Waste fusing and curing treatment system and method

A melting solidification and treatment system technology, applied in the field of waste treatment, can solve the problems of incomplete treatment of molten slag, lower heat conversion efficiency, easy ash accumulation, etc., to ensure the thermal ignition loss rate of ash slag, improve heat exchange efficiency, The effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

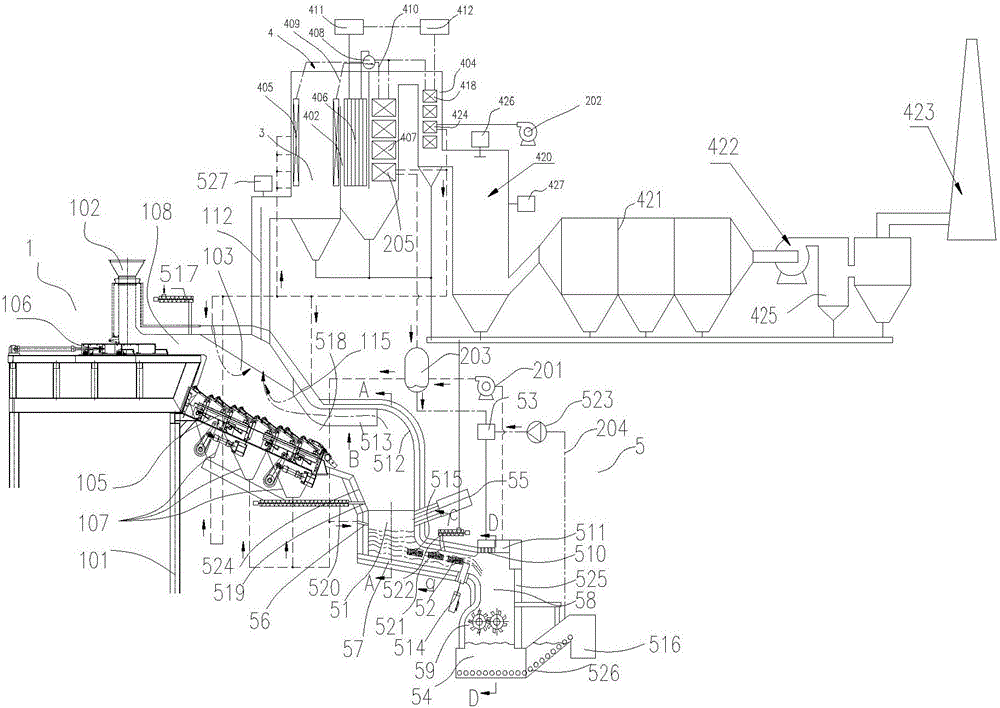

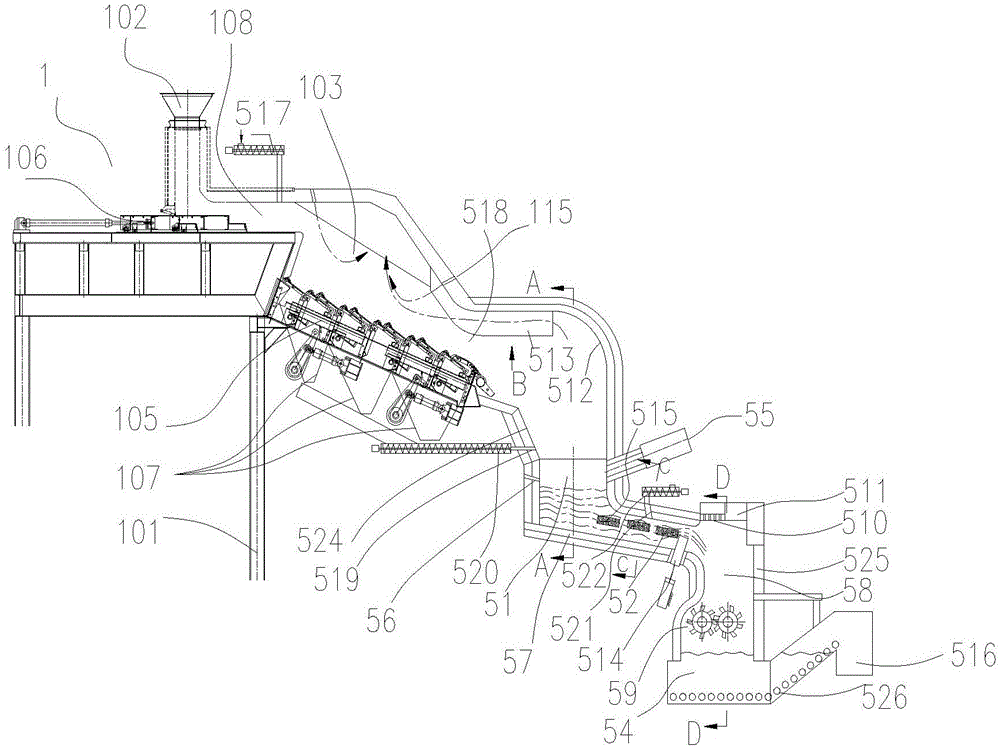

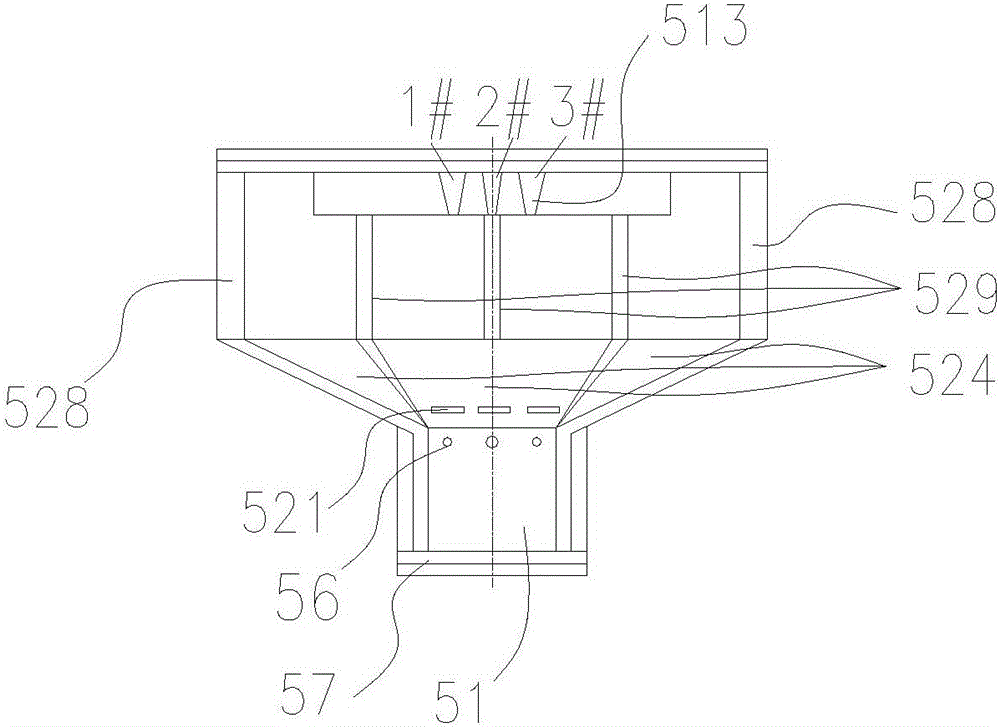

[0055] see Figure 1 to Figure 9 , is a preferred embodiment of the waste melting and solidification treatment system. In this embodiment, a gasifier part and a boiler system are added, and the waste melting and solidification processing system includes a furnace frame, and a feed bin, a gasification furnace, and a melting and solidification processing system are sequentially arranged on the furnace frame along the feeding direction , the discharge end of the melting and solidification treatment system is the glass body slag discharge port.

[0056] The grate is provided with a waste main pusher, and the waste main pusher is located below the feed bin, and is used to push the waste in the feed bin into the gasifier. The feed bin, A stockpile sealing section is provided between the gasifiers, and a base material feeding port is provided on the top wall of the stockpile sealing section, and the base material feeding port is connected to a base material feeding device, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com