Air single regenerative burner

A single heat storage and air technology, applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as insufficient fuel combustion, affecting burner life, and polluting the environment, achieving sufficient combustion, compact structure, and reduced The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

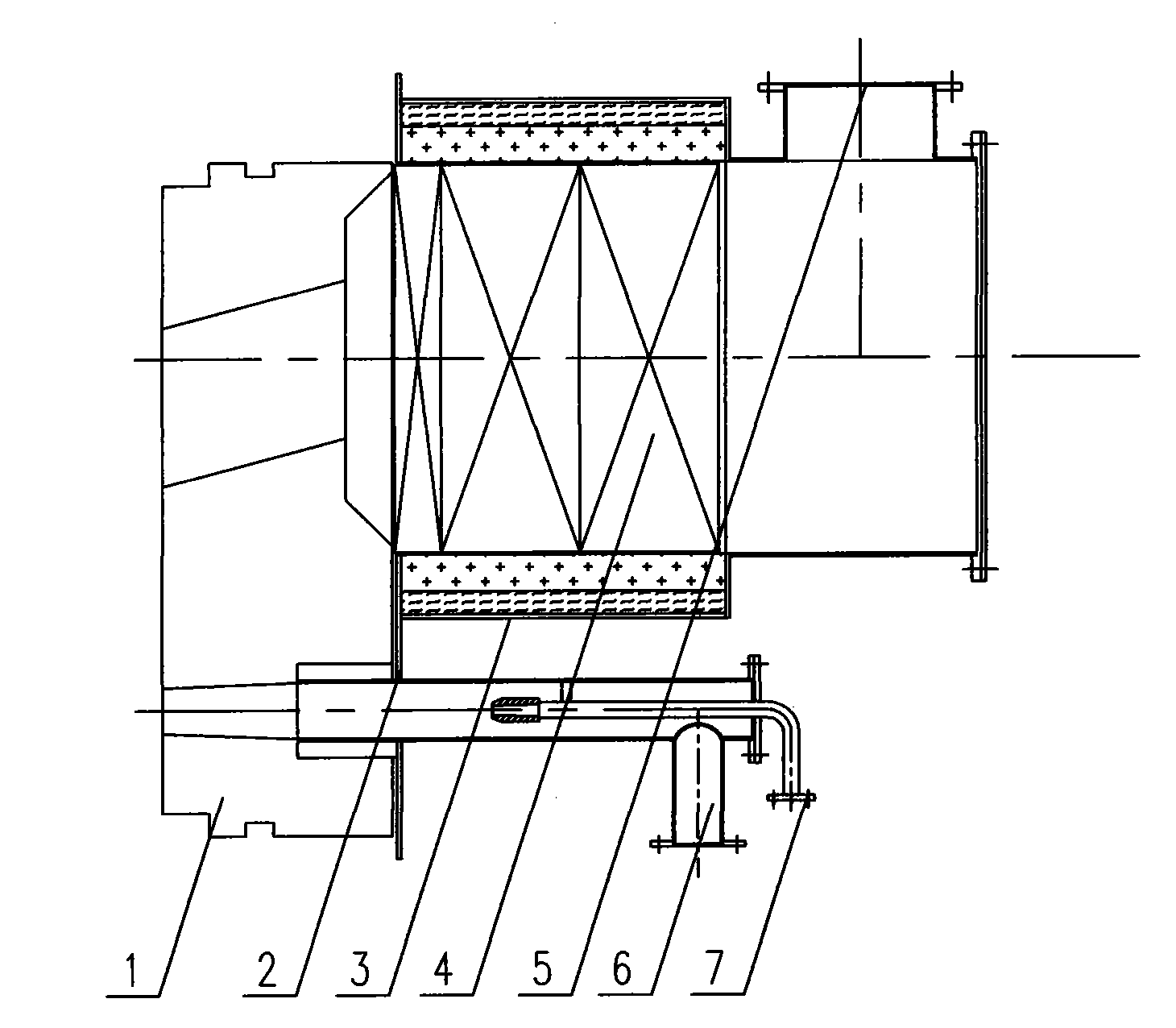

[0021] An air single heat storage burner, comprising a burner brick 1 and a burner mounting plate 2, a burner housing 3 is provided on the burner mounting plate 2, and a heat storage body 4 is provided in the burner housing 3, A secondary air pipeline 5 leading to the furnace is provided on the burner housing 3, and a gas pipeline 6 is provided outside the burner housing 3, and the end of the gas pipeline 6 is inserted into the burner brick 1, and in the gas pipeline 6 A primary air duct 7 is provided.

[0022] In this embodiment, the entire air-only regenerative burner is in a split structure, and the burner brick 1 is arranged in a labyrinth structure, so that it can effectively prevent the crossfire between the burner brick and the gap between the furnace wall, and further improve the cost efficiency. Invented safety features.

Embodiment 2

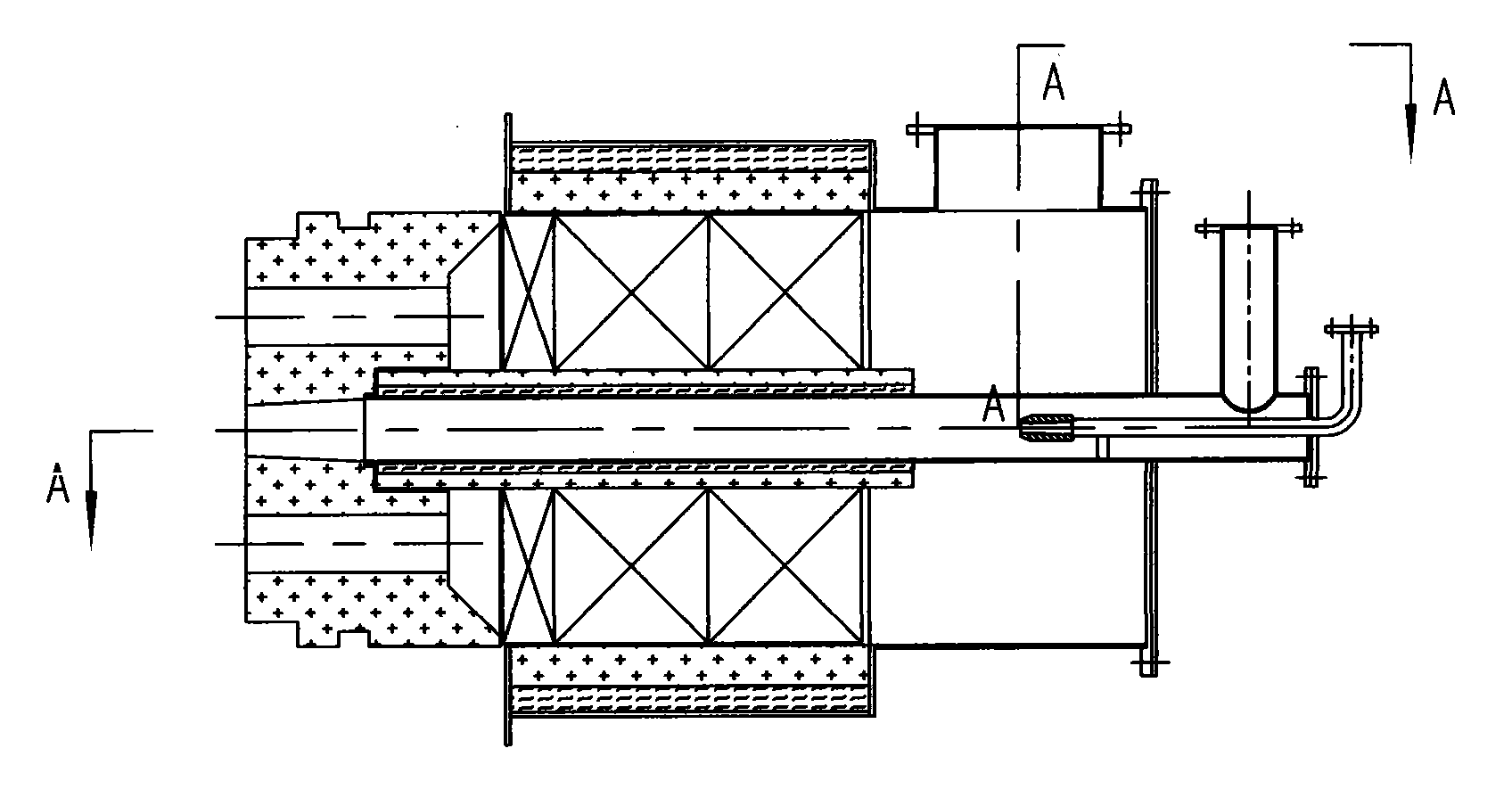

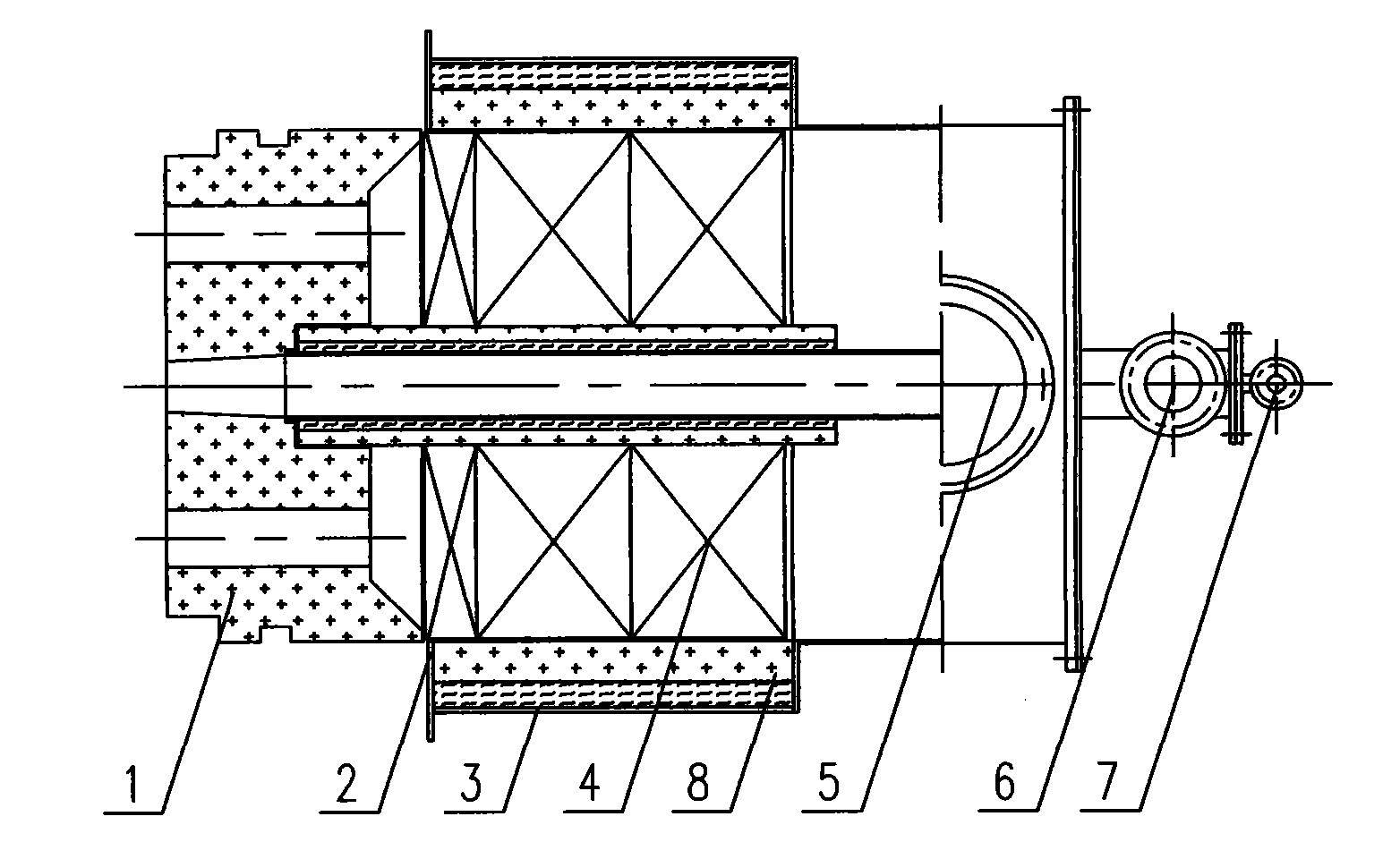

[0024] refer to figure 2 with image 3 , an air-only regenerative burner, including a burner brick 1 and a burner mounting plate 2, a burner housing 3 is provided on the burner mounting plate 2, and a heat storage body 4 is provided in the burner housing 3 , A secondary air pipeline 5 leading to the furnace body is provided on the burner housing 3, a gas pipeline 6 is provided in the burner housing 3, and the gas pipeline 6 passes through the regenerator 4 and the burner brick 1 part The exterior of the burner is provided with refractory insulation material 8, and the primary air pipe 7 is provided in the gas pipe 6, and the described burner brick 1 adopts a labyrinth structure.

[0025] In this embodiment, the entire burner has an integrated structure, which makes the structure of the burner more compact. The gas pipeline 6 and two air pipelines are placed in the burner housing 3, and the secondary air and the heat stored in the burner The body 4 is preheated to a high tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com