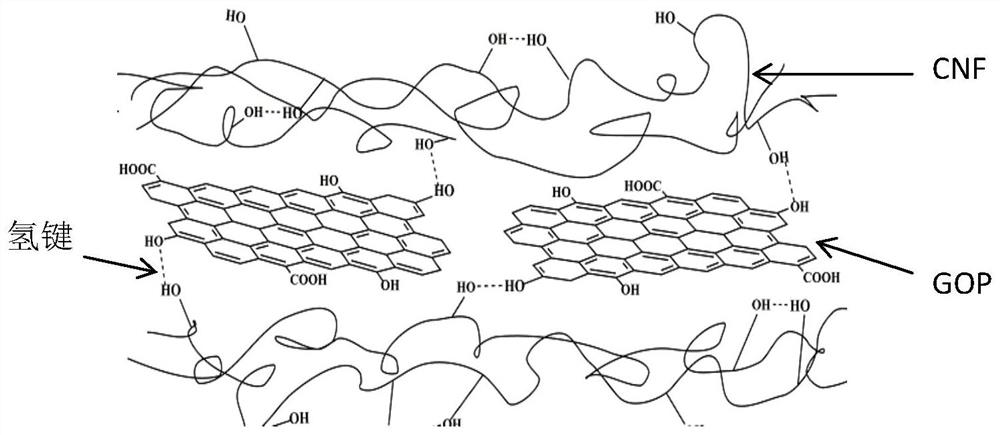

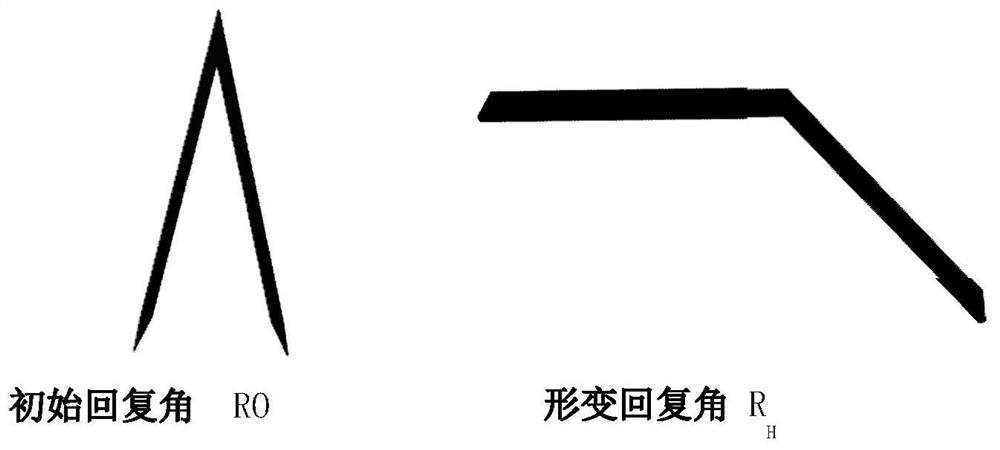

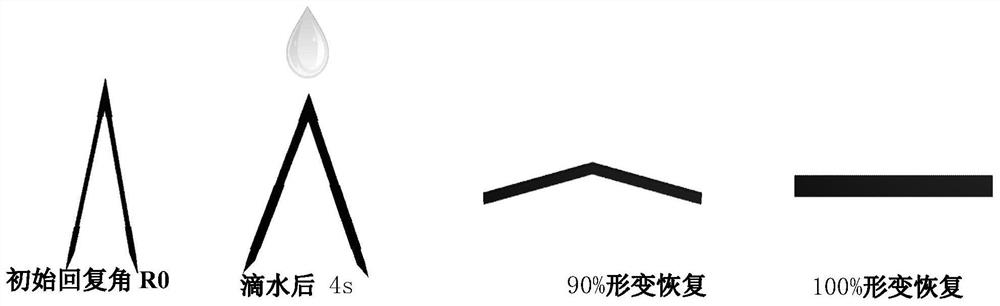

Preparation method and test method of gop/cnf composite material with water-induced deformation memory function

A composite material and water-induced technology, which is applied in the direction of applying repeated force/pulsating force to test the strength of materials, can solve the problems of less research on deformation memory function, lack of preparation and acquisition of composite materials, etc., and achieve good thermal stability and deformation Excellent recovery ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Cotton fiber pretreatment: crush 100g cotton fiber with a plant pulverizer (length 1-2mm), put it into 2000g sodium hydroxide (4wt%) aqueous solution, heat to 150°C for 2h, cool down to 80°C, Add 50 g of sodium hypochlorite for bleaching for 1 h, then repeatedly rinse with deionized water and filter (filter hole 5 μm) to prepare pretreated swollen cotton fibers and weigh 112.6 g.

[0050] 2. Preparation of CNF aqueous solution: Weigh 120g of acetic acid and acetic anhydride (50wt%, 50wt%) and add deionized water to form a mixed aqueous solution of acetic acid and acetic anhydride (about 1200ml) containing 10wt%, add 0.24g of concentrated sulfuric acid (95% v / v) as a catalyst, and then put the above-mentioned swollen cotton fiber into the above-mentioned pre-prepared mixed aqueous solution of acetic acid and acetic anhydride, carry out ultrasonication in a water bath at 50°C and fully hydrolyze and partially acetylate the reaction (frequency 100Hz, power 600-1000w) 1...

Embodiment 2

[0060] 1. According to the implementation step 1, 100g of cotton fiber is crushed with a plant pulverizer (length 1-2mm), put into 2000g of sodium hydroxide (4wt%) aqueous solution, heated to 150°C for 2h, cooled to 80°C, Add 50 g of sodium hypochlorite for bleaching for 1 hour, then repeatedly rinse with deionized water and filter (filter hole 5 μm) to prepare pretreated swollen cotton fibers and weigh 112.6 g.

[0061] 2. Preparation of CNF aqueous solution: Measure 120g of acetic acid and acetic anhydride (50wt%, 50wt%) and add deionized water to form a mixed aqueous solution of 10wt% acetic acid and acetic anhydride (about 1200ml), add 0.24g of concentrated sulfuric acid (95% v / v) as a catalyst, then put the above-mentioned swollen cotton fiber into the above-mentioned mixed aqueous solution of acetic acid and acetic anhydride, carry out ultrasonication in a water bath at 50°C and fully hydrolyze and partially acetylate (frequency 100Hz, power 600-1000w) for 120min . The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com