Patents

Literature

58results about How to "Guaranteed heat reduction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

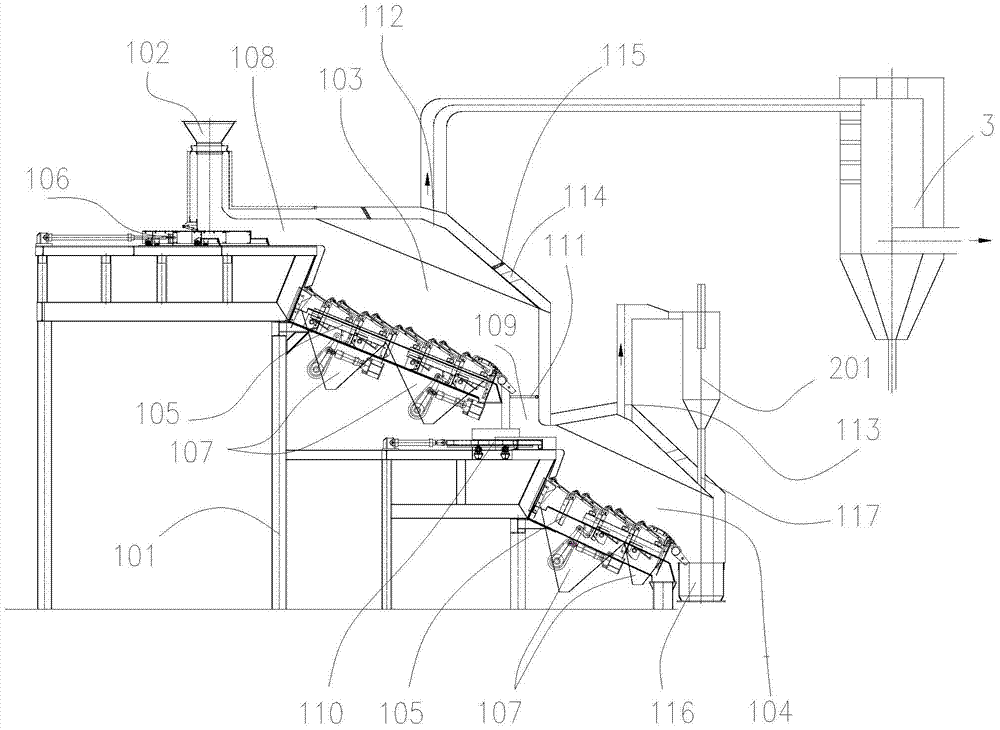

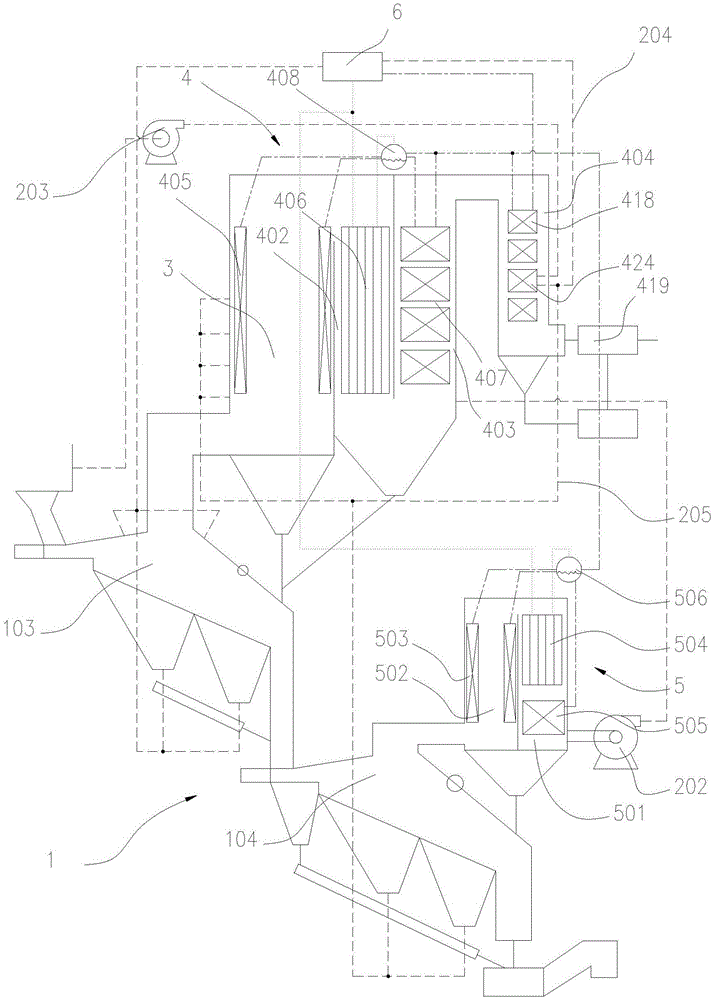

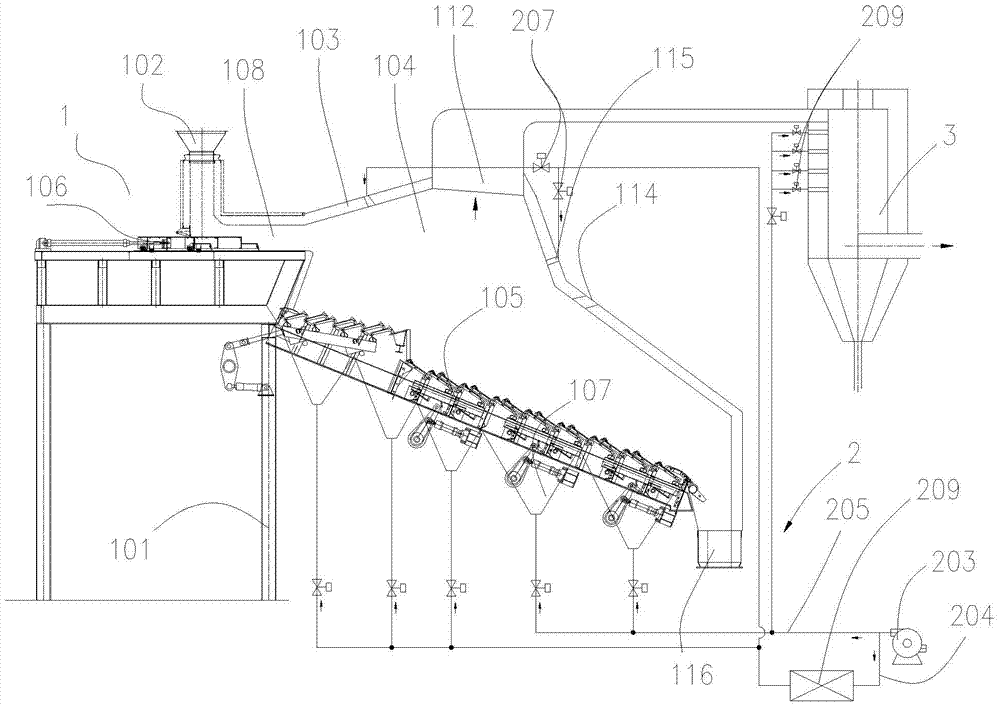

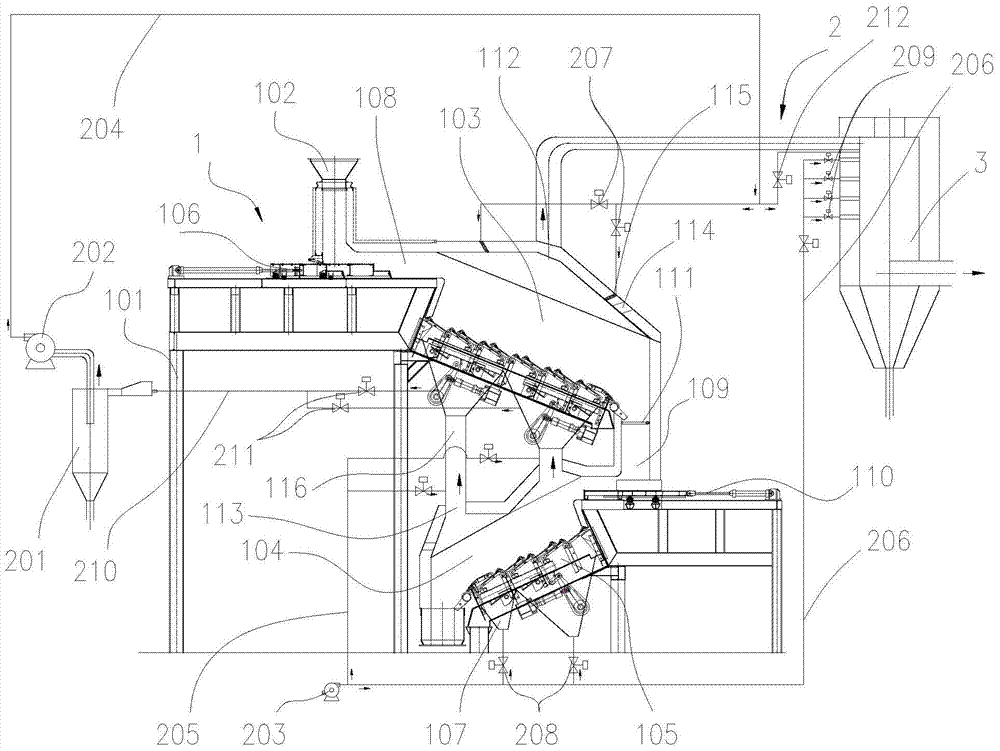

Mechanical grate type single-furnace garbage gasifying incineration system and disposal method thereof

ActiveCN105444183AImprove recycling efficiencyEmission reductionIncinerator apparatusCombustion chamberFlue gas

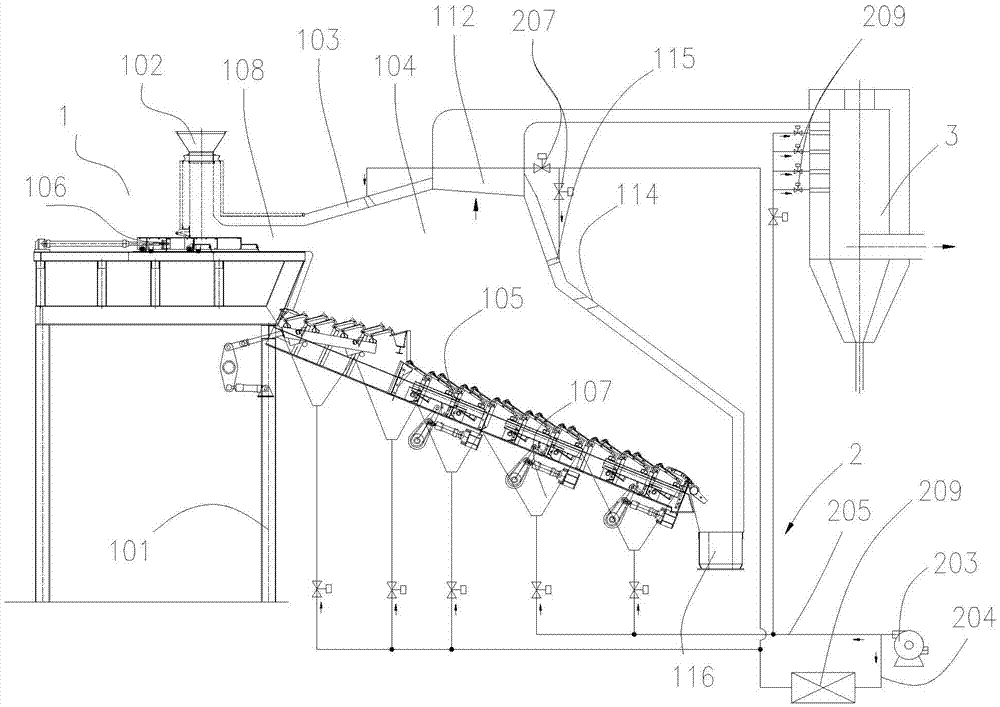

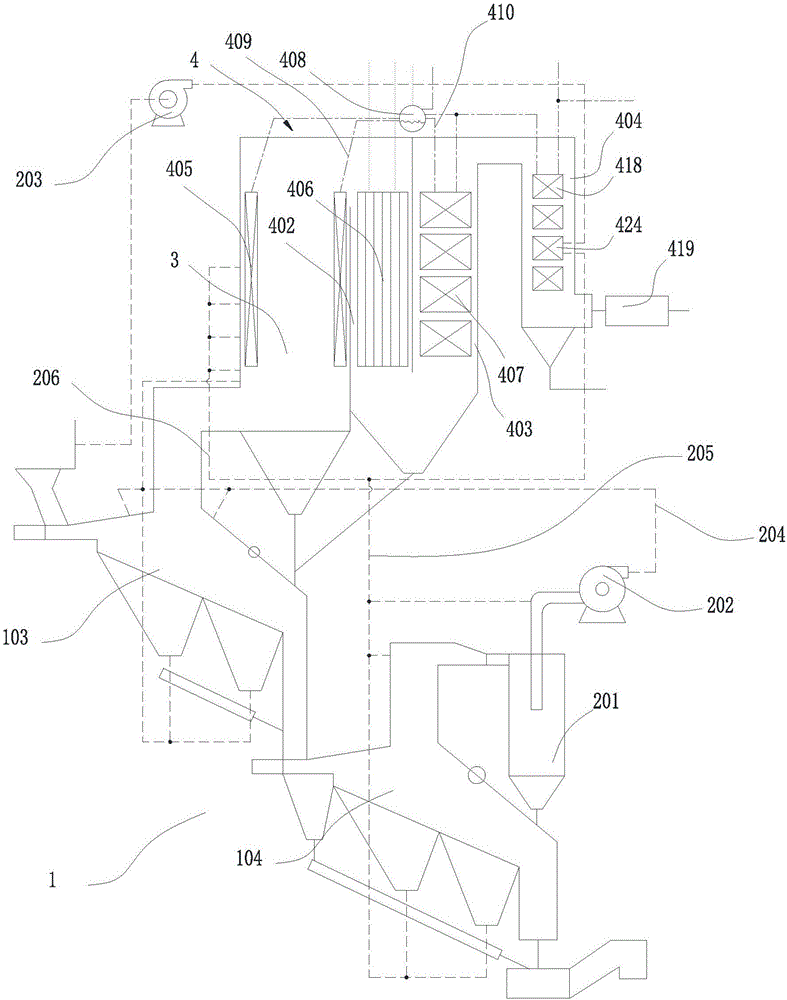

The invention discloses a mechanical grate type single-furnace garbage gasifying incineration system which comprises a gasifying incinerator, a cyclone combustion chamber and an air supply system, wherein the gasifying incinerator comprises a feed hopper and a furnace body; a stockpile sealing segment is arranged between the feed hopper and the furnace body; the upper end of the furnace body is arched and provided with a first flue gas outlet; and the cyclone combustion chamber is used for secondary combustion and is provided with a flue gas inlet connected with the first flue gas outlet. A garbage disposal method comprises the following steps: Step A, starting and drying the incinerator; Step B, burning garbage in a furnace chamber; Step C, realizing continuous garbage gasifying incineration disposal; and Step D, shutting down the mechanical grate type single-furnace garbage gasifying incineration system after the garbage and garbage residues burn out. By the use of the mechanical grate type single-furnace garbage gasifying incineration system, large-scale continuous garbage gasifying incineration disposal can be realized, the garbage disposal capacity and the garbage transport capacity are higher, the heat recovery efficiency is high, and the emission of pollutants is effectively reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

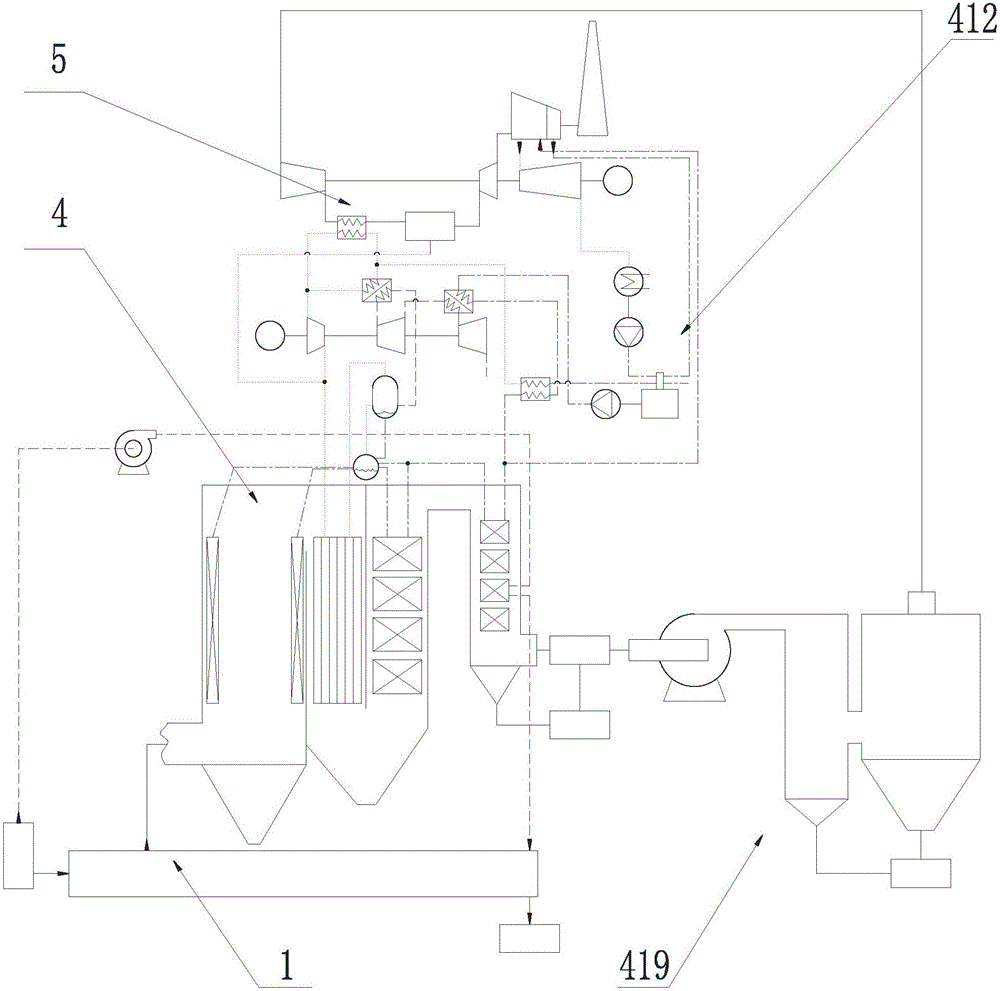

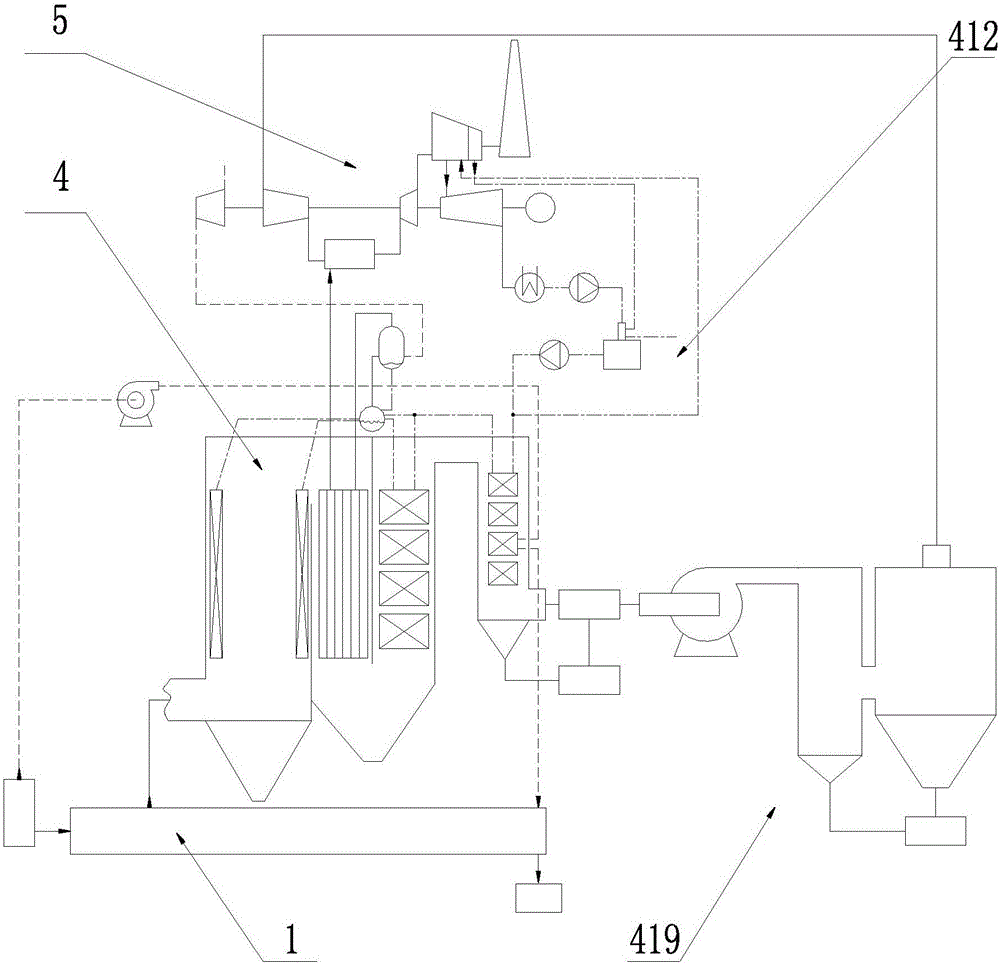

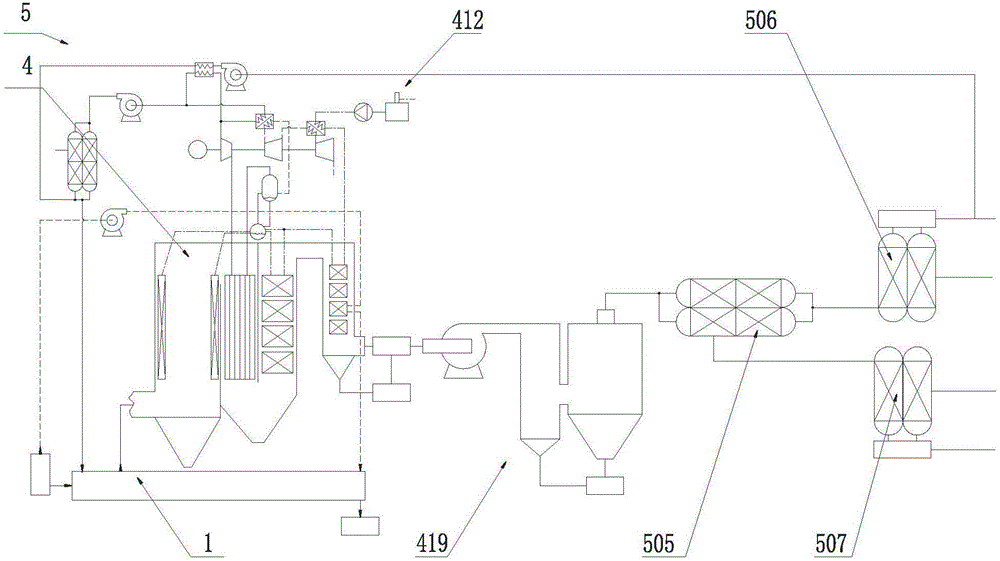

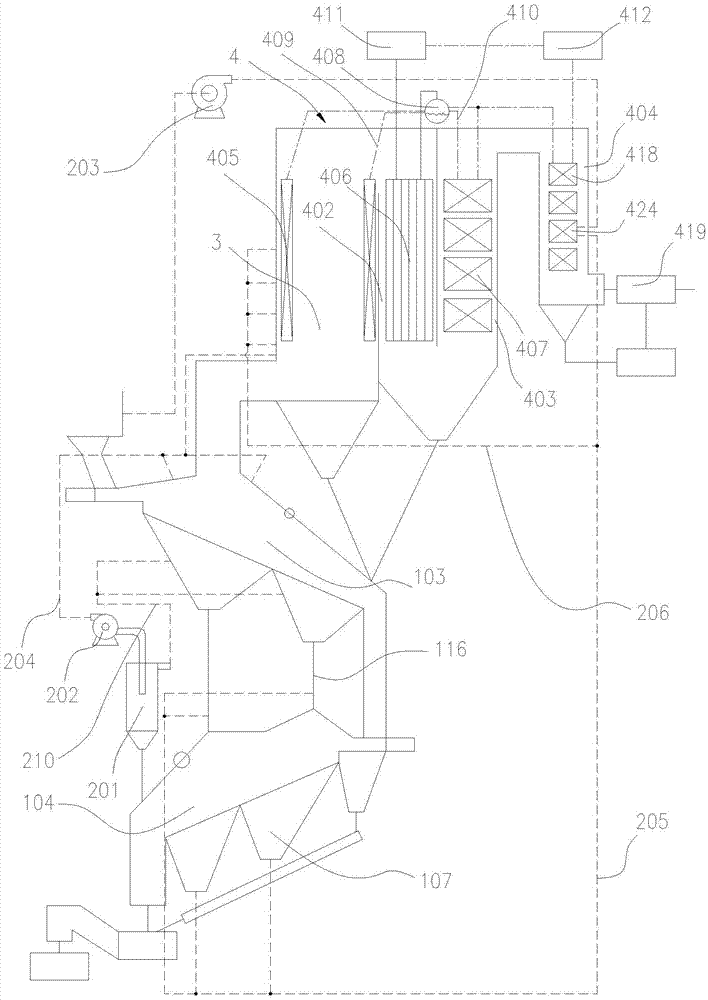

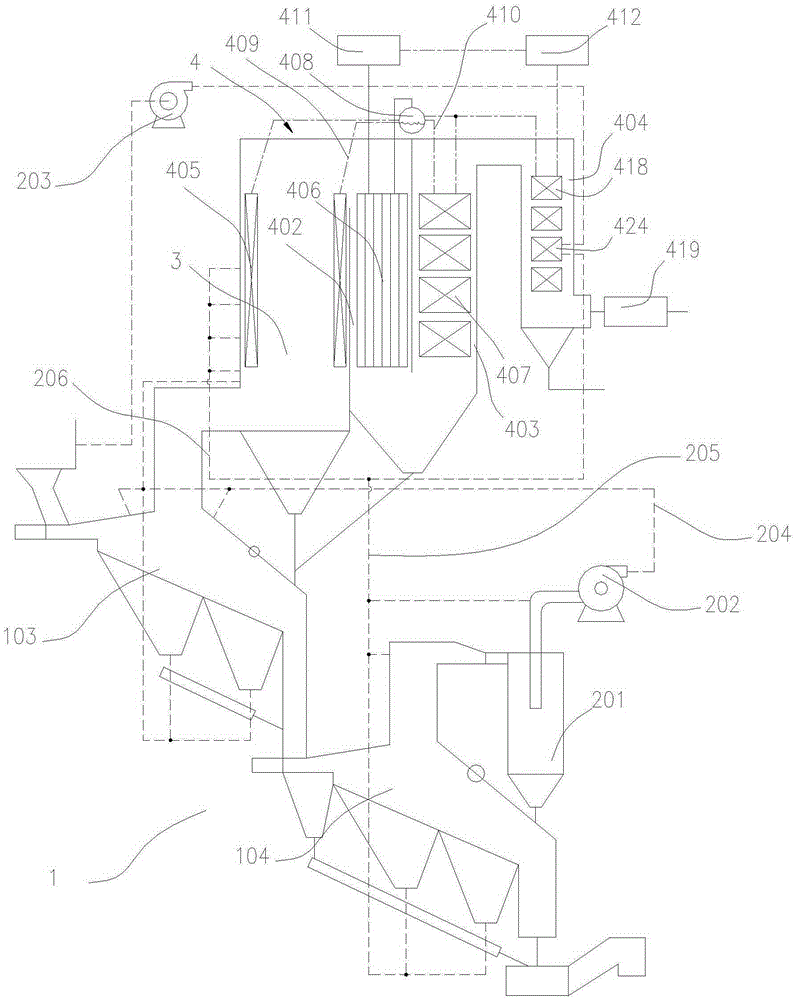

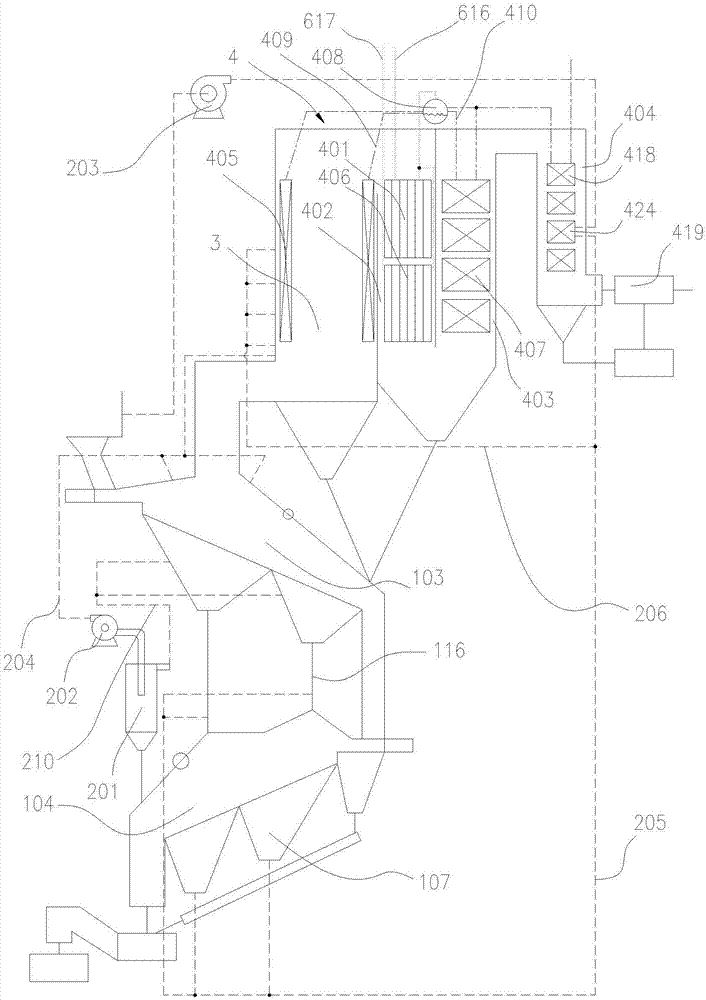

Garbage gasified fuel gas and steam turbine combined power generation system adopting multi-stage heat exchange mode

ActiveCN106224036AEmission reductionImprove recycling efficiencyGas turbine plantsSolid fuel combustionCombustion chamberGas compressor

The invention discloses a garbage gasification fuel gas and steam turbine combined power generation system adopting a multi-stage heat exchange mode. The garbage gasified fuel gas and steam turbine combined power generation system comprises a garbage gasification system, a boiler system and a power generation system; the power generation system comprises a mixer, an air compressor, a synthesized smoke gas compressor, a synthesized smoke gas combustion chamber, a turbine a, a turbine b, a steam turbine, a power generator a, a power generator b and a waste heat boiler. A heating channel of a synthesized gas steam-gas heat exchanger, a heating channel of an air steam-gas heat exchanger and a heating channel of a steam-water heat exchanger are connected between a gas outlet of the turbine a and a water feeding hole of a water feeding input system. A heated channel of a gas-water heat exchanger is connected between a low-pressure air compressor and a high-pressure air compressor. According to the garbage gasification fuel gas and steam turbine combined power generation system adopting the multi-stage heat exchange mode disclosed by the invention, large-scale garbage continuous gasification treatment is realized, garbage treatment capacity is greater, heat recycling efficiency is high, and emission of pollutants can be effectively reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Waste fusing and curing treatment system and method

ActiveCN106524175ARealize continuous gasification and melting processingLarge amount of processingIncinerator apparatusCombustorSlag

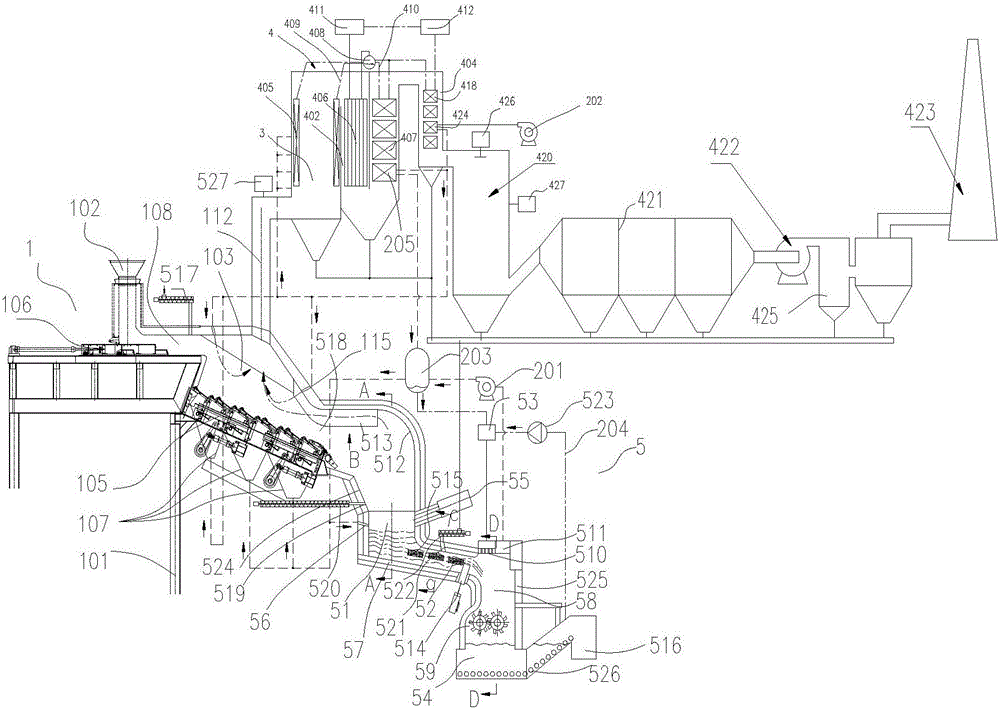

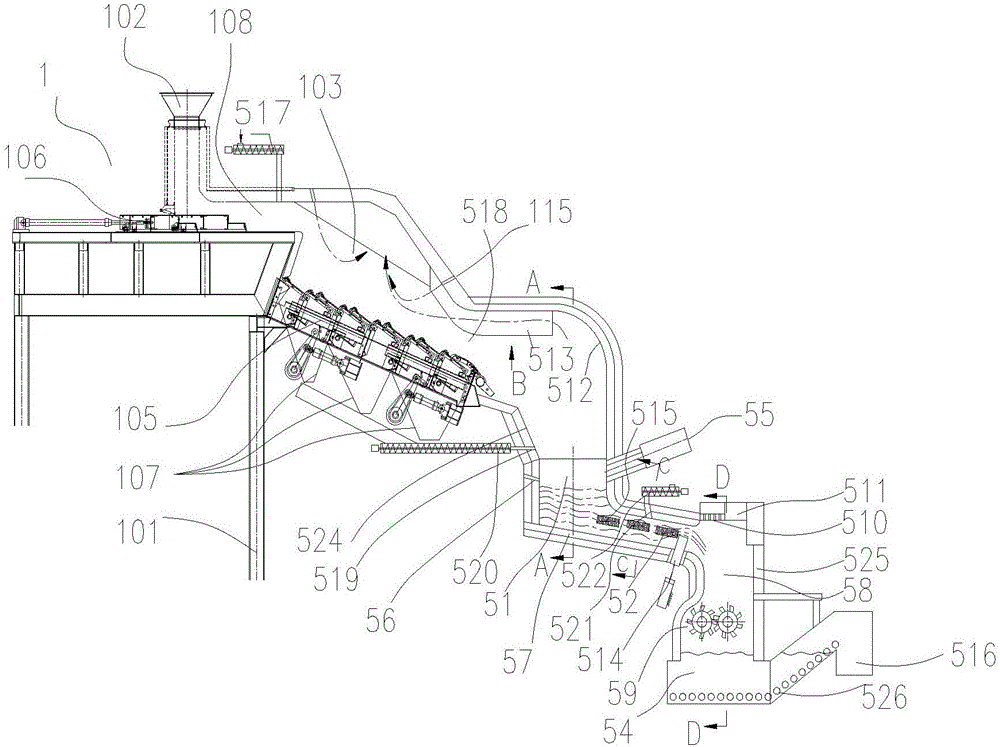

The invention discloses a waste fusing and curing treatment system and method. When the waste fusing and curing treatment system and method are used for treating rubbish, the rubbish conveying capacity is higher, the rubbish treating capacity is larger, the thermal loss can be reduced, the heat exchanging efficiency can be improved, the recovery efficiency of heat is relatively high, and the emission load of pollutants can be effectively reduced. The waste fusing and curing treatment system comprises a fusion hearth, a laminar flow channel, a water-cooling breaking system and a water seal deslagging system all of which are sequentially arranged in the feeding direction. A high-temperature burner and a gasifying agent inlet are formed in the side wall of the fusion furnace. The water-cooling breaking system comprises a water-cooling system, a water-cooling cavity and a glass body pulverizer. The method comprises the first step of furnace starting and drying; the second step of enabling residues into the fusion hearth to be fused; the third step of fusing inorganic waste in the laminar flow channel; the fourth step of carrying out water cooling on fusion slag and curing the fusion slag into glass body dregs, and breaking and discharging the dregs; and the fifth step of turning off the waste fusing and curing treatment system after the waste fusion dregs are discharged completely.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

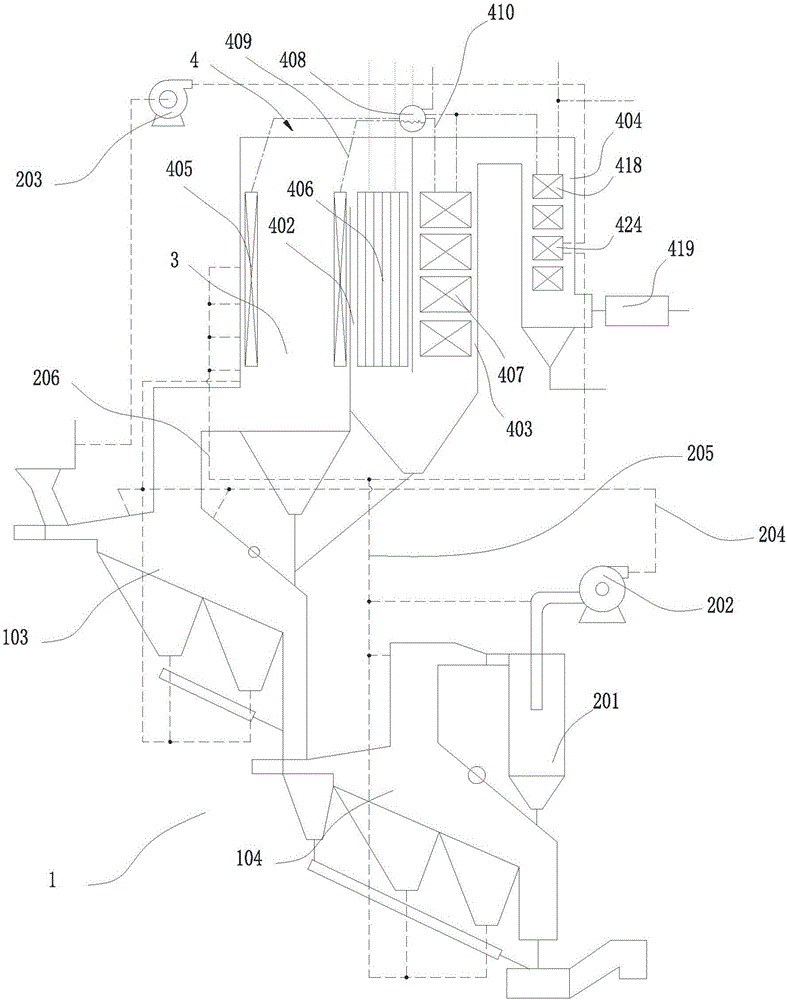

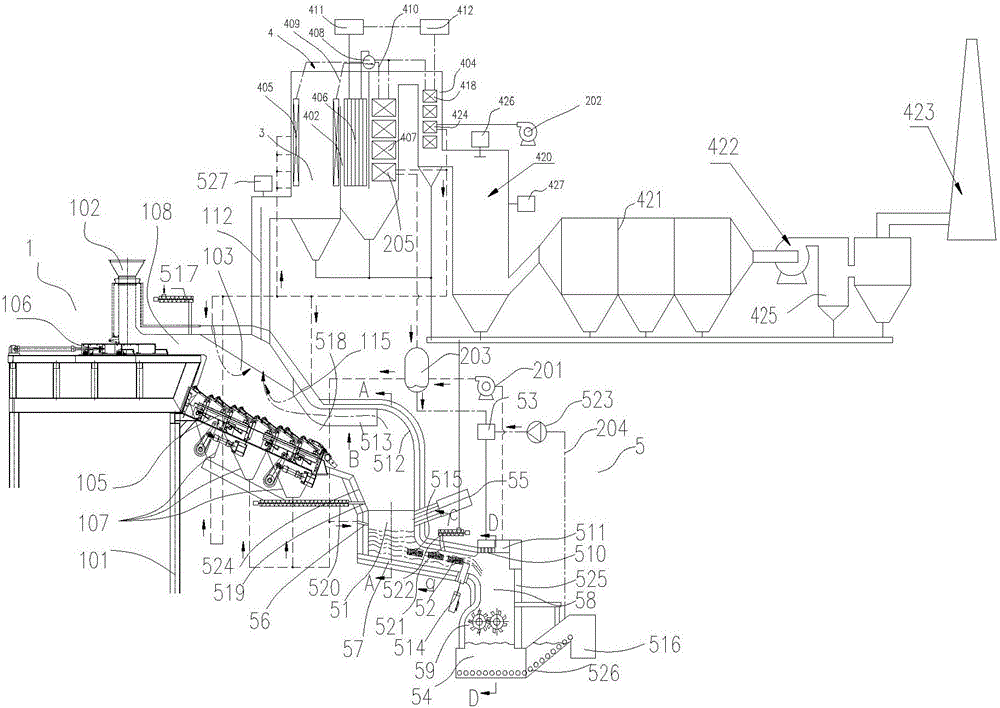

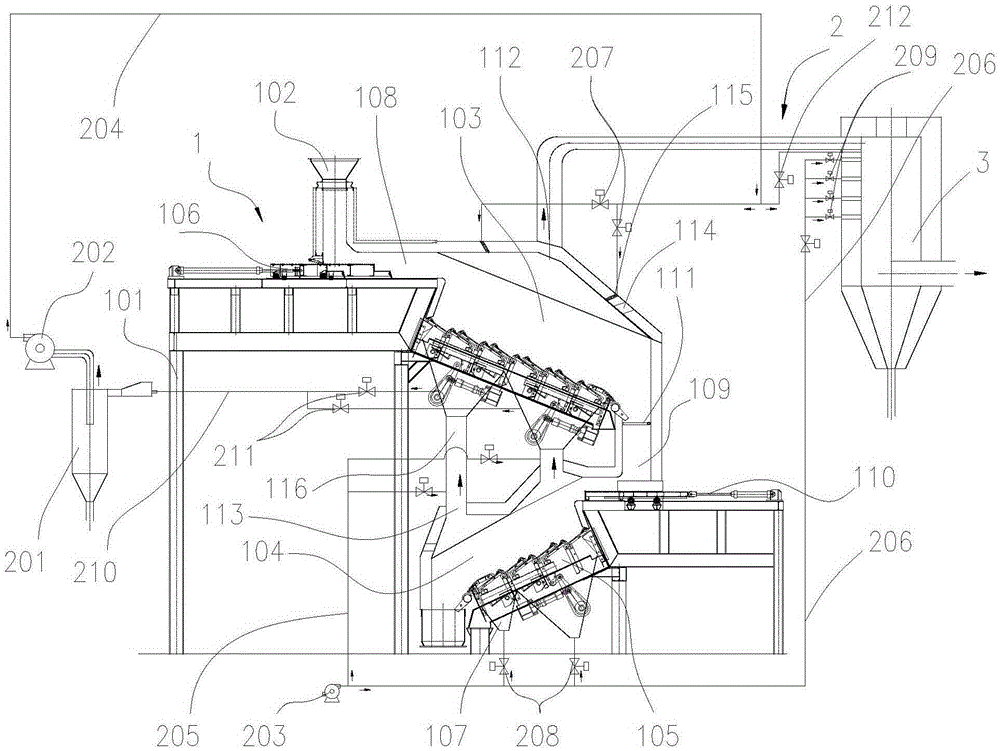

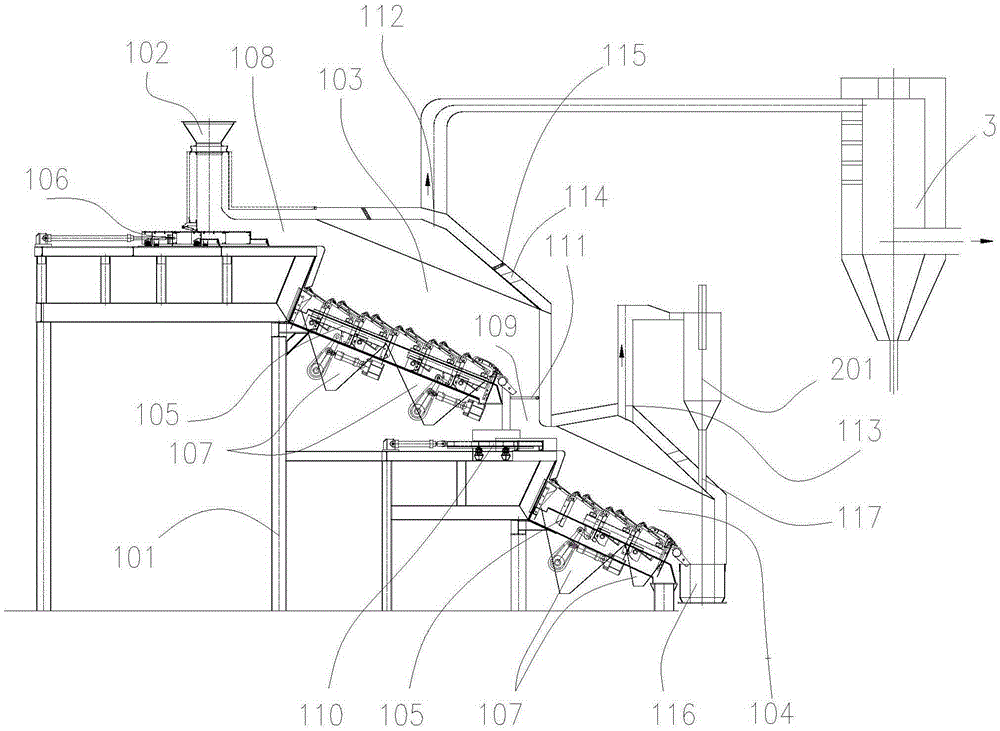

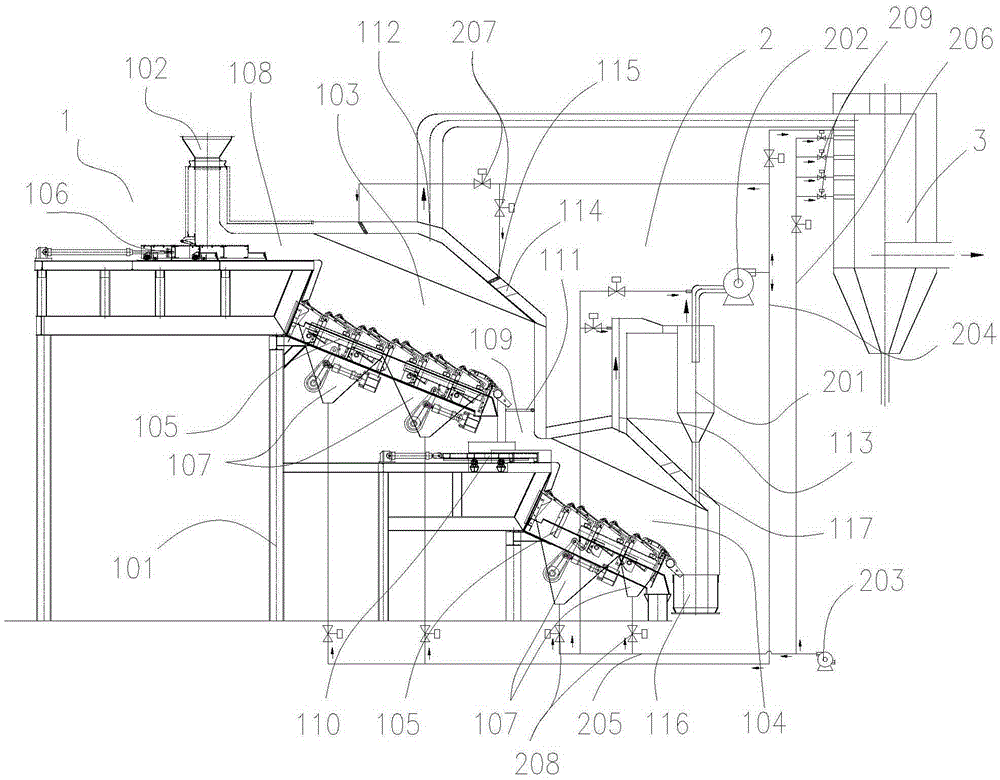

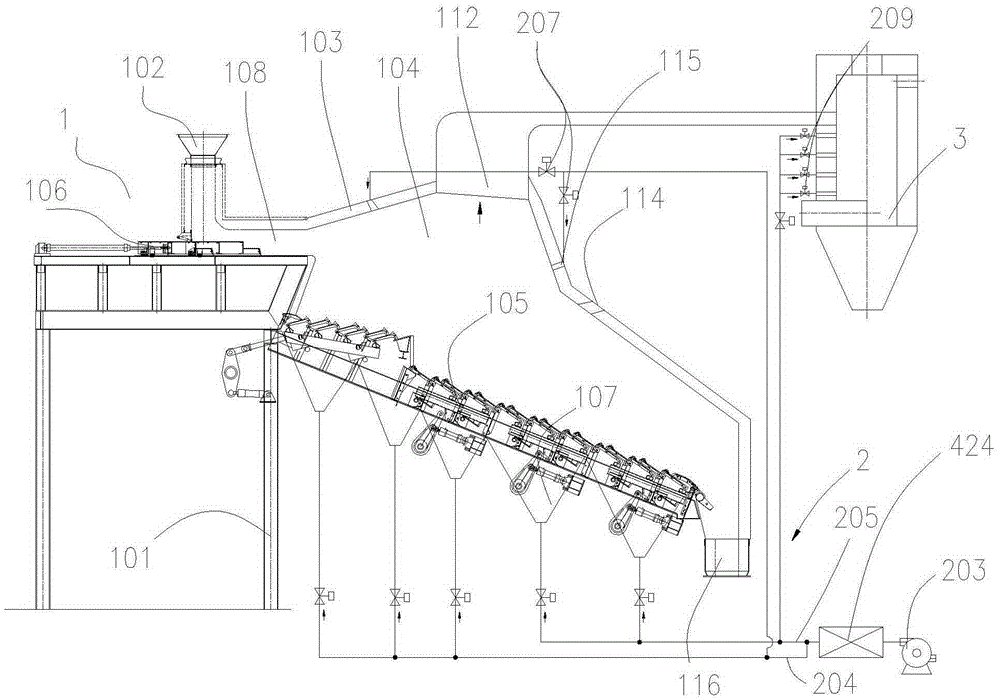

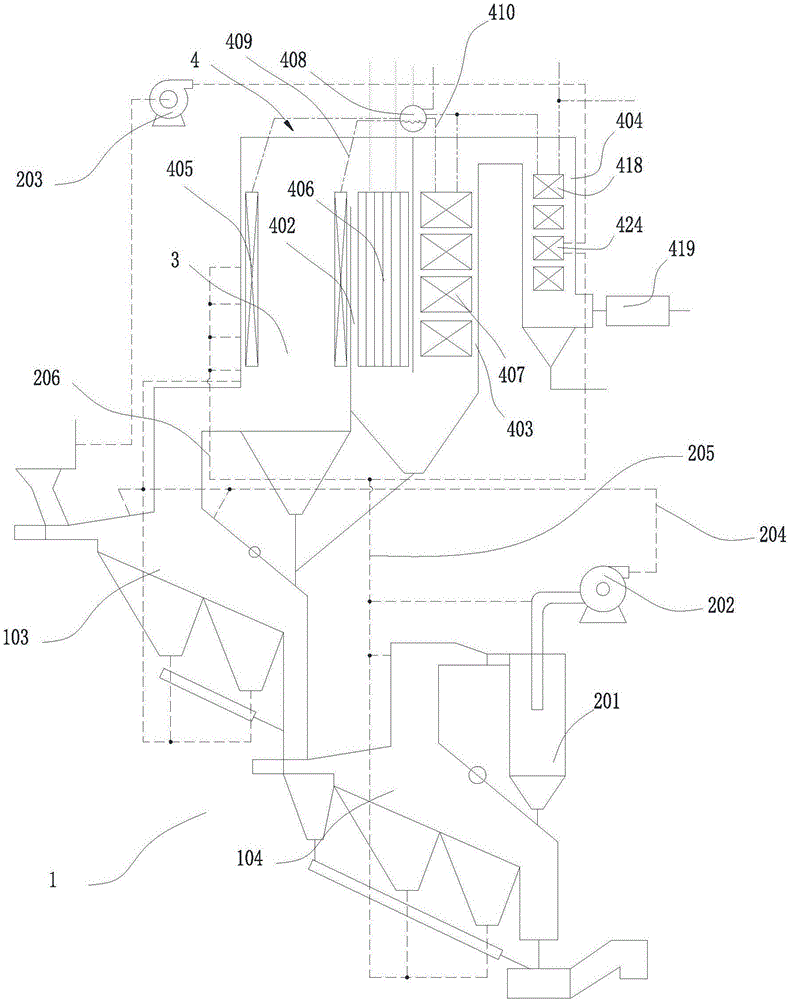

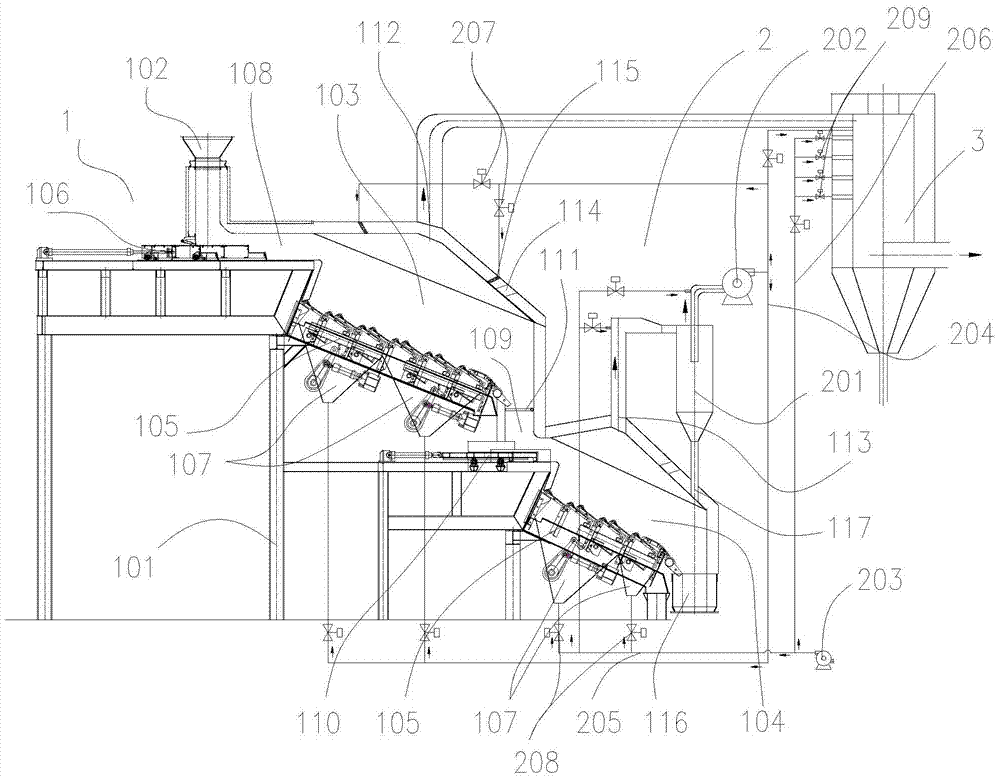

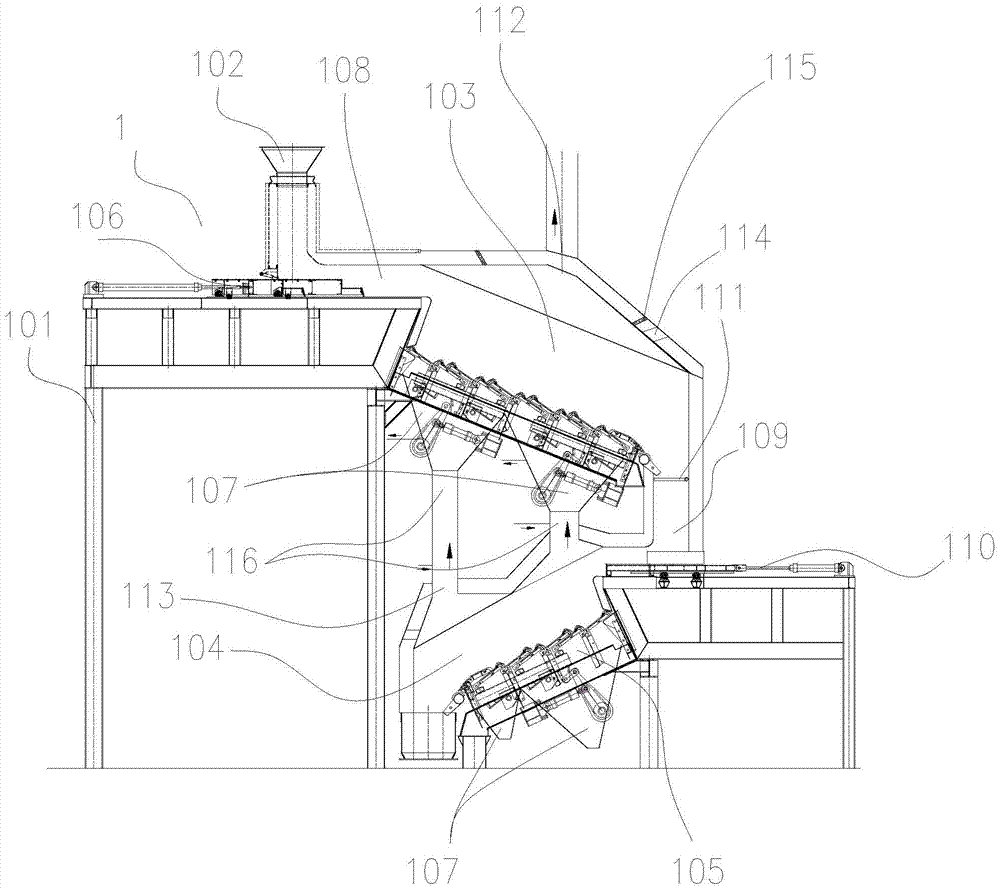

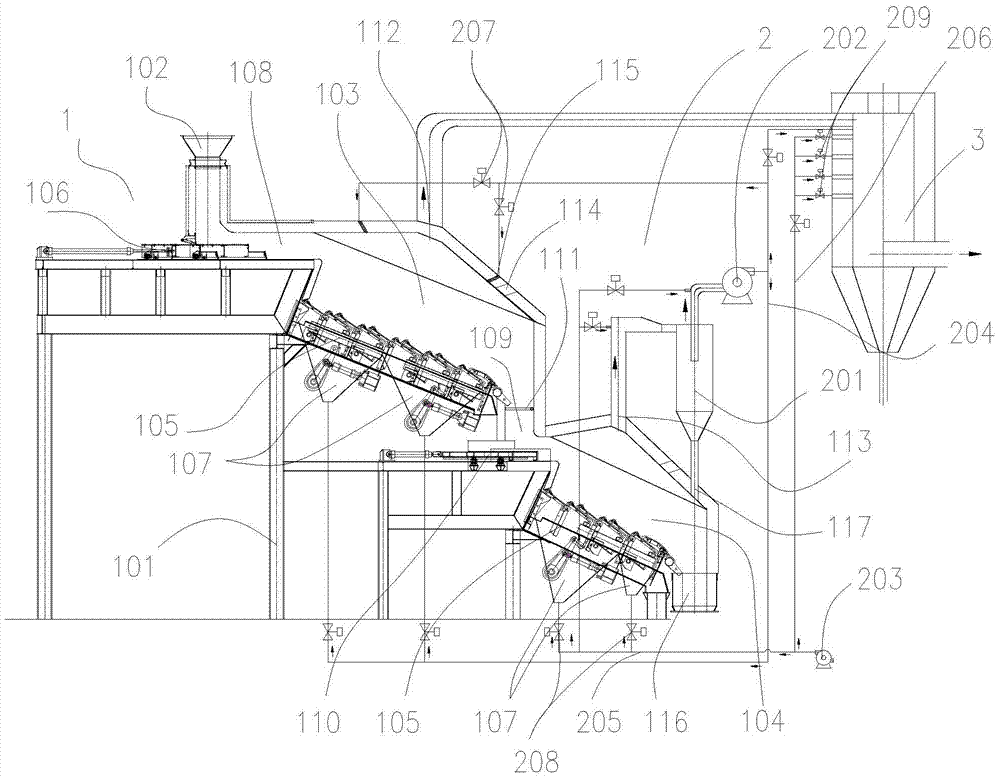

Double-layer mechanical grate type garbage gasification and incineration system and treatment method adopting same

ActiveCN105402736AImprove insulation effectPrevent leakageIncinerator apparatusPollutant emissionsProcess engineering

The invention discloses a double-layer mechanical grate type garbage gasification and incineration system. The system comprises a double-layer garbage gasification and incineration furnace, wherein the double-layer garbage gasification and incineration furnace comprises a feeding bin, a gasification furnace and an ash combustion furnace which is located right below the gasification furnace; the feeding direction of the ash combustion furnace is opposite to that of the gasification furnace; a stacking sealing section is arranged between the feeding bin and the gasification furnace; a residue pusher is arranged between the gasification furnace and the ash combustion furnace; exhaust gas outlets are formed in the upper end of the gasification furnace and the upper end of the ash combustion furnace; the double-layer mechanical grate type garbage gasification and incineration furnace further comprises a circular air supply system. The garbage treatment method comprises steps as follows: step A, furnace ignition and drying are performed; step B, garbage is combustedin a hearth of the gasification furnace; step C, continuous garbage gasification and incineration treatment is realized; step D, the double-layer mechanical grate type garbage gasification and incineration furnace shuts down after ash combustion. With the adoption of the double-layer mechanical grate type garbage gasification and incineration furnace for treating the garbage, the garbage treatment amount is large, the recovery efficiency of heat is relatively high, and pollutant emission can be effectively reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

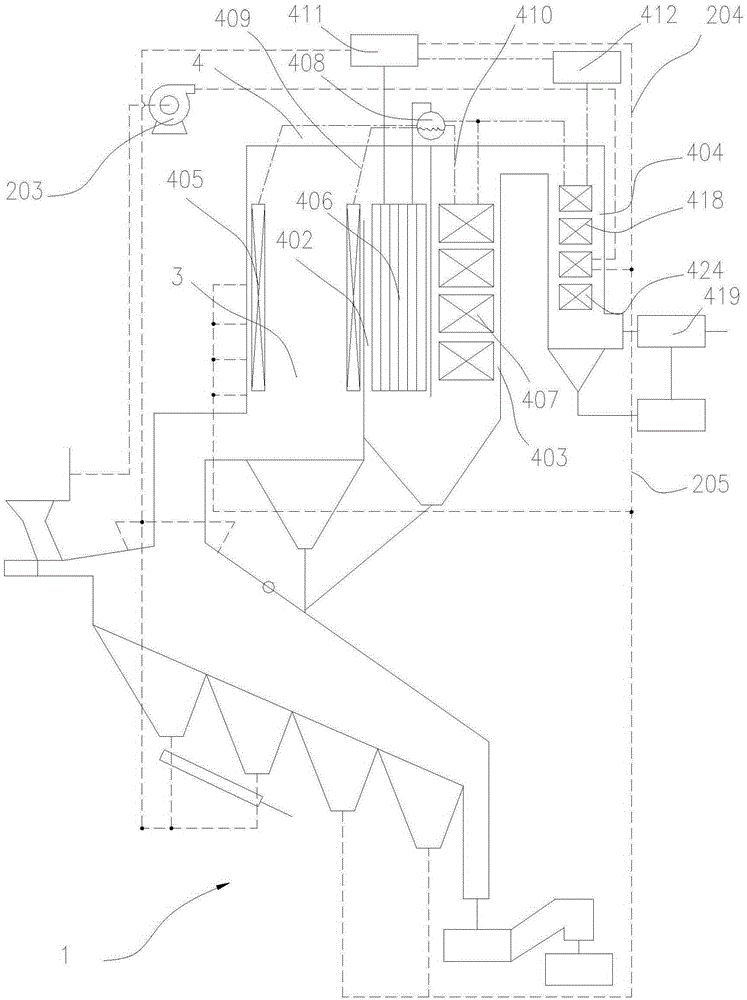

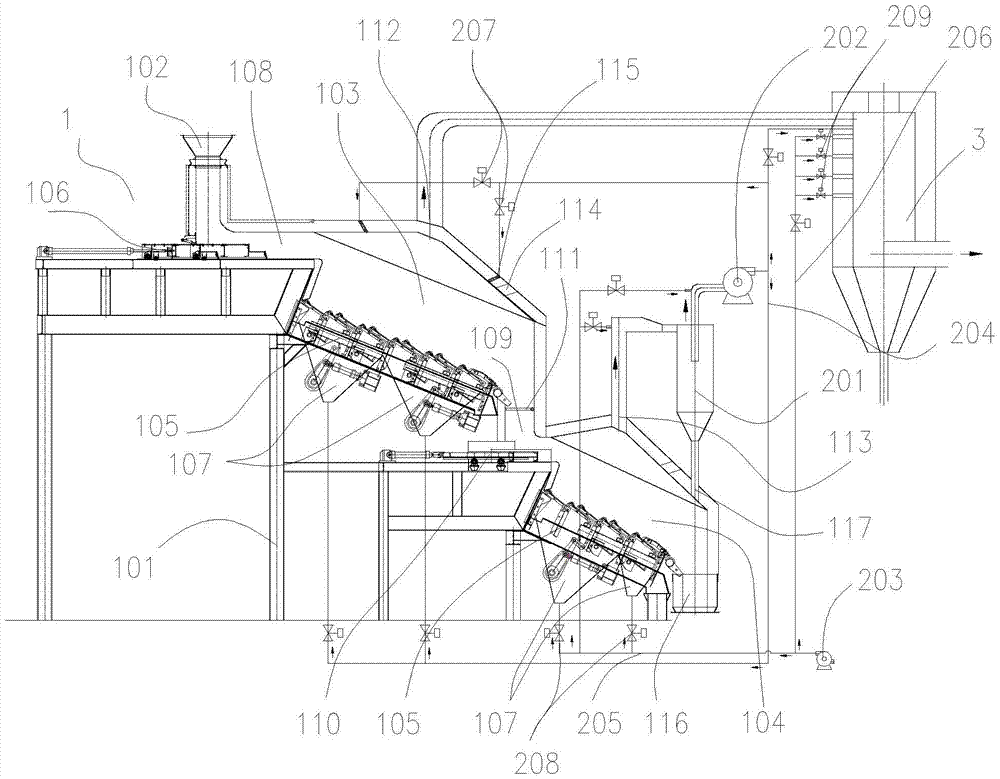

Mechanical grate type waste gasifying incinerator and boiler power generation system thereof

ActiveCN105509060AImprove qualityEasy to remove dustSteam engine plantsIncinerator apparatusCombustion chamberEngineering

The invention discloses a mechanical grate type waste gasifying incinerator which is smaller in heat conversion efficiency loss and is higher heat recovery efficiency, and a boiler power generation system thereof. The mechanical grate type waste gasifying incinerator comprises a gasifying incinerator, a boiler system, an air supply system and a power generation system, wherein the gasifying incinerator comprises a gasifier and an incinerator, the gasifier and the incinerator can be sealed or communicated, and an upper end of the gasifier and the incinerator are respectively provided with a smoke outlet; the boiler system comprises a boiler body, the boiler body is provided with a cyclone combustion chamber, a furnace chamber a and a furnace chamber b which are communicated with one another, a water-cooled wall is arranged in the cyclone combustion chamber, superheaters are arranged in the furnace chamber a, an evaporator is arranged in the furnace chamber b, and a top end of the boiler body is provided with a steam drum; the power generation system comprises a steam turbine, a power generator and a steam input pipe, an output end of the steam turbine is sequentially connected with a condenser, a water pump, a low-pressure steam water heater, a deaerator, a booster pump and a high-pressure steam water heater, and first-stage and second-stage water-steam separators and first-stage and second-stage high-pressure steam-steam heaters are arranged between air cylinders of the steam turbine.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Mechanical grate type waste gasifying incinerator and processing method thereof

The invention discloses a mechanical grate type waste gasifying incinerator and a processing method thereof. The gasifying incinerator comprises a feed bin, a gasifying furnace and a burning furnace, wherein the burning furnace is positioned on the front lower part of a slag dropping opening of the gasifying furnace, a stockpile sealing section is formed between the feed bin and the gasifying furnace, a residue stoker is arranged between the gasifying furnace and the burning furnace, the upper ends of the gasifying furnace and the burning furnace are respectively arched, and smoke outlets are respectively formed in the upper ends of the gasifying furnace and the burning furnace. The waste processing method comprises the steps of A. igniting and drying; B. burning waste in a hearth of the gasifying furnace; C. performing continuous gasification and incineration on the waste; D. shutting off the mechanical grate type waste gasifying incinerator after the waste and waste residues are burnt out. When the mechanical grate type waste gasifying incinerator is used for processing the waste, the waste conveying capability is strong, the waste processing capacity is large, the heat recovering efficiency is high, and the pollutant discharge can be effectively reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Mechanical grate-type garbage single-furnace gasifying incineration and boiler system

The invention discloses a mechanical grate-type garbage single-furnace gasifying incineration and boiler system which is smaller in transformation heat efficiency loss and higher in heat recovery rate. The system comprises a gasifying incineration furnace, a boiler system and an air supply system, wherein the gasifying incineration furnace comprises a material feeding cabin and a furnace body; a material stacking sealing section is arranged between the material feeding cabin and the furnace body; the upper end of the furnace body is upwards convex and is provided with a first smoke outlet; the boiler system comprises a boiler body; the boiler body comprises a cyclone combustor, a furnace chamber a and a furnace chamber b which are communicated with one another; a water-cooling wall is arranged in the cyclone combustor; a superheater is arranged in the furnace chamber a; an evaporator is arranged in the furnace chamber b; the smoke inlet of the cyclone combustor is connected with the first smoke outlet; the top end of the boiler body is provided with a steam pocket; a steam-water inlet is formed in the steam pocket; the steam pocket is connected with water-cooling wall and the water inlet of the evaporator for outputting water; the water-cooling wall and the steam outlet of the evaporator are connected with the steam inlet of the steam pocket for steam backflow; and the saturated steam outlet of the steam pocket is used for outputting superheated steam through the superheater.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

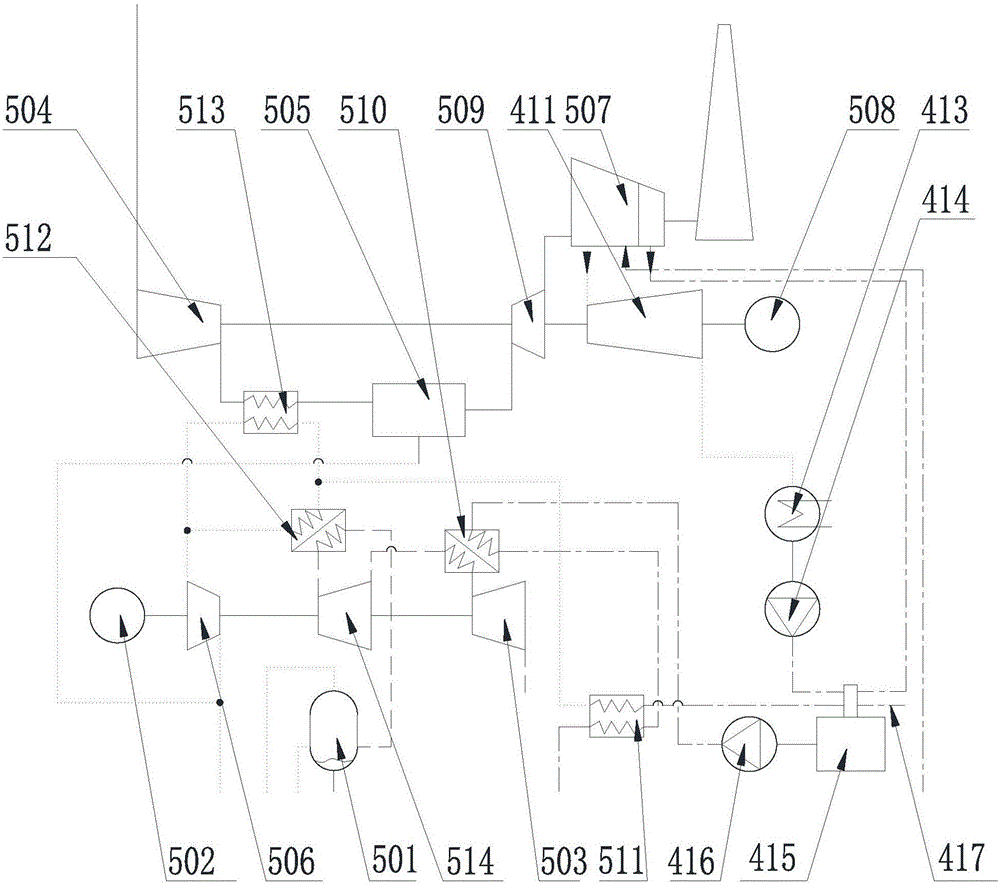

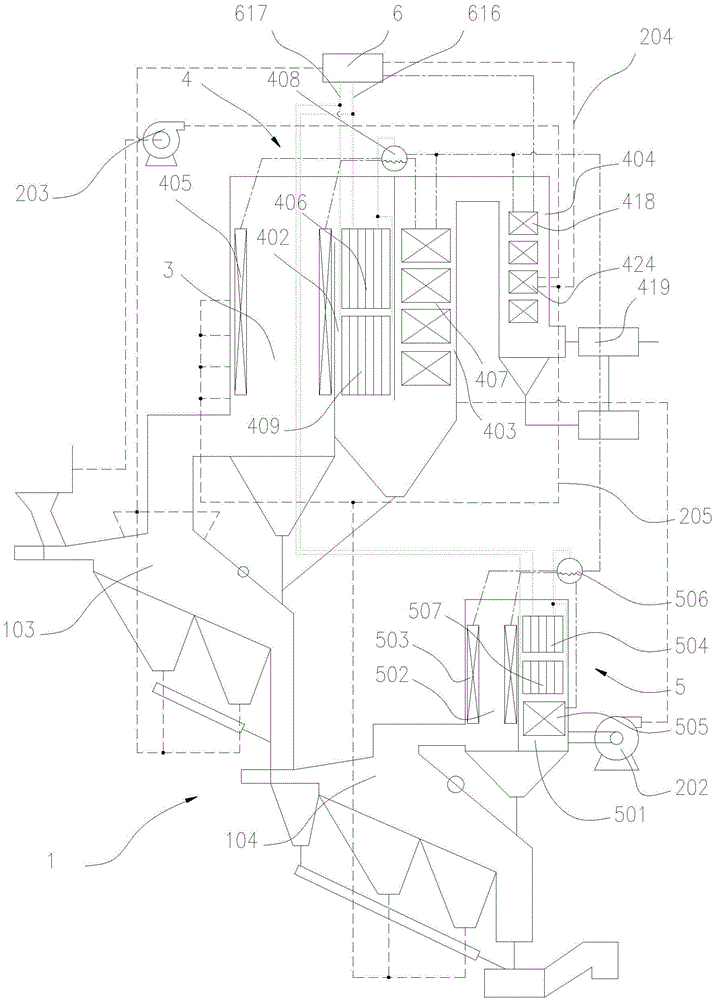

Mechanical fire grate type rubbish gasification incinerator and dual-boiler energy-saving power generation system thereof

ActiveCN105588131AImprove qualityEasy to remove dustMachines/enginesSteam generation plantsCycloneCombustion chamber

The invention discloses a mechanical fire grate type rubbish gasification incinerator which is smaller in heat efficiency conversion loss and higher in heat recovery rate and a dual-boiler energy-saving power generation system of the mechanical fire grate type rubbish gasification incinerator. The mechanical fire grate type rubbish gasification incinerator comprises a gasification incinerator body, a boiler system, a circulation air supply system and a power generation system; the gasification incinerator body comprises a gasification boiler and a burning ash boiler which can be sealed or communicated; the boiler system comprises boiler bodies a and b, the boiler body a is provided with a cyclone burning chamber and boiler chambers a and b, the boiler body b is provided with a boiler chamber d and a cyclone dust removal chamber, water cooling walls are arranged in the cyclone burning chamber and the cyclone dust removal chamber, a superheater unit is arranged in the boiler chamber a, and an evaporator is arranged in the boiler chamber b; and a superheater unit and an evaporator are arranged in the boiler chamber d, steam pockets are arranged at the top ends of the two boiler bodies, a smoke inlet of the cyclone burning chamber is connected with a smoke outlet of the gasification incinerator body, and a smoke inlet of the cyclone dust removal chamber is connected with a smoke outlet of the burning ash boiler. The power generation system comprises a steam input pipe, a steam turbine and a power generator, and the steam input pipe is connected with the superheater units a and b and the steam turbine.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

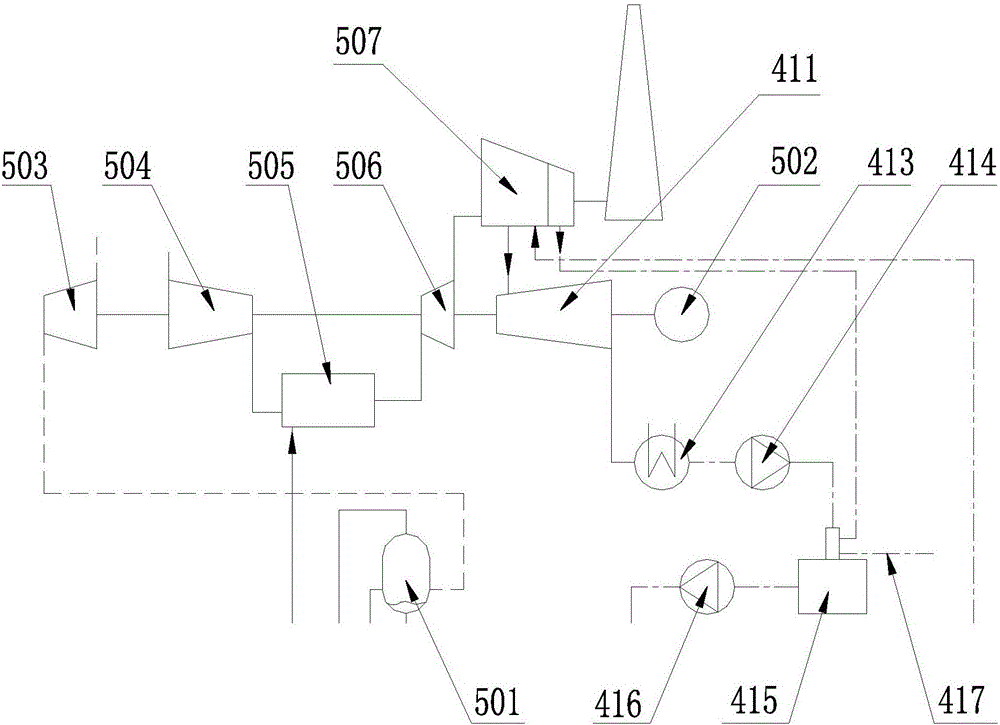

Gas turbine-steam turbine coaxial combined power generation system based on waste gasification

ActiveCN106287642AImprove qualityEasy to remove dustSteam generation plantsSteam engine plantsCombustion chamberGas compressor

The invention discloses a gas turbine-steam turbine coaxial combined power generation system based on waste gasification. The gas turbine-steam turbine coaxial combined power generation system comprises a waste gasification incineration system, a boiler system and a power generation system, wherein the power generation system comprises a mixer, an air compressor, a synthetic flue gas compressor, a synthetic flue gas combustion chamber, a turbine, a steam turbine, a power generator, a waste heat boiler and a water supply input system; the inlet of the mixer is connected with the saturated steam outlet of a steam manifold and the air outlet of the air compressor; the water outlet of the mixer is connected with the water inlet of the steam manifold; the steam outlet of the mixer is connected with the steam inlet of a super-heater; the gas inlet of the flue gas compressor is connected with the waste gas discharge outlet of the boiler system; the steam outlet of the super-heater and the gas outlet of the flue gas compressor are connected with the synthetic flue gas combustion chamber, the turbine and the waste heat boiler in sequence; the steam outlet of the waste heat boiler is connected with the steam inlet of the steam turbine; the turbine, the steam turbine and the power generator are in power connections. By adopting the gas turbine-steam turbine coaxial combined power generation system, large-scale continuous waste gasification treatment can be performed, high heat recovery efficiency is achieved, and pollutant discharge is reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Waste gasification melting furnace

ActiveCN106642138ARealize continuous gasification and melting processingLarge amount of processingIncinerator apparatusCombustorHeat losses

The invention discloses a waste gasification melting furnace; and the waste gasification melting furnace is used for treating garbage, is higher in garbage conveying capacity, is higher in garbage treatment quantity, can reduce the heat loss and improve the heat exchange efficiency, is higher in heat recovery efficiency, and can effectively reduce the pollutant discharge. The waste gasification melting furnace comprises a furnace frame, and a feeding bin, a gasification furnace and a melting curing treatment system arranged on the furnace frame in sequence in a feeding direction; the melting curing treatment system includes a melting hearth, a laminar channel, a water cooling crushing system and a water seal deslagging system arranged in the feeding direction in sequence; a high-temperature combustor and a gasification agent inlet are arranged on a side wall of the melting hearth; the water cooling crushing system includes a water cooling system, a water cooling cavity and a glass body crusher; and a discharge end of the water seal deslagging system is connected with a glass body deslagging outlet.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Boiler power generation system utilizing rubbish gasification and incineration synthesis gas

ActiveCN105464727AIncrease profitLarge amount of garbage disposalLiquid degasificationSteam engine plantsSyngasEngineering

The invention discloses a boiler power generation system utilizing rubbish gasification and incineration synthesis gas. The boiler power generation system is small in heat conversion efficiency loss and higher in heat recovery efficiency. The boiler power generation system comprises a steam turbine, a generator, a high-pressure steam input pipe and a medium-pressure steam input pipe. The steam turbine comprises a high-pressure steam cylinder, a medium-pressure steam cylinder and a low-pressure steam cylinder. A first-stage water-steam separator and a first-stage high-pressure steam-steam heater are connected between the high-pressure steam cylinder and the medium-pressure steam cylinder. A second-stage water-steam separator and a second-stage high-pressure steam-steam heater are connected between the medium-pressure steam cylinder and the low-pressure steam cylinder. The steam output end of the low-pressure steam cylinder is connected with a condenser, a water pump, a low-pressure steam-water heater, a deaerator, a booster water pump and a high-pressure steam-water heater in sequence through a pipeline. The high-pressure steam input pipe is connected with the high-pressure steam cylinder and is connected with the deaerator through the heating end of the first-stage high-pressure steam-steam heater, the heating end of the high-pressure steam-water heater, the heating end of the second-stage high-pressure steam-steam heater and the heating end of the low-pressure steam-water heater.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

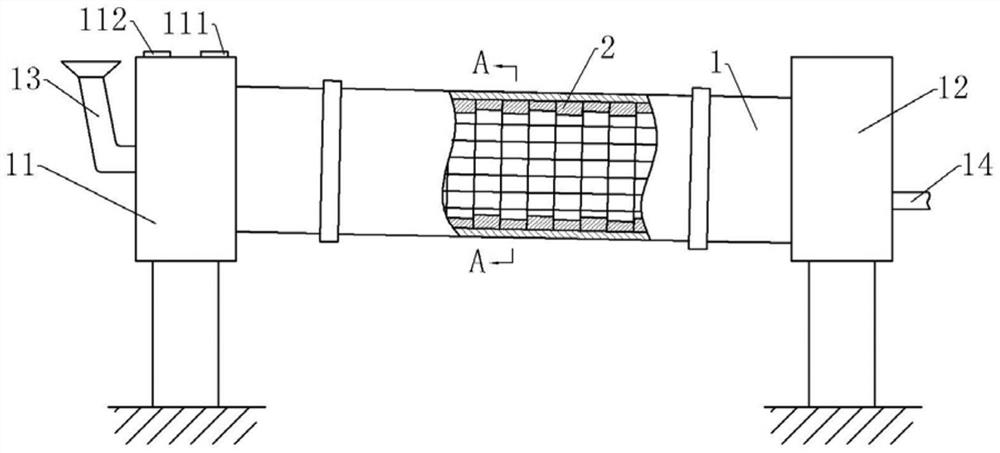

Hazardous waste rotary kiln incineration process

The invention belongs to the technical field of hazardous waste incineration, and discloses a hazardous waste rotary kiln incineration process which is realized by adopting a hazardous waste rotary kiln. The hazardous waste rotary kiln comprises a cylinder body, the two ends of the cylinder body are respectively provided with a kiln head cover and a kiln tail cover in a rotatably and hermeticallyconnected manner, the lower part of the kiln tail cover is provided with a slag outlet, and the kiln head cover is cylindrical; a main air hole and an auxiliary air hole are formed in the side wall ofthe kiln head cover, the main air hole is located in the top of the kiln head cover, the main air hole and the auxiliary air hole are not located in the same circumferential line of the kiln head cover, the main air hole is formed close to the cylinder body, and the auxiliary air hole is formed in the side away from the cylinder body; hazardous waste is thrown into the cylinder body to be incinerated, after the temperature in the cylinder body rises to 1000-1150 DEG C, air is supplied into the kiln head cover from the main air hole and the auxiliary air hole, and the air speed of the main airhole and the air speed of the auxiliary air hole are consistent; and after the hazardous waste is incinerated, ash slag is guided out from the slag outlet. By means of the hazardous waste rotary kilnincineration process, it can be guaranteed that the ignition loss rate is low after hazardous waste is incinerated, and the excess air coefficient is low, so that the hazardous waste can be fully incinerated, and heat losses in the incineration process can be reduced.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

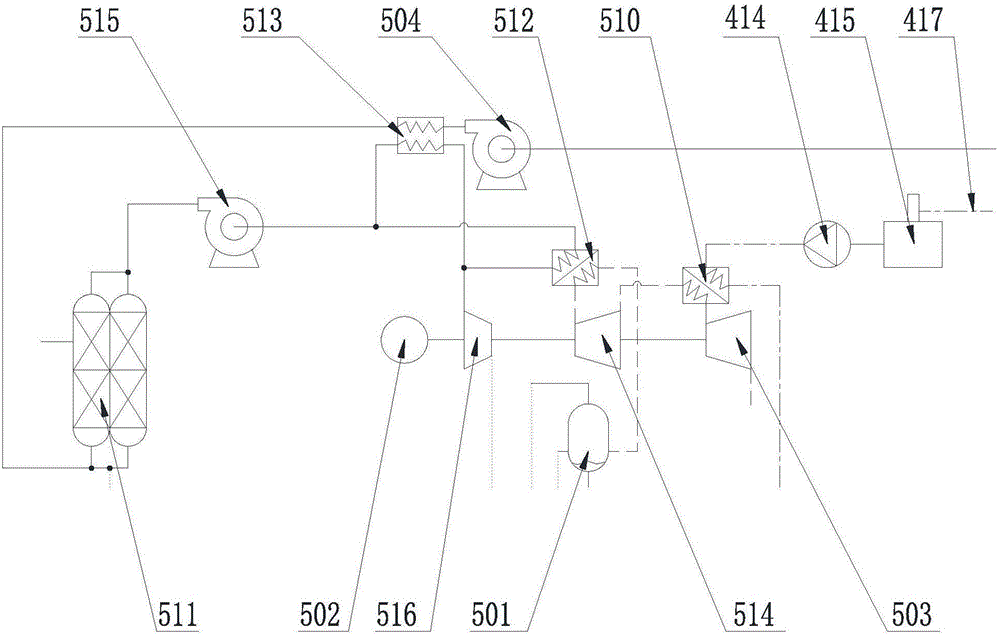

Wet air turbine power generation system based on recycling of garbage gasifying synthesis gas

ActiveCN106224035AImprove recycling efficiencyPyrolysis is beneficialChemical industrySteam useProcess engineeringAir compressor

The invention discloses a wet air turbine power generation system based on recycling of garbage gasifying synthesis gas. The wet air turbine power generation system based on recycling of the garbage gasifying synthesis gas comprises a garbage gasifying system, a boiler system and a power generation system, wherein the power generation system comprises a mixer, a low-pressure air compressor, a high-pressure air compressor, a turbine, a generator, an air steam-gas heat exchanger, a CO2 steam-gas heat exchanger, a CO2 fan, a recycling fan, a mixing separator, a CO2 separator and a water supply feeding system of the boiler system; the CO2 separator is connected to space between a waste gas discharge opening of the boiler system and a gas inlet of the CO2 fan; and a gas outlet of the turbine is in parallel connection with heating channels of the CO2 steam-gas heat exchanger and the air steam-gas heat exchanger, and is then connected with the recycling fan and the mixing separator. By the wet air turbine power generation system based on recycling of garbage gasifying synthesis gas, a large amount of garbage is continuously gasified and incinerated, the treatment amount of the garbage is high, recycling efficiency of heat is high, regenerated chemical raw materials and synthesized natural gas can be extracted, and near zero emission of pollutants and CO2 can be realized effectively.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

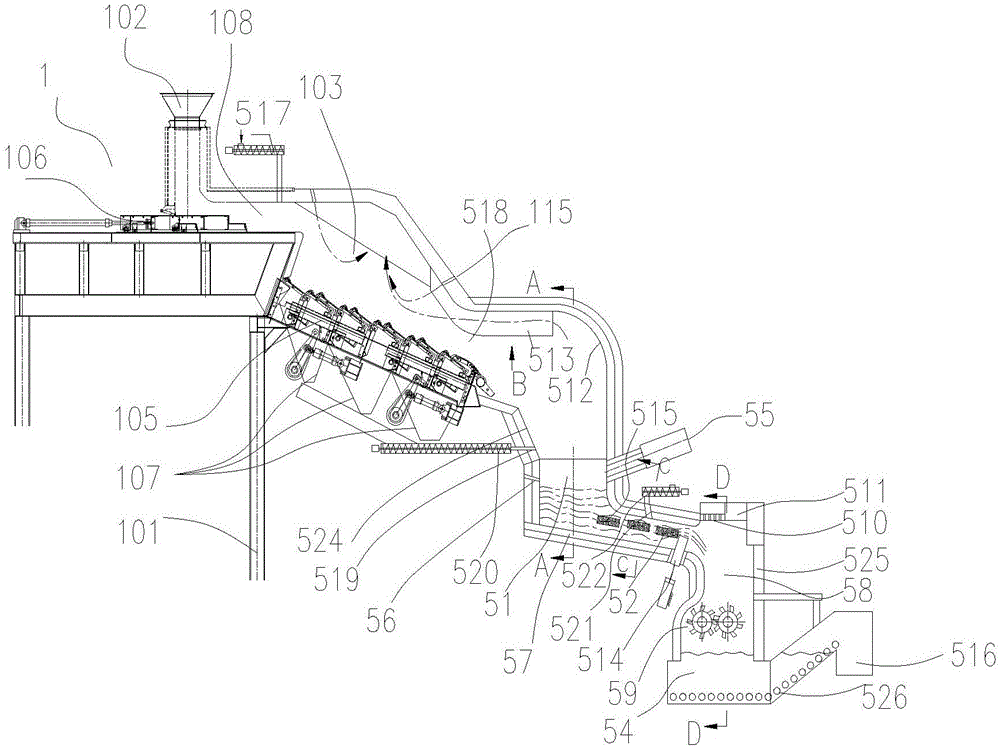

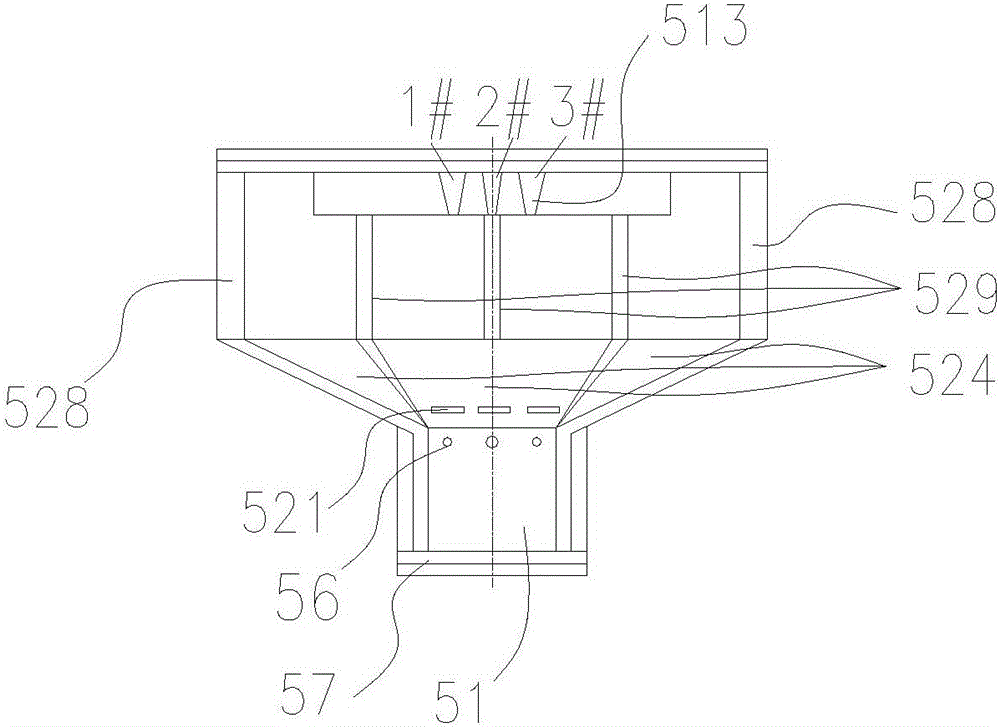

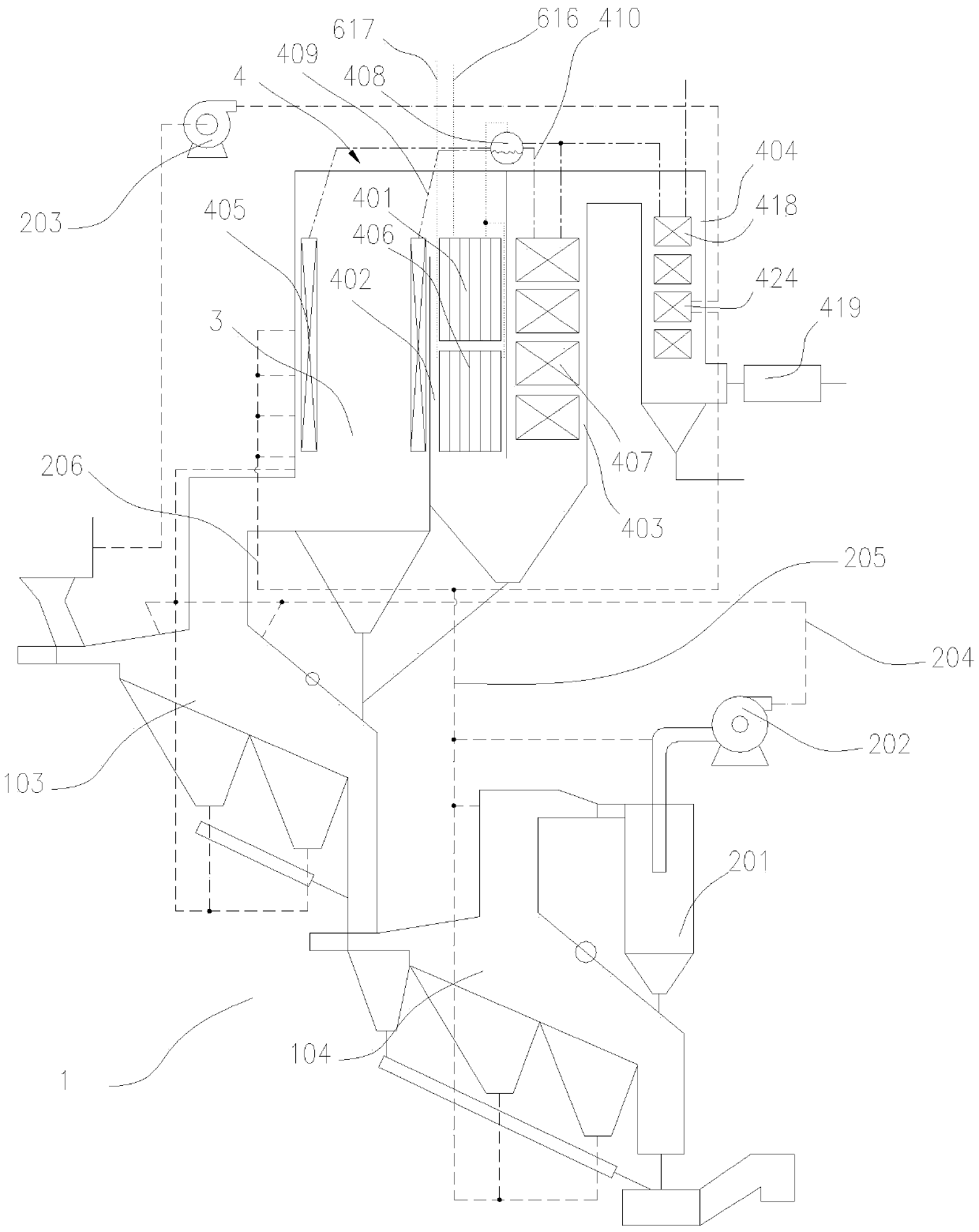

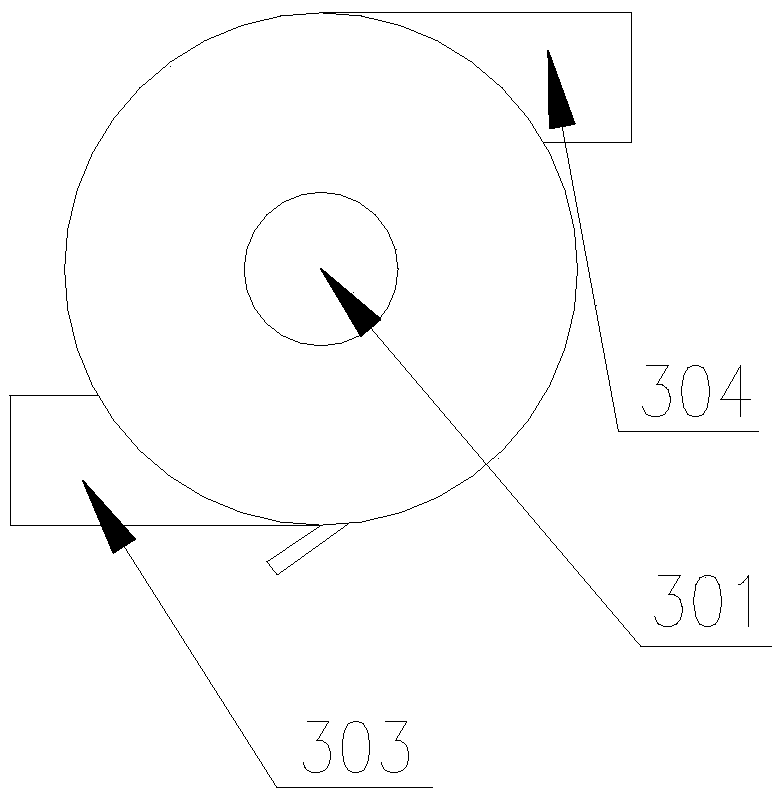

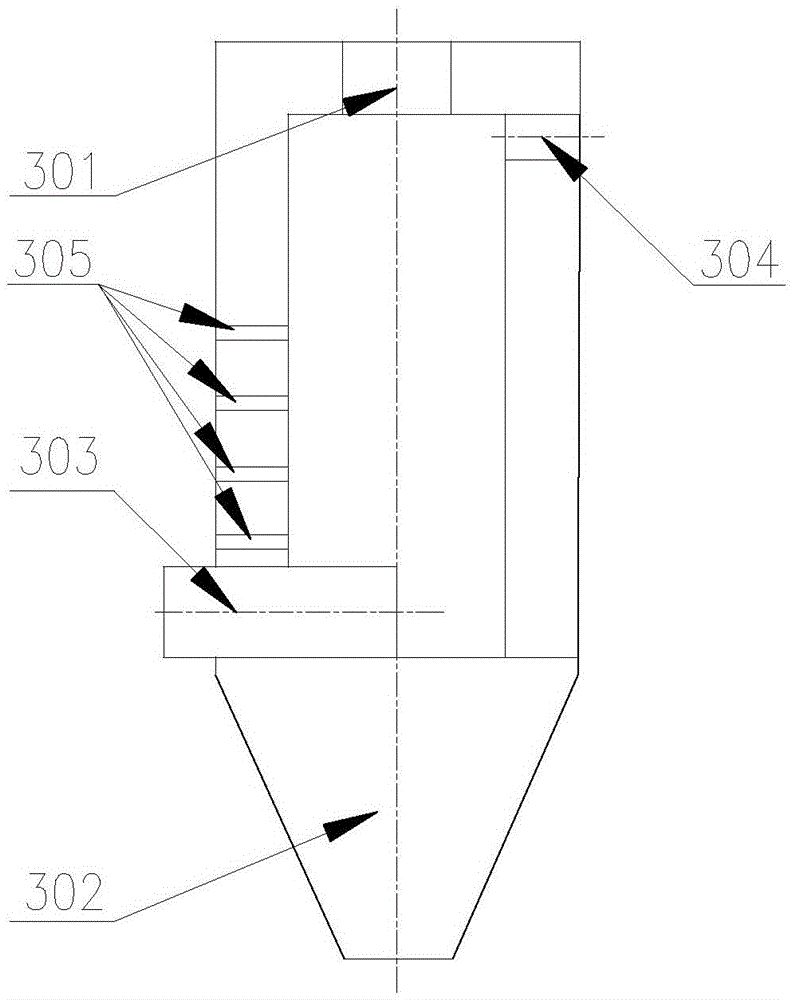

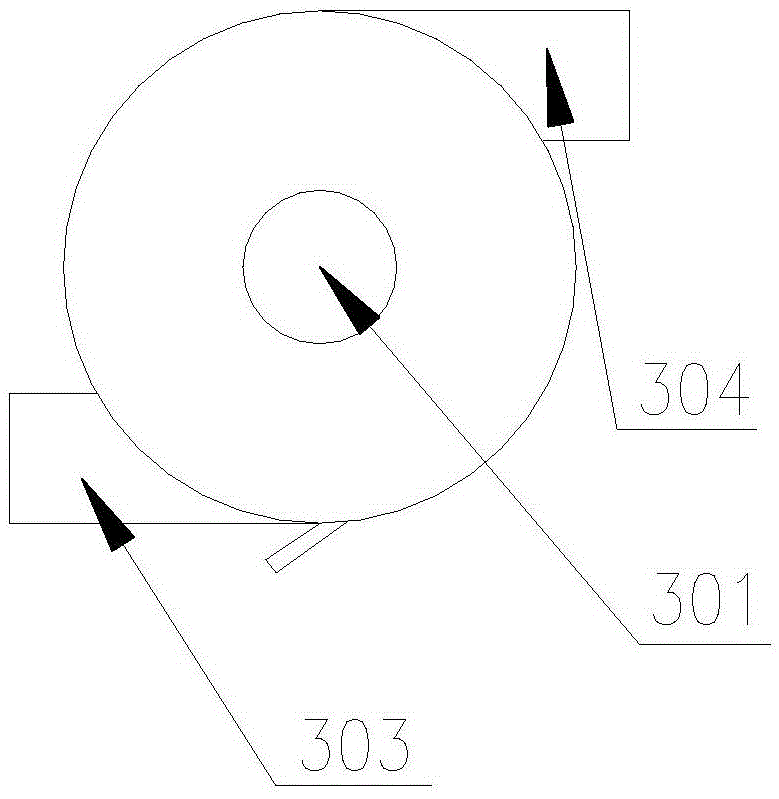

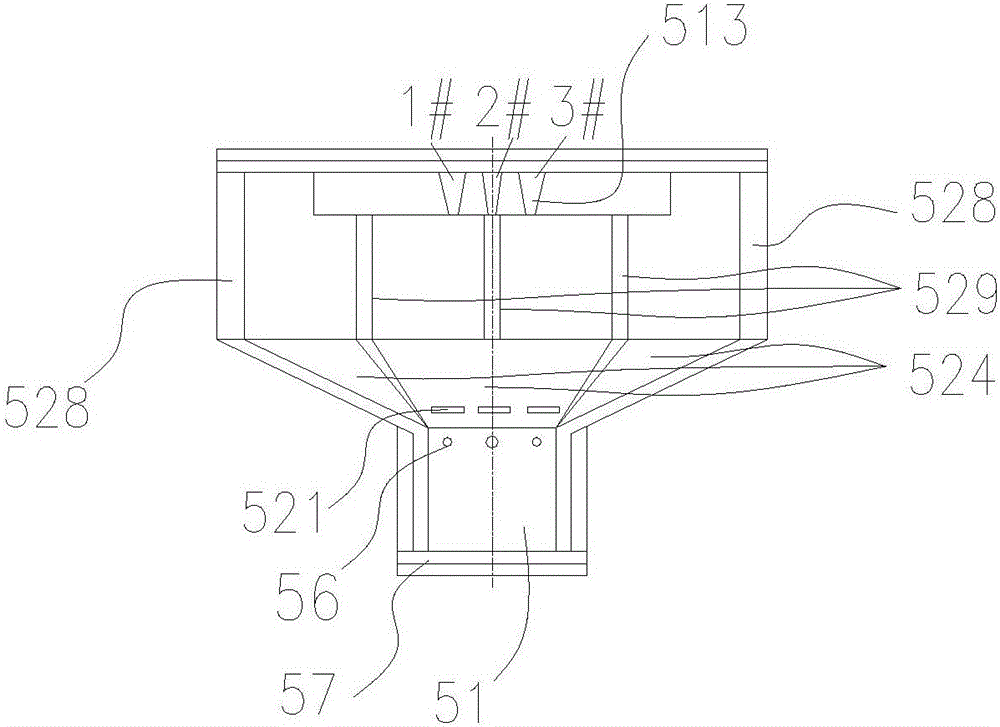

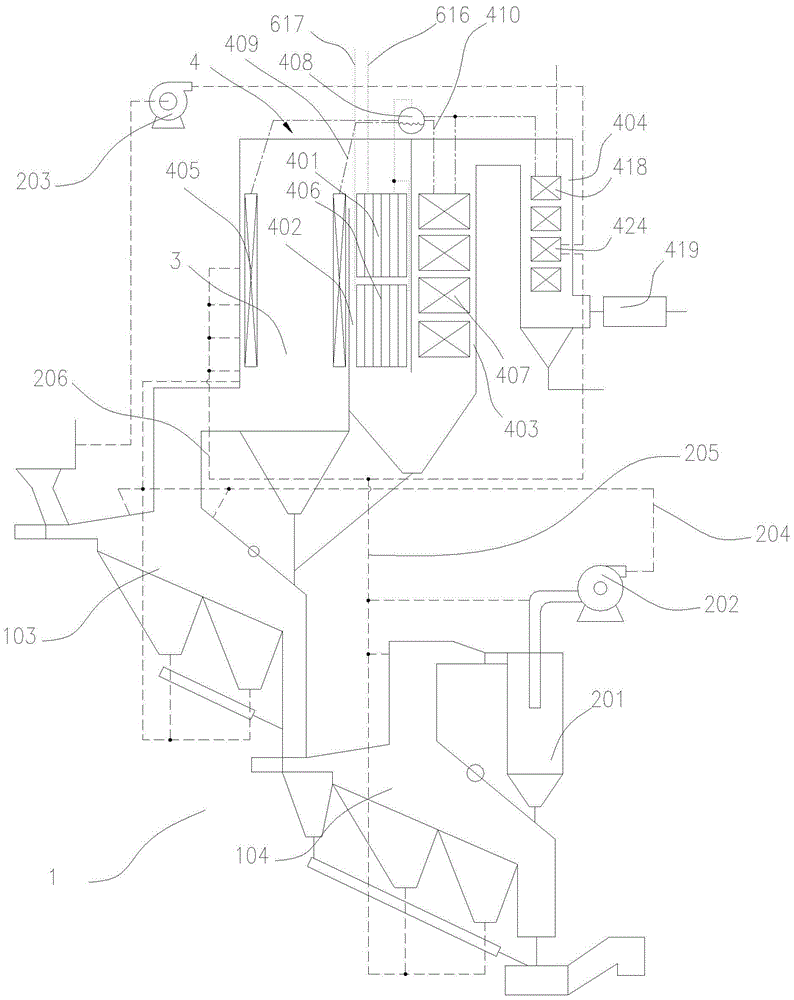

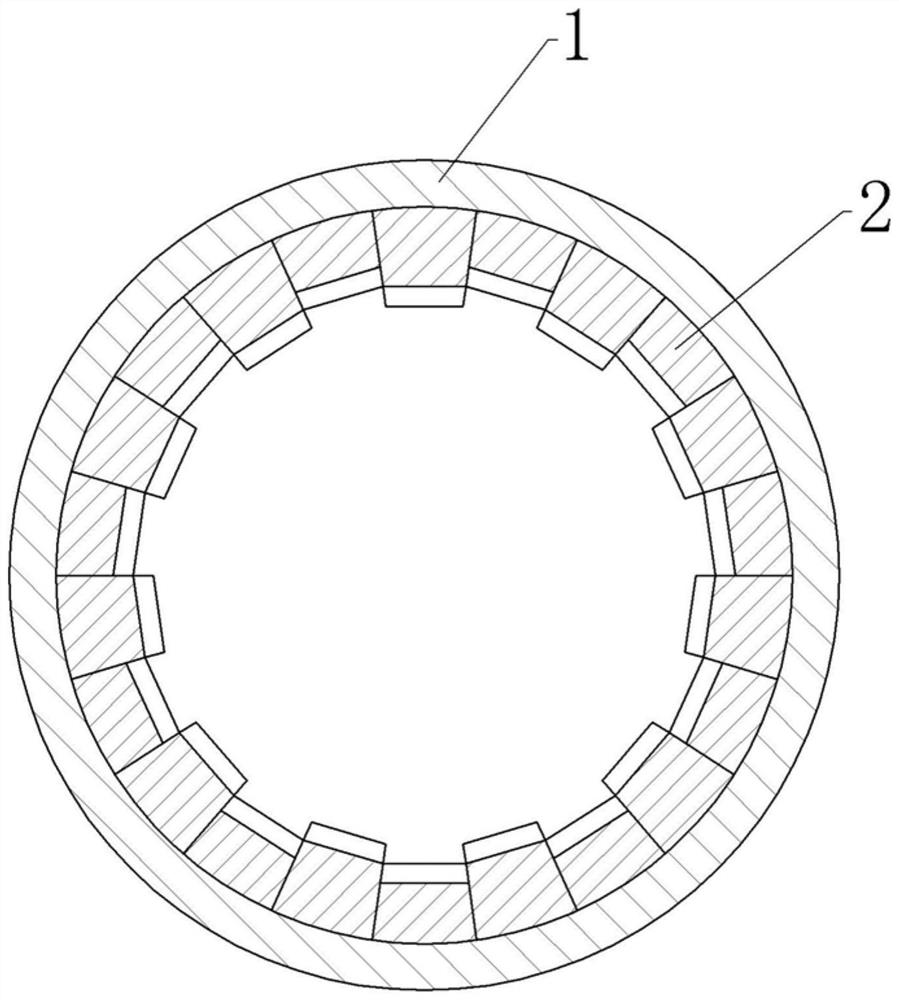

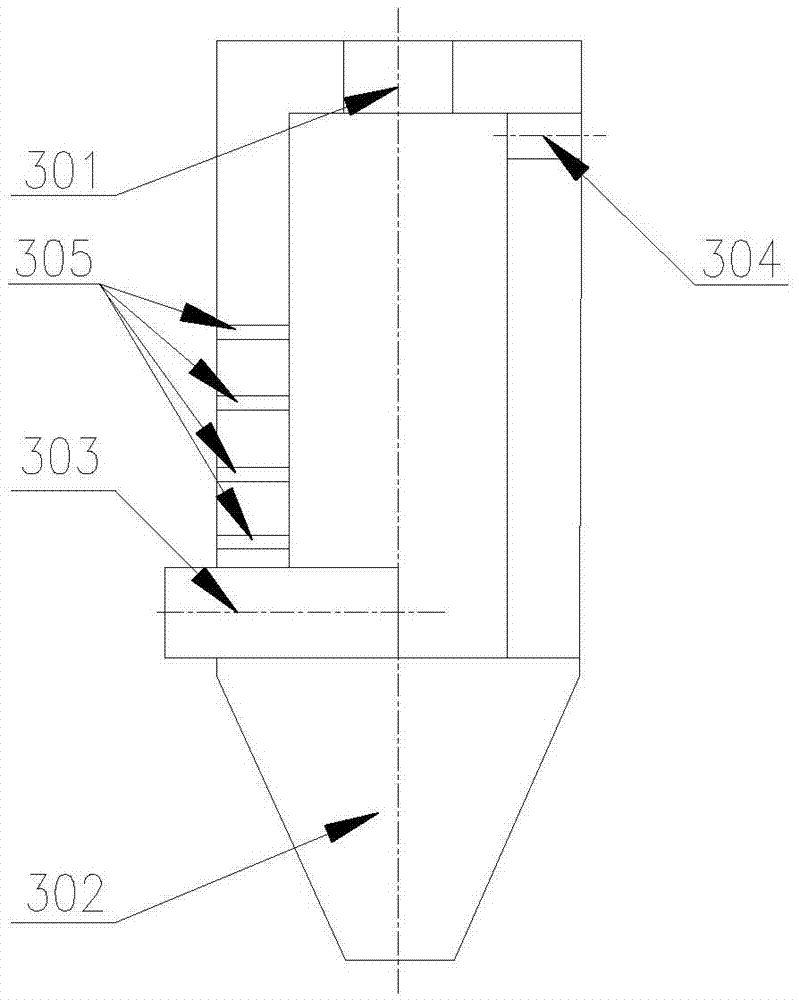

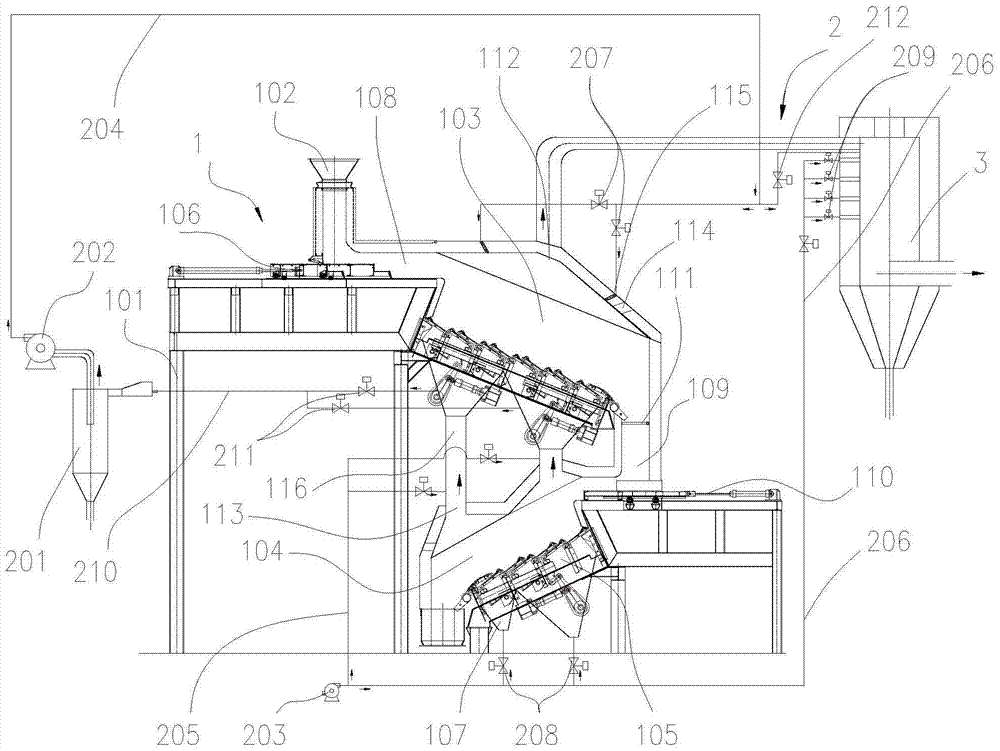

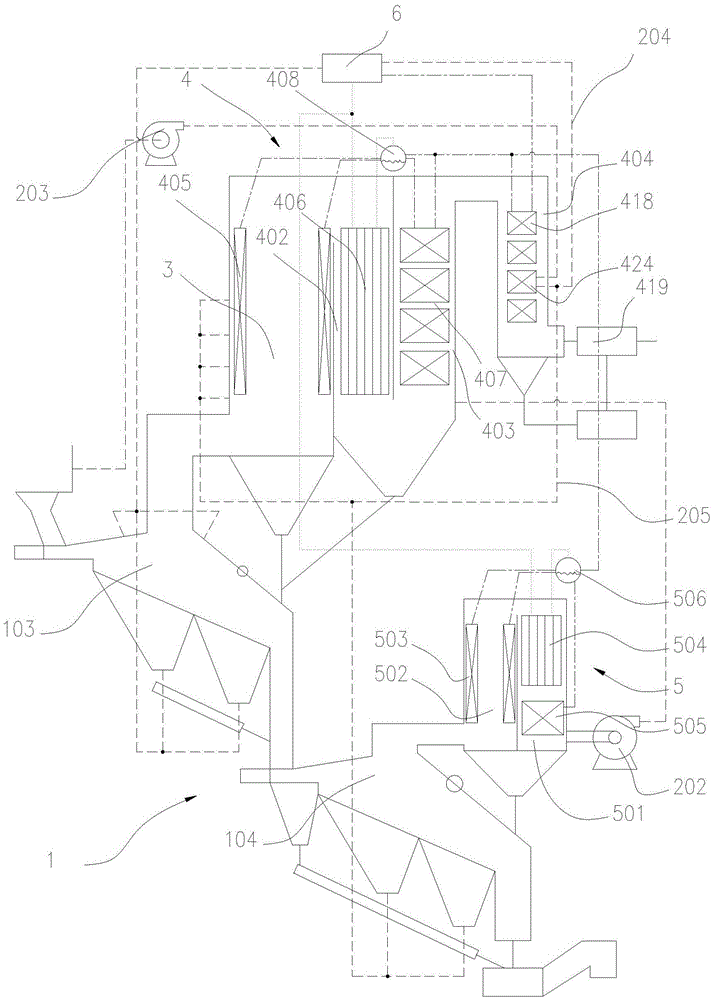

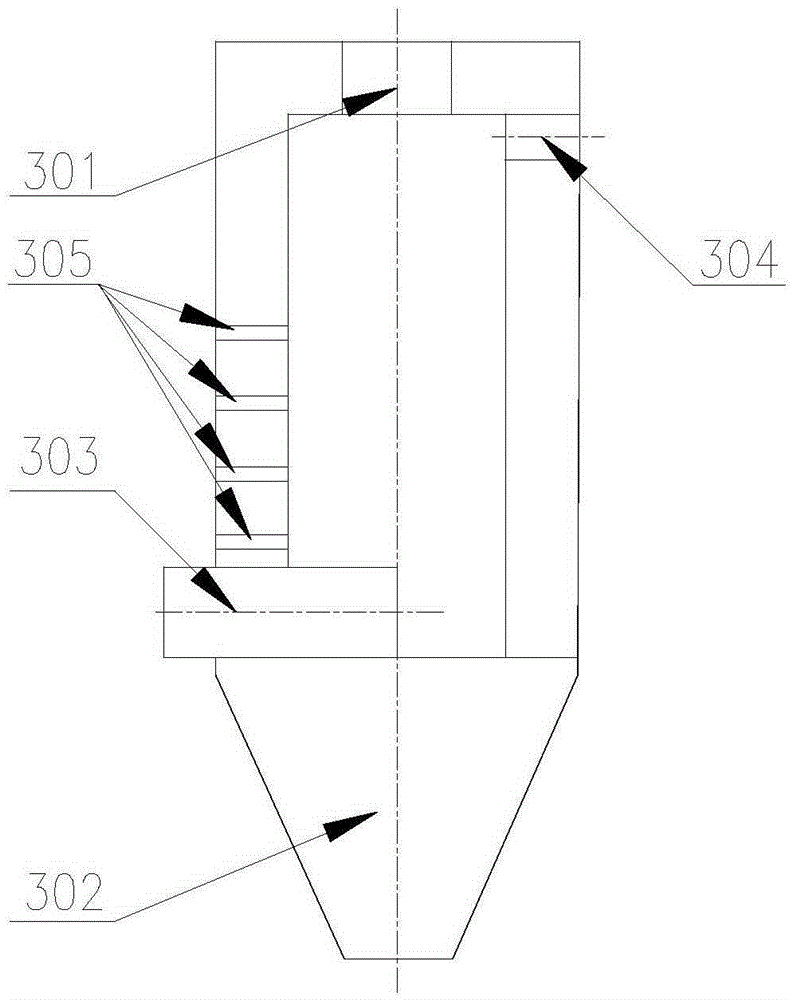

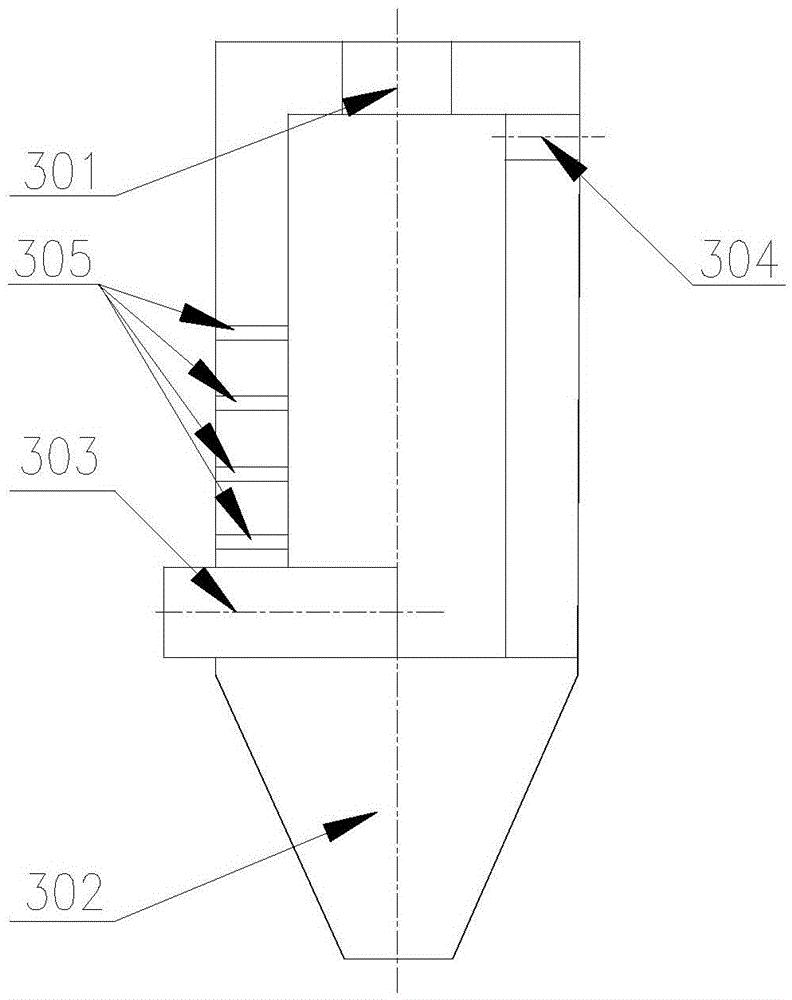

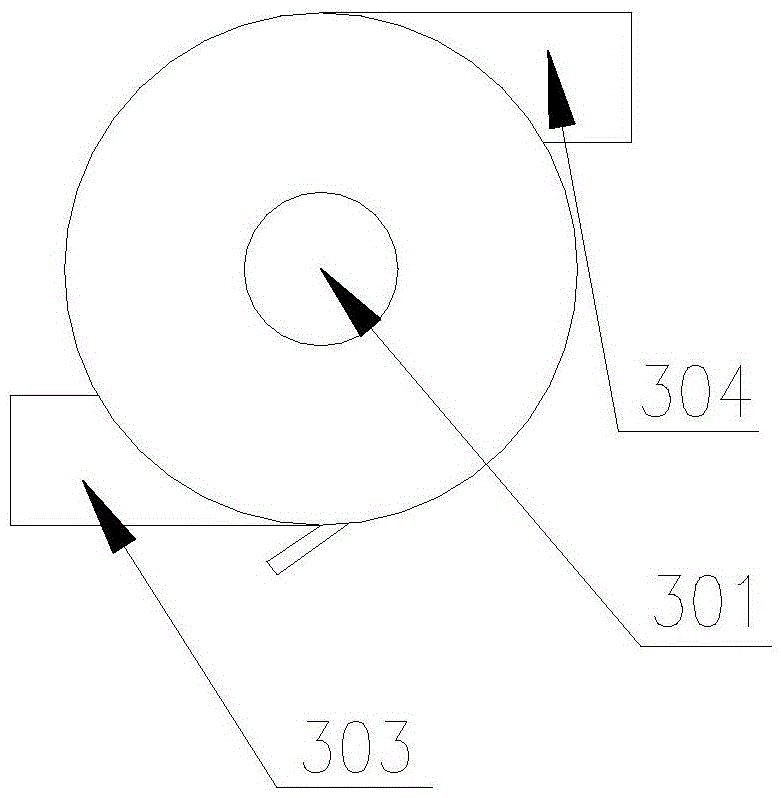

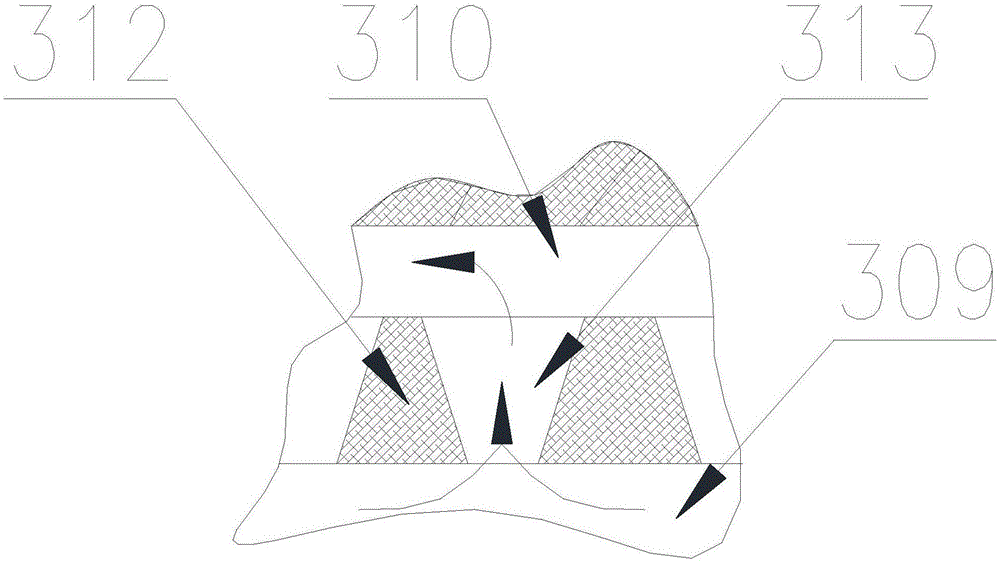

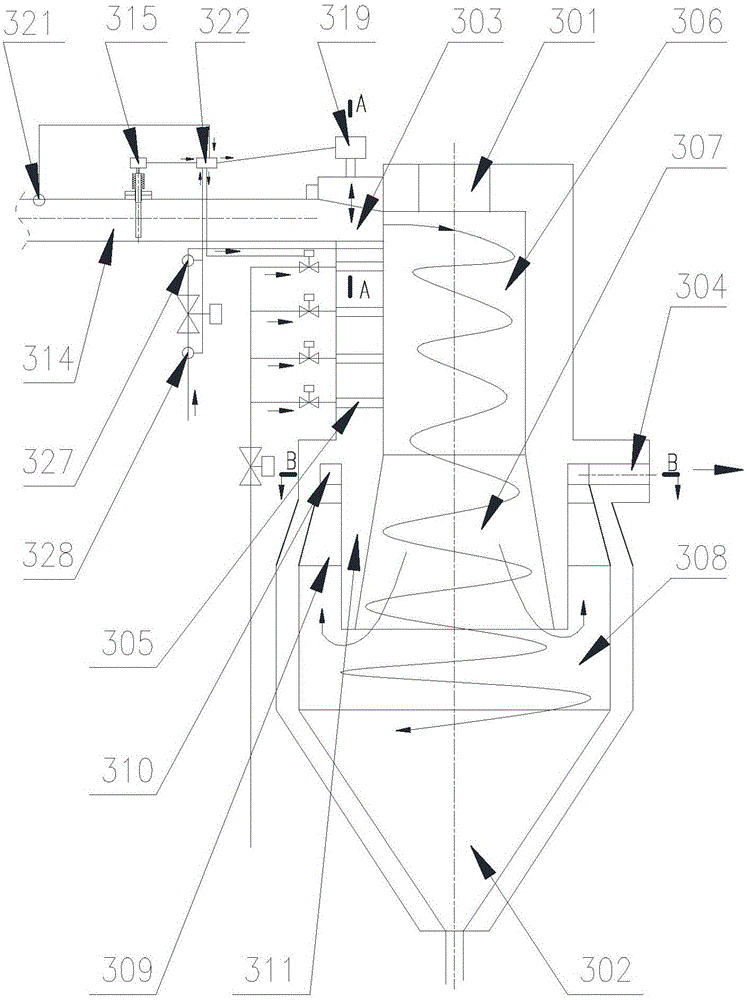

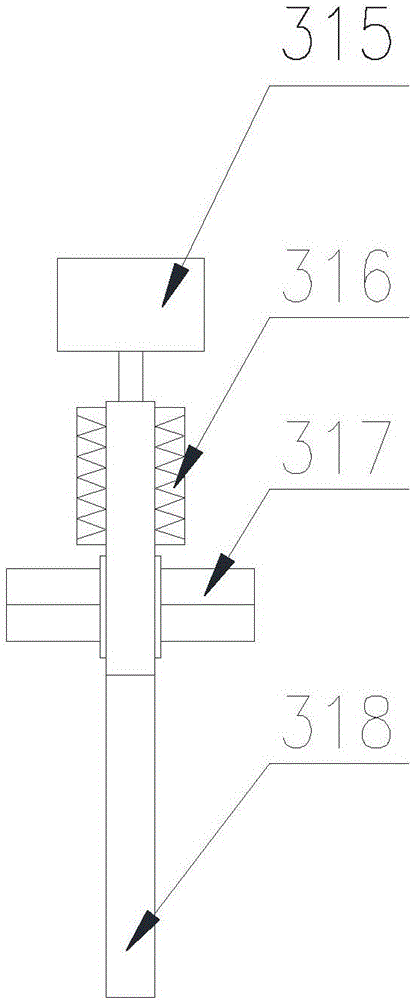

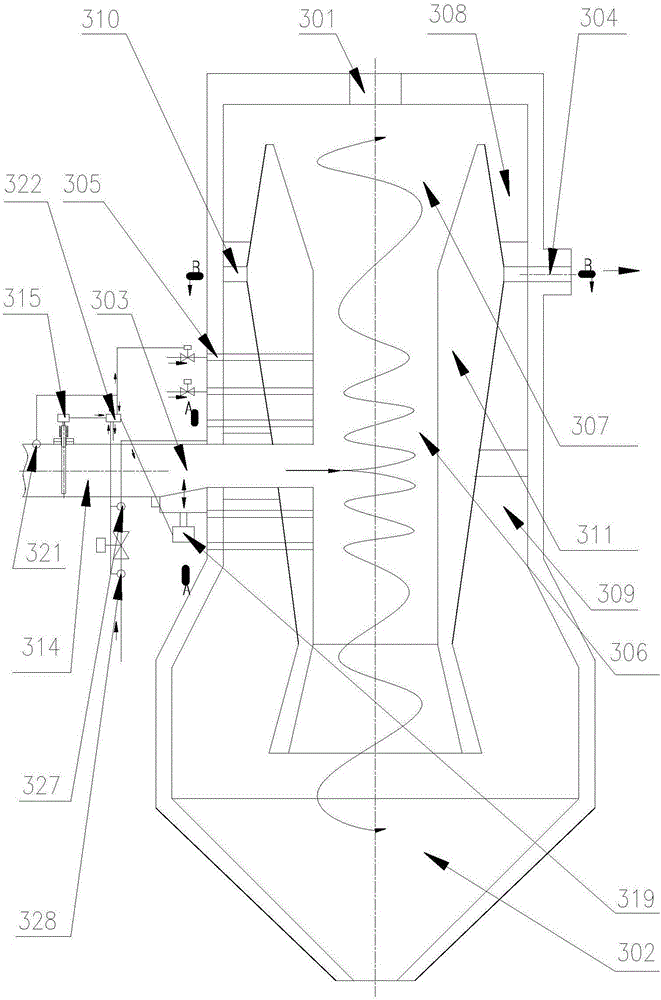

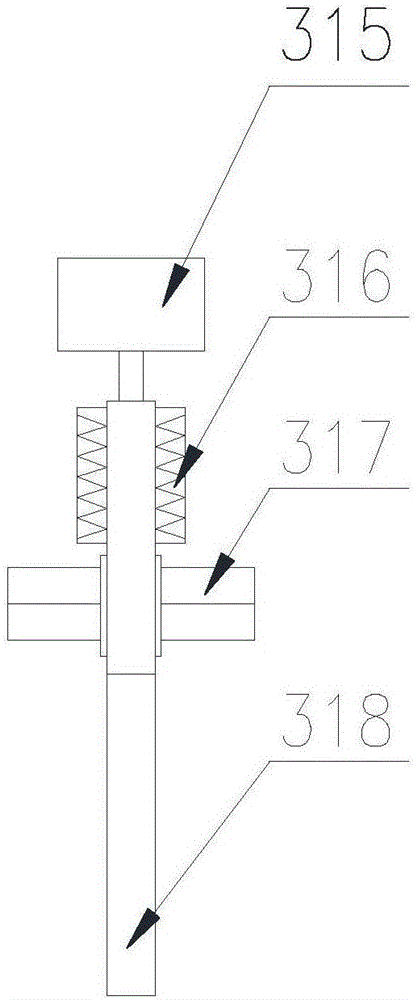

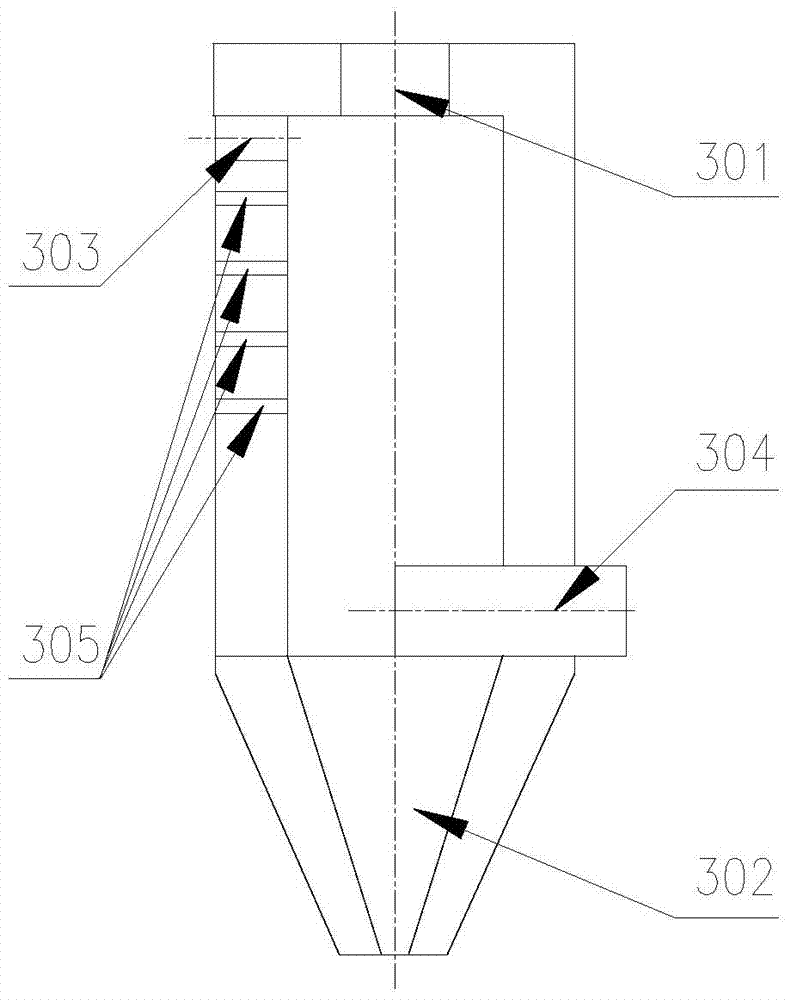

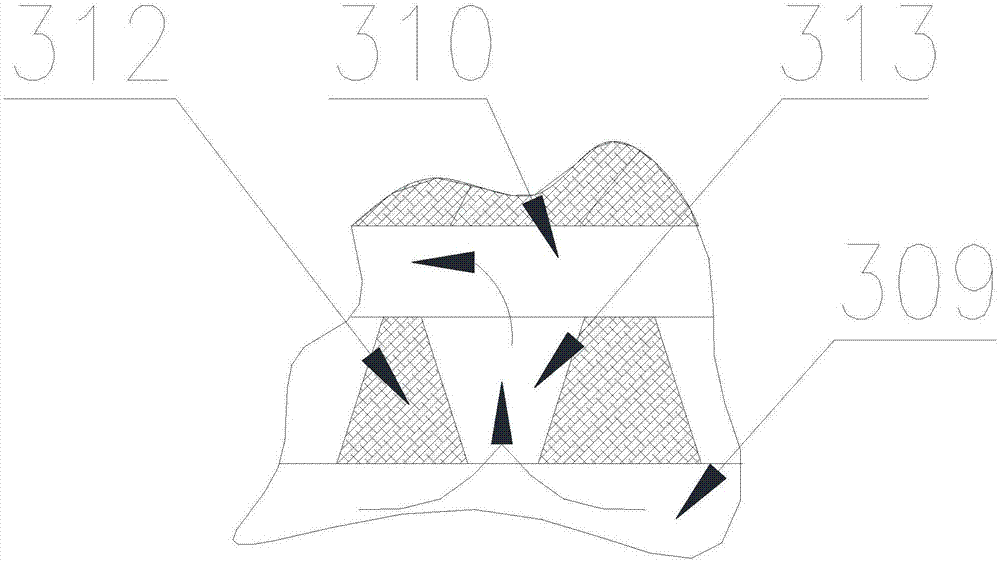

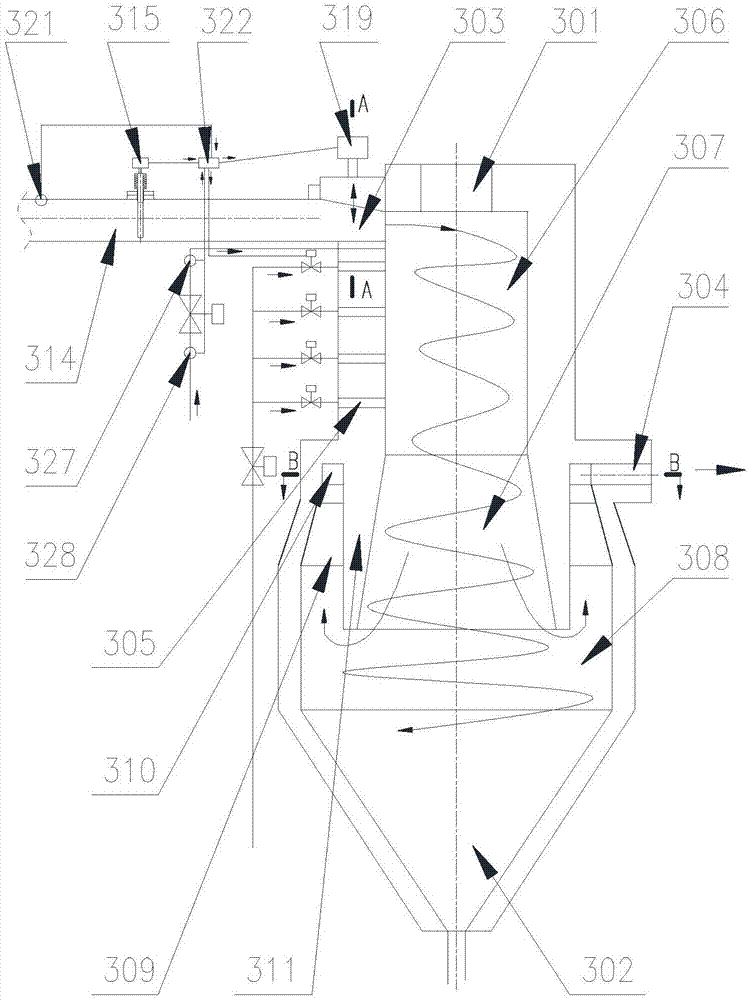

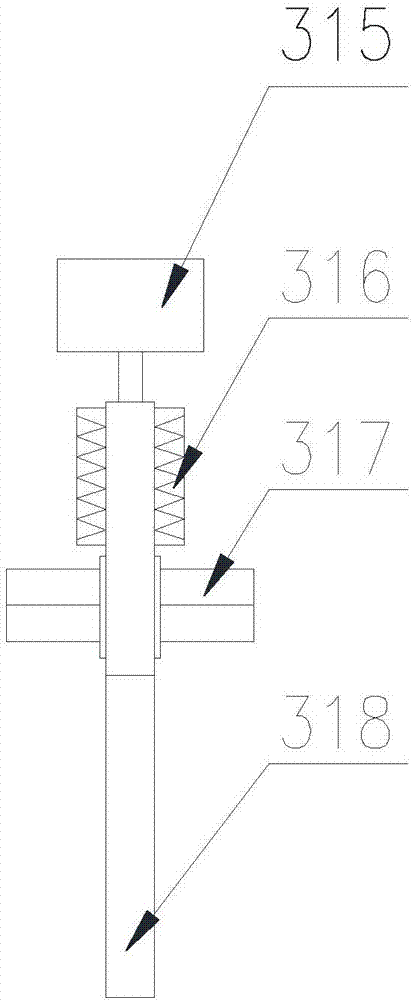

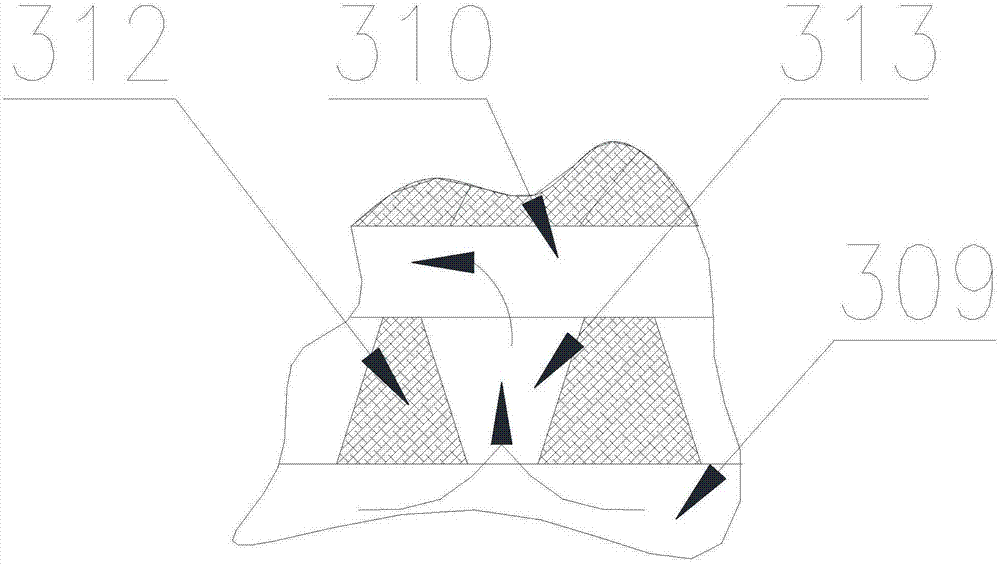

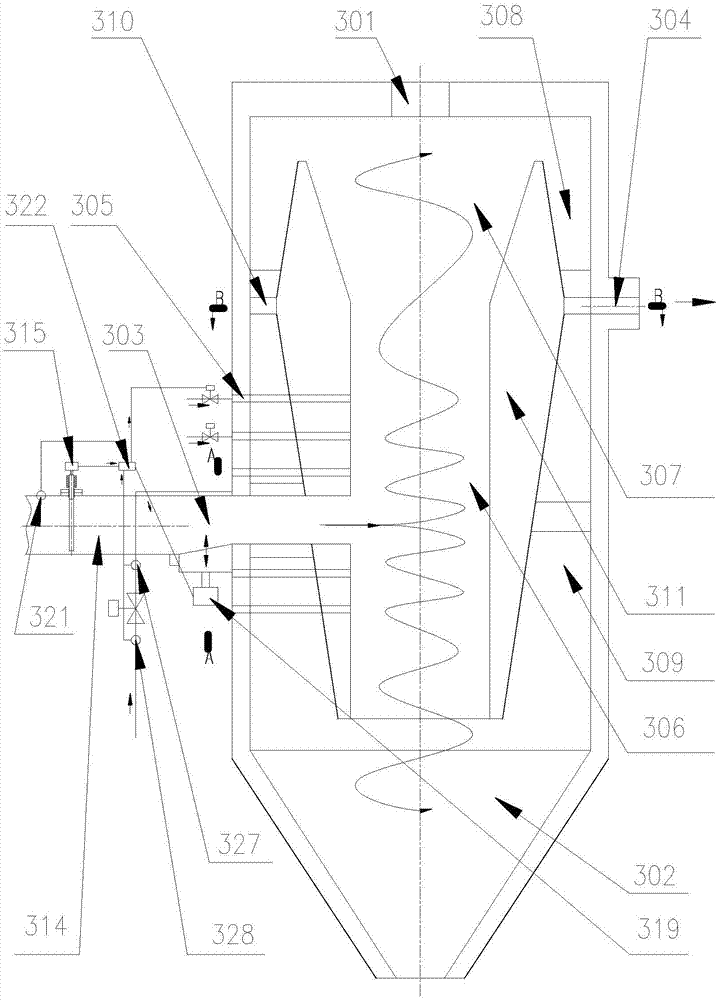

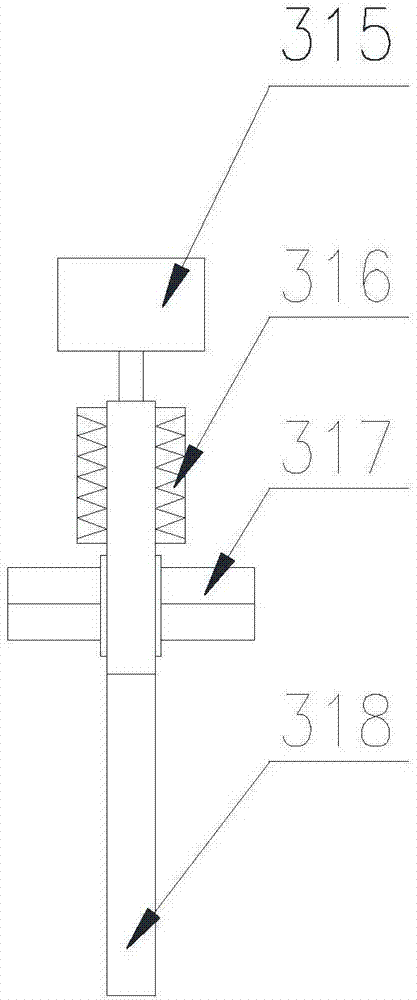

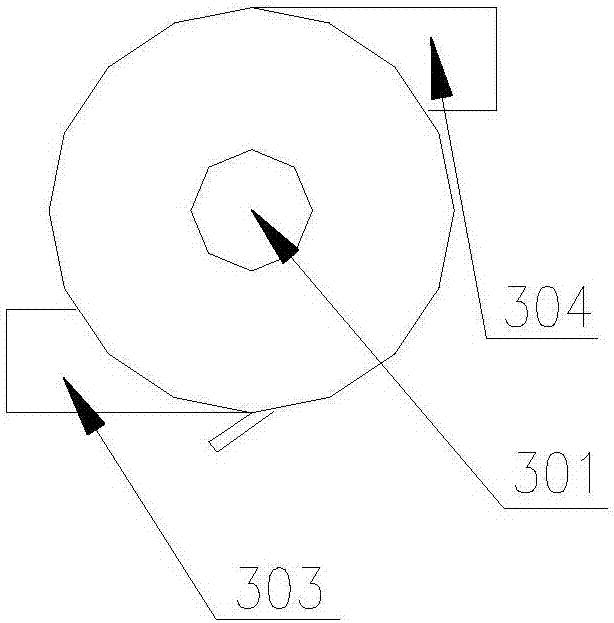

Circulating air supply system of mechanical grate type garbage gasification incinerator

ActiveCN105465792BLarge amount of processingImprove energy conversion efficiencyIncinerator apparatusCombustionHeat losses

The invention discloses a circulating air supply system of a mechanical fire gate type waste gasification incinerator. The circulating air supply system comprises a gasifier and a combustion furnace. A primary air chamber is arranged below the gasifier and a furnace hearth of the combustion furnace. The gasifier is provided with a secondary air supply port and a first smoke outlet. The combustion furnace is provided with a second smoke outlet. The circulating air supply system further comprises a dust removal device, a first draught fan and a second draught fan. The air inlet end of the dust removal device is connected with the second smoke outlet. The air outlet end of the dust removal device is connected with the air inlet end of the first draught fan. The air outlet end of the first draught fan is connected with a first manifold. A branch pipe of the first manifold is communicated with the primary air chamber of the combustion furnace and the secondary air supply port. The air outlet of the second draught fan is connected with a second manifold. A branch pipe of the second manifold is communicated with the primary air chamber of the combustion furnace and the two ends of the dust removal device. After the circulating air supply system is used, continuous gasifying incineration disposal of a large scale of waste can be achieved, heat losses can be reduced, heat exchange efficiency can be improved, the heat recovery efficiency is high, and the discharge quantity of pollutants can be effectively reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Double-layered mechanical grate type garbage gasifying incinerator and boiler system

ActiveCN105444182AImprove insulation effectPrevent leakageIncinerator apparatusCombined combustion mitigationCombustion chamberFlue gas

The invention discloses a double-layered mechanical grate type garbage gasifying incinerator and boiler system which comprises a double-layered garbage gasifying incinerator, a boiler system and a circulating air supply system, wherein the double-layered garbage gasifying incinerator comprises a feed hopper, a gasifier and a burn-out furnace; the burn-out furnace is located under the gasifier; the feeding direction of the burn-out furnace is opposite to that of the gasifier; flue gas outlets are formed in the upper end of the gasifier and the upper end of the burn-out furnace; the boiler system comprises a boiler body; the boiler body is provided with a cyclone combustion chamber, a furnace chamber a and a furnace chamber b, which communicate with one another; a water wall is arranged in the cyclone combustion chamber; a superheater is arranged in the furnace chamber a; an evaporator is arranged is the furnace chamber b; a steam drum is arranged at the top end of the boiler body; a steam-water inlet is formed in the steam drum; the steam drum is connected with a water inlet of the water wall and a water inlet of the evaporator to output water; a steam outlet of the water wall and a steam outlet of the evaporator are connected with a steam inlet of the steam drum to reflux steam; and a saturated steam outlet of the steam drum outputs superheated steam through the superheater.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Mechanical grate type garbage gasification incinerator and its treatment method

The invention discloses a mechanical grate type waste gasifying incinerator and a processing method thereof. The gasifying incinerator comprises a feed bin, a gasifying furnace and a burning furnace, wherein the burning furnace is positioned on the front lower part of a slag dropping opening of the gasifying furnace, a stockpile sealing section is formed between the feed bin and the gasifying furnace, a residue stoker is arranged between the gasifying furnace and the burning furnace, the upper ends of the gasifying furnace and the burning furnace are respectively arched, and smoke outlets are respectively formed in the upper ends of the gasifying furnace and the burning furnace. The waste processing method comprises the steps of A. igniting and drying; B. burning waste in a hearth of the gasifying furnace; C. performing continuous gasification and incineration on the waste; D. shutting off the mechanical grate type waste gasifying incinerator after the waste and waste residues are burnt out. When the mechanical grate type waste gasifying incinerator is used for processing the waste, the waste conveying capability is strong, the waste processing capacity is large, the heat recovering efficiency is high, and the pollutant discharge can be effectively reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Double-layer mechanical grate type garbage gasification incinerator and its treatment method

ActiveCN105423306BImprove insulation effectPrevent leakageIncinerator apparatusWaste processingIncineration

The invention discloses a double-layer mechanical grate type waste gasifying incinerator and a processing method thereof. The gasifying incinerator comprises a feeding bin, a gasifying furnace and an ember furnace. The ember furnace is located under the gasifying furnace. The feeding direction of the ember furnace is opposite to that of the gasifying furnace. A piled material sealing section is arranged between the feeding bin and the gasifying furnace. A residue pusher is arranged between the gasifying furnace and the ember furnace. The upper end of the gasifying furnace and the upper end of the ember furnace protrude upwards and are each provided with a smoke outlet. The waste processing method comprises the steps that A, the incinerator is started and heated; B, waste is burned in a hearth of the gasifying furnace; C, continuous waste gasifying and incineration processing is achieved; and D, after the waste and waste residues are burned out, the double-layer mechanical grate type waste gasifying incinerator is turned off. By using the double-layer mechanical grate type waste gasifying incinerator for waste processing, the waste processing capacity is larger, the heat recycling efficiency is high, and the pollutant discharge amount can be effectively reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Mechanical grate type garbage gasification and incineration furnace and double-boiler power generation system

ActiveCN105627320AImprove qualityEasy to remove dustSteam engine plantsIncinerator apparatusCycloneCombustion chamber

The invention discloses a mechanical grate type garbage gasification and incineration furnace and double-boiler power generation system with relatively small heat conversion efficiency loss and higher heat recovery efficiency. The system comprises a gasification and incineration furnace, a boiler system, a circulating air supply system and a power generation system, wherein the gasification and incineration furnace comprises a gasifier and an incinerator, which can be sealed or communicated; the boiler system comprises boiler bodies a and b; the boiler body a comprises a cyclone combustion chamber and furnace chambers a and b; the boiler body b comprises a furnace chamber d and a cyclone dust chamber; water cooling walls are arranged in the cyclone combustion chamber and the cyclone dust chamber; a superheater is arranged in the furnace chamber a; an evaporator is arranged in the furnace chamber b; a superheater and an evaporator are arranged in the furnace chamber d; steam pockets are arranged at the top ends of the two boiler bodies; a smoke inlet of the cyclone combustion chamber is connected with a smoke outlet of the gasifier; a smoke inlet of the cyclone dust chamber is connected with a smoke outlet of the incinerator; the power generation system comprises a steam inlet pipe, a steam turbine and a power generator; and the steam inlet pipe is connected with the superheaters a and b and the steam turbine.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Mechanical grate type waste gasification incinerator and boiler system thereof

ActiveCN105423307AImprove qualityEasy to remove dustSteam superheatersIncinerator apparatusCombustion chamberSlag

The invention discloses a mechanical grate type waste gasification incinerator with less conversion thermal efficiency loss and higher thermal recovery efficiency and a boiler system of the waste gasification incinerator. The mechanical grate type waste gasification incinerator comprises a gasification incinerator, the boiler system and a circulating air supply system, wherein the gasification incinerator comprises a feeding bin, a gasifier and a burnout furnace, a stockpiling sealing section is arranged between the feeding bin and the gasifier, a transition slag blanking section is arranged between the gasifier and the burnout furnace, and flue gas outlets are formed in the upper ends of the gasifier and the burnout furnace respectively. The boiler system comprises a boiler body, the boiler body is provided with a cyclone combustion chamber, a furnace chamber a and a furnace chamber b which are mutually communicated, a water cooling wall is arranged in the cyclone combustion chamber, a superheater is arranged in the furnace chamber a, an evaporator is arranged in the furnace chamber b, a steam drum is arranged at the top end of the boiler body, a steam-water inlet is formed in the steam drum, the steam drum is connected with water inlets of the water cooling wall and the evaporator and used for outputting water, steam outlets of the water cooling wall and the evaporator are connected with a steam inlet of the steam drum for backflow of steam, and a saturated steam outlet of the steam drum outputs superheated steam through the superheater.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Double-boiler power generating system capable of incinerating syngas through garbage gasification

ActiveCN105627324AGuaranteed qualityReduce lossSteam generation plantsIndirect carbon-dioxide mitigationSyngasDeaerator

The invention discloses a double-boiler power generating system capable of incinerating syngas through garbage gasification, and the double-boiler power generating system is small in heat conversion efficiency loss and higher in heat recovery efficiency. The double-boiler power generating system comprises a steam input pipe, a steam turbine and a power generator. The steam input pipe is connected with the steam input end of the steam turbine. The steam output end of the steam turbine is sequentially connected with a condenser, a water pump, a low-pressure steam water heater, a deaerator, a booster water pump and a high-pressure steam water heater. The heated input end of the low-pressure steam water heater is connected with the water pump, and the heated output end of the low-pressure steam water heater is connected with the deaerator. The heated input end of the high-pressure steam water heater is connected with the booster water pump, and the heated output end of the high-pressure steam water heater is used for outputting water which is used for boilers. The steam turbine is provided with a first steam fetching pipe and a second steam fetching pipe which are used for fetching steam from the steam output end of the steam turbine. The output end of the first steam fetching pipe is connected with the heating input end of the high-pressure steam water heater. The output end of the second steam fetching pipe is connected with the heating input end of the low-pressure steam water heater.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

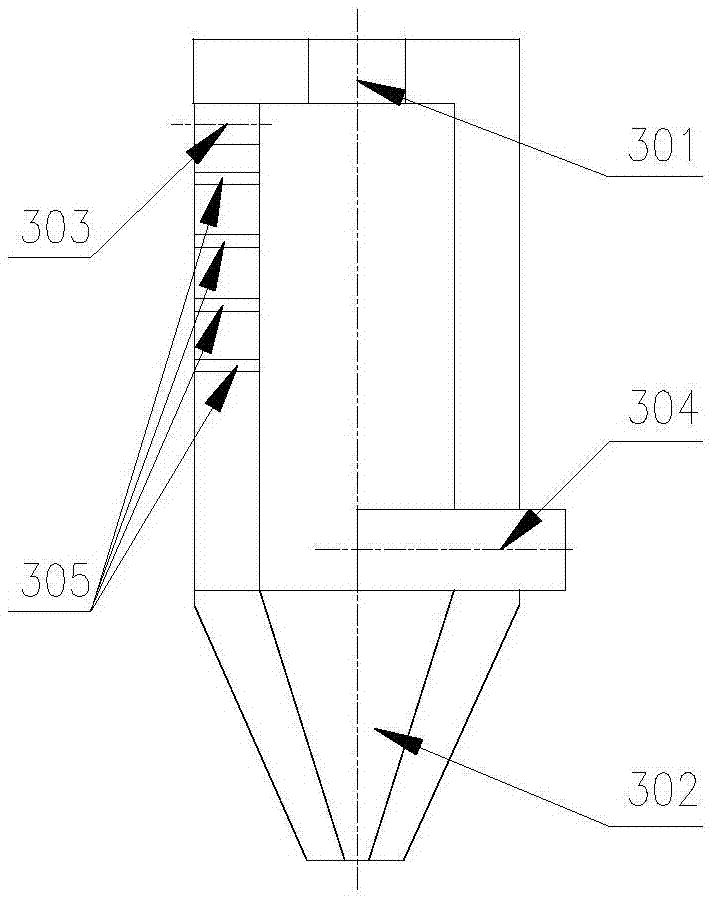

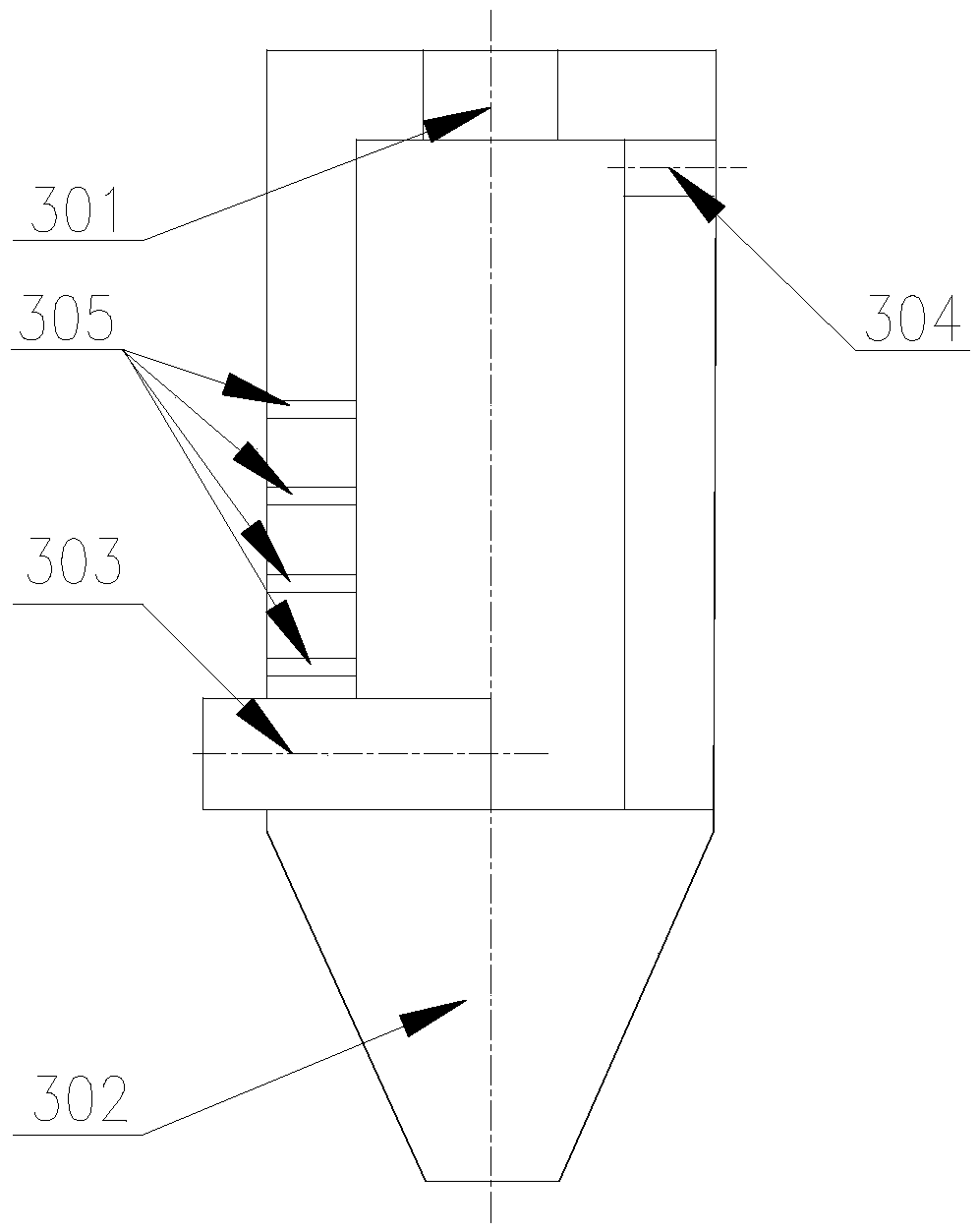

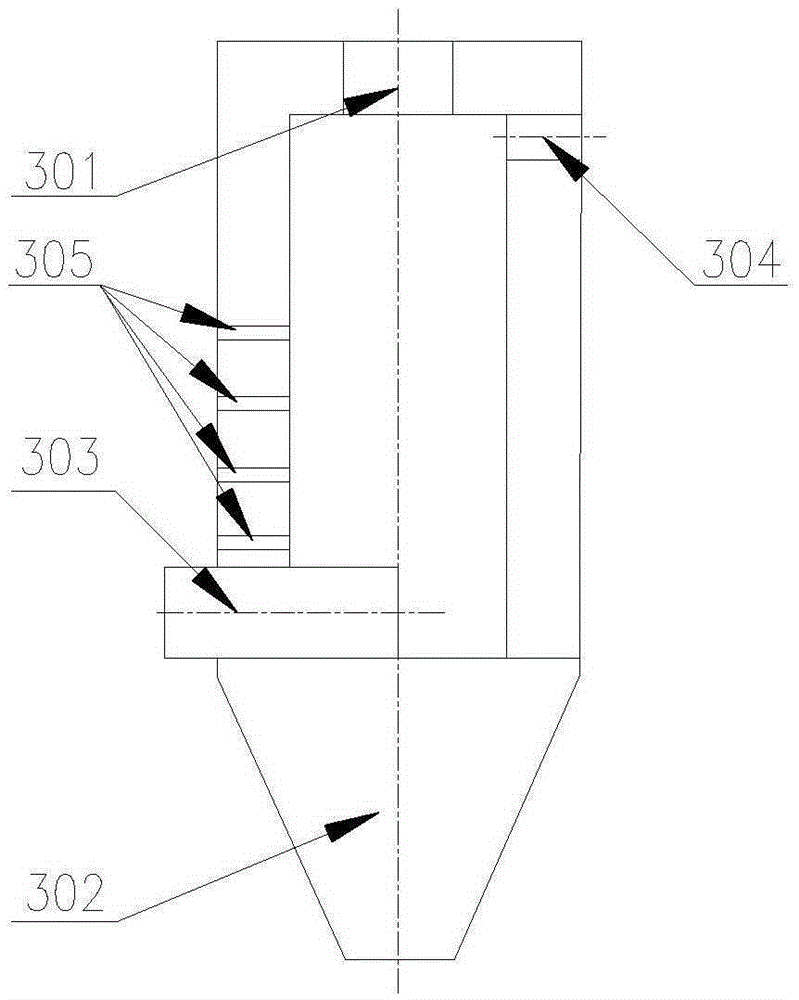

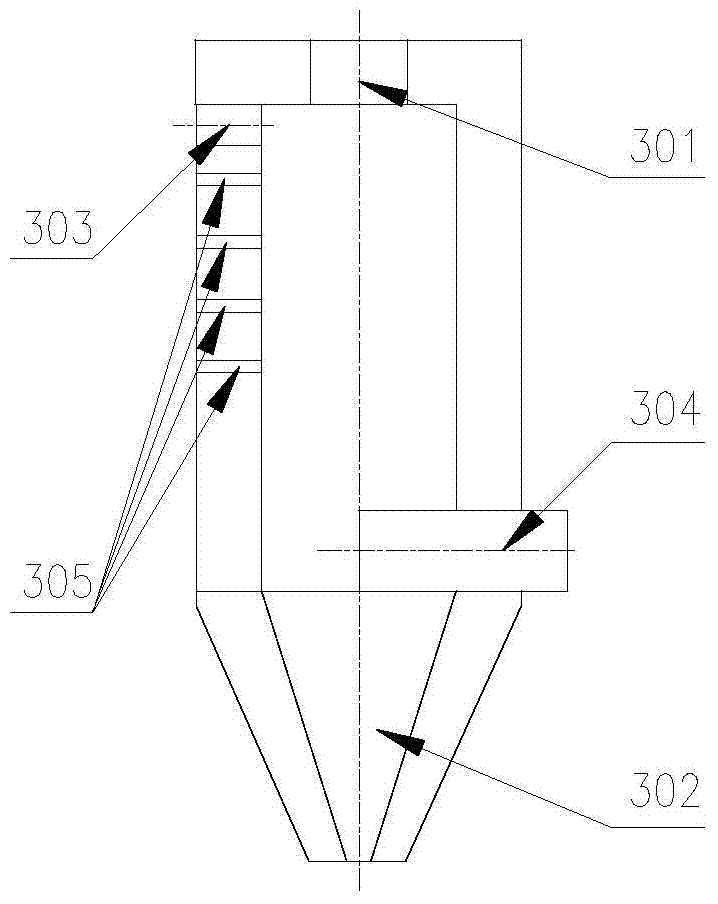

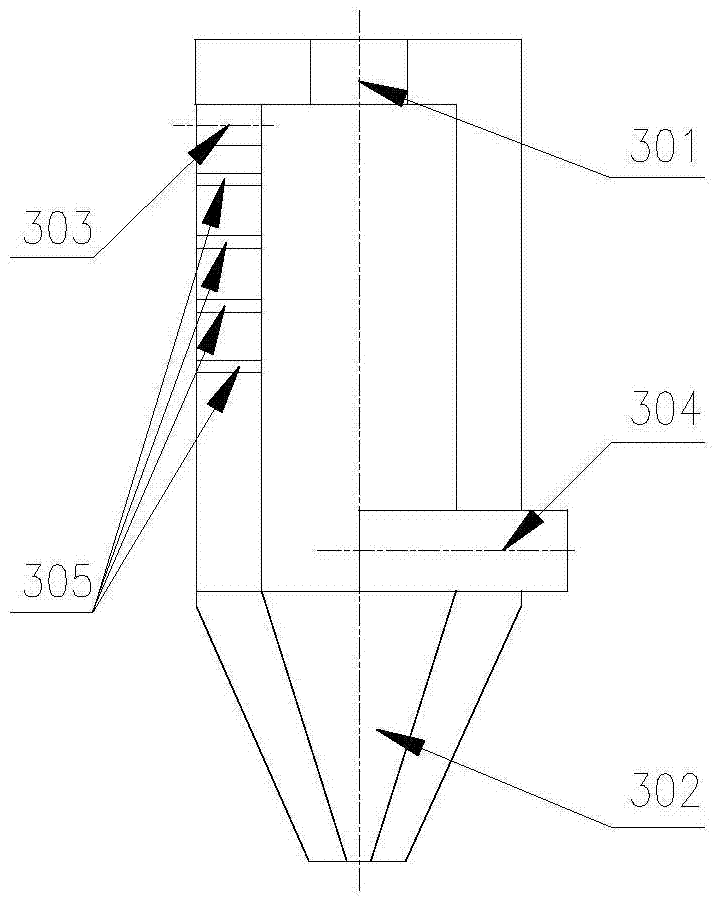

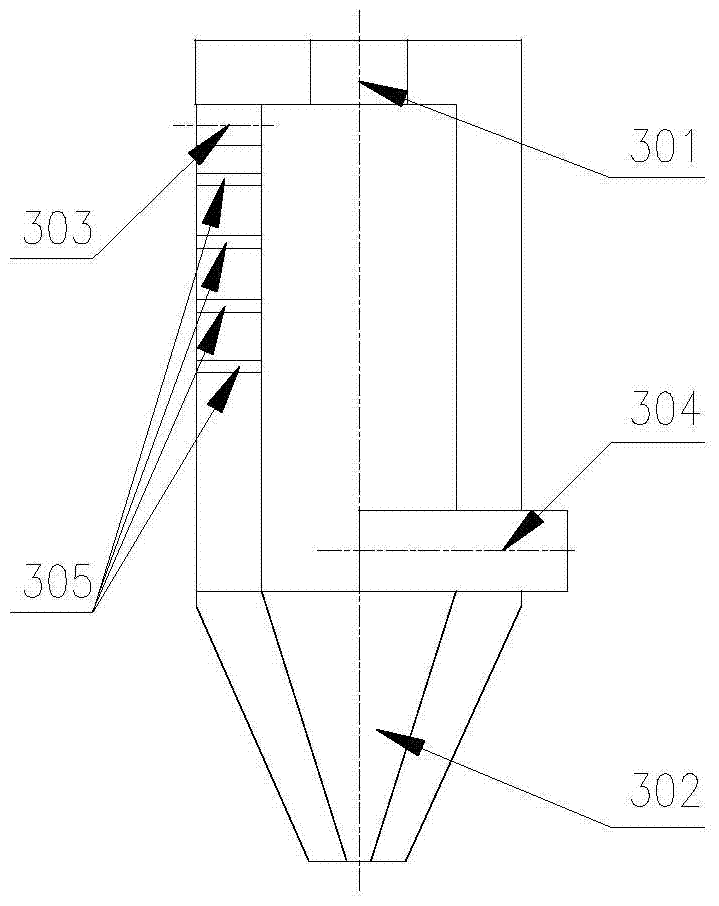

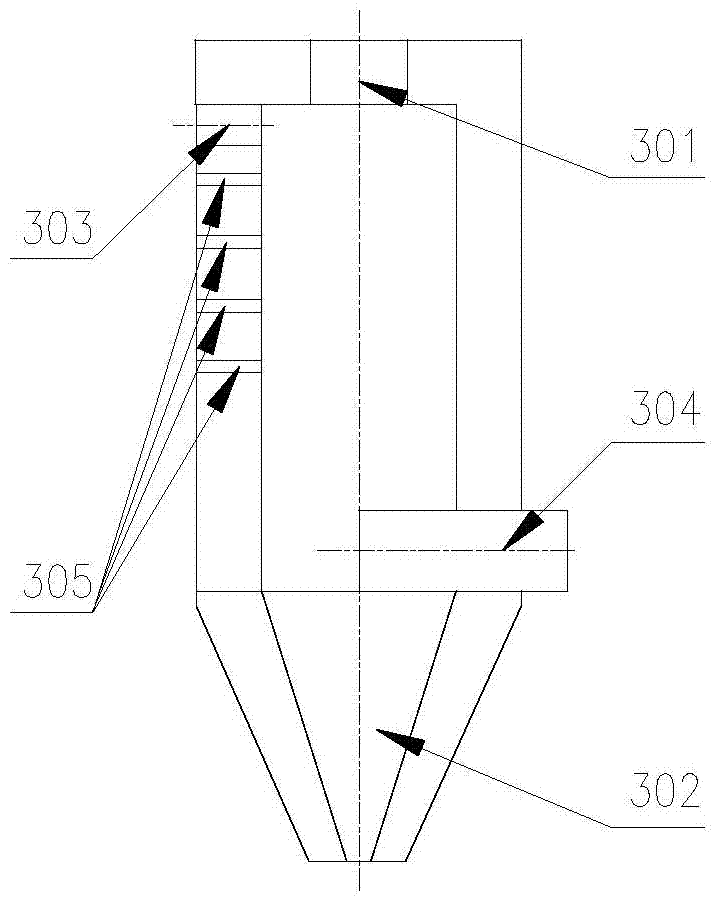

Mechanical grate type garbage gasifying and incinerating system and combustion chamber with inverted-cone-shaped cavity

ActiveCN106224970AAccelerated settlementLow suctionBlast-producing apparatusIncinerator apparatusCombustion chamberSlag

The invention discloses a mechanical grate type garbage gasifying and incinerating system and a combustion chamber with an inverted-cone-shaped cavity. The cavity of the combustion chamber with the inverted-cone-shaped cavity comprises a combustion channel, a conical channel, a fly ash settling chamber, a conical slag outlet, an annular smoke channel and an annular draught flue, wherein the combustion channel, the conical channel, the fly ash settling chamber and the conical slag outlet are successively arranged from top to bottom; the annular smoke channel and the annular draught flue surround the conical channel; the top of the conical channel is small while the bottom of the conical channel is large; the diameter of the fly ash settling chamber is greater than that of the lower end of the conical channel; the annular smoke channel is conical; the top of the annular smoke channel is small while the bottom of the annular smoke channel is large; the lower end of the annular smoke channel communicates with the fly ash settling chamber; the lower end of the annular draught flue communicates with the upper end of the annular smoke channel; and the top of the conical slag outlet is large while the bottom of the conical slag outlet is small. The combustion chamber with the inverted-cone-shaped cavity has relatively high dust removal efficiency and combustion efficiency and relatively high heat recycling efficiency; controlled combustion and controlled collection can be realized; heat loss is reduced; and emission of pollutants can be reduced effectively.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

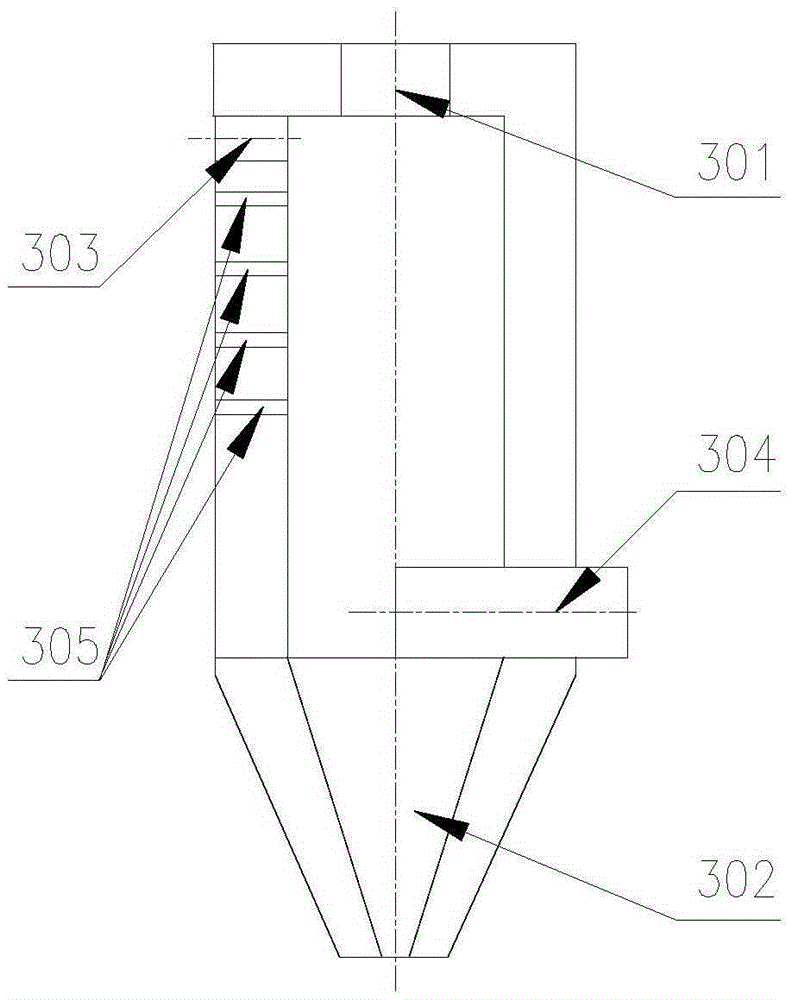

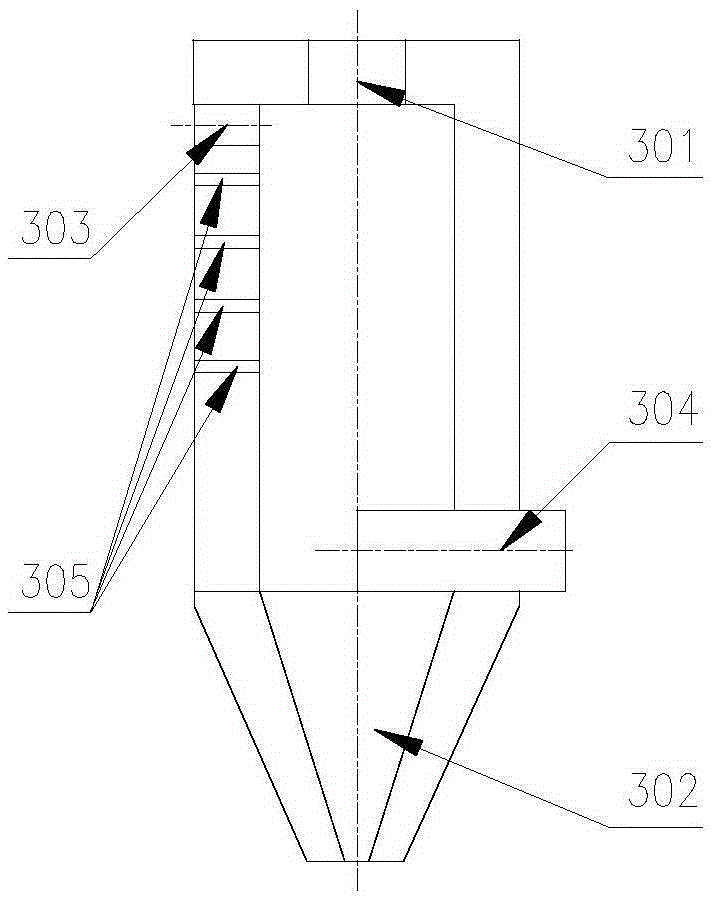

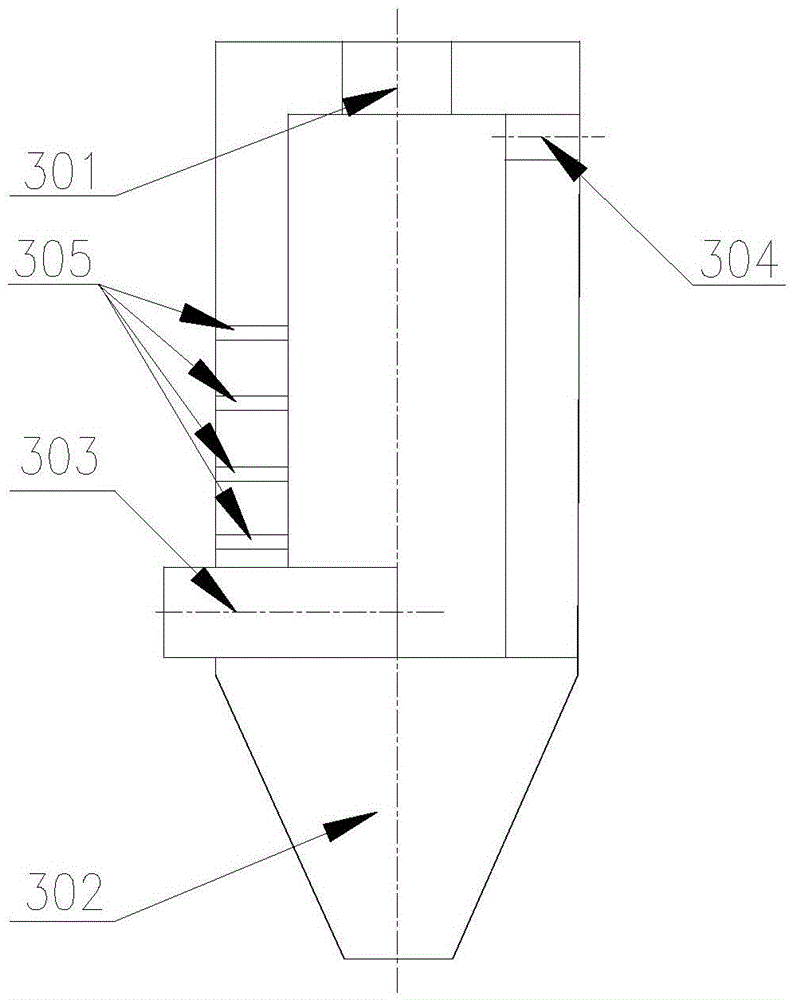

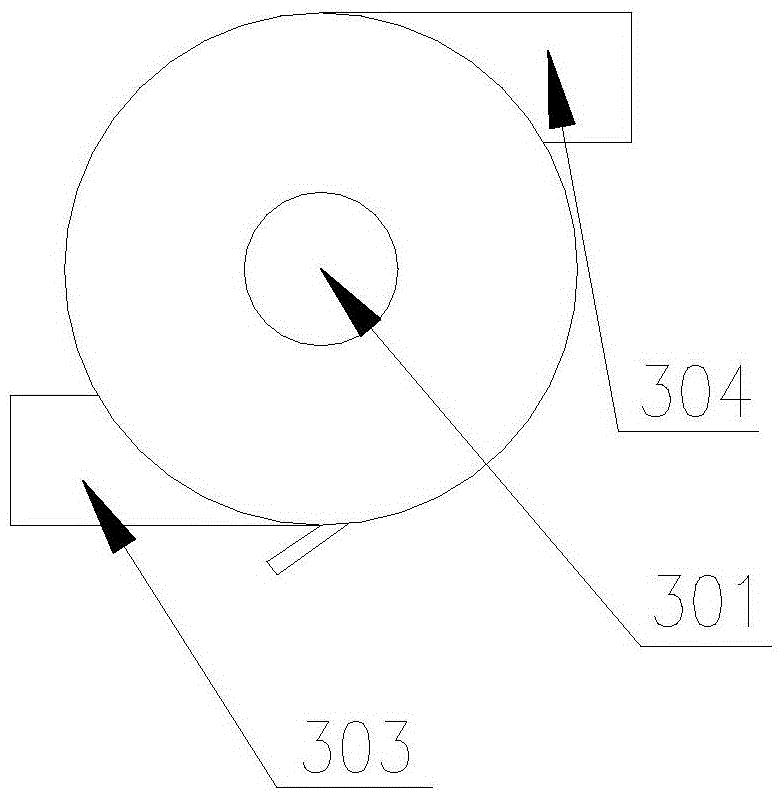

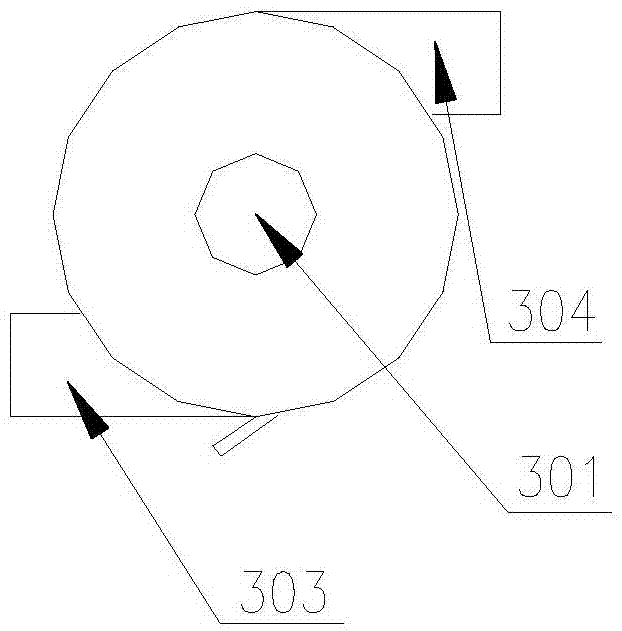

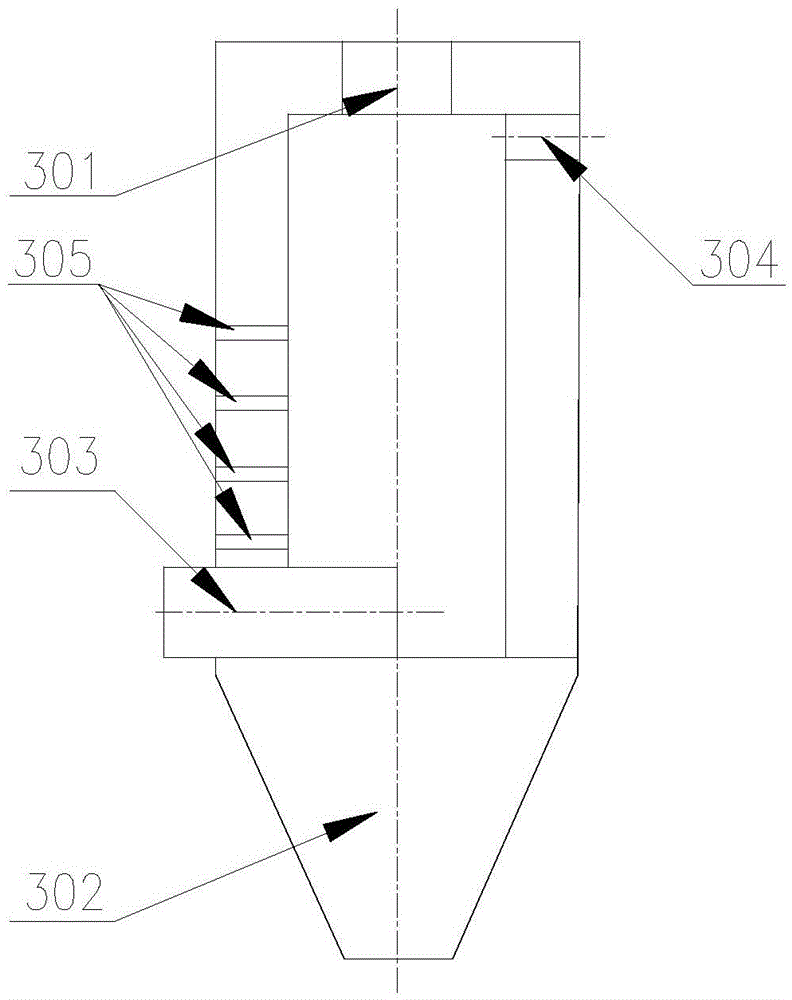

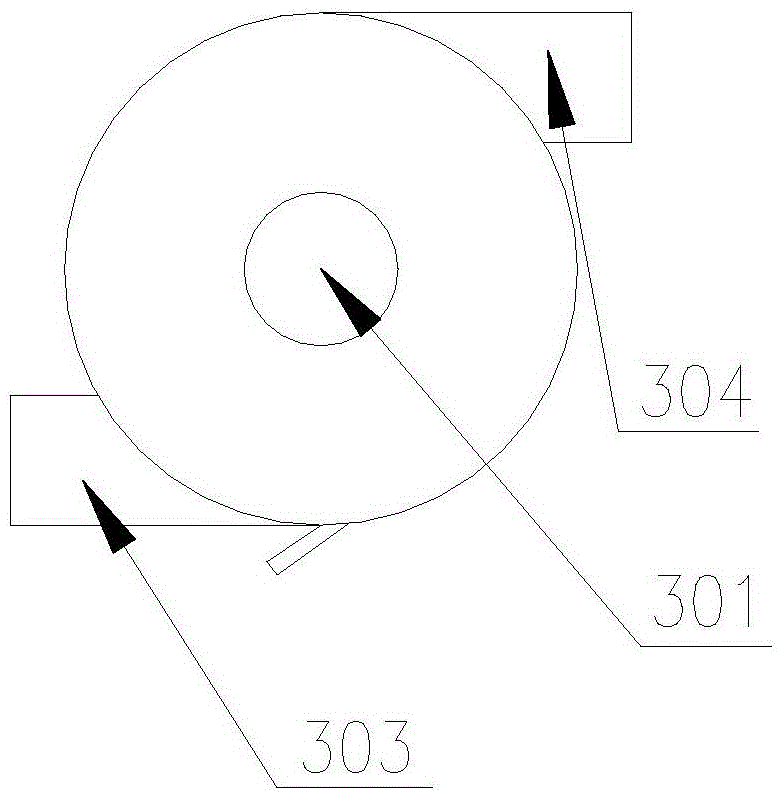

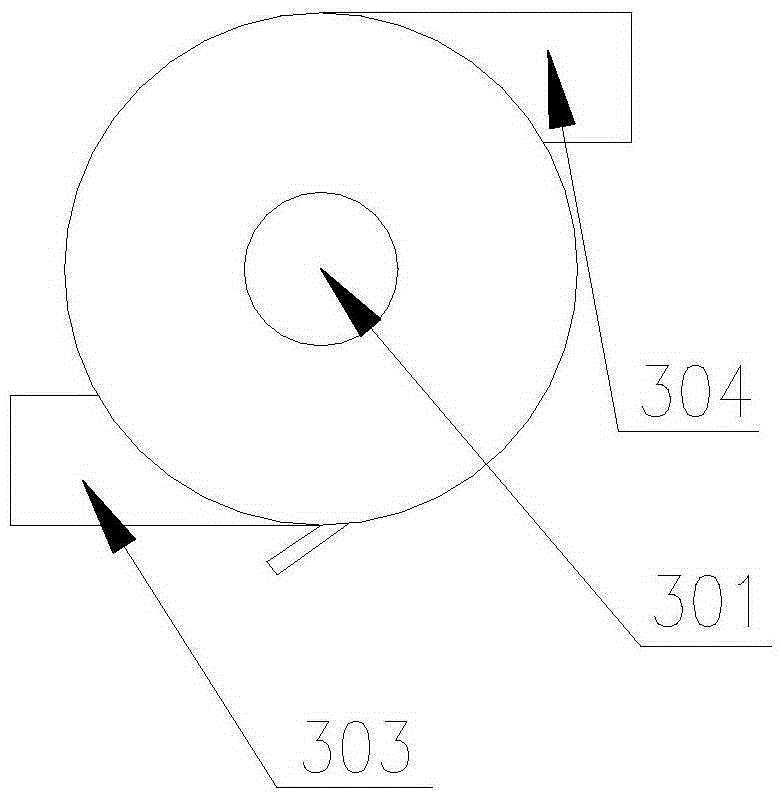

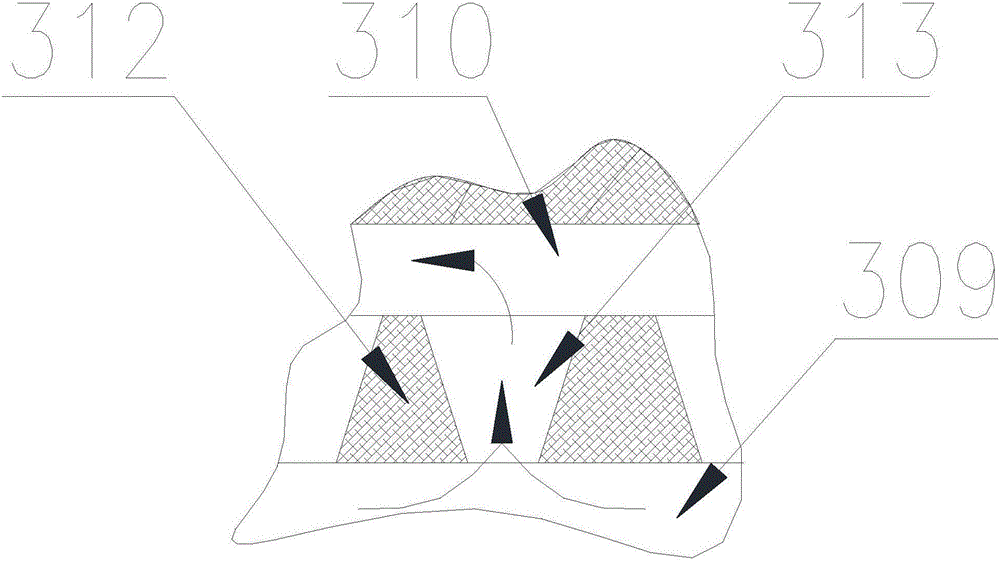

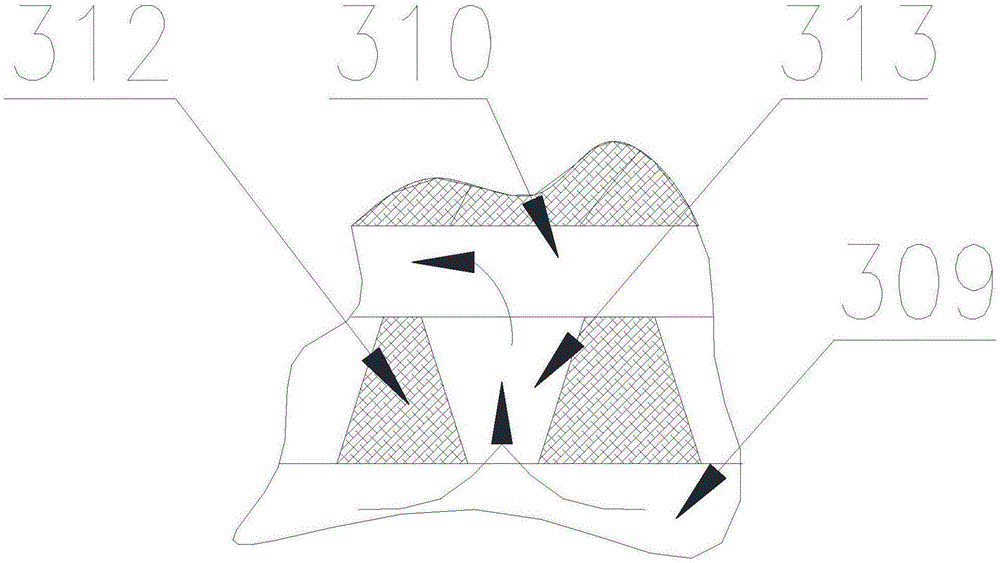

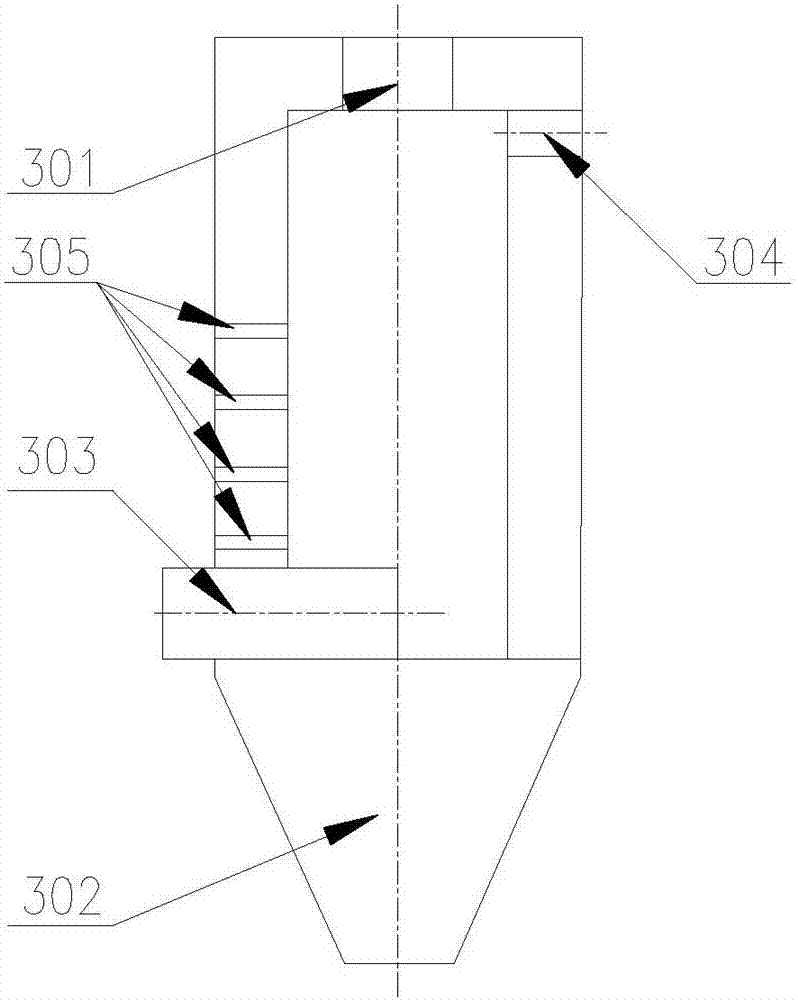

Mechanical grate type garbage gasifying and incinerating system and dovetail-shaped fly ash collecting device

ActiveCN106224967AAccelerated settlementLow suctionDispersed particle separationIncinerator apparatusCombustion chamberSlag

The invention discloses a mechanical grate type garbage gasifying and incinerating system and a dovetail-shaped fly ash collecting device. A cavity of the dovetail-shaped fly ash collecting device comprises a combustion channel, a fly ash settling chamber, a conical slag outlet, an upper annular smoke channel, an annular draught flue and a lower annular smoke channel, wherein the upper annular smoke channel, the annular draught flue and the lower annular smoke channel surround the combustion channel; the ventilating area of the lower annular smoke channel is gradually reduced from bottom to top; the ventilating area of the upper annular smoke channel is gradually reduced from top to bottom; a tangential smoke outlet is formed in a side wall of the fly ash collecting device and communicates with the annular draught flue; a cyclone combustion chamber inlet is formed in the middle of the side wall of the combustion channel in the tangential direction; and a plurality of combustion-supporting air supply openings are formed in the side wall of the combustion channel. The garbage gasifying and combusting fly ash collecting device has quite high fly ash collecting efficiency and combustion efficiency and relatively high heat recycling efficiency; controlled combustion and controlled collection can be realized; heat loss is reduced; and emission of pollutants can be reduced effectively.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Mechanical grate type garbage single-furnace gasification incineration system and its treatment method

ActiveCN105444183BImprove recycling efficiencyEmission reductionIncinerator apparatusCombustion chamberFlue gas

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Mechanical grate type garbage gasification incineration system and its treatment method

ActiveCN105627322BLarge amount of processingImprove energy conversion efficiencyIncinerator apparatusHearthGarbage disposal

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Double-layer mechanical grate type garbage gasification incineration system and its treatment method

ActiveCN105402736BImprove insulation effectPrevent leakageIncinerator apparatusPollutant emissionsProcess engineering

The invention discloses a double-layer mechanical grate type garbage gasification and incineration system. The system comprises a double-layer garbage gasification and incineration furnace, wherein the double-layer garbage gasification and incineration furnace comprises a feeding bin, a gasification furnace and an ash combustion furnace which is located right below the gasification furnace; the feeding direction of the ash combustion furnace is opposite to that of the gasification furnace; a stacking sealing section is arranged between the feeding bin and the gasification furnace; a residue pusher is arranged between the gasification furnace and the ash combustion furnace; exhaust gas outlets are formed in the upper end of the gasification furnace and the upper end of the ash combustion furnace; the double-layer mechanical grate type garbage gasification and incineration furnace further comprises a circular air supply system. The garbage treatment method comprises steps as follows: step A, furnace ignition and drying are performed; step B, garbage is combustedin a hearth of the gasification furnace; step C, continuous garbage gasification and incineration treatment is realized; step D, the double-layer mechanical grate type garbage gasification and incineration furnace shuts down after ash combustion. With the adoption of the double-layer mechanical grate type garbage gasification and incineration furnace for treating the garbage, the garbage treatment amount is large, the recovery efficiency of heat is relatively high, and pollutant emission can be effectively reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

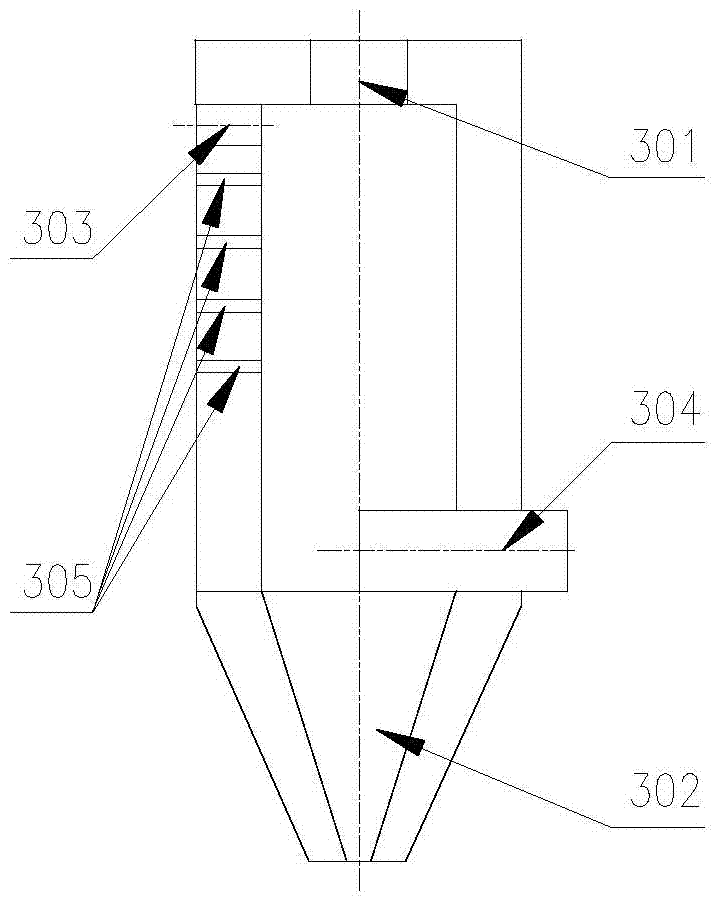

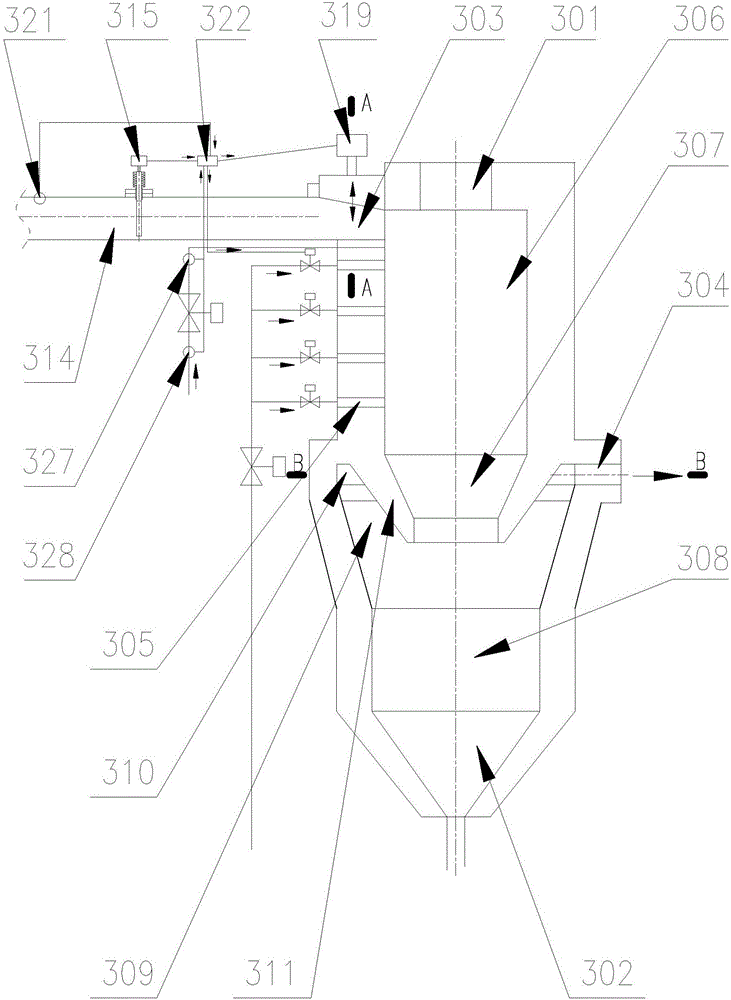

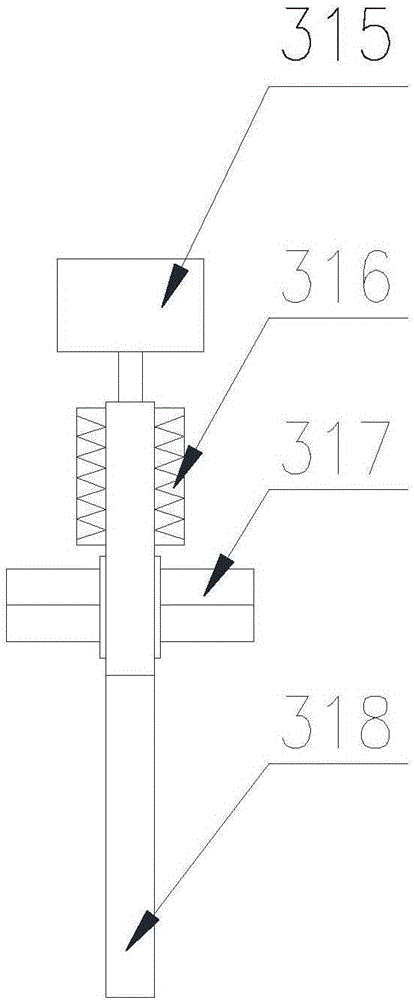

Mechanical grate-type garbage gasifying incineration system and combustion device capable of feeding back parameters of synthetic gas

The invention discloses a mechanical grate-type garbage gasifying incineration system and a combustion device capable of feeding back parameters of synthetic gas. A combusting passage, a V conical passage, a fly ash settling chamber, a conical slag notch, and an annular flue gas passage and an annular exhaust flue which are arranged in a manner of encircling the V conical passage are sequentially arranged inside the inner cavity of the combustion device from the top to the bottom; the V conical passage has a big upper part and a small lower part; the diameter of the fly ash settling chamber is greater than that of the upper end of the V conical passage; the venting area of the annular flue gas passage gradually decreases from the bottom to the top; the lower end of the annular flue gas passage is communicated with the fly ash settling chamber; the lower end of the annular exhaust flue is communicated with the upper end of the annular flue gas passage; the conical slag notch has a big upper part and a small lower part. The combustion device capable of feeding back the parameters of the garbage gasifying synthetic gas has relatively high dust-removing efficiency and combustion efficiency and relatively high heat-recycling efficiency, can achieve controllable combustion and controllable collection, can reduce heat loss and can effectively reduce pollutant emission.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Mechanical grate type waste gasification incineration system and inverted cone type inner cavity combustion chamber

ActiveCN106224970BAccelerated settlementLow suctionBlast-producing apparatusIncinerator apparatusCombustion chamberSlag

The invention discloses a mechanical grate type garbage gasifying and incinerating system and a combustion chamber with an inverted-cone-shaped cavity. The cavity of the combustion chamber with the inverted-cone-shaped cavity comprises a combustion channel, a conical channel, a fly ash settling chamber, a conical slag outlet, an annular smoke channel and an annular draught flue, wherein the combustion channel, the conical channel, the fly ash settling chamber and the conical slag outlet are successively arranged from top to bottom; the annular smoke channel and the annular draught flue surround the conical channel; the top of the conical channel is small while the bottom of the conical channel is large; the diameter of the fly ash settling chamber is greater than that of the lower end of the conical channel; the annular smoke channel is conical; the top of the annular smoke channel is small while the bottom of the annular smoke channel is large; the lower end of the annular smoke channel communicates with the fly ash settling chamber; the lower end of the annular draught flue communicates with the upper end of the annular smoke channel; and the top of the conical slag outlet is large while the bottom of the conical slag outlet is small. The combustion chamber with the inverted-cone-shaped cavity has relatively high dust removal efficiency and combustion efficiency and relatively high heat recycling efficiency; controlled combustion and controlled collection can be realized; heat loss is reduced; and emission of pollutants can be reduced effectively.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Mechanical grate waste gasification incineration system and syngas straight tube combustion chamber

ActiveCN106224971BAccelerated settlementLow suctionAir supply regulationDispersed particle separationSyngasCombustion chamber

The invention discloses a mechanical grate type waste gasifying and incinerating system and a synthesized gas straight tube combustion chamber. An inner cavity of the synthesized gas straight tube combustion chamber comprises a combustion channel, a conical ash outlet, an upper annular smoke channel, an annular exhaust flue and a lower annular smoke channel, wherein the combustion channel is surrounded by the upper annular smoke channel, the annular exhaust flue and the lower annular smoke channel, the smoke circulation area of the lower annular smoke channel is gradually reduced from the bottom to the top, the smoke circulation area of the upper annular smoke channel is gradually reduced from the top to the bottom, a tangential smoke outlet is arranged on the side wall of the synthesized gas straight tube combustion chamber and communicates with the annular exhaust flue, an inlet of the synthesized gas straight tube combustion chamber is arranged in the middle of the side wall of the combustion channel in a tangential direction, and a plurality of combustion support air supply openings are formed in the side wall of the combustion channel. By using the synthesized gas straight tube combustion chamber, the mechanical grate type waste gasifying and incinerating system has high dust collecting efficiency, high combustion efficiency and high energy recycling efficiency, can realize controllable combustion and controllable collection, can reduce heat losses and can effectively reduce pollutant emission.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Double-layer mechanical grate type garbage gasification incinerator and its boiler power generation system

ActiveCN105465789BImprove insulation effectPrevent leakageSteam engine plantsIncinerator apparatusCombustion chamberFlue gas

The invention discloses a double-layer mechanical grate type garbage gasification incinerator and its boiler power generation system, including a double-layer garbage gasification incinerator, a boiler system, a circulating air supply system, a power generation system, and a double-layer garbage gasification incinerator The ember furnace is located directly below the gasification furnace, and the gasification furnace and the upper end of the ember furnace are provided with flue gas outlets. The boiler system includes a boiler body, and the boiler body has a cyclone combustion chamber, furnace chamber a, furnace chamber b, and cyclone A water-cooled wall is set in the combustion chamber, a superheater is set in the furnace room a, an evaporator is set in the furnace room b, a steam drum is set on the top of the boiler body, and the superheater outputs superheated steam; the power generation system includes a steam turbine, a generator, a steam input pipe, and a steam turbine The output end is sequentially connected to the condenser, water pump, low-pressure steam-water heater, deaerator, booster water pump, and high-pressure steam-water heater. The first and second-stage water-steam separators and the first and second-stage high-pressure Steam heater.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

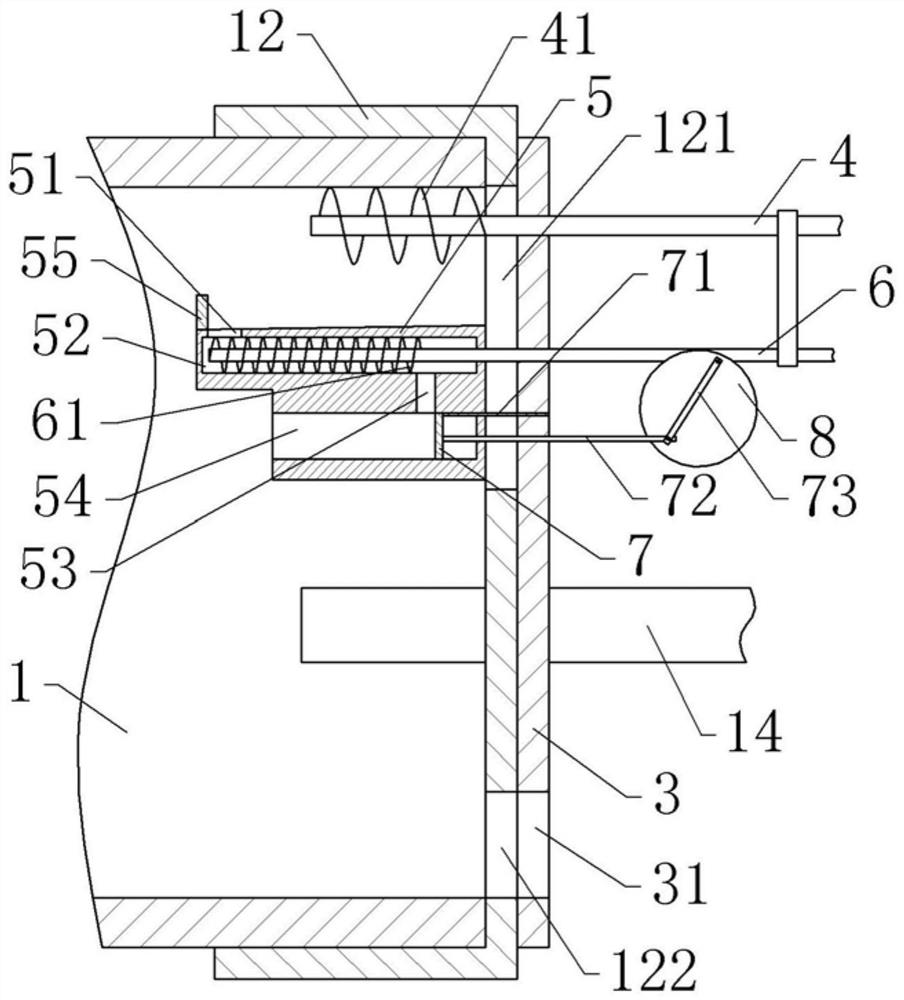

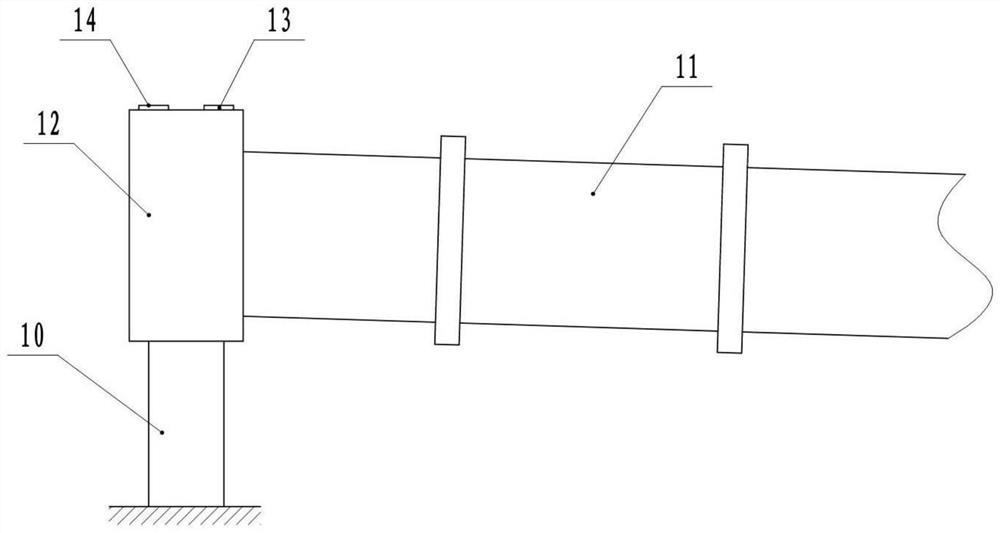

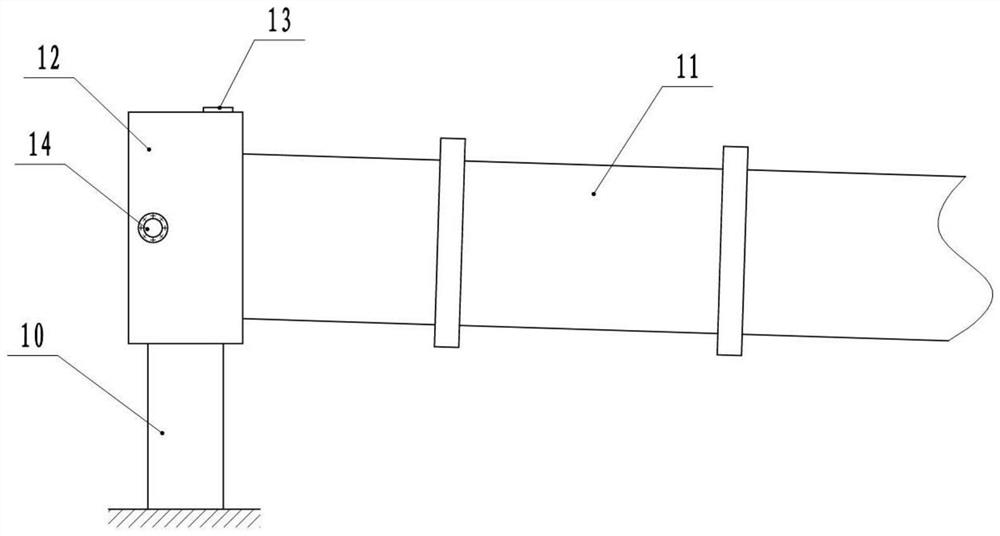

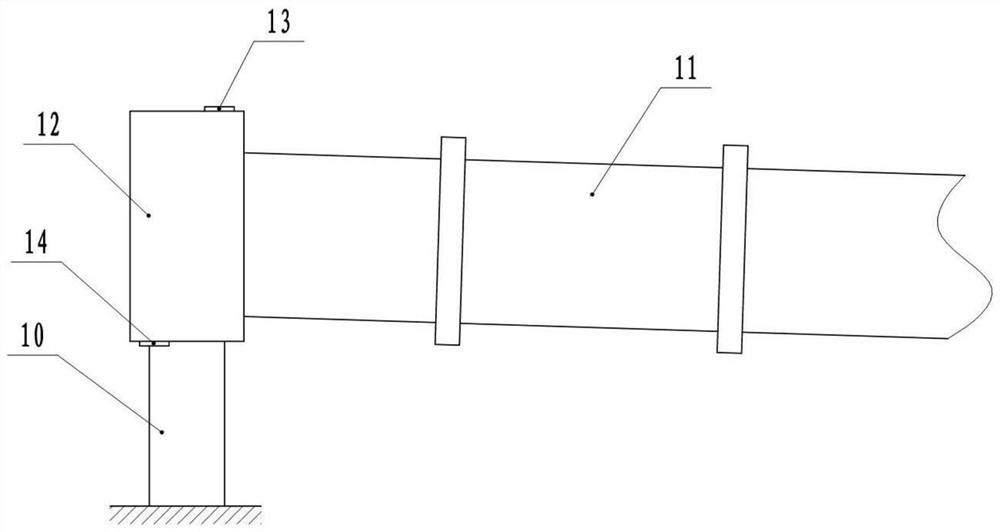

Hazardous waste rotary kiln incineration air supply method

PendingCN112361355AHazardous waste incineration heat loss rate is lowReduce heat burn rateIncinerator apparatusAir velocityEnvironmental engineering

The invention relates to the technical field of hazardous waste incineration, and particularly discloses a hazardous waste rotary kiln incineration air supply method. The method is achieved through animproved air supply structure. The air supply structure comprises a supporting frame, a rotary drum and a kiln head cover. The kiln head cover is cylindrical, a main air hole and an auxiliary air hole are formed in the side wall of the kiln head cover, the main air hole is located in the top of the kiln head cover, the main air hole and the auxiliary air hole are not located in the same circumferential line of the kiln head cover, the main air hole is close to the rotary drum, and the auxiliary air hole is away from one side of the rotary drum. When the temperature in the rotary drum rises toa preset value, air is supplied into the kiln head cover from the main air hole and the auxiliary air hole, and the air speeds of the main air hole and the auxiliary air hole are consistent. Throughmodel simulation, the air excess coefficient of hazardous waste incineration is controlled to range from 0.8 to 1.0 to adjust the air supply amount, the rotary turbulence flow field of the scheme is obtained through calculation, the hazardous waste incineration heat ignition loss rate of a rotary kiln can be lower than 3%, thus, the scheme can guarantee the much lower heat ignition loss rate on the premise that the low excess coefficient is guaranteed, and the combustion rate is increased.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com