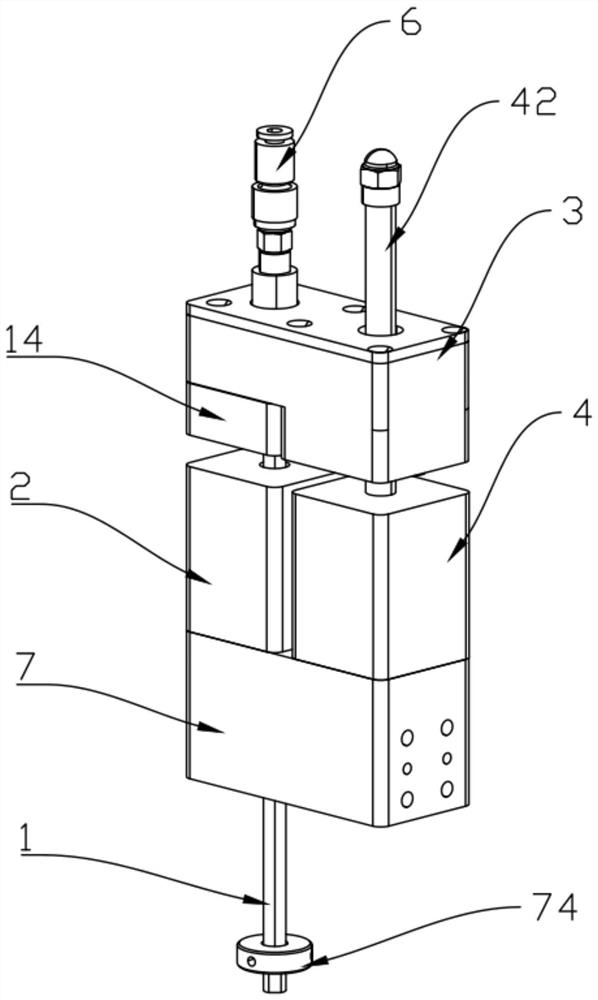

Accurate pressing composite type motion actuator with built-in pressure sensor

A technology of pressure sensors and actuators, which is applied in the direction of transmission, electric components, and mechanical energy control. It can solve the problems of uncontrollable, large volume, and low integration, and achieve the effects of high pressure accuracy, small volume, and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

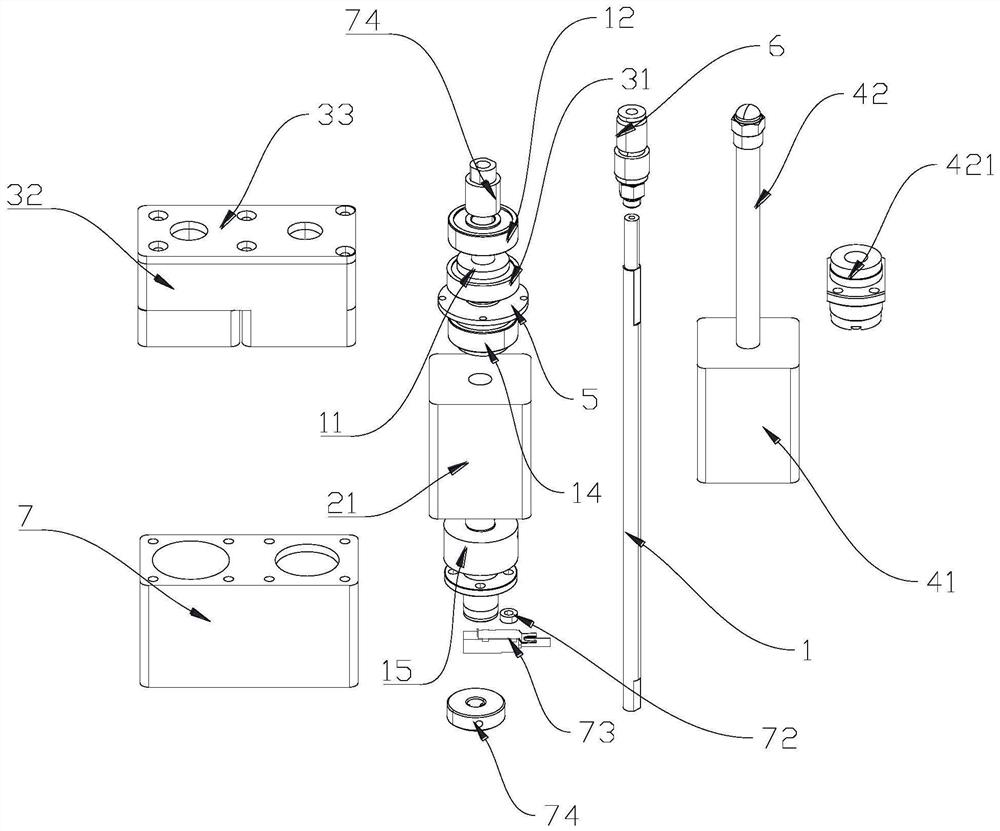

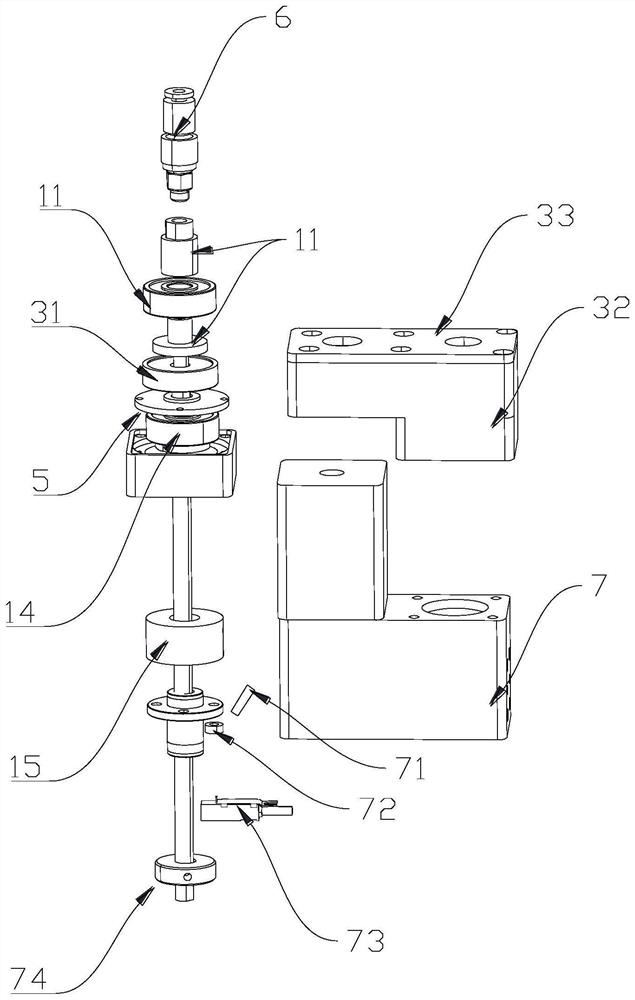

Examples

Embodiment

[0046] 35 type hollow motor, 35-0810 type ball screw motor, B628ZZ type bearing, BSR0810 type ball screw nut, because under the limitation of these standard motor and bearing type, the type of accessories is also limited accordingly, so it is not mentioned here Let me repeat; assemble the motor connection block, hollow motor, connection block, first bearing, pressure plate, spline screw, ball spline screw, ball spline nut and direct screw motor, and the spline screw One end of it is connected to the load, and the other end is inserted into the connection block. The connection block accommodates a suitable bearing and a bearing support seat; then the ball screw motor and the hollow motor are installed side by side on the motor mounting seat, and the ball screw is also inserted into the connection Block, the ball screw nut socketed on the shaft is fixed with the connecting block; by turning the magnetic sensor and ultra-small proximity sensor into the mounting seat to sense the z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com