Copper bar bending device

A technology of bending device and bending mechanism, which is applied in the fields of manual bending device for metal pipes and manual bending and forming of copper bars for turbine generator rotors, which can solve the problems of high equipment cost, large bending resistance, and easy Wrinkle and other problems, to achieve high processing efficiency, low bending resistance, avoid wrinkling and thickening out of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

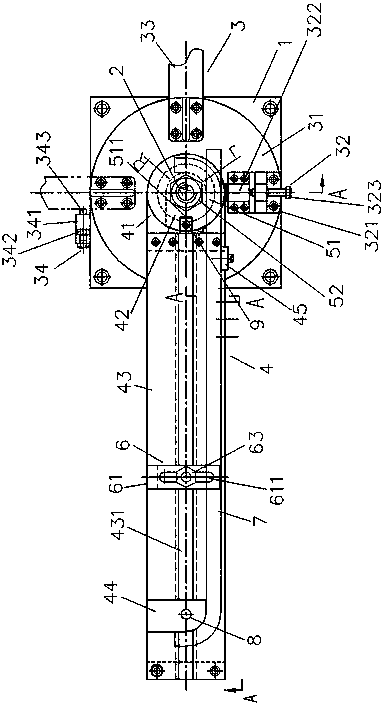

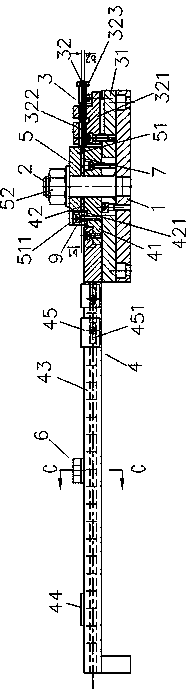

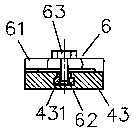

[0019] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a bottom plate 1 fixed on the workbench by fasteners, a main shaft 2 vertically welded and fixed in the middle of the bottom plate 1, a copper bar bending mechanism 3 sequentially fitted on the main shaft from bottom to top, and copper bar positioning Mechanism 4, locking mechanism 5 and copper bar pressing mechanism 6; copper bar bending mechanism 3 includes a rotating disc 31, a wire crimping device 32, a handle 33 and a handle limiter 34, the rotating disc 31 is set on the main shaft 2, and It can rotate freely around the main shaft 2. The center line of the thread crimping device 32 and the axis of the handle 33 are perpendicular to each other, and are respectively fixed on the radially outer sides of the rotating disk 31 by fasteners. The handle limiter 34 is located on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com