High-precision pipeline diameter measuring device and its inflation speed regulation method

A high-precision, diameter-measuring technology, applied to measuring devices, optical devices, instruments, etc., can solve problems such as inaccurate diameter measurement results, misjudgment of pipe diameter parameters, and low measurement accuracy, so as to shorten the detection cycle and improve deformation Ability, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

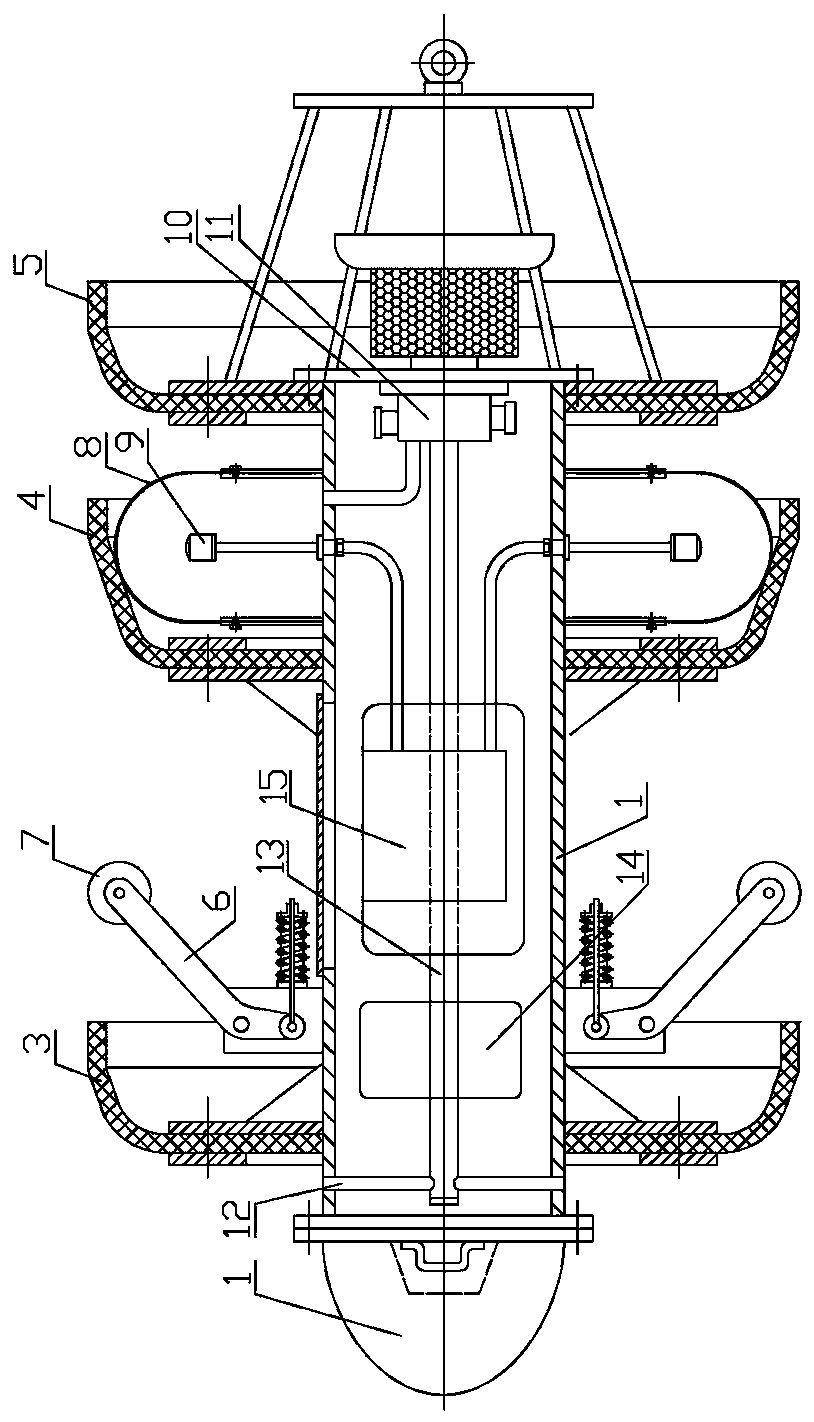

[0025] Embodiment 1, as attached figure 1 , 2 As shown, the high-precision pipe diameter measuring device includes a measuring body 1, a guide cup 3, a driving cup 5, and a mileage wheel 7; the measuring body 1 is in a tubular structure, and the left end of the measuring body 1 is closed. The anti-collision head 2 is fixedly installed on the left end of the caliper body 1, the guide cup 3 is fixedly installed on the left outer wall of the caliper body 1, and the deformation cup 3 is fixedly installed on the right outer wall of the caliper body 1 from left to right. Induction cup 4 and driving cup 5; at least two sets of mileage wheel mounting brackets 6 are fixedly installed on the outer wall of the diameter measuring body 1 between the guide cup 3 and the deformation induction cup 4, and each set of mileage wheel mounting brackets The end of 6 is equipped with mileage wheel 7, is also provided with rotational speed sensor on mileage wheel 7; Induction airbag 8, the outer si...

Embodiment 2

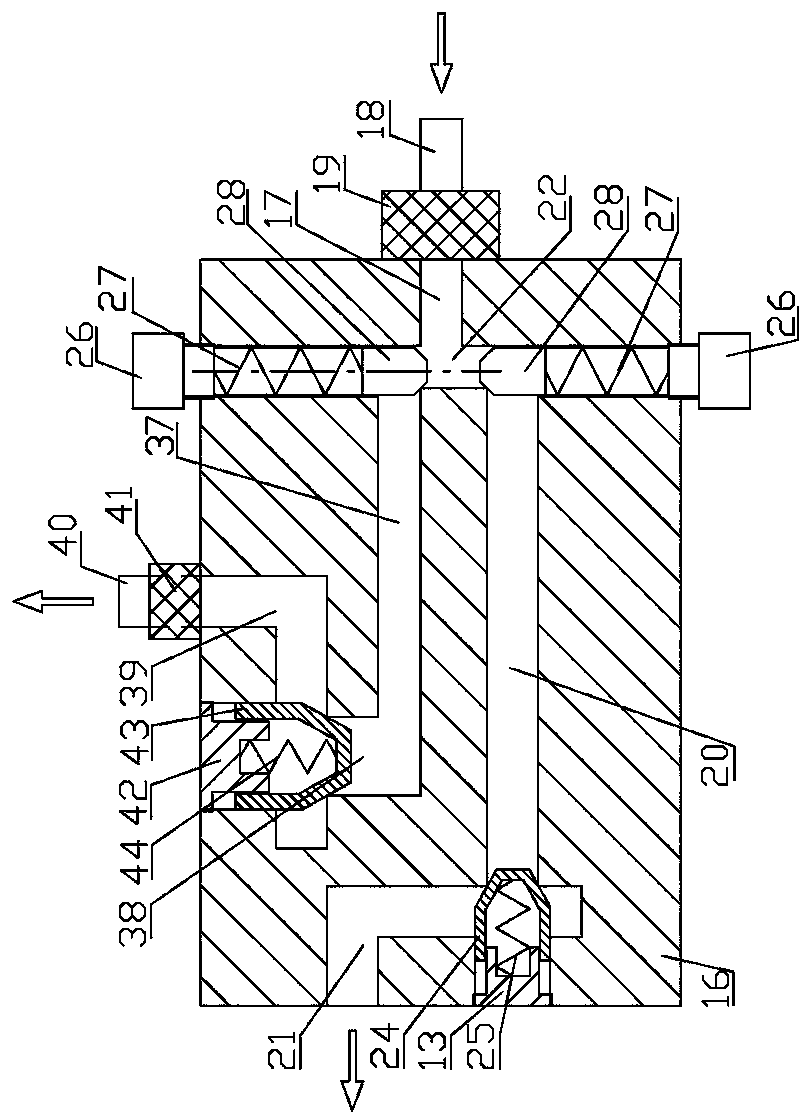

[0027] Embodiment 2, as the optimization of embodiment 1, as attached figure 1 , 2As shown, the combination valve includes a valve body 16, a speed regulating check valve and a speed regulating regulating valve. A horizontal air intake passage 17 communicating with the outside of the valve body 16 is arranged in the right part of the valve body 16, corresponding to the air intake passage 17. The valve body 16 of the valve body 16 is fixedly installed with the air intake pipe 18 that communicates with the air intake passage 17, and the positive pressure filter 19 is connected in series on the air intake pipe 18. The speed control channel, the speed control channel includes a horizontal speed control section 20 and an L-shaped curved hole section 21, the left end of the horizontal speed control section 20 is a stepped hole with a large left and a small right, and the air intake hole on the blind plate 10 is connected with the intake pipe 18 The air inlet of the speed regulating...

Embodiment 3

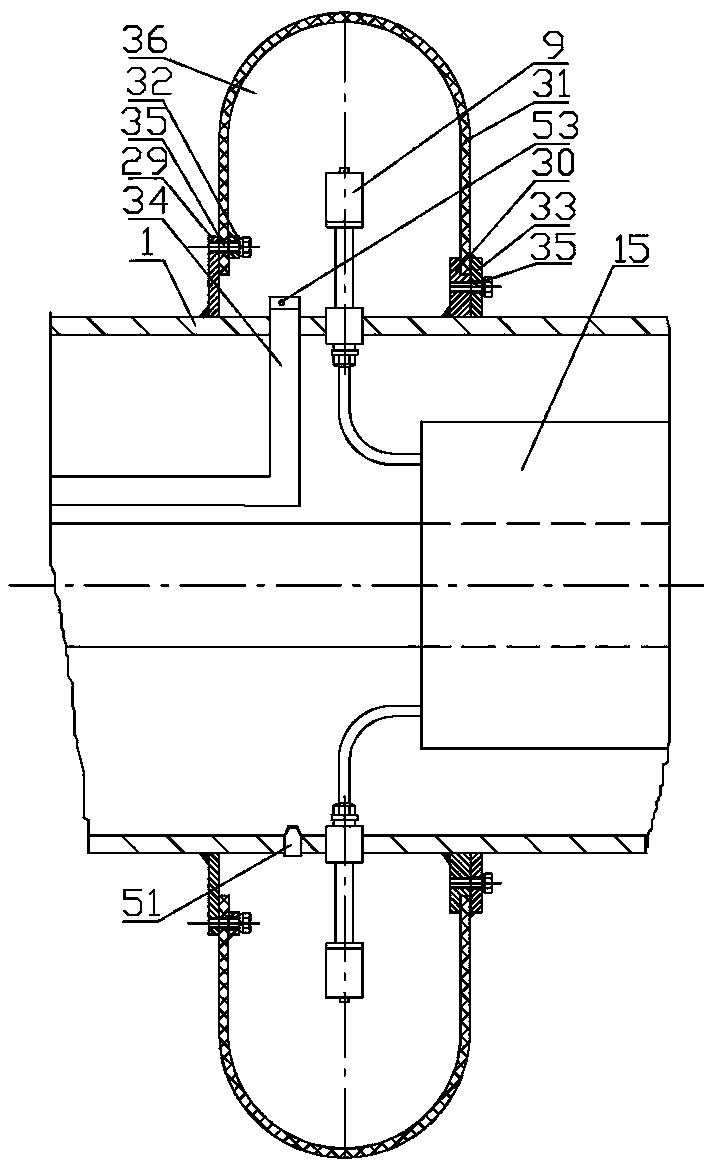

[0029] Embodiment 3, as the optimization of embodiment 2, as attached figure 1 , 2 , 3, the induction airbag 8 includes a left mounting ring plate 29, a right mounting ring plate 30, a flexible connector 31, a left connecting ring plate 32, a right connecting ring plate 33 and an inflation pipeline 34; the left mounting ring plate 29, the right mounting The ring plates 30 are respectively sealed and welded on the outer wall of the caliper body 1 in the corresponding deformation induction cup 4, the outer diameter of the left mounting ring plate 29 is greater than the outer diameter of the right mounting ring plate 30, and the flexible connector 31 has a section of C The inner end inner wall of the left part of the flexible connector 31 is bonded or vulcanized together with the left side wall of the left connecting ring plate 32, and the outer wall of the right inner end of the flexible connecting part 31 is connected to the right connecting ring plate. The left side walls of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com