Display panel and display device

A display panel and substrate technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of reducing the bending resistance of the display panel, the display brightness and luminous efficiency of the display panel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

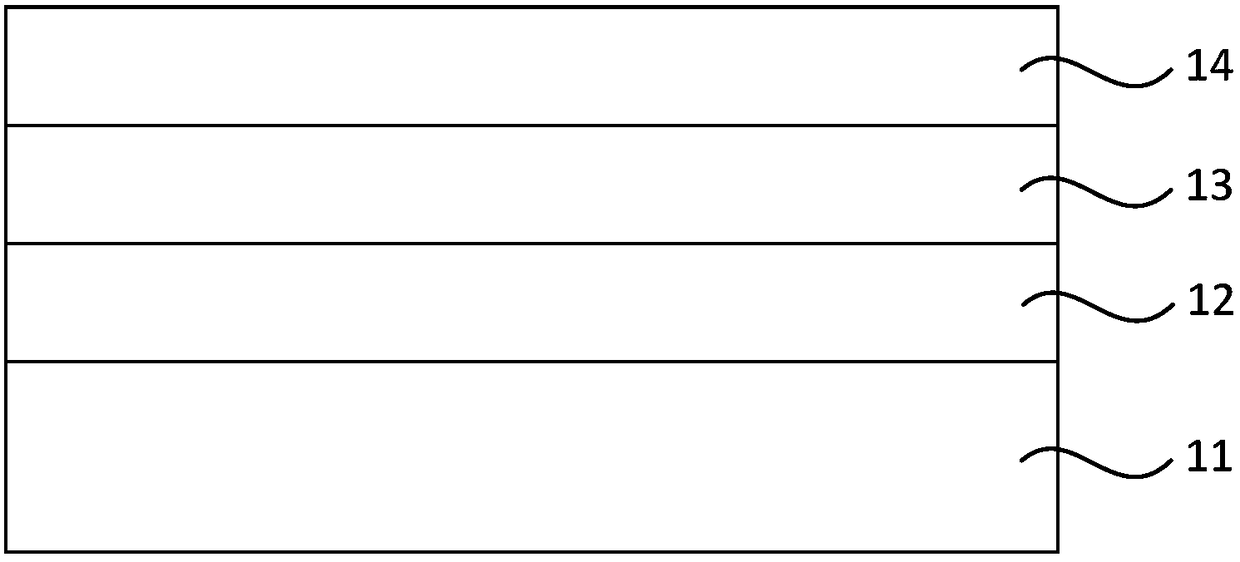

[0032] Embodiment 1 of the present invention provides a display panel. The display panel includes a substrate, an organic light emitting device arranged on the substrate, and a thin film encapsulation layer covering the organic light emitting device. The thin film encapsulation layer includes a plurality of film layers stacked, and the refractive index of each film layer constituting the thin film encapsulation layer increases gradually along the direction approaching the organic light emitting device.

[0033] In actual design, by selecting appropriate materials and thicknesses for making each film layer constituting the thin film encapsulation layer, it can be made that when in use, the external ambient light will be different in the thin film encapsulation layer after it is incident on the film encapsulation layer. The interface of the film layer forms reflected light with a phase difference of 180°, and such reflected light can destructively interfere and cancel each other...

Embodiment 2

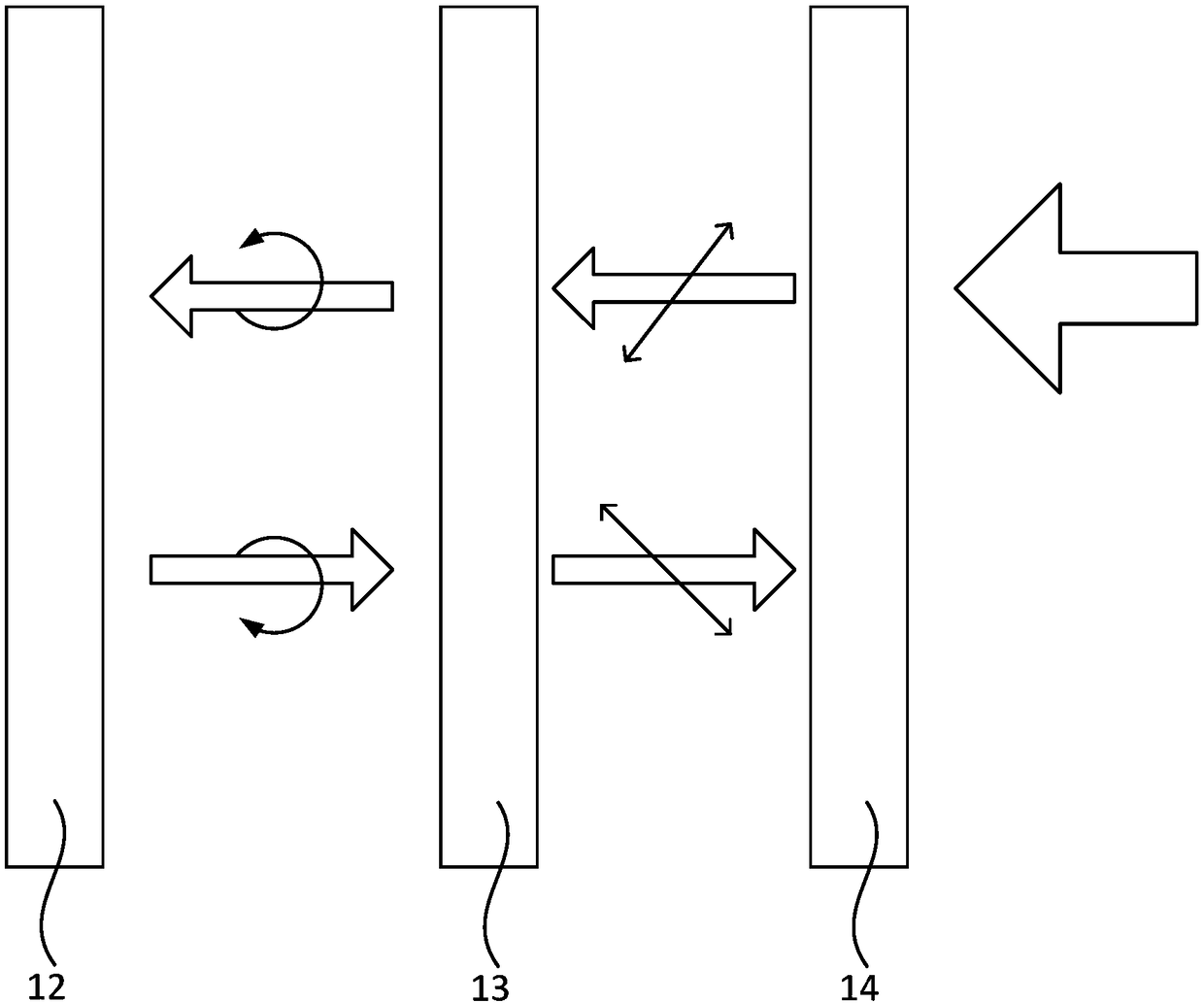

[0038] Figure 2a It is a schematic structural diagram of the display panel provided in Embodiment 2 of the present invention, Figure 2b for Figure 2a Schematic diagram of the working principle of the display panel provided. The technical solution of this embodiment is a specific example of the display panel provided in Embodiment 1. In this embodiment, the thin film encapsulation layer includes three film layers.

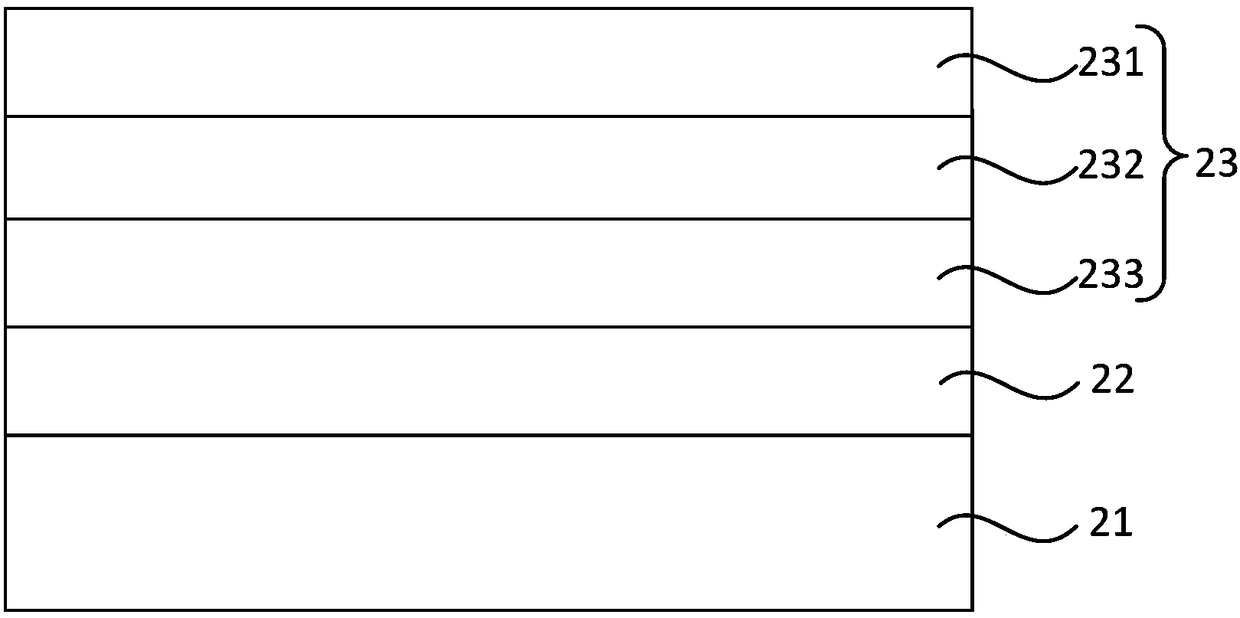

[0039] Specifically, see Figure 2a , the display panel includes a substrate 21, an organic light emitting device 22 disposed on the substrate 21, and a thin film encapsulation layer 23 covering the organic light emitting device 22. The thin film encapsulation layer 23 includes three film layers stacked, and the refractive index of the three film layers constituting the thin film encapsulation layer gradually increases along the direction approaching the organic light emitting device 22 .

[0040] continue to see Figure 2a, the three film layers constitutin...

Embodiment 3

[0045] image 3 It is a schematic structural diagram of a display panel provided by Embodiment 3 of the present invention. Compared with the technical solutions provided by the above embodiments, the display panel provided by the present application further includes a filter film.

[0046] see image 3 , in the display panel, the organic light-emitting device includes pixel light-emitting regions 31 and pixel-defining regions 32 located between the pixel light-emitting regions 31 . The display panel also includes a filter film 26 disposed on the side of the thin film encapsulation layer 23 facing away from the organic light emitting device 22. The filter film 26 includes an opening area 261 and a light-shielding area 262. The opening area 261 corresponds to the pixel light-emitting area 31, and the light-shielding area 262 corresponds to The pixel definition area 32 corresponds. The opening area 261 of the filter film 26 is used to transmit the light emitted by the organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com