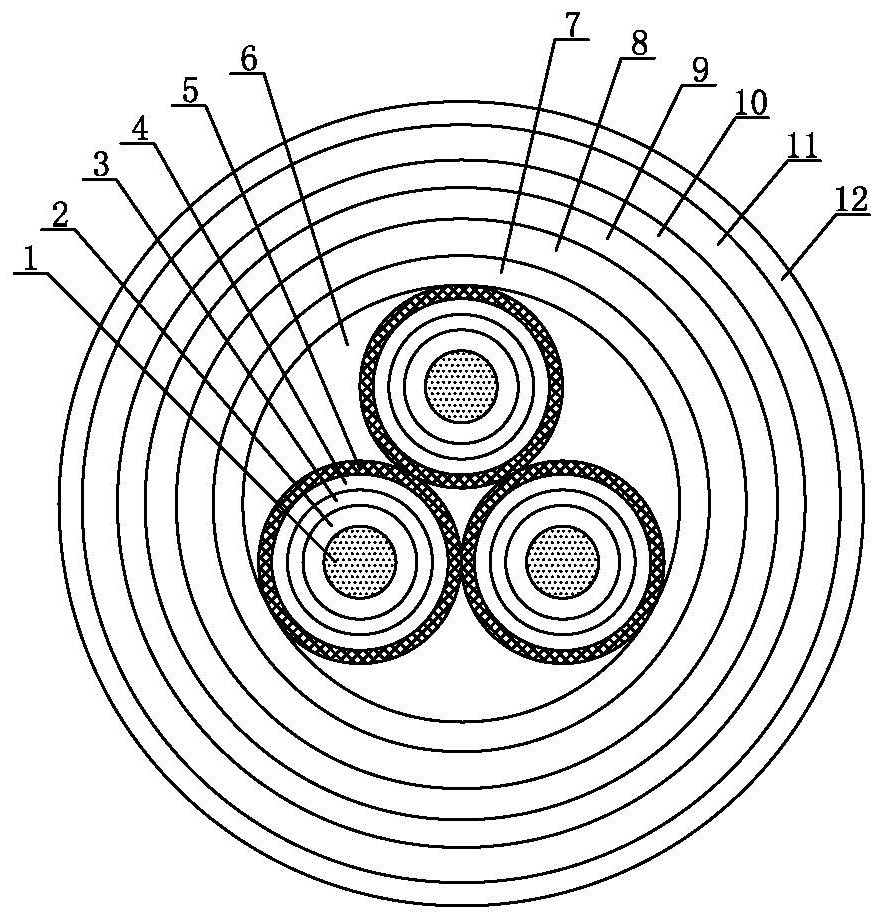

Jet flame and hydrocarbon flame resistant medium-voltage cable for offshore oil platform and manufacturing method thereof

An offshore oil and flame technology, which is applied in the direction of cable/conductor manufacturing, insulating cables, conductor/cable insulation, etc., can solve the problems of lack of resistance to hydrocarbon flames and jet flames, hidden safety hazards, etc., and achieve good deformation and structure Stable, contributes to fire prevention, and increases elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

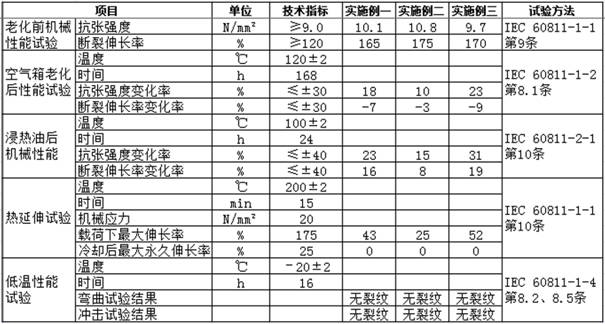

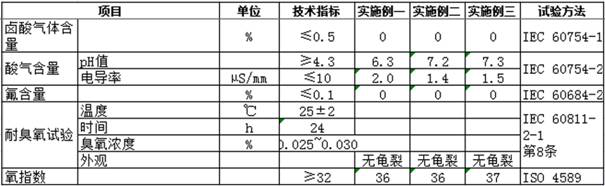

Embodiment 1

[0038]Wherein, the manufacture of jet flame and hydrocarbon flame-resistant inner sheath 11 includes the following steps in turn: (1) Prepare raw materials according to the following components and weight content, LEVAPREN 500HV (VA content is 50%wt): 20 parts; Flame agent nano-metal aluminum hydroxide: 30 parts; flame retardant nano-ammonium pentaborate: 2 parts; nano-montmorillonite: 4 parts; bis-tert-butylperoxycumene: 0.6 parts; Isocyanate: 0.2 parts; antioxidant XH-3: 0.4 parts; 2-mercaptobenzimidazole: 0.2 parts; methyl silicone oil: 0.5 parts; fumed silica: 6 parts; coupling agent A-172: 0.2 parts; Colorant masterbatch: 0.6 parts, glass powder with a softening temperature of 360°C: 4 parts and blend modifier Elvaloy 742: 2 parts;

[0039] (2) Mix and banbury other raw materials except Evapine rubber, bis-tert-butylperoxycymene and triallyl isocyanurate. The temperature of the banbury mixer is 25°C, and the mixing time is 6 minutes;

[0040] (3) Raise the temperature of...

Embodiment 2

[0046] Wherein, the manufacture of jet flame and hydrocarbon flame-resistant inner sheath 11 includes the following steps in turn: (1) Prepare raw materials according to the following components and weight content, LEVAPREN 500HV (VA content is 50%wt): 20 parts; Flame agent nano metal magnesium hydroxide: 32 parts; flame retardant nano barium metaborate: 3 parts; nano montmorillonite: 6 parts; bis-tert-butylperoxycumene: 0.8 parts; Isocyanate: 0.3 parts; antioxidant XH-3: 0.5 parts; 2-mercaptobenzimidazole: 0.3 parts; methyl silicone oil: 0.8 parts; fumed silica: 8 parts; coupling agent A-172: 0.3 parts; Colorant masterbatch: 0.8 parts, glass powder with a softening temperature of 400°C: 6 parts and blend modifier Elvaloy 742: 3 parts;

[0047] (2) Mix and banbury other raw materials except Evapine rubber, bis-tert-butylperoxycumene and triallyl isocyanurate. The temperature of the banbury mixer is 30°C, and the mixing time is 7 minutes;

[0048] (3) Raise the temperature of ...

Embodiment 3

[0054] Wherein, the manufacture of jet flame and hydrocarbon flame-resistant inner sheath 11 includes the following steps in turn: (1) Prepare raw materials according to the following components and weight content, LEVAPREN 500HV (VA content is 50%wt): 20 parts; Flame agent nano-metal aluminum hydroxide: 35 parts; flame retardant nano-zinc fluoroborate: 5 parts; nano-montmorillonite: 8 parts; bis-tert-butylperoxycumene: 1 part; Isocyanate: 0.4 parts; antioxidant XH-3: 0.6 parts; 2-mercaptobenzimidazole: 0.4 parts; methyl silicone oil: 1 part; fumed silica: 10 parts; coupling agent A-172: 0.5 parts; Colorant masterbatch: 1 part, glass powder with a softening temperature of 500°C: 8 parts and blend modifier Elvaloy 742: 4 parts;

[0055] (2) Mix and banbury other raw materials except Evapine rubber, bis-tert-butylperoxycumene and triallyl isocyanurate. The temperature of the banbury mixer is 35°C, and the mixing time is 8 minutes;

[0056] (3) Raise the temperature of the inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| change rate of elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com