Double-swing main jet wefting insertion mechanism of jet loom

A technology of weft insertion mechanism and air-jet loom, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of energy loss of compressed gas, influence of weft insertion rate in weaving, and inability to adapt to air-jet looms well, and achieve Reduced bending resistance, smooth flight, and improved weft insertion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

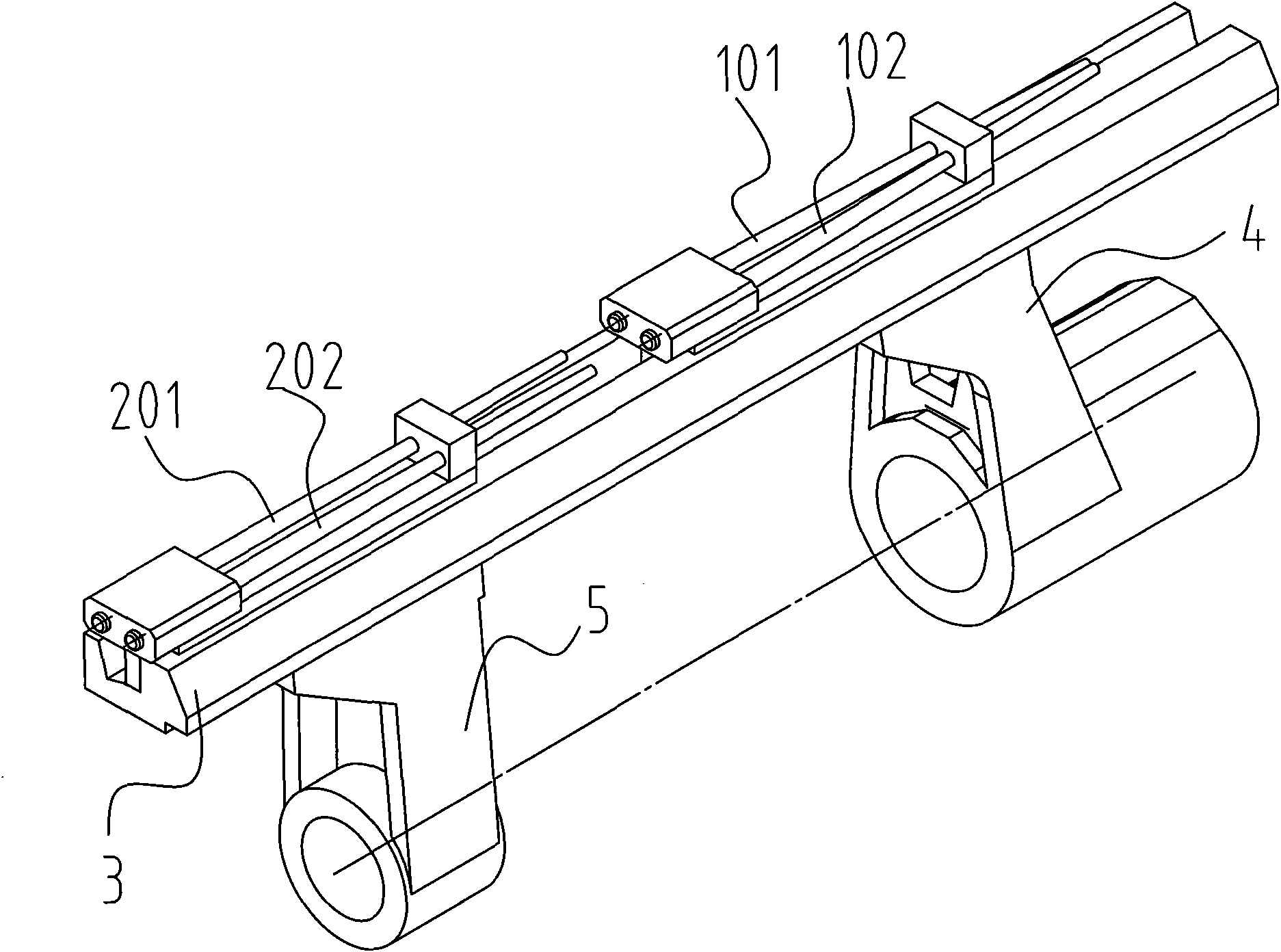

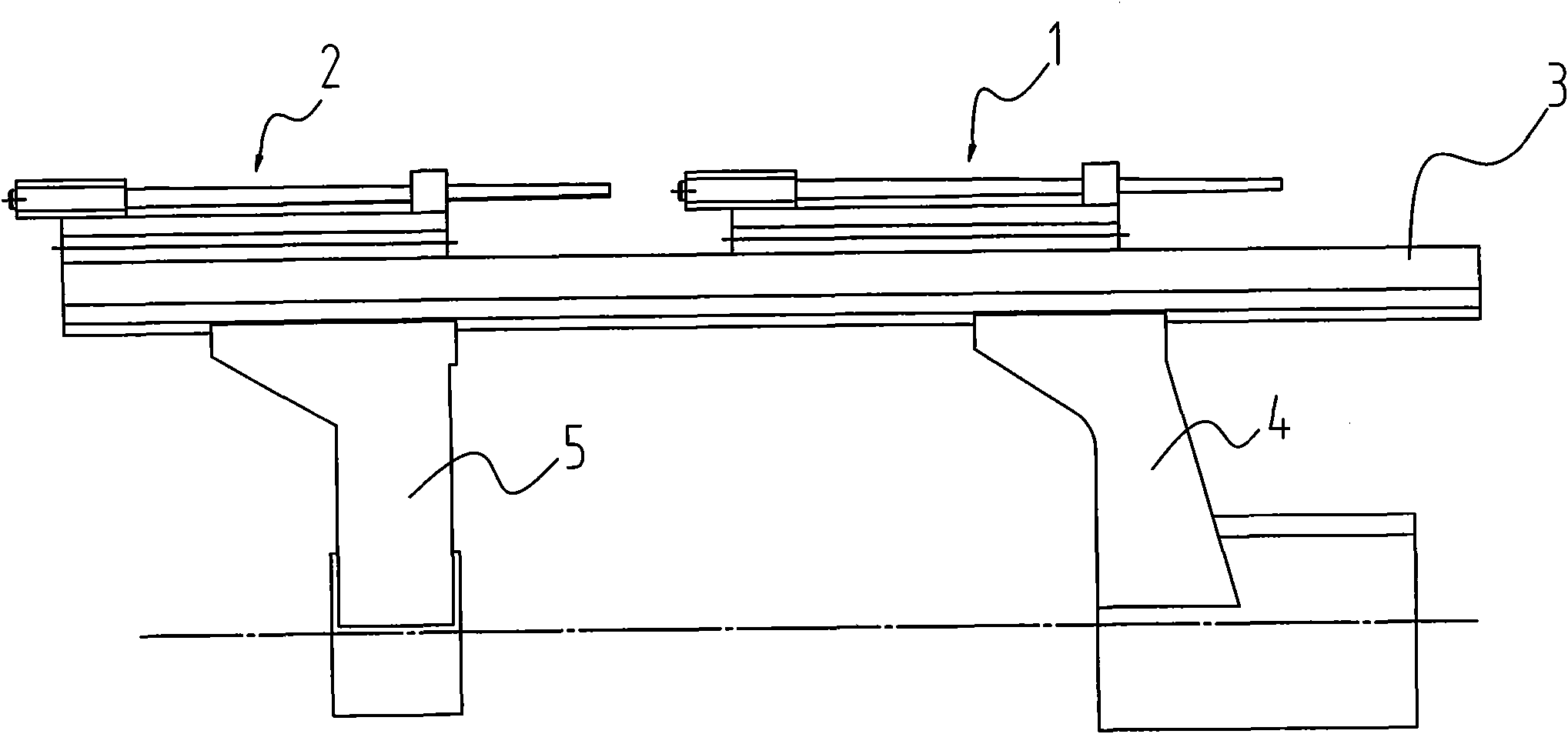

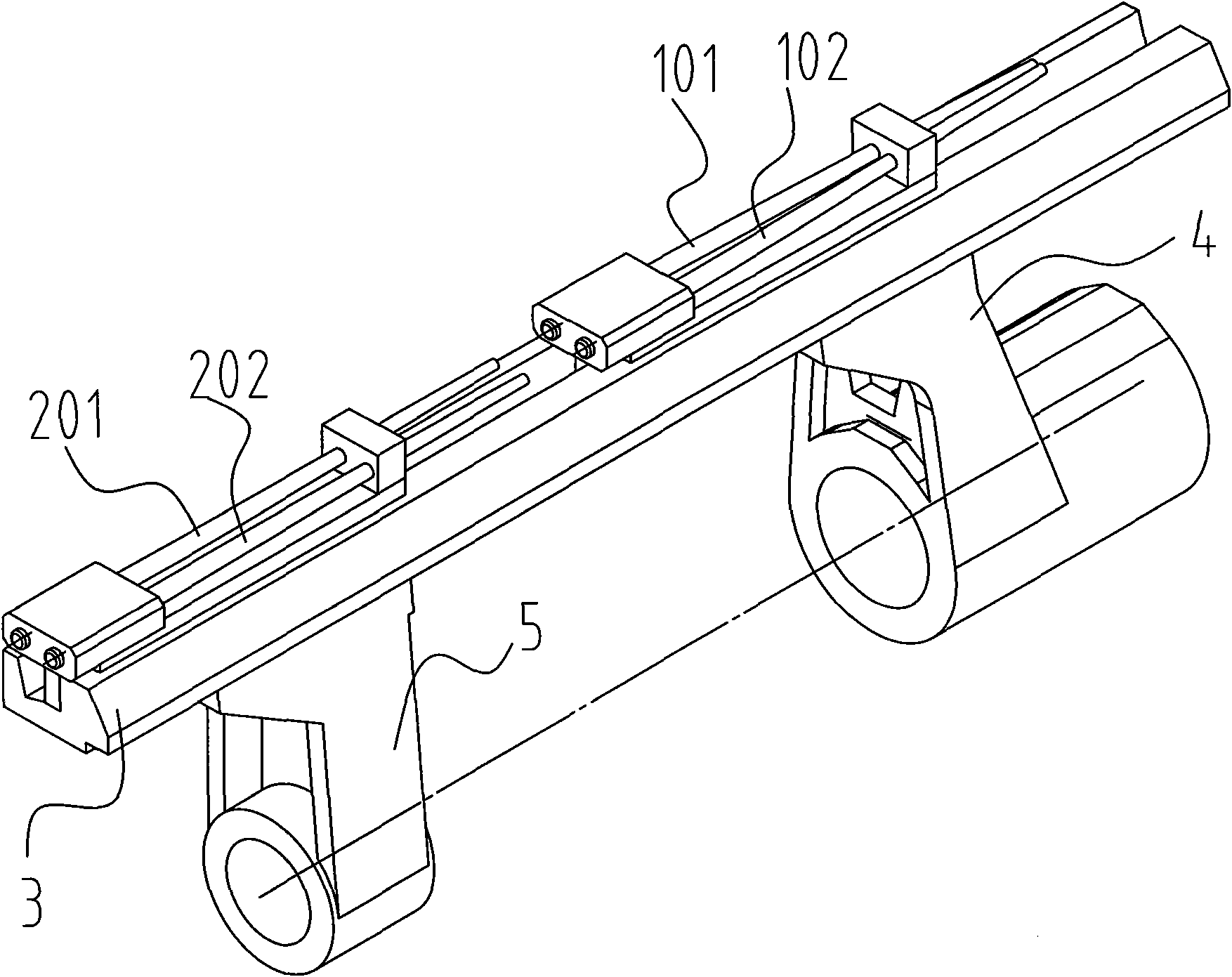

[0013] to combine figure 1 and figure 2 , an air-jet loom double-oscillating main spray weft insertion mechanism, comprising a primary main spray 1 and a secondary main spray 2, the primary main spray is arranged on a button seat 3, and it has two nozzles 101, 102, and the secondary main spray Spray is also arranged on the buckle seat 3, and it also has two nozzles 201,202, the above-mentioned first-level main spray 1 position is in the front, the second-level main spray 2 position is behind, the nozzle 201 of the second-level main spray 2 and the first-level main spray The nozzle 101 of 1 is aligned, that is, the nozzle 201 is directly facing the nozzle 101, and the nozzle 202 of the secondary main spray 2 is aligned with the nozzle 102 of the primary main spray 1, that is, the nozzle 202 is directly facing the nozzle 102. The main spray 2 swings synchronously with the buckle seat 3. The above-mentioned buckle seat 3 is provided with a front buckle seat foot 4 and a rear b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com