Water cooled fully-areated burner

A pre-mixed combustion, water-cooled technology, applied in the direction of burner, burner, burner cooling, etc., to achieve simple processing, high combustion efficiency, and reduce thermal stress deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in combination with specific embodiments.

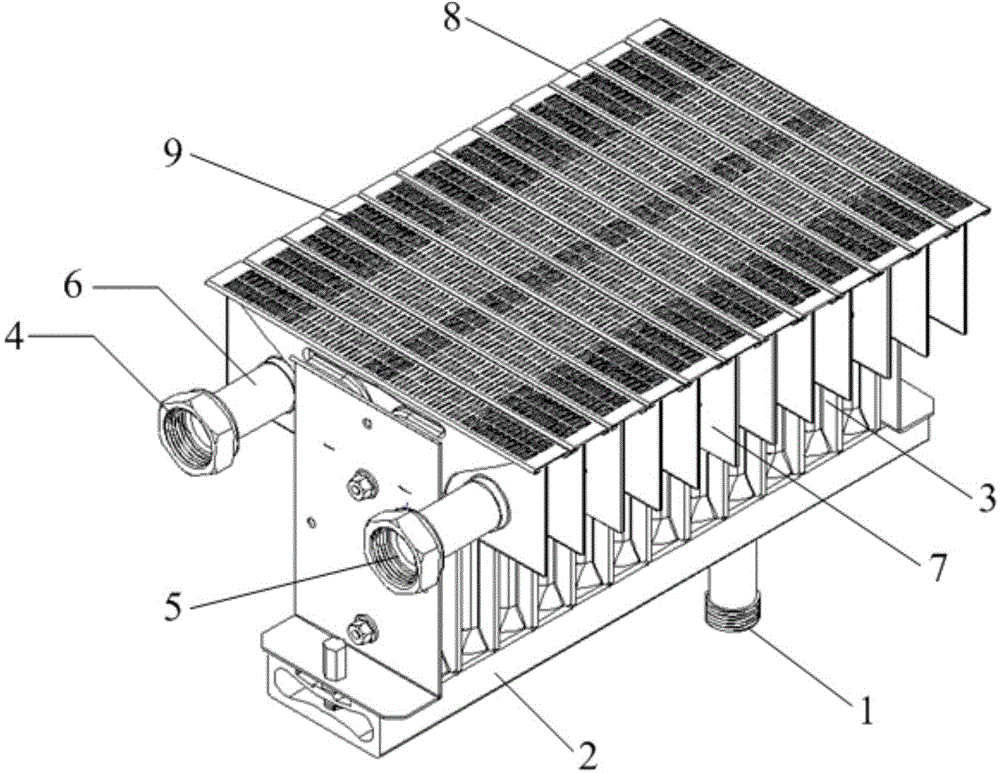

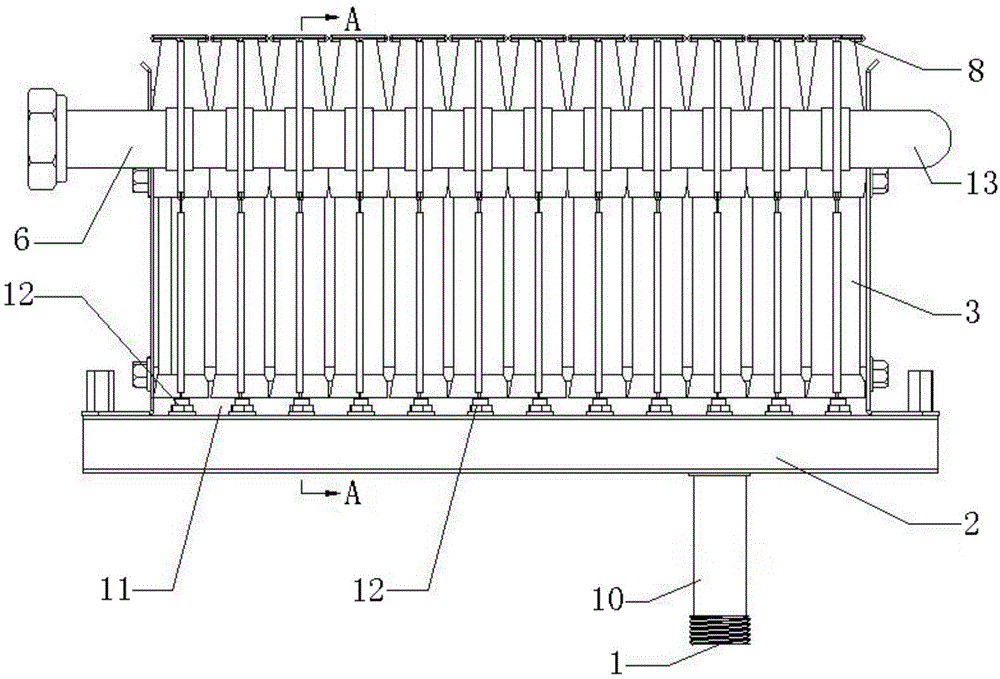

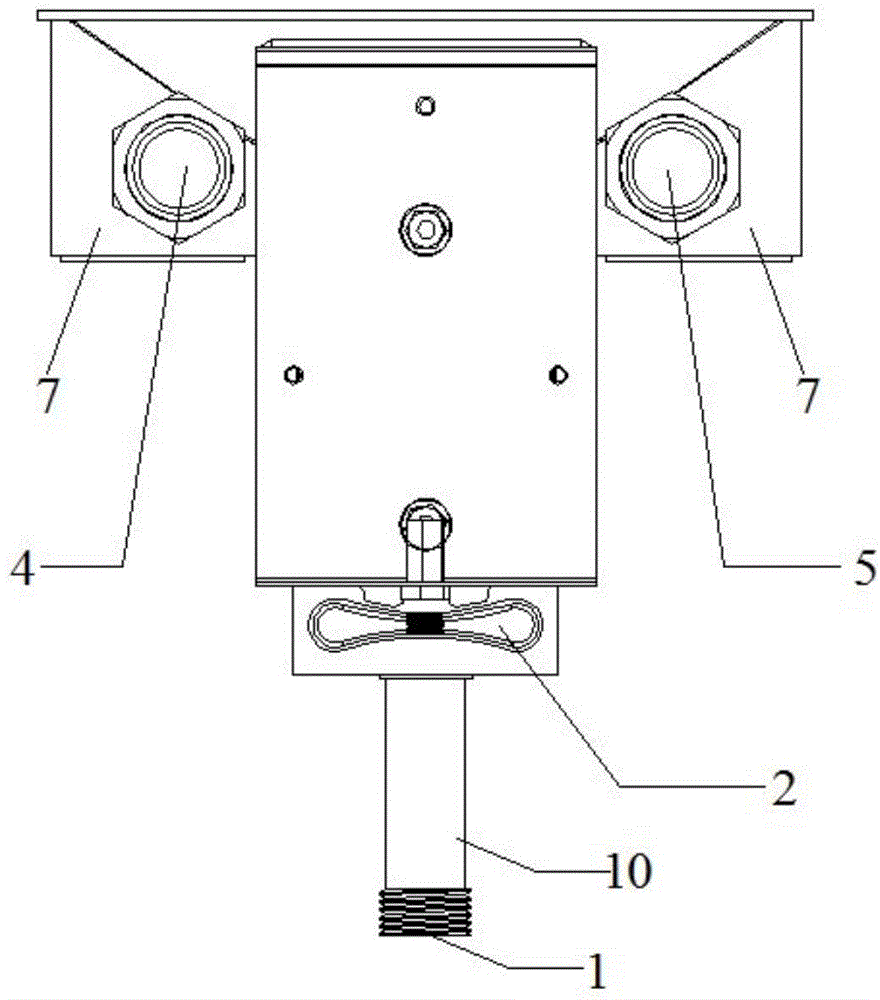

[0019] Such as figure 1 , Figure 2a , Figure 2b and 2c As shown, a water-cooled complete premix burner of the present invention includes a gas fuel distribution system, a gas fuel-air mixing system, a combustion system and a cooling system arranged from bottom to top.

[0020] The gas fuel distribution system includes a gas distribution chamber 2 connected to the gas inlet pipe 10, and the top of the gas distribution chamber 2 is provided with two rows of nozzles 12 arranged at equal intervals. In this embodiment, each row has 12 nozzles , a total of 24 nozzles. The diameter of the nozzle is 0.5-1.5mm, and the distance between two adjacent nozzles is 20-80mm; the gas distribution chamber 2 can be connected with a plurality of gas inlet pipes 10 . The gas inlet pipe 10 is connected to the gas source through the gas inlet pipe 1 .

[0021] The gas fuel-air m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com