Method for separating high flux and low pollution membrane with biomimetic spiral membrane

A membrane separation and spiral membrane technology, applied in the field of membrane separation, can solve the problems of rigid membrane module structure, increase material consumption, difficult to master, etc., so as to improve mass transfer and separation efficiency, increase energy consumption and material consumption, and reduce concentration difference. The effect of polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

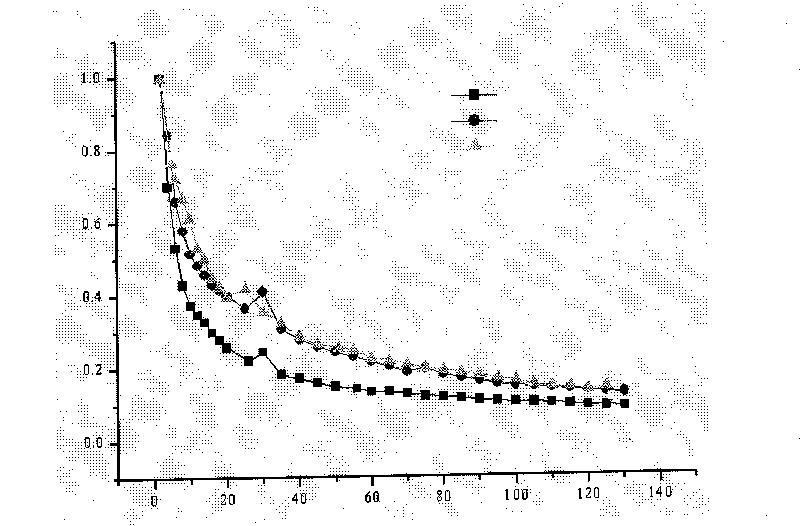

[0022] A flat plastic pad is cut into a fishbone-like or comb-like support structure on both sides, with a large degree of free torsion, and the surface is covered with a microfiltration or ultrafiltration membrane separation material, sealed, and flows out of the water pipe. Flat membranes with different length and width ratios of 5:1 are spirally twisted so that the relative angle between the upper edge and the lower edge of the membrane module is 90 degrees, and fixed in the membrane separation device through the outside. The membrane module can also use thermal deformation to rotate the supporting plastic into a bionic helical structure, keep the shape when heated, and fix the shape after cooling. The outlet pipe of the membrane module can be connected to a vacuum pressure gauge and a suction pump. An aeration device that can control the gas flow is installed at the bottom of the membrane separation device, and a simulated particle suspension prepared with kaolin is added. ...

Embodiment 2

[0026] In the biomimetic spiral membrane module prepared by the same method as in Example 1, the angle between the upper edge and the lower edge is 180 degrees. Under the same device and conditions, its flux is also higher than ordinary flat membrane, 15% higher in a period of time. And the flux drops off more slowly.

Embodiment 3

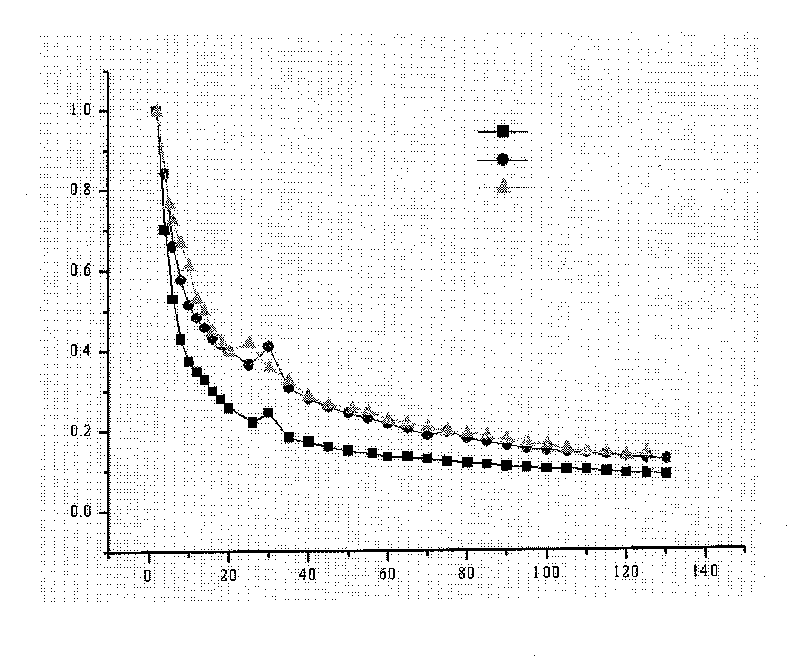

[0028] A row of quasi-flat membranes consisting of 10 bundles of 10 PP hollow fiber membranes fixed at the upper and lower ends are twisted and braided with soft fibers or hollow fibers outside the membrane filament bundles that are approximately parallel to each other. , showing a looser bondage. In the same way as in Example 1, the row of membrane filaments is rotated and twisted, and arranged in a bionic helical shape in space, when the upper and lower ends are at an angle of 90 degrees. The flux decay curve of this membrane has the same characteristics as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com