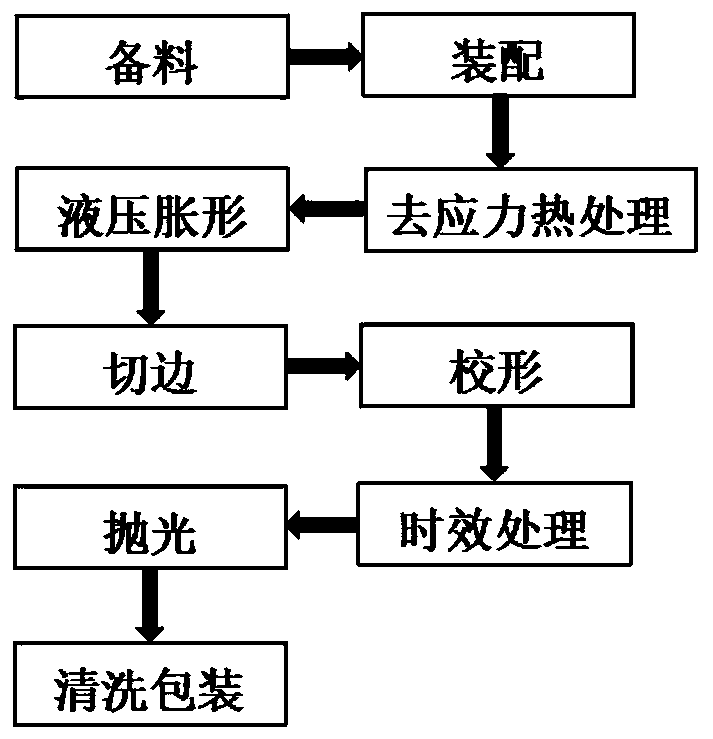

Hydroforming method for manufacturing multilayer metal sealing gasket

A metal sealing gasket and sealing gasket technology, applied in the field of metal plastic forming, can solve the problems of difficult rolling forming, poor versatility, and poor forming accuracy of parts, and achieve good dimensional consistency, wide application range, and processing good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

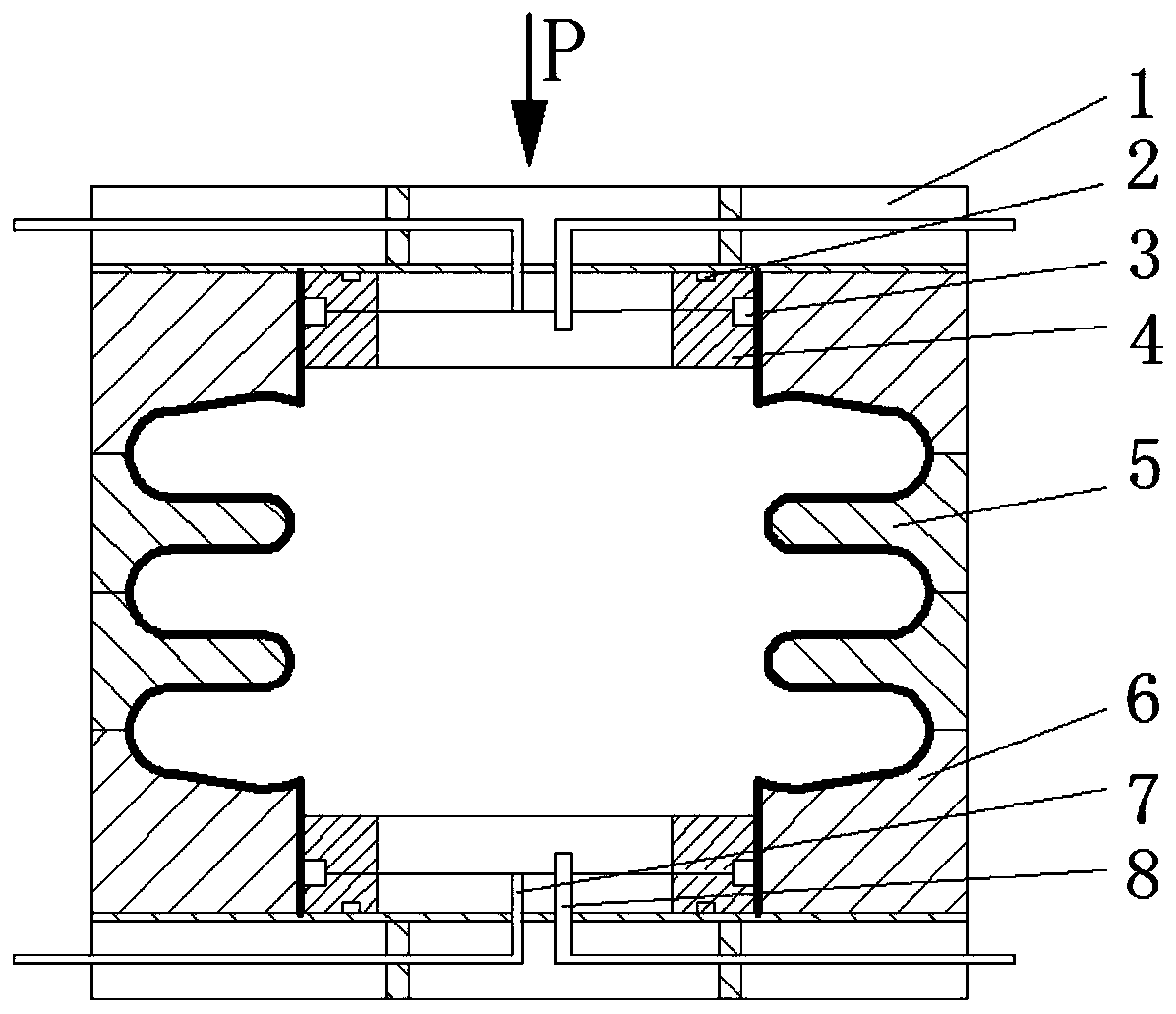

Method used

Image

Examples

Embodiment 1

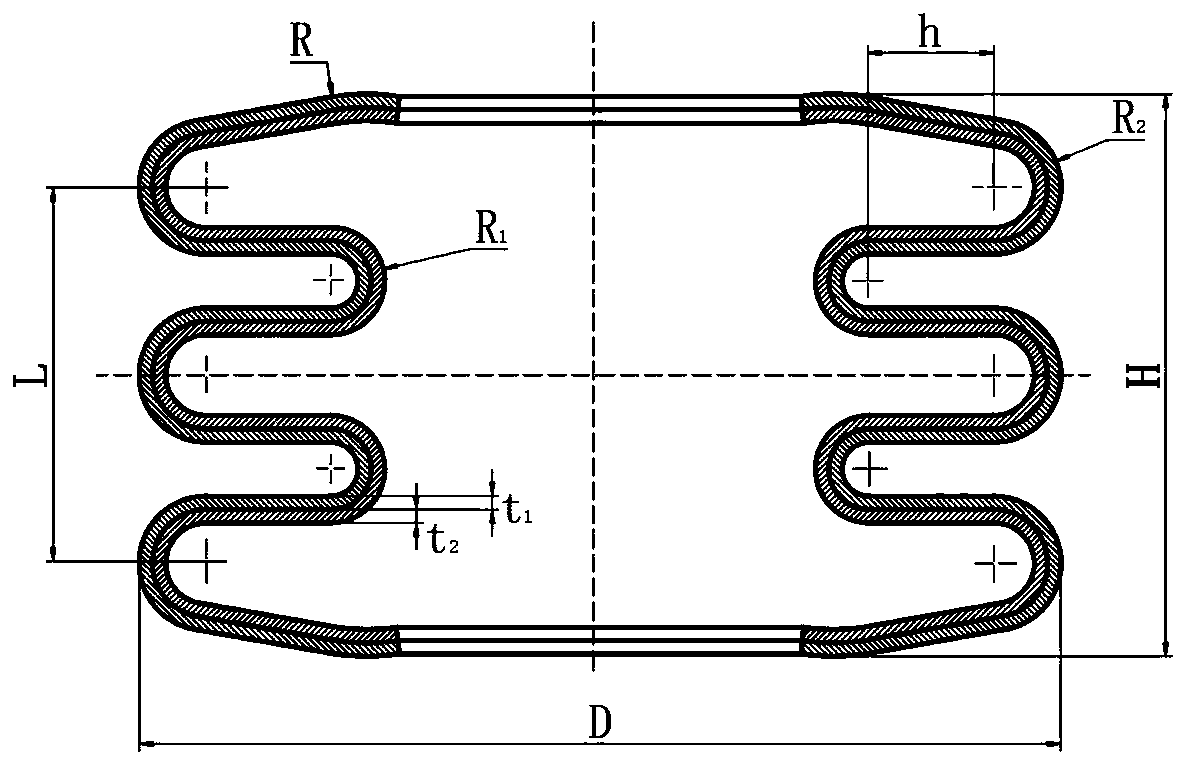

[0098] Double-layer GH4169 material E-shaped circular structure metal sealing gasket, the structure diagram is as follows image 3 shown.

[0099] The initial structural parameters are as follows: the outer diameter of the sealing ring D = 300mm, the free height of the sealing ring H = 13.16mm, the radius of curvature of the contact surface R = 4mm, the single-layer wall thickness t 1 = t 2 =0.3mm, number of layers n=2, trough radius R 1 =1.2mm, crest radius R 2 =1.5mm, wave height h=5mm, 3 corrugations.

[0100] 1) Prepare materials. Calculated inner diameter d of the first layer blank 1 is 284.22mm, the first layer of metal sealing gasket cross-sectional development length L 1 ' is 50.85mm, the tube length L 1 Take 2 times L 1 'Length, rounded to 102mm; inner diameter of the second layer blank d 2 282.82mm, the second layer of metal sealing gasket cross-sectional development length L 2 'is 49.81mm, and the length of the tube blank is L 2 Take 2 times L 2 'The len...

Embodiment 2

[0110] Double-layer GH4738 material C-shaped runway-shaped metal sealing gasket, the structure diagram is as follows Figure 6 shown.

[0111] The initial structural parameters are as follows: the outer diameter of the sealing ring D = 300mm, the radius of the C-shaped section R = 8mm, the included angle of the C-shaped opening θ = 80°, and the single-layer wall thickness t 1 = t 2 =0.3mm, number of layers n=2, 1 corrugation.

[0112] 1) Prepare materials. The outer diameter of the arc section of the outermost blank cross section D 0 =271.74mm, straight edge section M=200mm; after calculation, the inner diameter of the arc section of the first layer of billet d 1 271.14mm, the first layer of metal sealing gasket cross-sectional development length L 1 ' is 39.1mm, the tube length L 1 Take 2 times L 1 'Length, rounded to 78mm; the inner diameter of the arc section of the second layer blank d 2 is 270.34mm, the second layer of metal sealing gasket cross-sectional developm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com