Self-heating three-section biomass low-tar carbon gas co-production regulation and control device

A control device and biomass technology, applied in the production of bulk chemicals, gasification process, petroleum industry, etc., can solve the problems of low gasification efficiency and high tar content, and achieve the effect of maintaining energy self-balance and improving pyrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

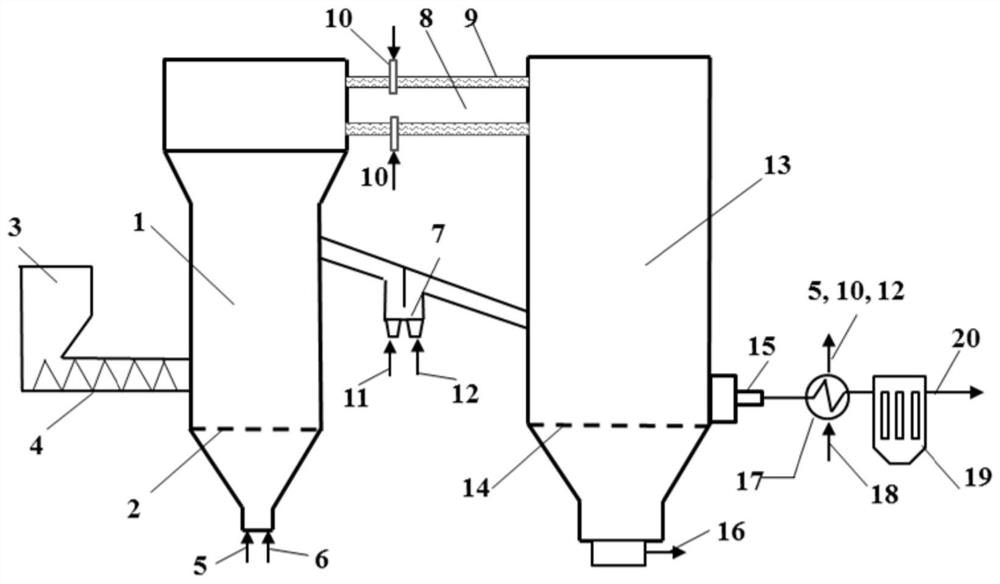

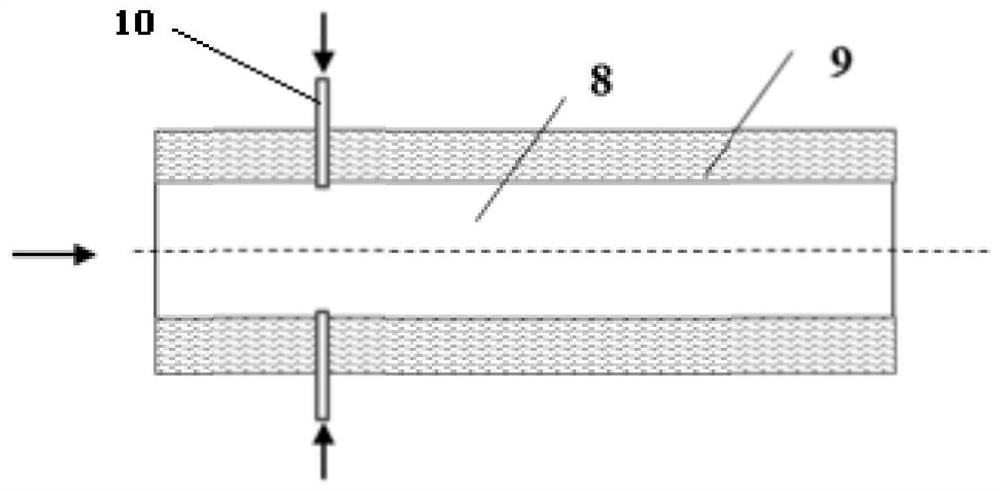

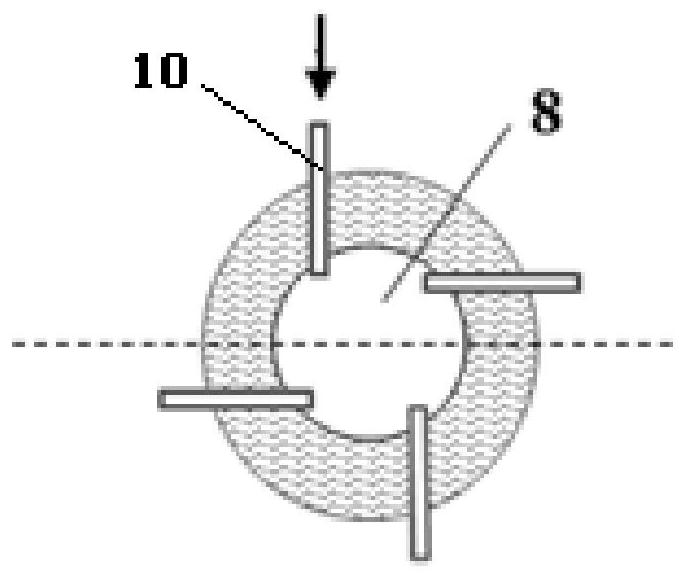

[0024] as attached figure 1 , figure 2 , image 3 As shown, a self-heating three-stage biomass low-tar charcoal gas cogeneration control device includes a fluidized bed pyrolysis reactor 1, a reforming reactor 8, a gasification reactor 13, and a reforming reactor 8 connected in sequence. The two ends are respectively connected with the upper ends of the fluidized bed pyrolysis reactor 1 and the gasification reactor 13; one side of the fluidized bed pyrolysis reactor 1 is connected with the screw feeder 4, The lower part is provided with a fluidized bed air distribution plate 2, and the lower end of the fluidized bed pyrolysis reactor 1 is respectively provided with a pyrolysis air inlet 5 and a pyrolysis water vapor inlet 6; A nozzle 10; a U-shaped feeder 7 is arranged between the fluidized bed pyrolysis reactor 1 and the gasification reactor 13, and a nitrogen inlet 11 and a first air inlet 12 are respectively arranged on the U-shaped feeder 7; the gasification reaction A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com