Patents

Literature

76results about How to "Fully mixed combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

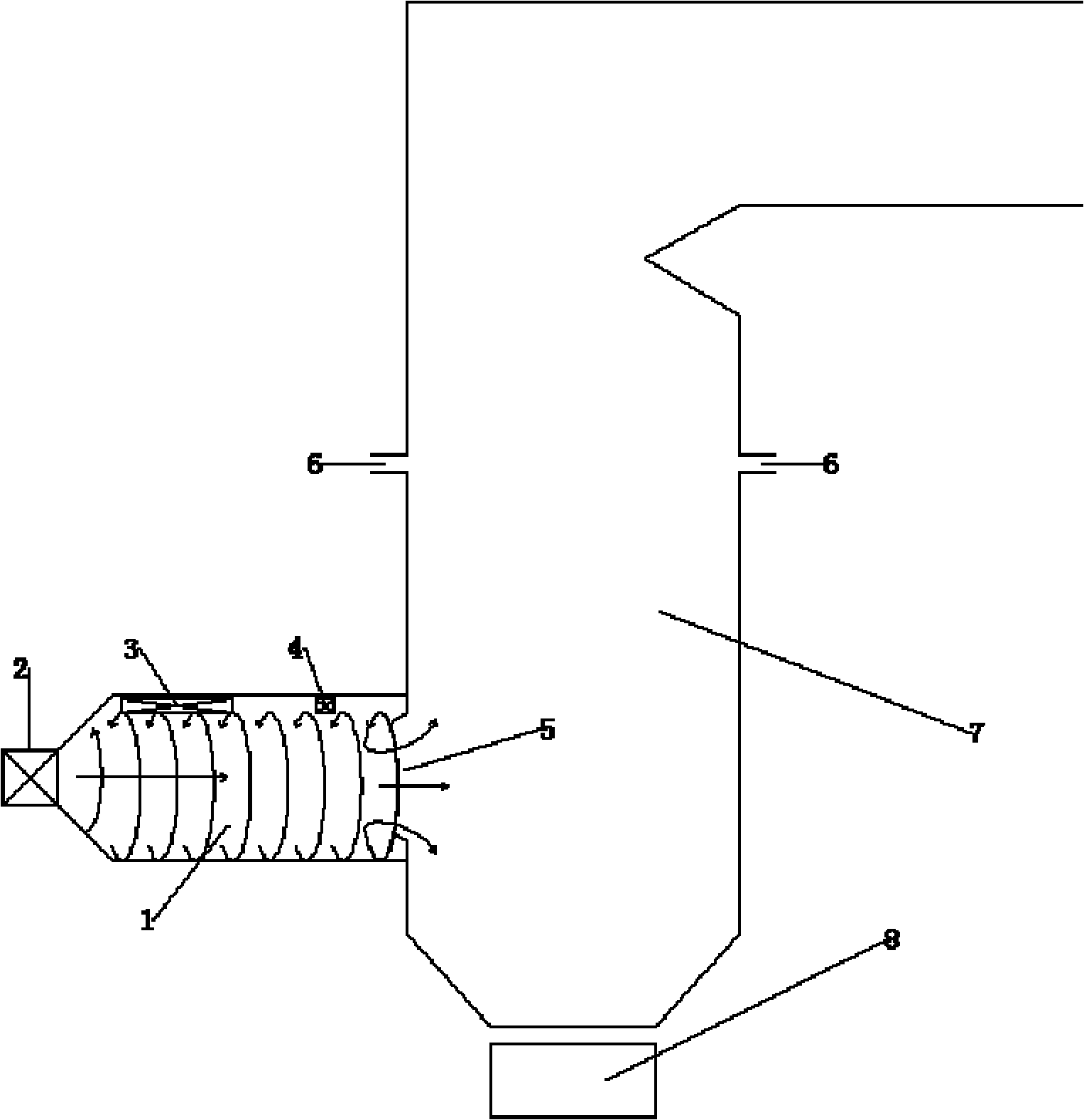

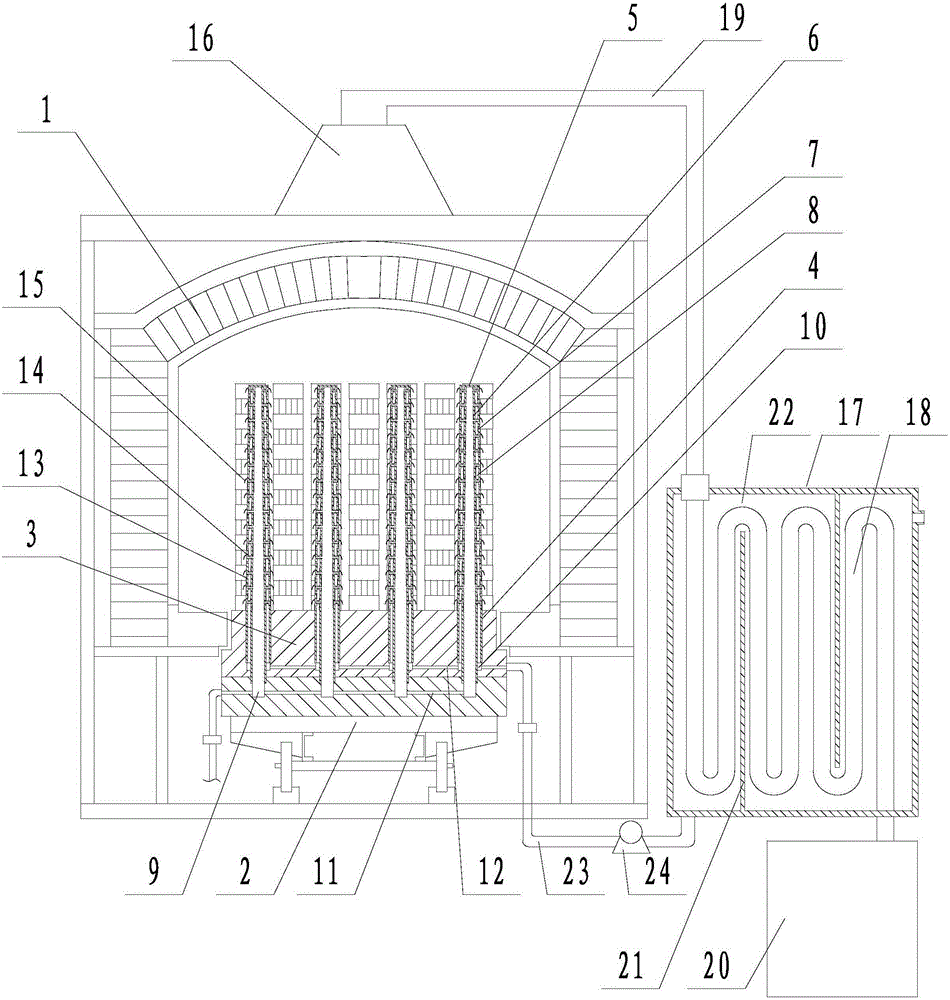

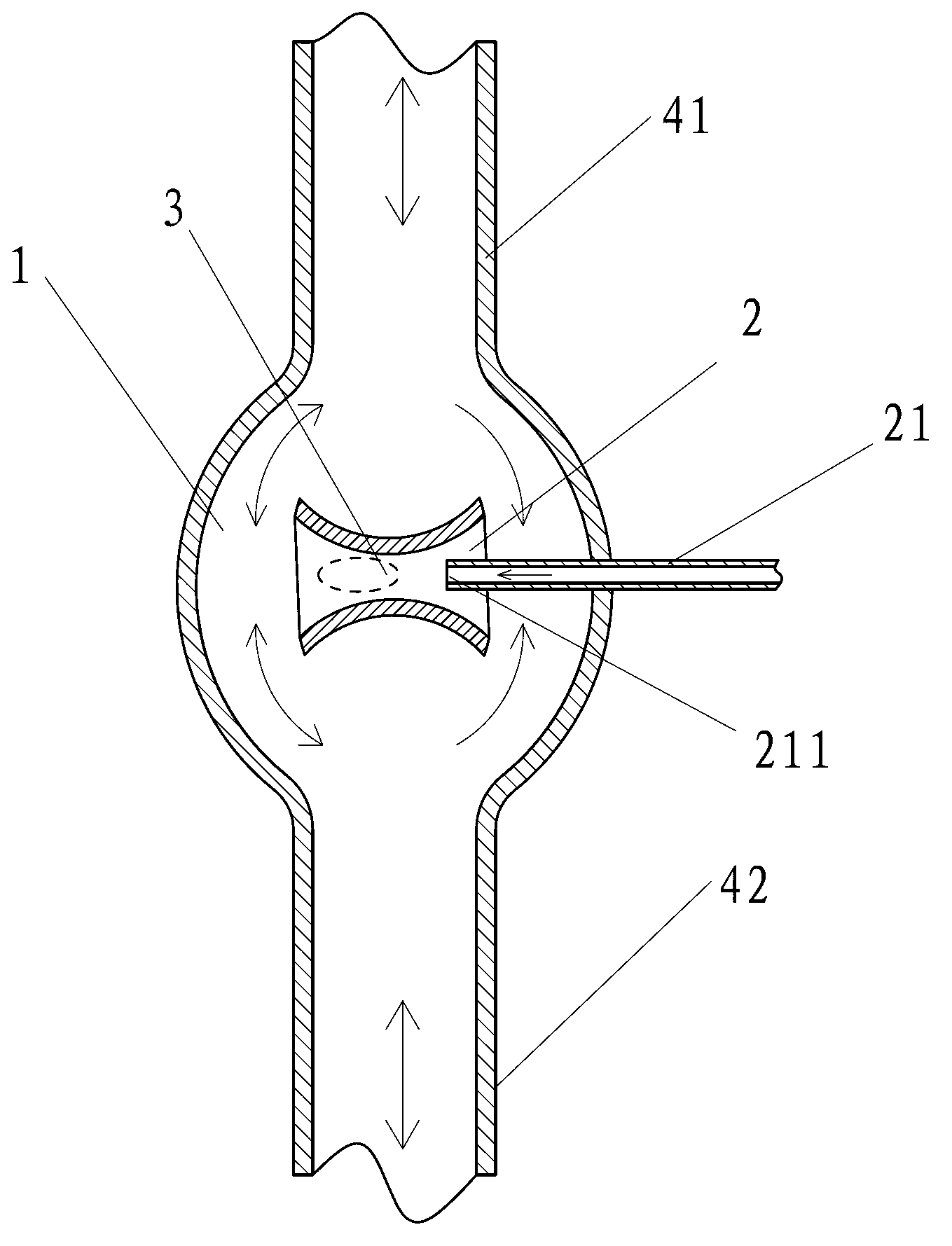

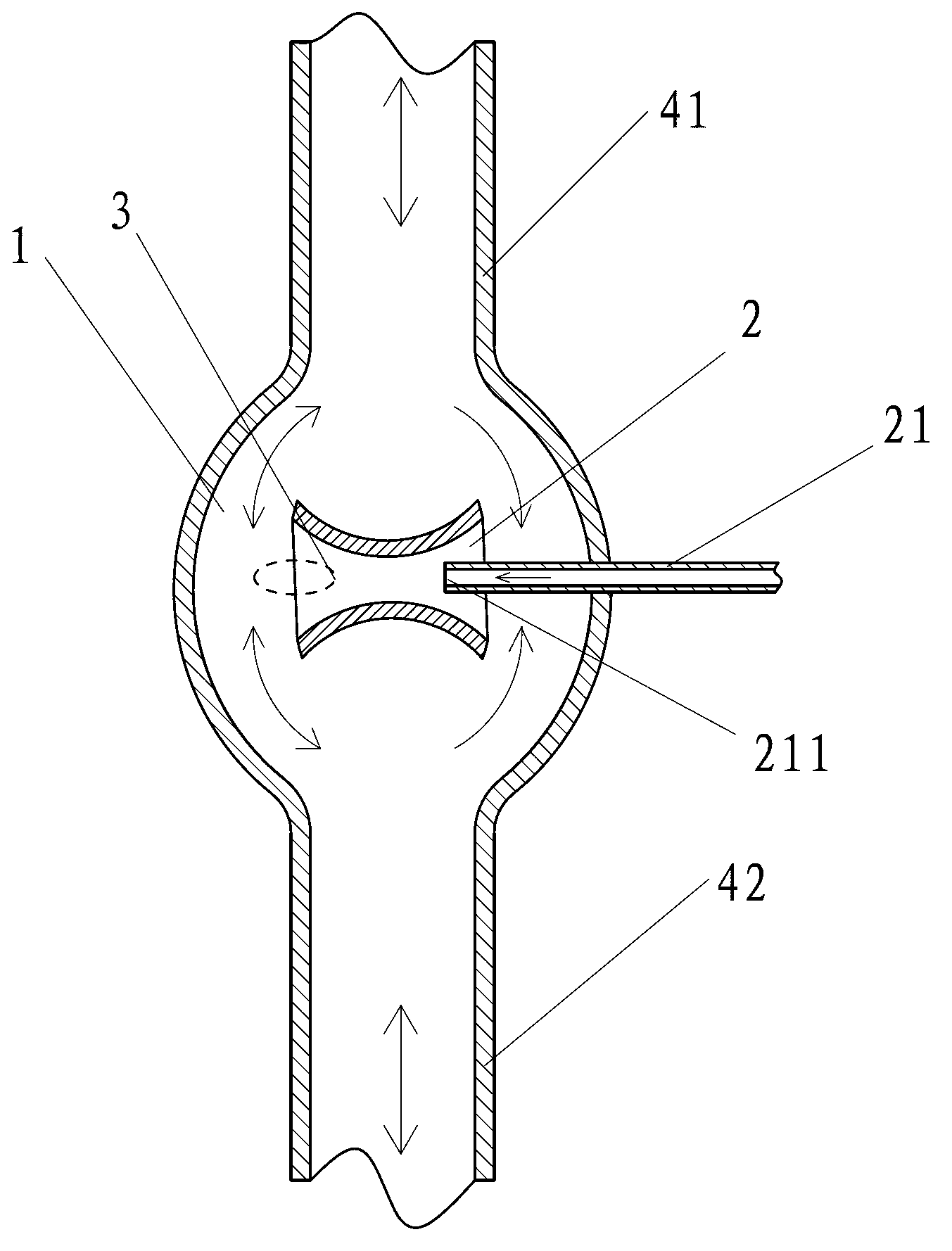

Cyclone burning method and device for reburning fuel in cyclone drum for denitration

InactiveCN102062393AExtended staySolve the problem of high smoke temperatureCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSocial benefitsLiquid slag

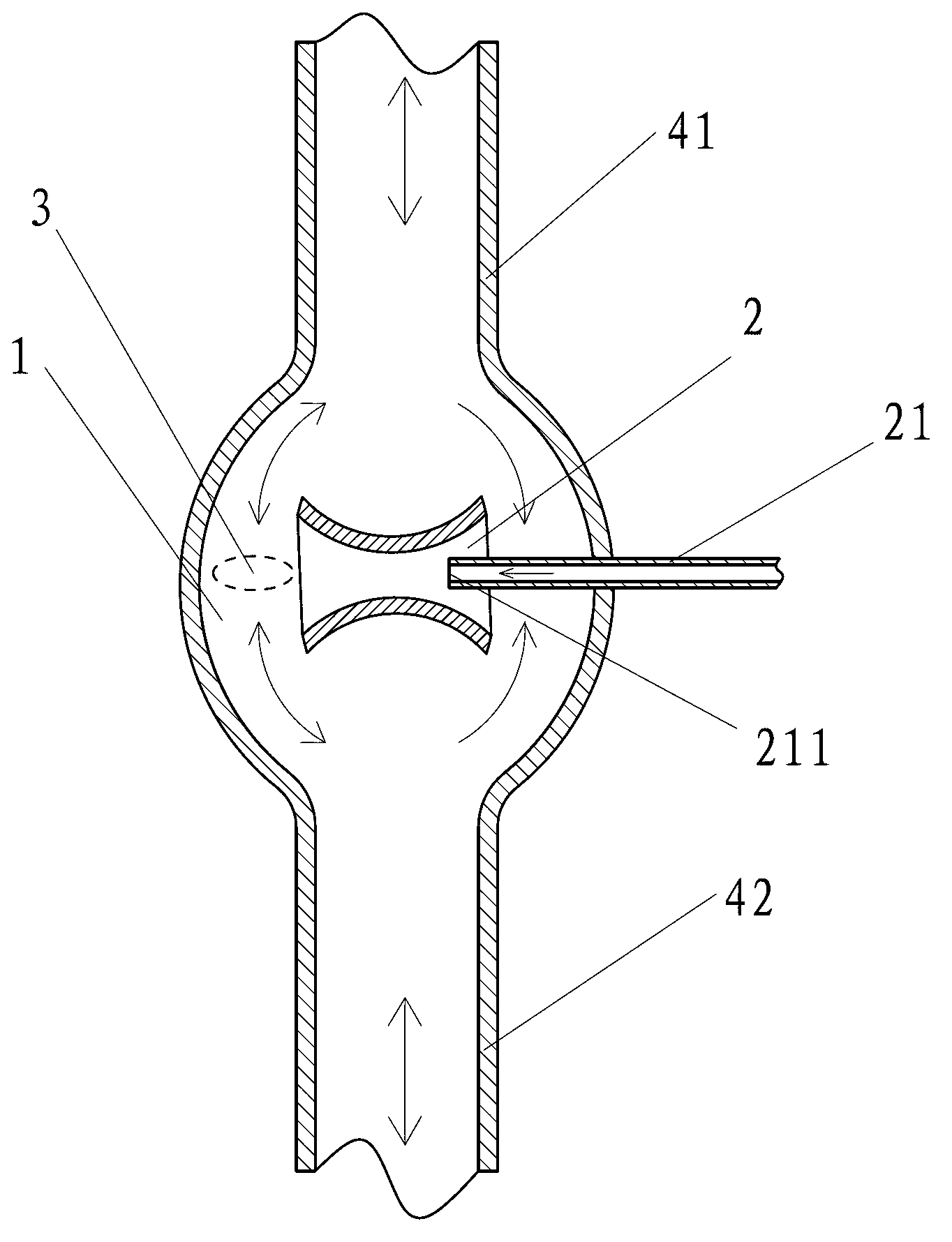

The invention discloses a cyclone reburning method and device for reburning fuel in a cyclone drum for denitration. The device comprises a cyclone drum, a boiler main hearth and a granulating water tank, wherein the cyclone drum and the boiler main hearth are connected seamlessly through a concave outlet of the cyclone drum, overfire air nozzles are distributed at the upper part of the boiler main hearth, and the granulating water tank used for granulating liquid slag is arranged at the bottom of the boiler main hearth. In the invention, since reburning denitration is realized in the cyclone drum, reburnt fuel can stay in a boiler for a longer time; meanwhile, the upper part of the boiler main hearth at the rear part of the boiler has enough space for the distribution of the overfire air nozzles; therefore, the problem that the normal operation of a cyclone furnace boiler is threatened when a conventional reburning technology is adopted is solved very well, and the problems of the reburning technology per se, such as low burn-off rate of reburnt fuel and high smoke temperature of a hearth outlet and the like, can be overcome very well. The method disclosed in the invention not only has high denitration rate, but also uses simple equipment, is convenient and easy to implement, has low cost, is easy in the reformation of a traditional boiler, has remarkable social benefit and can be promoted and applied widely.

Owner:XI AN JIAOTONG UNIV

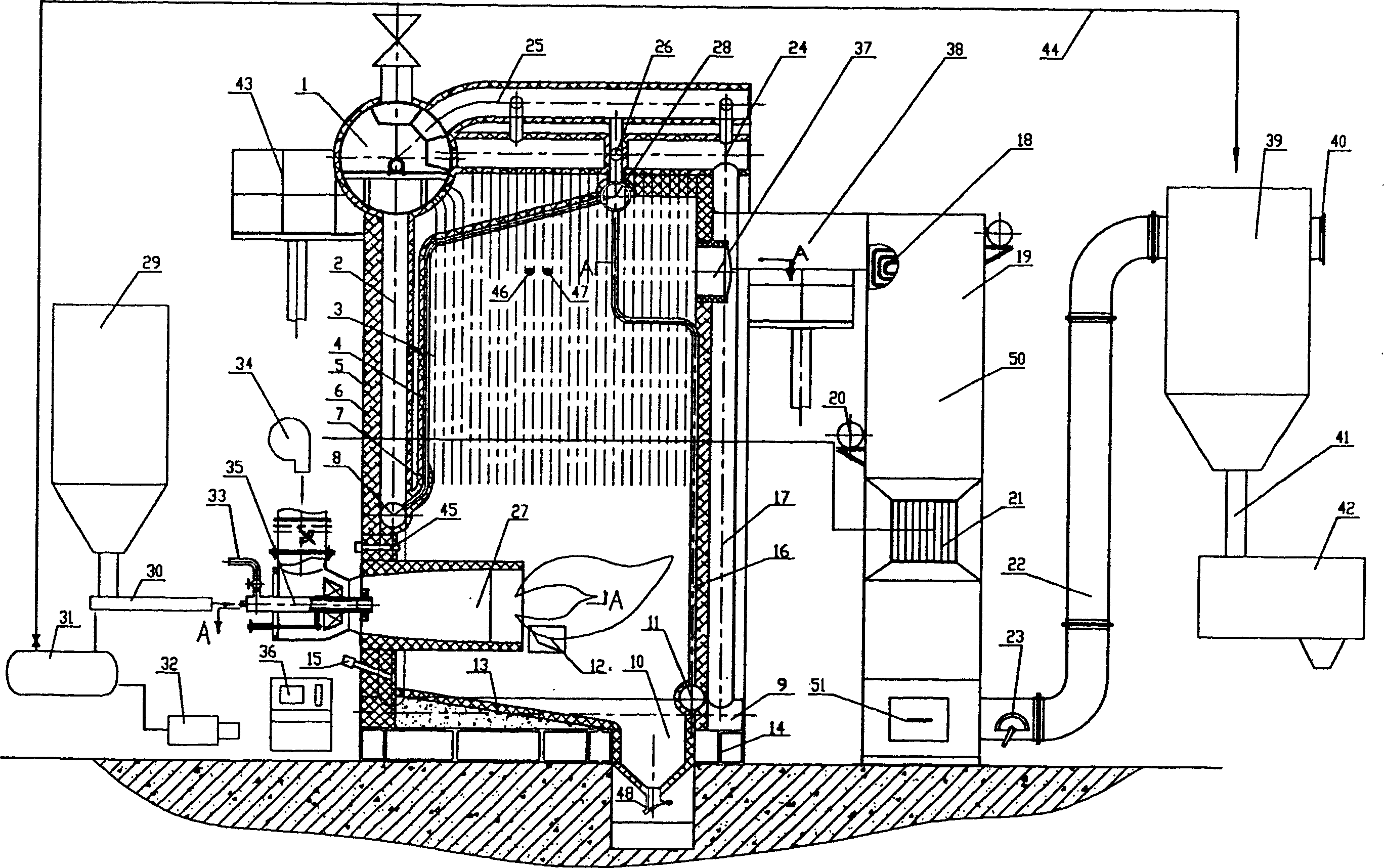

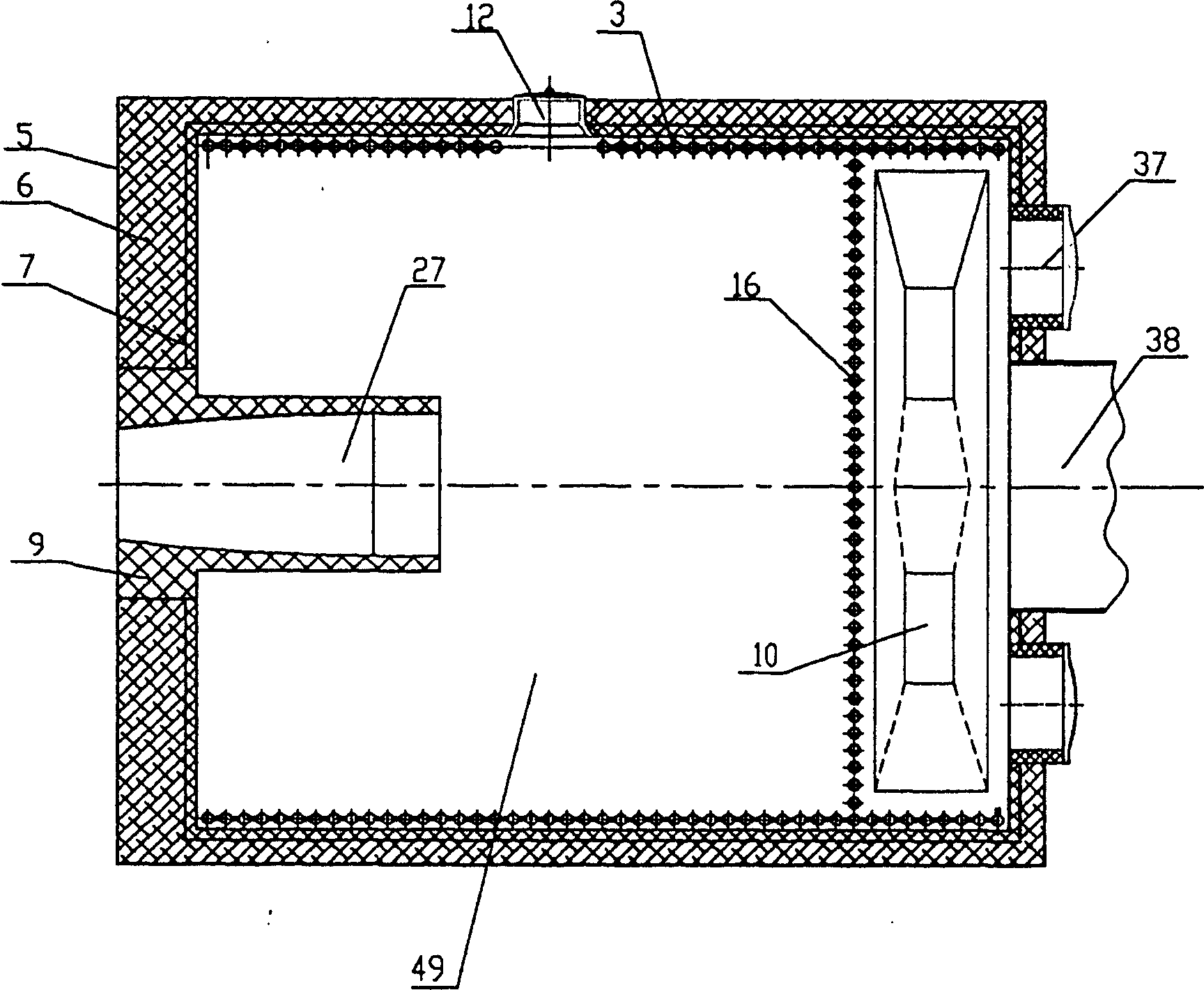

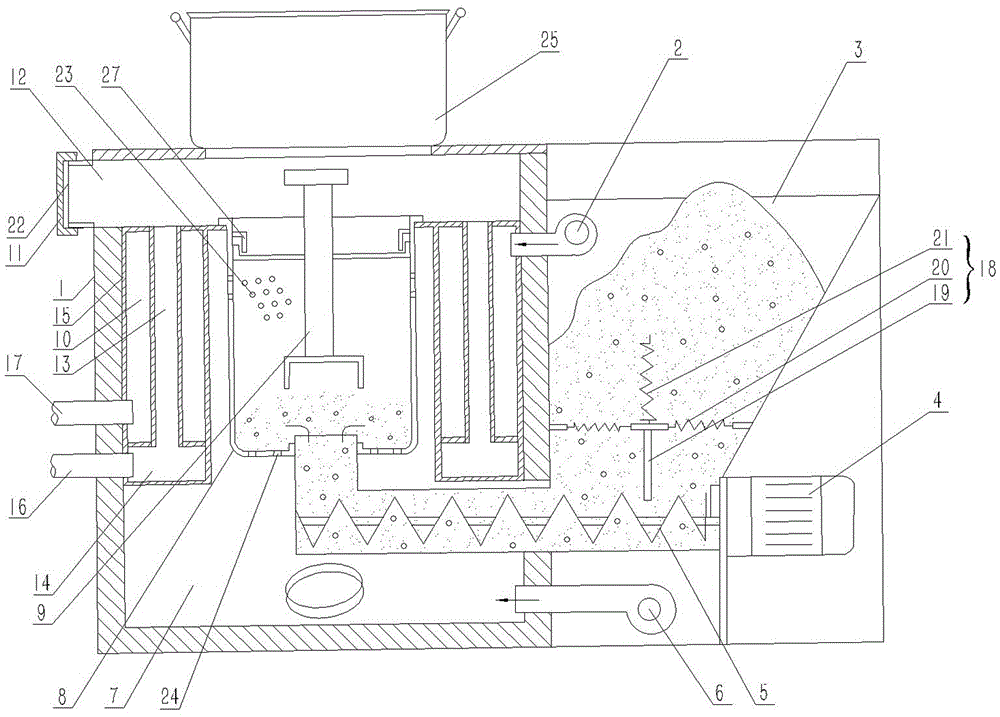

Industrial boiler of multi-fuel burning using ultrafine coal dust as main fuel

InactiveCN1724928AImprove burnout rateFully mixed combustionBurnersCombustion using multiple fuelsMultifuelCoal dust

The invention discloses an industrial boiler fired by multiple mixed fuels with superfine powder coal(water coal slurry) as the primary and natural gas or oil products as the auxiliary, and it is an industrial boiler with the advantages of high firing efficiency, low cost, auto control and reduction of environmental pollution, especially applied to middle-small scale industrial boilers.

Owner:姜政华

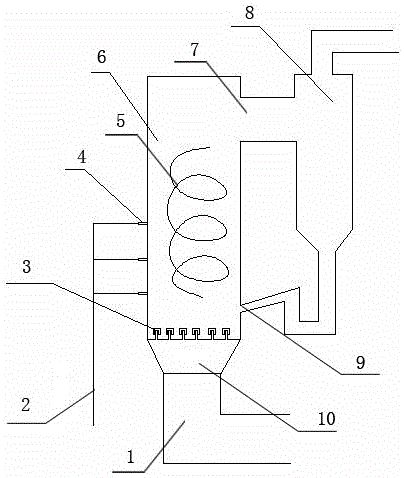

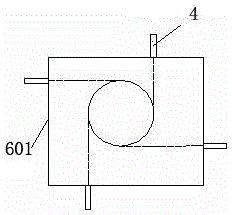

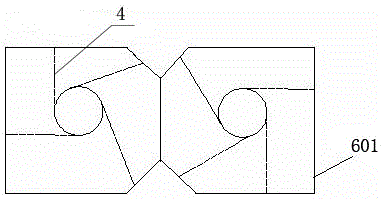

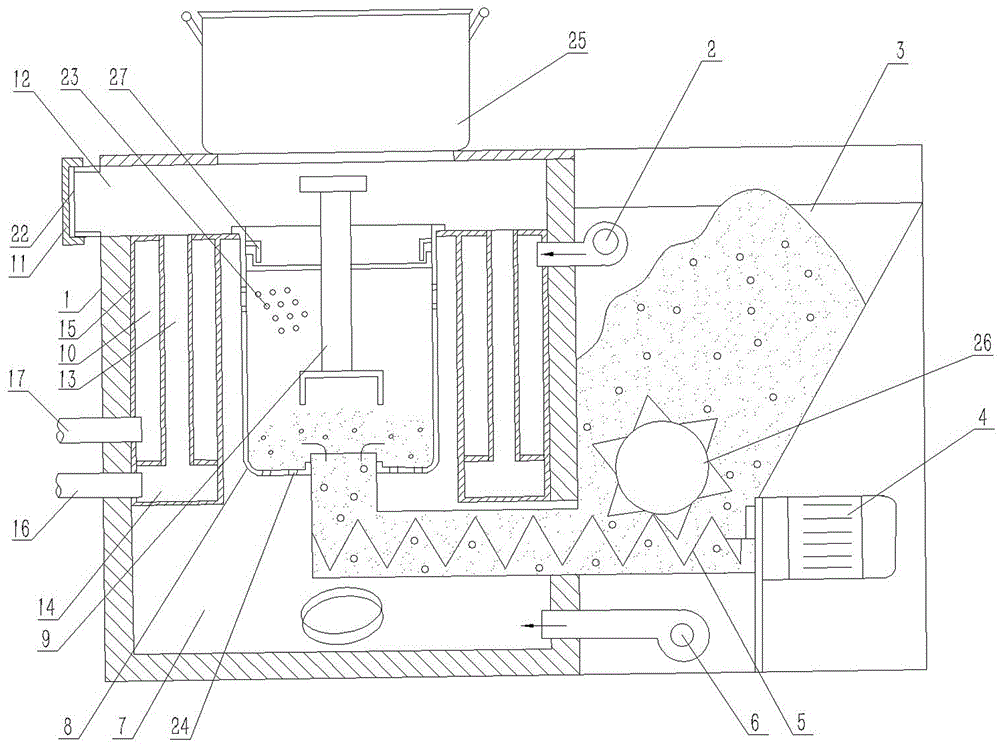

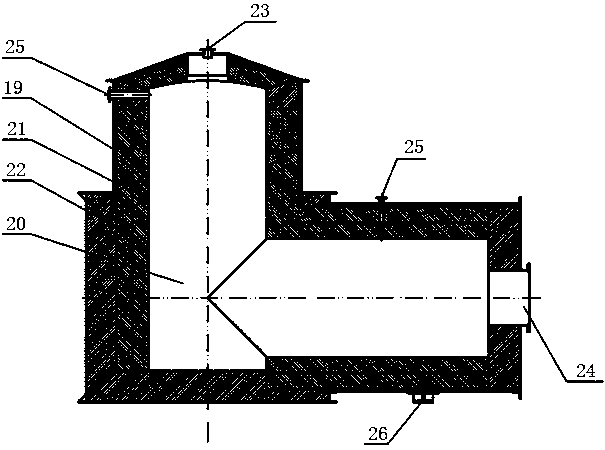

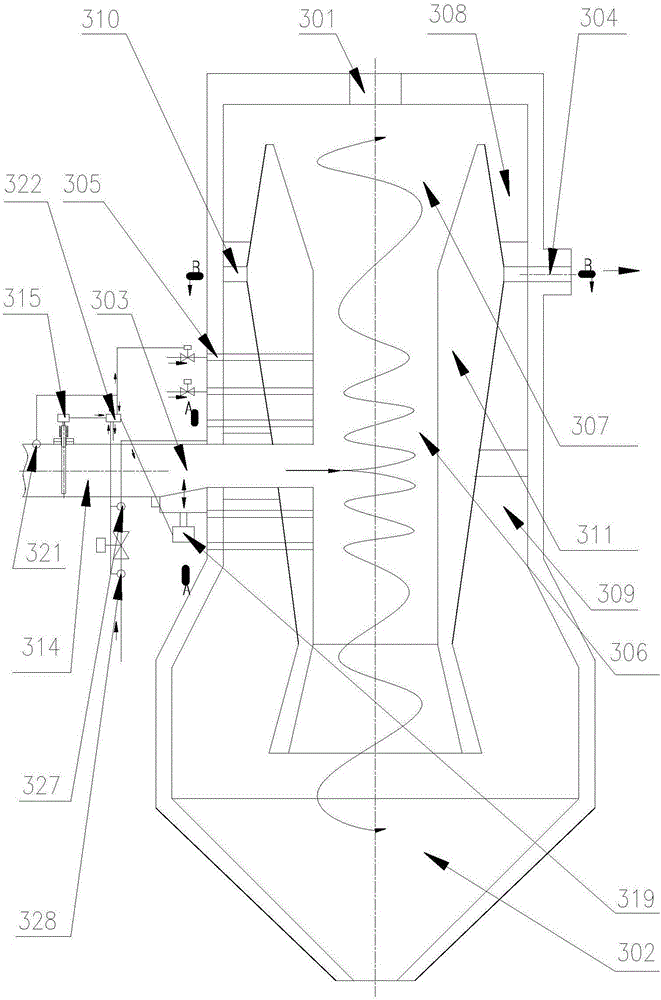

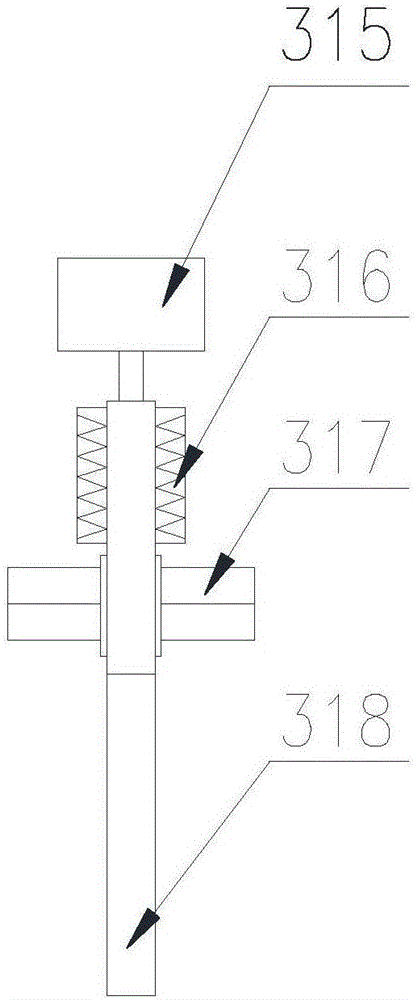

Spiral-flow type fluidized bed incinerator

ActiveCN105090980AEnhanced lateral mixingReduce carbon contentIncinerator apparatusCombustionFluidized bed

The invention discloses a spiral-flow type fluidized bed incinerator which comprises an incinerator body and a cyclone separator. The incinerator body is used for providing combustion space for a fluidized bed, and the cyclone separator is used for recycling insufficiently-combusted ingredients for secondary combustion. At least three layers of secondary air jet orifices are further formed in the walls of the incinerator body and located in a transition zone between a dense-phase zone and a lean-phase zone. The other ends of the secondary air jet orifices are communicated with a secondary air source. The secondary air jet orifices on the same layer are distributed in the walls of the incinerator body. The air flow is spiral so as to enhance transverse mixing of particles and air in the incinerator body and prolong the residence time of the particles in the incinerator body. High-speed secondary air is jetted into the lean-phase zone on the upper portion of an air distribution plate of the circulation fluidized bed incinerator body in a classified manner through wall type tangential firing, so that transverse mixing of particles and air is enhanced, temperature distribution in different areas in the dense-phase zone is more uniform, the combustion efficiency and the desulphurization efficiency are improved, NOx emissions are lowered, the heat transferring is enhanced, and the equipment size is reduced.

Owner:潍坊联荣环保设备有限公司

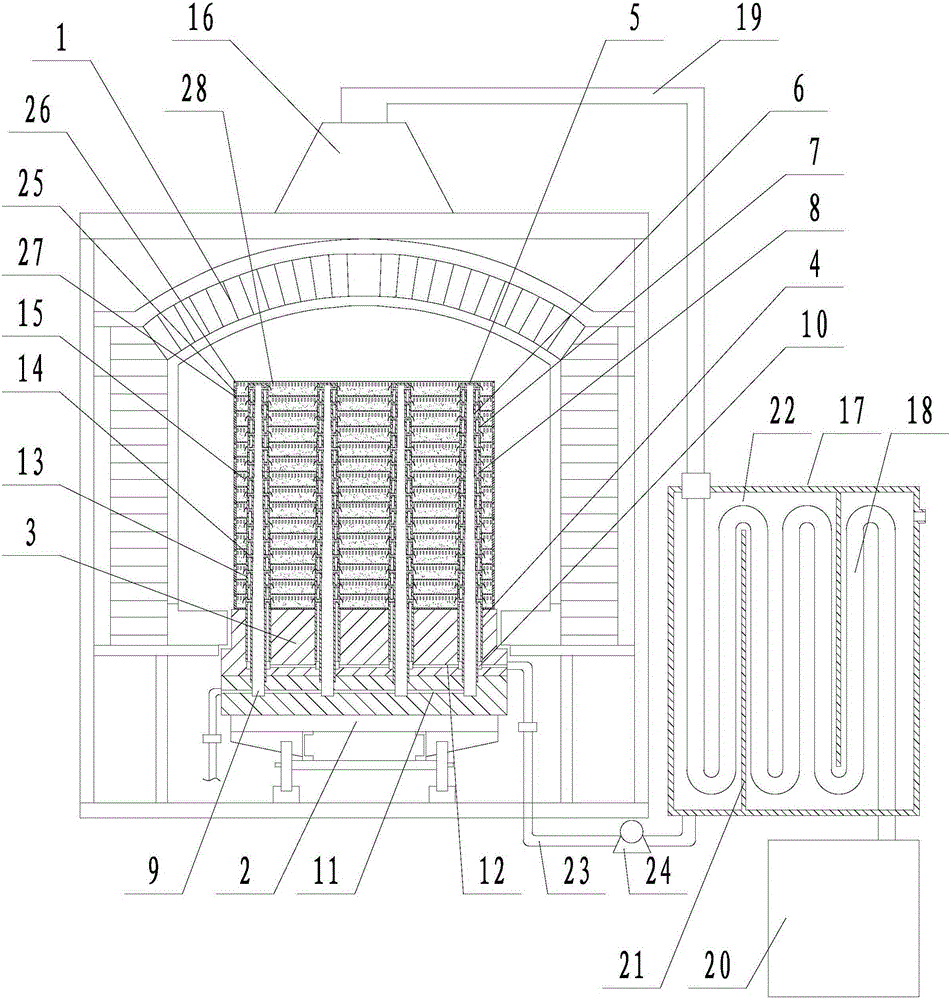

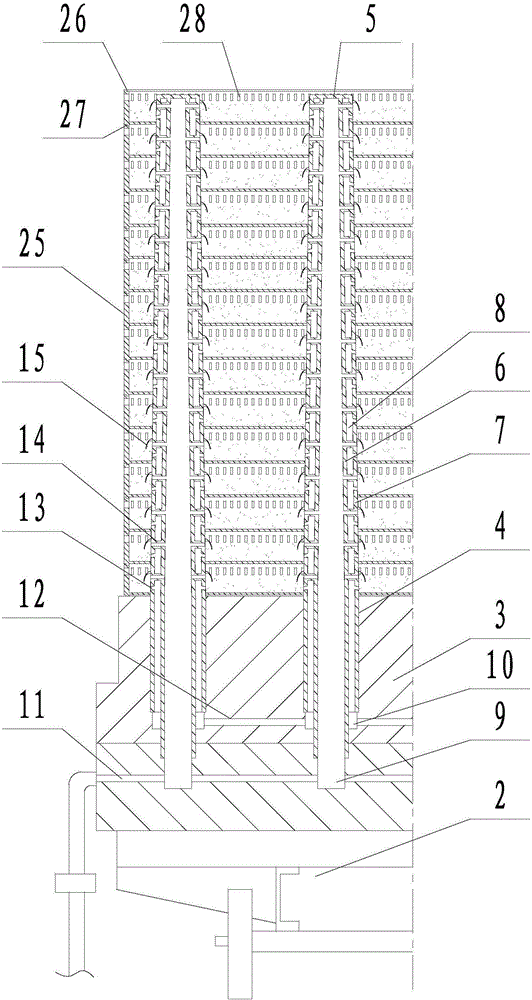

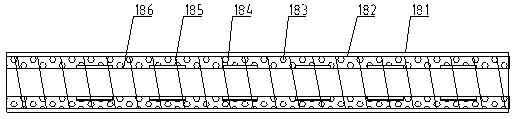

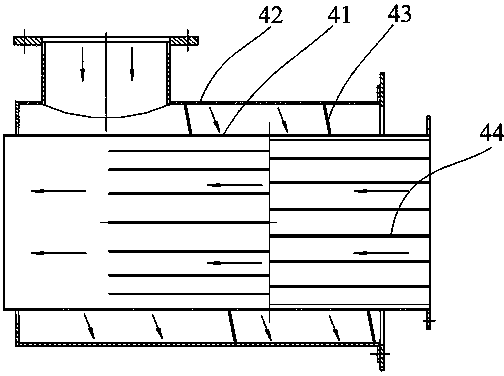

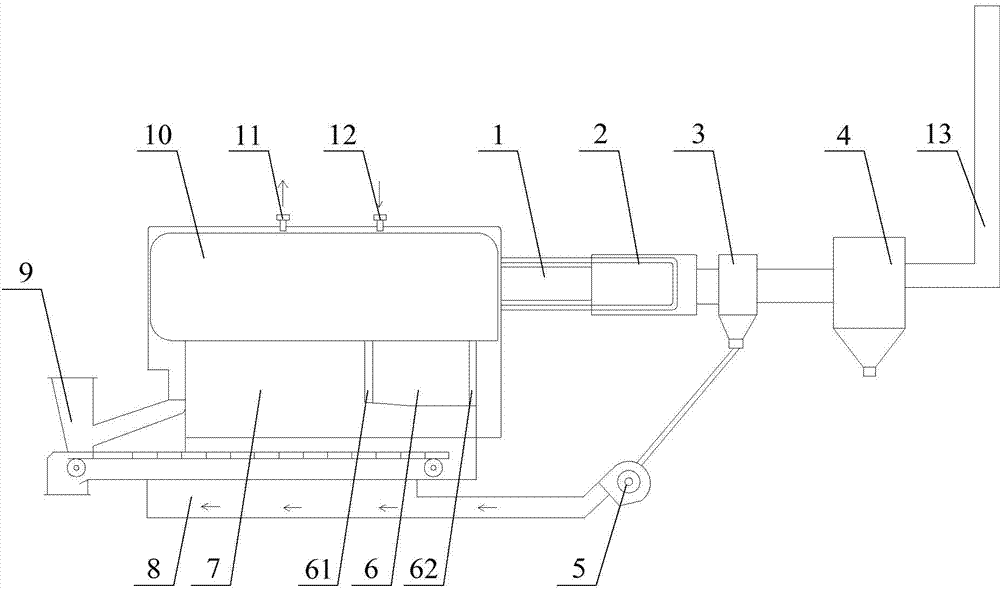

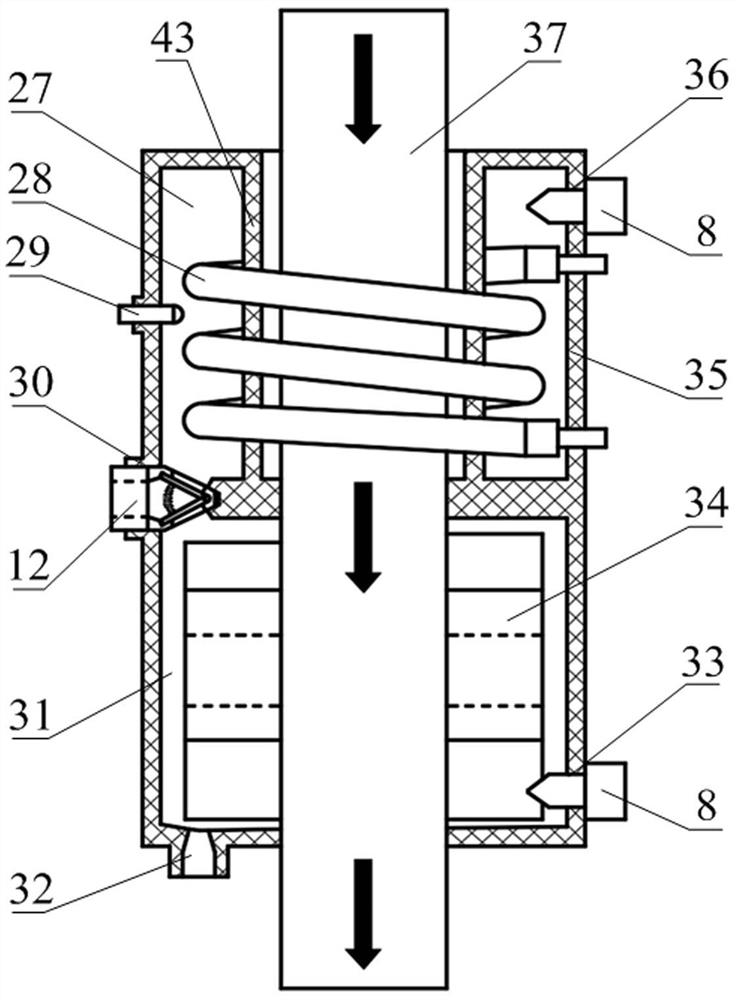

Production technology and device of high-quality calcium oxide

ActiveCN105217974AGuarantee the quality of calcium oxideEvenly heatedLime productionCalciteCalcination

The present invention discloses a production technology and device of high-quality calcium oxide, and is intended to address the deficiencies that the calcium oxide produced after calcination of the existing limestone can be easily mixed with ash, underfiring and overburning are common in the calcining process, and the calcium oxide has lower quality. The process is as below: 1, selecting calcite as the raw material, cleaning and draining; 2, crushing the calcite and sieving calcite particles in similar size for standby; 3, sending the calcite raw material into a shuttle kiln for calcining; 4, taking calcium oxide out of the kiln, cooling calcium oxide to about 400 DEG C, and milling the calcium oxide at a temperature more than 200 DEG C; 5, after milling, sending the calcium oxide immediately into a sealed dry container for cooling, cooling to around 50 DEG C, and packaging immediately, wherein the time interval between taking calcium oxide out of the kiln and packaging is 30 min.

Owner:建德市泰合新材料有限公司

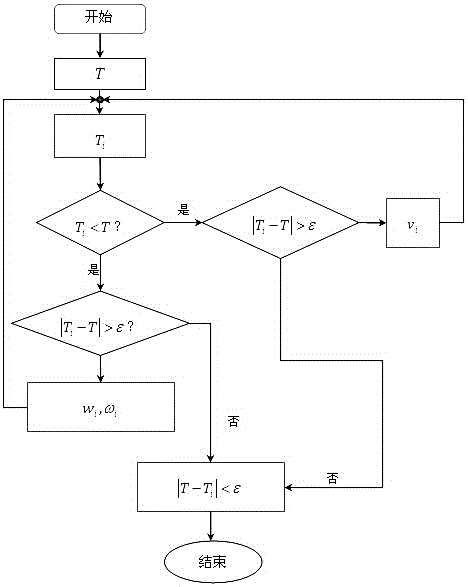

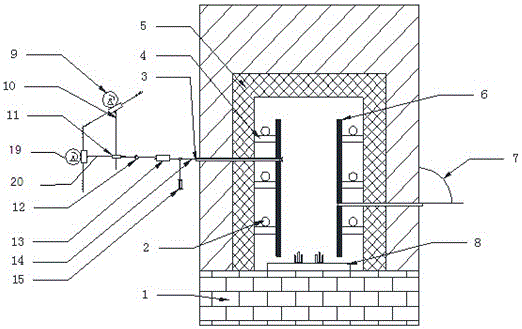

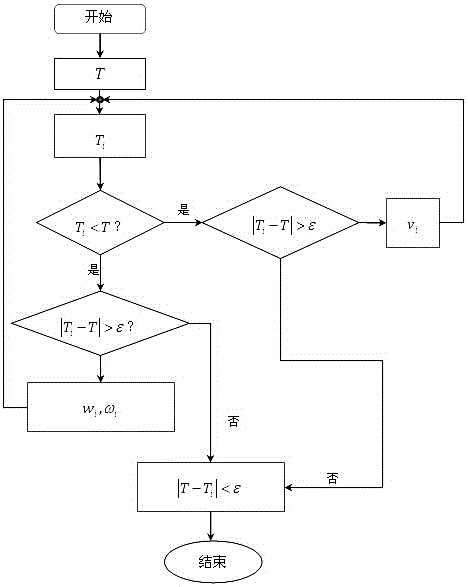

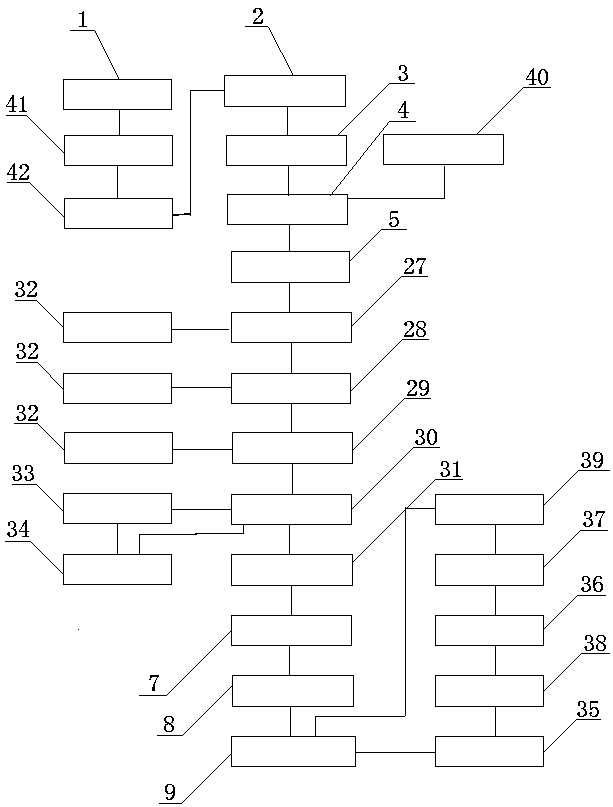

Tunnel kiln environment conditioning method and device of automatically adjusting temperature in kiln

ActiveCN106444914AImprove intelligenceGood energy saving effectTemperatue controlTunnel kilnEngineering

The invention discloses a tunnel kiln environment conditioning method and a device of automatically adjusting the temperature in a kiln. The tunnel kiln environment conditioning method includes the following steps: S1, environmental information acquisition equipment is arranged in a tunnel kiln, wherein the environmental information acquisition equipment is used for acquiring environmental parameters of the environment to be conditioned in the tunnel kiln and sending the environmental parameters to a controller; S2, the controller generates an environment conditioning command according to the environmental parameters acquired by the environmental information acquisition equipment, and sends the environment conditioning command to an environment conditioning execution mechanism; and S3, the environment conditioning execution mechanism conditions the environment in the tunnel kiln according to the environment conditioning command sent from the controller. The tunnel kiln environment conditioning method can control the angle of a temperature adjustment burner, the combustion gas injection rate, the angular rate of the temperature adjustment burner, the kiln tail blast rate, and the like, of the tunnel kiln, and can perform sintering research on various refractory materials, thus increasing diversity of research.

Owner:YANCHENG INST OF TECH

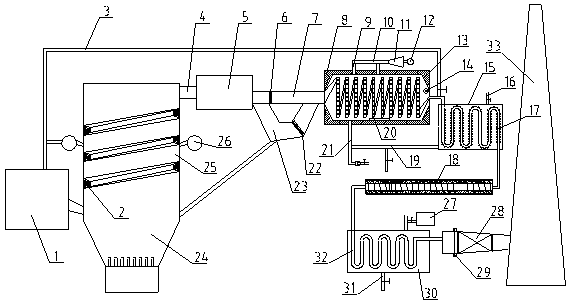

Smoke purifying and waste heat utilizing system of waste incineration power plant

ActiveCN109395496AIncrease temperatureLow costGas treatmentDispersed particle filtrationDecomposerWaste heat recovery unit

The invention discloses a smoke purifying and waste heat utilizing system of a waste incineration power plant. The smoke purifying and waste heat utilizing system comprises an incinerator body, a steam turbine, a power generator, a smoke purifying treatment device and a smoke discharge chimney. The smoke purifying treatment device comprises a pipeline combustor, a steam generator, a waste heat recoverer, a smoke decomposer, a washing tank and an adsorption purifier which are sequentially arranged from a high-temperature smoke outlet and the smoke discharge chimney. The smoke discharge pipe isarranged between the pipeline combustor and the steam generator. A particle collecting pipe is arranged on the lower side of the smoke discharge pip. A spiral smoke pipe is arranged in the steam generator. A heat pipe is arranged in the waste heat recoverer. An outer cylinder, an inner cylinder and a decomposition ball are arranged in the smoke decomposer. An inner electrode is arranged on the inner side of the inner cylinder. An outer electrode is wound on the outer surface of the outer cylinder. A washing pipe is arranged in the washing tank. The adsorption purifier is filled with adsorptionfiller. By means of the system, the combustion state is improved, combustion efficiency is improved, the dioxin content is reduced, and the waste heat recovery efficiency is improved.

Owner:QUJING YUNDIAN TOUXIN ENERGY POWER GENERATION

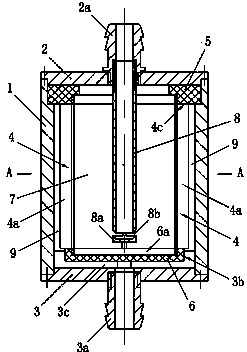

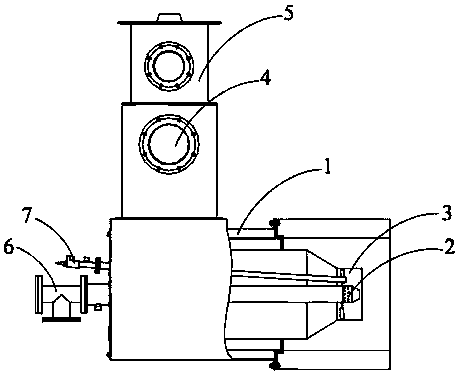

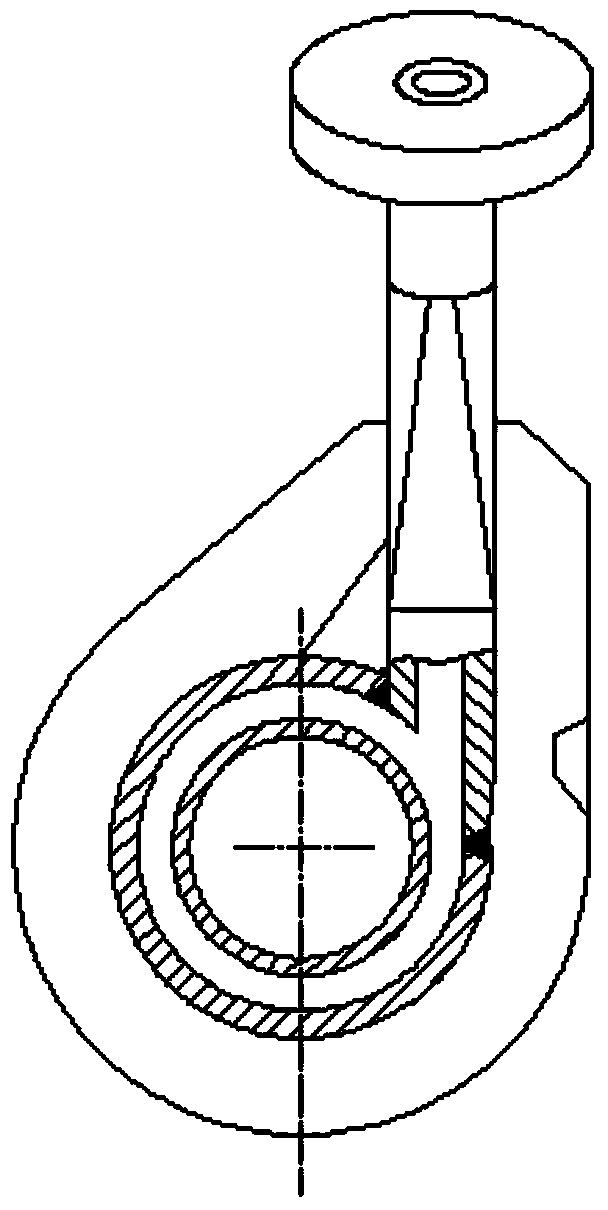

Fuel activation device

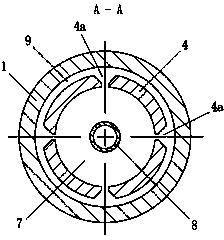

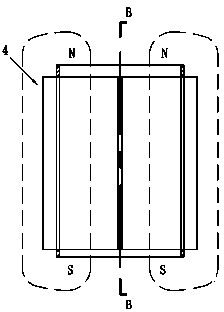

ActiveCN103821639APromoting and intensifying activityHigh activityInternal combustion piston enginesCombustion-air/fuel-air treatmentJet flowMagnet

Disclosed is a fuel activation device. A fuel inlet joint is formed in a first end cover (2) at one end of a shell body (1), an oil outlet joint is formed in a second end cover (3) at the other end of the shell body (1), a sealing ring (5) is arranged at the upper end of a permanent magnet cylinder (4) inside the shell body, a sealing plate (6) is arranged at the lower end of the permanent magnet cylinder (4) inside the shell body, a jet pipe (8) connected to the first end cover (2) is arranged in a fuel flow area (7), a plurality of jet flow holes (8b) are formed in the end in the jet pipe, and a fuel flow channel (9) is formed between the outer wall face of the permanent magnet cylinder and the inner wall face of the shell body. A plurality of V-shaped grooves (4a) are formed in the wall of the permanent magnet cylinder, a first groove (3b) matched with the sealing plate (6) is formed in the inner wall face of the second end cover, and a radial fuel channel (3c) communicated with the fuel flow channel (9) is formed in the wall body. The magnetic field intensity of the permanent magnet cylinder (4) is the intensity of a gradient magnetic field which is changed in a gradient mode along the axis of the permanent magnet cylinder. The fuel activation device has the advantages of improving the fuel magnetization effect, enhancing the activation and kinetic energy of the fuel, saving the fuel, reducing pollutants in exhausted gas and the like.

Owner:HUNAN JINANCHANG TECH

Grading fuel gas low-nitrogen burner

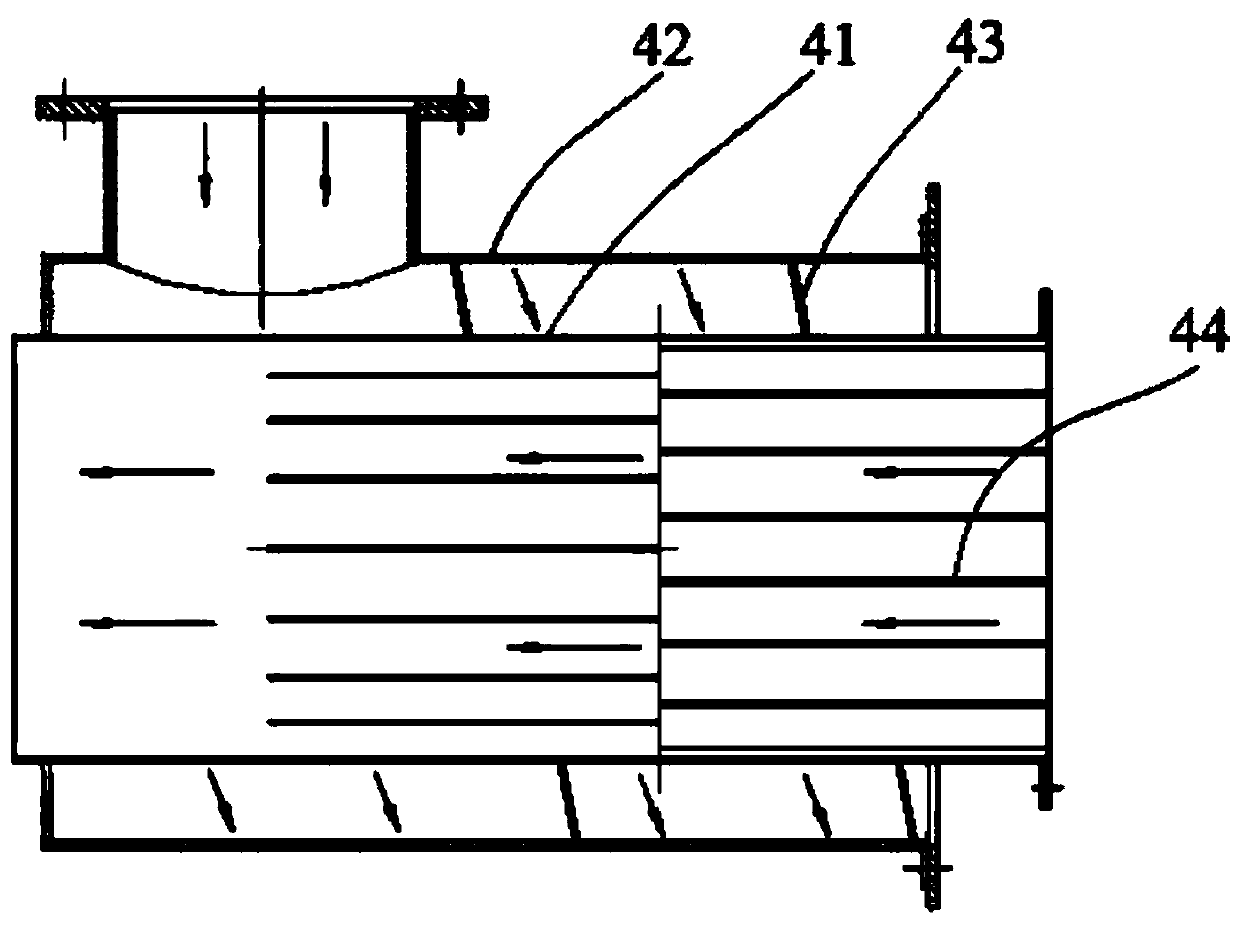

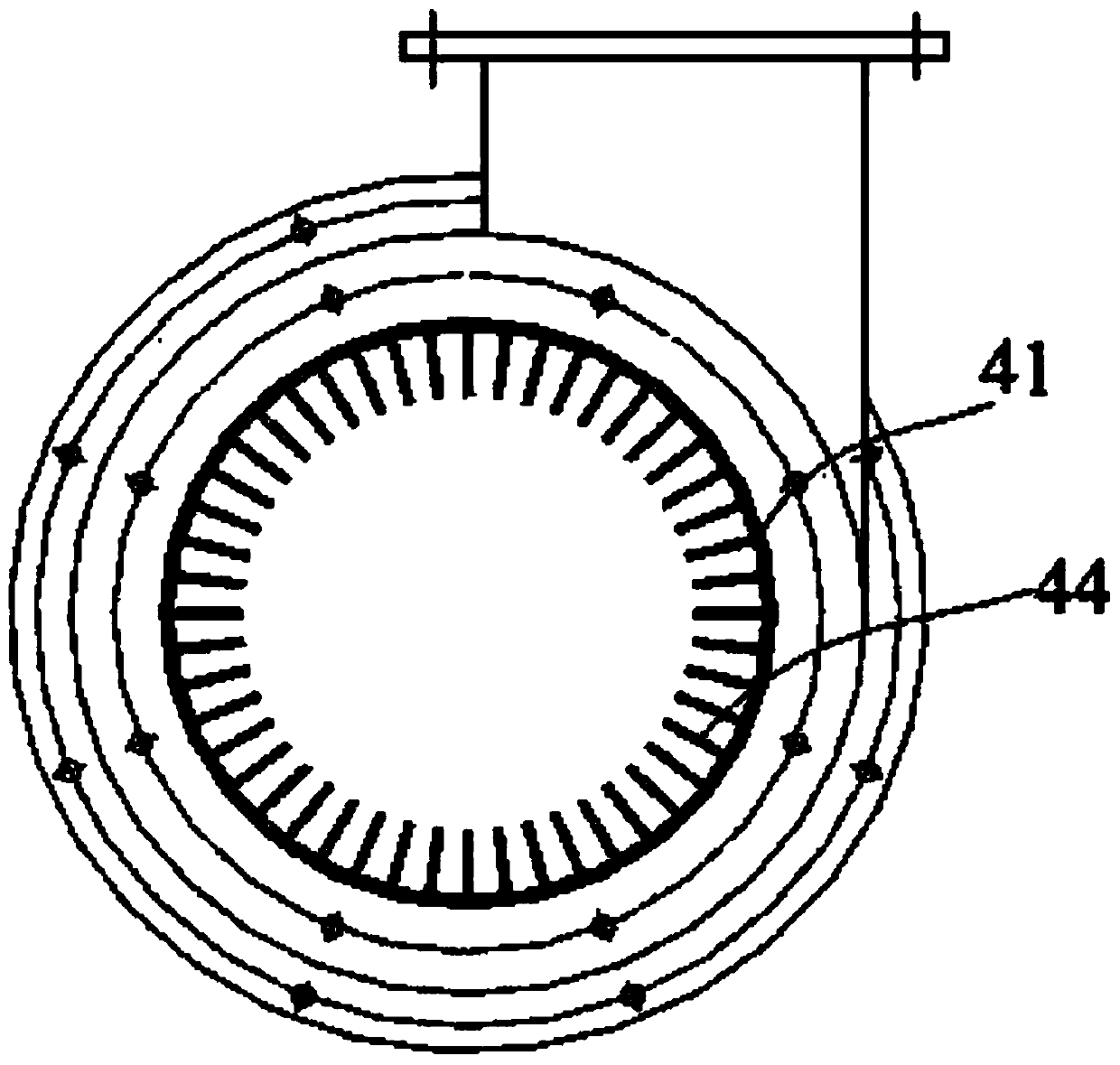

The invention discloses a grading fuel gas low-nitrogen burner and relates to the technical field of burners. The grading fuel gas low-nitrogen burner comprises a grading fuel gas distributor. The grading fuel gas distributor comprises a distributor body, multiple grading fuel spraying pipes and a burner barrel body. The distributor body is a barrel body with an interlayer. Multiple fuel distribution cavities arranged at intervals are formed on the top of the interlayer. The multiple grading fuel spraying pipes and the multiple fuel distribution cavities are in one-to-one correspondence and butt connection. Each fuel distribution cavity and the corresponding grading fuel spraying pipe form a corresponding fuel gas flow path. Fuel gas flows in the corresponding fuel gas flow paths and sprayed out of the corresponding grading fuel spraying pipes in a grading mode. The burner barrel body is formed outside the grading fuel gas distributor and used for providing a mixing and burning site for fuel gas and air. The distributor is provided with the multiple grading fuel spraying pipes to evenly spray out and burn fuel gas in a grading mode, the NOx emission is effectively reduced, and current environmental requirements are met.

Owner:北京水木清源环保科技有限公司

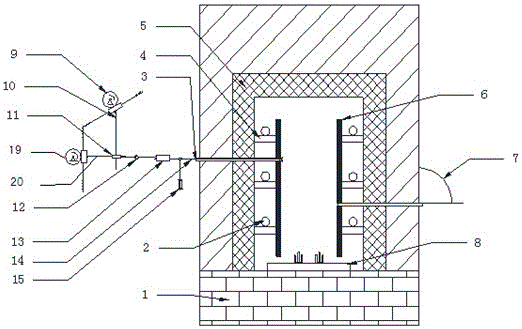

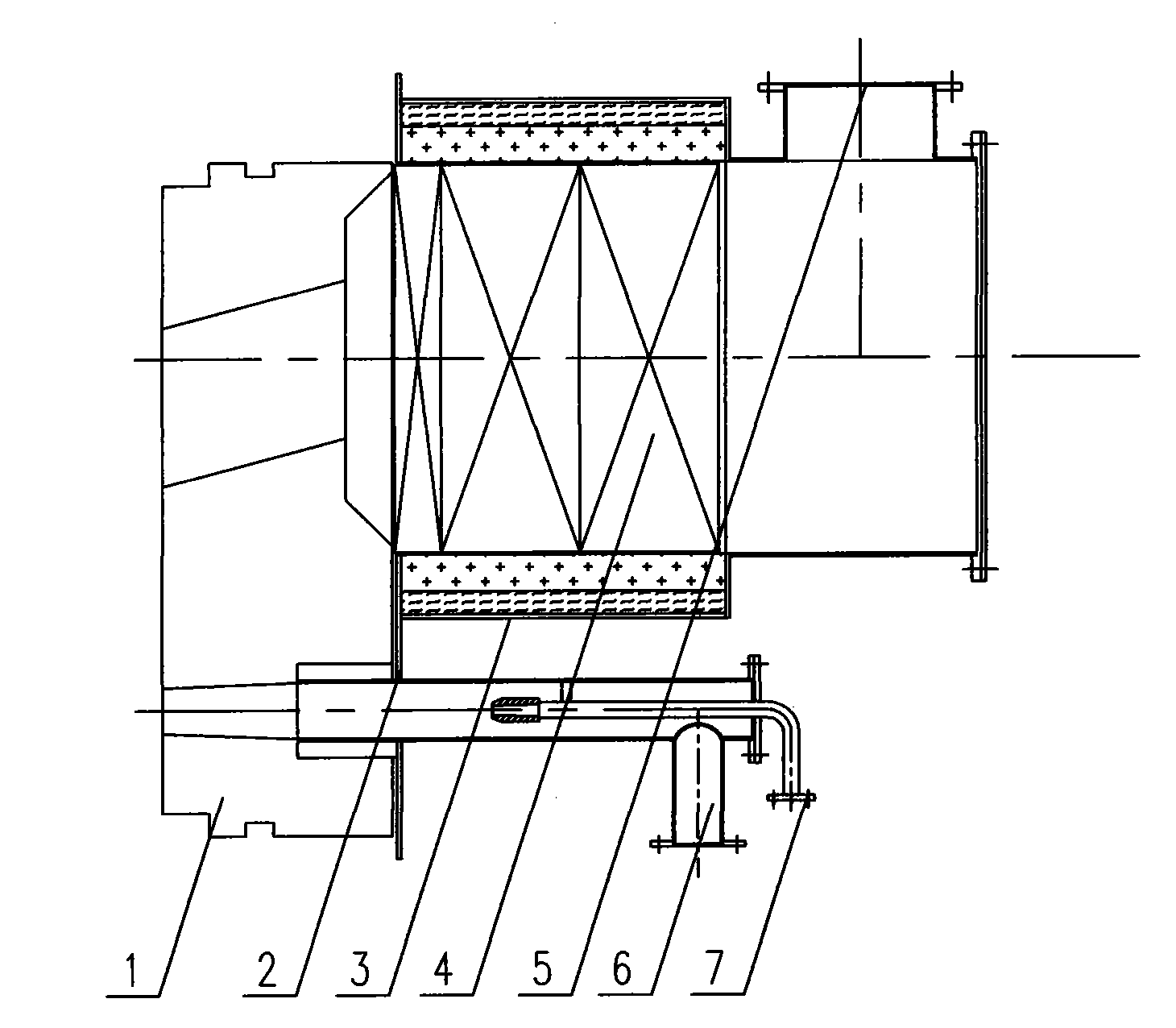

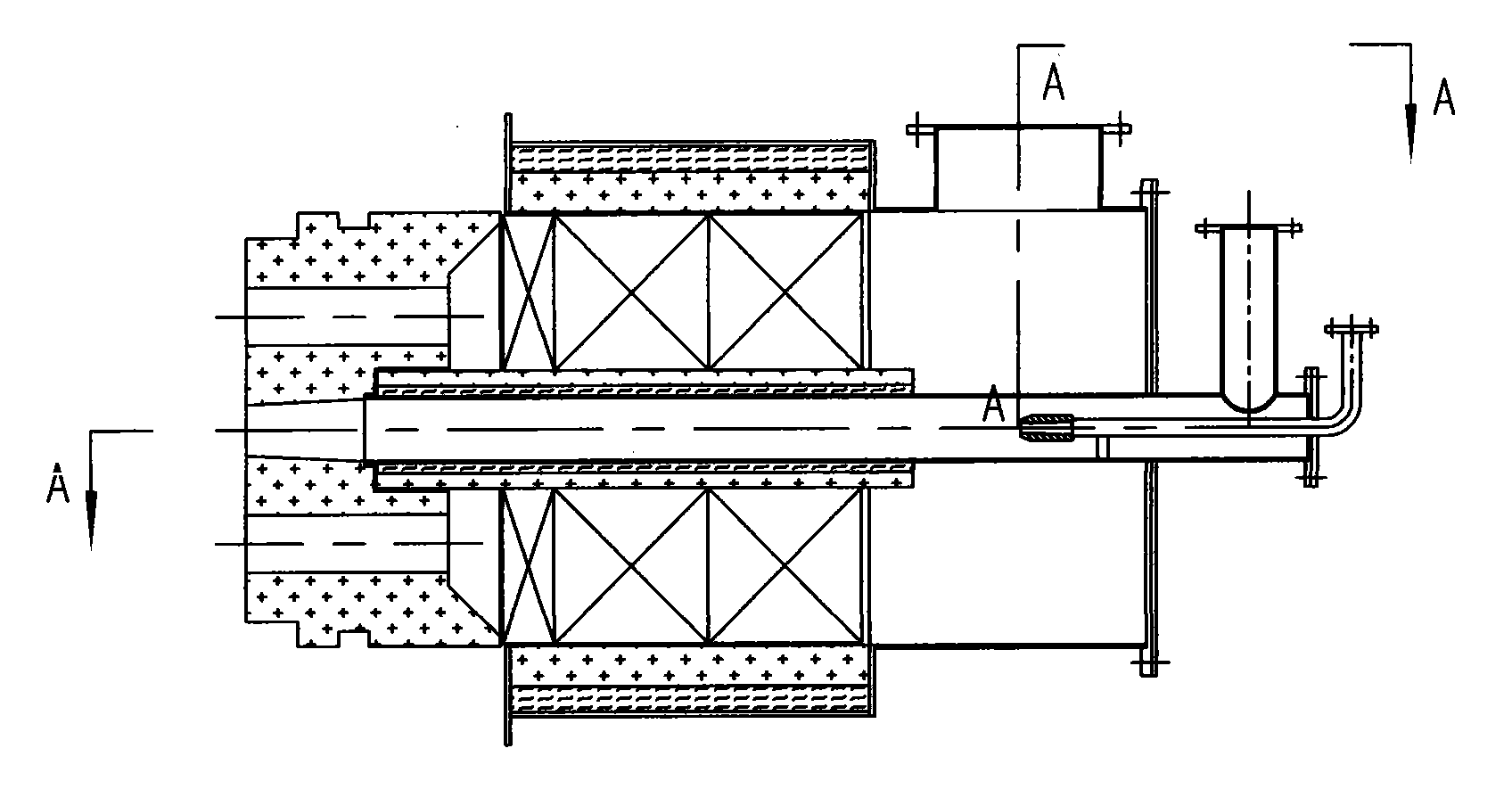

Air single regenerative burner

InactiveCN101799158APrevent backfireImprove securityIndirect carbon-dioxide mitigationGaseous fuel burnerBrickHearth

The invention discloses an air single regenerative burner, which comprises a burner brick (1) and a burner mounting plate (2). A burner shell (3) is arranged on the burner mounting plate (2); a heat accumulator (4) is arranged in the burner shell (3); a secondary air pipeline (5) leading to a hearth is arranged on the burner shell (3); a gas pipeline (6) is arranged outside the burner shell (3); the tail end of the gas pipeline (6) is inserted into the burner brick (1); a primary air pipeline (7) is arranged in the gas pipeline (6); and the gas pipeline (6) and the primary air pipeline (7) can also be arranged in the burner shell (3). The air single regenerative burner of the invention can fully burn fuel in industrial furnaces and kilns so as to reduce the generation of NOX, save energy and protect environment, can effectively prevent backfire in the gas pipeline and has good safety.

Owner:HUATIAN ENG & TECH CORP MCC +1

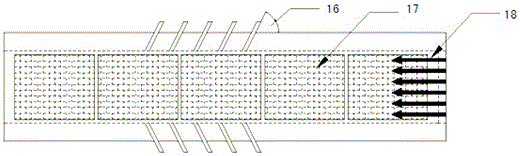

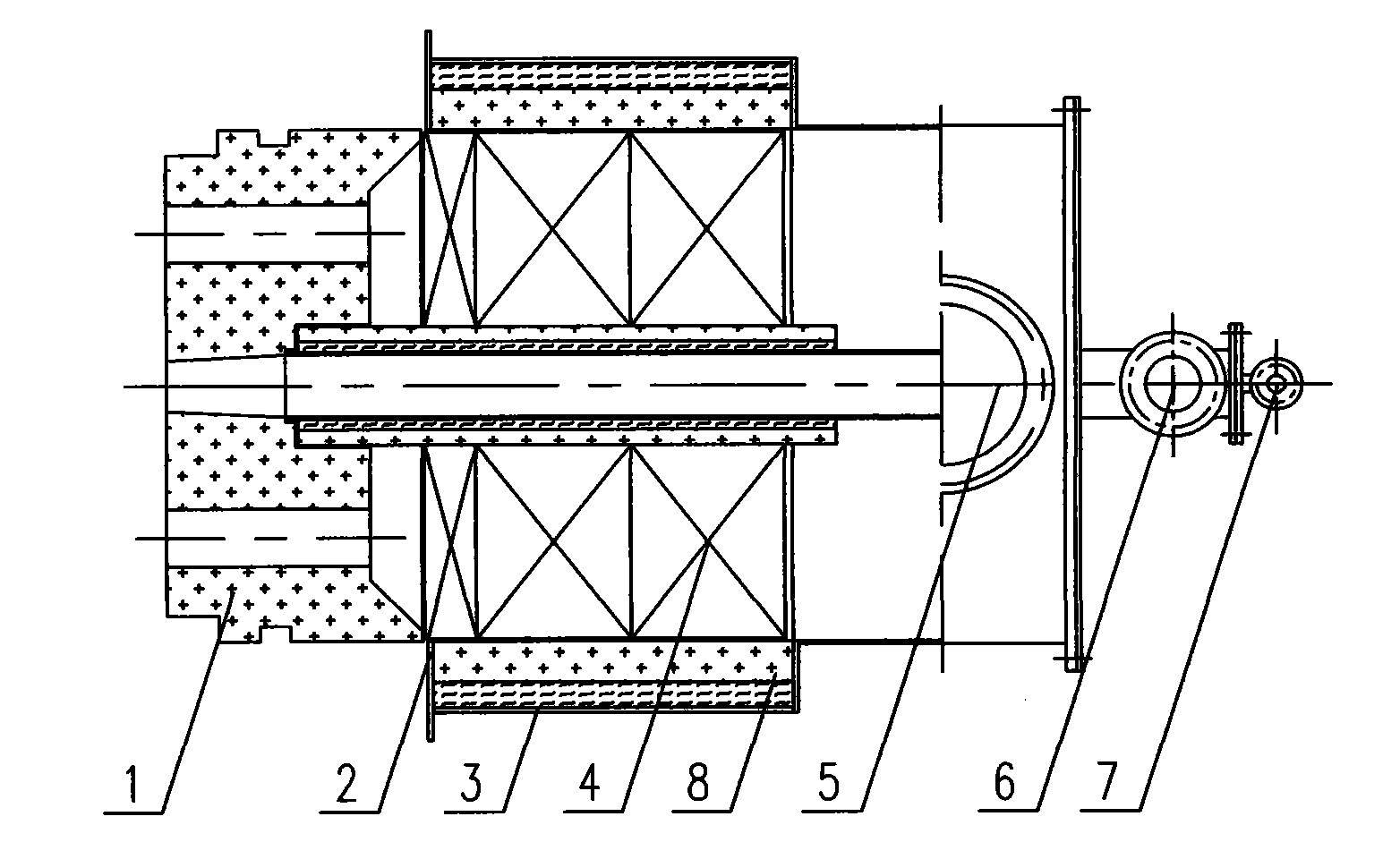

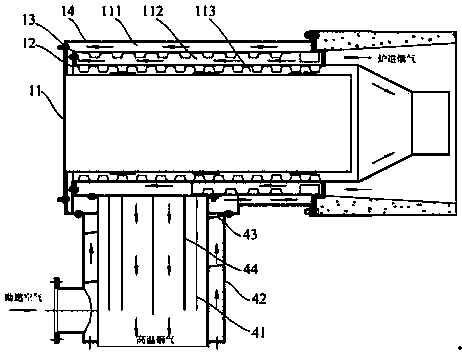

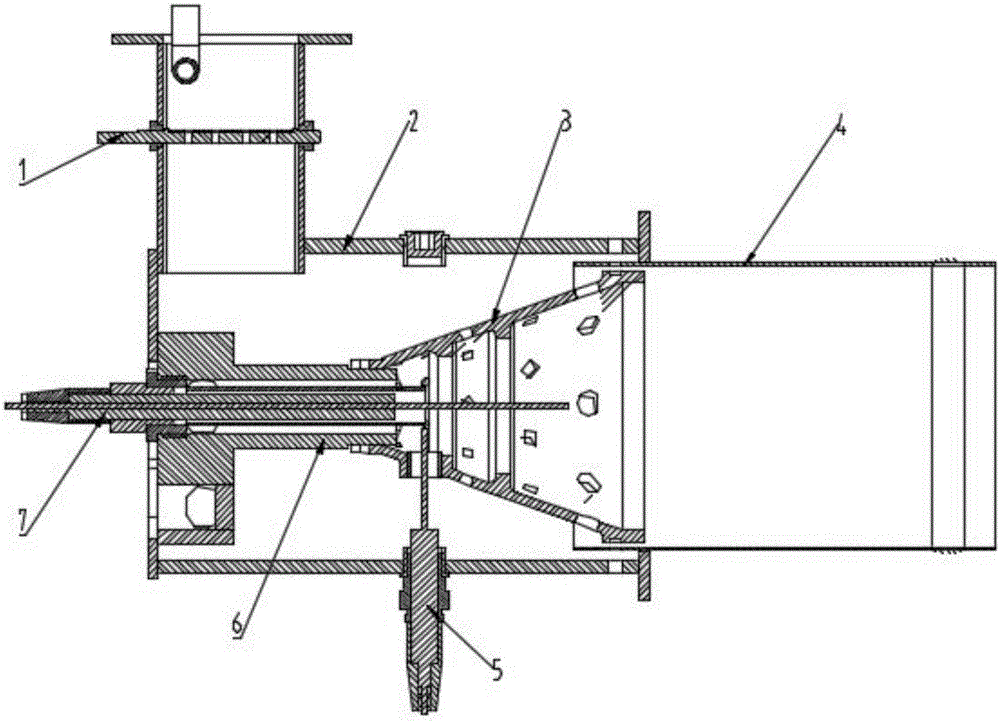

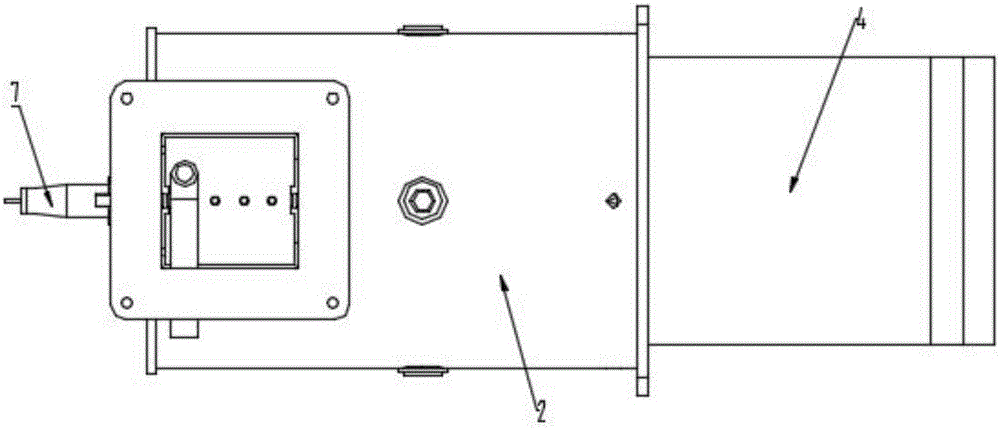

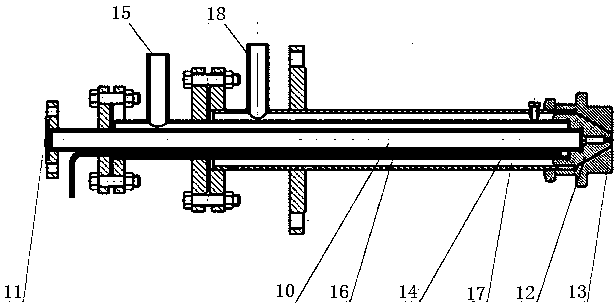

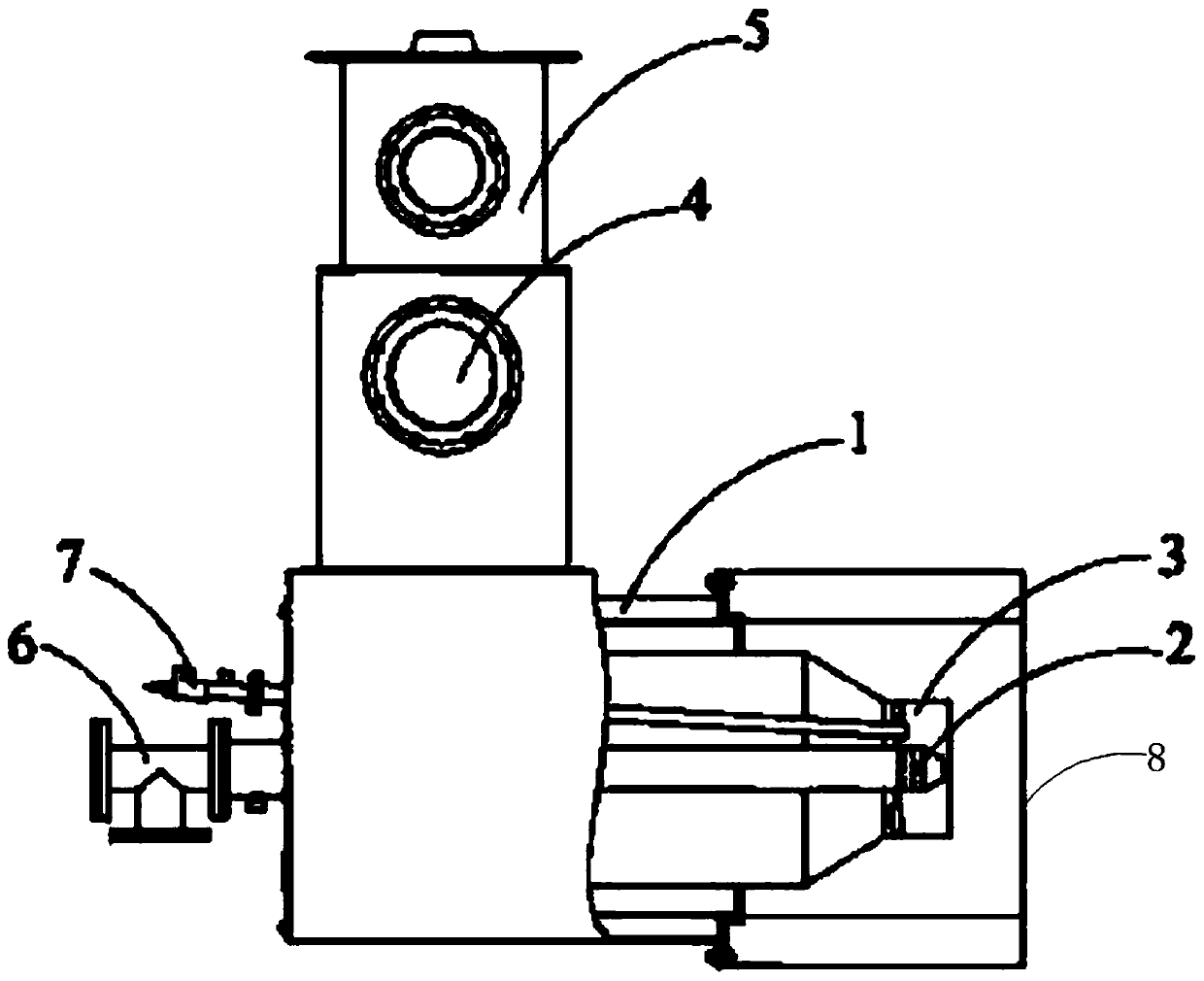

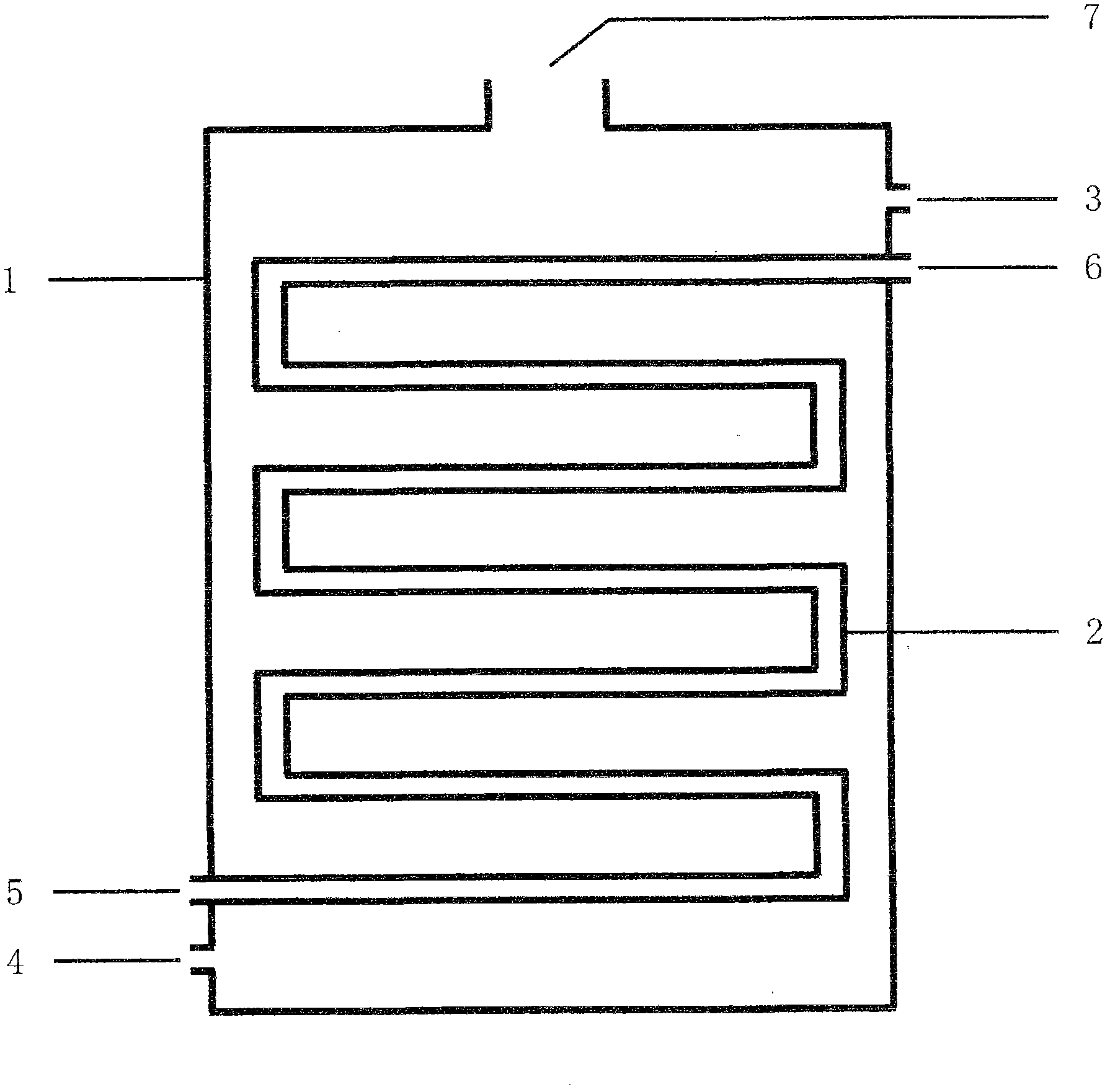

High-power heat exchange burner for industry kiln stove

ActiveCN104033902AIncrease the heat exchange areaImprove heat transfer efficiencyIndirect carbon-dioxide mitigationGaseous fuel burnerExhaust gasProducer gas

The invention discloses a high-power heat exchange burner for an industry kiln stove. The high-power heat exchange burner for the industry kiln stove is characterized by being mainly composed of a heat exchanger (1), an air inlet pipe (4), a combustor (3), a mixer (2) and a main gun (6), the heat exchanger (1) is provided with an air channel and an exhaust gas channel, the air inlet pipe (4) is arranged on the heat exchanger (1) and communicated with the air channel of the heat exchanger (1), the combustor (3) is communicated with the air channel of the heat exchanger (1) and the air inlet pipe (4), the mixer (2) is arranged in the combustor (3), and the main gun (6) is communicated with the mixer (2) and used for conveying fuel gas. The heat exchanger and the burner are integrated, the high-power heat exchange burner is suitable for fuel media such as natural gas, coke oven gas and producer gas, preheated combustion air and fuel gas can be fully mixed and burnt in the combustor after being mixed, and the maximum burning power reaches 4000 KW and is more than twice that of a traditional burner.

Owner:SICHUAN HUASUO AUTOMATION INFORMATION ENGCO

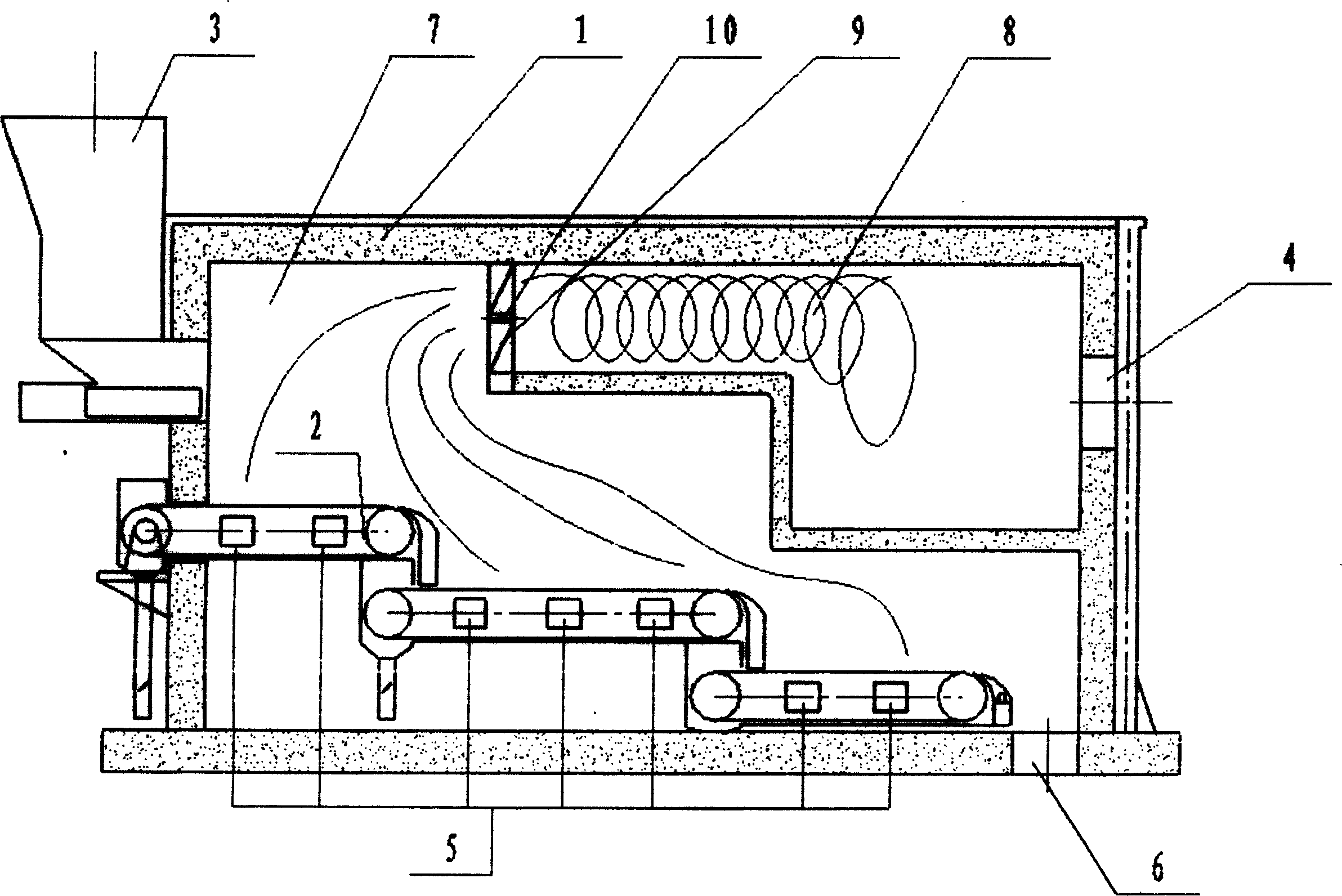

Life refuse incinerator

The domestic refuse incinerator includes incinerator body and fire grate assembly. The incinerator body has refuse inlet and smoke outlet in the upper part, air inlet and slag outlet in the lower part, and hearth divided into the first combustor and the second combustor. The incinerator has fire grate assembly inside the first combustor and divided into three stepped parts, the second combustor in the top front of the first combustor, smoke inlet in the back of the first combustor and smoke outlet in the front of the second combustor, cyclonic unit installed inside the second combustor for the fume to burn spirally and fully inside the second combustor for over 2 sec.

Owner:徐万禄

Device with annular cold air low-heat-storage quick start ignition and combustion system

InactiveCN103438443AReduce heat storage capacityFully mixed combustionFluidized bed combustionCombustion ignitionCold airCombustion system

The invention relates to a device with an annular cold air low-heat-storage quick start ignition and combustion system. The device is characterized in that an ignition and combustion device is composed of a combustor body and an ignition device of which an ignition end extends into the combustor body, wherein the ignition and combustion device is arranged in a combustion air duct; the combustion air duct is connected with an air supplementing duct and an air distribution duct; the air supplementing duct is provided with an adjusting damper; a communicating chamber is provided with an expansion joint; a thermal fire-proof layer is arranged outside the device with the annular cold air low-heat-storage quick start ignition and combustion system. In an ignition starting process of a boiler, primary hot air volumes of the air supplementing duct and the air distribution duct are adjusted through the adjusting damper, so that hot air and fuel are fully mixed and combusted and the combustion efficiency is improved; the purposes of low oil consumption and quick start of a circulating fluidized bed boiler are reached by reducing the lengths of the ducts, reducing the using amount of the thermal fire-proof material and reducing the heat storage capacity of the ducts.

Owner:鞍山锅炉厂有限公司

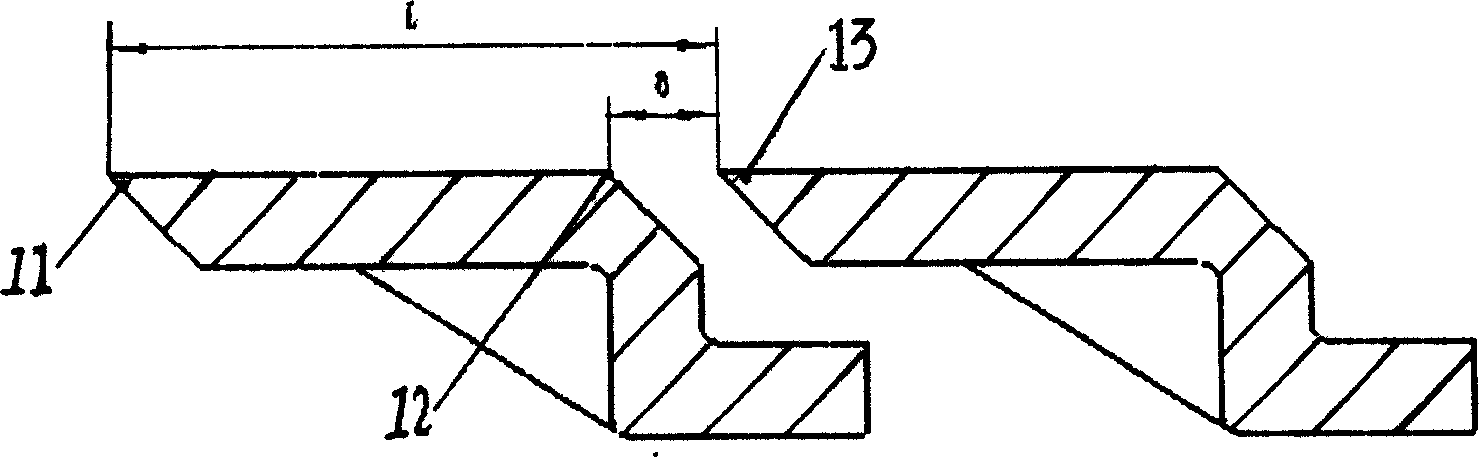

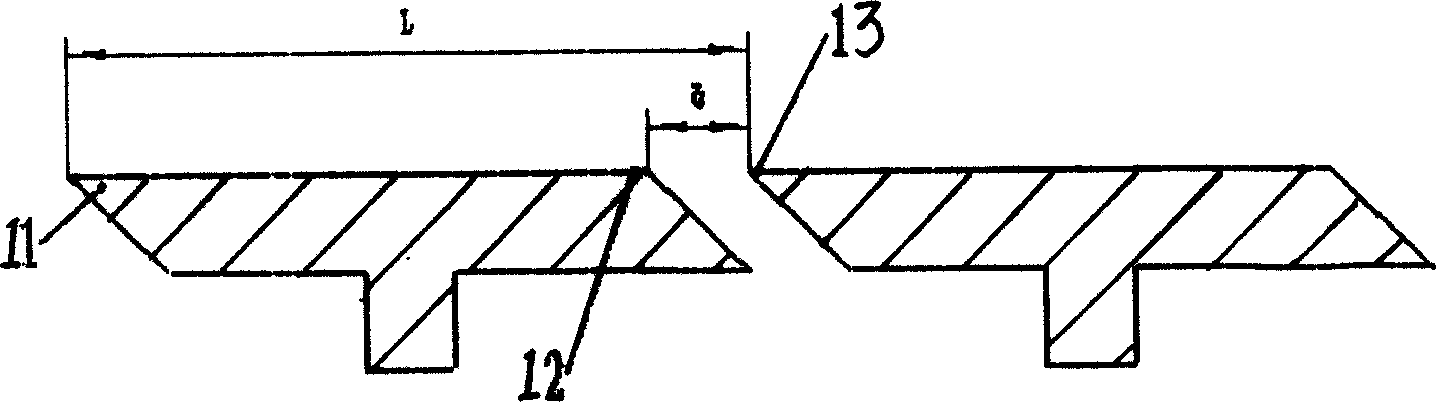

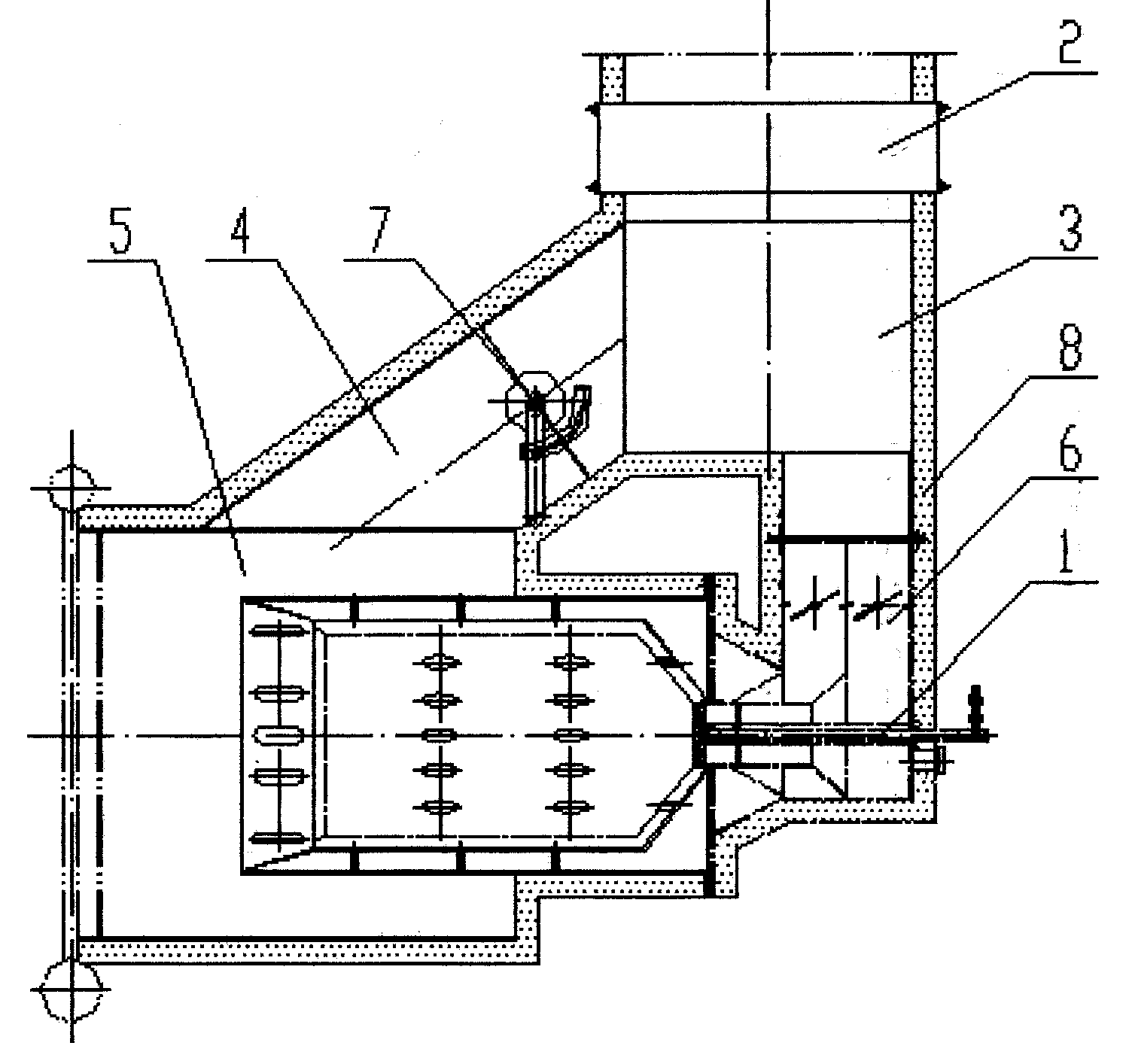

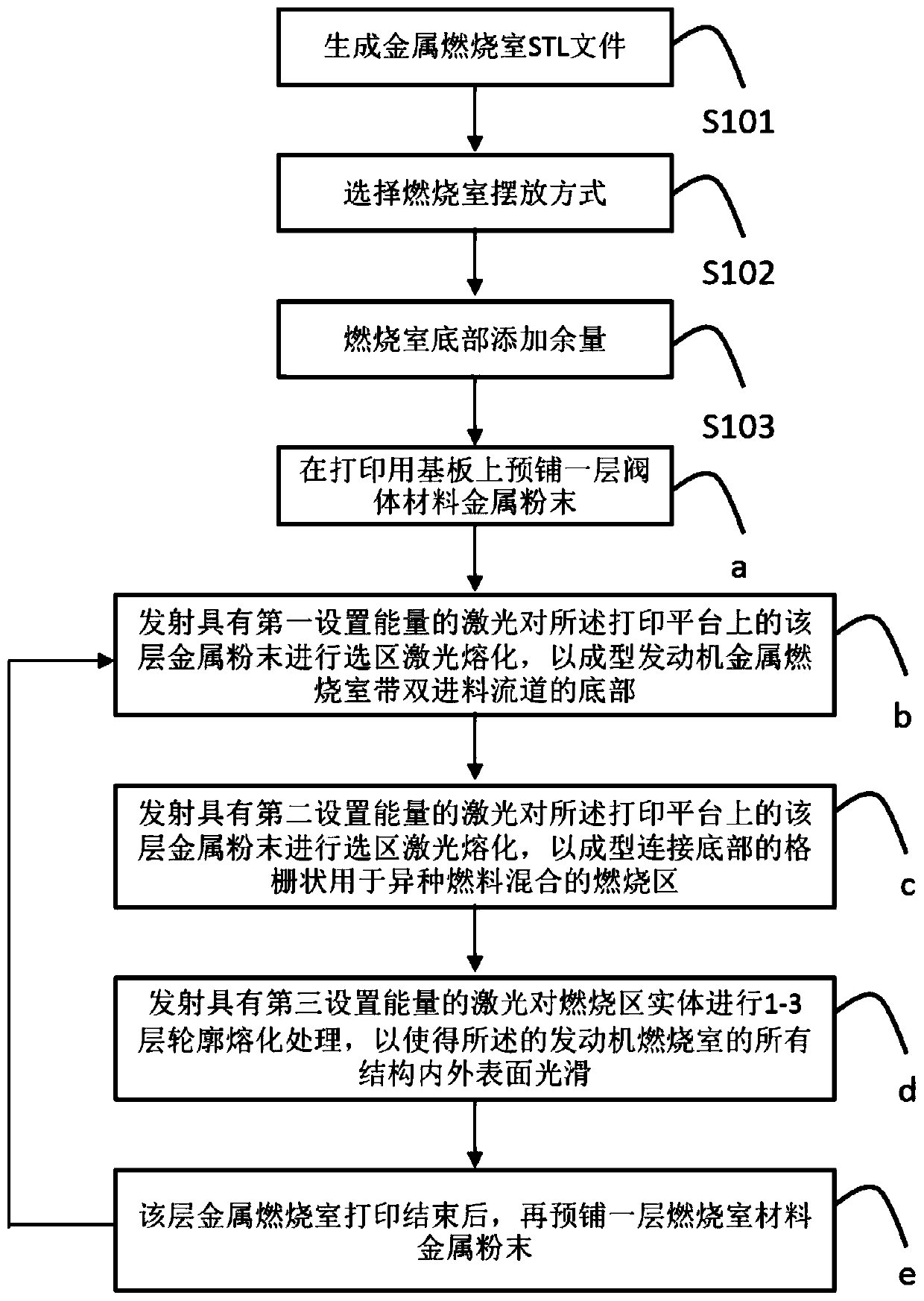

3D printing method for metal combustion chamber of civil rocket engine

ActiveCN110586937AFully mixed combustionAdditive manufacturing apparatusIncreasing energy efficiencyCombustion chamberMetal powder

The invention provides a 3D printing method for a metal combustion chamber of a civil rocket engine. The 3D printing method includes the steps that a, the placement manner of the combustion chamber and the adding margin of the bottom of the combustion chamber are determined, then operation is conducted according to a printing program of a metal combustion chamber part STL file, and a layer of metal powder of an engine combustion chamber material is pre-laid on a base plate used for printing; b, a laser with first set energy is transmitted so that the bottom, with double feeding runners, of themetal combustion chamber of the engine can be formed; c, a laser with second set energy is transmitted, and forming connection of a bottom grid shape is achieved; d, a laser with third set energy istransmitted so that the inner and outer surfaces of all the structures of the combustion chamber of the engine can be smooth; and e, after smelting of a preference zone of the previous layer of metalpowder is over, powder with the same thickness is laid continuously, and operation is conducted continuously according to the sequence till the operation is completed according to the printing programof a metal combustion chamber part STL file. By means of the 3D printing method, the rocket engine combustion chamber better facilitating heterogeneous fuel mixed combustion can be manufactured, andthe inner and outer surfaces of the structures are smooth.

Owner:NANJING ZHONGKE RAYCHAM TECH

Industrial boiler of multi-fuel burning using ultrafine coal dust as main fuel

InactiveCN100447484CImprove combustion efficiencyFully purchasedBurnersCombustion using multiple fuelsCombustionAutomatic control

The invention discloses an industrial boiler for mixed combustion of various fuels mainly based on ultrafine coal powder, which is mainly based on ultrafine coal powder (coal-water slurry) and supplemented by natural gas or oil products , is an industrial boiler with high combustion efficiency, low cost, automatic control, and reduced environmental pollution, especially suitable for small and medium-sized industrial boilers.

Owner:姜政华

Working medium internal combustion heater

ActiveCN103174546AChemical reaction stabilityStable jobHot gas positive displacement engine plantsStable stateChemical reaction

The invention discloses a working medium internal combustion heater which comprises a working medium enveloping space, a jet pump and a combustion chamber, wherein the jet pump is arranged in the working medium enveloping space, and a high-pressure power fluid nozzle on the jet pump is communicated with an oxidizing agent source and / or a reducing agent source. The combustion chamber is arranged at a fluid outlet of the jet pump, or between the fluid outlet of the jet pump and the high-pressure power fluid nozzle of the jet pump, or outside the fluid outlet of the jet pump. By means of the working medium internal combustion heater, fluid jetted into the working medium enveloping space (for example, a space in a reciprocating passageway) is enabled to be mixed (a mixing process is contained and a chemical reaction happens) with fluid in the reciprocating passageway and to stay in a stable state, and therefore the fluid can work stably and react chemically and stably (combust fully in a mixed mode).

Owner:山东沃达纸制品有限公司

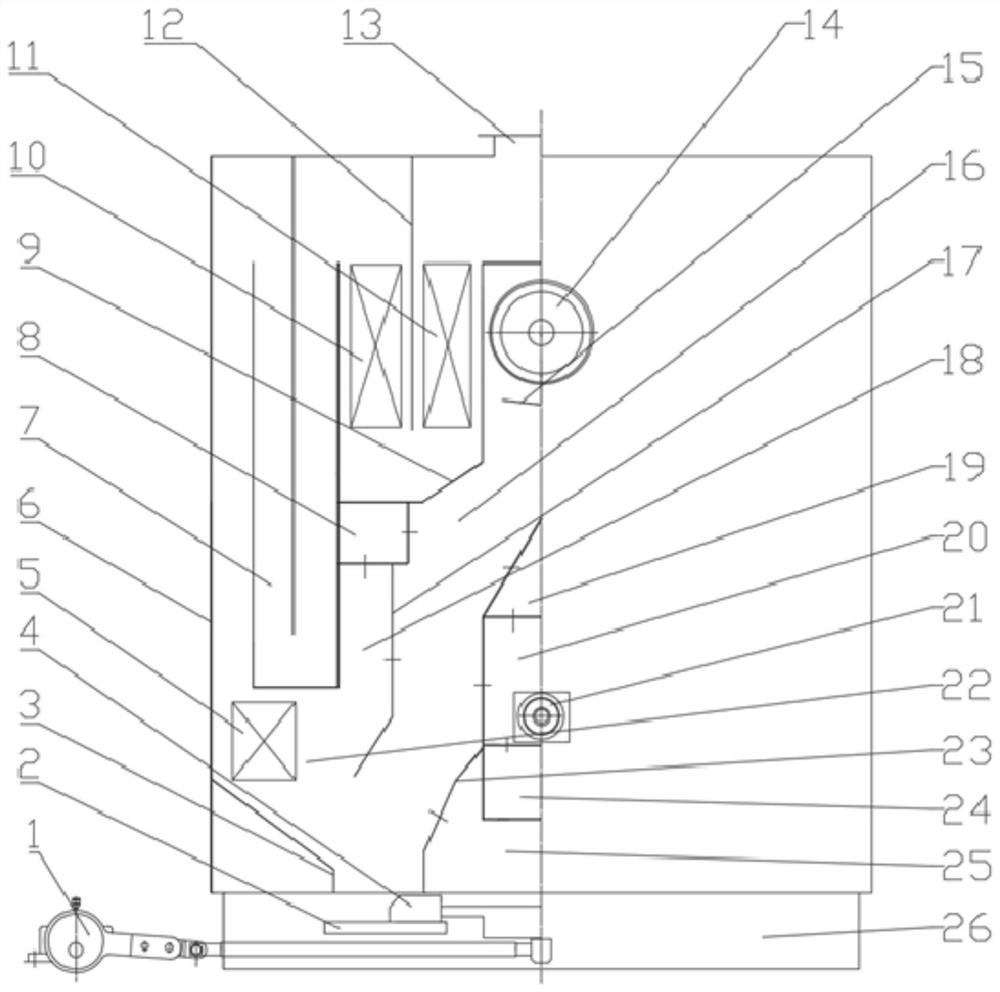

Temperature self-adjusting device for inner tunnel kilns

ActiveCN106440777AIncreased mixed combustion areaReduce generationFurnace typesTunnel kilnReaction rate

The invention discloses a temperature self-adjusting device for inner tunnel kilns. The device comprises a kiln body, a temperature adjustment burner which is installed on the side wall of the kiln body, a blower which is installed at the end part of the kiln body, a temperature sensor which is installed inside the kiln body, a PID controller and a central controller, and a temperature adjustment burner angle adjusting mechanism. The device of the invention can control the angle of the temperature adjustment burner nozzle, the fuel gas injection speed, the speed of temperature adjustment burner nozzle, and the kiln tail blowing rate of the tunnel kiln; sintering researches on various refractory materials can be carried out, which increases the diversity of researches; compared with the original tunnel kilns, the accuracy of temperature adjustment is increased, the efficiency is increased, the reaction rate of execution mechanism is faster, the automatic degree is higher with less pollution, and environmental protection and energy saving performance are improved.

Owner:YANCHENG INST OF TECH

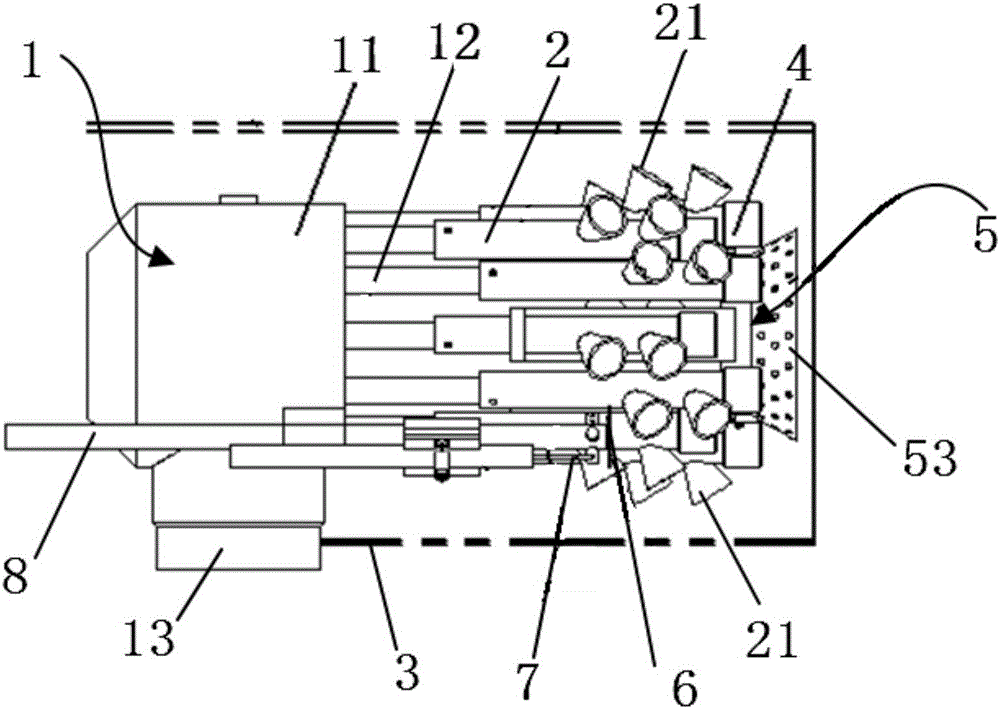

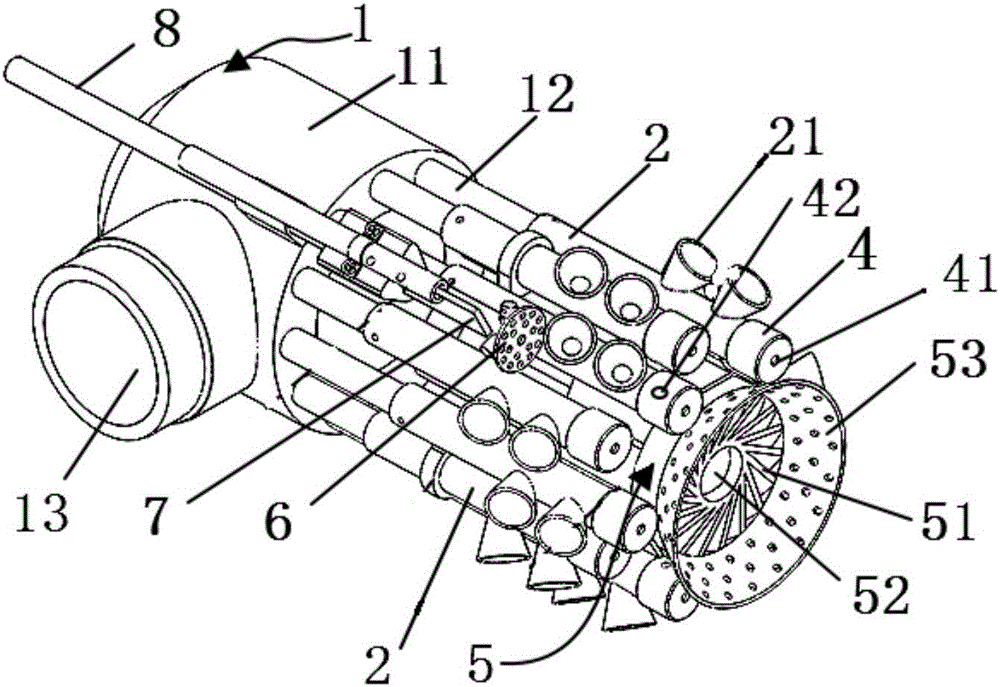

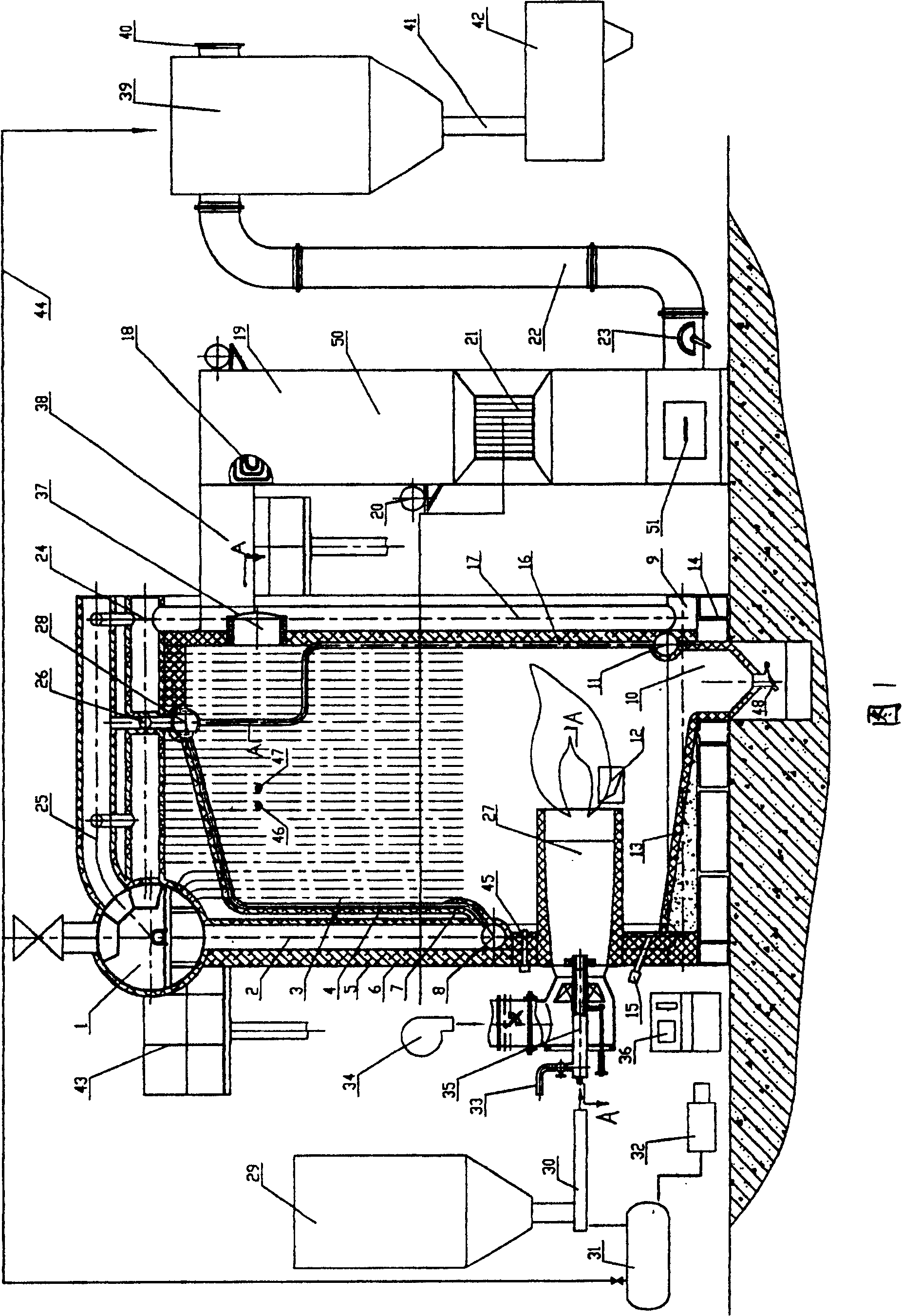

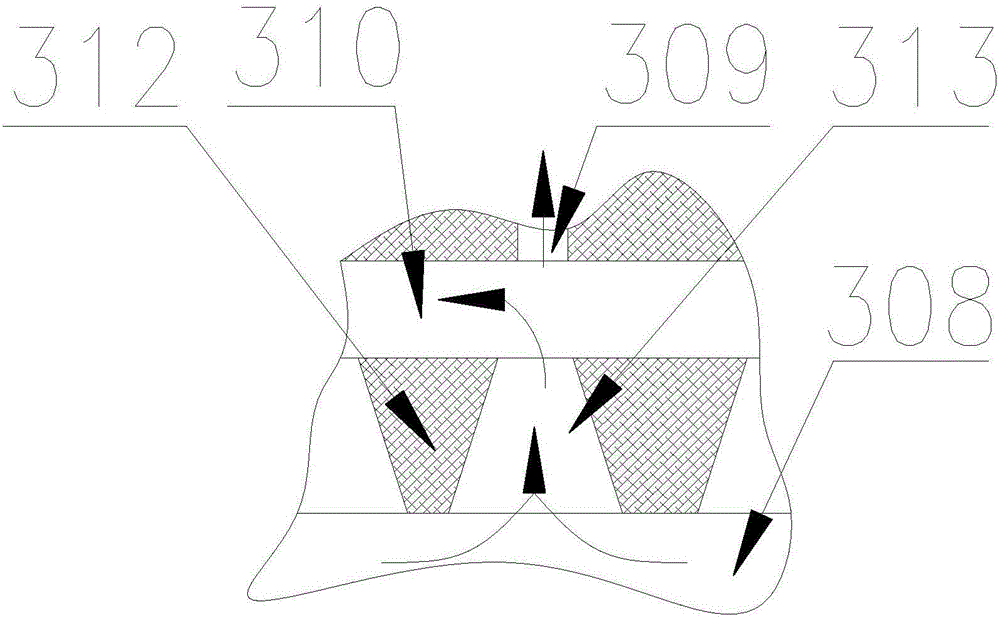

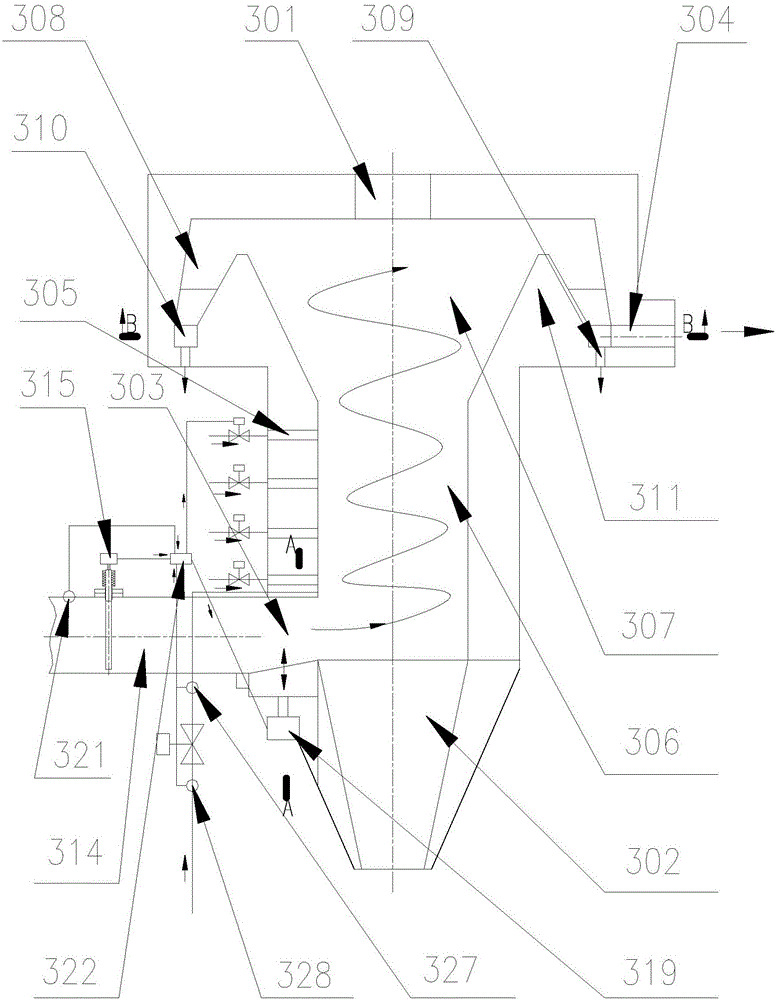

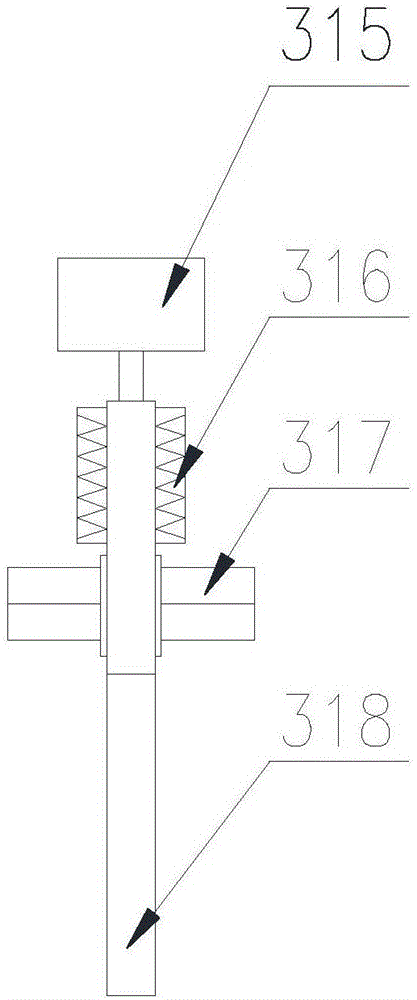

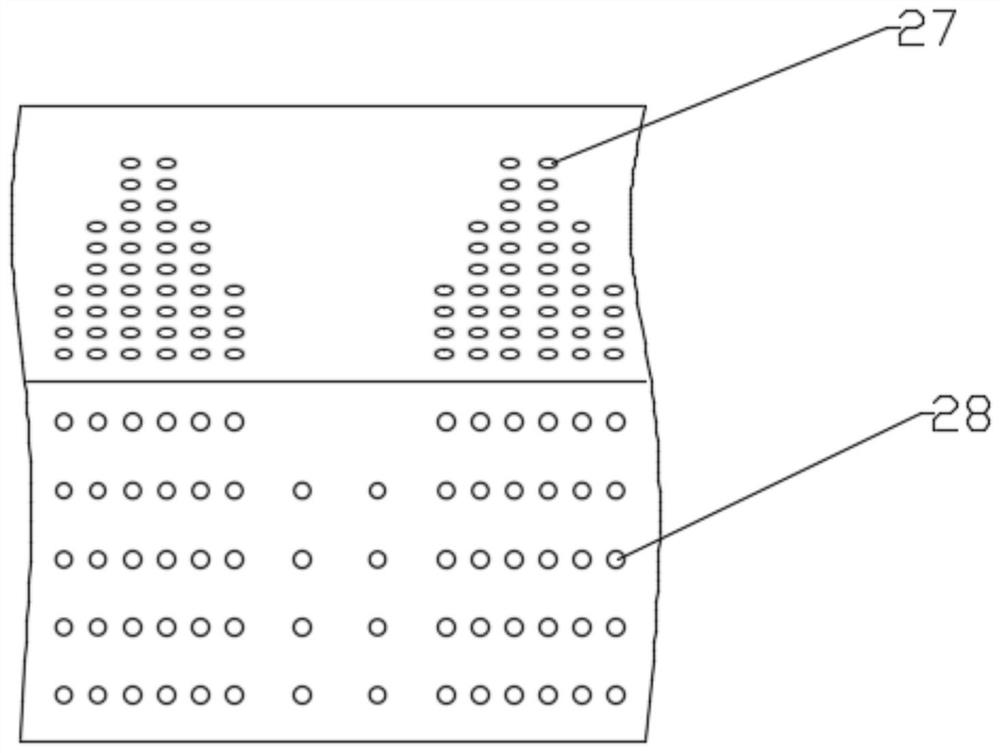

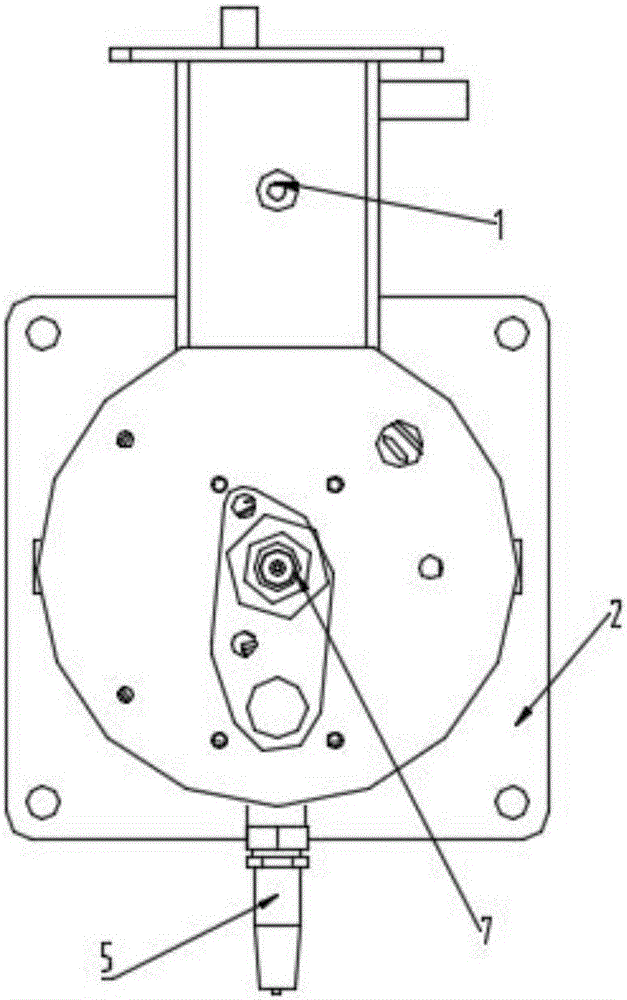

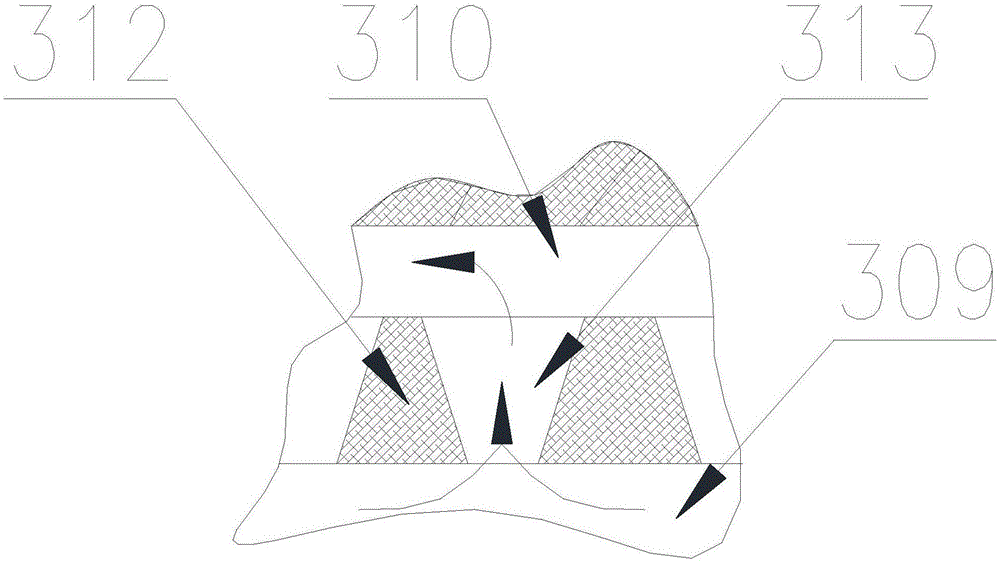

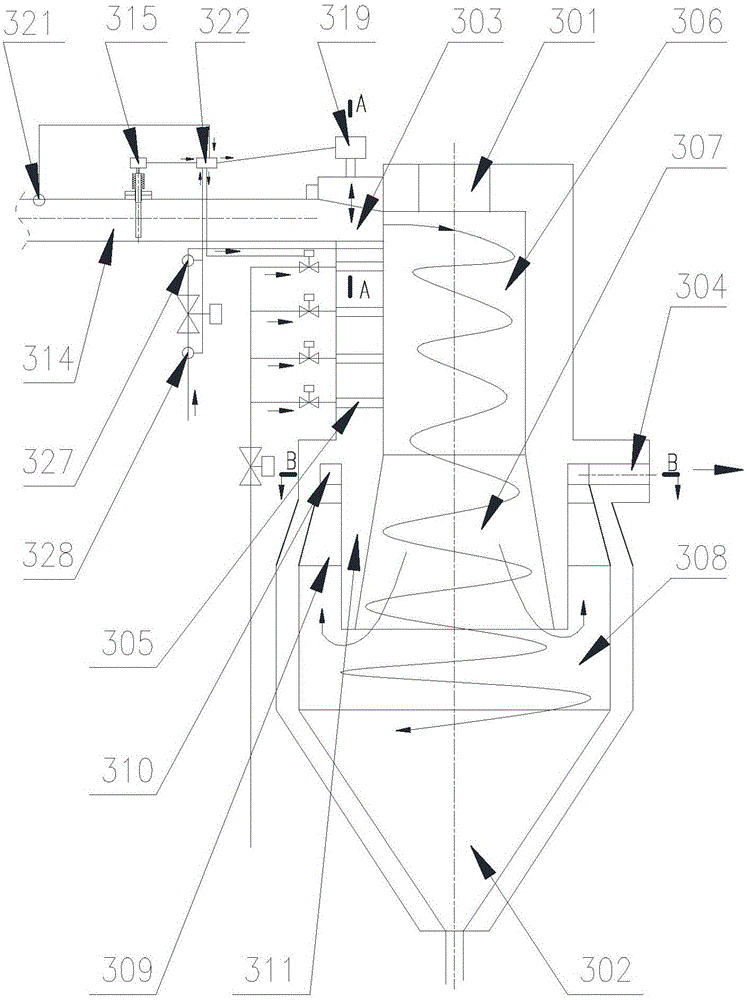

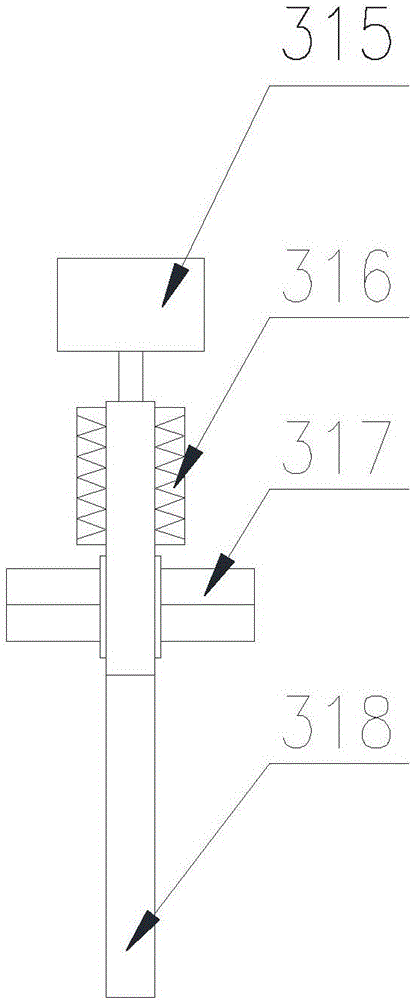

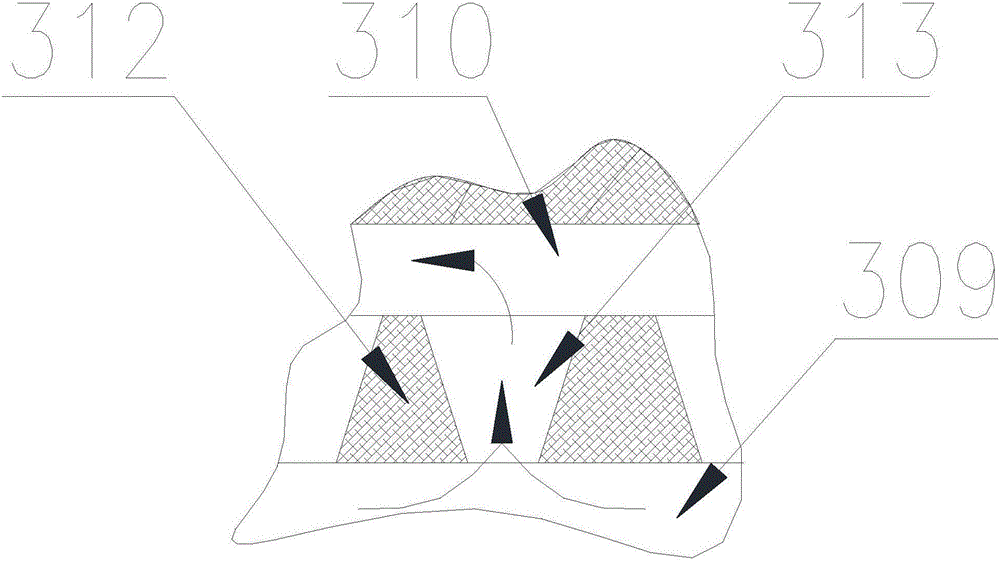

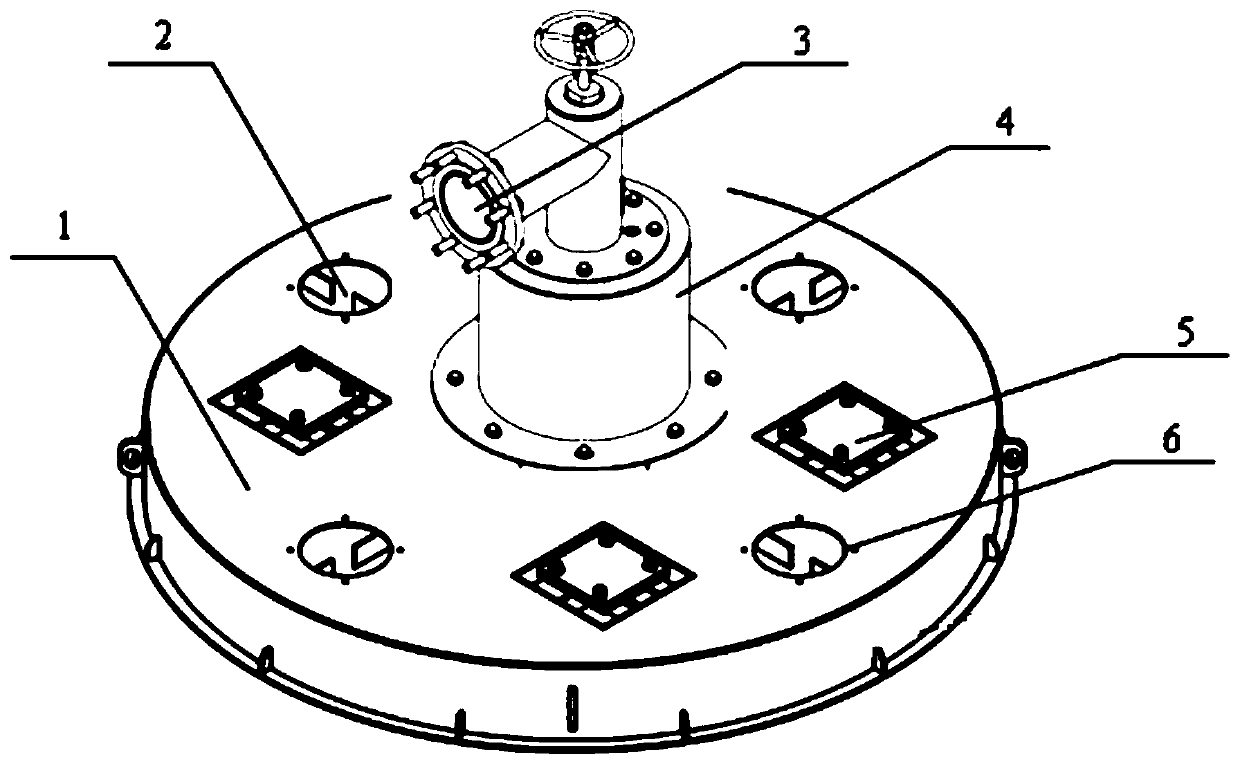

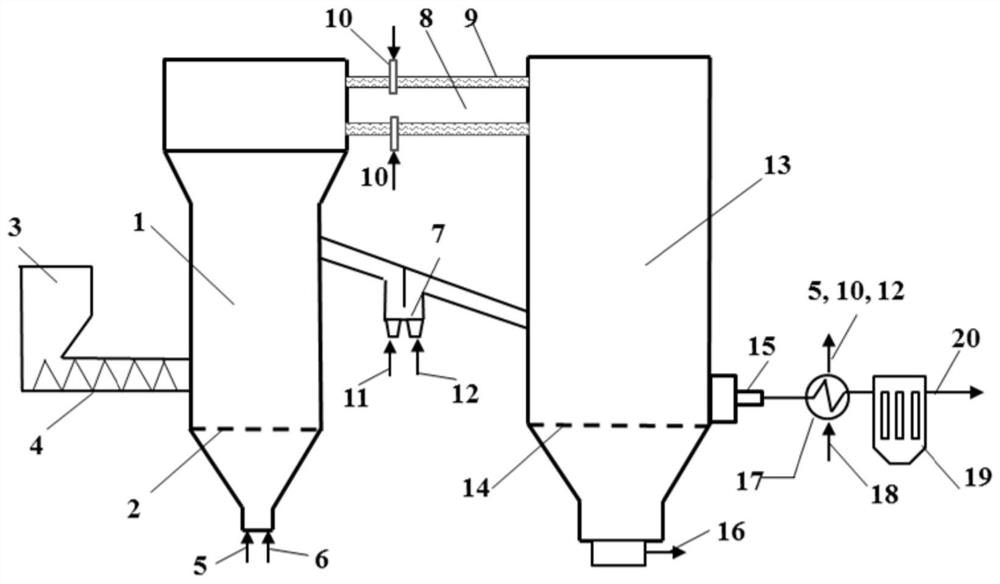

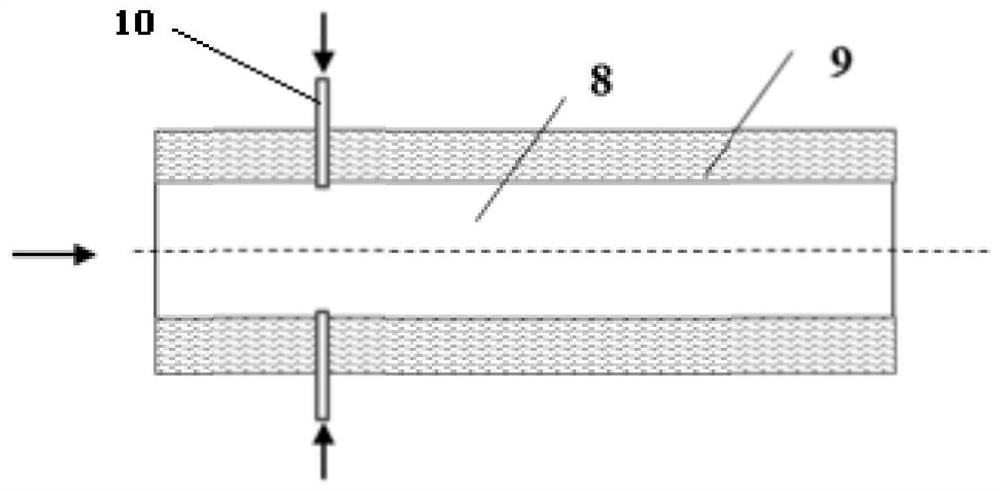

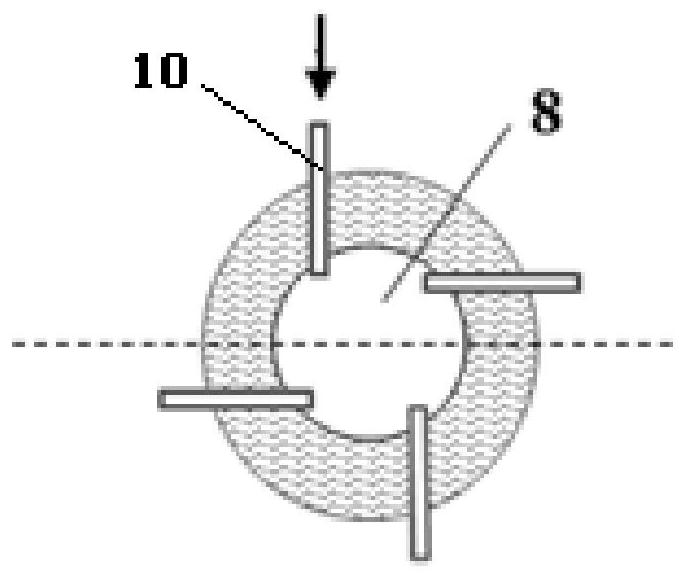

Mechanical grate type garbage gasifying and incinerating system and cyclone combustor

ActiveCN106224969ANovel ideaLarge amount of processingDispersed particle separationIncinerator apparatusSlagFlue

The invention discloses a mechanical grate type garbage gasifying and incinerating system and a cyclone combustor. A cavity of the cyclone combustor comprises a conical slag outlet, a combustion channel, a V-shaped conical channel, an annular smoke channel and an annular draught flue, wherein the conical slag outlet, the combustion channel and the V-shaped conical channel are arranged from bottom to top; the annular smoke channel and the annular draught flue surround the V-shaped conical channel from top to bottom; a cyclone combustor inlet is formed in the lower end of a side wall of the combustion channel in the tangential direction; the ventilating area of the annular smoke channel is gradually reduced from top to bottom; the upper end of the annular smoke channel communicates with the upper end of the V-shaped conical channel; a tangential smoke outlet is formed in the side wall of the cyclone combustor and communicates with the annular draught flue; and an annular ash discharge opening is formed in the lower end of the annular draught flue. The cyclone combustor has relatively high dust removal efficiency and combustion efficiency and relatively high heat recycling efficiency; controlled combustion and controlled collection can be realized; heat loss is reduced; and emission of pollutants can be reduced effectively.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Lower feeding biomass smokeless multi-purpose furnace capable of directly combusting crushed straw

InactiveCN105485661ABurn fullyIncrease storage spaceSolid fuel combustionLump/pulverulent fuel feeder/distributionProcess engineeringOxygen supply

The invention discloses a lower feeding biomass smokeless multi-purpose furnace capable of directly combusting crushed straw. The lower feeding biomass smokeless multi-purpose furnace comprises a furnace body, a movable combustion barrel arranged in the furnace body and a lower feeding mechanism supplying materials into the combustion barrel through the bottom of the combustion barrel. A lower feeding spiral feeder is arranged at the bottom of the furnace body. Biomass crushed materials in a storage hopper are spirally conveyed into the combustion barrel from the bottom of the combustion barrel to be combusted, coking generated at the bottom of the combustion barrel after the biomass crushed materials are combusted is crushed along with the bottom feeding process, and the problems that due to coking, oxygen supply is insufficient and combustion is insufficient are solved. An arch breaking device simple in structure is arranged in the storage hopper, and biomass material crushing and leaking are continuous and smooth. The lower feeding biomass smokeless multi-purpose furnace is reasonable in structure and suitable for smokeless combustion of various kinds of biomass fuel, fuel is combusted sufficiently, the thermal efficiency is high, and the smoke pollution is reduced. The lower feeding biomass smokeless multi-purpose furnace can be applied to family cooking, heating of industries and shops and heating of greenhouses and the cultivation industry and can also be used for small industry drying.

Owner:王晓凯

Boiler

InactiveCN103884011AImprove coal usageReduce coal lossSolid fuel combustionCombustion apparatusFlueCoal

The invention discloses a boiler which comprises a combustor, an air supplying device, a smoke discharging device and a coal feeding device. A smoke duct of the smoke discharging device and the coal feeding device are both communicated with the combustor, the air supplying device comprises an air feeder and an air supplying pipe, and the two ends of the air supplying pipe are communicated with the air feeder and the combustor respectively. The boiler further comprises a microwave chamber formed in the lateral portion of the combustor and used for delivering microwaves to the combustor, and the microwave chamber comprises a magnetron, a microwave chamber body and a microwave output window installed on the microwave chamber body. Due to the fact that the microwave chamber delivers the microwaves to the combustor, a large amount of heat is released, coal can be dry through microwave combustion supporting, the utilization rate of the coal can be improved, and resource waste caused by coal gradual discharging is avoided. According to the microwave combustion supporting principle, coal graduals and hot air in the combustor are disturbed through the microwaves to be sufficiently mixed and combusted, sulfur oxide corrosion, nitrogen oxide generation and coal gradual discharging are avoided, environment pollution is reduced, and therefore according to the boiler, the environment pollution can be reduced while resource waste is reduced.

Owner:成都曙光光纤网络有限责任公司

Solid waste decoupling combustion device, solid waste decoupling combustion system device and combustion method of solid waste decoupling combustion device

PendingCN112879912AIncrease temperatureEasy to dry and heat up quicklyIncinerator apparatusCombustion systemFlue gas

The invention provides a solid waste decoupling combustion device, a solid waste decoupling combustion system device and a combustion method of the solid waste decoupling combustion device. The combustion device comprises a shell, wherein the interior of the shell is divided into a feeding combustion channel, a flue gas mixed combustion channel and a flue gas afterflame channel which are sequentially communicated through partition plates in the material flowing direction, and the feeding combustion channel is divided into a preheating drying area, a pyrolysis gasification area, a semi-coke area and a burnout area in the material flowing direction; an air distribution device is arranged below the feeding end in the feeding combustion channel, and vent holes are formed in the outer wall of the side, close to the preheating drying area and the pyrolysis gasification area, of the air distribution device; at least one deflection baffle is arranged in the flue gas afterflame channel, and a rotary deflection flue gas flow channel is formed in the flue gas afterflame channel through the deflection baffles; and an air-smoke heat exchanger is arranged in the flue gas afterflame channel close to the outlet. Through the reasonable flue and air distribution design and the optimized combustion process, materials are fully combusted, and the combustion device has the advantages of being compact in structure, small in pollutant emission and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

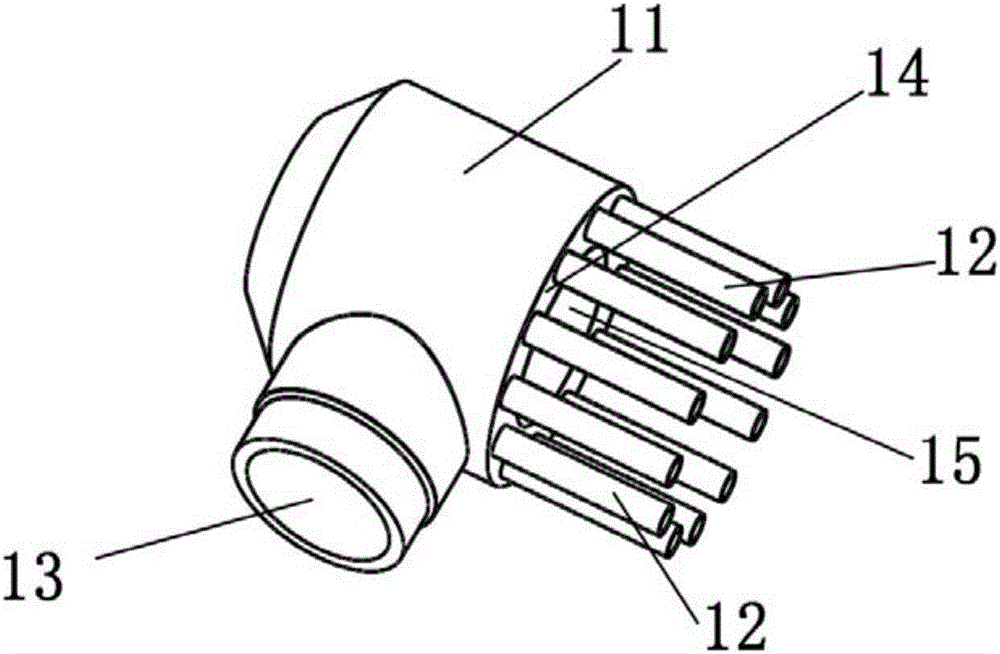

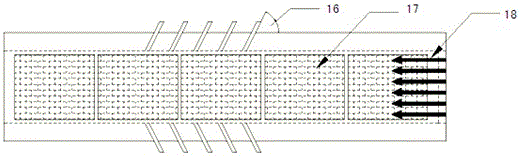

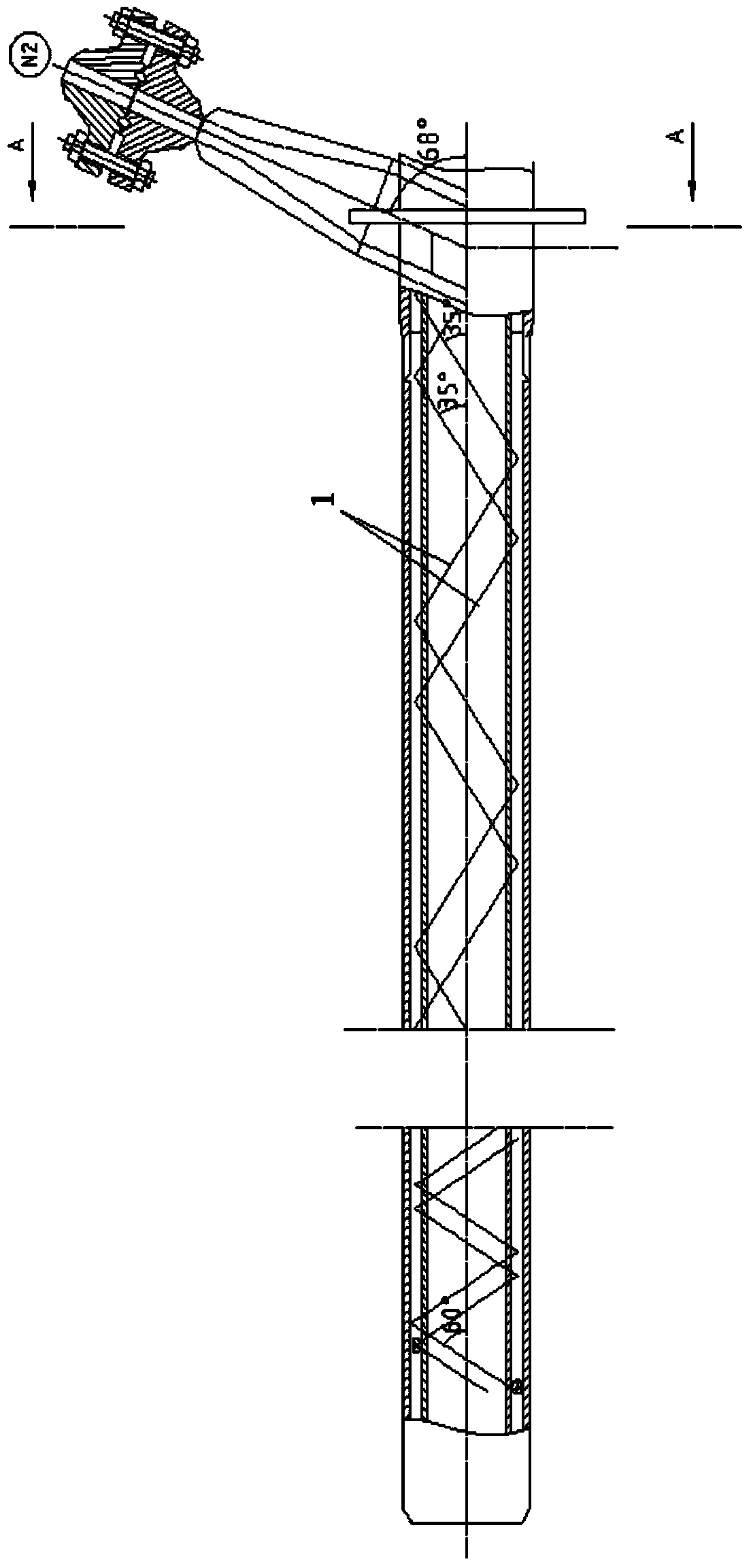

Novel pulverized coal nozzle and pulverized coal feeding mode

ActiveCN103740412AFully mixed combustionConvey evenlyGranular/pulverulent flues gasificationCoalNitrogen

The invention provides a novel pulverized coal nozzle and a pulverized coal feeding mode. A pulverized coal inlet is formed on the pulverized coal nozzle, a channel of the pulverized coal inlet is tangential to the outer wall of a pulverized coal channel, and the included angle between the nozzle and the center line of the pulverized coal channel is 68 degrees; two reinforcing steel bars are parallely arranged in the pulverized coal channel, so that a cyclone pulverized coal channel is formed in the pulverized coal channel; the two reinforcing steel bars are wound on the inner wall of the pulverized coal channel, the winding angle of the pulverized coal inlet is 35 degrees, and that of the pulverized coal outlet is 60 degrees; pulverized coal and nitrogen rotate forward along the cyclone pulverized coal channel formed between the two reinforcing steel bars to be rotatably sprayed out of the pulverized coal channel at a certain angle, and the pulverized coal sprayed out of the nozzle is still of a certain suspension degree. According to the invention, pulverized coal and an oxidant are fully mixed and combusted, the pulverized coal can be uniformly conveyed into a hearth, and the novel pulverized coal nozzle is stable and reliable to use.

Owner:科林能源技术(北京)有限公司

Conical air supply combustion device with large regulating ratio

InactiveCN106642113AFully mixed combustionMeet the needs of useBurner control devicesBurner ignition devicsSpray nozzleAir conditioning

The invention discloses a conical air supply combustion device with a large regulating ratio. The conical air supply combustion device with the large regulating ratio comprises an air regulating baffle, an air bellows, a conical diffusion disc, a flame tube, an ignition electrode, a gas nozzle and a flame detecting bar. The air regulating baffle is hinged to an air inlet of the air bellows, the gas nozzle is installed at the front end inside the air bellows, and the conical diffusion disc is installed at the rear end inside the air bellows and connected with the gas nozzle. The flame detecting bar penetrates through the whole gas nozzle, one end of the flame tube is inserted into the air bellows and overlaps part of the conical diffusion disc, and the ignition electrode is installed at the lower end of the air bellows. According to the device, the air regulating baffle, the gas nozzle and the conical diffusion disc are matched, an air duct distributed in a trapezoid shape is arranged in the conical diffusion disc, and thus sufficient mixing combustion of fuel and combustion air can be guaranteed, it can also be guaranteed that the regulating ratio of the device reaches 40:1, and the use requirements of production equipment are met. The device is further provided with the flame detecting bar, whether flames exist or not can be judged, and safe use of the combustion device is guaranteed.

Owner:SHANGHAI LINGYUN RUISHENG COMBUSTION EQUIP CO LTD

Liquid sulfur dioxide production device and method

The invention discloses a liquid sulfur dioxide production device and method. The device comprises a sulfur melting tank, a sulfur burning spray gun, a sulfur combusting furnace, an air exchanger, a desulfurizing tower, a purifying device, a compressor, an oil filter and a SO2 condenser, an outlet of the sulfur melting tank is connected with a liquid sulfur inlet of the sulfur burning spray gun, anozzle of the sulfur burning spray gun is connected with the sulfur combusting furnace, a flue gas outlet of the sulfur combusting furnace is connected with the air exchanger which is connected witha flue gas inlet of the desulfurizing tower, a flue gas discharging port of the desulfurizing tower is connected with the purifying device which is connected with the compressor, and the compressor isconnected with the oil filter which is connected with the SO2 condenser. The device is high in product quality, sulfur dioxide (SO2), residue and moisture contained in liquid sulfur dioxide producedby the device are greater than or equal to 99.97%, less than or equal to 0.010% and less than or equal to 0.020% respectively, and indexes reach superior-product requirements in liquid sulfur dioxideproduct quality standards; three wastes are discharged in an up-to-standards manner, so that no damage is caused to environment, energy consumption is reduced, and cost is lowered.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

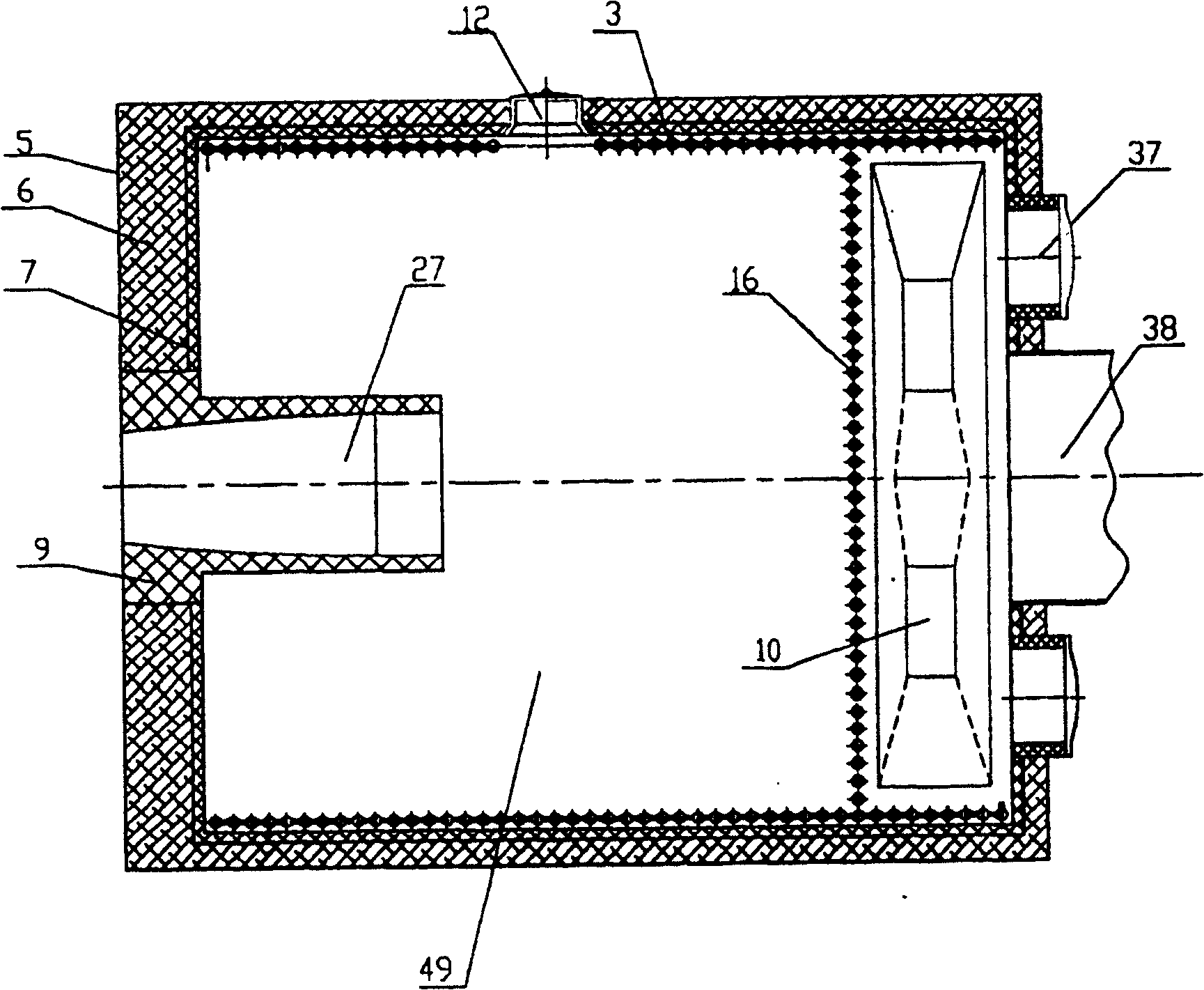

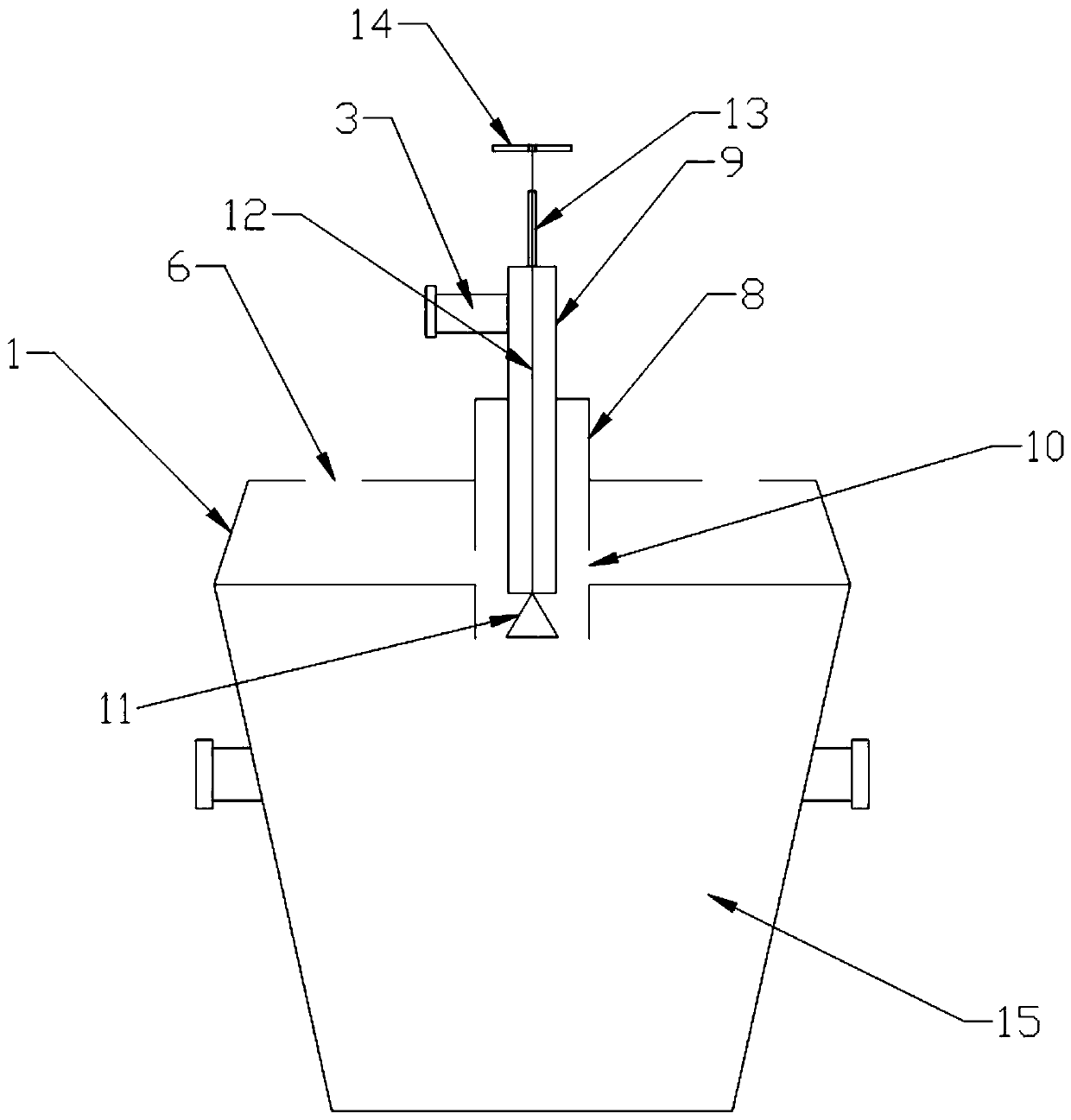

Mechanical grate type garbage gasifying and incinerating system and combustion chamber with inverted-cone-shaped cavity

ActiveCN106224970AAccelerated settlementLow suctionBlast-producing apparatusIncinerator apparatusCombustion chamberSlag

The invention discloses a mechanical grate type garbage gasifying and incinerating system and a combustion chamber with an inverted-cone-shaped cavity. The cavity of the combustion chamber with the inverted-cone-shaped cavity comprises a combustion channel, a conical channel, a fly ash settling chamber, a conical slag outlet, an annular smoke channel and an annular draught flue, wherein the combustion channel, the conical channel, the fly ash settling chamber and the conical slag outlet are successively arranged from top to bottom; the annular smoke channel and the annular draught flue surround the conical channel; the top of the conical channel is small while the bottom of the conical channel is large; the diameter of the fly ash settling chamber is greater than that of the lower end of the conical channel; the annular smoke channel is conical; the top of the annular smoke channel is small while the bottom of the annular smoke channel is large; the lower end of the annular smoke channel communicates with the fly ash settling chamber; the lower end of the annular draught flue communicates with the upper end of the annular smoke channel; and the top of the conical slag outlet is large while the bottom of the conical slag outlet is small. The combustion chamber with the inverted-cone-shaped cavity has relatively high dust removal efficiency and combustion efficiency and relatively high heat recycling efficiency; controlled combustion and controlled collection can be realized; heat loss is reduced; and emission of pollutants can be reduced effectively.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Mechanical grate type garbage gasifying and incinerating system and dovetail-shaped fly ash collecting device

ActiveCN106224967AAccelerated settlementLow suctionDispersed particle separationIncinerator apparatusCombustion chamberSlag

The invention discloses a mechanical grate type garbage gasifying and incinerating system and a dovetail-shaped fly ash collecting device. A cavity of the dovetail-shaped fly ash collecting device comprises a combustion channel, a fly ash settling chamber, a conical slag outlet, an upper annular smoke channel, an annular draught flue and a lower annular smoke channel, wherein the upper annular smoke channel, the annular draught flue and the lower annular smoke channel surround the combustion channel; the ventilating area of the lower annular smoke channel is gradually reduced from bottom to top; the ventilating area of the upper annular smoke channel is gradually reduced from top to bottom; a tangential smoke outlet is formed in a side wall of the fly ash collecting device and communicates with the annular draught flue; a cyclone combustion chamber inlet is formed in the middle of the side wall of the combustion channel in the tangential direction; and a plurality of combustion-supporting air supply openings are formed in the side wall of the combustion channel. The garbage gasifying and combusting fly ash collecting device has quite high fly ash collecting efficiency and combustion efficiency and relatively high heat recycling efficiency; controlled combustion and controlled collection can be realized; heat loss is reduced; and emission of pollutants can be reduced effectively.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Steel ladle baking device

InactiveCN110918959ASolve the phenomenon of flameout and flameoutImprove securityMelt-holding vesselsInsulation layerThermal insulation

The invention discloses a steel ladle baking device which has an above structure. A rotary connector is omitted, a metal flexible pipe is adopted for connecting an external fuel gas pipeline so as toeliminate a potential safety hazard of gas leakage since the rotary connector is frequently damaged, meanwhile, a thermal insulation layer is added, a specially-designed nozzle is adopted, an originalcombustion fan, an induced draft fan and a heat accumulator are omitted, and the residual heat of a ladle cover is used for heating air. Since fuel gas owns certain pressure, the exhaust inlet of theladle cover generates negative pressure under a function of fuel gas pulling power, external air is automatically sucked into the interlayer channel of the ladle cover, and then, and the external airis preheated to be fully mixed and burnt with the fuel gas in the nozzle.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Self-heating three-section biomass low-tar carbon gas co-production regulation and control device

PendingCN113150832AAchieve incomplete gasificationStrong crackingGasification processes detailsBulk chemical productionPartial oxidationWater vapor

The invention discloses a self-heating three-section biomass low-tar carbon gas co-production regulation and control device. The device comprises a self-heating fluidized bed pyrolysis reactor, a homogeneous partial oxidation reforming reactor and a fixed bed gasification reactor. The fluidized bed pyrolysis reactor adopts air and water vapor as reaction media; in the partial oxidation reforming section, pure oxygen and volatile components are subjected to a strong partial combustion reaction, a large amount of heat is released, and tar is promoted to be subjected to strong cracking; and biomass coke generated by the pyrolysis section enters the gasification reduction section through a gas locking and material returning device, a small amount of residual tar after the gasification reduction reaction is subjected to deep catalytic cracking through a carbon bed, and the tar content at the outlet of the gasification furnace reaches an extremely low level. According to the invention, agriculture and forestry biomass wastes are converted into high-added-value synthesis gas and biomass activated carbon in a segmented conversion manner, self-heating and large-scale amplification of a gasification furnace pyrolysis process are realized by utilizing directional distribution of a gasification medium, and meanwhile, high-efficiency in-furnace removal of tar is realized.

Owner:NANJING INST OF TECH

Production device for industrial kiln

InactiveCN110726308AImprove anti-burn performanceExtended service lifeGaseous fuel burnerWaste heat treatmentCombustion chamberBrick

The invention discloses a production device for an industrial kiln, and relates to a combustor. The production device is mainly composed of a heat exchanger, an air inlet pipe, a combustion chamber, amixer arranged in the combustion chamber and a main gun, wherein the heat exchanger is provided with an air runner and a smoke runner, the air inlet pipe is arranged on the heat exchanger and communicates with the air runner of the heat exchanger, the combustion chamber communicates with the air runner of the heat exchanger and the air inlet pipe, and the main gun communicates with the mixer andis used for gas conveying. The combustion chamber of the production device is of a cylinder cavity structure formed by a burner brick formed by combining a heat-resistant steel pipe framework and fireproof materials, the combustion chamber and the burner brick are of an integrated structure, and therefore the burning loss resisting capability of the combustion chamber can be greatly improved, andthe service life is prolonged; and through a through hole, the device ventilation effect is improved, and the service life of the device is prolonged.

Owner:湖北中琛窑炉设备有限公司

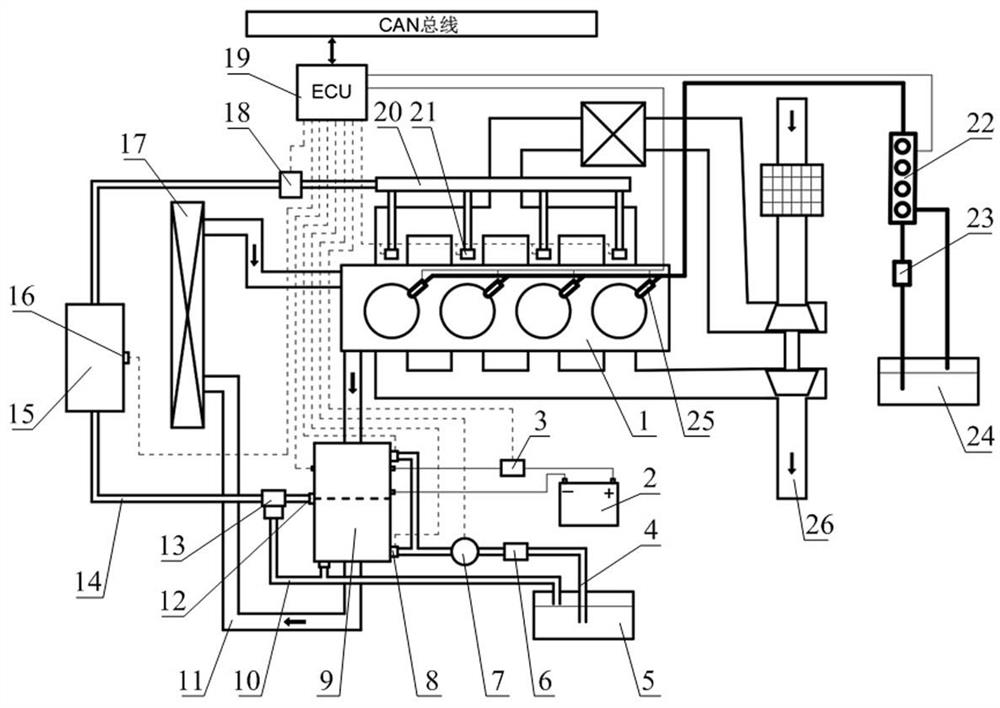

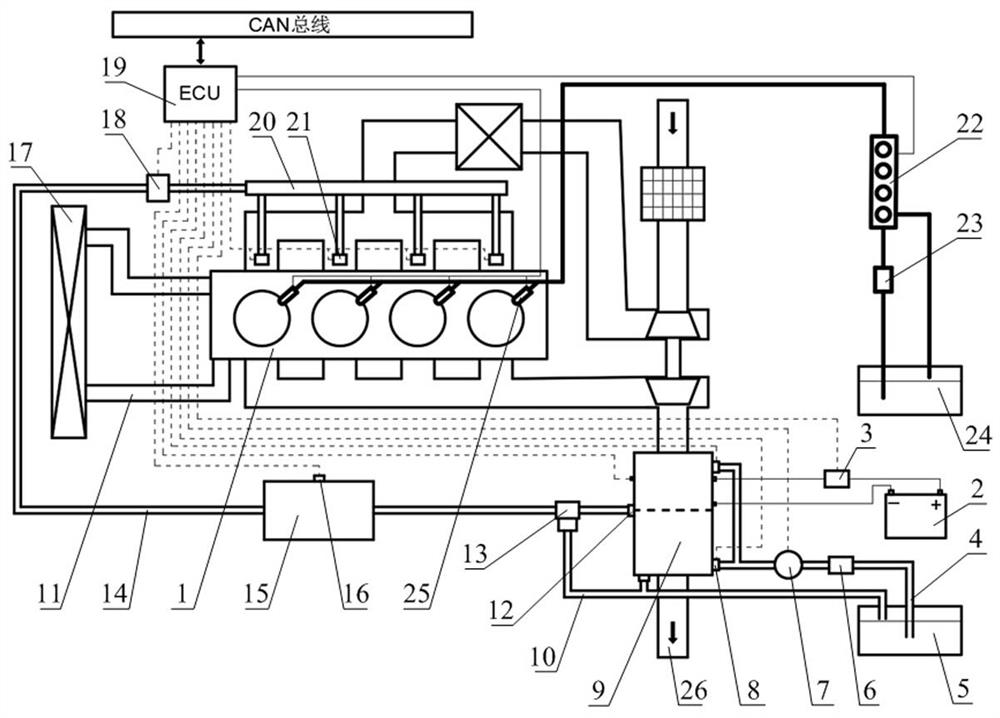

Alcohol combustion system for gasifying methanol based on waste heat of engine

ActiveCN112682223APromote combustionImprove emission performanceElectrical controlInternal combustion piston enginesDiesel engineMixed gas

The invention discloses an alcohol combustion system for gasifying methanol based on waste heat of an engine. The alcohol combustion system comprises a diesel engine, a methanol supply system, a methanol gasification generator, a methanol steam injection system and a control system. The methanol supply system comprises a methanol tank, a filter and a methanol pump which are sequentially connected to the methanol gasification generator through an alcohol-resistant pipeline. The methanol gasification generator is divided into an electric heating gasification part and a waste heat gasification part, each part comprises a methanol atomizing nozzle and a one-way outlet, and gasified methanol is connected with the methanol steam injection system through the outlet. The methanol steam injection system comprises a gas-liquid separator, a gas storage tank, a pressure regulating valve, a methanol gas rail and a methanol steam nozzle which are sequentially connected through an alcohol-resistant heat preservation pipeline. The alcohol combustion system improves the concentration and temperature of mixed gas of methanol and air and improves the low-temperature starting performance of a methanol fuel engine in a manner of atomizing, gasifying and pressurizing methanol. The method has the characteristics of sufficient methanol combustion and high alcohol-diesel ratio.

Owner:TAIYUAN UNIV OF TECH

Diesel oil economizer of diesel engine

InactiveCN103032215AImprove surface activityPromote atomizationMachines/enginesThermal treatment of fuelHigh surfaceThermal water

A diesel oil economizer of a diesel engine comprises a water tank, a coil pipe, a hot water inlet, a cold water outlet, a cold diesel oil inlet and a hot diesel oil outlet, wherein the hot water inlet and the cold water outlet extend out of the water tank to be communicated with the cooling water of a cylinder to circulate, so that heat is continuously supplied to a diesel oil source in the coil pipe. The coil pipe in the water tank is communicated with the cold diesel oil inlet and the hot diesel oil outlet, the cold diesel oil inlet is communicated with a diesel oil tank, the hot diesel oil outlet is communicated with the cylinder, diesel oil in the coil pipe and hot water outside the pipe are subjected to countercurrent heat exchange, and the temperature of the diesel oil on the hot water outlet is basically same with the temperature of the hot water outside the pipe. The diesel oil economizer has very high surface activity, the diesel oil can be fully burnt in the cylinder, the output power of the diesel engine is increased, so that the diesel engine can save the diesel oil.

Owner:赵晓俊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com