Electric automobile brake power-assisted vacuum pump controller circuit and control method

A technology for assisting vacuum pumps and electric vehicles. It is applied in the fields of automatic control, pressure sensors, and amplifier circuits. It can solve the problems of low safety and reliability, inability to detect the working status of vacuum pumps, frequent startup or non-stop of vacuum pumps, etc., and achieve reliable safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

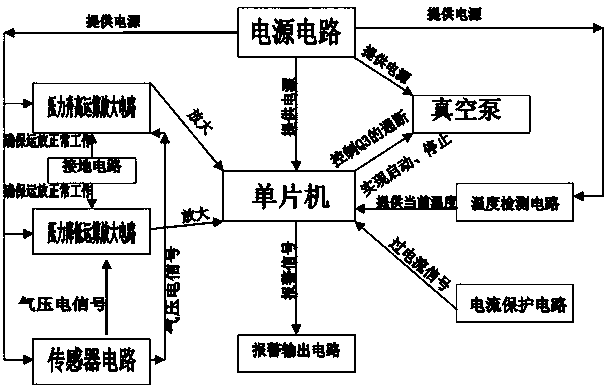

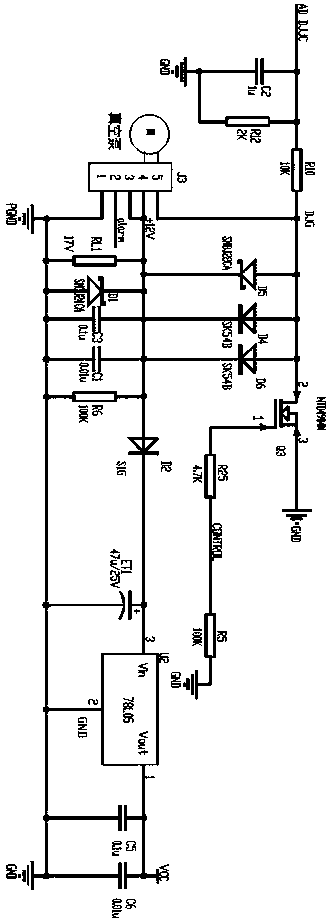

[0034] Such as Figure 1 to Figure 10 As shown, a brake booster vacuum pump controller circuit for an electric vehicle includes a vacuum pump, a vacuum pump controller, and a vacuum tank. The vacuum pump controller is connected to the vacuum pump, the vacuum pump is connected to the vacuum tank, and the vacuum pump controller is embedded in the vacuum tank.

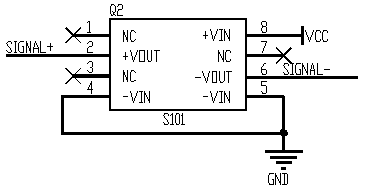

[0035] The vacuum pump controller circuit includes a single-chip microcomputer, a power supply circuit, a pressure increase operation amplifier circuit, a pressure decrease operation amplifier circuit, a grounding circuit, a sensor circuit, an alarm output circuit, a temperature detection circuit, and a current protection circuit.

[0036] The single-chip microcomputer is respectively connected with the pressure increase operational amplifier circuit, the pressure decrease operational amplifier circuit, the grounding circuit, the sensor circuit, the alarm output circuit, the temperature detection circuit, the current prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com