Patents

Literature

36results about How to "Control pressure value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

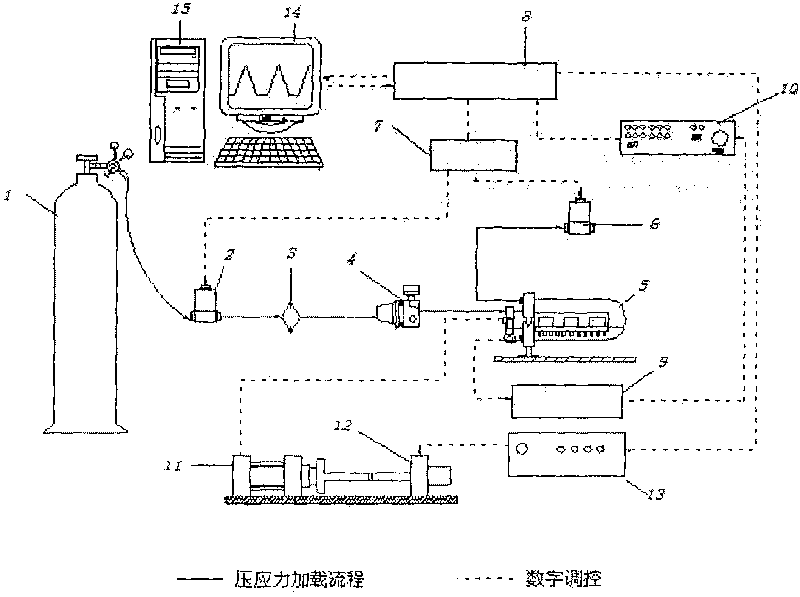

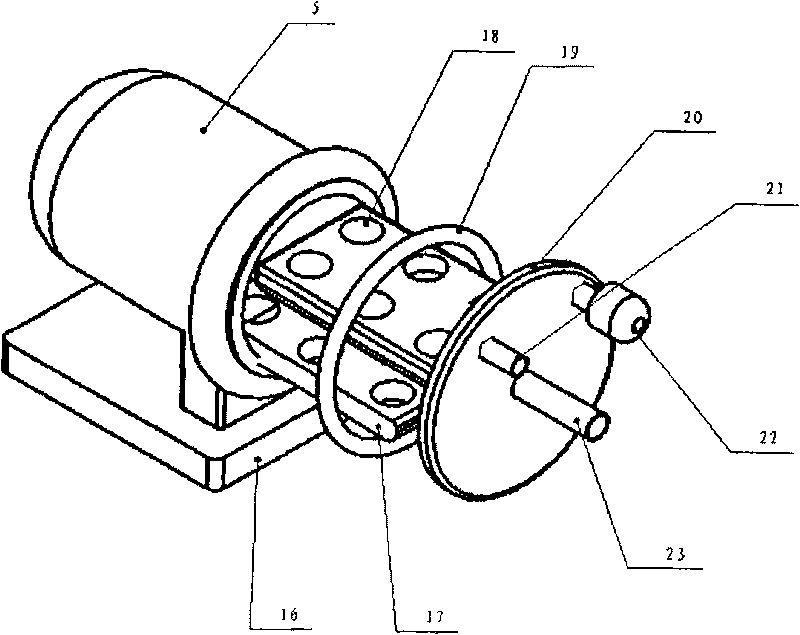

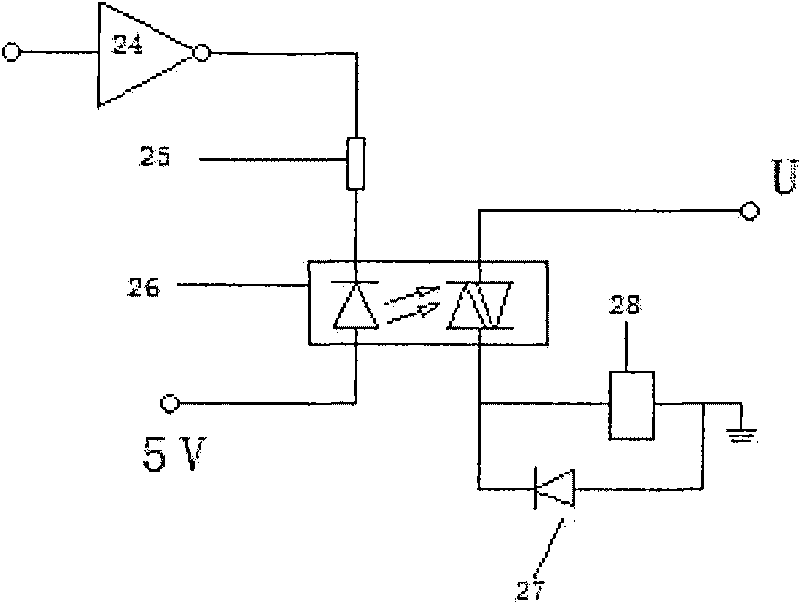

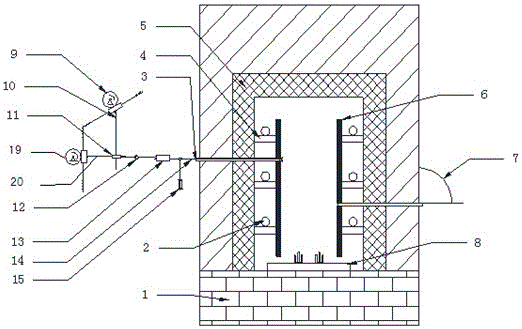

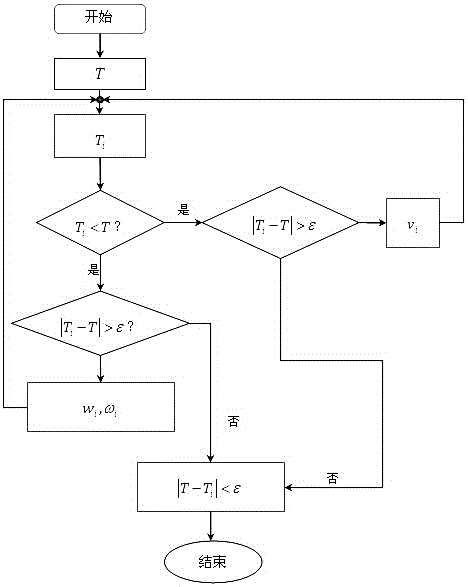

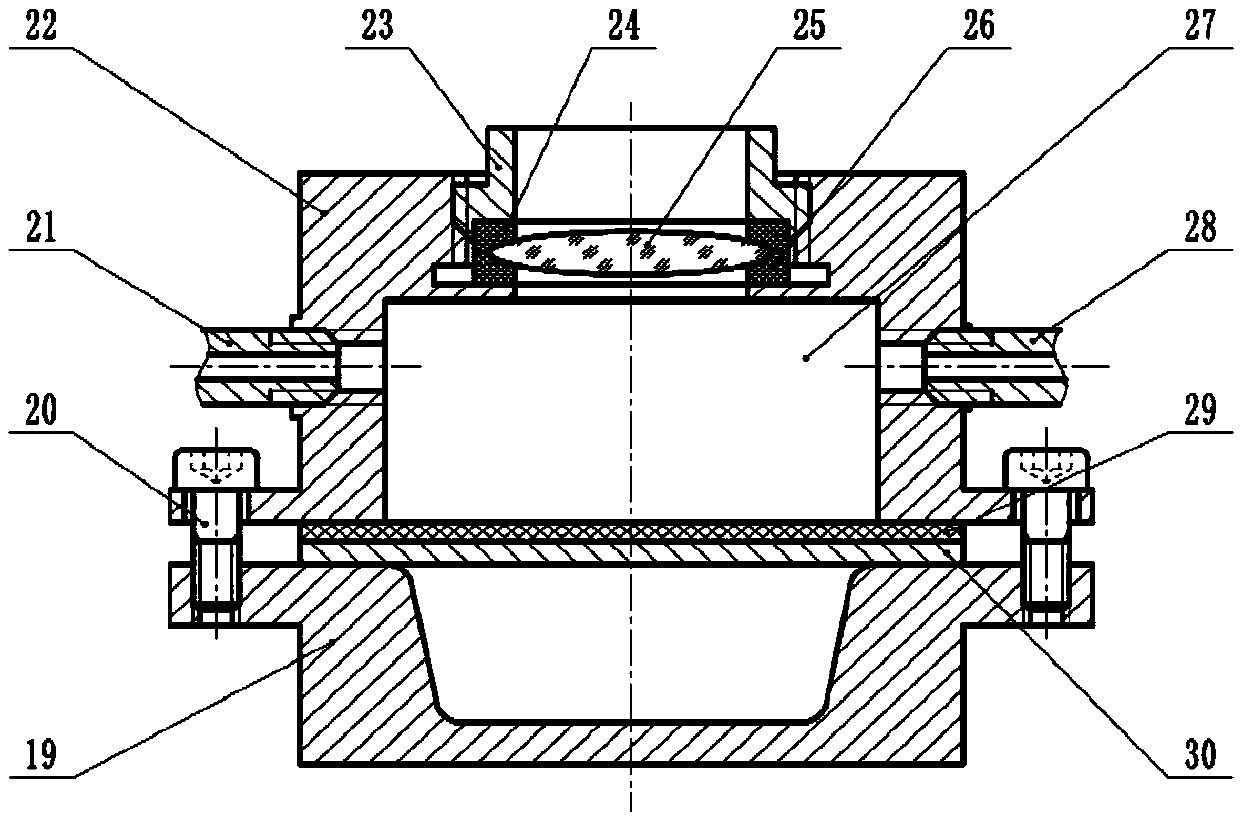

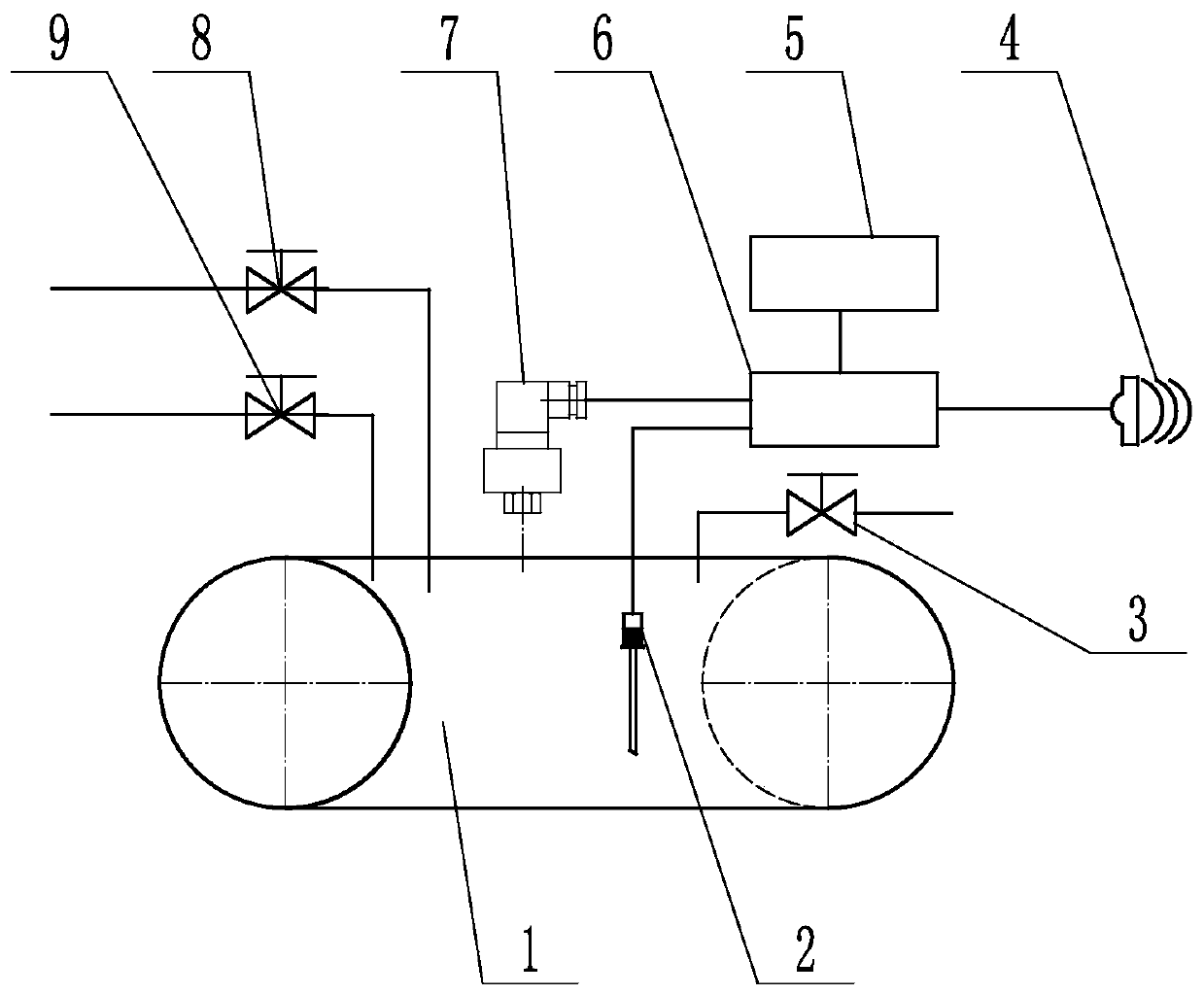

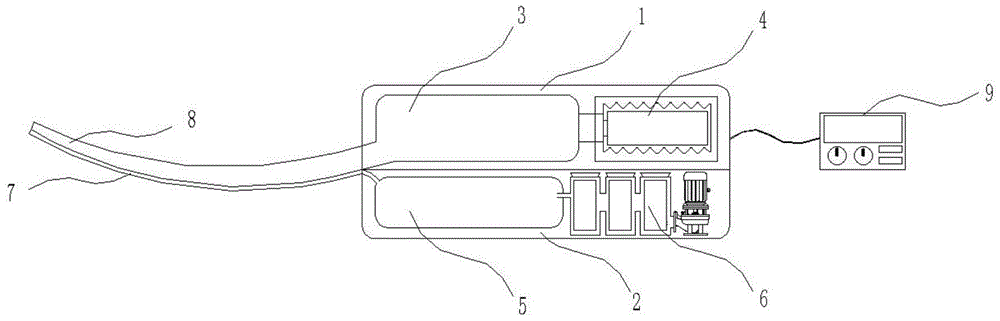

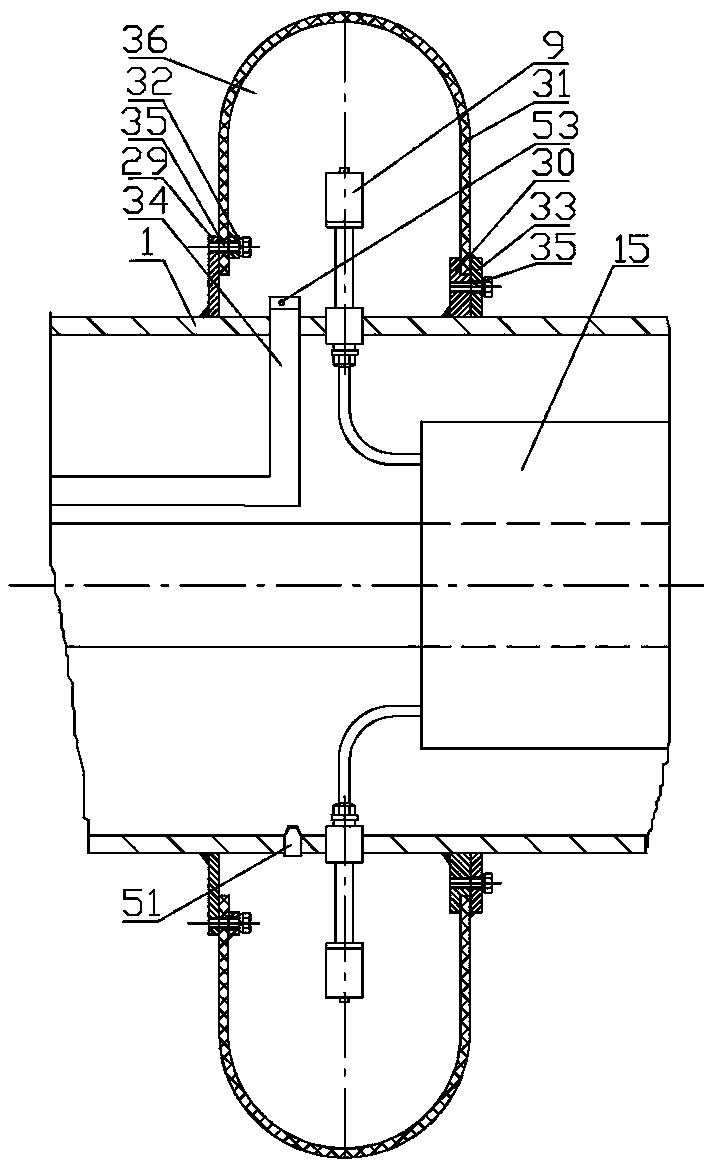

In-vitro cell pressure loading device and in-vitro cell pressure loading method thereof

InactiveCN101717719ASimple and efficient operationThe effect of pressure is accurate and reliableSkeletal/connective tissue cellsTissue/virus culture apparatusProgrammable-gain amplifierEngineering

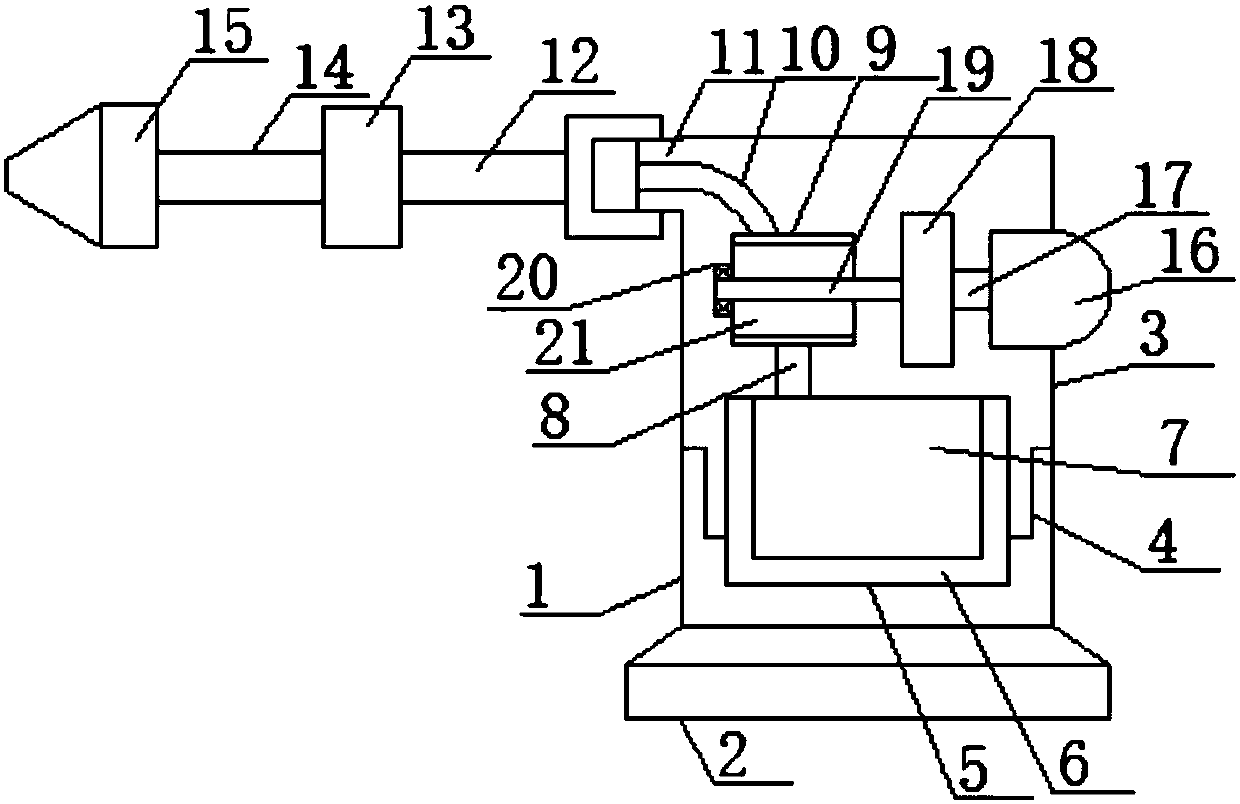

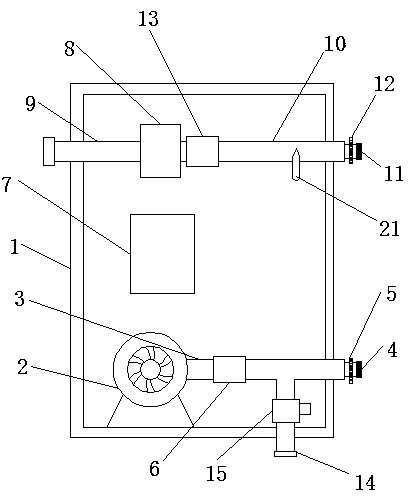

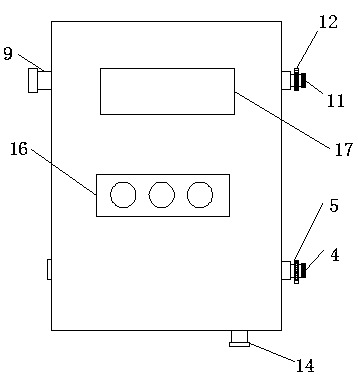

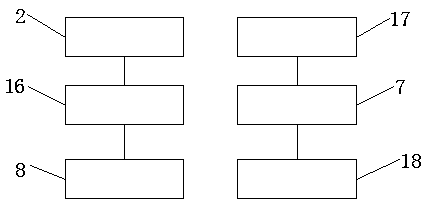

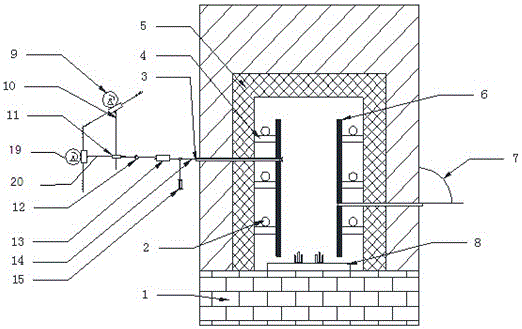

The invention discloses an in-vitro cell pressure loading device and an in-vitro cell pressure loading method thereof. The in-vitro cell pressure loading device is characterized by comprising a pneumatic source (1), an air inlet electromagnetic valve (2), a filter (3), a decompressing valve (4), a pressure cavity (5) and a digital regulation and control system, wherein the pneumatic source is connected with the pressure cavity by the air inlet electromagnetic valve, the filter and the decompressing valve; one end of the pressure cavity (5) is connected with an air outlet electromagnetic valve (6); the air outlet electromagnetic valve is connected with a computer (14) by a drive circuit (7) and a multifunctional data acquisition card (8); the other side of the drive circuit (7) is connected with the air inlet electromagnetic valve (2); the other end of the pressure cavity (5) is connected with a pressure sensor (9); the pressure sensor is connected with the computer (14) by a programmable gain amplifier (10) and the multifunctional data acquisition card (8); and the pressure cavity (5) is connected with the computer (14) by a standard cylinder (11), a linear stepping motor (12), a power amplifier (13) and the multifunctional data acquisition card (8).

Owner:SICHUAN UNIV

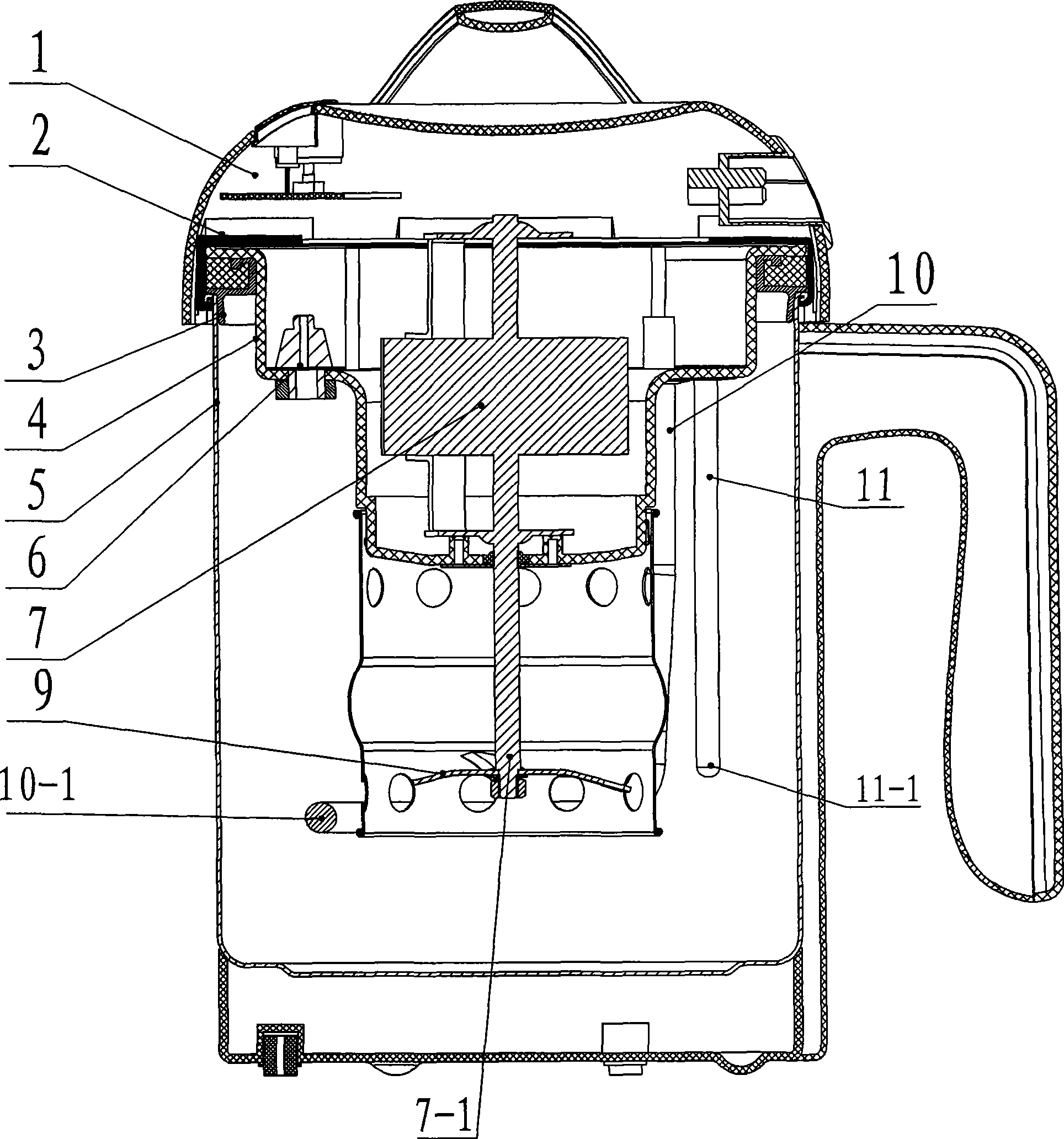

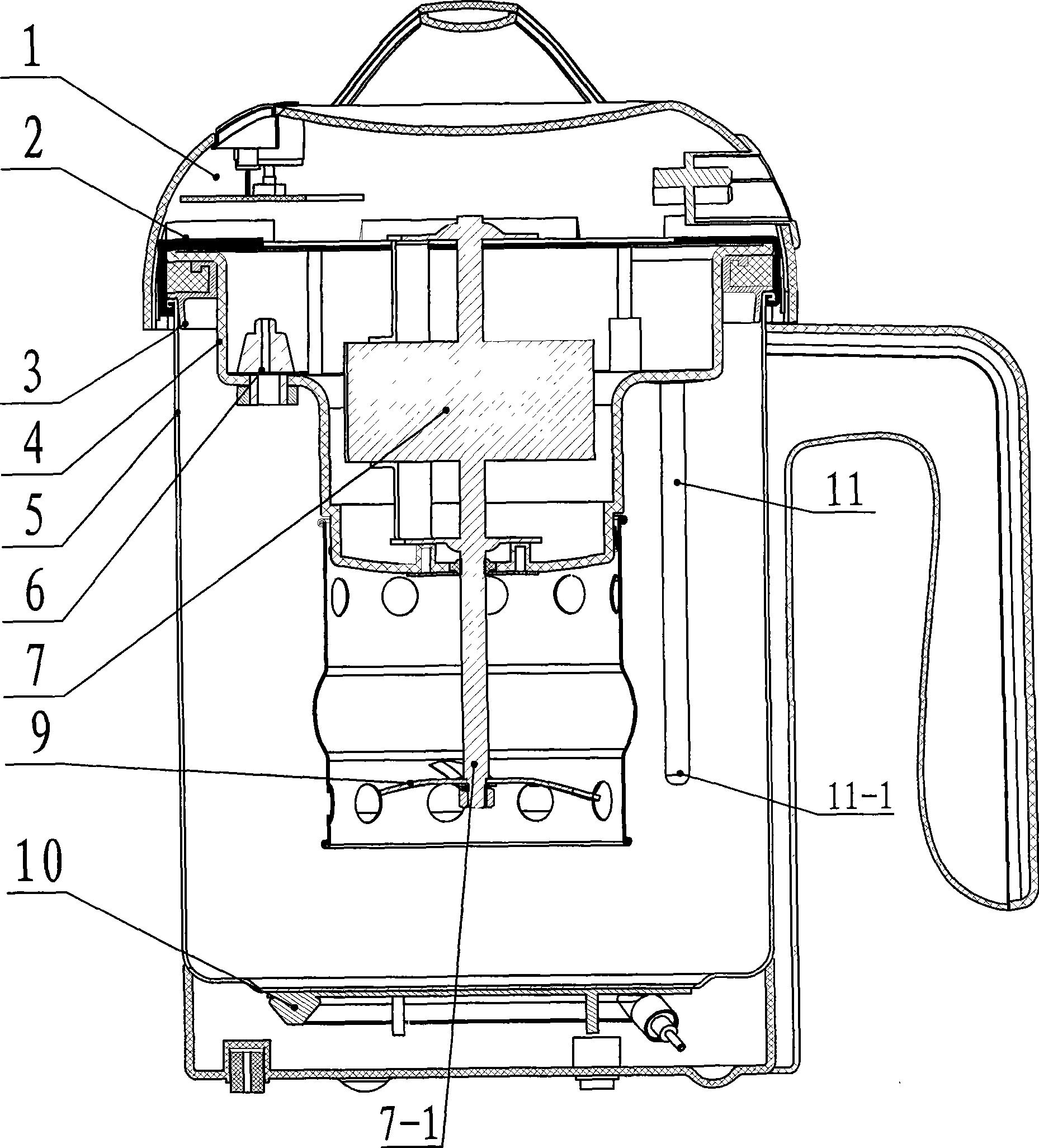

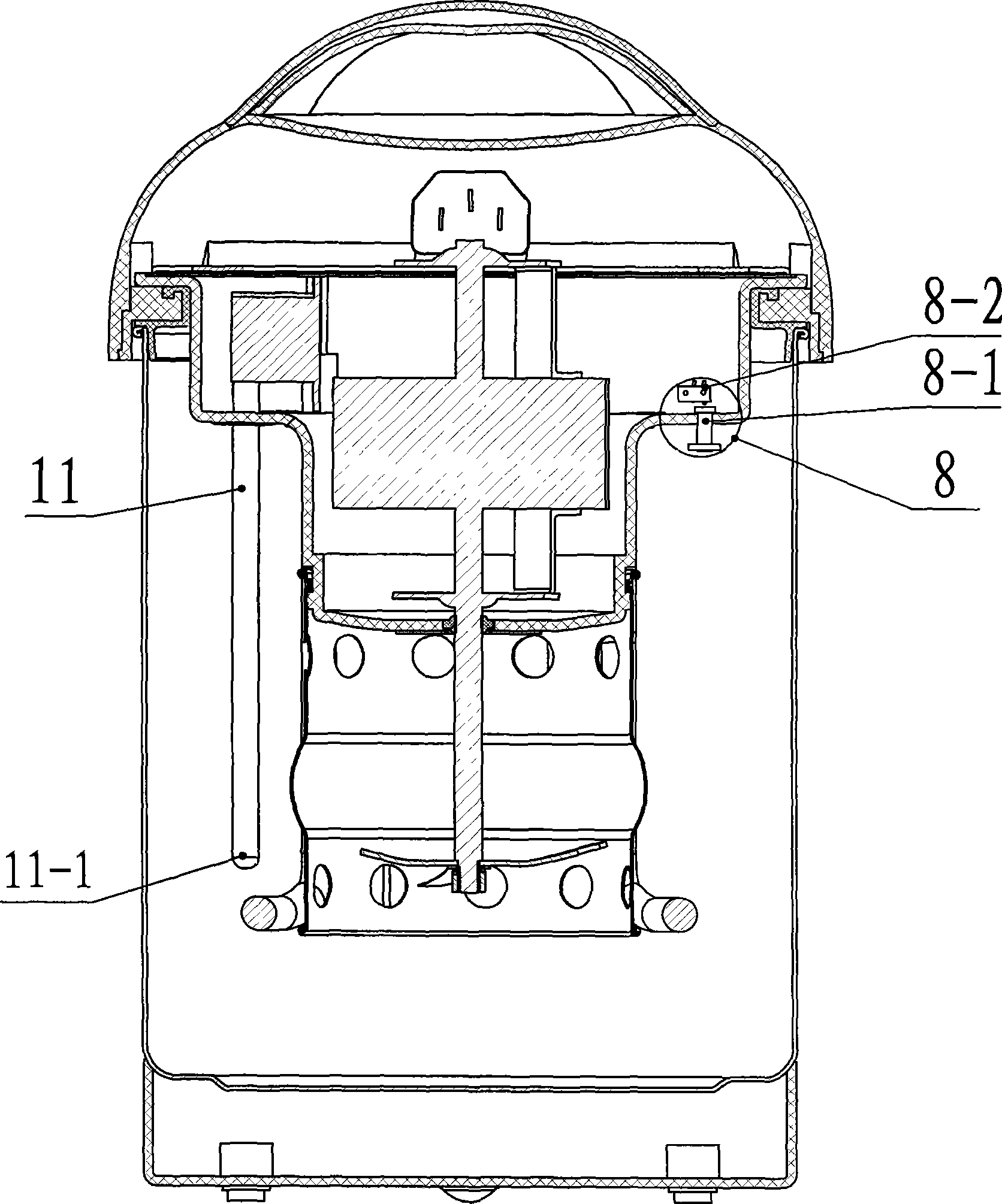

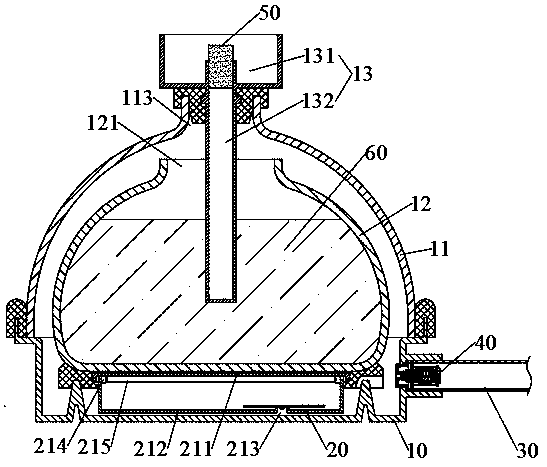

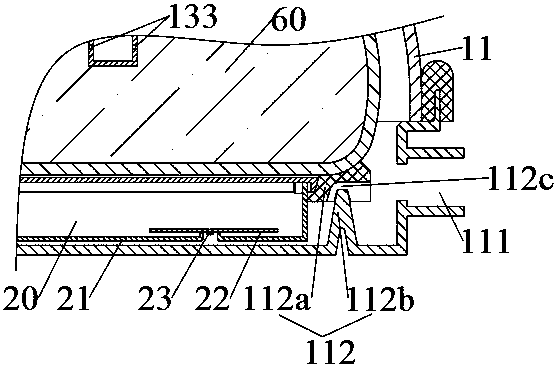

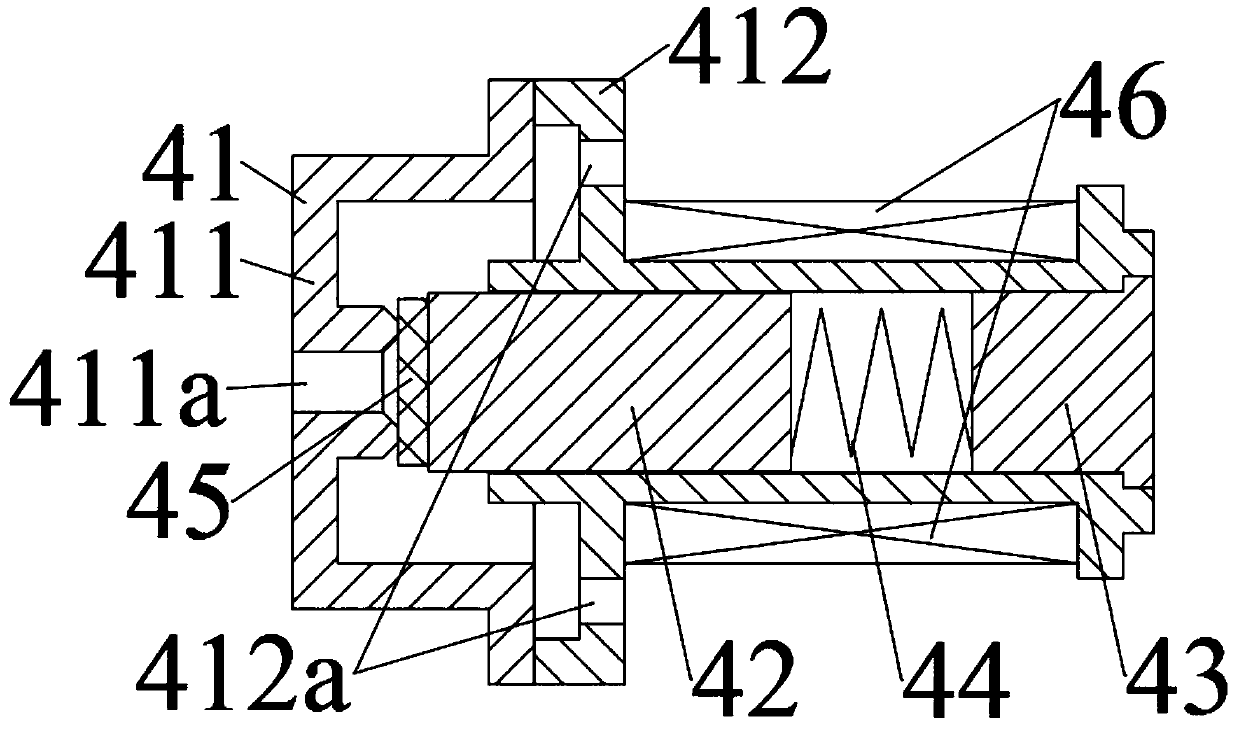

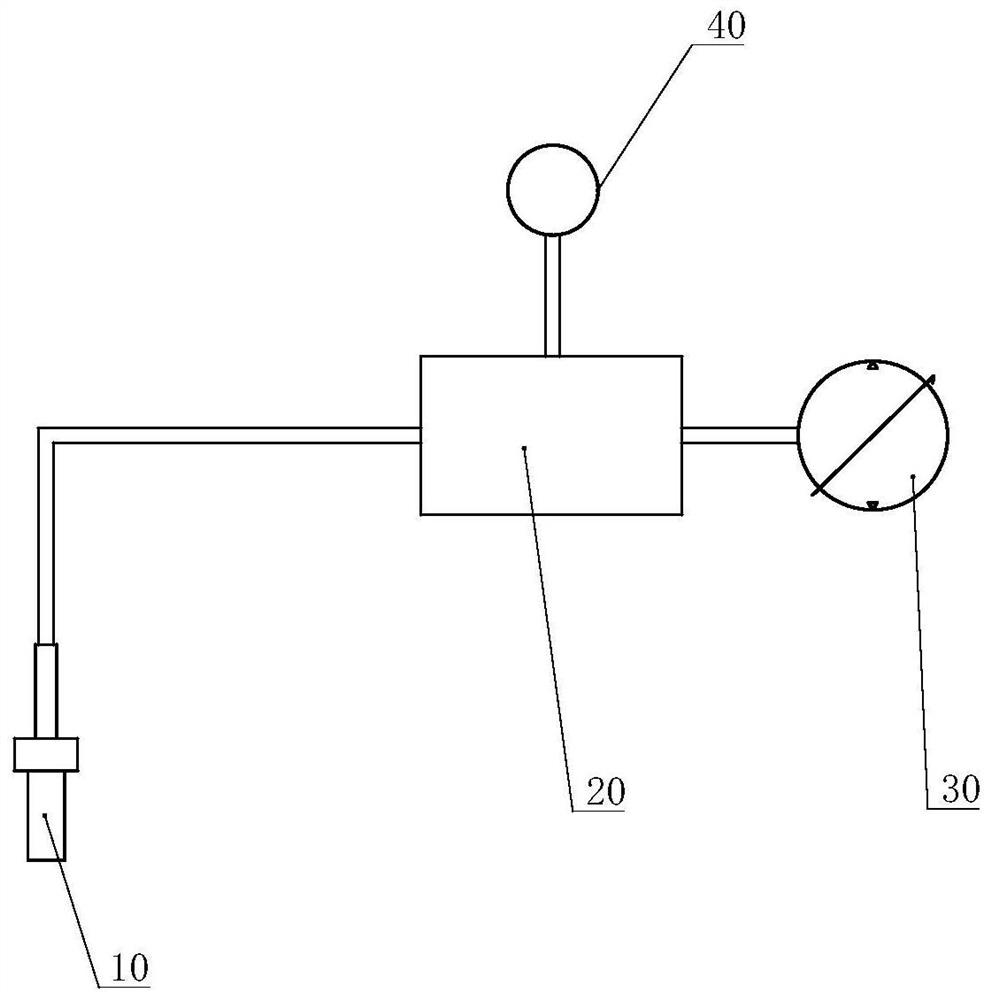

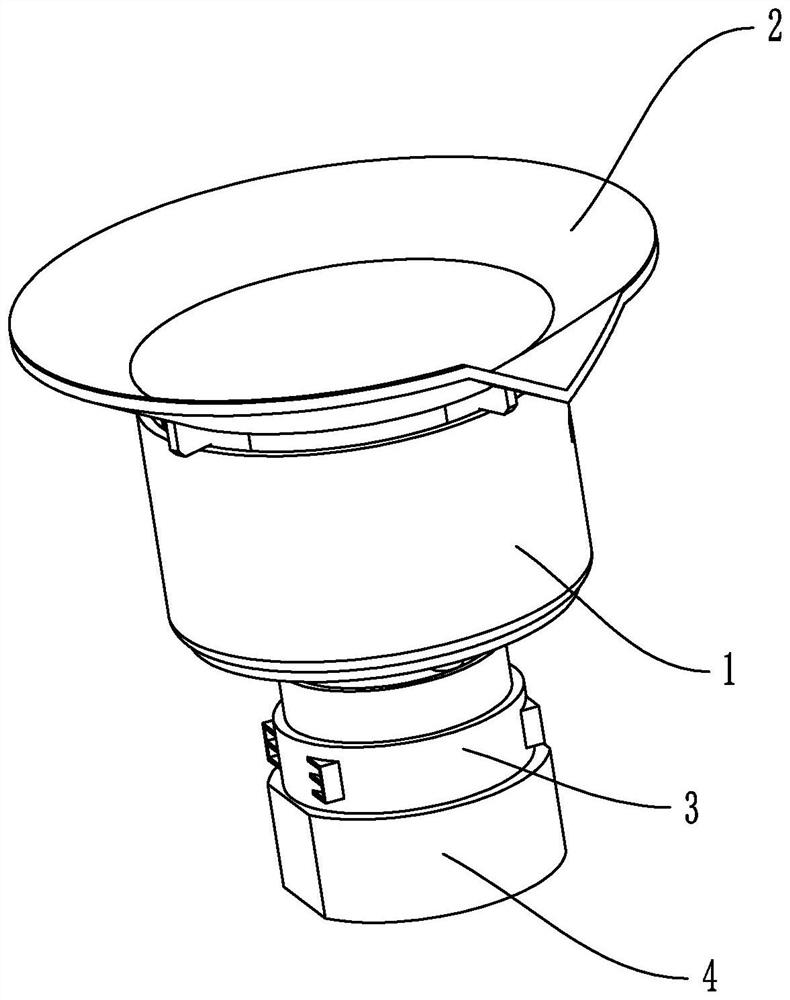

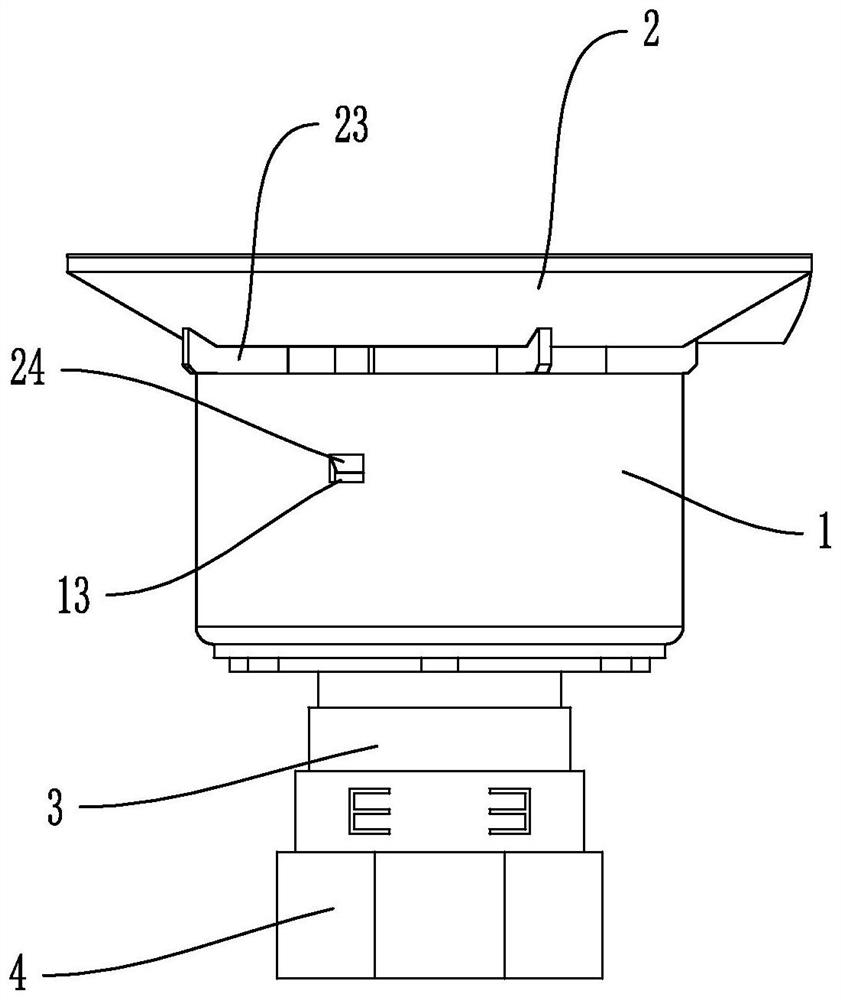

Automatic pressure soybean milk machine and method for producing soybean milk

ActiveCN101485422AControl pressure valueFully emulsifiedBeverage vesselsFood preparationAdditive ingredientDrive shaft

The invention provides an automatic pressure soybean milk machine, and belongs to the technical field of household food cuisine. The machine comprises a machine seat provided inside with a driving motor supplying power, blades arranged at the tail end of a driving shaft of the motor, a cup body, a cup cover arranged above the cup body, a heating element, a temperature detecting device and a circuit board of a control circuit; the cup cover and the mouth of the cup body are provided with sealing elements; under the state of closed cover, a sealed cavity is formed in the cup body, the continuous rise of pressure in the sealed cavity is allowed after heating, and a pressure relief device is also arranged; and air can be discharged by the pressure relief valve when the pressure in the cup body is higher than the preset pressure P0. The temperature for cooking the soybean milk can reach more than 106 DEG C; when the soybean milk is continuously cooked in the sealed cavity, the overflow phenomenon cannot happen so as to shorten the process of cooling the soybean milk and saving time; moreover, the cooked soybean milk is fully emulsified and well cooked; and due to the continuous and quick heating, the loss of the nutrient contents in the food is inhibited in the heating process, so that the cooked soybean milk is fragrant and pure, and tastes good.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

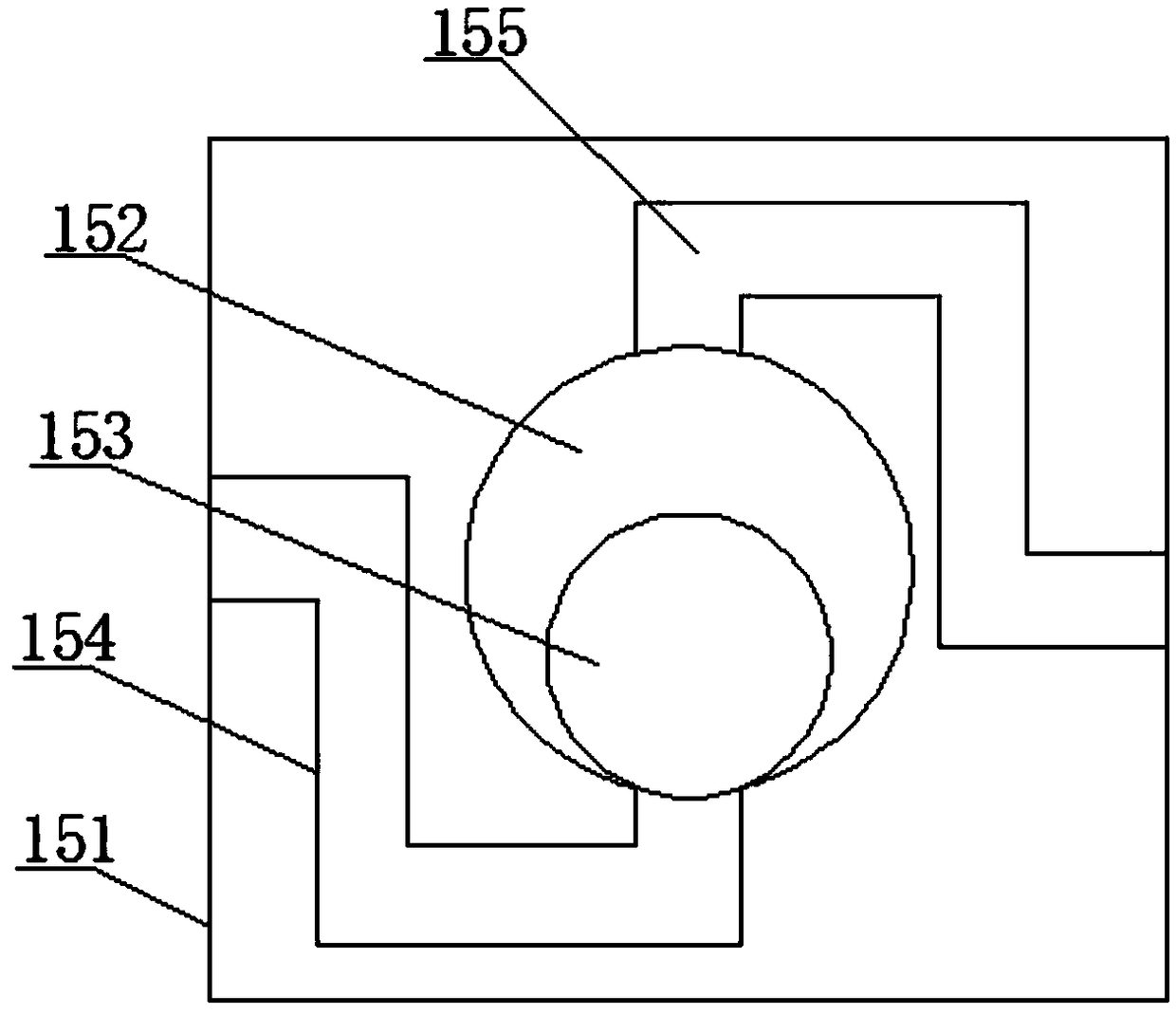

Punching device strong in pressure control effect

InactiveCN108856424AQuality improvementIncrease success rateMetal-working feeding devicesPress ramPunchingMechanical components

The invention discloses a punching device strong in pressure control effect. The punching device comprises a bottom supporting base plate and a main thread sleeve with the center provided with a mainthread section. The punching device can control the pressure during punching every time, and accordingly the punched product quality and success rate are improved. In addition, the device conducts control under the combination action of various mechanical components, and therefore the manufacturing cost of the device is low, the usage cost and the maintaining cost are lower, and the beneficial effect of economy is achieved. In addition, the device is provided with a three-point positioning and clamping control mechanism, the three-point positioning and clamping control mechanism conducts positioning so that the components can be located at the center position, and accordingly the punching production quality is improved. Furthermore, the device is provided with a large air pressure air one-way flow control mechanism, large air air-pressure one-way flow can be controlled, and the phenomenon of air backflow is avoided. In addition, the device is provided with a top thread screwing type maximum air pressure control mechanism, the punching air pressure maximum value can be controlled under the action of the air pressure, and accordingly the pressure value is controlled.

Owner:郭毅义

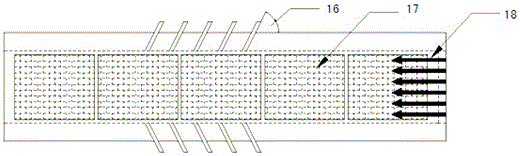

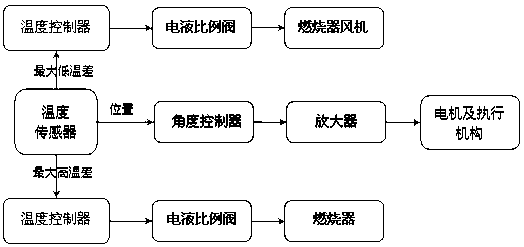

Tunnel kiln environment conditioning method and device of automatically adjusting temperature in kiln

ActiveCN106444914AImprove intelligenceGood energy saving effectTemperatue controlTunnel kilnEngineering

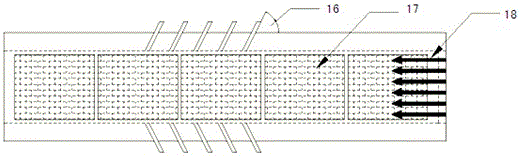

The invention discloses a tunnel kiln environment conditioning method and a device of automatically adjusting the temperature in a kiln. The tunnel kiln environment conditioning method includes the following steps: S1, environmental information acquisition equipment is arranged in a tunnel kiln, wherein the environmental information acquisition equipment is used for acquiring environmental parameters of the environment to be conditioned in the tunnel kiln and sending the environmental parameters to a controller; S2, the controller generates an environment conditioning command according to the environmental parameters acquired by the environmental information acquisition equipment, and sends the environment conditioning command to an environment conditioning execution mechanism; and S3, the environment conditioning execution mechanism conditions the environment in the tunnel kiln according to the environment conditioning command sent from the controller. The tunnel kiln environment conditioning method can control the angle of a temperature adjustment burner, the combustion gas injection rate, the angular rate of the temperature adjustment burner, the kiln tail blast rate, and the like, of the tunnel kiln, and can perform sintering research on various refractory materials, thus increasing diversity of research.

Owner:YANCHENG INST OF TECH

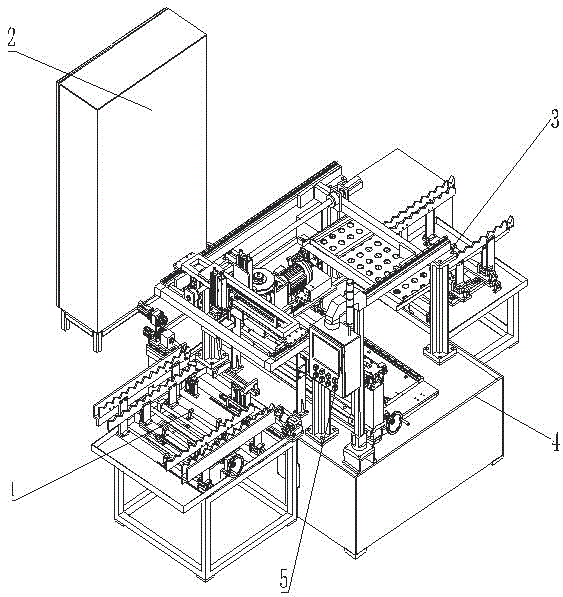

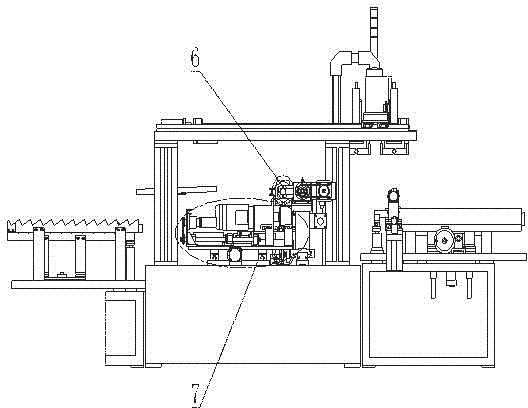

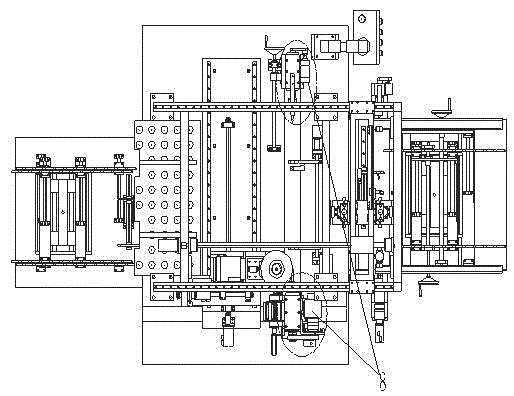

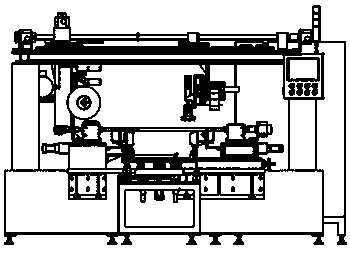

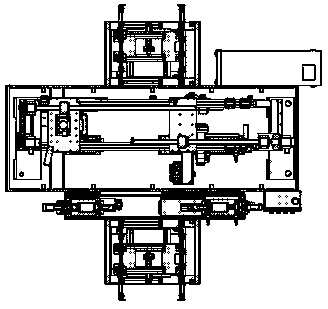

Longitudinal rack polishing machine

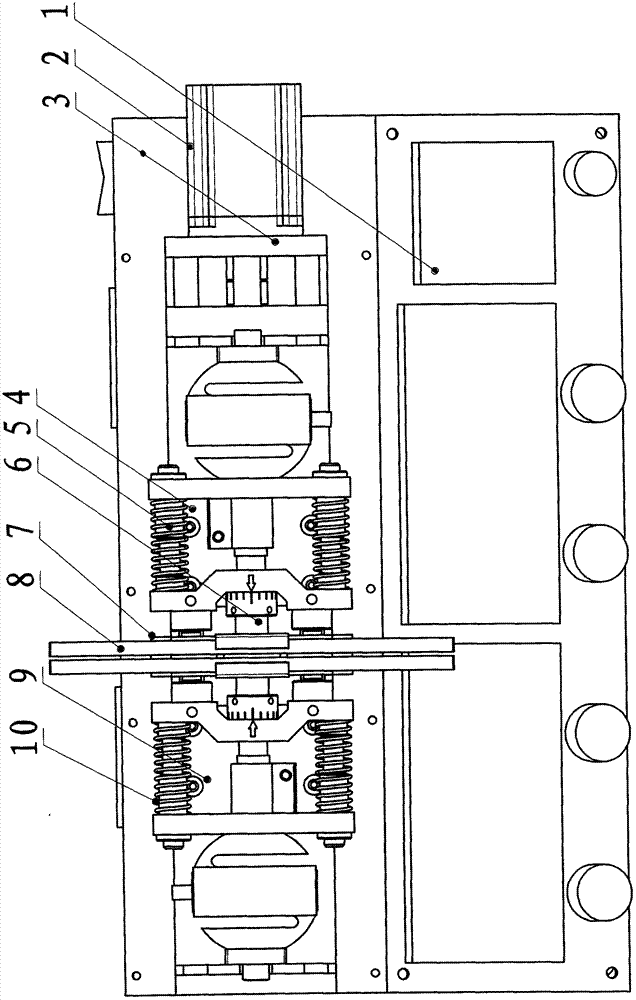

ActiveCN105983896AMeet polishing requirementsGuaranteed reflowPolishing machinesGrinding drivesMotor driveProgrammable logic controller

The invention belongs to the field of ultra-precision machining equipment and relates to a longitudinal rack polishing machine. The longitudinal rack polishing machine comprises an automatic discharging mechanism, a PLC (programmable logic controller) electrical control box, an automatic feeding mechanism, a frame, a touch screen control board, an automatic shape modifying mechanism, a polishing mechanism and a centre driving mechanism. A nylon resin polishing wheel is adopted for longitudinal polishing of a tooth back portion and a shaft portion of a rack. The polishing wheel in high-speed rotation has a certain floating quantity and can completely fit the rack, and the polishing wheel has a certain precompression force on the rack by the aid of a servo motor and a pressure sensor. Angular rotation of the rack is also realized under action of the servo motor, and full coverage of the tooth back portion can be realized. The servo motor drives the polishing wheel to move longitudinally to meet requirements of workpieces in different lengths. In electrical control, A PLC and a touch screen are adopted for controlling, and the servo motor and an air cylinder serve as power sources to be responsible for all operation instructions of equipment and implementation.

Owner:吉林瑞铭机电设备有限公司

Backflow prevention amniotic fluid aspirator special for the obstetrics and gynecology department

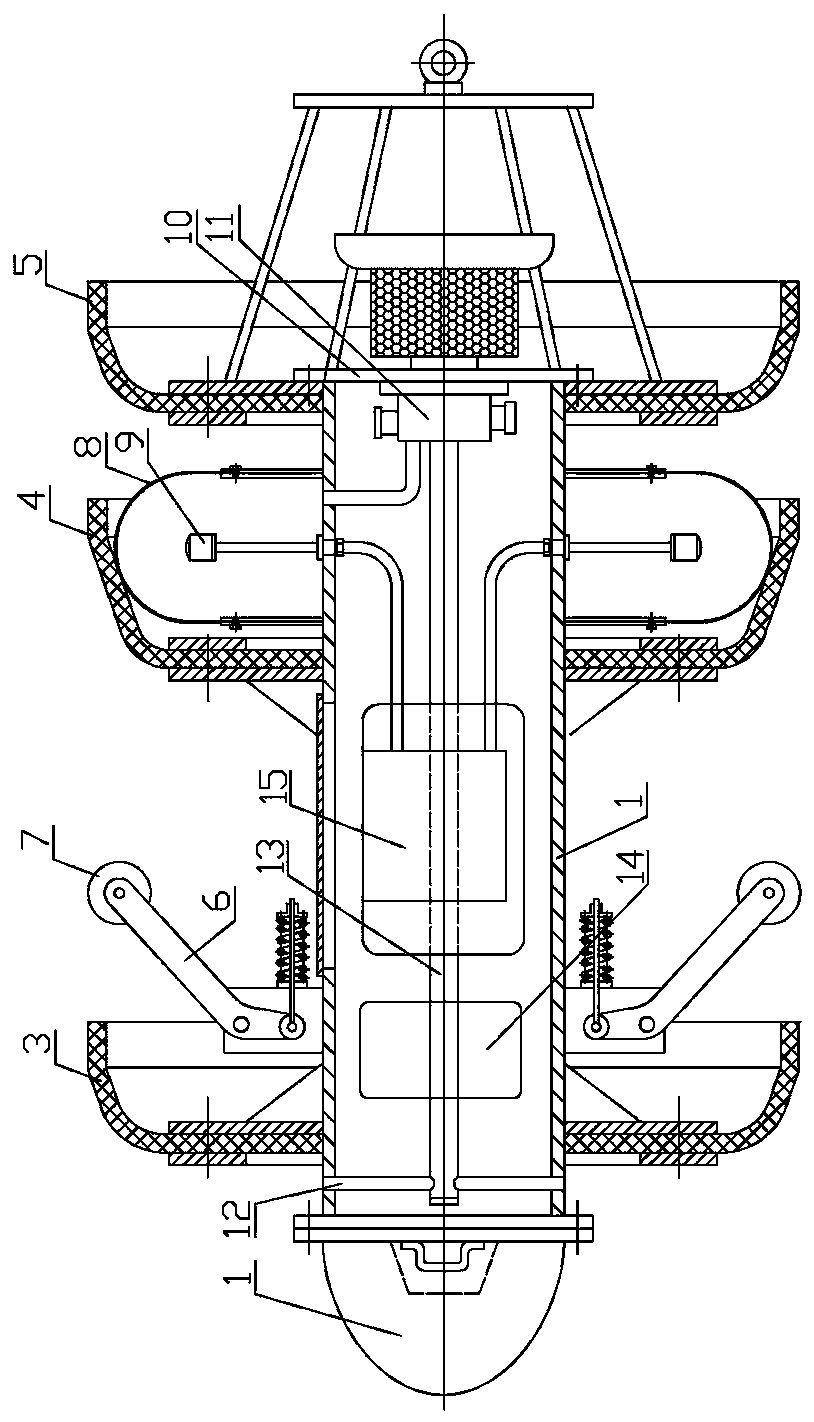

InactiveCN107802897APrevent backflowControl pressure valueMedical devicesIntravenous devicesSide effectObstetric history

The invention discloses a backflow prevention amniotic fluid aspirator special for the obstetrics and gynecology department. The backflow prevention amniotic fluid aspirator comprises a bottom hollowshell and a top hollow hell, main hollow structures are both arranged in the centers of the upper surface of the bottom hollow shell and the lower surface of the top hollow shell, the inner side of the upper surface of the bottom hollow shell is connected with the outer side of the lower surface of the top hollow shell through a main threaded structure, the bottom of the bottom hollow shell is installed on the upper surface of a supporting baseboard, and a turbine mounting space is arranged at the portion, located over the main hollow structure, inside the top hollow shell. Aerodynamics is utilized, so that the device has the adsorption capacity, and therefore amniotic fluid is adsorbed; meanwhile, the device is provided with an amniotic fluid backflow prevention mechanism, and the occurrence that the amniotic fluid flows back due to the liquid height difference can be effectively prevented; besides, the device is provided with an absorption air pressure control mechanism, the pressurevalue when the amniotic fluid is adsorbed can be effectively controlled, and therefore side effects caused when the amniotic fluid adsorption pressure is too large are effectively prevented.

Owner:刘顺杰

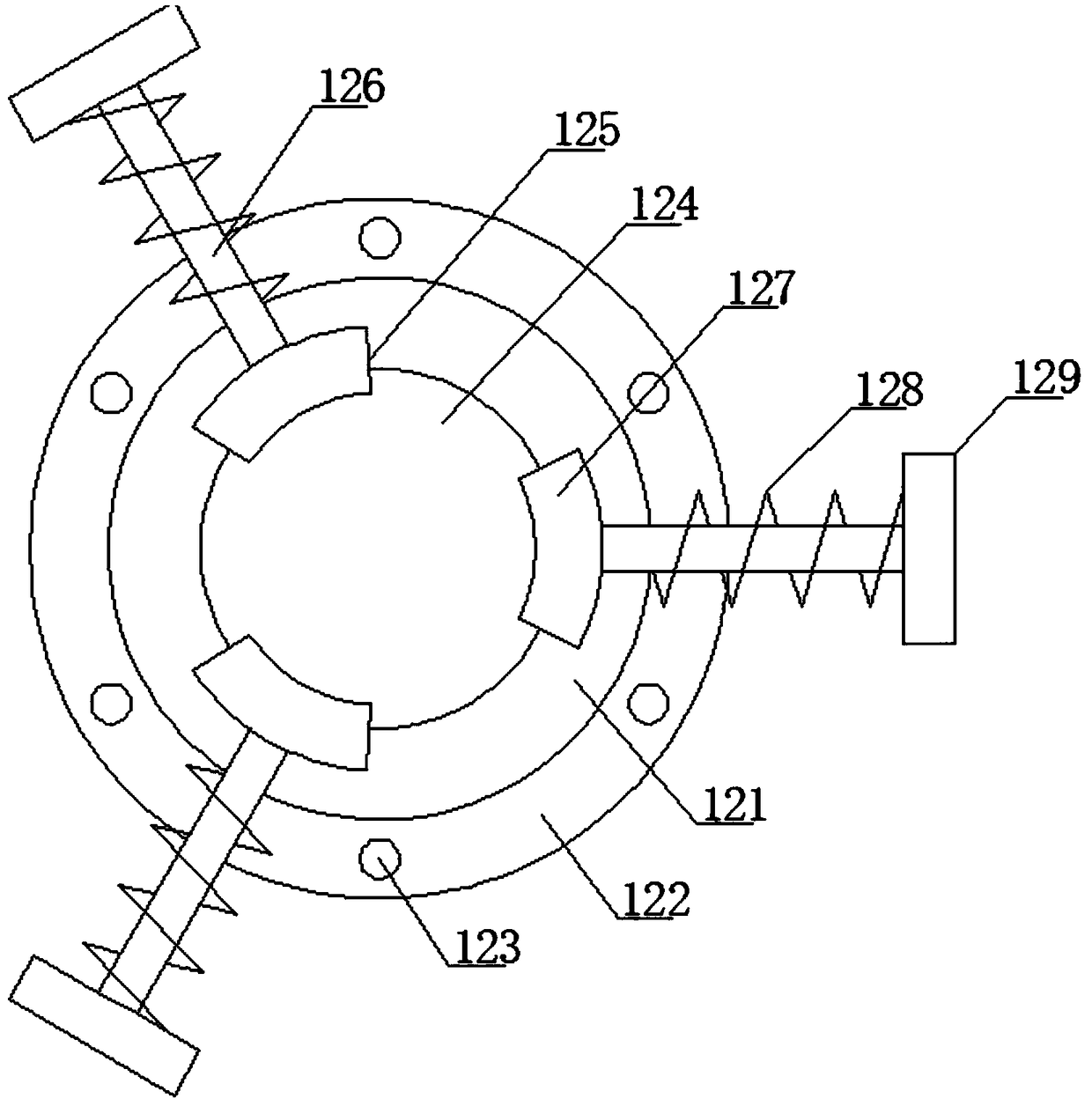

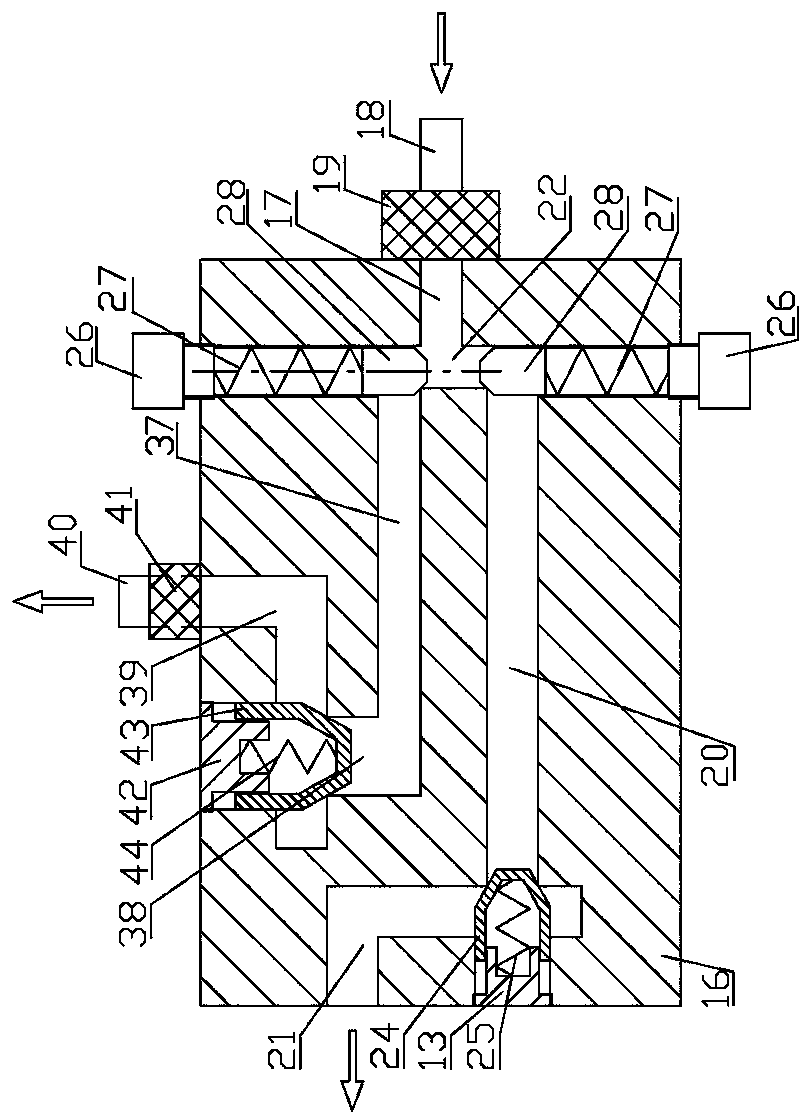

Liquid flow type pressurization device

ActiveCN111219337AIncrease rotation speedRealize the driving functionPump componentsPump controlGear wheelElectric machinery

The invention discloses a liquid flow type pressurization device. The liquid flow type pressurization device comprises a main body shell. By using a driving motor, a driving function of liquid duringinjection can be achieved, a pressure auxiliary function is formed when the air enters, and two variables are determined, so that the energy when the liquid is discharged is controllable, and the pressurization can be carried out under the premise of the continuous flow of water. Moreover, the device is provided with a gear set meshing rotary speed enhancement mechanism and the rotation speed of the driving motor can be strengthened, so that the working efficiency is improved. Moreover, the device is provided with a circular array spiral spring abutting rotation resistance control mechanism, and the strength of a spiral spring is used for controlling the air pressure value. In addition, the device is provided with a large pressure sphere type air-liquid one-way flow mechanism, and the large pressure sphere type air-liquid one-way flow mechanism can control the one-way flow of gas-liquid liquid.

Owner:苏州德尔得机电设备有限公司

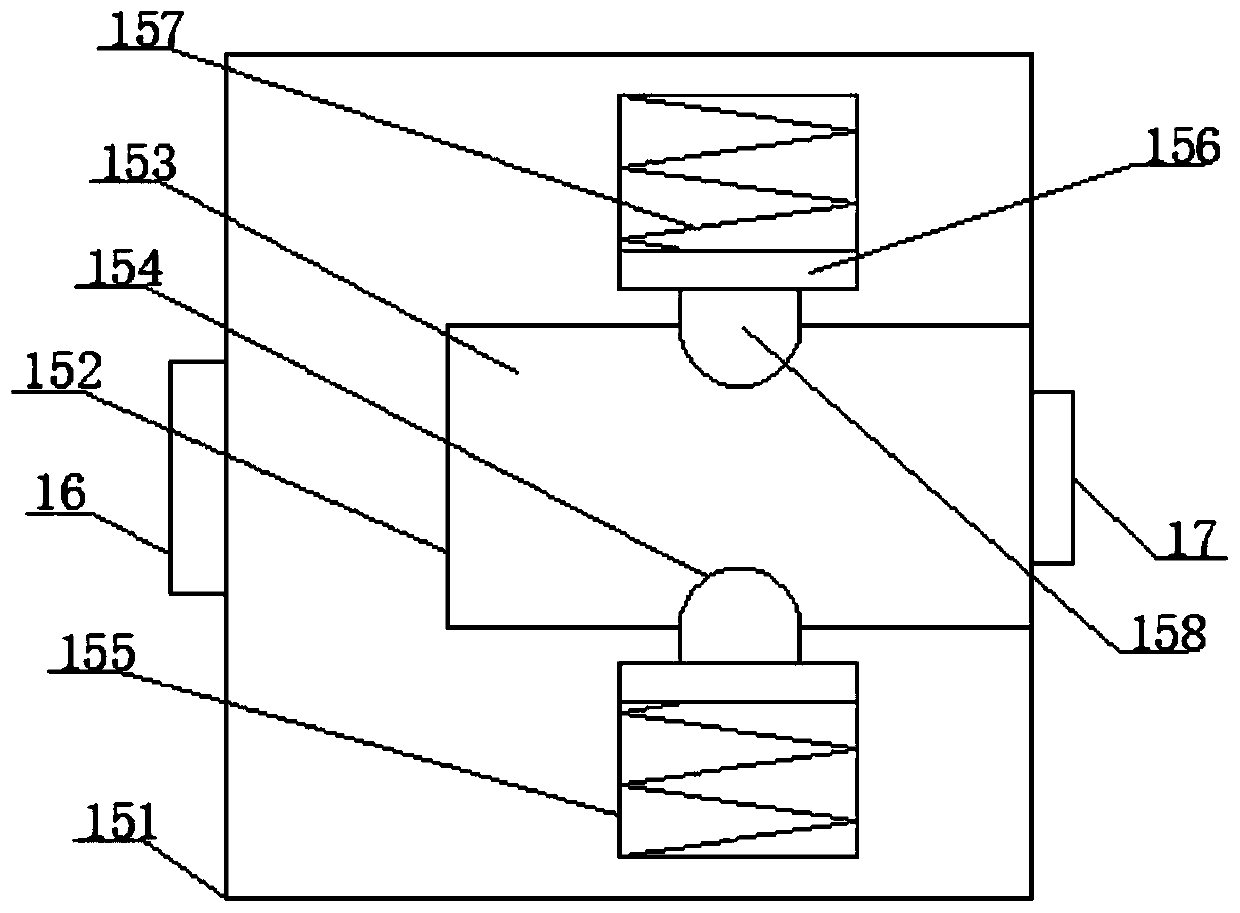

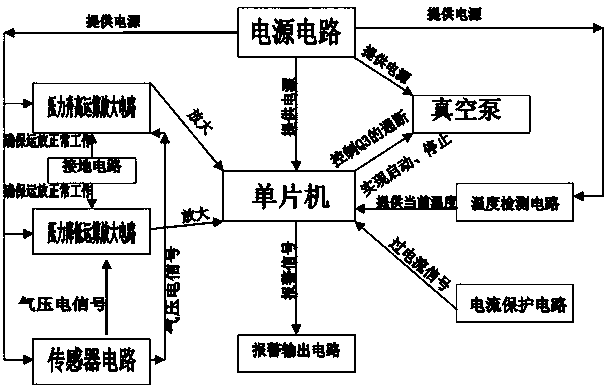

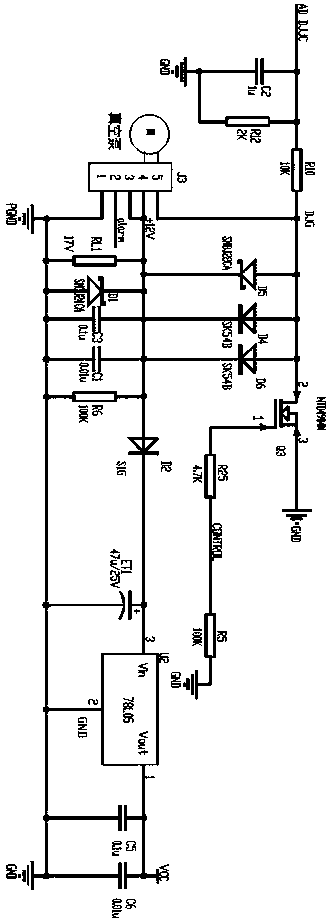

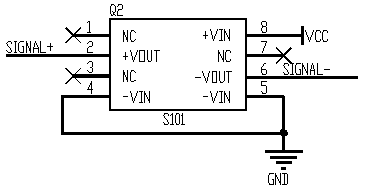

Electric automobile brake power-assisted vacuum pump controller circuit and control method

PendingCN107728539ASafe and reliableImproved temperature compensationProgramme controlComputer controlMicrocontrollerElectric vehicle

The invention relates to an electric automobile brake power-assisted vacuum pump controller circuit and a control method. A pressure increase operation amplifying circuit and a pressure reduction operation amplifying circuit provide amplifying signals to a single-chip microcomputer respectively, an alarm output circuit provides an alarm signal to the single-chip microcomputer, a temperature detection circuit provides a current temperature signal to the single-chip microcomputer, a current protection circuit provides an over-current signal to the single-chip microcomputer, the single-chip microcomputer controls a vacuum pump to be started, a sensor circuit provides an air pressure electric signal, a grounding circuit ensures that the two operation amplifying circuits work normally, and a power circuit supplies a power source for the pressure increase operation amplifying circuit, the pressure reduction operation amplifying circuit, the grounding circuit, the sensor circuit, the single-chip microcomputer, the temperature detection circuit and the vacuum pump. By controlling the vacuum pump to start and stop, the air pressure value in a vacuum tank is controlled, and the effect of braking assistance is achieved. The controller circuit has multiple protection functions, avoids burnout of the vacuum pump, and prolongs the service life of the vacuum pump and a storage battery.

Owner:TIANJIN ZHONGHUAN SANFENG ELECTRONICS

Hose sealability detection device

InactiveCN109269740AIncrease air pressureControl pressure valueMeasurement of fluid loss/gain rateSolenoid valveEngineering

The present invention relates to a hose sealability detection device. The device comprises a box body; an air inflation pump is arranged at the bottom of the inner cavity of the box body; the air outlet of the air inflation pump is connected with a first flow guide tube; one end of the first flow guide tube passes through the other side of the box body; a first sealing ring is disposed at the end opening of the first flow guide tube; a first hose clamp is arranged to one side of the first sealing ring; the first flow guide tube is provided with a first check valve and a pressure relief tubewhich are sequentially arranged from the left side to the right side of the first flow guide tube; one end of the pressure relief tube passes through the lower end of the box body; the pressure relieftube is provided with a solenoid valve; a PLC is disposed above the air inflation pump; a water pump is arranged above the PLC; one side of the water pump is connected with a water incoming tube; thewater incoming tube passes through the top of one side of the box body; and the other side of the water pump is connected with a second flow guide tube. The hose sealability detection device has theadvantages of simple structure and reasonable design. With the hose sealability detection device of the invention adopted, a method that applies direct water injection to realize detection can be avoided, a drying step can be eliminated, work efficiency can be improved, and a leak point can be tracked when a hose leaks.

Owner:扬州尚翔汽车零部件有限公司

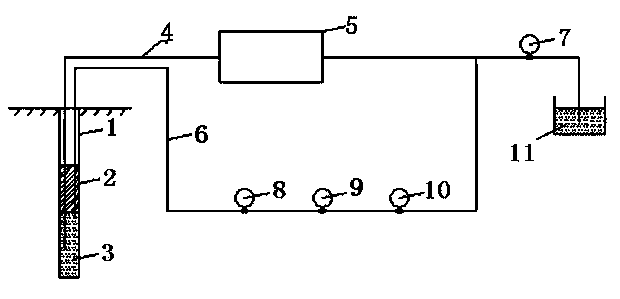

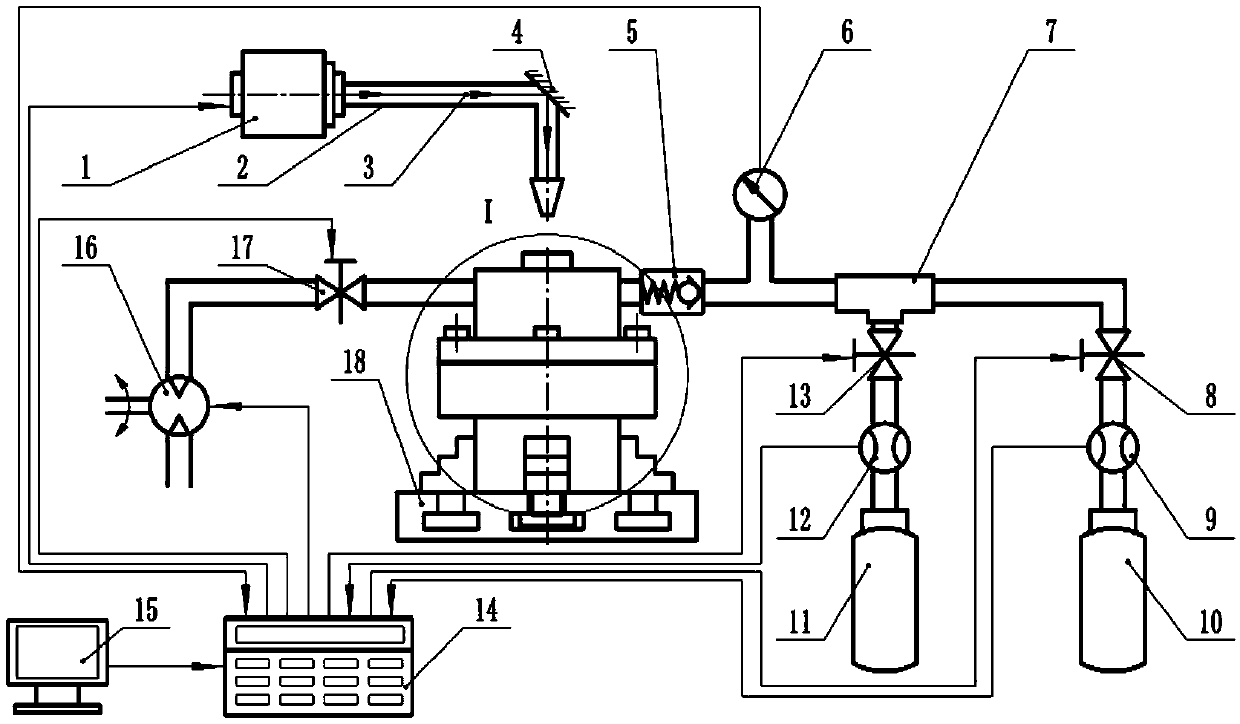

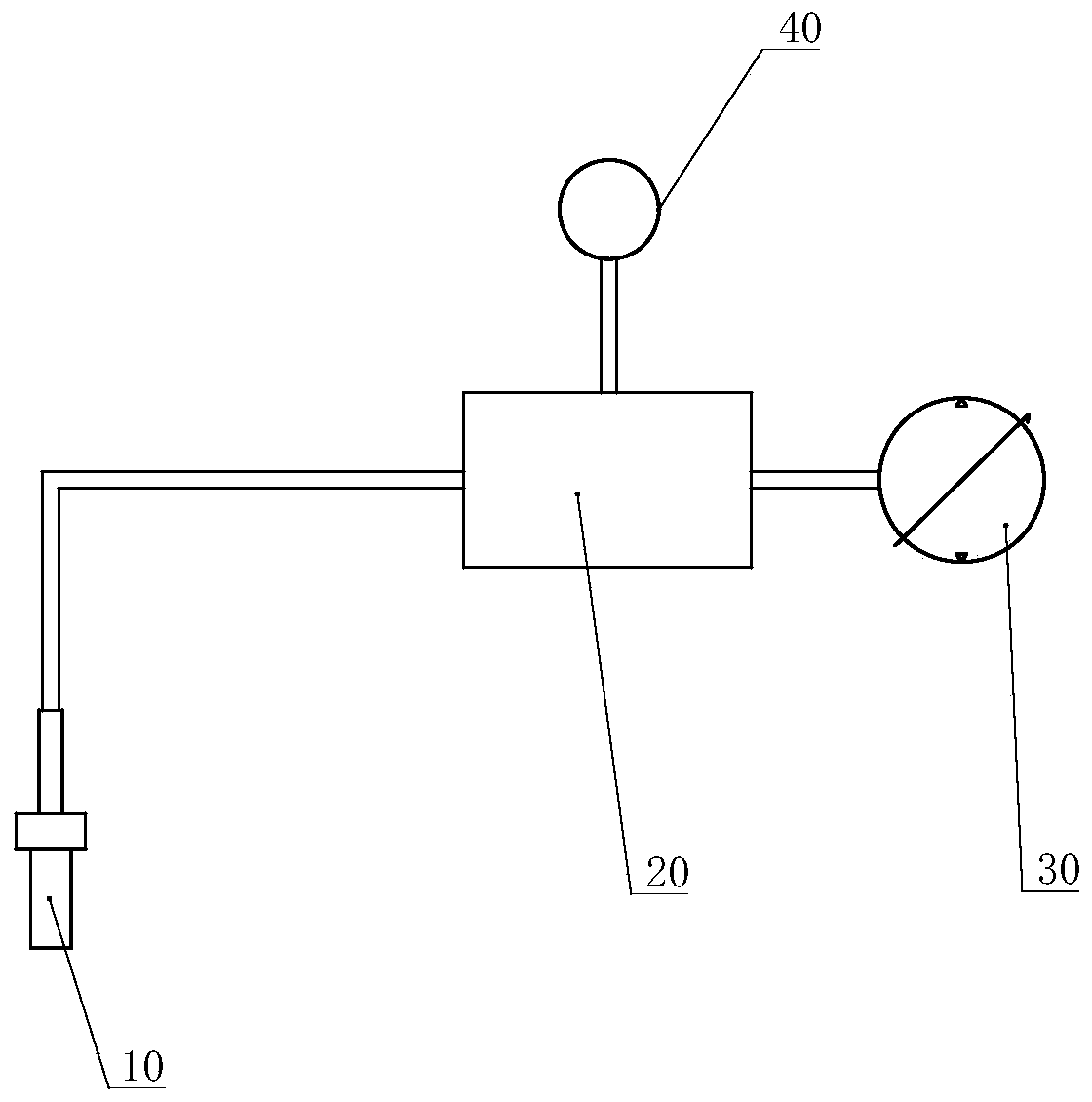

Drill-hole high-pressure water pump-in test loading system

The invention discloses a drill-hole high-pressure water pump-in test loading system which comprises a test cavity and a water reservoir. The test cavity is formed in a test observation hole and is communicated with the water reservoir through a water inlet pipe, a high-pressure water pump unit is mounted on the water inlet pipe, and a water return pipe is communicated between the test cavity and the high-pressure water pump unit and provided with a pressure gauge. In the drill-hole high-pressure water pump-in test loading system, pipeline connection way is modified, the water return pipe is added to be assembled into double-pipeline connection way together with the water inlet pipe. Water pressure value of the test cavity is controlled by regulating pressure of the water return pipe and is free of affection from water flow state of the water inlet pipe when water pressure of the test cavity is tested by being connected with a pressure sensor, and head loss of pipelines is low; test value is smaller than practical pressure and is safer for drill-hole high-pressure water pump-in test reaching certain set pressure value.

Owner:POWERCHINA ZHONGNAN ENG

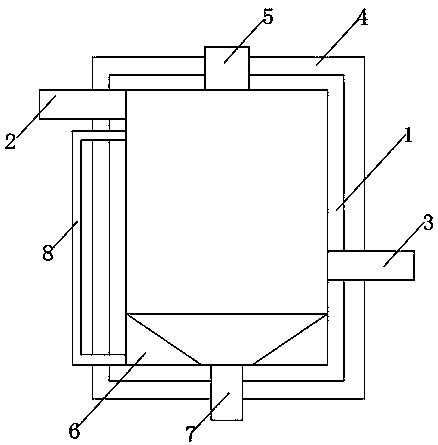

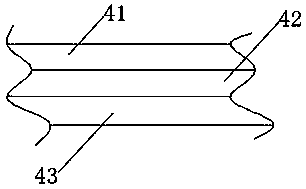

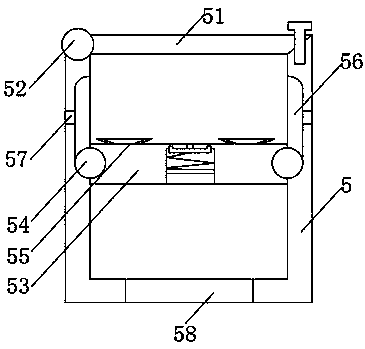

Temperature self-adjusting device for inner tunnel kilns

ActiveCN106440777AIncreased mixed combustion areaReduce generationFurnace typesTunnel kilnReaction rate

The invention discloses a temperature self-adjusting device for inner tunnel kilns. The device comprises a kiln body, a temperature adjustment burner which is installed on the side wall of the kiln body, a blower which is installed at the end part of the kiln body, a temperature sensor which is installed inside the kiln body, a PID controller and a central controller, and a temperature adjustment burner angle adjusting mechanism. The device of the invention can control the angle of the temperature adjustment burner nozzle, the fuel gas injection speed, the speed of temperature adjustment burner nozzle, and the kiln tail blowing rate of the tunnel kiln; sintering researches on various refractory materials can be carried out, which increases the diversity of researches; compared with the original tunnel kilns, the accuracy of temperature adjustment is increased, the efficiency is increased, the reaction rate of execution mechanism is faster, the automatic degree is higher with less pollution, and environmental protection and energy saving performance are improved.

Owner:YANCHENG INST OF TECH

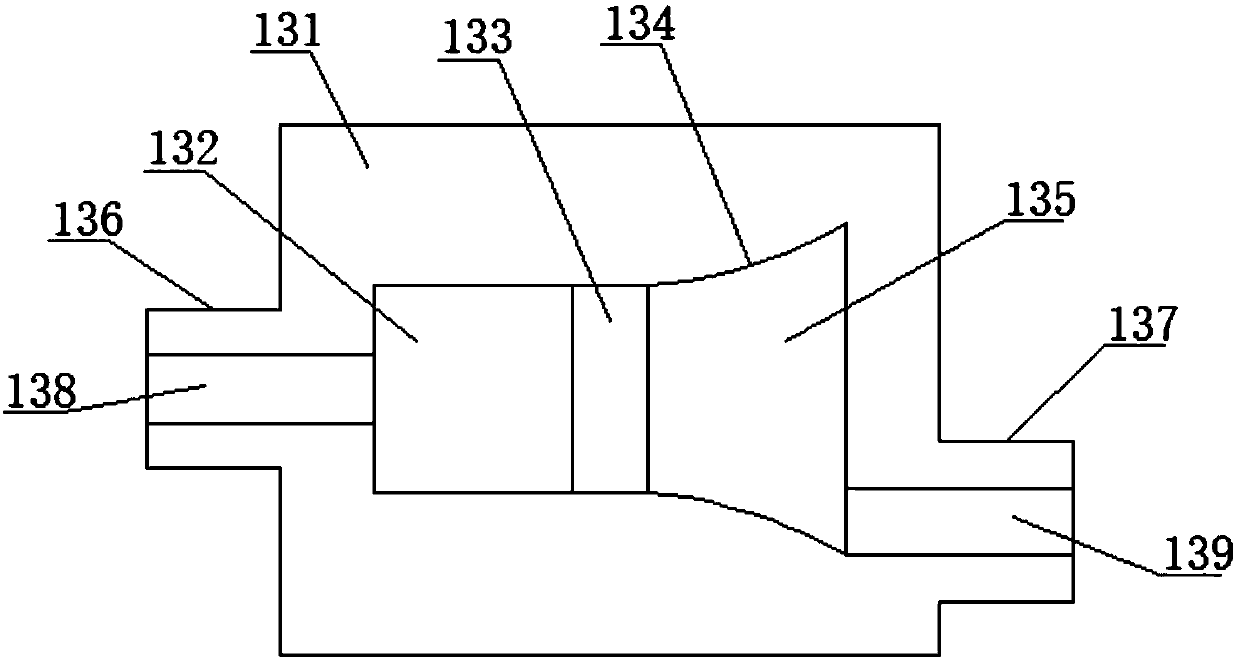

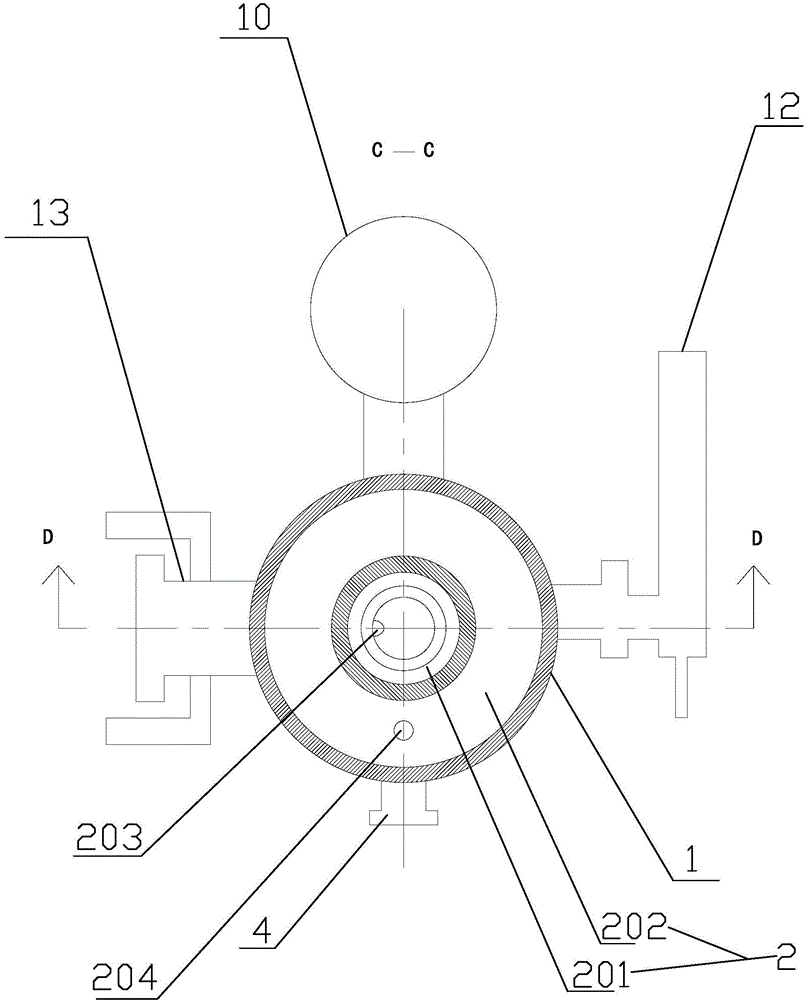

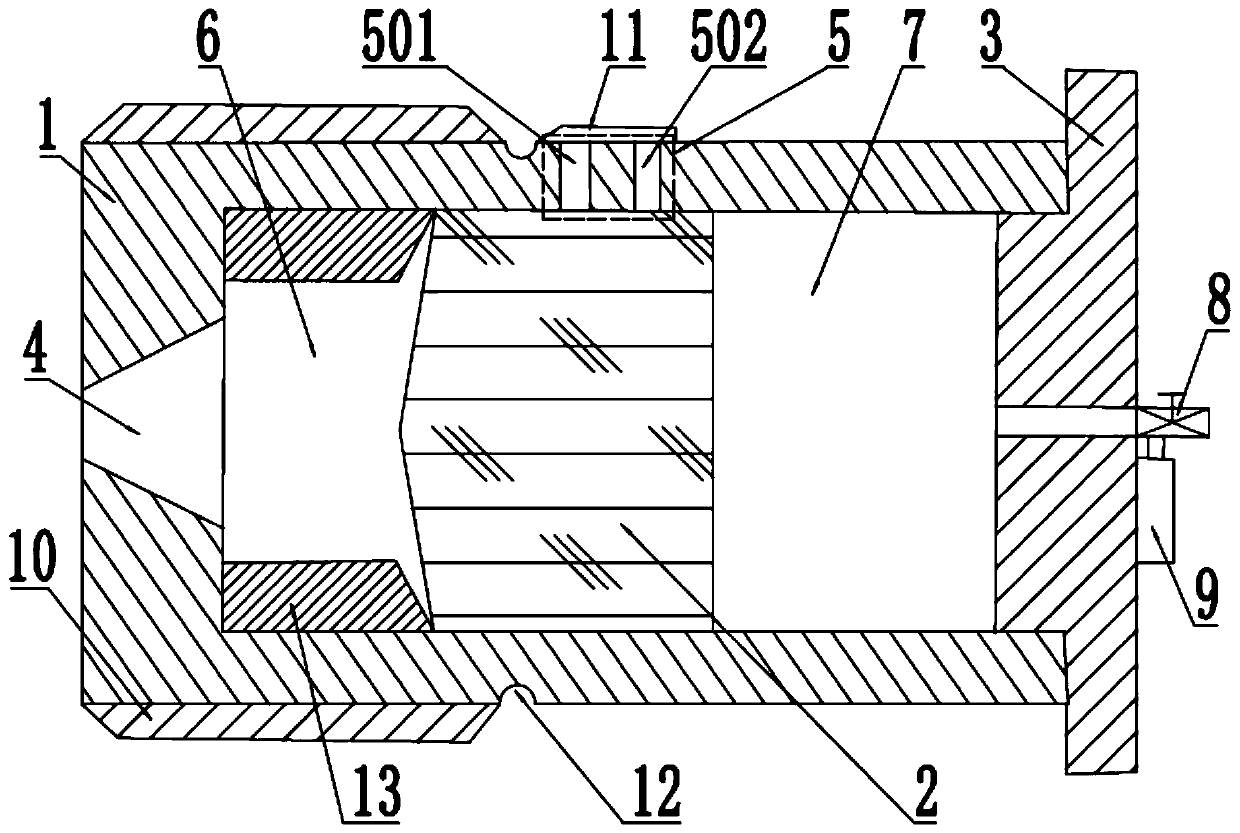

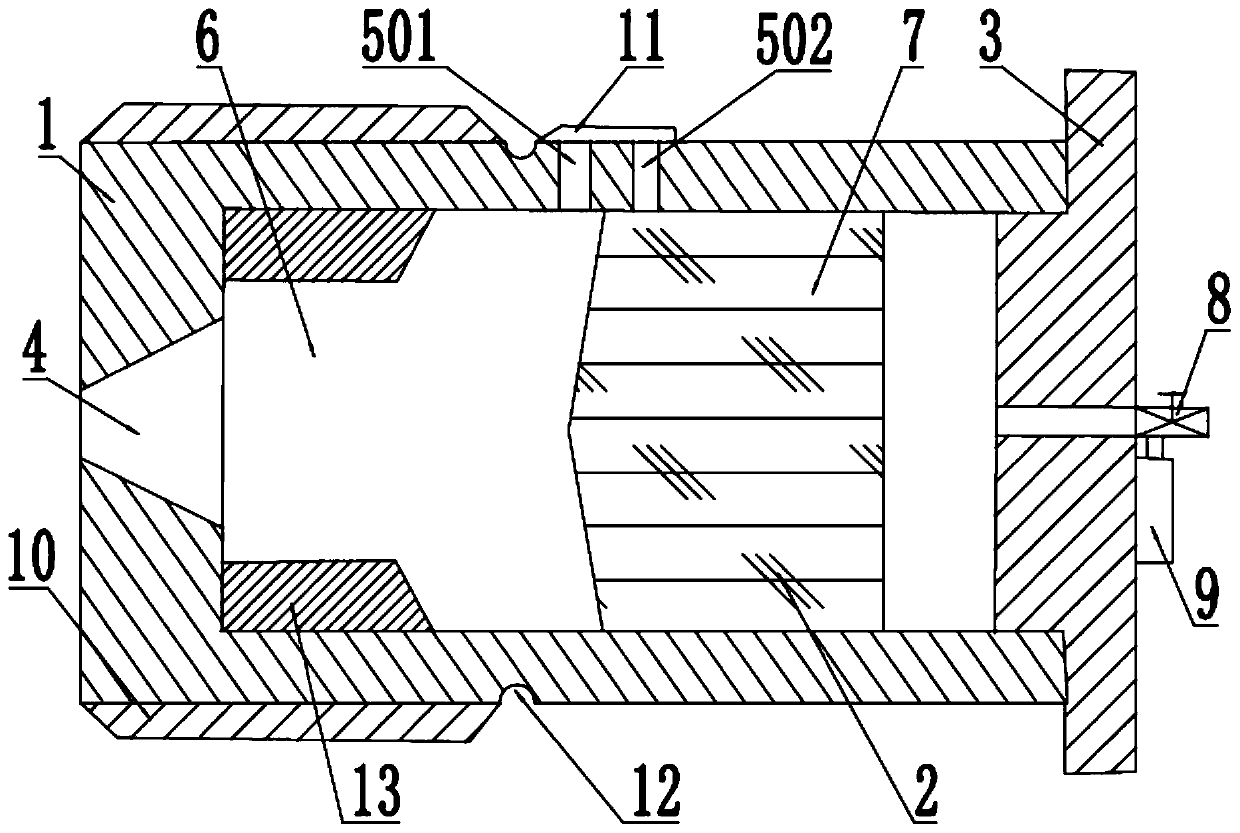

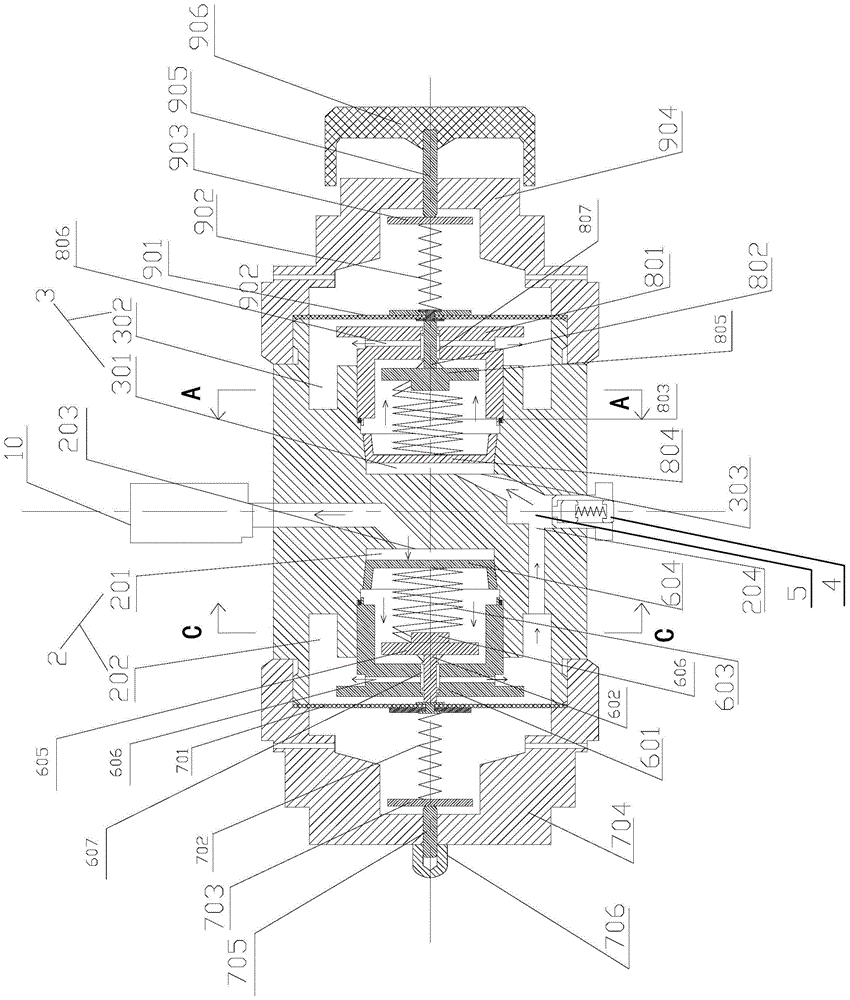

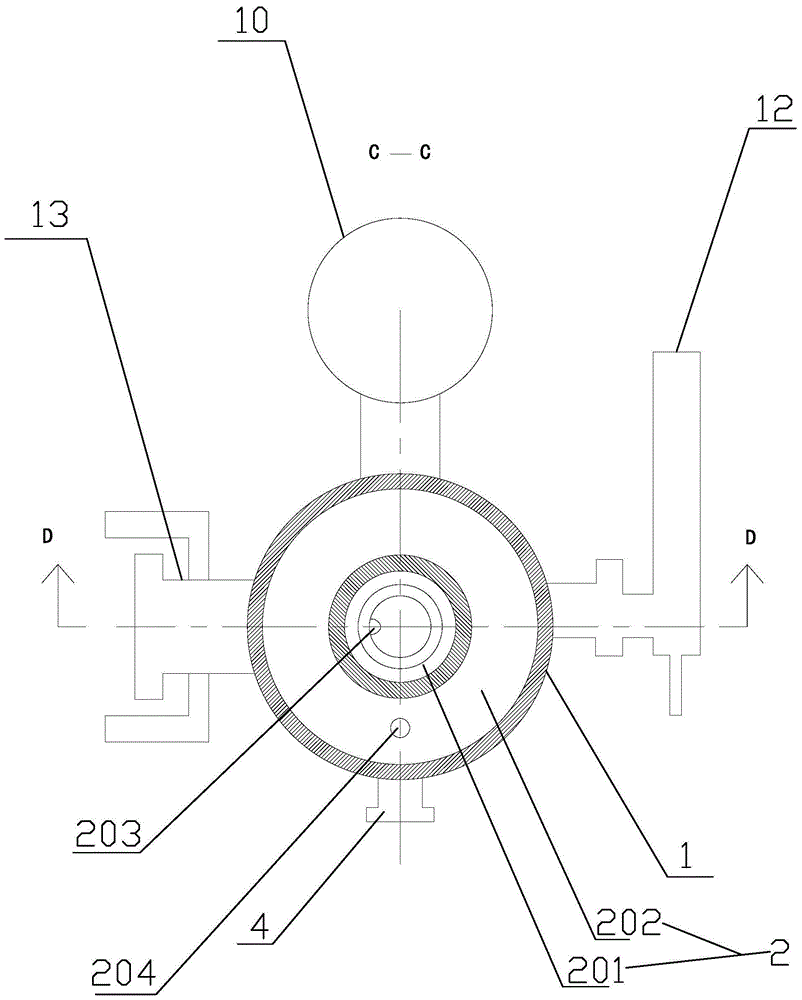

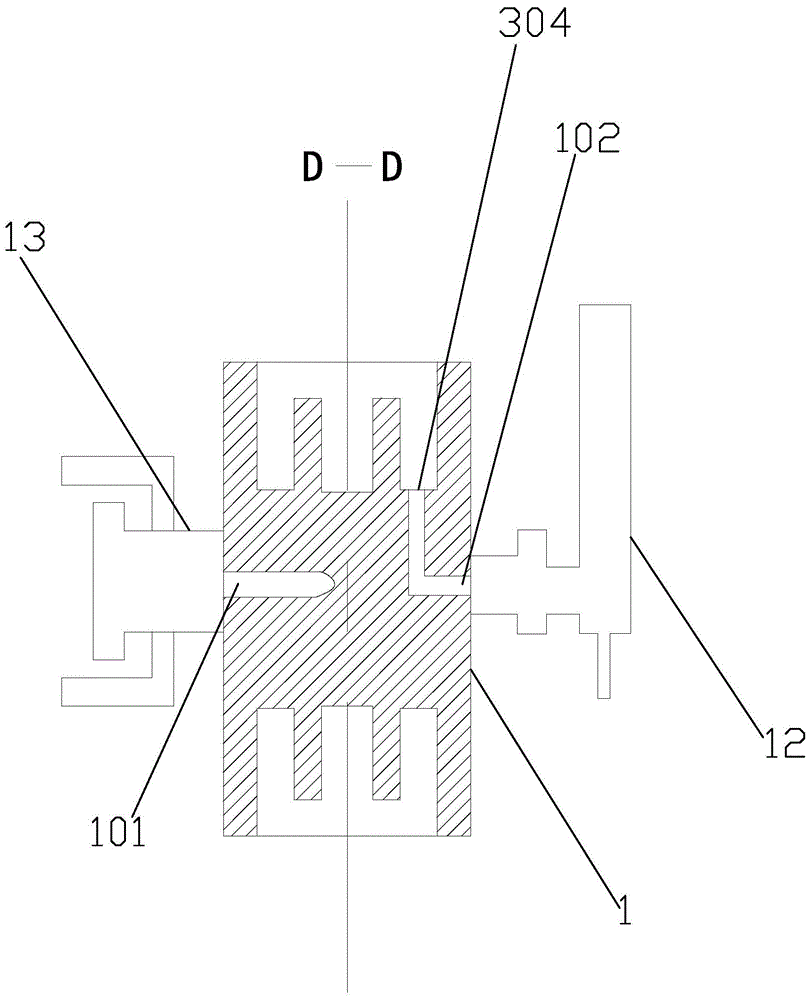

Double-stage gas energy-saving valve

ActiveCN104676062AReduce momentumReduce flow rateValve members for heating/coolingEqualizing valvesEngineeringPressure reduction

The invention discloses a double-stage gas energy-saving valve. The double-stage gas energy-saving valve comprises a pressure reducing valve main body (1), wherein the pressure reducing valve main body (1) is provided with a main air inlet (101) and a main air outlet (102); one end of the pressure reducing valve main body (1) is provided with a first enclosed cavity (2) for reducing the pressure of gas; the air inlet (203) of the first enclosed cavity is communicated with the main air inlet (101); the first enclosed cavity (2) is communicated with a second enclosed cavity (3); the other end of the pressure reducing valve main body (1) is provided with the second enclosed cavity (3) for reducing the pressure of gas; the air outlet (304) of the second enclosed cavity is communicated with the main air outlet (102). The double-stage gas energy-saving valve has the advantages that secondary pressure reduction of gas is finished in the same pressure reducing valve, so that the impact force and flow speed of output low-pressure gas are small and low.

Owner:NINGBO SUNRISE ELECTOR MECHANICAL

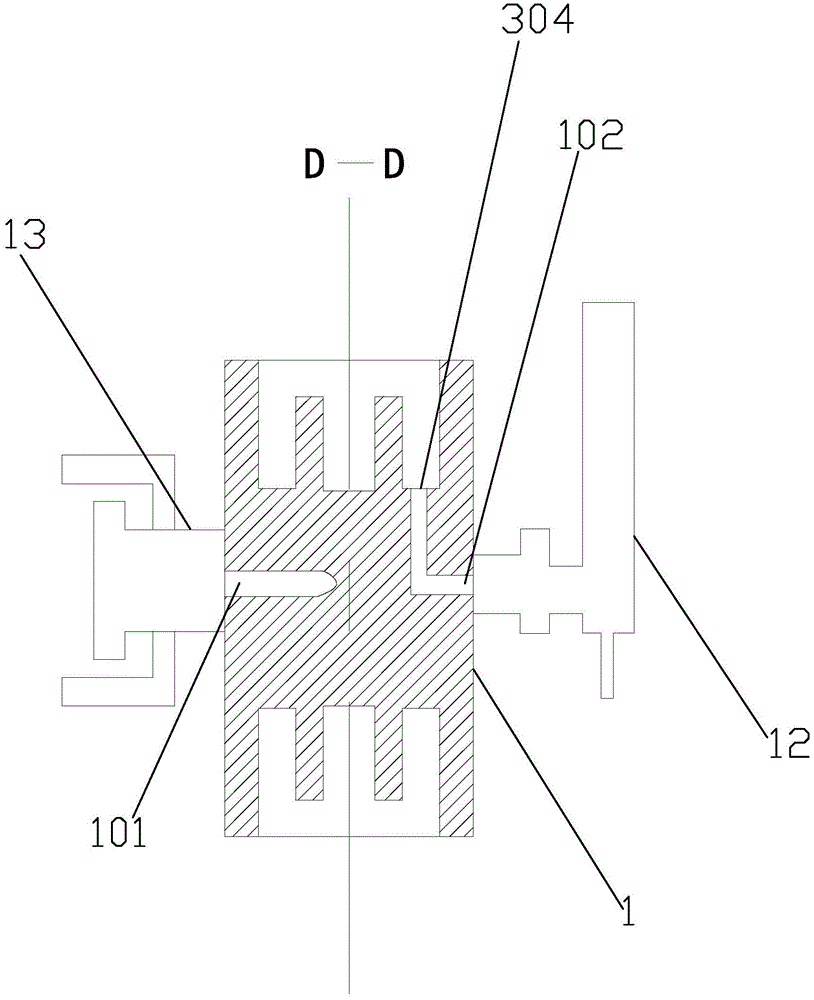

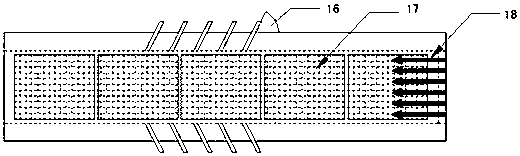

Metal sheet shock wave forming method and device

The invention discloses a metal sheet shock wave forming method and device, and belongs to the technical field of sheet plastic machining. The metal sheet shock wave forming device includes a laser device, a laser guide system, a sheet die system, a gas supply system and a control feedback system. The metal sheet shock wave forming device uses the gas supply system to supply hydrogen and oxygen toa pressure chamber at a volume ratio of 2 to1; a pulsed laser beam emitted by the laser device irradiates on an absorption layer through the laser guide system, the absorption layer is gasified and ionized to produce high temperature and high pressure plasma, the shock wave produced due to rapid expansion of the plasma acts on a workpiece, and at the same time, the shock wave generated due to thefact that the high temperature and high pressure plasma detonates mixed gas in the pressure chamber further acts on a sheet. Through the combined action of the shock wave induced by laser and a shockwave generated by an explosion of the mixed gas, the insufficiency that large-area forming of thick plates is difficult to realize in laser shock forming can be effectively solved, and the market application prospect is good.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Water smoking set and air pressure control method thereof

InactiveCN109998166AControl pressure valueReduce air pressureTobacco pipesFluid pressure control using electric meansEngineeringSmoke

The invention discloses a water smoking set and an air pressure control method thereof. The water smoking set comprises a smoking set body, a pressure control device arranged in the smoking set and afirst air pipe connected with the smoking set body; a first air vent communicating with the first air pipe is formed in the smoking set body, and a one-way valve is arranged in the first air vent; andthe pressure control device is used for detecting an air pressure value in the smoking set body and opening the one-way valve when the air pressure value exceeds a preset value. Due to the fact thatthe pressure control device is arranged in the smoking set body, when the air pressure value in the smoking set body reaches the preset value, the one-way valve is opened to release smoke so as to reduce the air pressure value in the smoking set body, thus the magnitude of the air pressure in the smoking set body is controlled, and the problem that a smoker is choked due to the excessive air pressure value in the smoking set body is solved.

Owner:东莞朗勤电子科技有限公司

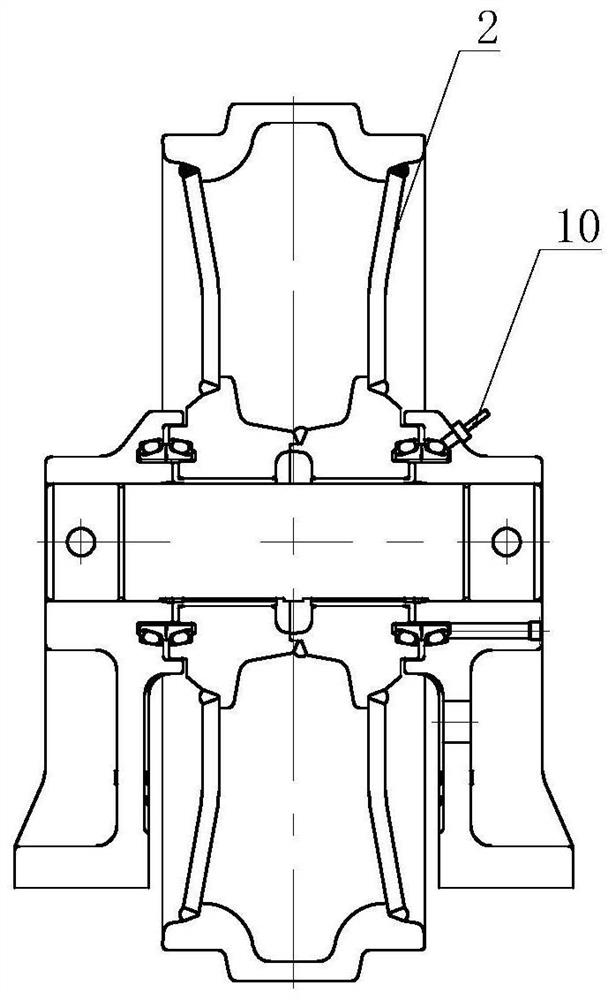

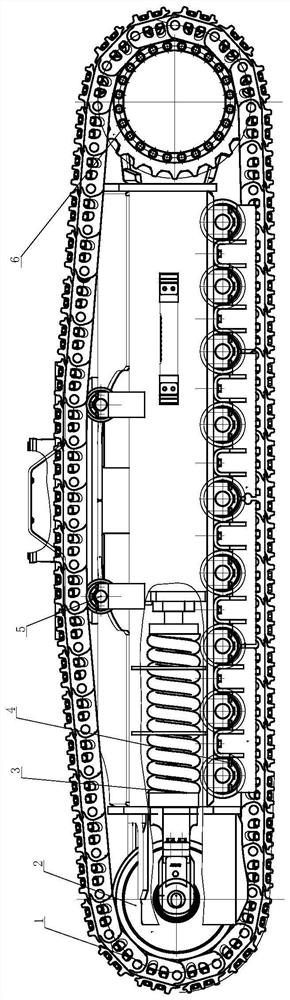

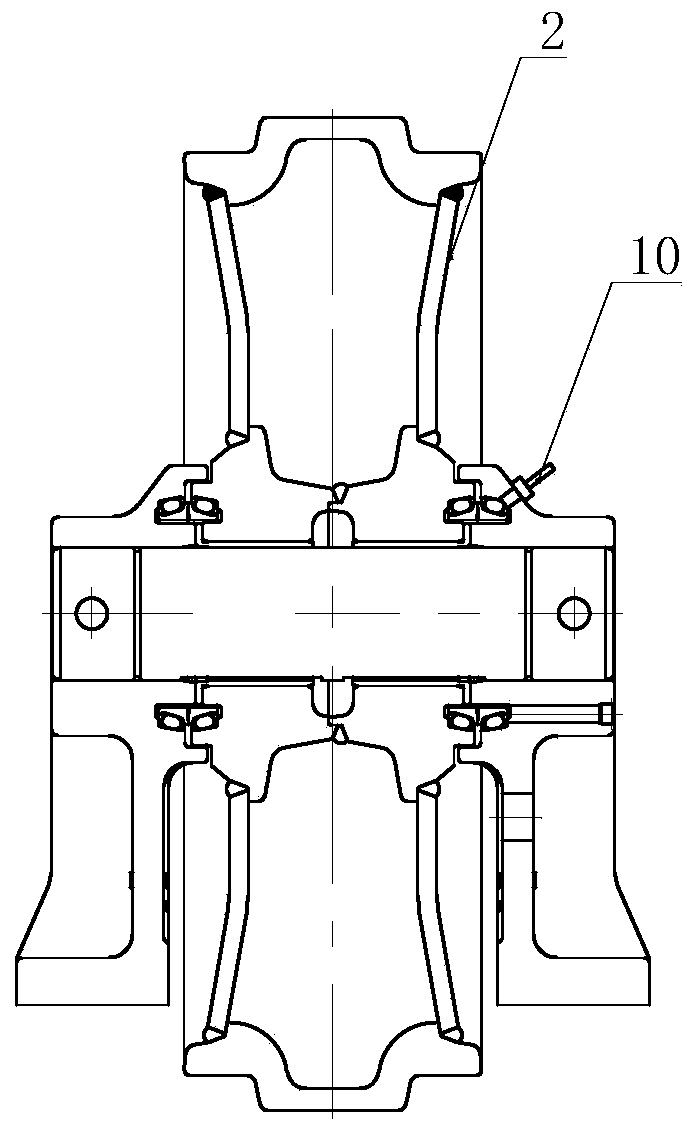

Wheel Body Internal Pressure Control System, Construction Machinery and Control Method

ActiveCN111017059BReduce internal pressureControl pressure valueSignalling/lighting devicesLubricating systemControl systemMechanical engineering

The invention provides a wheel body internal pressure control system, construction machinery and a wheel body internal pressure control method of the wheel body internal pressure control system, and relates to the technical field of construction machinery lubrication. The internal pressure control system of the wheel body includes a pressure sensor, a controller and a driving device. The pressure sensor is used to detect the pressure value of the lubricating oil in the wheel body and transmit the pressure value of the lubricating oil in the wheel body to the controller. The controller is used to receive the wheel pressure value transmitted by the pressure sensor. The lubricating oil pressure value in the wheel body sends a deceleration signal to the driving device when the lubricating oil pressure value in the wheel body is higher than the preset threshold, and the driving device is used to reduce the walking speed according to the deceleration signal of the controller. The invention solves the technical problem that the internal pressure of the wheel body cannot be effectively controlled, and achieves the technical effect of effectively controlling the pressure value of lubricating oil in the wheel body.

Owner:SANY HEAVY MACHINERY

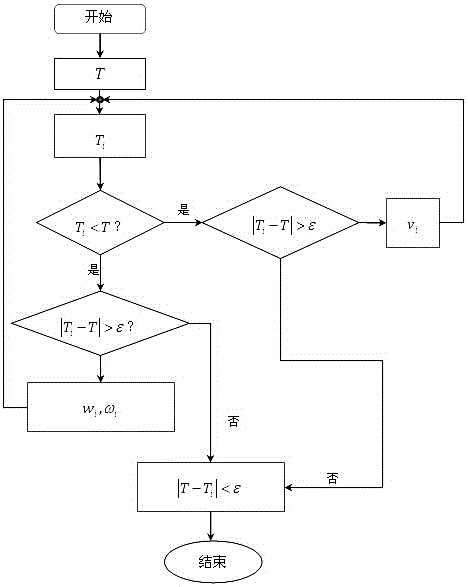

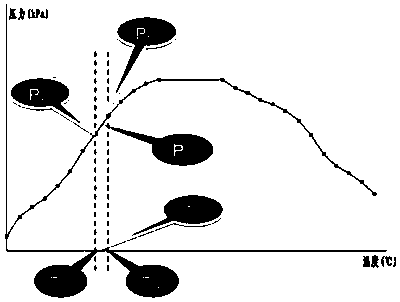

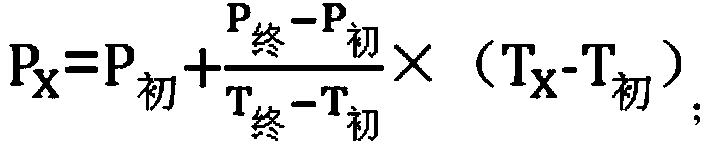

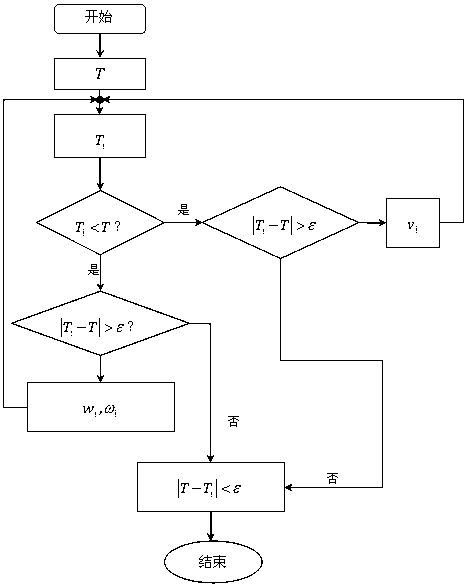

Accurate shape control method and device used after sterilization of infusion type products

InactiveCN110433314AControl pressure valueGuaranteed pressure valueTemperatue controlPackage sterilisationEngineeringMedical device

The invention relates to an accurate shape control method and device used after sterilization of infusion type products and belongs to the technical field of medical equipment. The method comprises the steps as follows: (1) setting temperature and pressure of a sterilization heating stage and a sterilization cooling stage at stages; and (2) corresponding to each stage, setting initial temperatureT initial and final temperature T final, setting initial pressure P initial and final pressure P final, setting temperature change rate delta T and controlling temperature change, wherein the relationbetween the pressure PX and instant temperature TX required in the stage is shown in the description; and detecting actual pressure P actual in a cavity of a sterilizer and enabling P actual to approach PX by a pressure control method. By the aid of the sterilization heating stage and the sterilization cooling stage, the temperature change rate can be controlled accurately, the pressure can be adjusted accurately, pressure inside and outside a product can be kept balanced, and the good shape of the product can be kept.

Owner:SHINVA MEDICAL INSTR CO LTD

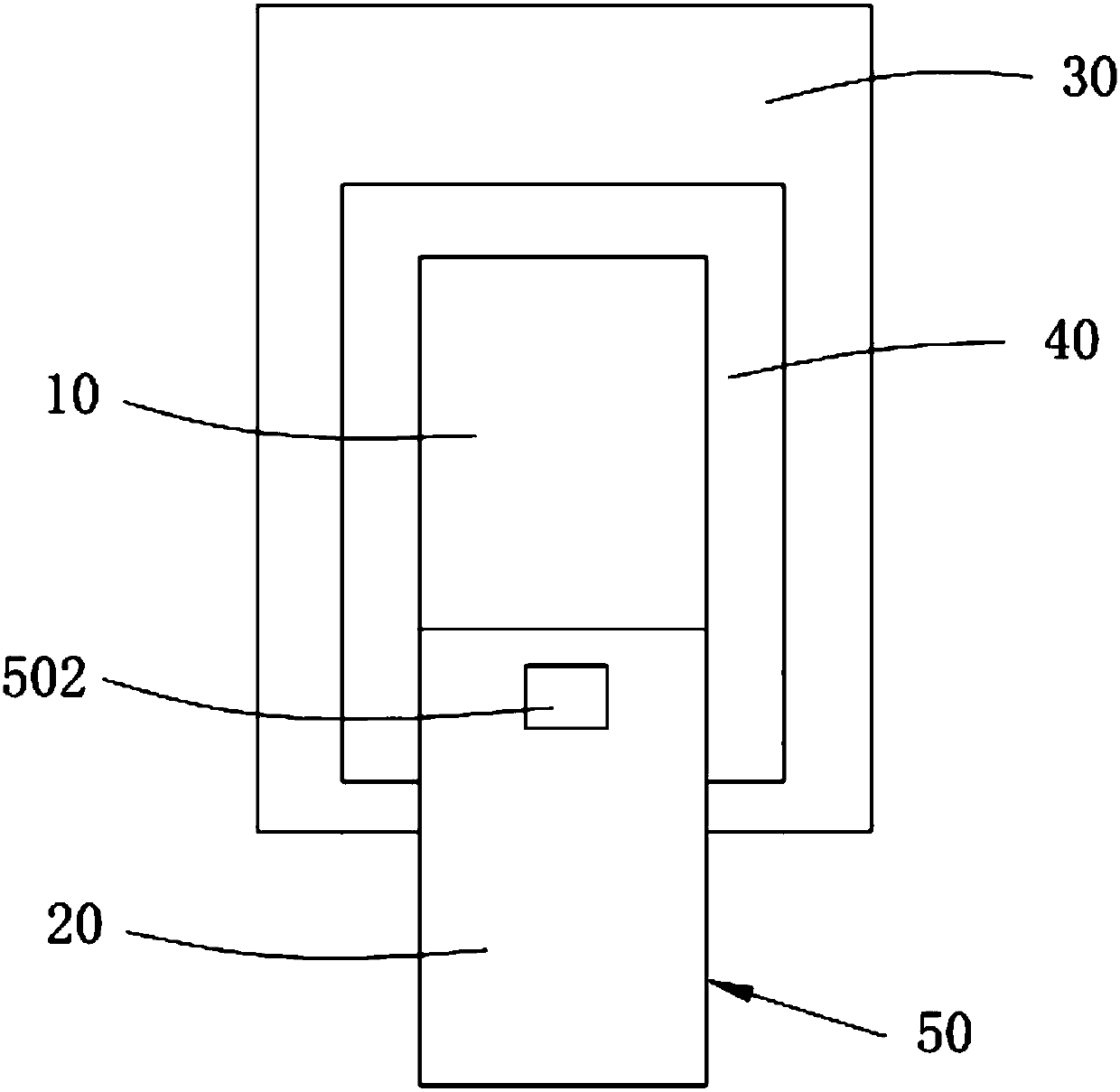

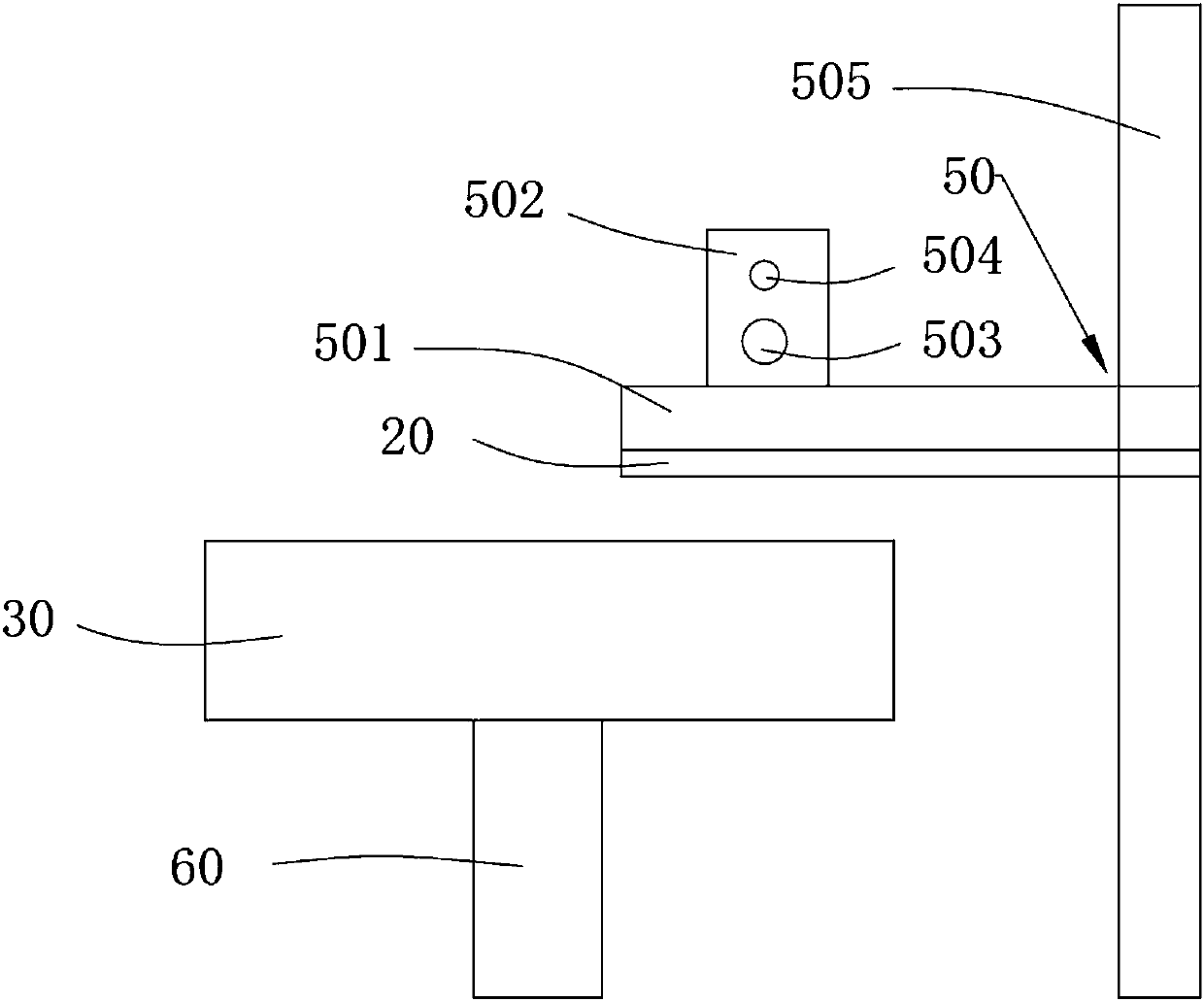

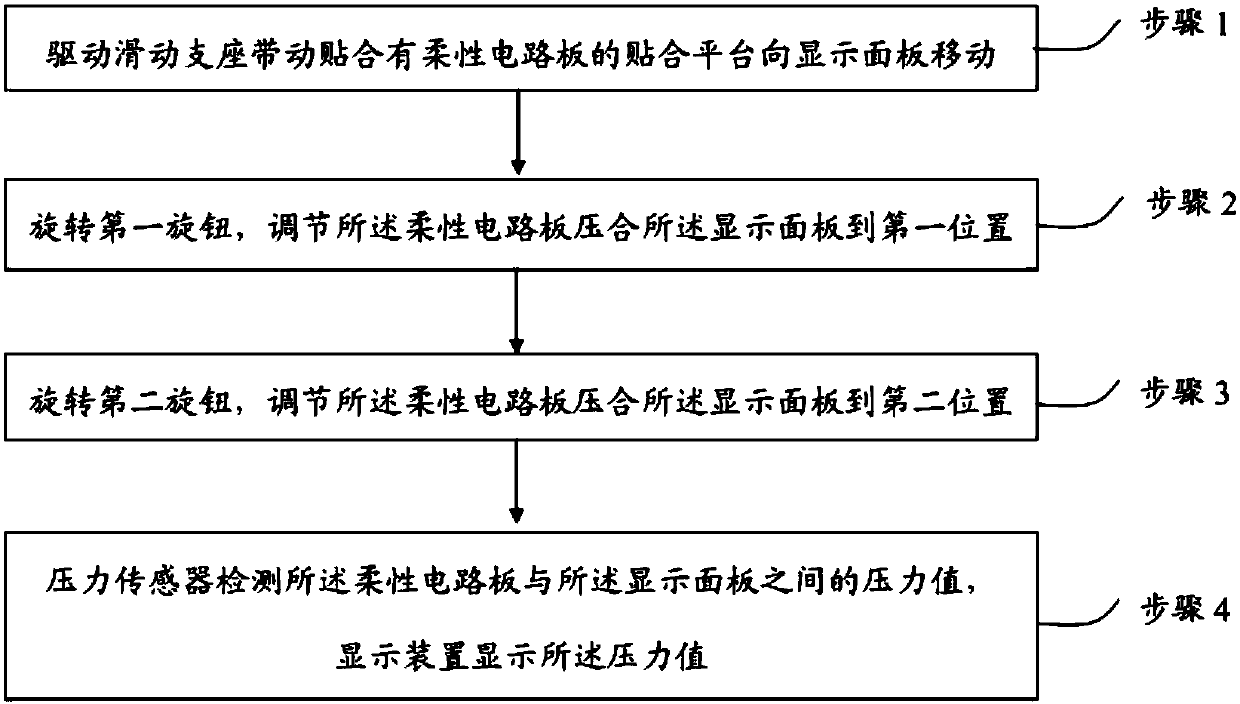

Display panel test device and display panel test method

InactiveCN107860499AJudgment of poor contactReduce false positive rateApparatus for force/torque/work measurementElectricityFlexible circuits

The invention provides a display panel test device which is used for the pressure test in prepressing of a flexible circuit board and a display panel. The display panel comprises a conductive terminalarea. The flexible circuit board comprises an electric connecting area. The display panel test device comprises a fixture platform equipped with an embedded groove, a pressure sensor which is arranged in the embedded groove and a pressing part. The display panel is borne on the pressure sensor. The pressing part drives the flexible circuit board so that the electric connecting terminal of the electric connecting area and the terminal of the display panel are enabled to be pressed together, and the pressure sensor detects the pressure between the display panel and the flexible circuit board. The situation of poor contact of the display panel can be accurately judged according to the pressure value so that the misjudgment rate can be reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

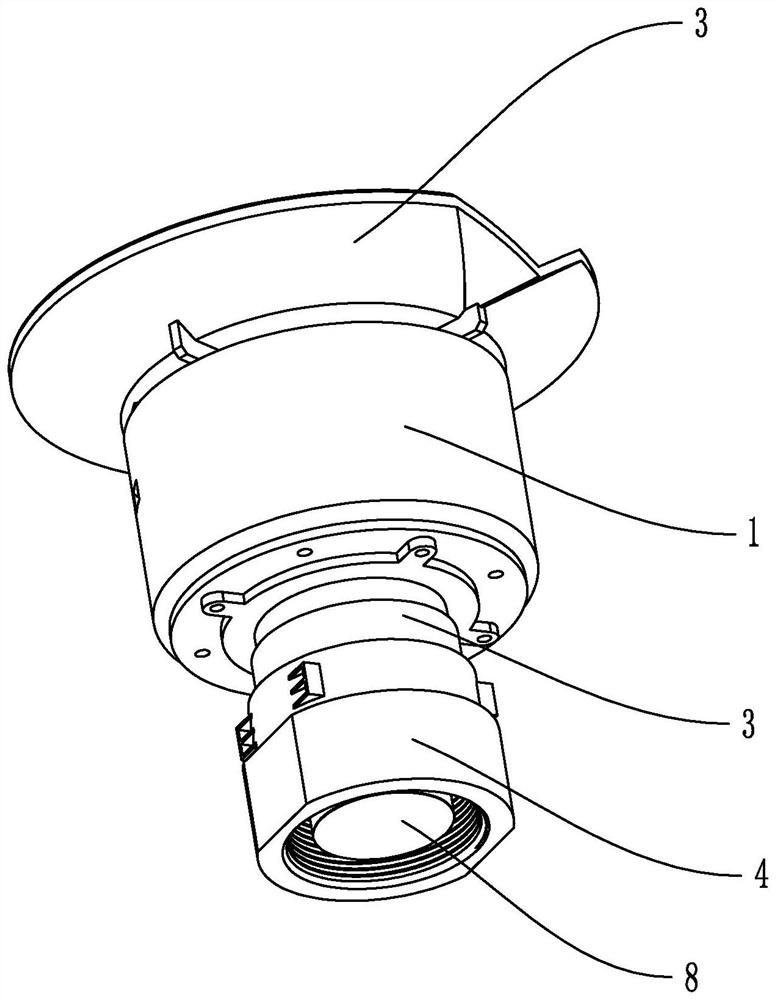

Vacuum pressure valve for oil storage tank of gas station

PendingCN113566003AStable pressureHigh sensitivityDispersed particle filtrationLarge containersCircular discVacuum pressure

The invention discloses a vacuum pressure valve for an oil storage tank of a gas station. According to the main points of the technical scheme, the vacuum pressure valve comprises a vacuum pressure valve shell, a disc cap and a fixing sleeve, wherein the disc cap and the fixing sleeve are located at the upper side and the lower side of the vacuum pressure valve shell; a fixing support and a shell notch matched with the fixing support are arranged in the vacuum pressure valve shell; a pressure adjusting plate capable of sliding up and down is arranged in the fixing support in a penetrating manner; a plurality of ventilation notches are formed in the side surface of the fixing support; the outer side of the fixing support is covered with a first filter screen structure matched with the fixing support; an adjusting groove is formed in the bottom of the pressure adjusting plate; an adjusting rod sliding up and down is arranged in the adjusting groove in a penetrating manner, and the lower end of the adjusting rod is fixedly connected with an adjusting piston; a plurality of adjusting through holes are further formed in the adjusting groove; and the upper side of the adjusting rod is sleeved with an elastic support matched with the pressure adjusting plate. The vacuum pressure valve has the advantages of being simple in structure, stable in tank pressure and high in reliability, effectively filters impurities in air and avoids the influence on oil quality.

Owner:浙江海博石油设备有限公司

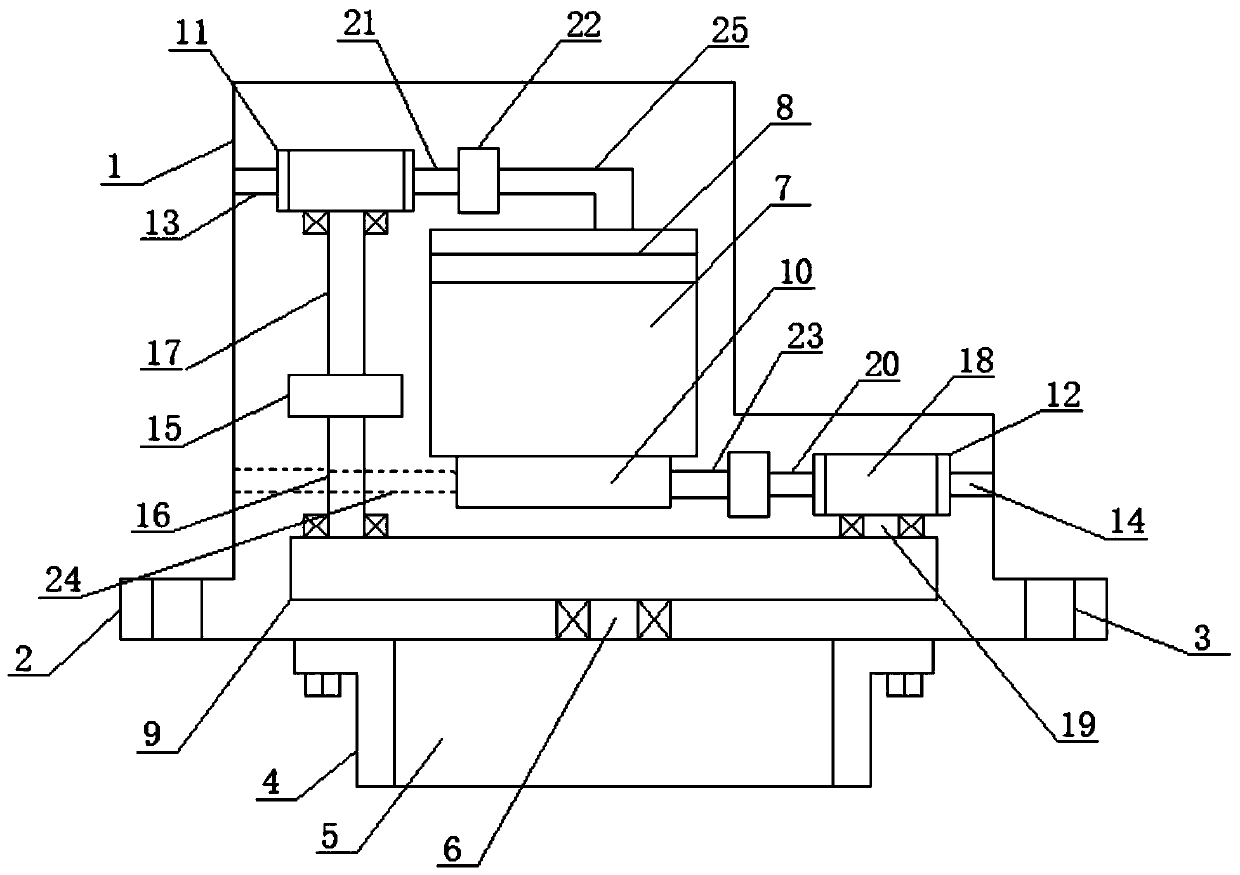

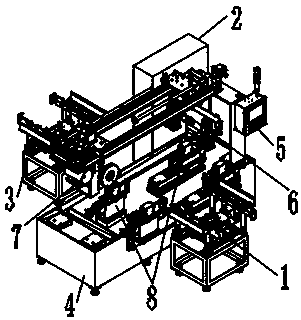

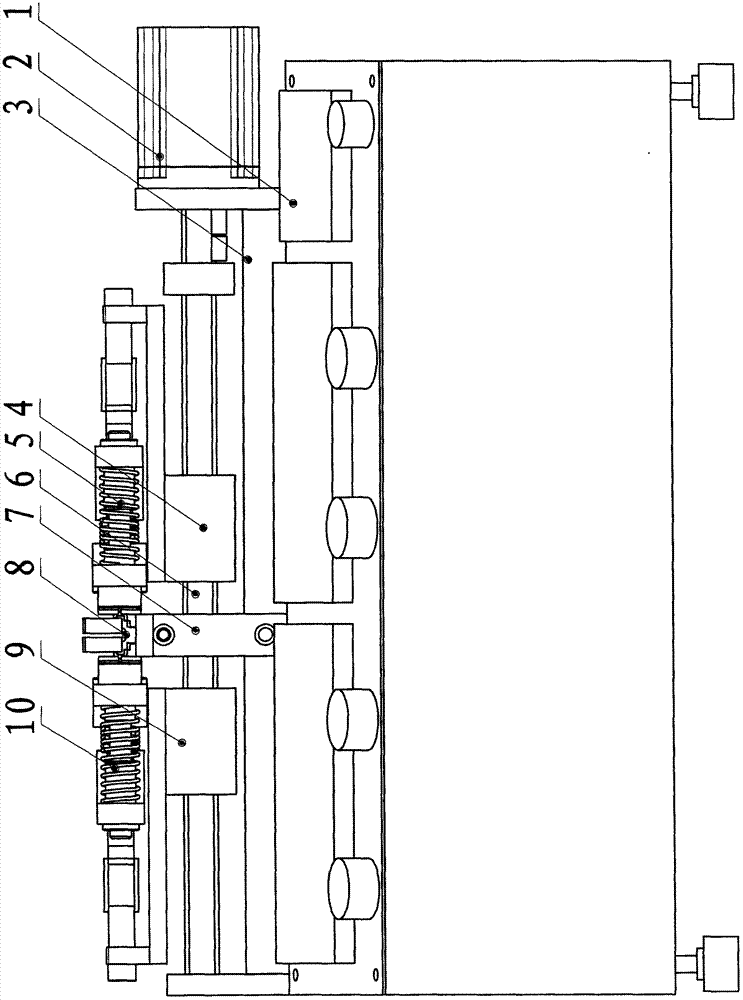

Full-automatic vertical rack longitudinal polishing machine

PendingCN110757325AFulfil requirementsAccurate pressureGrinding carriagesPolishing machinesPolishingElectrical control

The invention relates to a full-automatic vertical rack longitudinal polishing machine, and belongs to the field of ultra-precision machining devices. The full-automatic vertical rack longitudinal polishing machine includes an automatic feeding mechanism, a PLC electrical control box, an automatic discharge mechanism, a rack, a touch screen control panel, an automatic batch turning mechanism, a polishing mechanism, and an apex drive mechanism. A vertical installation method is adopted by a polishing wheel of the device, an air cylinder is adopted as a power source to balance the gravity of thepolishing mechanism, so that the applied pressure is more accurate. The polishing wheel has a certain floating amount while rotating at high speed, and a servo motor and a pressure sensor are adoptedto make the polishing wheel have a certain precompression on the rack. The servo motor is also adopted for the rotation of the angle of the rack, and the full coverage of a toothed back can be met. The servo motor is used for driving the polishing wheel to make lateral movement, and the requirements of workpieces of different lengths can be met. Compared with a horizontal type polishing machine,a patching plate is integrated above the apex drive mechanism, and the structure is simplified.

Owner:吉林瑞铭机电设备有限公司

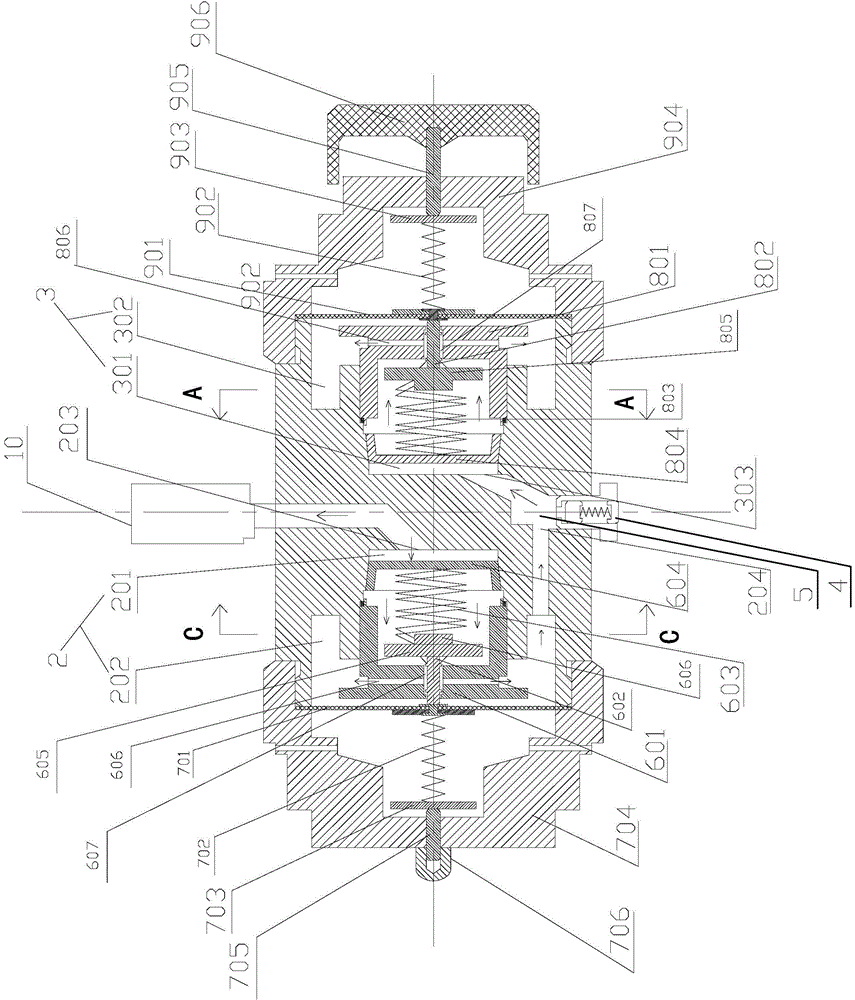

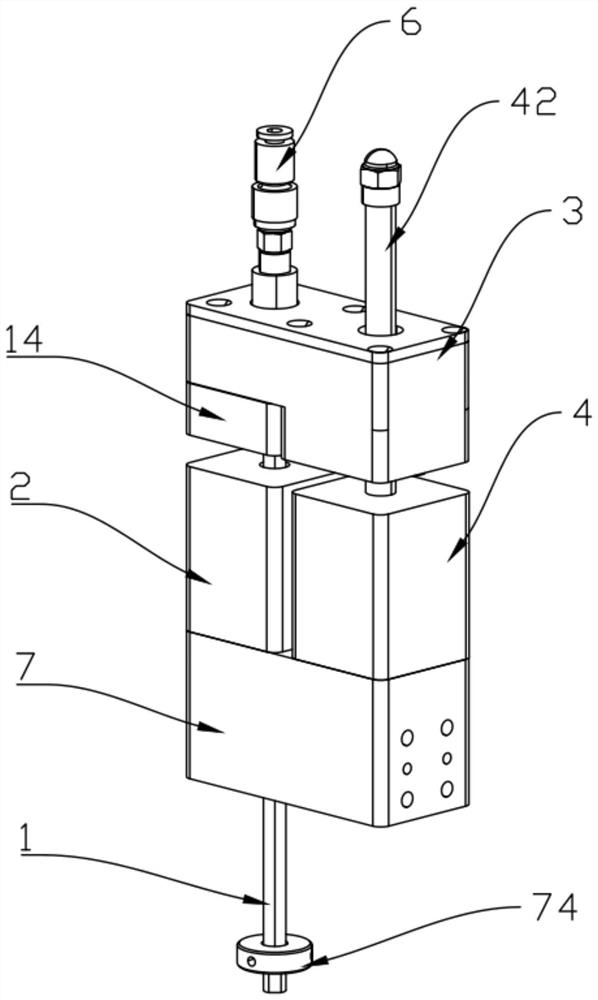

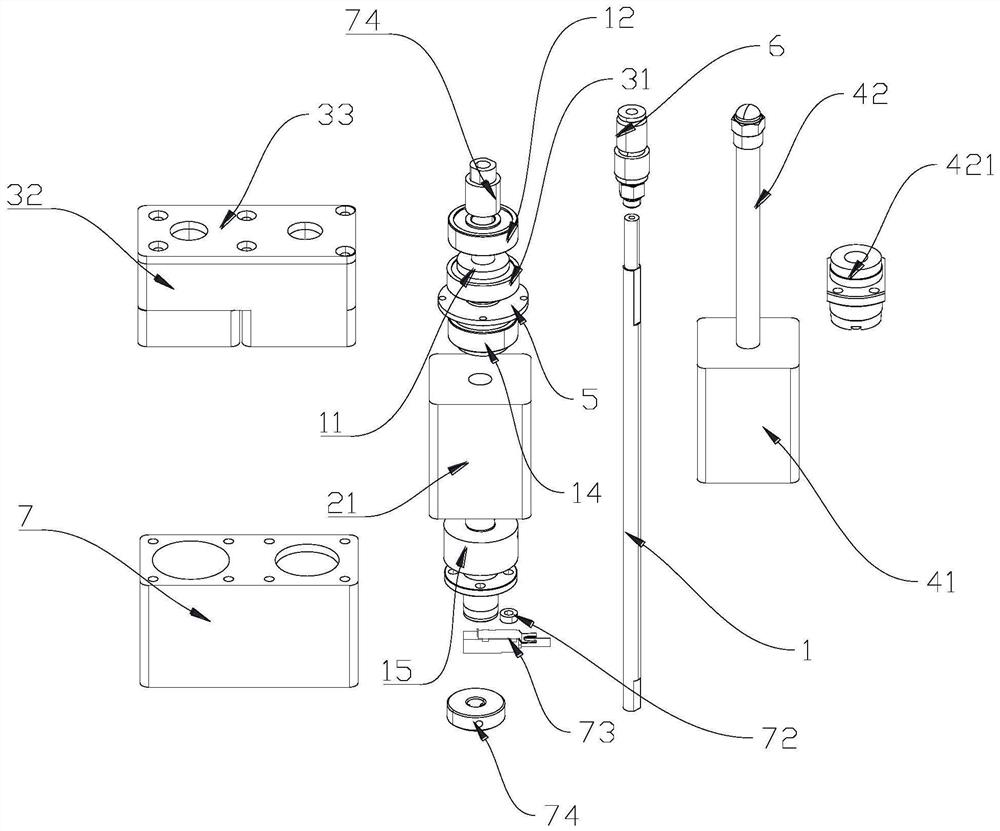

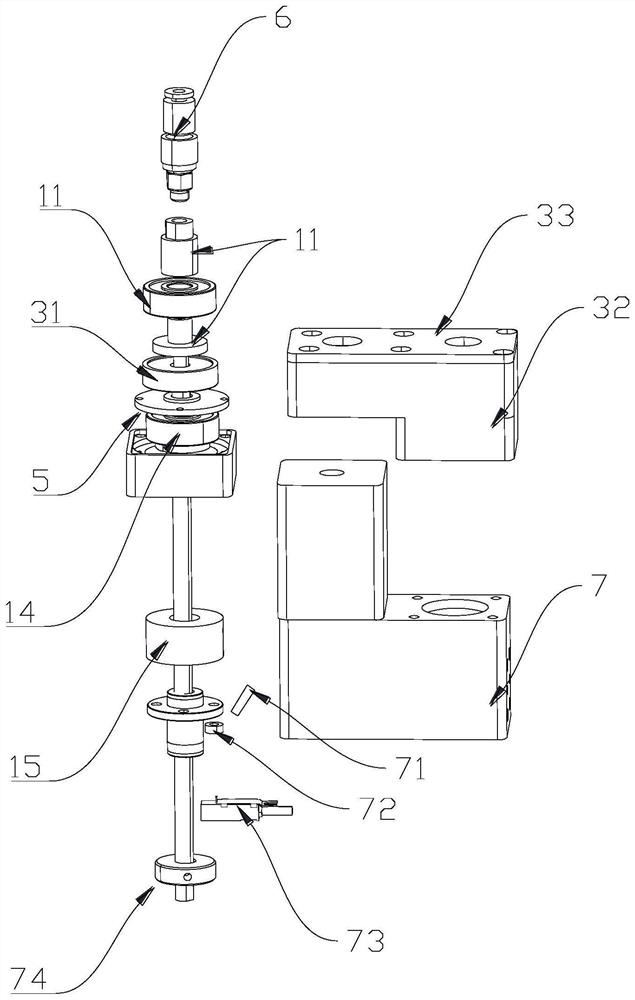

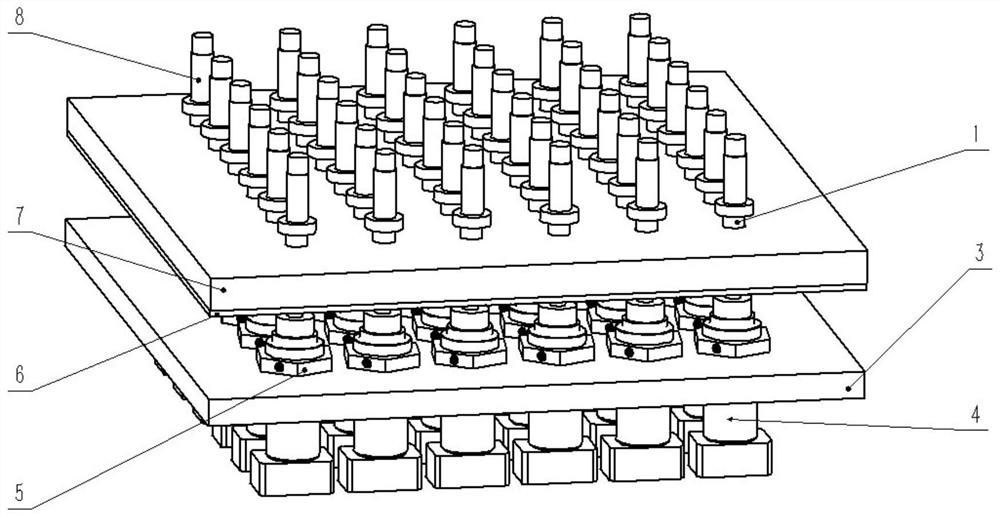

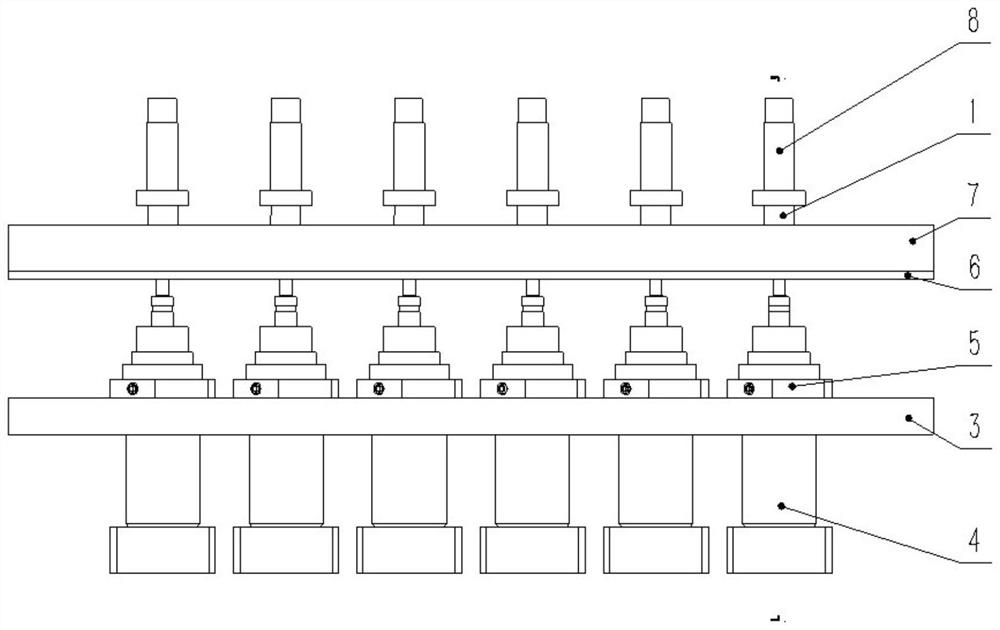

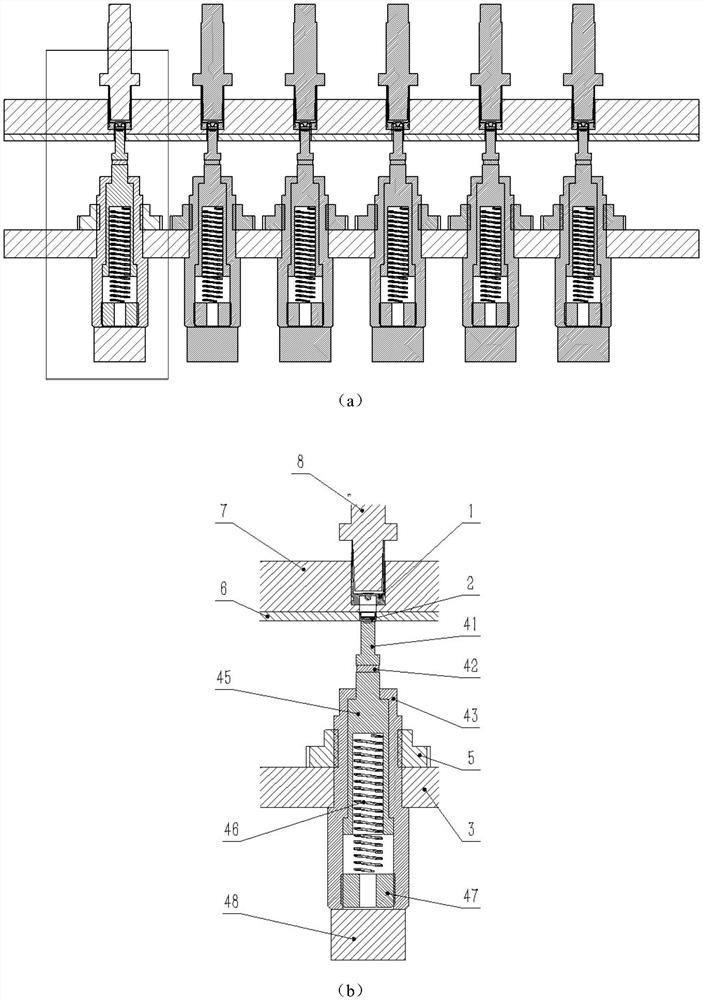

Accurate pressing composite type motion actuator with built-in pressure sensor

PendingCN111720509AControl pressure applicationReduce volumeGearingMechanical energy handlingLinear motionReciprocating motion

The invention provides an accurate pressing composite type motion actuator with a built-in pressure sensor. The accurate pressing composite type motion actuator comprises a bearing shaft and a rotarymotion actuator; one end of the bearing shaft is used for being connected with a load, and the other end is connected with a connecting block; the connecting block is fixedly connected to a linear motion actuator, the linear motion actuator drives the connecting block to perform linear motion, and therefore, the bearing shaft is driven to perform axial reciprocating motion; a pressed sheet is arranged between the rotary motion actuator and the connecting block and arranged on the bearing shaft in a sleeving manner, and besides, the pressure sensor is connected with the side, close to the pressed sheet, of the connecting block; clearance is reserved between the pressed sheet and the pressure sensor, and slide clearance is reserved between the connecting block and the bearing shaft; when themotion, driven by the connecting block, of the bearing shaft to the load is blocked, the connecting block drives the pressure sensor to slide downwards relative to the bearing shaft, and the pressuresensor is contacted with the pressed sheet; and by means of limited space, the whole module has small size, cannot be disturbed by other structures, detects a value of applied pressure online and controls the value of pressure required to be applied.

Owner:恒科鑫(深圳)智能科技有限公司

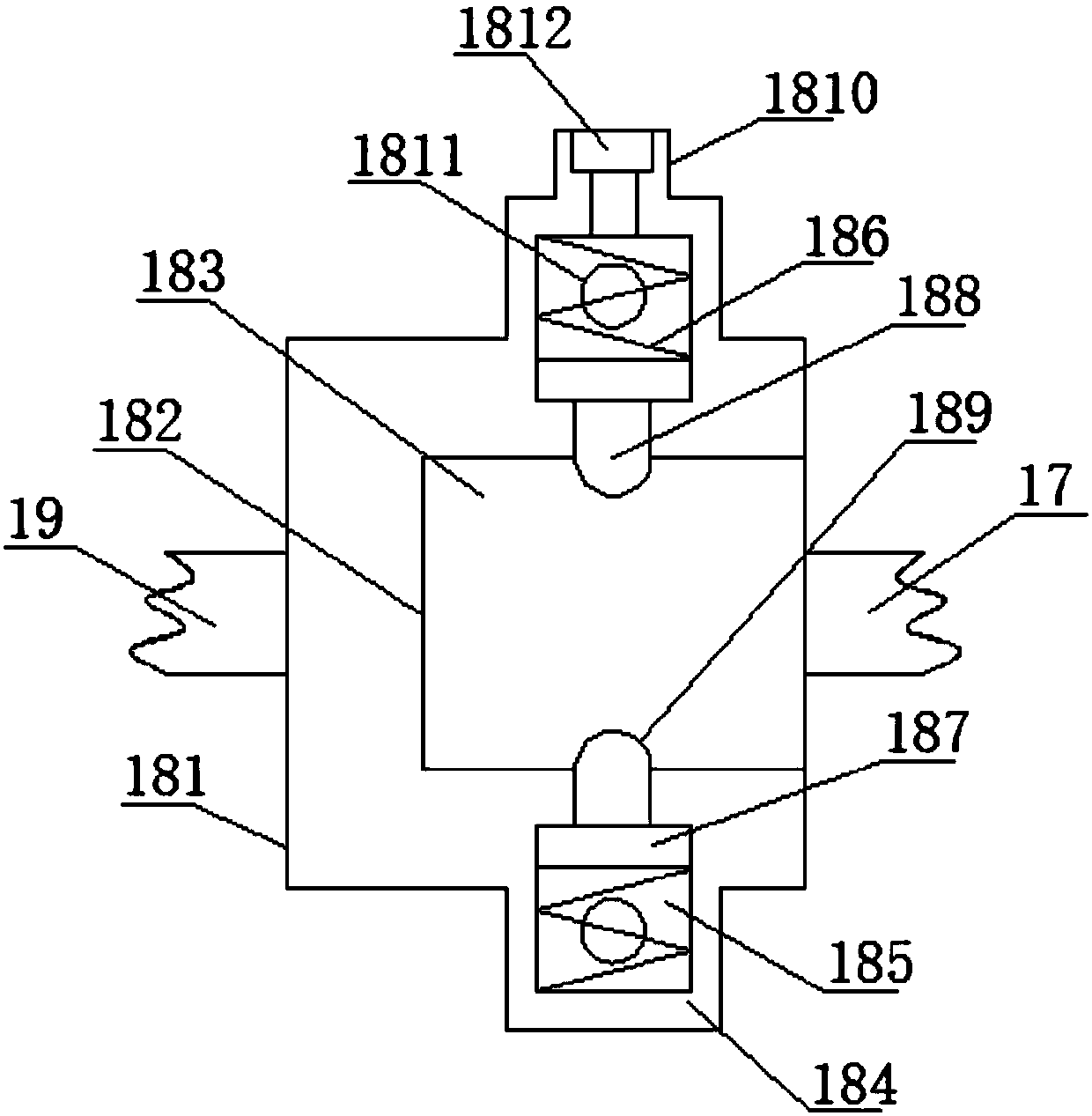

Controllable pressure release device for gas-sealed high-voltage electrical equipment

InactiveCN110081215AControl pressure valueSwitchgear arrangementsEqualizing valvesControl roomEngineering

The invention provides a controllable pressure release device for gas-sealed high-voltage electrical equipment. The controllable pressure release device comprises a main body part, a piston and an endcover; one end of the main body part is provided with an air inlet hole, the other end of the main body part is fixedly connected with the end cover, an exhaust hole is formed in the side wall of themain body part, the piston is arranged in the main body part, the outer wall of the piston is tightly matched with the inner wall of the main body part, the piston can move in an inner cavity of themain body part, and the piston divides the inner cavity of the main body part into an exhaust chamber and a control chamber; the air inlet hole communicates with the exhaust chamber, and the exhaust hole communicates with the exhaust chamber; and an inflation valve and a pressure meter are arranged on the end cover, and the inflation valve and the pressure meter communicates with the control chamber. The controllable pressure release device is used for grading pressure release of the high-voltage electrical equipment and can control the pressure release speed and control the high-voltage electrical box body to be maintained at a required pressure value.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Child clysis device

InactiveCN105664279AReasonable distribution of spaceCompact structureEnemata/irrigatorsPeristaltic pumpHydraulic pump

The present invention relates to the field of medical device design, in particular to an enema device for children, which includes a body of the enema device for children, an enema tube, and a control center. Through the optimization of parts, the space of the enema device is reasonably distributed, so that the overall structure of the enema device is more efficient. It is compact, and a mobile bracket is added to facilitate the mobile transportation of the device; the rationally designed enema device can effectively control the pressure value during the enema process by using micro hydraulic pumps and micro peristaltic pumps, reducing the discomfort caused by the enema process, and The enema tube is adjusted to a corrugated structure to facilitate the entry and stretching of the tube.

Owner:JILIN UNIV

Primer press-fitting system and method

PendingCN114102099AMonitoring of indentation depthSolution depthMetal working apparatusProcess engineeringCartridge

The invention provides a primer press-fitting system which comprises a press-fitting mechanism used for pushing primer into a cartridge case to complete press-fitting. The pressure acquisition mechanism is used for acquiring the real-time press-fitting pressure in the press-fitting process; the displacement acquisition mechanism is used for acquiring the real-time press fitting depth in the press fitting process; and the regulation and control mechanism makes regulation feedback according to the real-time press-fitting pressure and the real-time press-fitting depth. The press-fitting process is improved, the press-in depth of the primer is monitored, and the pressure value in the press-fitting process is controlled, so that the probability of crushing the primer and the cartridge case is reduced, and the problems that the press-fitting depth of the primer is not quantified and the pressure in the press-fitting process is uncontrollable are solved.

Owner:SHANGHAI PLATFORM FOR SMART MFG CO LTD

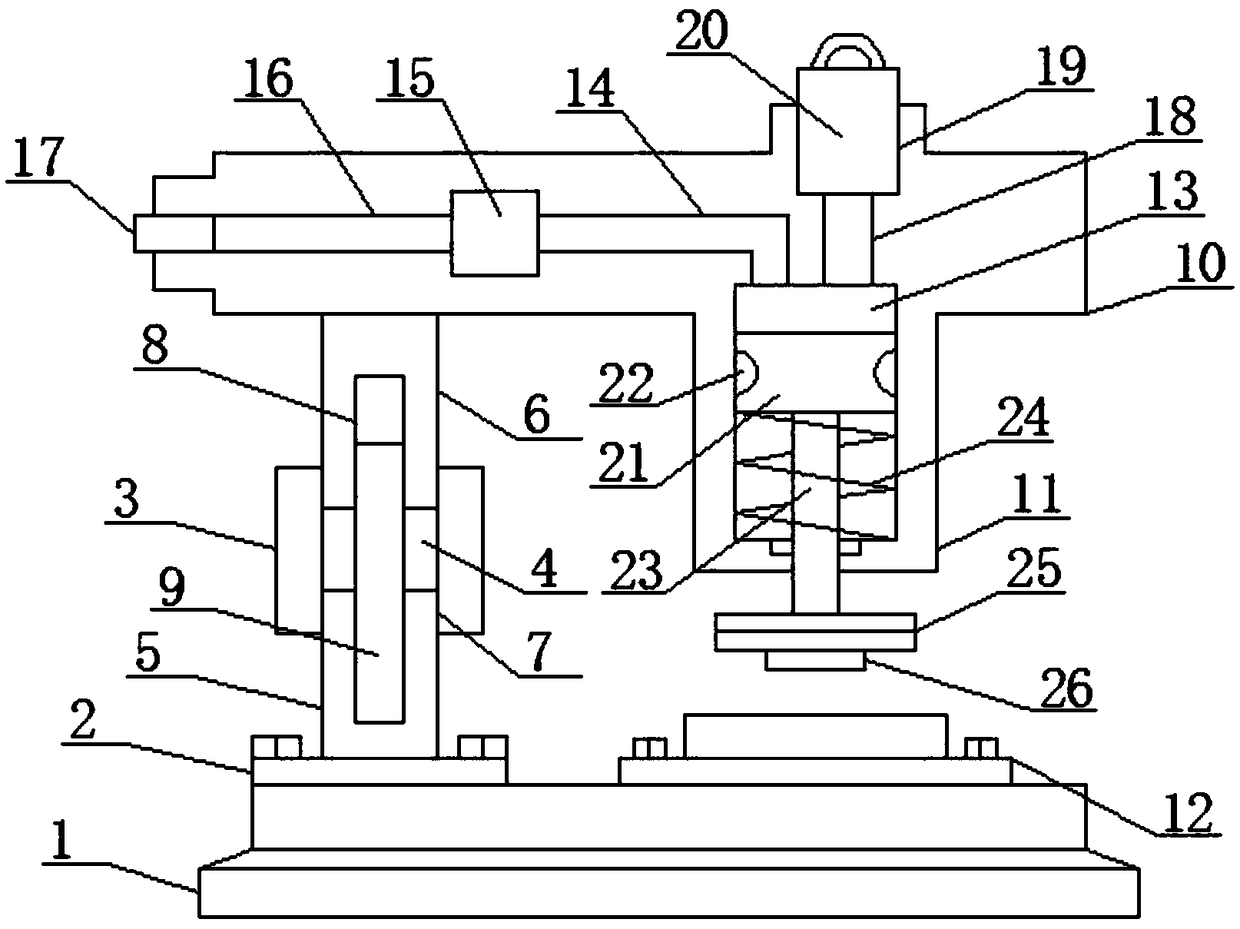

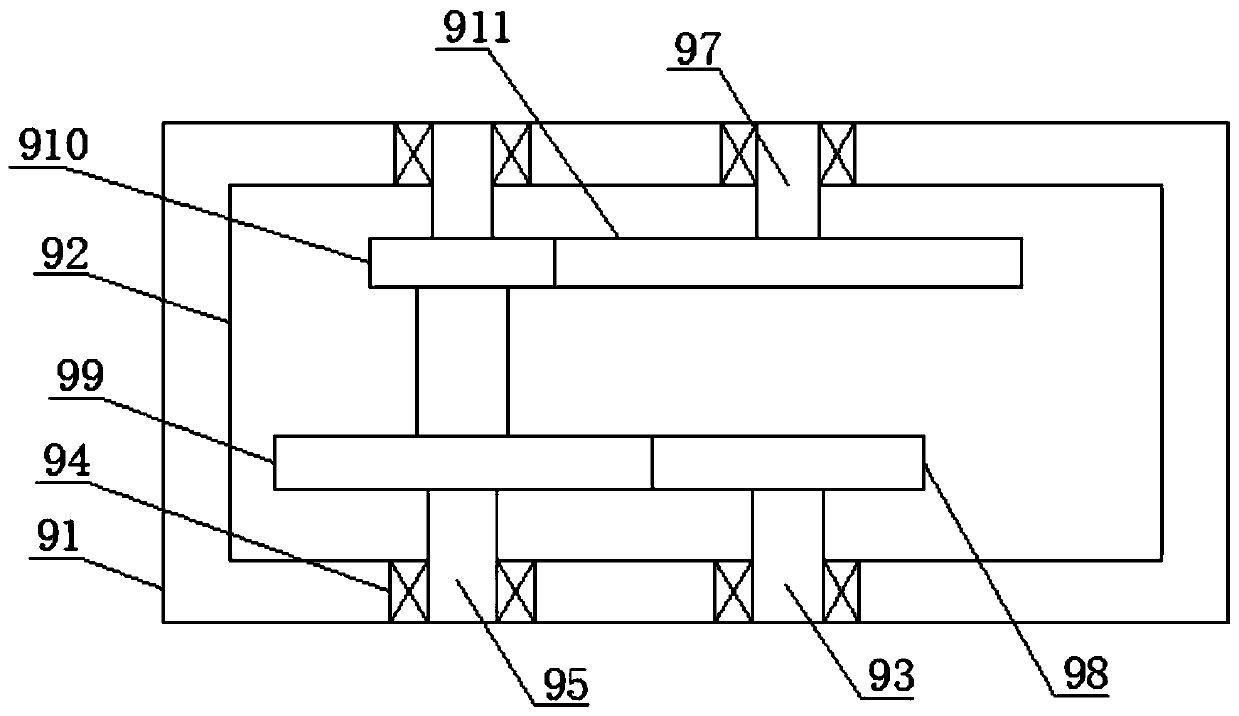

Bidirectional self-prove rated force measuring device

InactiveCN107192519AEffectively control the pressure valueControl pressure valueMaterial strength using repeated/pulsating forcesElasticity measurementElectricityMicrocomputer

The invention discloses a pressure testing machine, in particular, a bidirectional self-prove rated force measuring device. The bidirectional self-prove rated force measuring device comprises a rack (3); the rack is provided with a motor (2) and a transmission rod (6) which are connected with each other; the rack is provided with a fixture (7) located between the front part and rear part of the transmission rod; the transmission rod is provided with a left slider (3) and a right slider (4) which are correspondingly installed at two sides of the fixture; the left slider and the right slider are correspondingly connected with one end of a left pressure adjuster (10) and one end of a right pressure adjuster (5) respectively; and the left pressure adjuster and the right pressure adjuster are correspondingly installed on the left slider and the right slider and are both electrically connected with a microcomputer controller (1). According to the bidirectional self-prove rated force measuring device of the invention, with the left pressure adjuster and the right pressure adjuster adopted, bidirectional self-prove pressure impact tests can be performed at opposite directions, so that measurement results can be verified by each other. The bidirectional self-prove rated force measuring device has the advantages of simple structure, low workpiece loss, accurate and accurate result feedback and the like.

Owner:ZHEJIANG SHENGHUABO ELECTRICAL APPLIANCE

High-precision pipeline diameter measuring device and its inflation speed regulation method

ActiveCN106225700BGood deformation recoveryControl pressure valueUsing optical meansEngineeringMaterial resources

The invention relates to the technical field of pipeline diameter measuring devices, in particular to a high-precision pipeline diameter measuring device. The high-precision pipeline diameter measuring device comprises a diameter measuring body, a guide leather cup, a driving leather cup and a mileage wheel. The diameter measuring body is of a tubular structure, the left end of the diameter measuring body is sealed and fixedly provided with an anti-collision head, the guide leather cup is fixedly installed on the left outer wall of the diameter measuring body, and a deformation sensing leather cup and the driving leather cup are fixedly installed on the right outer wall of the diameter measuring body from left to right in sequence. The high-precision pipeline diameter measuring device is uniform in walking speed and high in implementation, the detection cycle is effectively shortened, and the measuring precision is effectively improved; besides, the high-precision pipeline diameter measuring device is high in measuring sensitivity, and the measuring precision is further improved; besides, under the cooperation of a ground marker, a front towing ring and a rear towing ring, the high-precision pipeline diameter measuring device is easy to position and take out, manpower and material resource consumption is reduced, the high-precision pipeline diameter measuring device is easy and convenient to machine and install, and parts are convenient and fast to replace.

Owner:乌鲁木齐市泰瑞赛驰机电科技有限公司

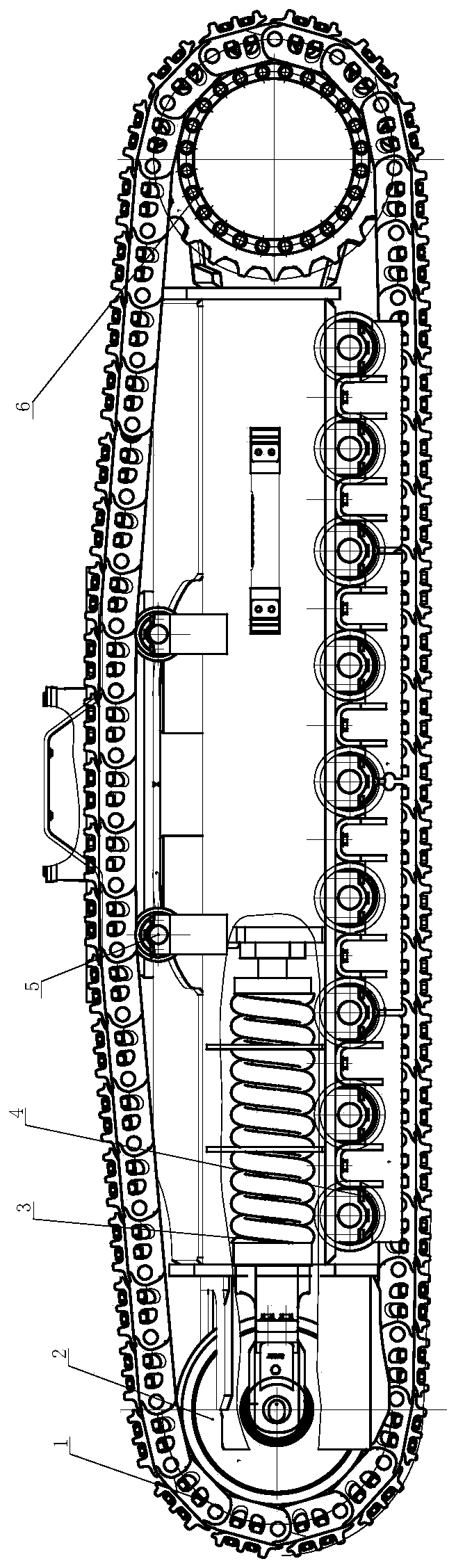

Wheel body internal pressure control system, engineering machinery and control method

ActiveCN111017059AReduce internal pressureControl pressure valueSignalling/lighting devicesLubricating systemControl systemControl theory

The invention provides a wheel body internal pressure control system, engineering machinery and a wheel body internal pressure control method of the wheel body internal pressure control system, and relates to the technical field of engineering machinery lubrication. The wheel body internal pressure control system comprises a pressure sensor, a controller and a driving device, wherein the pressuresensor is used for detecting a lubricating oil pressure value in the wheel body and transmitting the lubricating oil pressure value in the wheel body to the controller; the controller is used for receiving the lubricating oil pressure value in the wheel body transmitted by the pressure sensor and sending a deceleration signal to the driving device when the lubricating oil pressure value in the wheel body is higher than a preset threshold value; and the driving device is used for reducing the walking speed according to the deceleration signal of the controller. The technical problem that the internal pressure of the wheel body cannot be effectively controlled is solved, and the technical effect of effectively controlling the pressure value of lubricating oil in the wheel body is achieved.

Owner:SANY HEAVY MACHINERY

A two-stage gas energy-saving valve

ActiveCN104676062BReduce momentumReduce flow rateValve members for heating/coolingEqualizing valvesEngineeringProduct gas

Owner:NINGBO SUNRISE ELECTOR MECHANICAL

A temperature self-regulating device in a tunnel kiln

ActiveCN106440777BIncreased mixed combustion areaReduce generationFurnace typesTunnel kilnReaction rate

The invention discloses a temperature self-adjusting device for inner tunnel kilns. The device comprises a kiln body, a temperature adjustment burner which is installed on the side wall of the kiln body, a blower which is installed at the end part of the kiln body, a temperature sensor which is installed inside the kiln body, a PID controller and a central controller, and a temperature adjustment burner angle adjusting mechanism. The device of the invention can control the angle of the temperature adjustment burner nozzle, the fuel gas injection speed, the speed of temperature adjustment burner nozzle, and the kiln tail blowing rate of the tunnel kiln; sintering researches on various refractory materials can be carried out, which increases the diversity of researches; compared with the original tunnel kilns, the accuracy of temperature adjustment is increased, the efficiency is increased, the reaction rate of execution mechanism is faster, the automatic degree is higher with less pollution, and environmental protection and energy saving performance are improved.

Owner:YANCHENG INST OF TECH

Energy-saving water tank for air-source water heater

PendingCN107747819AControl pressure valueControl the highest pressure valueFluid heatersInsulation layerAgricultural engineering

The invention discloses an energy-saving water tank for an air energy water heater, comprising a water tank shell, a liquid inlet pipe is arranged at the upper left end of the water tank shell, a liquid outlet pipe is arranged at the lower right end of the water tank shell, and the water tank shell The outer side of the body is wrapped with an insulation layer, the insulation layer includes a heat insulation layer, a hollow layer and an insulation layer, the upper end of the water tank shell is provided with a pressure control valve, and the upper end of the pressure control valve is connected to the cover plate through a rotating shaft. The middle part of the inner cavity of the pressure control valve is provided with an air pressure control plate, which includes a communication groove, a support rod, a sealing plate, a spring, an air inlet hole and a sealing ring, and the upper end of the air pressure control plate is provided with a placement plate, The left and right ends of the air pressure control board are provided with balls. The energy-saving water tank for the air energy water heater can real-time control the air pressure value in the heat preservation water tank through the structure of the pressure control valve; through the structure provided with the heat preservation layer, the heat loss of the heat preservation water tank can be greatly slowed down.

Owner:SHANDONG AIRPOWER ENERGY SAVING EQUIP CO LTD

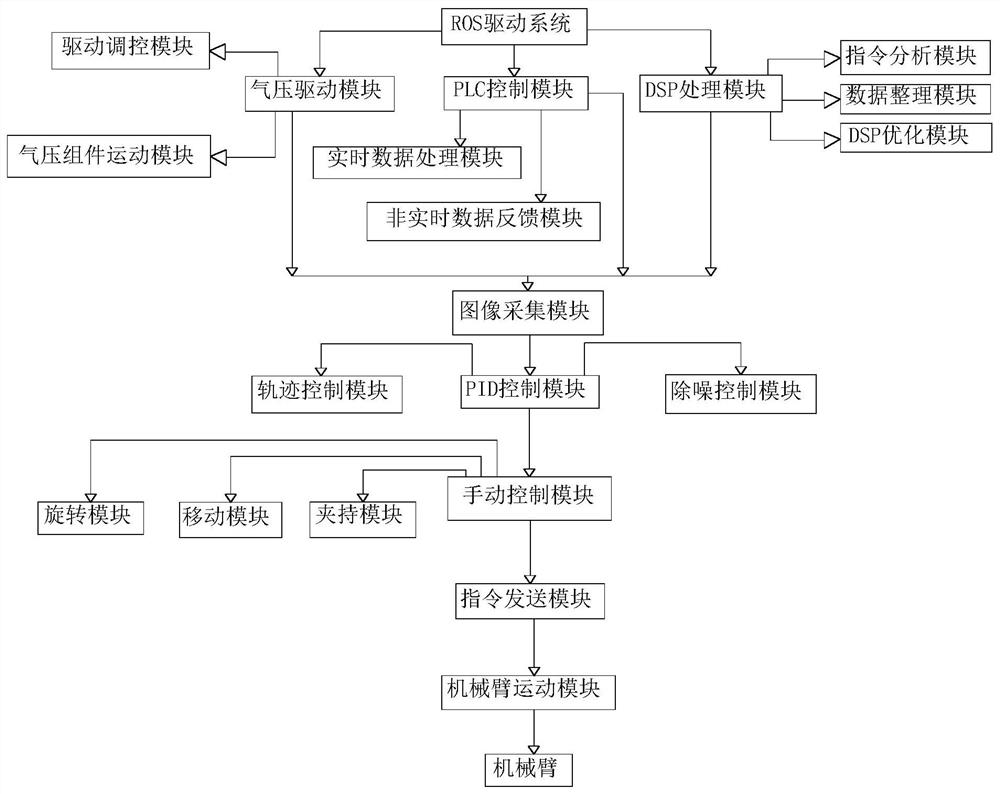

Intelligent industrial mechanical arm driving system based on ROS system

PendingCN114536327AGuaranteed flexibilityGuaranteed accuracyProgramme-controlled manipulatorTotal factory controlPhysical medicine and rehabilitationPressure.drive

The invention discloses an intelligent industrial mechanical arm driving system based on an ROS system, and relates to the technical field of mechanical arm driving systems. The intelligent industrial mechanical arm driving system based on the ROS system comprises the ROS driving system, the ROS driving system is in signal connection with an air pressure driving module, a PLC control module and a DSP processing module, and terminals of the air pressure driving module, the PLC control module and the DSP processing module are in signal connection with an image acquisition module. According to the intelligent industrial mechanical arm driving system based on the ROS system, the mechanical arm can rotate, move and clamp in a noise-free mode, then the movement flexibility of the mechanical arm is guaranteed, then it is guaranteed that the movement form, the movement freedom degree, the grabbing quality and the stress condition of the mechanical arm can be optimized and executed in time, the movement accuracy of the mechanical arm is guaranteed, and the working efficiency is improved. And it is guaranteed that the arm waist joint, the shoulder joint, the elbow joint and the wrist joint of the mechanical arm and the gripper at the tail end are opened and closed flexibly and freely, and the clamping work stability of the robot is improved.

Owner:四川广目科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com