Conical air supply combustion device with large regulating ratio

A combustion device and adjustment ratio technology, applied in the direction of burner control device, burner ignition device, burner, etc., can solve the problems of not meeting the needs of production equipment, incomplete combustion, and flame being blown out by wind, etc., and achieve structural Simple, safe to use, and stable in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

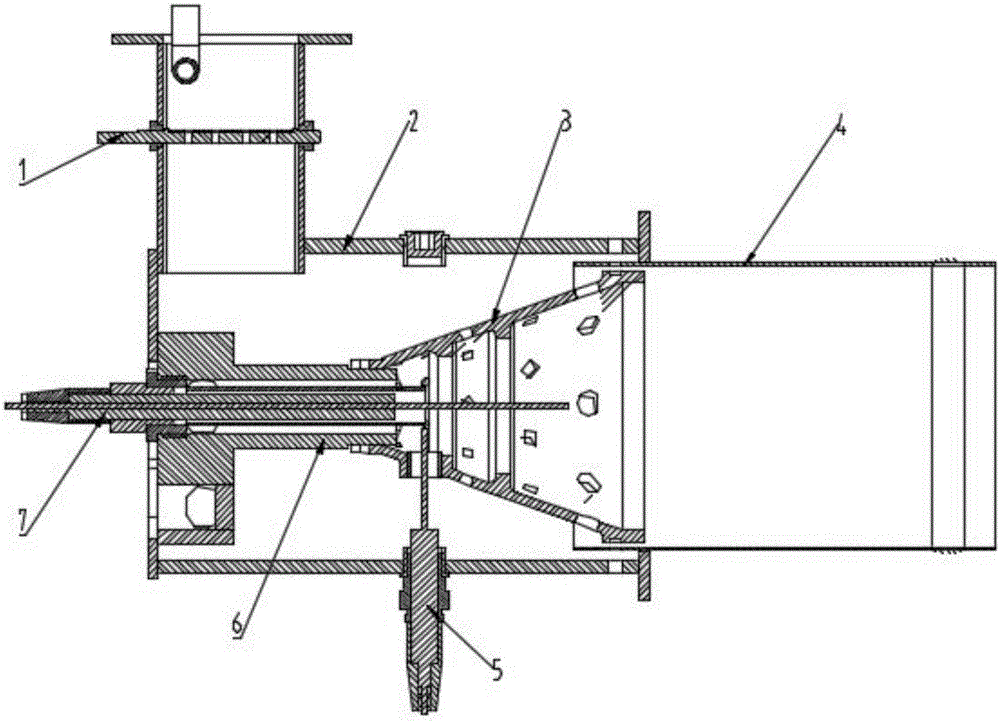

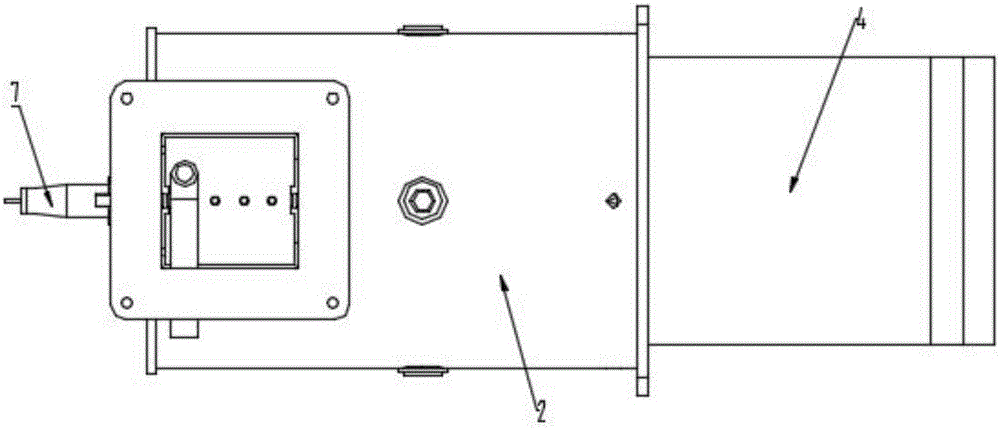

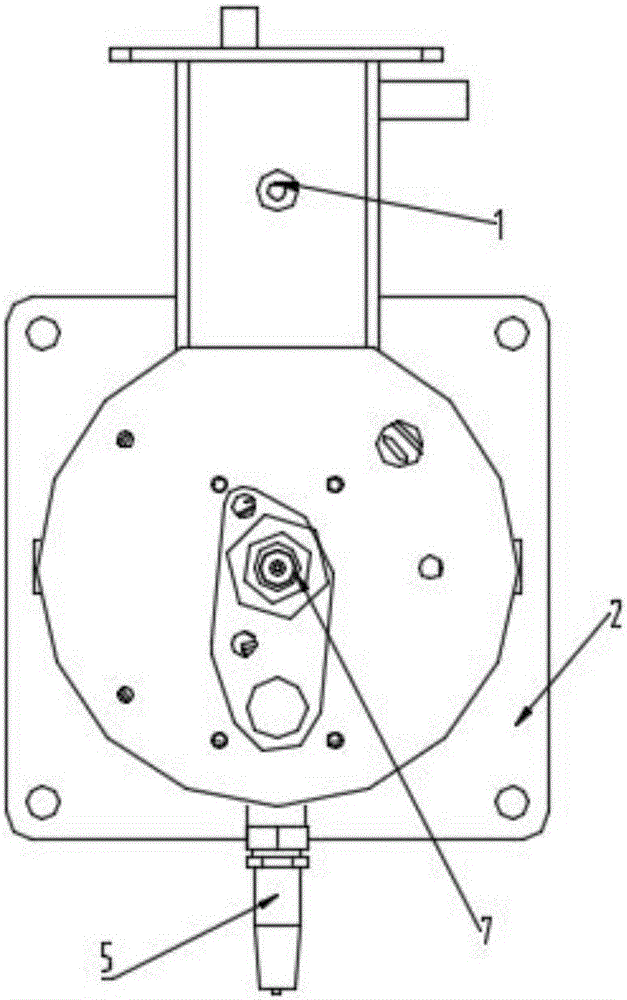

[0015] see Figure 1-3 , a conical air supply large adjustment ratio combustion device, comprising an air conditioning baffle 1, an air box 2, a conical diffuser 3, a flame cylinder 4, an ignition needle 5, a gas nozzle 6 and a flame detection rod 7, the air conditioning The baffle 1 is hinged at the air inlet of the air box 2, the gas nozzle 6 is installed at the front end of the air box 2 and the nozzle of the gas nozzle 6 adopts a porous ring structure, and the conical diffuser 3 is installed at the rear end of the air box 2 and has a conical shape. The diffuser plate 3 is connected to the gas nozzle 6, the flame detection rod 7 runs through the gas nozzle 6 and the flame detection rod 7 extends into the conical diffuser disc 3, the conical diffuser disc 3 is provided with trapezoidally distributed air passages, and the apertures of the air pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com