Metal sheet shock wave forming method and device

A metal sheet and shock wave technology is applied in the field of plastic processing and forming of sheet materials, which can solve the problems of potential safety hazards, low production efficiency and low degree of automation in explosives, and achieve the effects of reducing thermal effects, prolonging service life and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

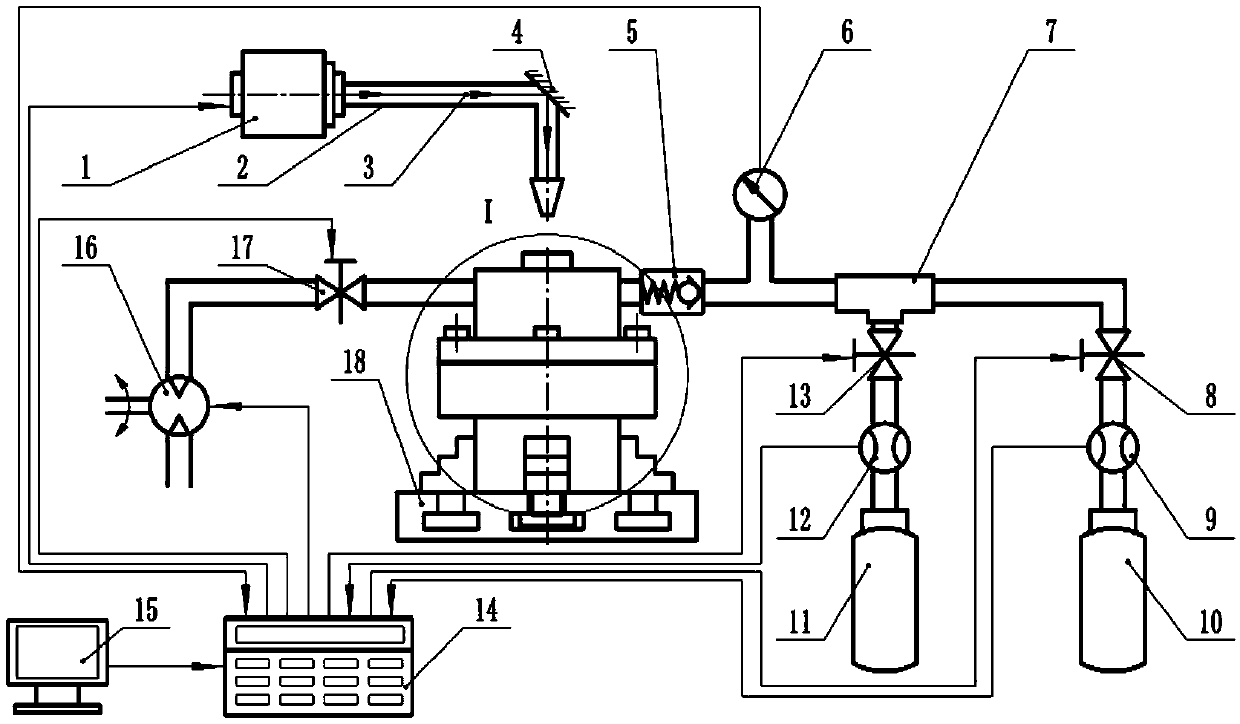

[0018] The invention provides a shock wave forming method for sheet metal. The specific steps of forming a workpiece with a large area, a large thickness and a deep forming depth in the forming device of the present invention are as follows:

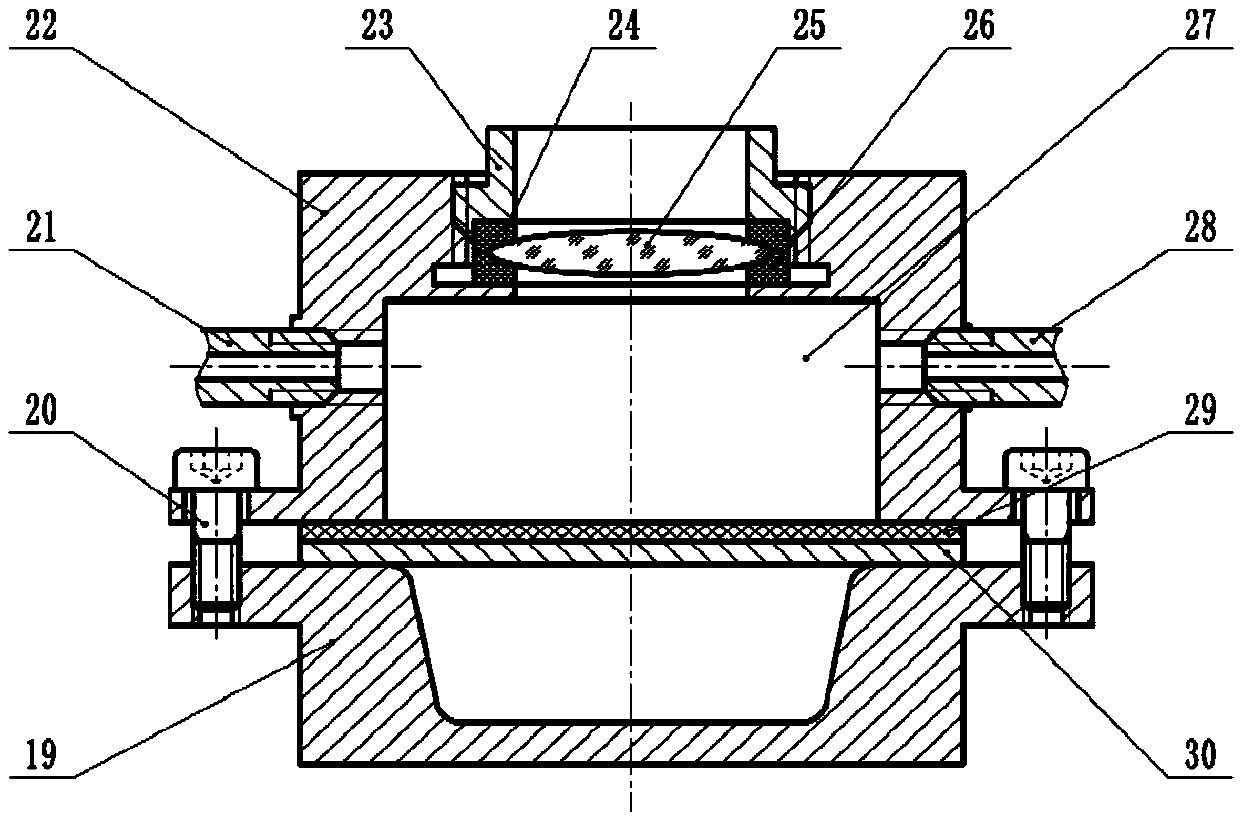

[0019](1) Place the sheet metal 30 on the die 19, and cover the surface of the sheet metal 30 with the absorbing layer 29, place the pressure chamber casing 22 on the absorbing layer 29, and use the pressure chamber bolt 20 to secure the pressure chamber casing The body 22 is connected to the die 19, wherein the pressure chamber bolts 20 are evenly distributed around the circumference, and the absorption layer 29 and the metal sheet 30 are compressed and fixed. Before starting to supply gas to the pressure chamber 27, check the gas pressure in the hydrogen cylinder 10 and the oxygen cylinder 11 to ensure that the gas pressure in the hydrogen cylinder 10 and the oxygen cylinder 11 is approximately equal; The pressure is higher than the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com