Vacuum pressure valve for oil storage tank of gas station

A technology for vacuum pressure and oil storage tanks, which is applied in the direction of safety valves, balance valves, valve devices, etc., and can solve problems such as the inability to quickly recover the pressure in the tank, affect the quality of oil in the tank, and affect the quality of refined oil. Stable, high reliability, guaranteed reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

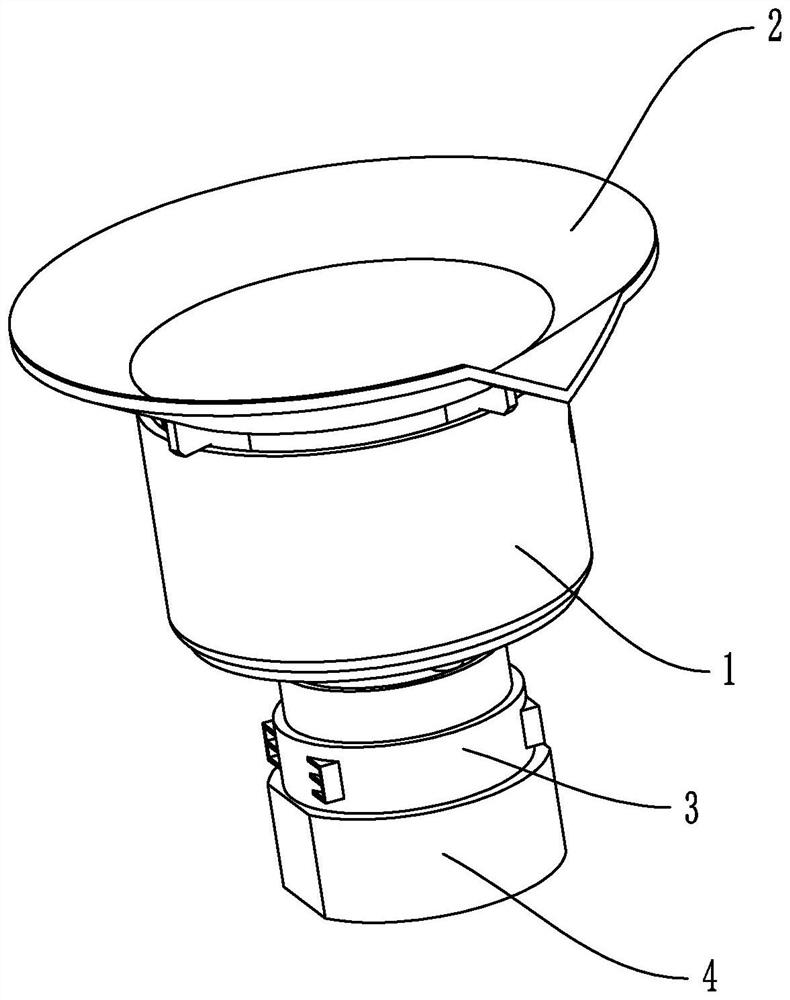

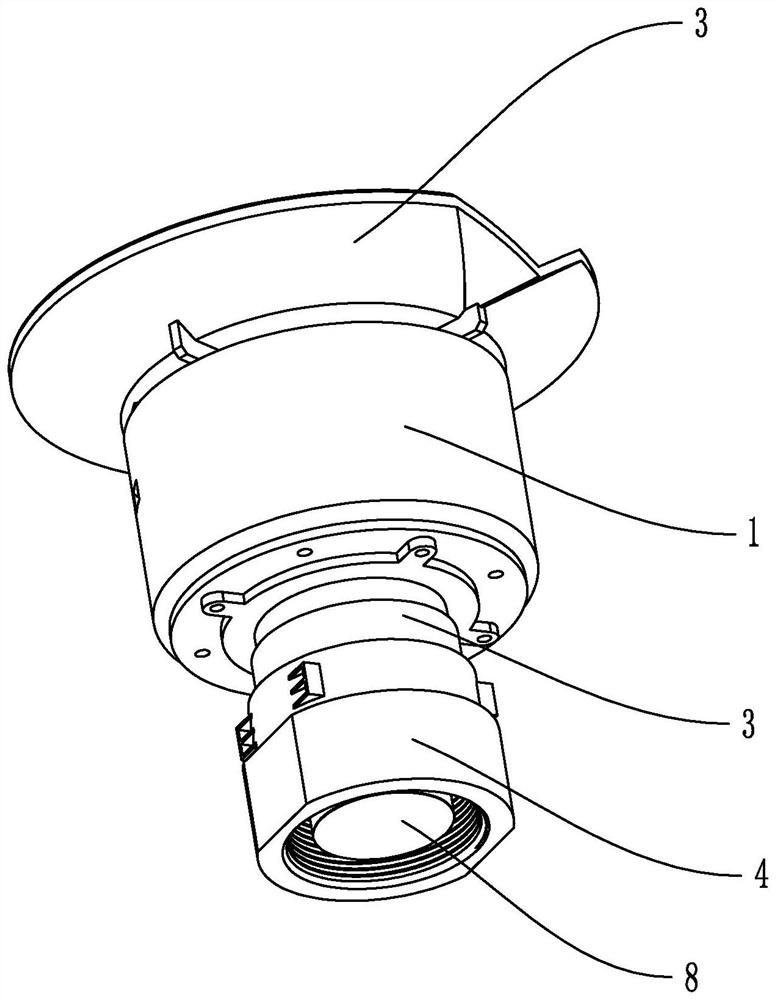

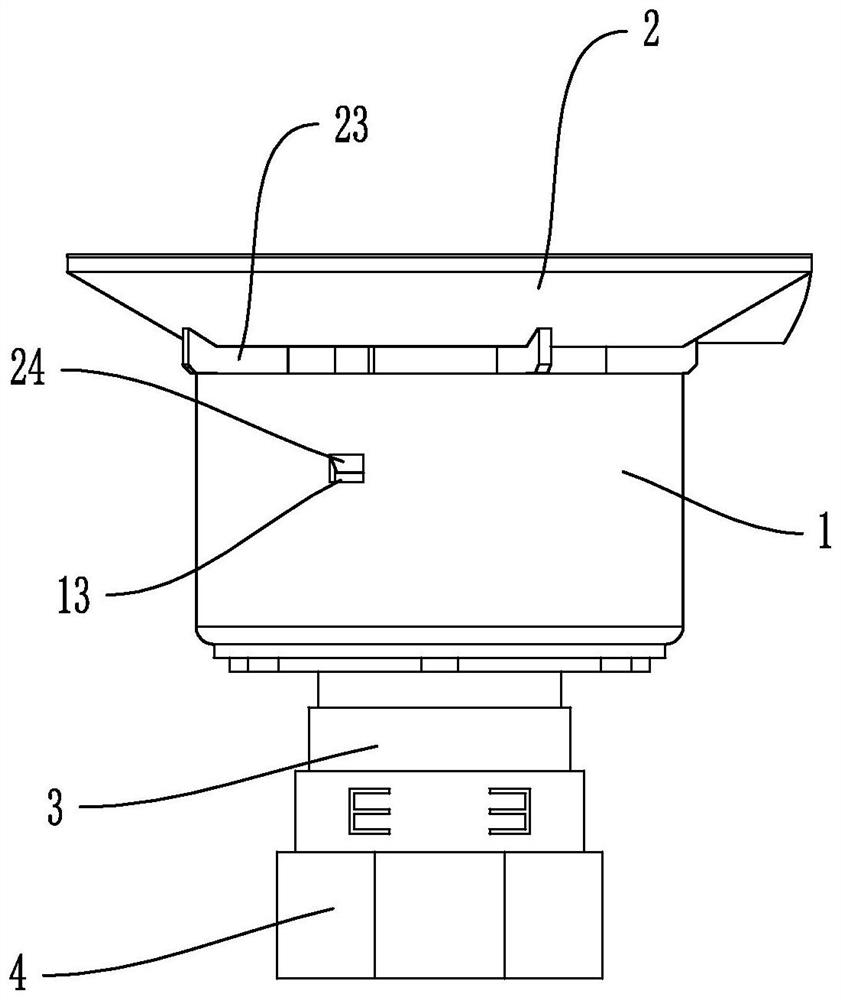

[0040] Embodiment 1. This embodiment discloses a vacuum pressure valve for an oil storage tank in a gas station, such as Figures 1 to 7 As shown, it includes a vacuum pressure valve housing 1, a disc cap 2 located on the upper and lower sides of the vacuum pressure valve housing 1, and a fixed sleeve 3. The lower end of the fixed sleeve 3 is provided with a connection port 4 connected to the oil storage tank. , the housing 1 of the vacuum pressure valve is provided with a fixed bracket 5 and a housing notch 11 adapted to the fixed bracket 5, the housing notch 11 communicates with the fixed sleeve 3, and the fixed bracket 5 is interspersed with a The pressure adjusting plate 6 that can slide up and down, the side of the fixed bracket 5 is provided with a number of evenly distributed ventilation slots 51, the outer cover of the fixed bracket 5 is provided with a first filter mesh structure 7 that matches it, the pressure adjusting plate 6 is The cylindrical structure is set, an...

Embodiment 2

[0051] Embodiment 2, the difference between this embodiment and Embodiment 1 is that, if Figure 8 As shown, the structure of the first filter screen structure 7 and the second filter screen structure 8 is the same, and the first filter screen structure 7 includes a filter paper layer 71 and a metal filter layer 72 positioned on both sides inside and outside the filter paper layer 71; The layer 71 can prevent the oil in the oil storage tank from spilling out of the oil storage tank, improve the air quality around the oil storage tank, and prevent the oil and gas in the air around the oil storage tank from easily causing a fire.

[0052] In summary, the present invention has the following beneficial effects:

[0053] 1. When the internal pressure of the oil storage tank is too high, the pressure regulating plate 6 overcomes its gravity and slides upwards, so that the internal pressure of the oil storage tank is discharged from the ventilation slot 51, otherwise it moves downwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com