Anti-backfire gas combustor

A gas burner and anti-backfire technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of short service life, poor safety performance, insufficient combustion, etc., to prevent backfire and easy to operate. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

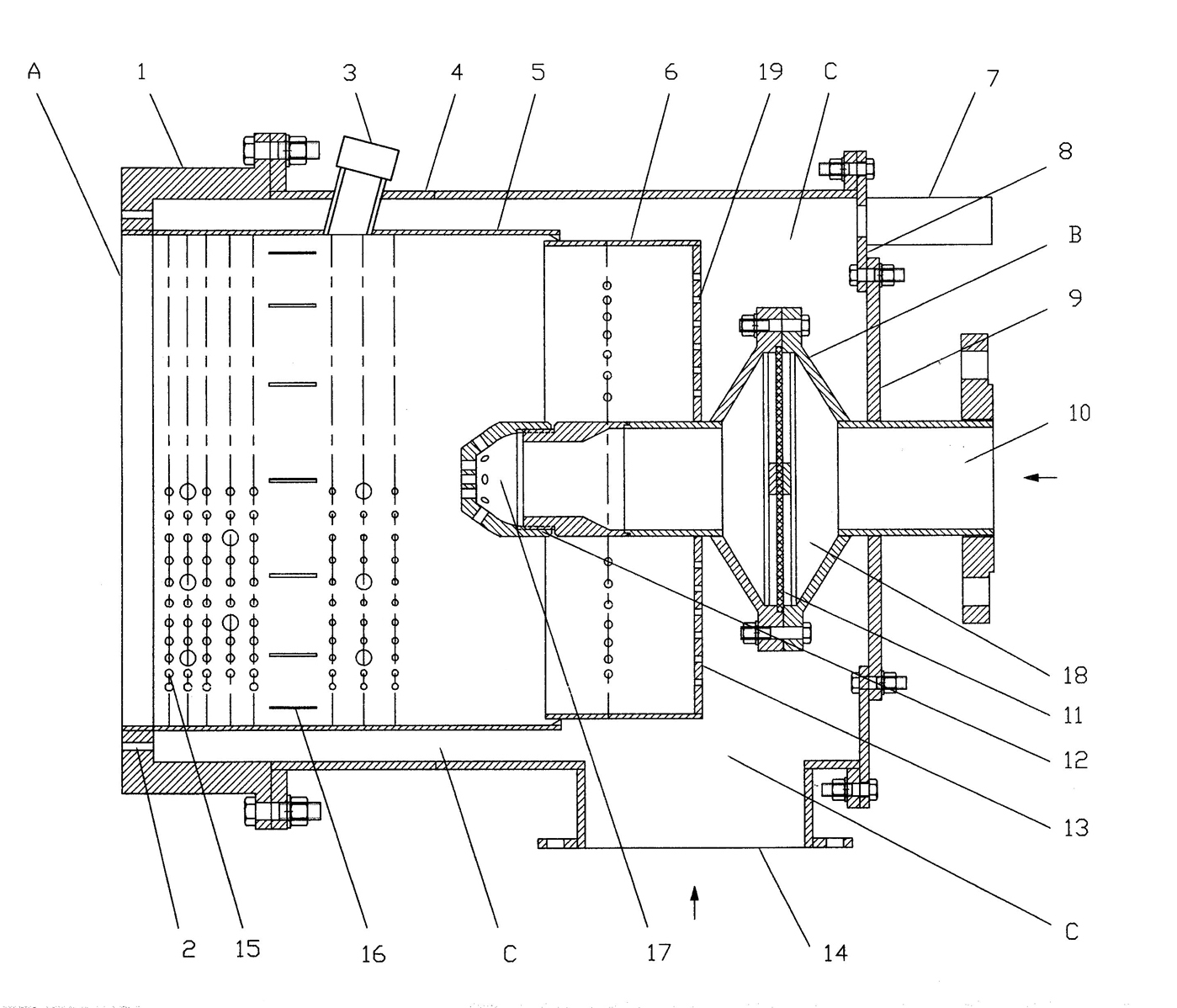

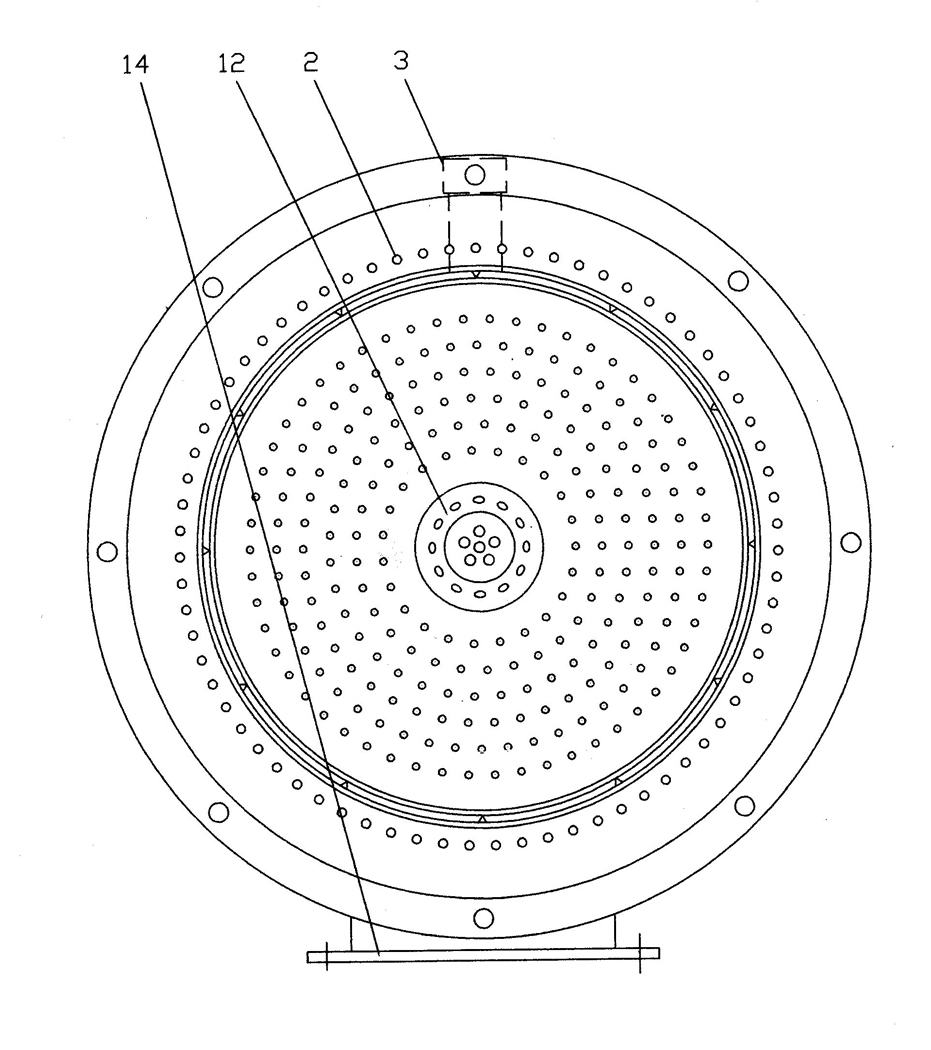

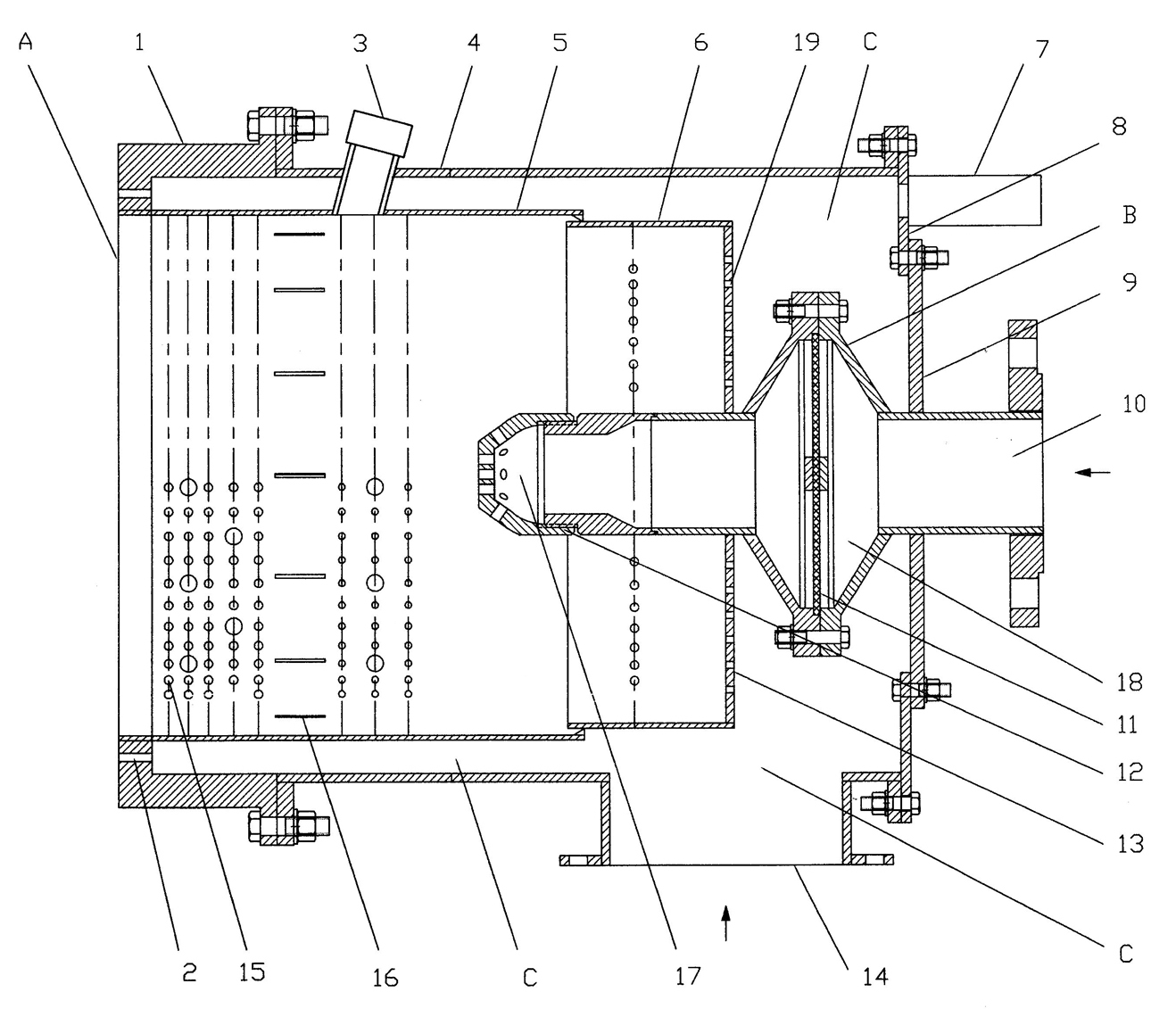

[0020] attached by figure 1 , 2 It can be seen that the present invention includes a combustion chamber A and an adjustable nozzle assembly B, wherein:

[0021] The combustion chamber A includes the external high-temperature combustion head 1, the casing 4, the casing end plate 8 and the internal flame tube and the flame tube end plate 13; the adjustable nozzle assembly B includes the nozzle 12, the flame arresting net 11, the gas inlet 10 and the rear end cover 9; wherein:

[0022] The adjustable nozzle assembly B is arranged in the middle of the end plate 13 of the flame tube, and its nozzle 12 extends into the flame tube, and its rear end cover 9 is fastened together with the shell end plate 8 by bolts;

[0023] The high-temperature combustion head 1, the casing 4 and the casing end plate 8 are connected as a whole by bolts, and an interlayer cavity C is provided between the flame tube inside the combustion chamber A and the adjustable nozzle assembly B;

[0024] The fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com