Antioxidant low-corrosion low-temperature-curing conductive ink

A conductive ink, low-corrosion technology, applied in the direction of ink, household utensils, applications, etc., can solve the problem of conductive ink plastic corrosion, etc., to achieve the effect of low yellowing and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

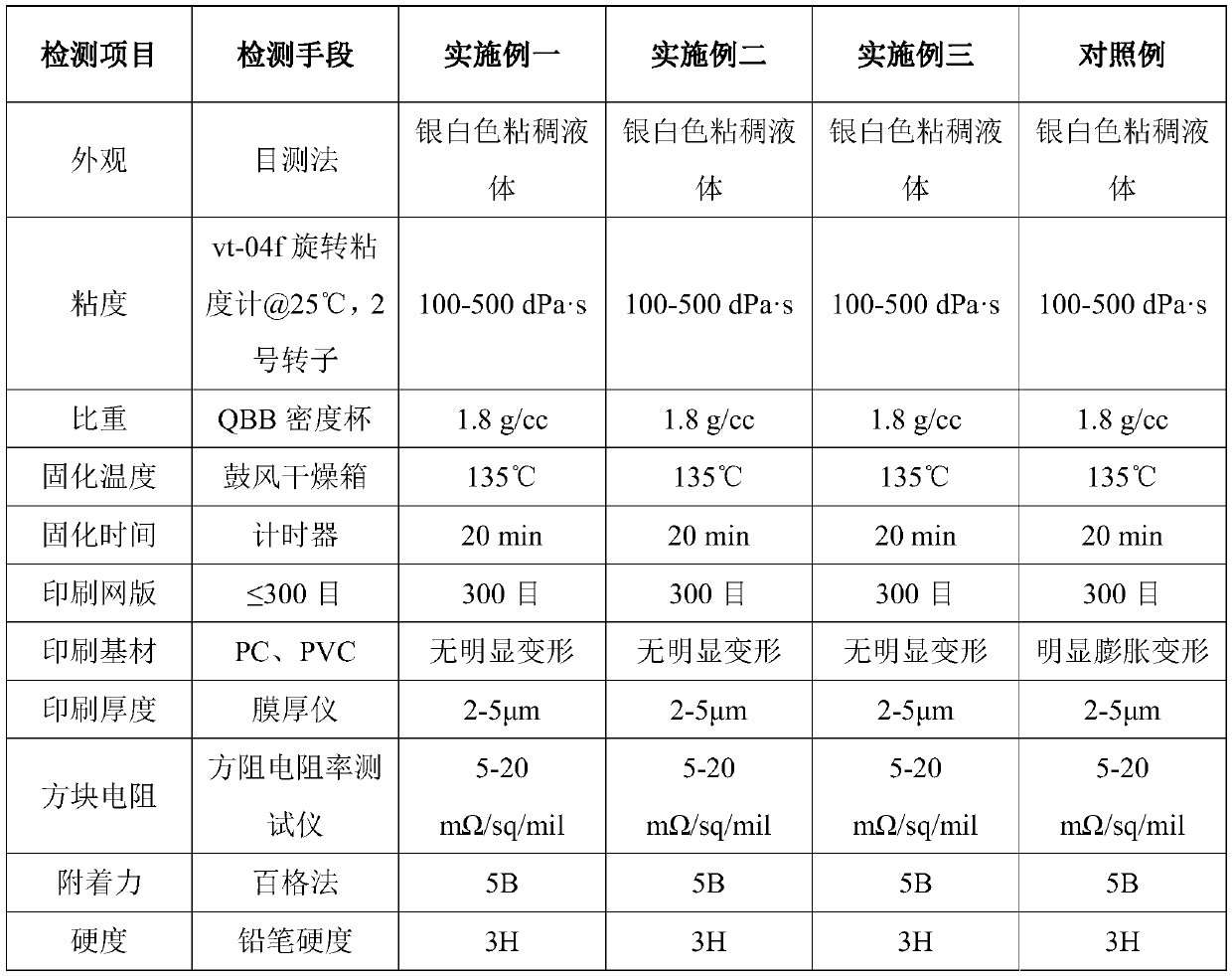

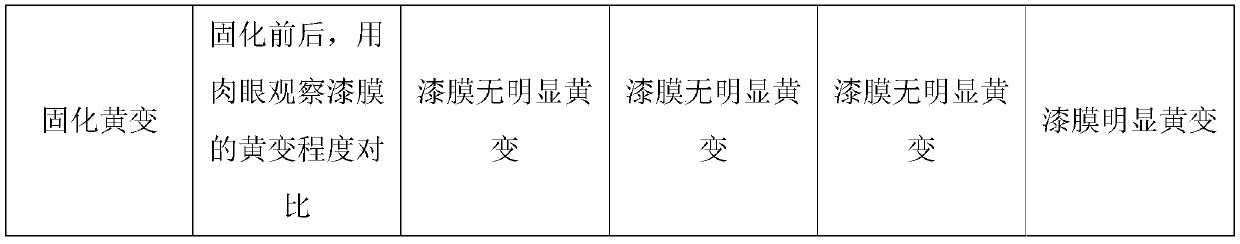

Examples

Embodiment 1

[0024] Embodiment 1 of the present invention conductive ink is made up of the raw material of following weight ratio: 45 weight parts of resin intermediate, 4 weight parts of ethylene glycol butyl ether acetate, 5 weight parts of ethylene glycol butyl ether, 1 weight part of tris[2.4- Di-t-butylphenyl] phosphite, 0.5 parts by weight 2-(2'-hydroxy-5'-tert-octylphenyl) benzotriazole, 0.5 parts by weight high molecular weight polyester adhesion promoter, 43 parts by weight Part silver powder, 0.5 parts by weight dispersant, 0.5 parts by weight defoamer, the resin intermediate is made up of 80 parts by weight of hydroxyl-modified ternary vinyl chloride resin, 20 parts by weight of butyl glycol ether.

[0025] Embodiment 1 of the present invention is a conductive ink manufacturing method, comprising the following steps:

[0026] Step 1: Mix resin intermediates, solvents, antioxidants, silver powder, and additives according to the set ratio, and preheat to 30-45°C;

[0027] Step 2:...

Embodiment 2

[0030] Embodiment 2 of the present invention The conductive ink is composed of the following raw materials in parts by weight: 55 parts by weight of resin intermediate, 10 parts by weight of solvent, 1 part by weight of tris[2.4-di-tert-butylphenyl] phosphite, 0.5 parts by weight of 2 -(2'-hydroxyl-5'-tert-octylphenyl)benzotriazole, 0.5 parts by weight of high molecular weight polyester adhesion promoter, 50 parts by weight of silver powder, 0.5 parts by weight of dispersant, 0.5 parts by weight of defoamer , the resin intermediate is composed of 60 parts by weight of carboxyl-modified terpolymer resin and 40 parts by weight of butyl glycol ether.

[0031] Embodiment 2 of the present invention is a conductive ink manufacturing method, comprising the following steps:

[0032] Step 1: Mix resin intermediates, solvents, antioxidants, silver powder, and additives according to the set ratio, and preheat to 30-45°C;

[0033] Step 2: Place the mixture obtained in Step 1 in a high-sp...

Embodiment 3

[0036] Embodiment 3 of the present invention Conductive ink is made up of the raw material of following weight ratio: resin intermediate 75 weight parts, solvent 25 weight parts, 1 weight part tris [2.4-di-tert-butylphenyl] phosphite, 0.5 weight part 2 -(2'-hydroxyl-5'-tert-octylphenyl)benzotriazole, 0.5 parts of high molecular weight polyester adhesion promoter, 20 parts by weight of silver powder, 0.5 parts by weight of dispersant, 0.5 parts of defoamer, The resin intermediate is composed of 40 parts by weight of hydroxy-modified ternary chloroacetic resin, 40 parts by weight of carboxy-modified ternary chloroacetic resin, and 20 parts by weight of ethylene glycol butyl ether.

[0037] Embodiment 3 of the present invention The method for making conductive ink comprises the following steps:

[0038] Step 1: Preheat the resin intermediate to 30-45°C, and disperse evenly in a high-speed shearing disperser under the condition of 500-1200r / min, and mix the resin intermediate, sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com