fastening patch according to the invention. Furthermore, a strip is provided from which a patch according to the invention is cut.

Owner:3M INNOVATIVE PROPERTIES CO

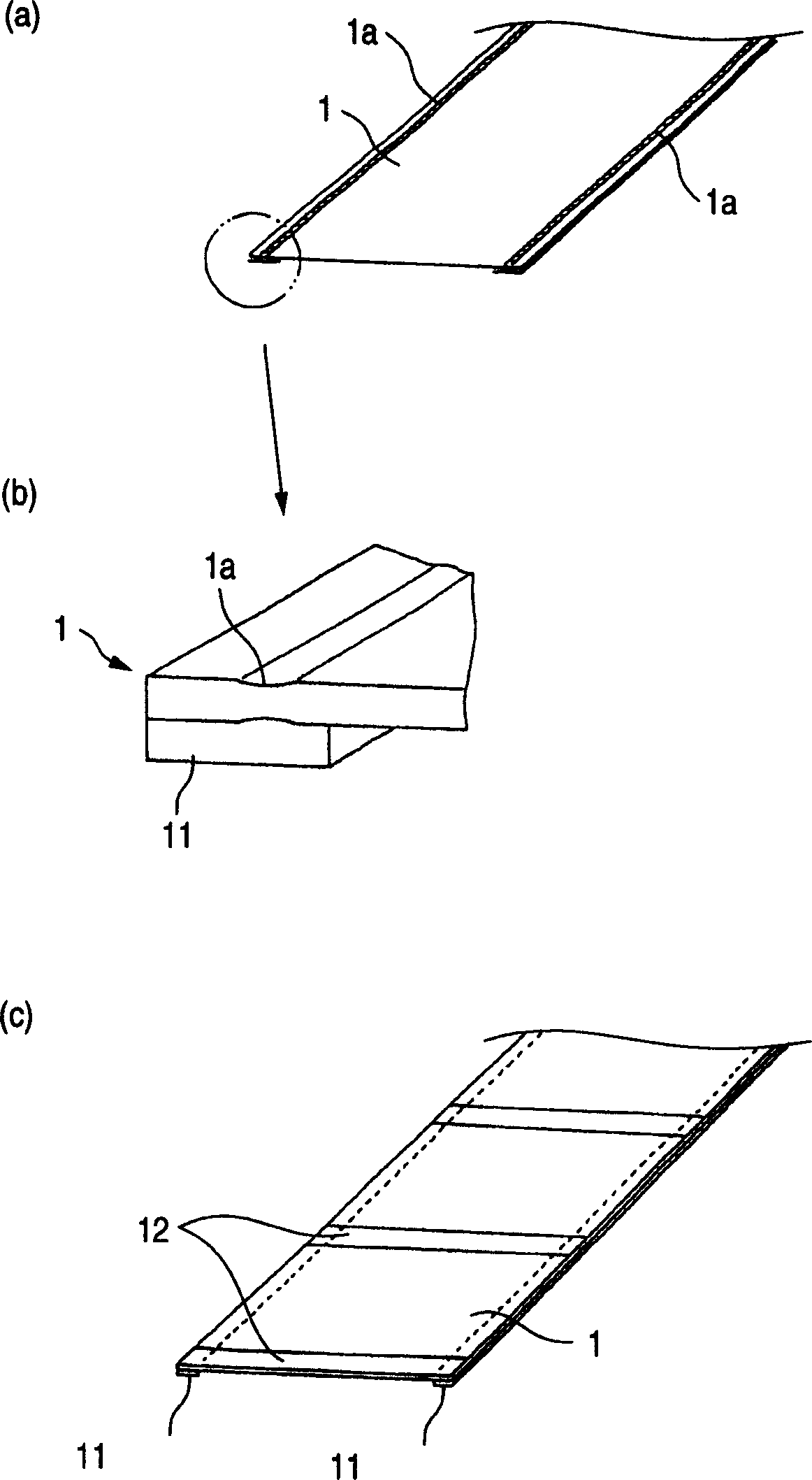

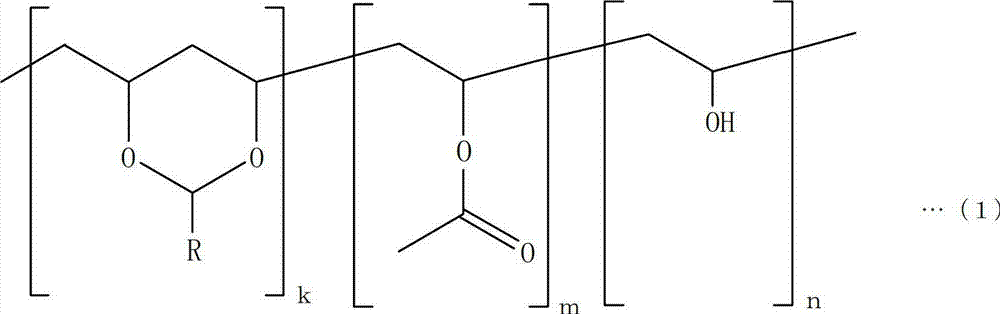

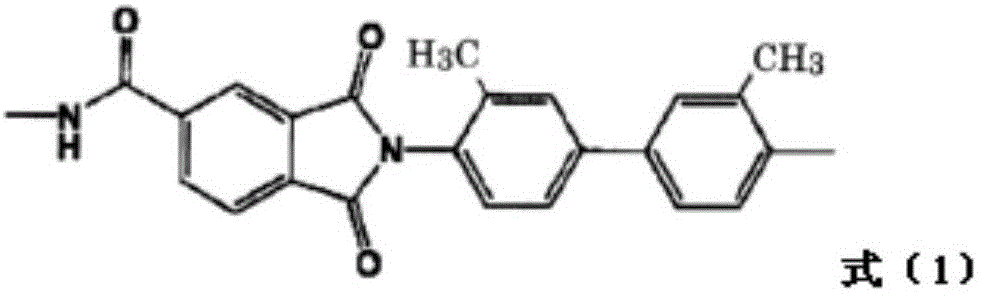

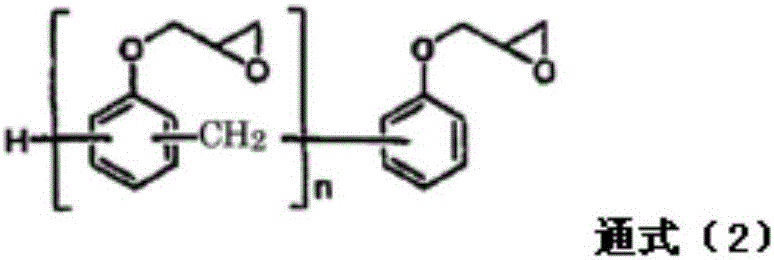

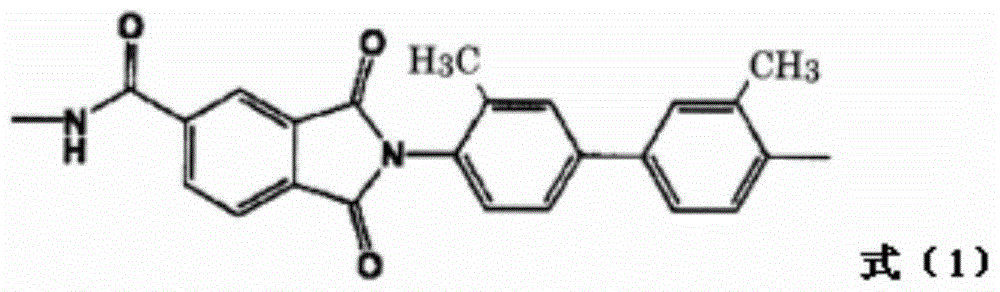

Resin composition for forming optical waveguide and optical waveguide using the composition

InactiveCN103176359ALow bending resistanceLow refractive index state exhibits excellent bending resistanceCoatingsOptical waveguide light guideChemical compoundPolyvinyl alcohol

A resin composition for forming an optical waveguide is used as a material for forming an optical waveguide, in particular, a material for forming a clad layer, and brings together excellent bending resistance, a low refractive index and low tackiness suitable for a roll-to-roll (R-to-R) process. The resin composition for forming the optical waveguide to be used in formation of an optical waveguide includes a polyvinyl acetal compound having a structural unit represented by the following general formula (1) as a main component: in the formula (1), R represents an alkyl group having 1 to 3 carbon atoms, and k, m, and n represent ratios of respective repeating units in a main chain and each represent an integer of 1 or more.

Owner:NITTO DENKO CORP

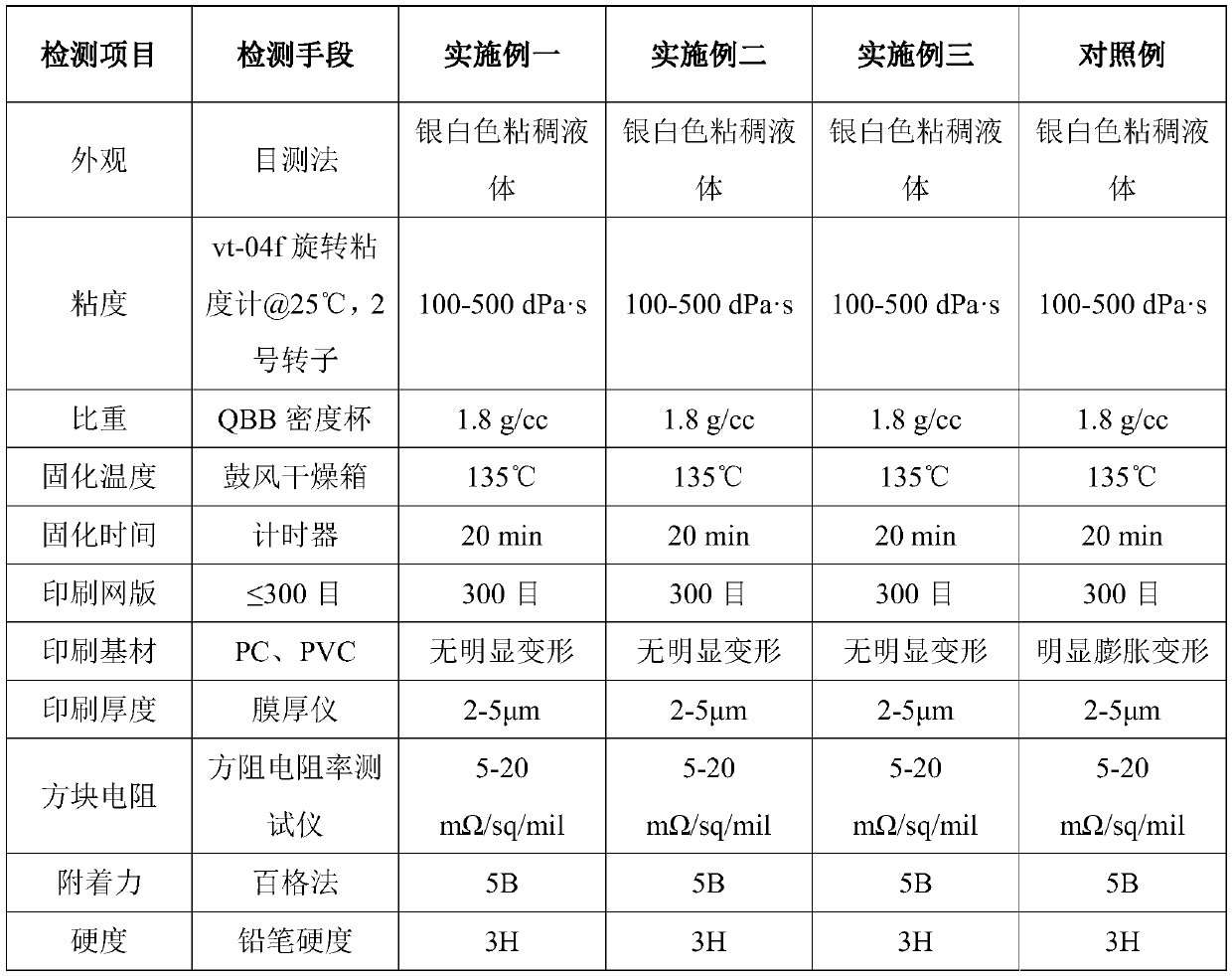

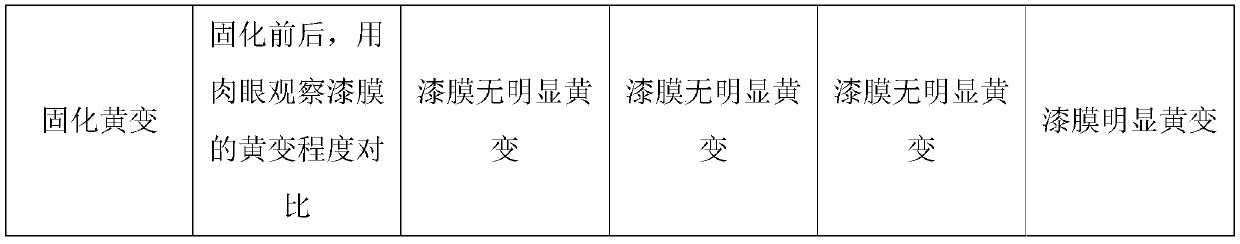

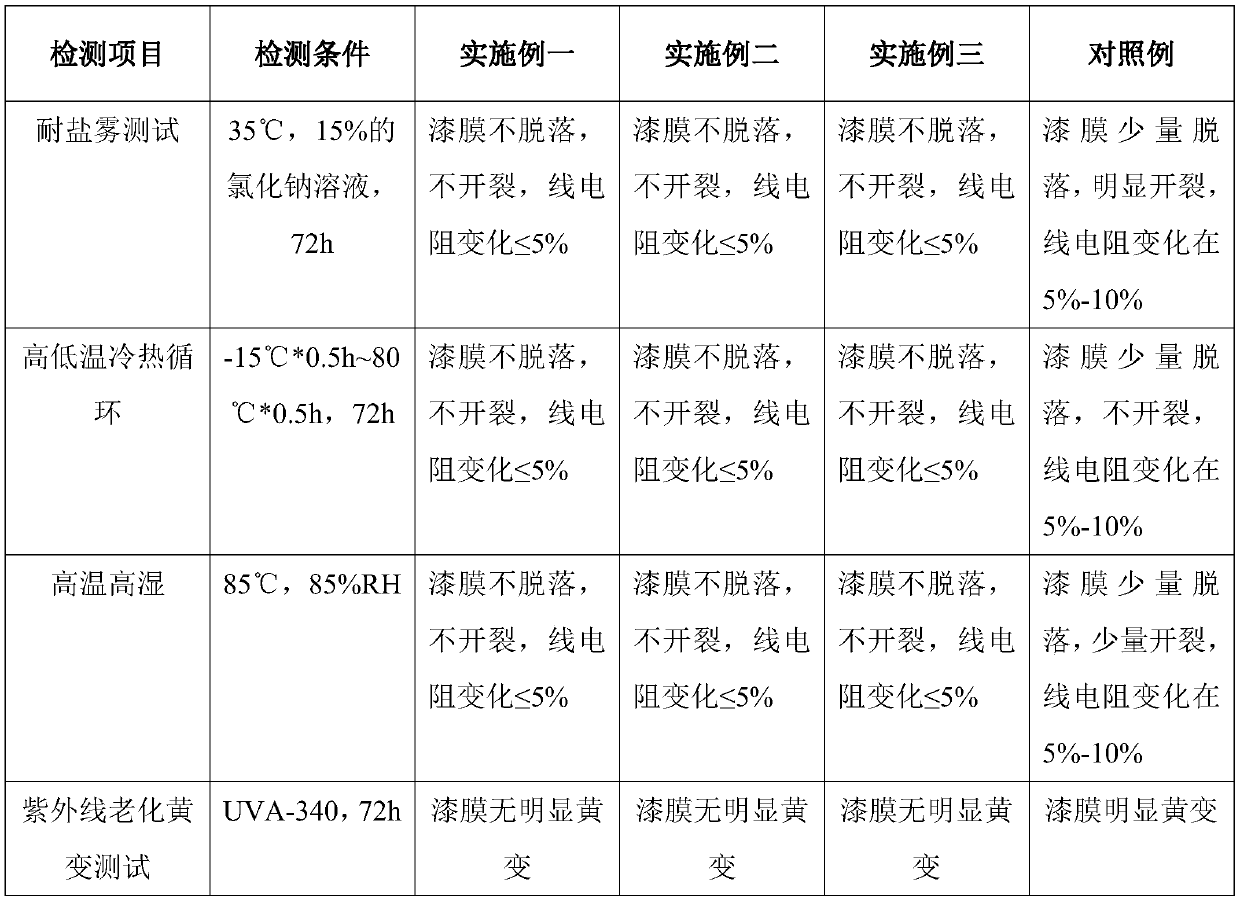

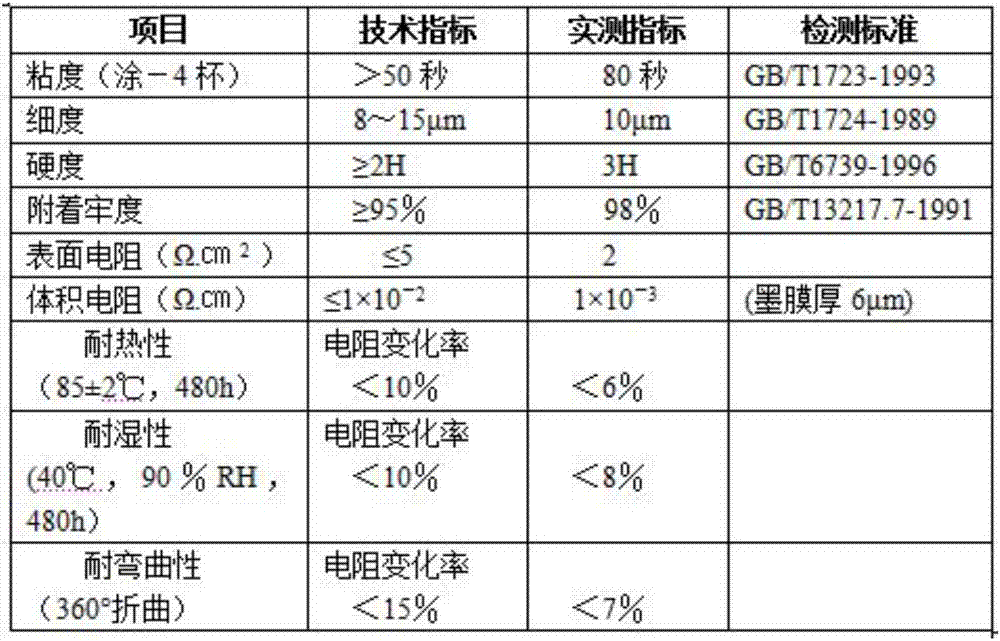

Antioxidant low-corrosion low-temperature-curing conductive ink

The invention discloses an antioxidant low-corrosion low-temperature-curing conductive ink. A formula of the antioxidant low-corrosion low-temperature-curing conductive ink comprises, by weight, 30 to75 parts of a resin intermediate, 4 to 25 parts of a solvent, 0.5 to 5 parts of an antioxidant, 10 to 50 parts of silver powder and 0.5 to 5 parts of an auxiliary agent; the resin is hydroxyl or carboxyl modified ternary vinyl chloride-vinyl acetate resin, the molecular weight ranges from 15000 to 65000, and K ranges from 35 to 60; the solvent is selected from one or more of diethylene glycol butyl ether acetate, diethylene glycol butyl ether, ethylene glycol, ethylene glycol butyl ether acetate, ethylene glycol butyl ether, 1, 4-butanediol, triethylene glycol butyl ether, tripropylene glycol, diethylene glycol, tripropylene glycol butyl ether, 3-methoxy-3-methyl-1-butanol and dipropylene glycol methyl ether; and the resin intermediate is a resin diluted by the solvent. The phenomenon that the surface of a conductive ink paint film is gradually yellowed is effectively changed, the bottom biting defect of conductive ink on plastic films such as PVC, PC, ABS and PMMA can be prevented, and the product quality is effectively improved.

Owner:佛山市顺德区百锐新电子材料有限公司

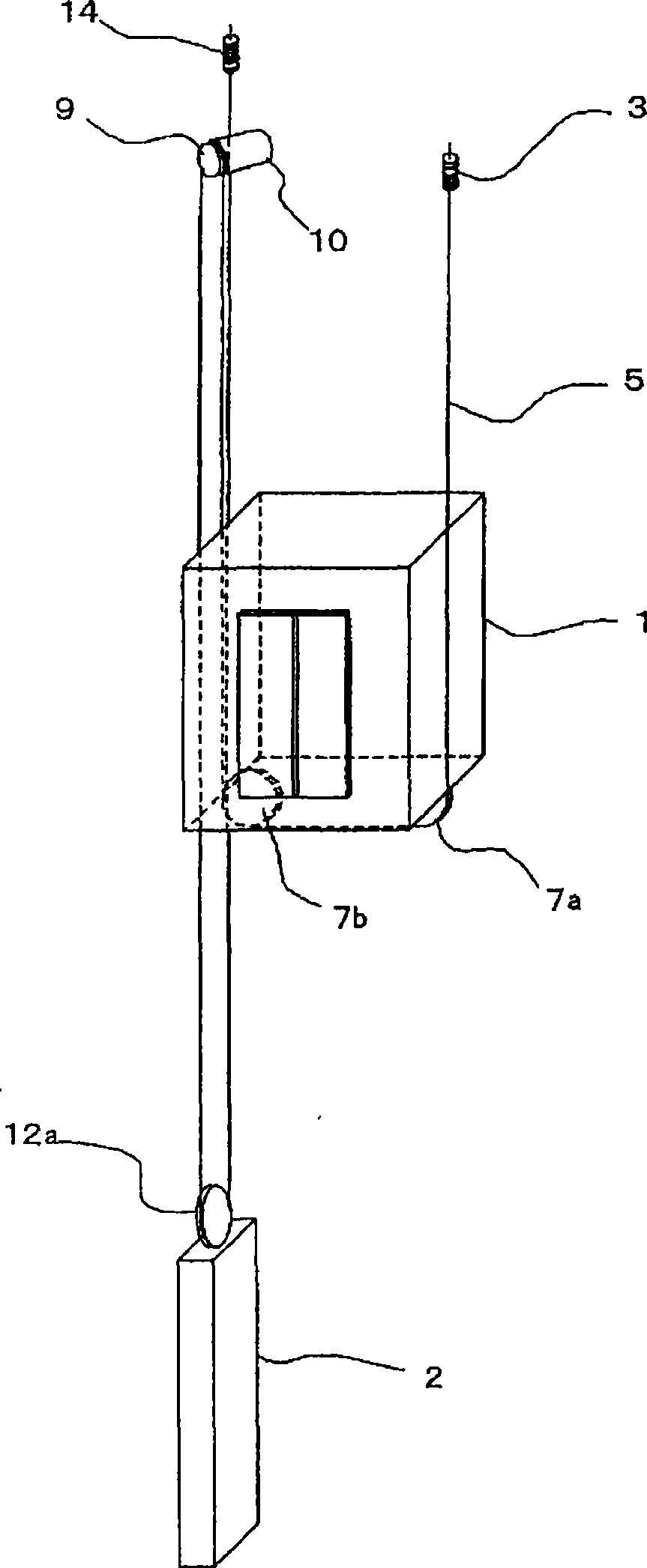

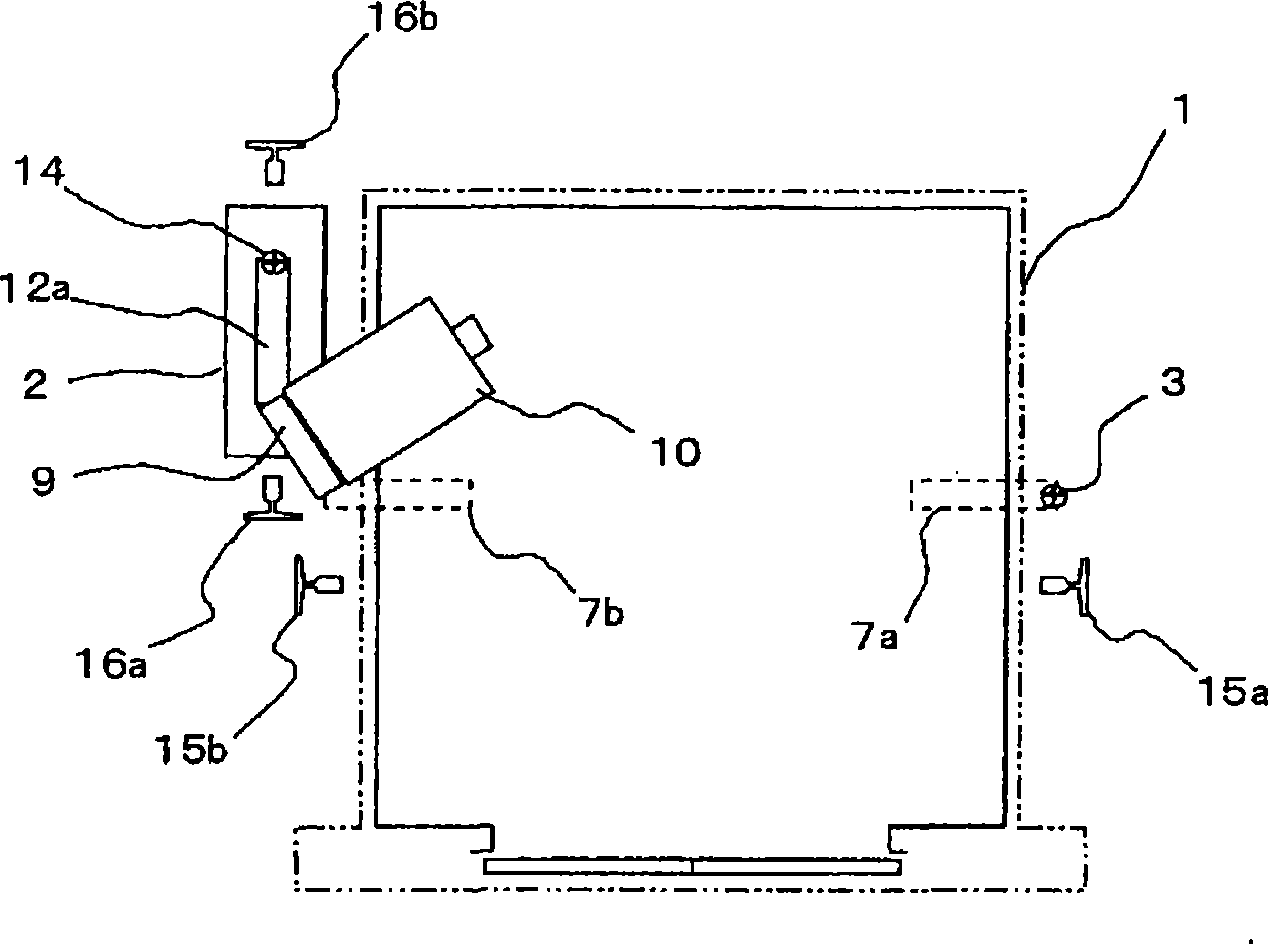

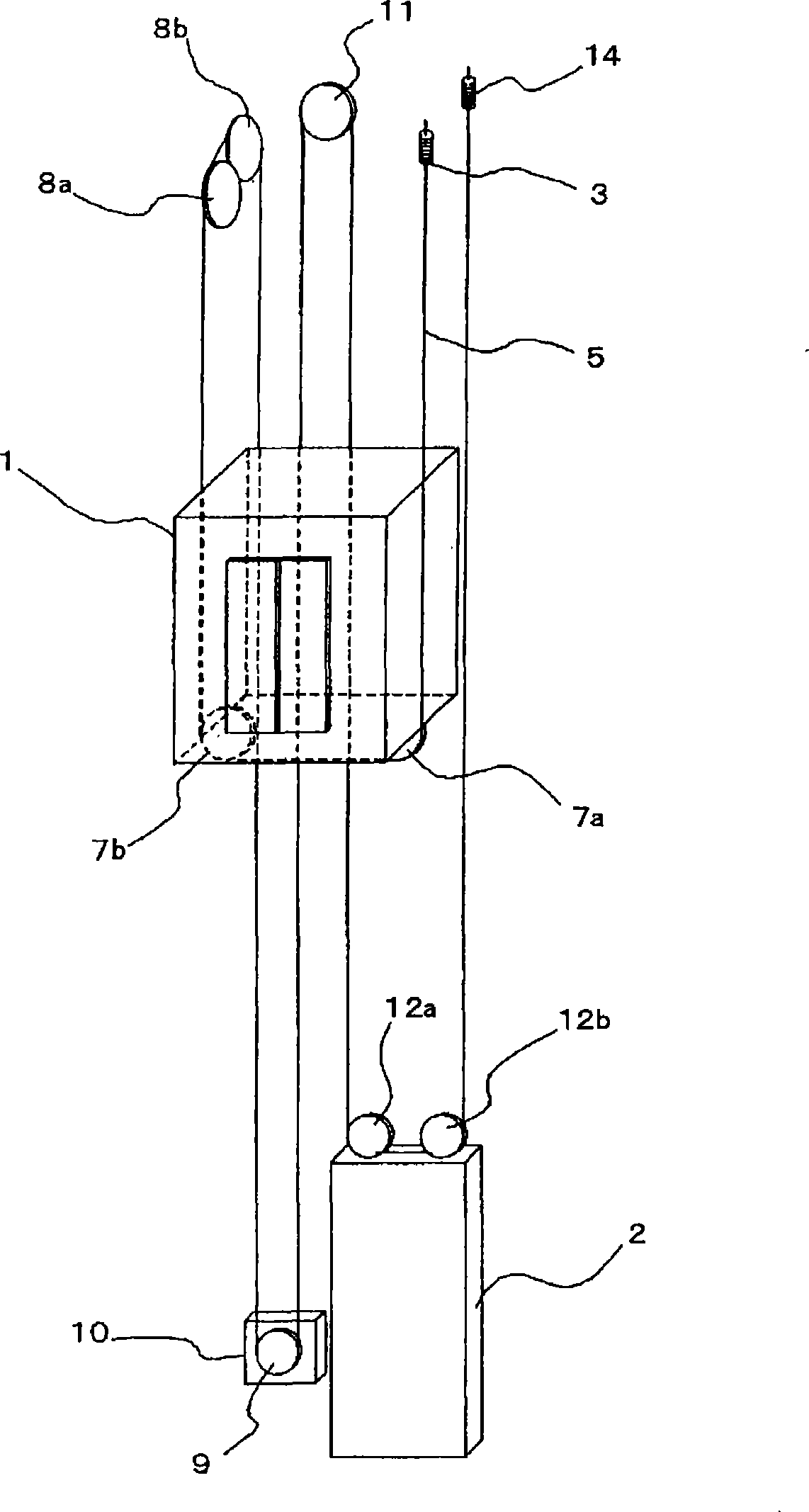

Elevator device

ActiveCN101426709AReduce bending stressLow bending resistanceElevatorsBuilding liftsPulleyAutomotive engineering

An elevator device where a reduction in the lifetime of the main rope is kept as small as possible even if the diameter of the drive sheave is reduced. The elevator device uses a hoist (10(10A)) having the drive sheave (9) with the diameter not more than 29 times as large as the diameter of the main rope, and at least an elevator car (1) and counterbalance weight (2) have rope sheaves (7a, 7b, 11 (12a, 12b)). The diameters of the rope sheaves (7a, 7b, 11 (12a, 12b)) are set greater than the diameter of the drive sheave (9).

Owner:HITACHI LTD +1

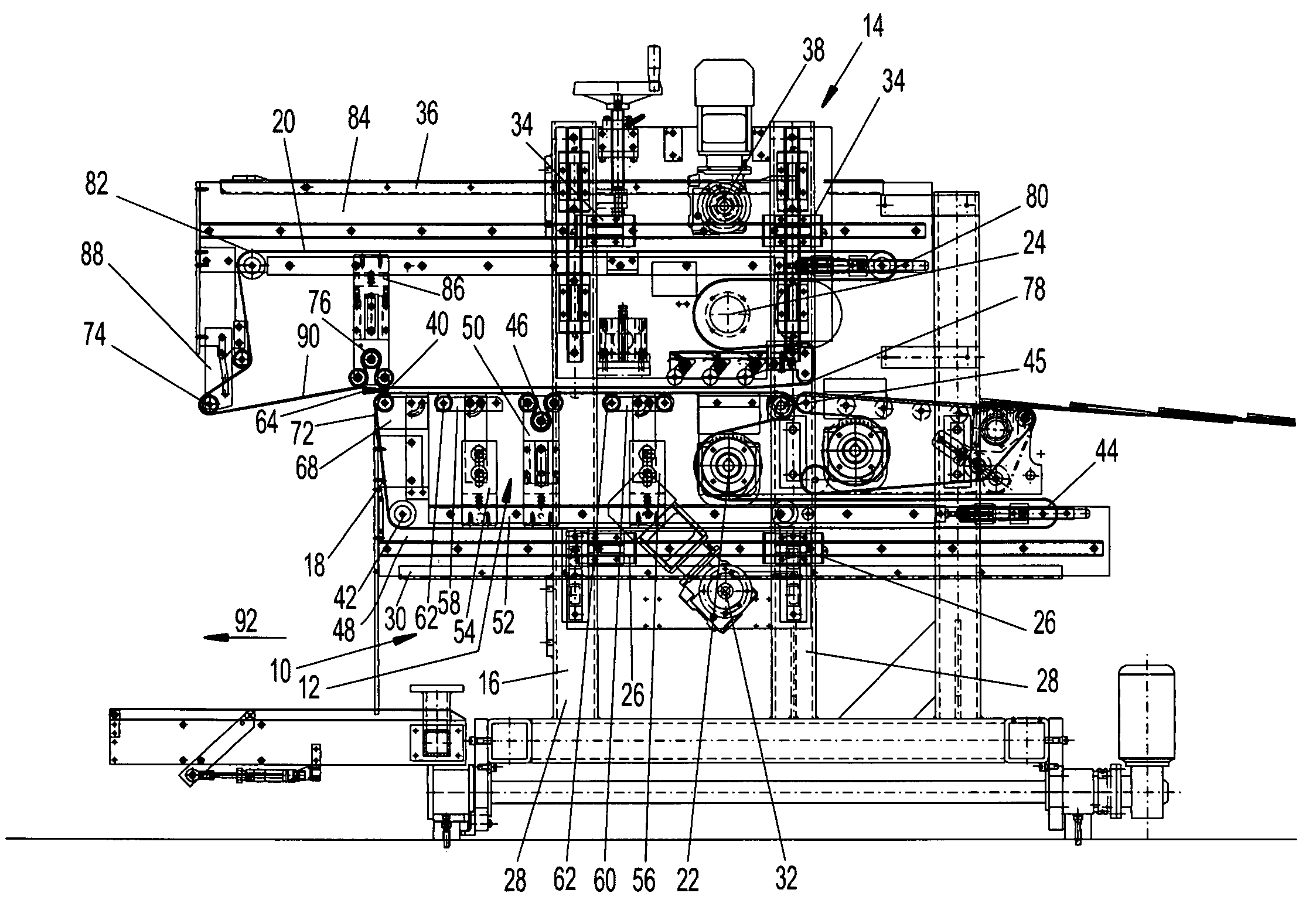

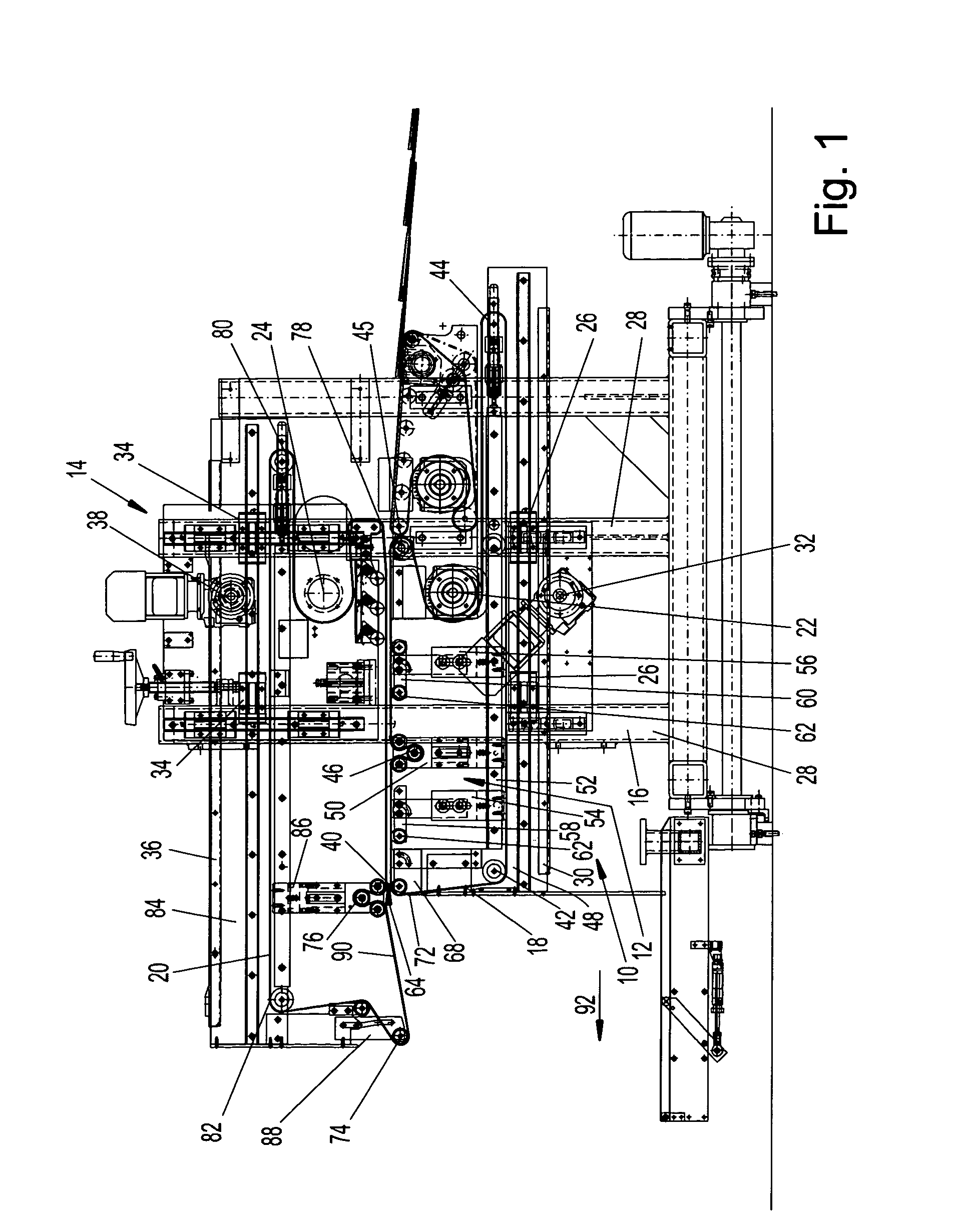

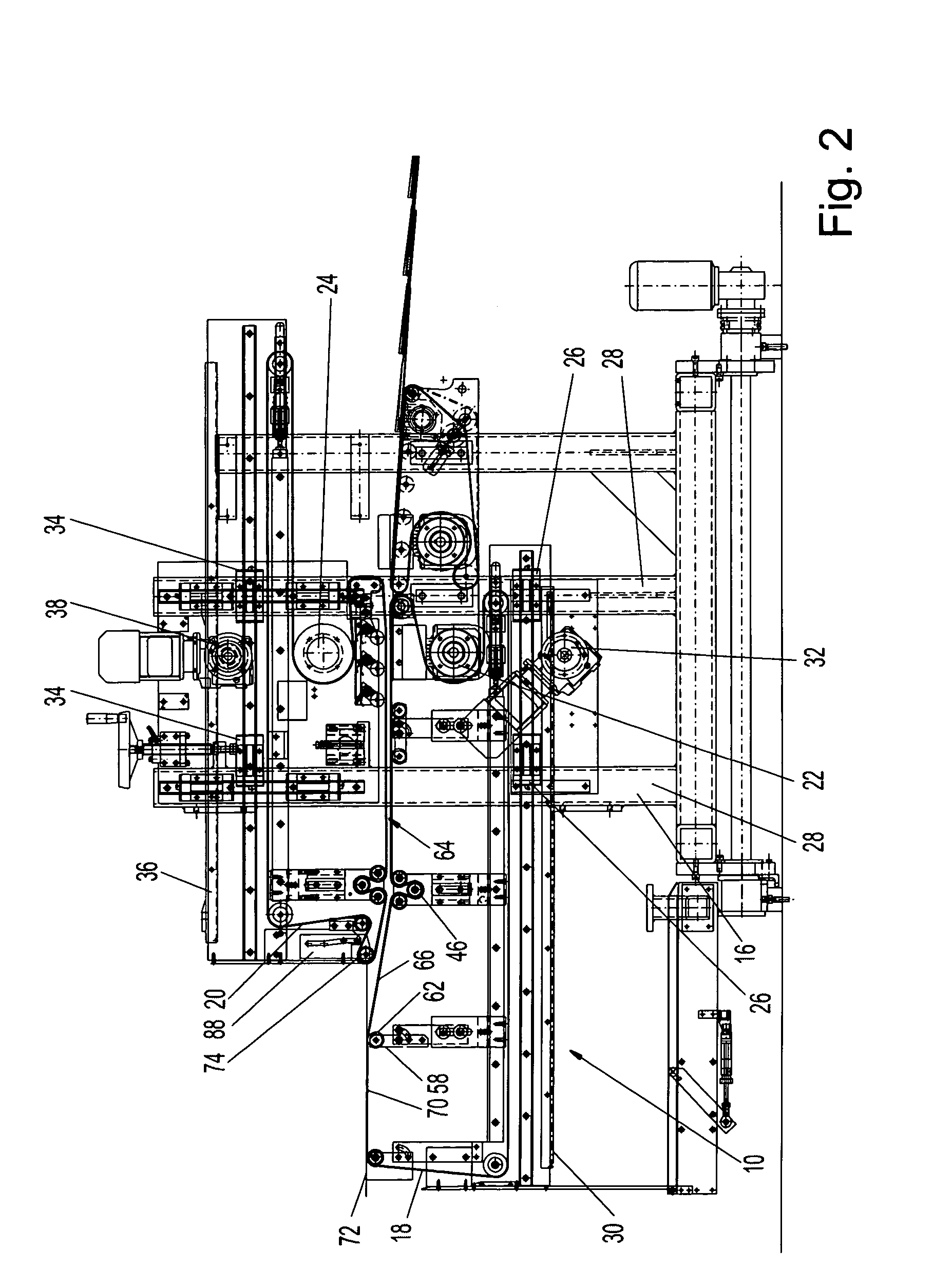

Device for stacking flat products

InactiveUS7540702B2Low bending resistanceFacilitates up-stackingConveyorsPile receiversEngineeringLower upper

The invention concerns a device for stacking flat products, in particular, folding boxes, comprising a lower and upper transport unit, wherein the flat products are transported between the transport units in the direction of a stack shaft, each transport unit comprising at least one conveyor belt, wherein the position of the front end, facing the stack shaft, of at least one conveyor belt can be adjusted and changed.

Owner:WILHELM BAHMULLER MASCHBAUU PRAZISIONSWERKZEUGE GMBH

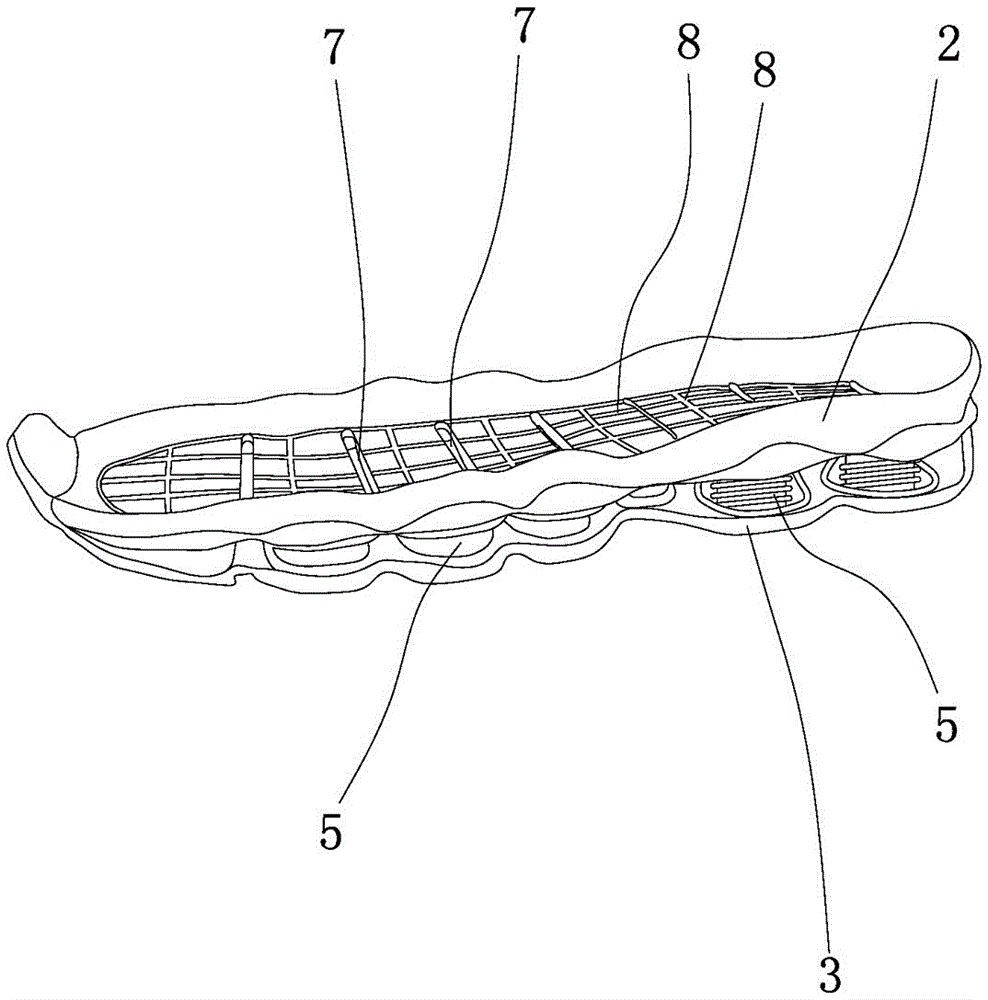

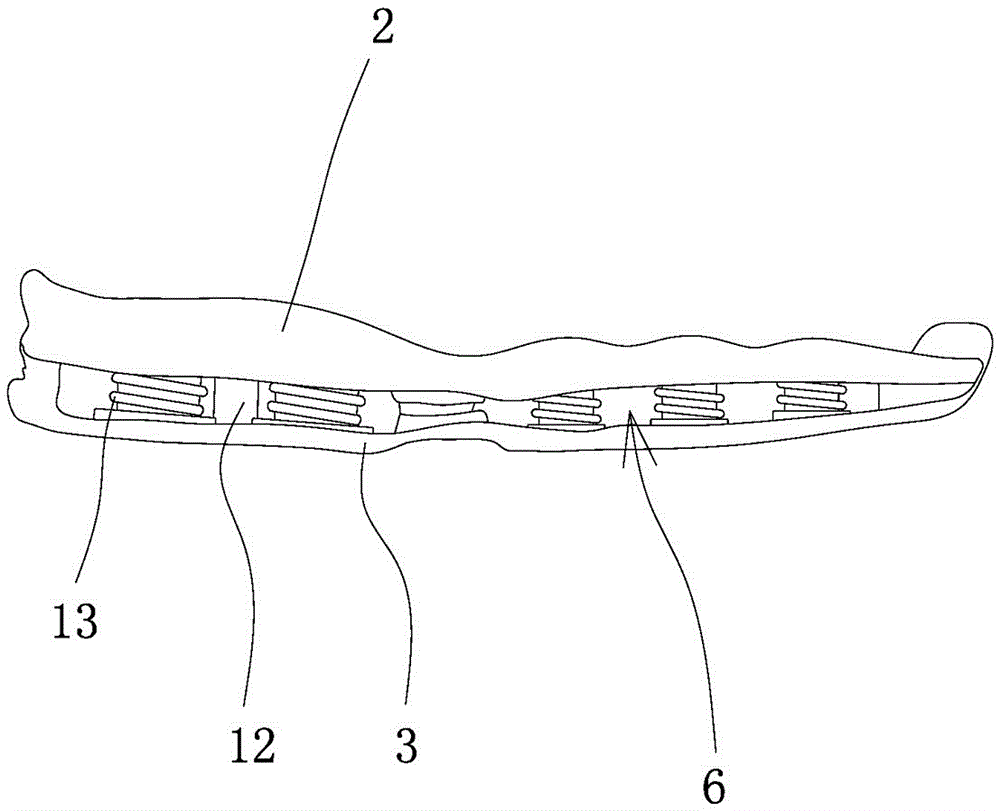

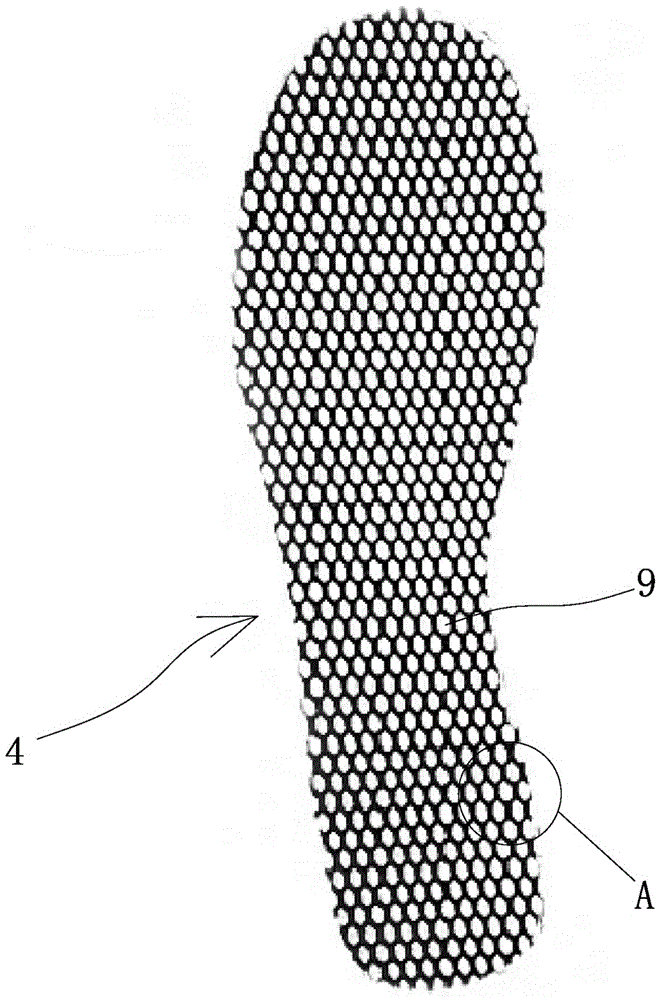

Sports shoe sole

The invention provides a sports shoe sole, belongs to the field of articles for daily use, and solves the problem that the conventional sports shoe sole is poor in breathability. The sports shoe sole sequentially comprises an upper sole, a middle sole and a lower sole from the top to the bottom sequentially, wherein mutually bonded breathable mesh cloth is arranged between the upper sole and the middle sole; the middle sole is connected with the lower sole through a plurality of shock-absorbing columns which are uniformly distributed at intervals; airflow chambers communicated with the outside are formed among the middle sole, the lower sole and the shock-absorbing columns; a plurality of breathing slots communicated with the airflow chambers are formed in the middle sole; airflow passages which are inwardly sunk and are in grid distribution are uniformly formed in the upper surface of the middle sole; a plurality of honeycomb holes in honeycomb distribution are uniformly formed in the breathable mesh cloth; a plurality of breathing holes are uniformly formed in the upper sole; the airflow chambers, the breathing slots, the airflow passages, the honeycomb holes and the breathing holes are mutually communicated. The sports shoe sole has the advantages of good sports performance, good breathability, good comfort and the like.

Owner:TAIZHOU FEIYING SHOES

Method for controlling standing-phase damping of artificial knee joint

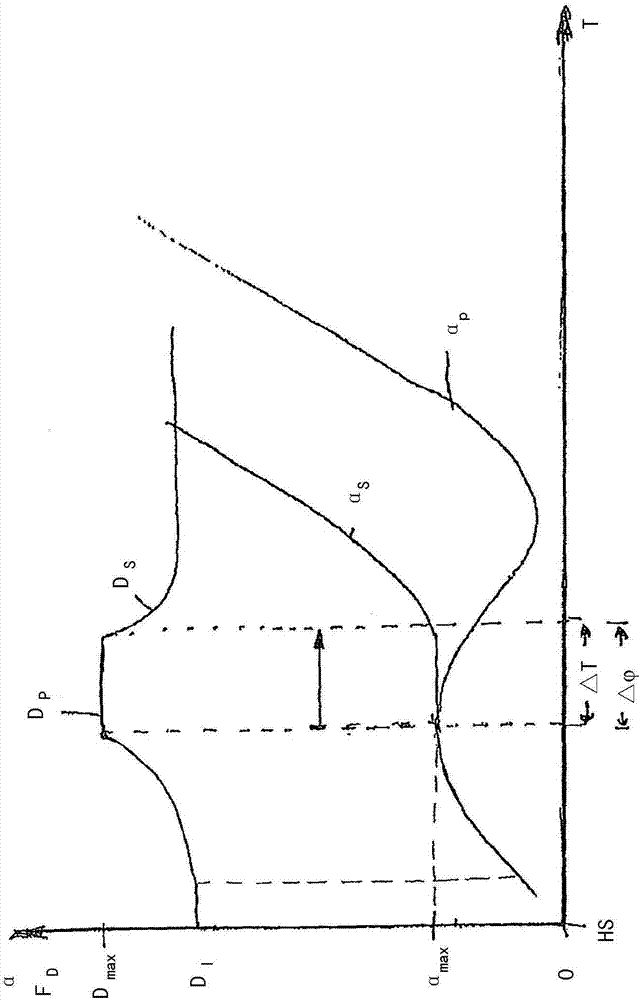

The invention relates to a method for controlling the standing-phase damping of an artificial knee joint. The artificial knee joint comprises an upper part (1) and a lower part (2) which are secured together in a pivotal manner about a pivot axis (4), and is provided with a resistance unit (6) which is arranged between the upper part (1) and the lower part (2) and has an adjustment device (7) viawhich the damping resistance (FD) can be modified, and a control unit (8) which is coupled to the adjustment device (7) and which is connected to at least one sensor (9). The adjustment is carried outon the basis of sensor data, and the knee angle (alpha) is detected by the at least one sensor (9) during the standing-phase inflexion up to the terminal standing phase. The flexion damping (FD) is increased to a level (FDmax) above an initial flexion damping (FDI) in order to prevent a further inflexion upon reaching a specified maximum knee angle ([alpha]max).

Owner:OTTO BOCK HEALTHCARE PROD GMBH

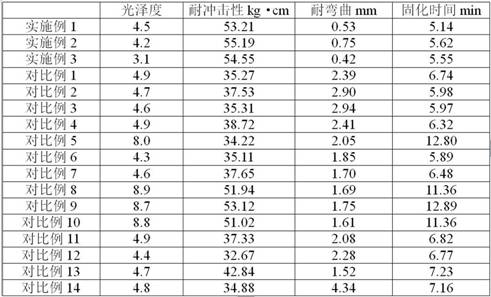

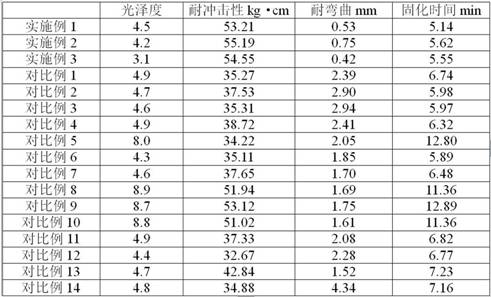

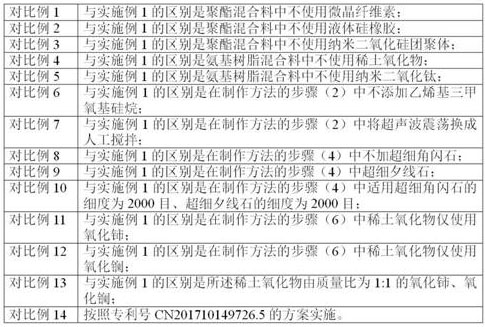

Quick-curing powder coating and preparation method thereof

ActiveCN112574634AImprove agglutinationImprove bonding effectChemical industryConjugated diene hydrocarbon coatingsPolyvinylidene fluorideMicrocrystalline cellulose

The invention relates to the field of powder coatings, in particular to a quick-curing powder coating and a preparation method thereof, and the powder coating comprises a polyester mixture and an amino resin mixture; wherein the polyester mixture is prepared from polyarylester, polybutylene terephthalate, polyethylene micronized wax, microcrystalline cellulose, polyvinyl acetate, liquid silicone rubber, nano silicon dioxide aggregate, barium sulfate and melamino-formaldehyde resin; wherein the amino resin mixture is prepared from urea resin, isoprene rubber, rare earth oxide, extinction calcium carbonate, polyacrylonitrile, nano titanium dioxide and polyvinylidene fluoride resin. The coating has the advantages of high surface energy receiving efficiency, high curing speed, favorable mechanical strength and wide application range.

Owner:宁波爱甬新材料科技有限公司

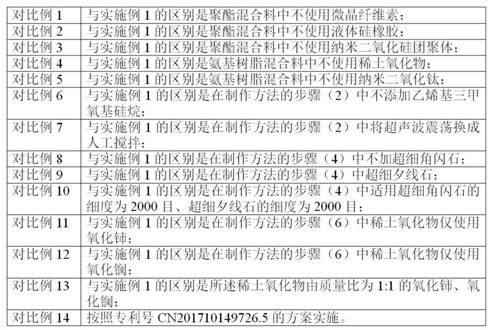

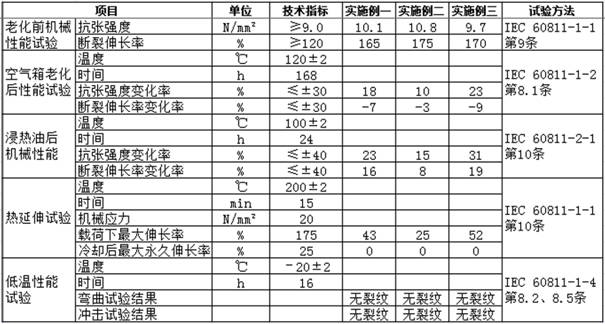

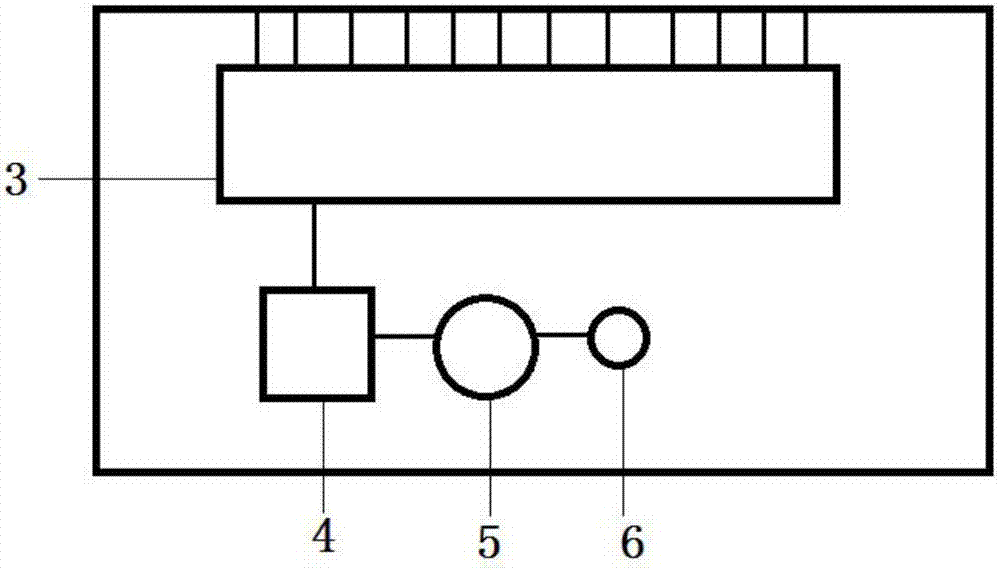

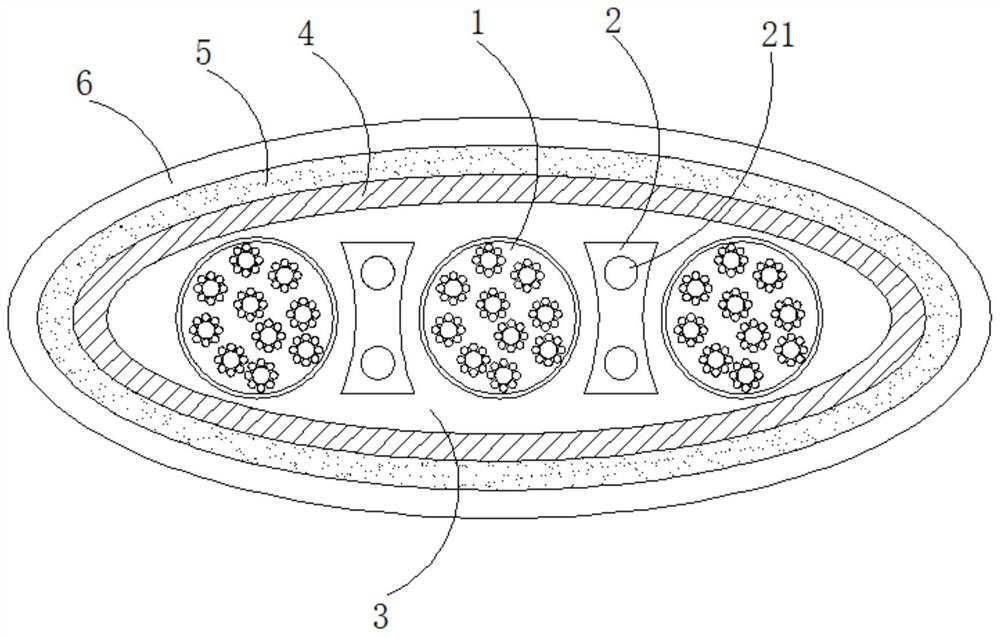

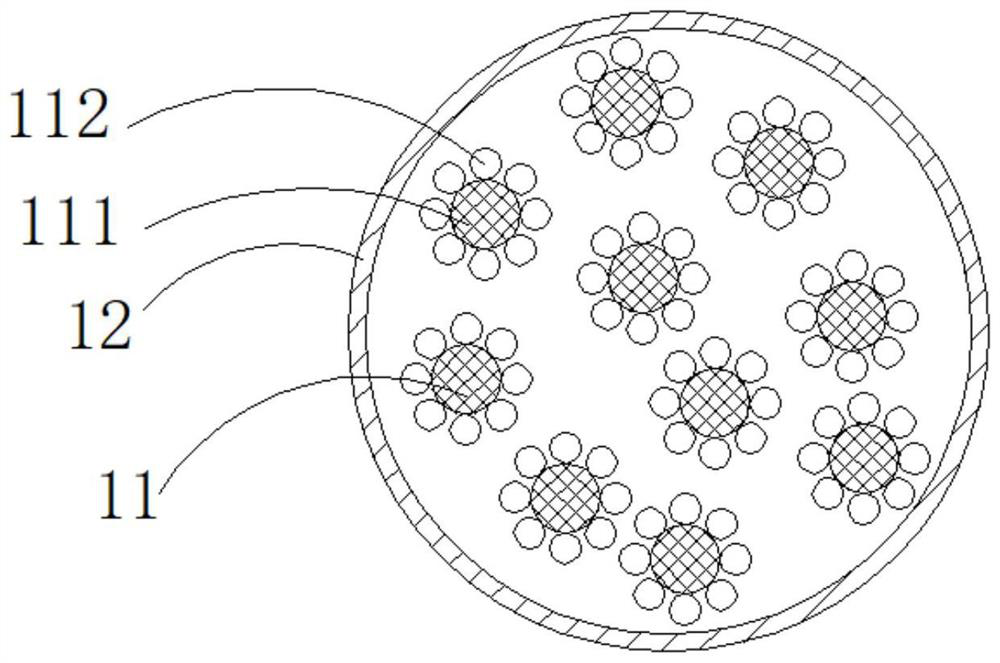

Jet flame and hydrocarbon flame resistant medium-voltage cable for offshore oil platform and manufacturing method thereof

ActiveCN112466536AEasy to slideSmall outer diameterClimate change adaptationInsulated cablesCopper conductorPolyolefin

The invention relates to a jet flame and hydrocarbon flame resistant medium-voltage cable for an offshore oil platform and a manufacturing method thereof. A semi-conductive conductor shielding layer,an insulating layer and a semi-conductive insulating shielding layer wrap the periphery of a stranded tin-plated annealed copper conductor from inside to outside in a three-layer co-extrusion mode; atinned copper wire shielding layer is woven on the periphery of a semi-conductive insulation shielding layer to form a shielding wire core, a plurality of shielding wire cores are twisted to form a cable core, an inner silicone oil layer is extruded on the periphery of the cable core, an inner lining layer is extruded on the periphery of the inner silicone oil layer, a fireproof wrapping tape is wrapped on the periphery of the inner lining layer, and an armor layer is wrapped on the periphery of the fireproof wrapping tape; the periphery of the armor layer is extruded with an outer silicone oil layer, the periphery of the outer silicone oil layer is extruded with a jet flame and hydrocarbon flame resistant inner sheath, and the periphery of the jet flame and hydrocarbon flame resistant inner sheath is extruded with a slurry resistant cross-linked polyolefin outer sheath. The cable adopts a double-layer composite sheath, can bear high-temperature flame of 1300 DEG C for 120 minutes under rated voltage, and does not have a grounding fault or a short circuit.

Owner:WUXI MINGZHU CABLE

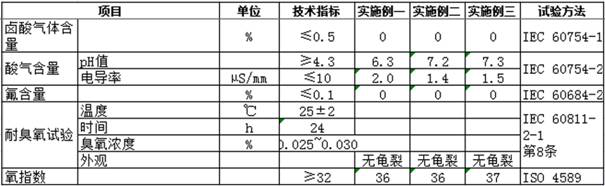

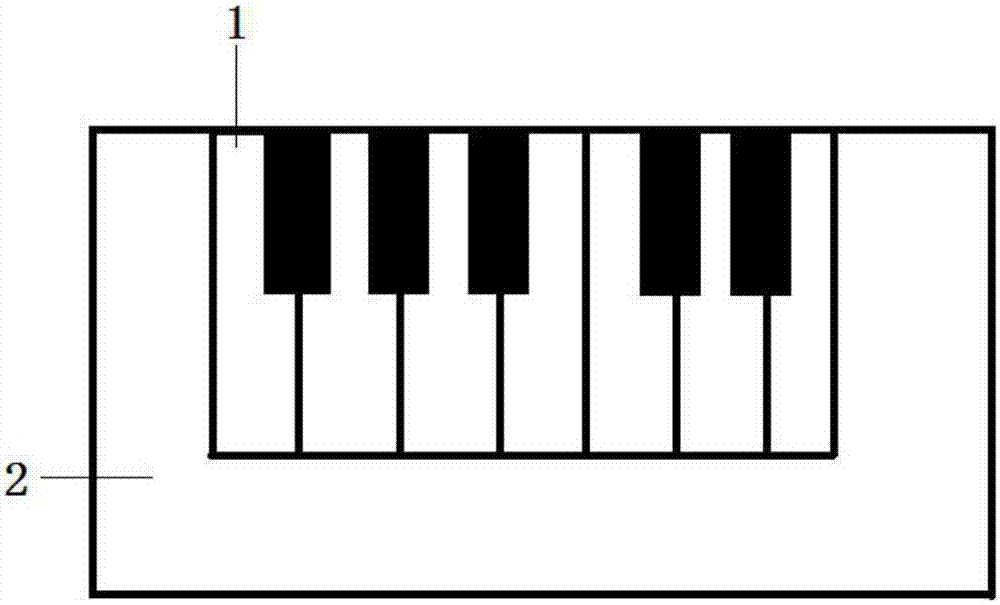

Touch electronic piano

InactiveCN107221314AEasy to carryReduce manufacturing costElectrophonic musical instrumentsInksElectricityPiano

The invention discloses a touch electronic piano which at least comprises an electric touch control chip, a sound generating chip and a sound generating device which are electrically connected and a keyboard equipped with key modules and a power supply which supplies power to the circuit. The keyboard is arranged on the upper surface of a hardboard. The conductive parts of the key modules are the keys covered by conductive ink. The key modules and the electric touch control chip are electrically connected through the conductive ink. The body of the electronic piano is only manufactured by the hardboard without using plastics to manufacture the keys or the body so that the manufacturing cost can be reduced, the size is small, the weight is low and the electronic piano can be easily carried by the user to enjoy the fun of music anytime and anywhere; the number of the keys can be increased or decreased according to the actual requirement, and the color of the keys can also be manufactured by black and white or color conductive ink according to the requirement so that the interestingness of the electronic piano can be increased; and the conductive ink of the keys on the key modules can be manufactured through printing and can also be manufactured through coating by the user so that the operability of the electronic piano can be increased.

Owner:武汉鸥易光电科技有限公司

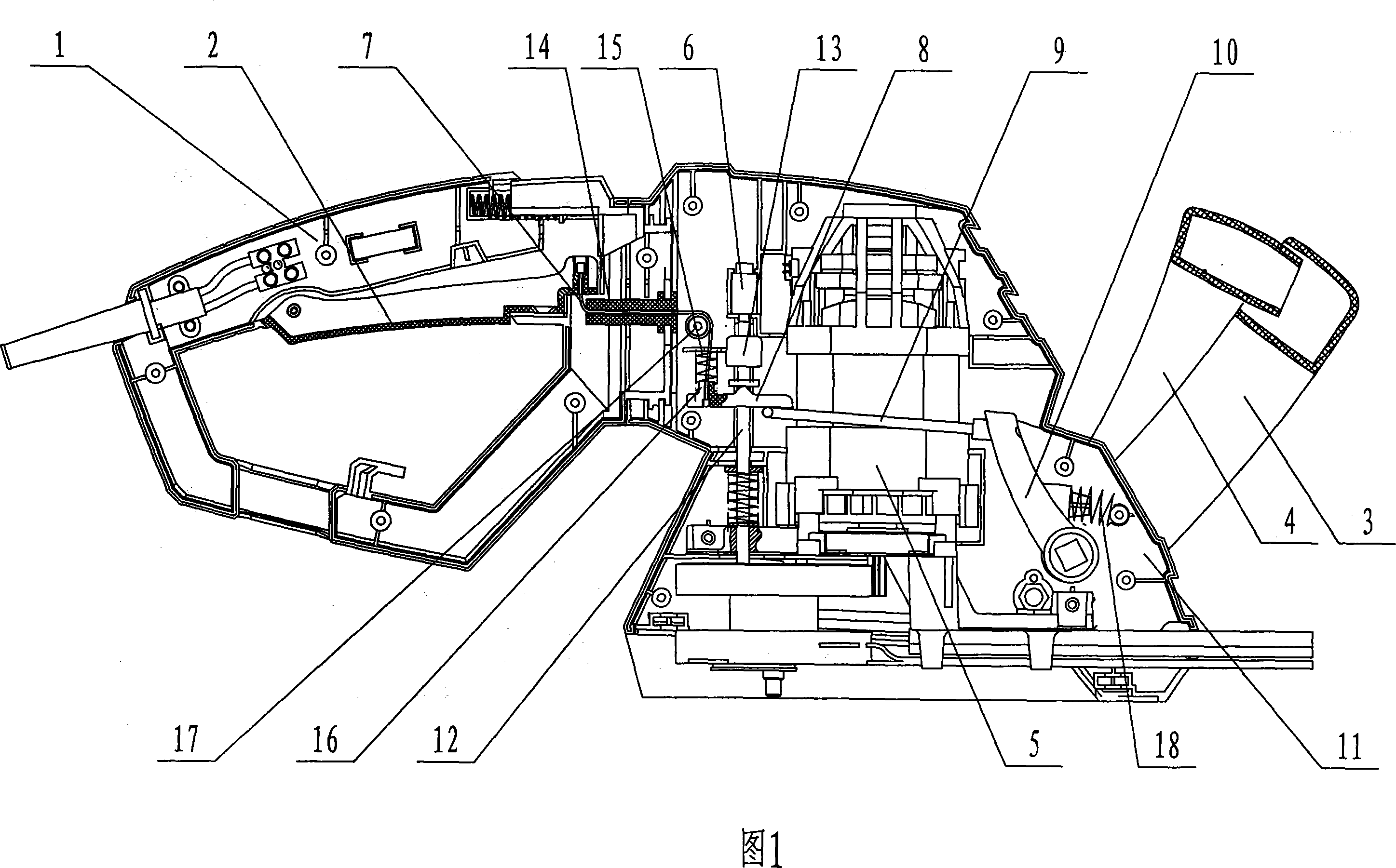

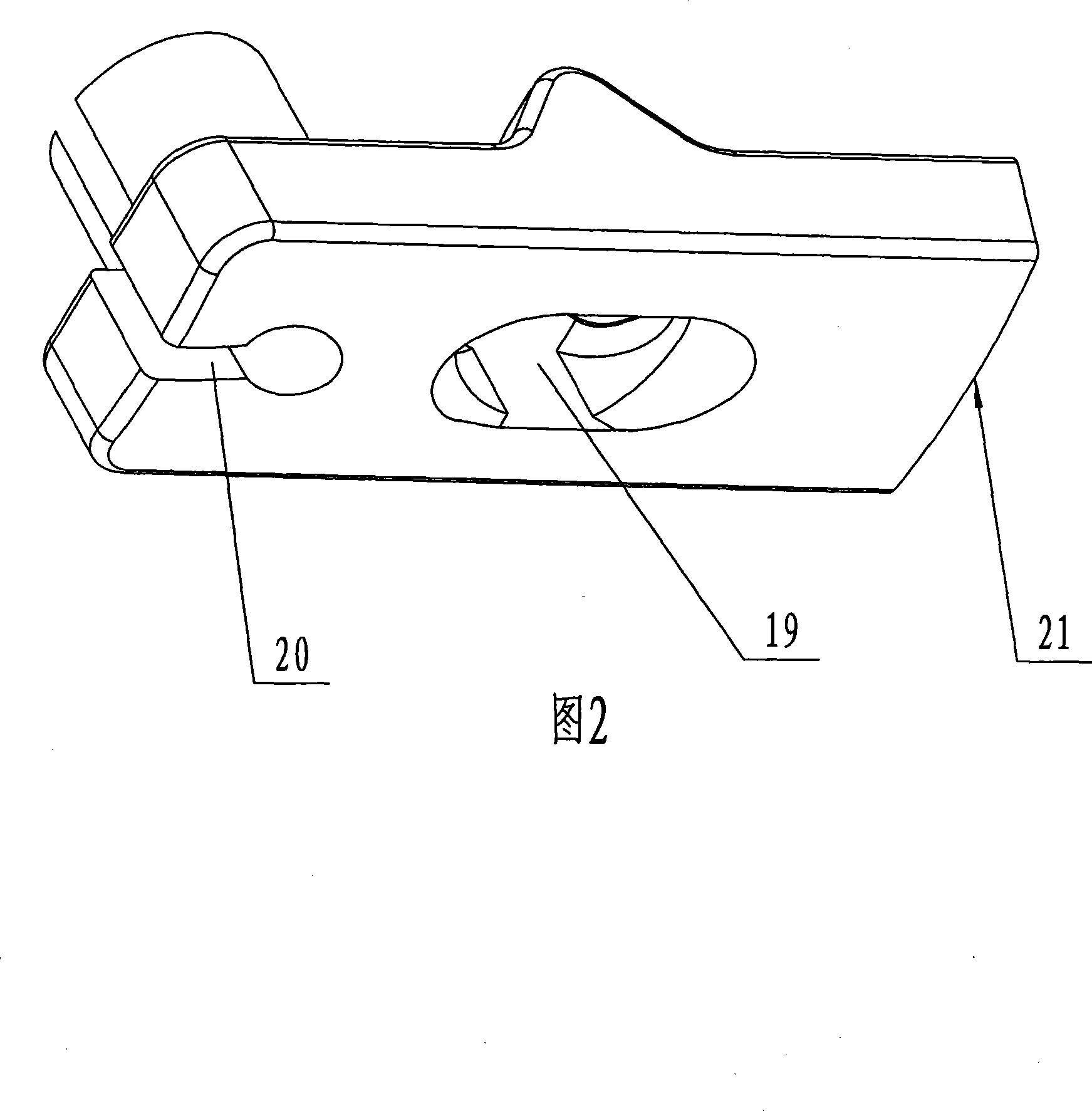

Pruning machine

ActiveCN101226415AShorten the lengthLess bendingCuttersCutting implementsThermal deformationEngineering

The invention discloses a pruning machine, wherein a steel wire shaft (7), an upright rod (12), a switch top block (13), a main button (2), a lifting plate (8) and an inching switch (6) are arranged at the left of a motor component (5), a draw plate (10) and a sub button (4) are arranged at the right of the motor component (5), two ends of the steel wire shaft (7) are respectively connected with the right end of the main button (2) and the left end of the lifting plate (8), a rigid metal rod (9) is connected between the right end of the lifting plate (8) and the upper end of the draw plate (10), the lower ends of the draw plate (10) and the sub button (3) are hinged with a shell (11), the lifting plate (8) is sliding sheathed on the upright rod (12) sheathed by the switch top block (13), and the inching switch (6) is above the switch top block (13). The invention has the advantages that the invention can turn on and off motor with small force and can prevent thermal deformation of driving mediums caused by the heat radiation of motor.

Owner:NINGBO ENERGY POWER TOOLS

Foldable flexible touch screen and flexible touch display panel

ActiveUS10303312B2Increased bending stressSolve the real problemInput/output processes for data processingEngineeringTouch function

A flexible touch screen fold along middle is provided. The flexible touch screen has a window region with a touch function, a folded section, and a non-window region for arranging leads. A part of the electrodes located at the folded section is made of transparent electrode material with a bending resistance. Because the electrodes of the folded section are made of the material with a bending resistance, the bending stress of the electrodes at the folded area of the flexible touch display panel can be improved, and the service life of the flexible touch display panel can be increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Copper Bending Device

The invention discloses a copper bar bending device. The copper bar bending device comprises a base plate, a main shaft, a copper bar bending mechanism, a copper bar locating mechanism, a locking mechanism and a copper bar pressing mechanism. The copper bar bending mechanism comprises a rotating disk, a wire pressing device, a handle and a handle limiting device, wherein the rotating disk is arranged on the main shaft in a sleeved mode, the wire pressing device and the handle are fixed to the radial outer side of the rotating disk, and the handle limiting device is fixed to the base plate. The copper bar locating mechanism comprises a backing plate, a core plate and a guide rail, wherein the backing plate and the core plate are sequentially arranged on the main shaft in a sleeved mode, a copper bar to be bent is longitudinally supported by the guide rail and one side of the backing plate, the inner side of one end of the copper bar to be bent abuts against one side of the core plate, and one end of the wire pressing device abuts against the outer side of one end of the copper bar to be bent. The copper bar pressing mechanism comprises an L-shaped pressing plate, a T-shaped nut and a pressing bolt. The locking mechanism comprises an upper pressing block and a locking nut. The copper bar bending device saves time and labor when operated, and is high in machining efficiency, low in cost, small in bending resistance in the bending process and suitable for single-piece or small-scale production.

Owner:ZHENJIANG ZHONGCHUAN XIANDAI GENERATING EQUIP CO LTD

Display component

ActiveUS10475864B2Low bending resistanceService life of the flexible touch display panel can be increasedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible display

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

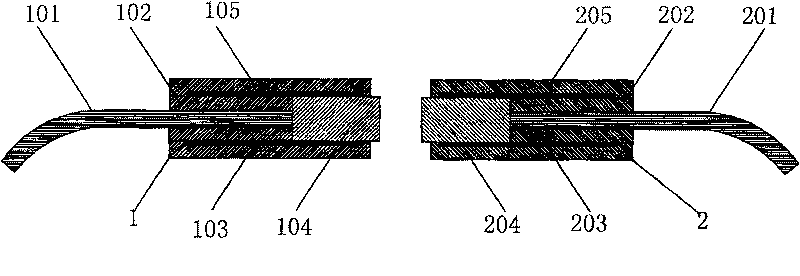

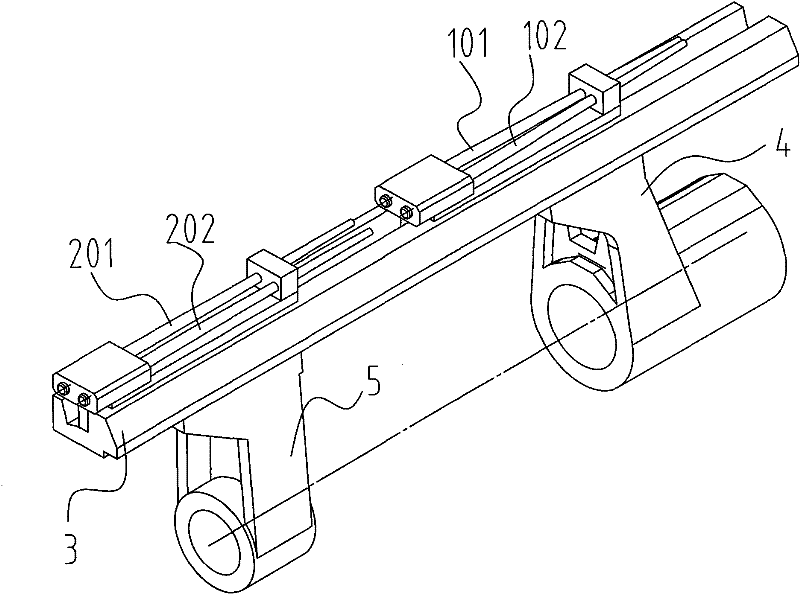

Plastic fibre-optical rotating connector

ActiveCN101334507BImprove coupling efficiencyFirmly connectedCoupling light guidesTransport systemInformation transmission

The invention provides a plastic fibre rotating connector. One end of the fixed end sleeve of a fixed head is embedded with a fixed end fibre and the other end thereof is embedded with a fixed end lens; the end surfaces of the fixed end fibre and the fixed end lens are closely matched with each other in a contacting way; a fixed metal sleeve is arranged outside the fixed end sleeve. A movable endfibre is embedded at one end of the movable end sleeve of the rotating head and a movable end lens is embedded at the other end thereof; the end surfaces of the movable end fibre and the movable end lens are closely matched with each other in a contacting way; a rotating metal sleeve is arranged outside the movable end sleeve. The fixed end fibre and the movable end fibre are plastic fibres; the fixed end fibre sleeve is arranged outside at the end of the fixed end fibre which is embedded into the fixed end sleeve; the movable end fibre sleeve is arranged outside at the end of the movable endfibre which is embedded into the movable end sleeve. The plastic fibre rotating connector of the invention solves the technical problems that: in the background technique, the numerical aperture and core diameter of the fibre are small, the requirements on the mechanical processing precision and the assembly coupling precision are extremely rigid, the coupling difficulty is large and the cost is high. The plastic fibre rotating connector is especially applicable to local area network with a plurality of connecting points, and the short-distance information transmission system.

Owner:西安和其光电科技股份有限公司

Double-swing main jet wefting insertion mechanism of jet loom

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY

Low-creep, fatigue-resistant, bending-resistant and stretching-resistant reel flat cable

PendingCN112466519AImprove tensile propertiesGood flexibilityRubber insulatorsNon-insulated conductorsTinningElectrical conductor

The invention discloses a low-creep, fatigue-resistant, bending-resistant and stretching-resistant reel flat cable, and the cable comprises a wire core, an insulating buffer block, a filler, a cord fabric layer, a nylon pipe belt layer and a sheath; the wire core comprises a conductor and an insulating layer wrapping the conductor, and the conductor is formed by twisting an aramid fiber wire reinforcer and a plurality of strands of tinned copper wires; an insulating buffer block is arranged between the wire cores, the wire cores and the insulating buffer block are provided with a filling material, the filling material wraps a cord fabric layer, the cord fabric layer is wrapped by a nylon pipe belt layer, and the nylon pipe belt layer extrudes a sheath. According to the winding drum flat cable, the conductor structure, the insulating layer, the buffer piece and the sheath are improved; and the cable has the characteristics of low creep, fatigue resistance, bending resistance and impactresistance.

Owner:湖南华菱线缆股份有限公司

A kind of fast curing powder coating and preparation method thereof

ActiveCN112574634BGood adhesionImprove high temperature stabilityChemical industryConjugated diene hydrocarbon coatingsAcrylonitrileMelamine formaldehyde resin

Owner:宁波爱甬新材料科技有限公司

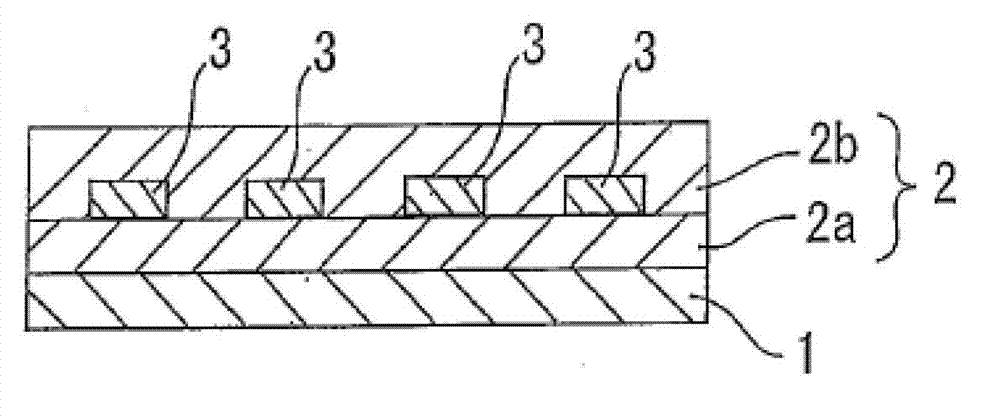

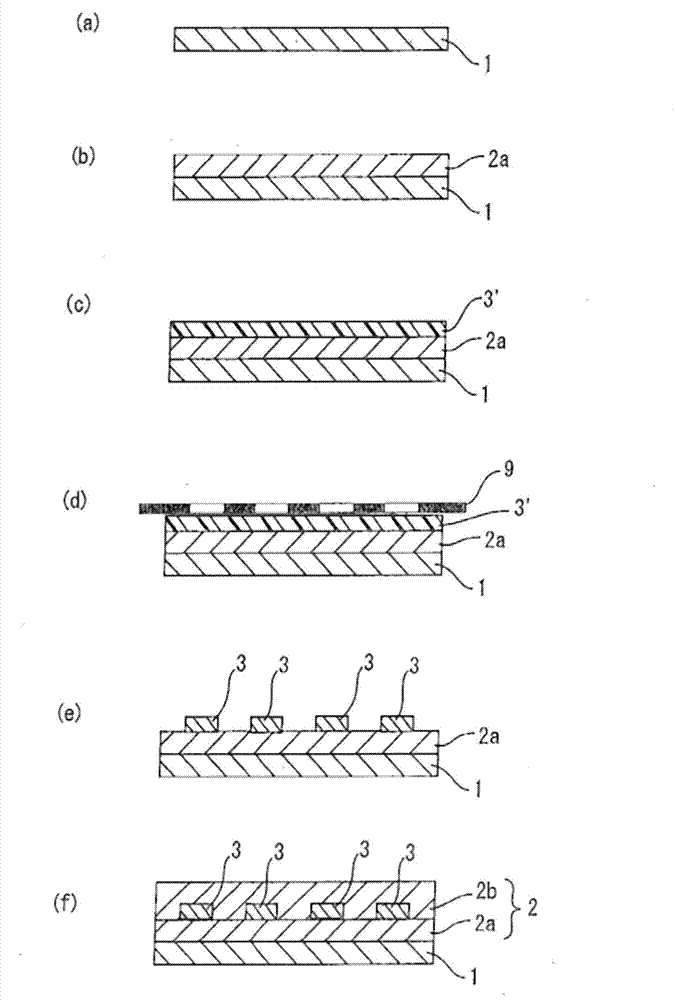

Metal foil laminate

ActiveCN105102221BCheap manufacturingAvoid dentsSynthetic resin layered productsPrinted circuit aspectsEpoxyMetal foil

The present invention realizes at the same time: the prevention of sinking into the substrate film layer of the chip when bonding the metal wiring and the chip (that is, the mountability), the trade-offs of bending resistance, folding resistance, flexibility, and bending of the substrate during mounting, etc. Reduction in springback, etc., which is considered a problem. Provided is a metal foil laminate, which is characterized in that it is a metal foil laminate comprising a base film and a metal foil on at least one surface of the metal foil, the heat-resistant resin composition containing Oxygen resin cross-linked polyimide resin, and the following (a) and (b): (a) when the total amount of polyimide resin and epoxy resin is set as 100% by mass, epoxy The mixing amount of the resin is not less than 0.1% by mass and not more than 10% by mass; (b) to the base film obtained by removing the metal foil from the metal foil laminate, adding N-methyl-2-pyrrolidone to the base film The concentration was changed to 0.5% by mass, and after heat treatment at 100° C. for 2 hours, the insolubility of the base film was 40% or more.

Owner:TOYOBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com