Temperature self-adjusting device for inner tunnel kilns

A self-regulating and internal temperature technology, which is applied in the direction of furnace types, furnaces, lighting and heating equipment, etc., can solve the problems of large temperature difference between upper and lower, difficult turbulent flow of gas and air, and insufficient combustion, so as to increase the gas mixed combustion area and solve the problem of The problem of the temperature difference between the upper and lower sides and the effect of reducing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

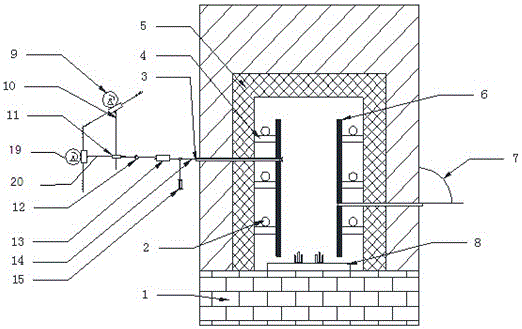

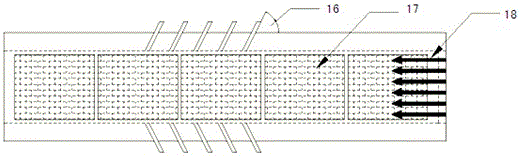

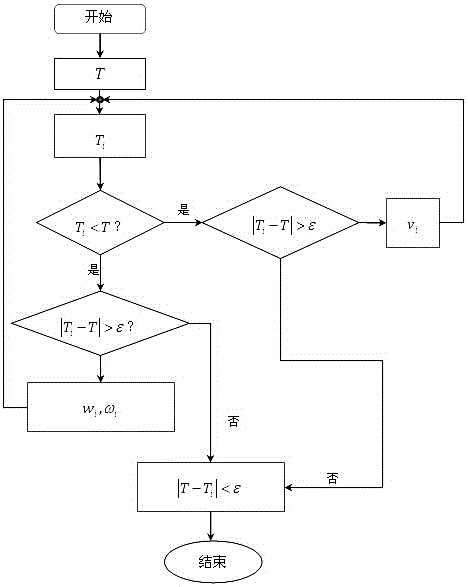

[0028] Such as Figure 1~Figure 2 As shown, a temperature self-regulating device in a kiln includes: a kiln body, a temperature-regulating burner 3 arranged on the side wall of the kiln body, a blower 18 arranged at the tail of the kiln body, a temperature sensor arranged in the kiln body, and a PID control device, and controller; also includes a first motor 9, a second motor 19, a first connecting shaft 10, a second connecting shaft 20, a first connecting block 11, a spherical pair 12, and a second connecting block arranged outside the kiln body 13 and a rotating hinge seat 15, wherein the first connecting shaft 10 and the second connecting shaft 20 are perpendicular to each other, the first motor 9 is connected to one end of the first connecting shaft 10 through a gear transmission pair, and the second motor 19 is driven through a gear One end of the pair and the second connecting shaft 20 is connected by transmission, and the other end of the first connecting shaft 10 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com