Printing prosthetic hand and manufacturing method thereof

A prosthetic hand and palm technology, applied in the direction of prosthesis, artificial arm, medical science, etc., can solve the problems of short service life, high resistance and easy fatigue, imprecise movements, etc., to reduce movement resistance, reduce weight, and connect accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiment of the present invention is one of many preferred solutions. The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Obviously, the described embodiments are part of the embodiments of the present invention, not all of them. , does not limit the partial realization of the prosthetic hand formed by 3D printing with other methods or structures

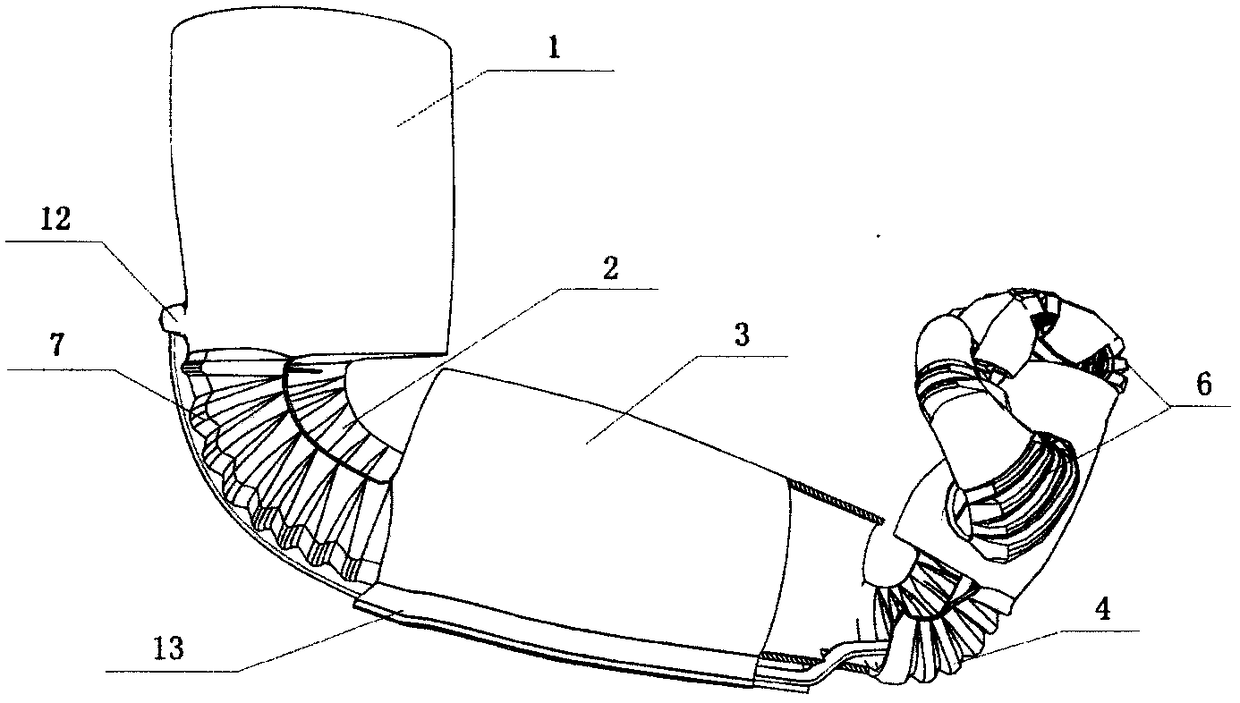

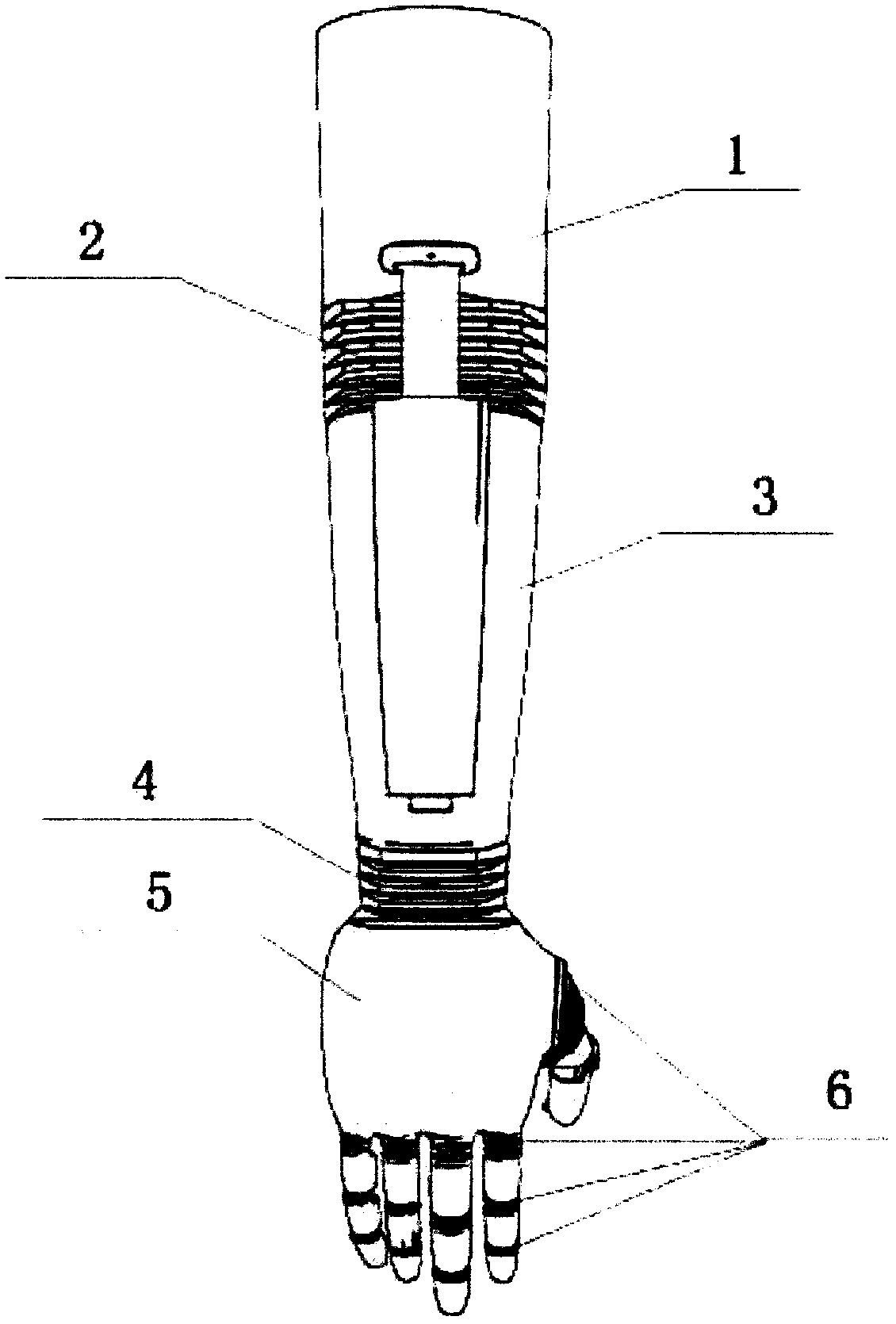

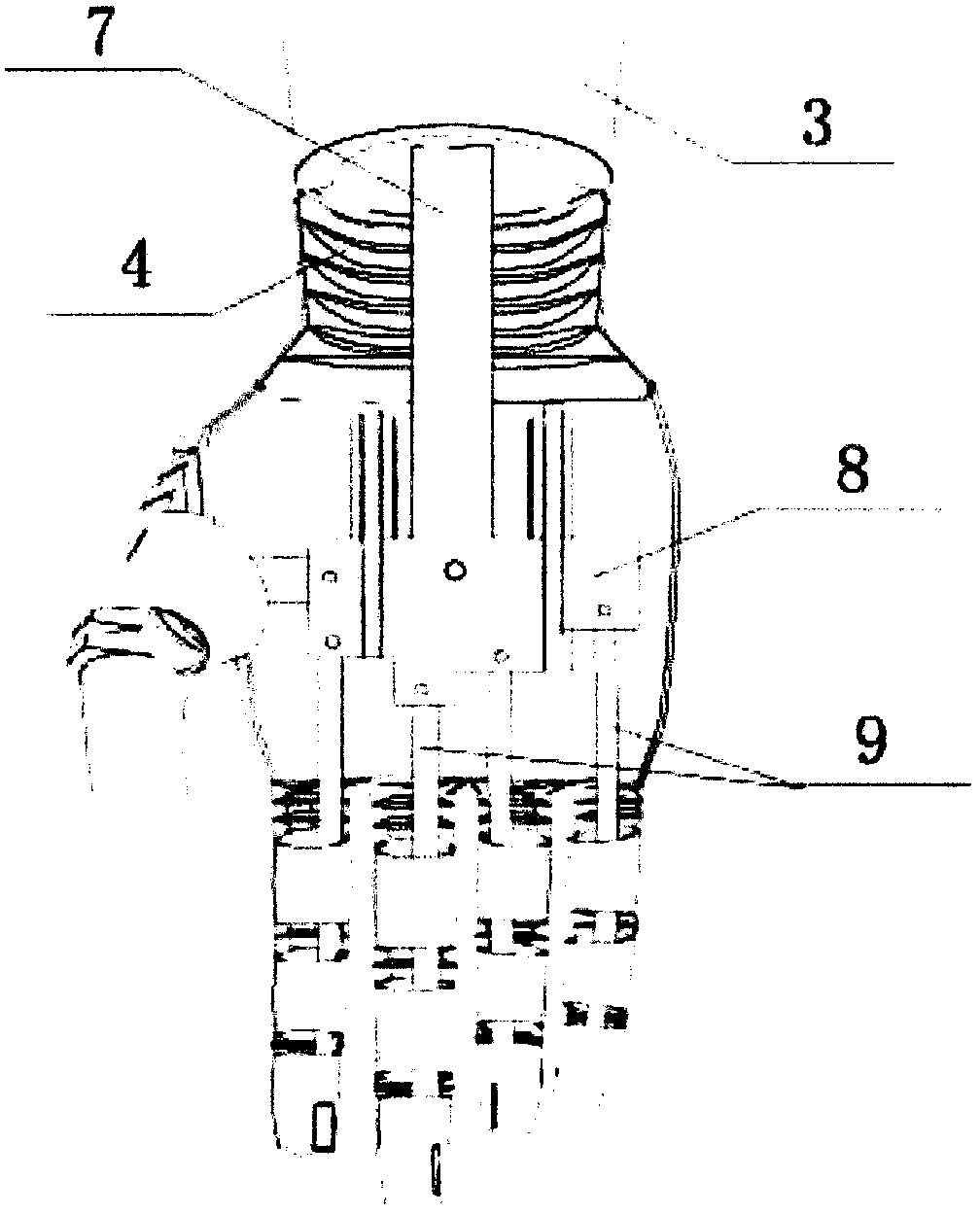

[0033] The specific embodiment of the present invention is that the large arm tube 1, the elbow joint 2, the forearm tube 3, the wrist joint 4, the palm 5, the thumb, the index finger, the middle finger, the ring finger, the little finger and the prosthetic hand are embedded in the hand from top to bottom. The grasping and stretching system constitutes;

[0034] The elbow joint 2, wrist joint 4, and all the metacarpophalangeal joints and interphalangeal joints of the five fingers of the thumb, index finger, midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com