Accurate shape control method and device used after sterilization of infusion type products

A precise control and product technology, applied in temperature control, packaging sterilization, water supply equipment, etc., can solve the problems of difficult to maintain the appearance, increase product waste rate, etc., to reduce product waste rate, reduce the probability of scrapping, and reduce raw materials the wasteful effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

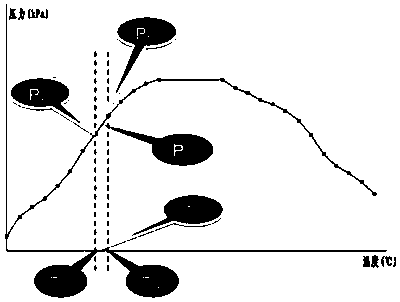

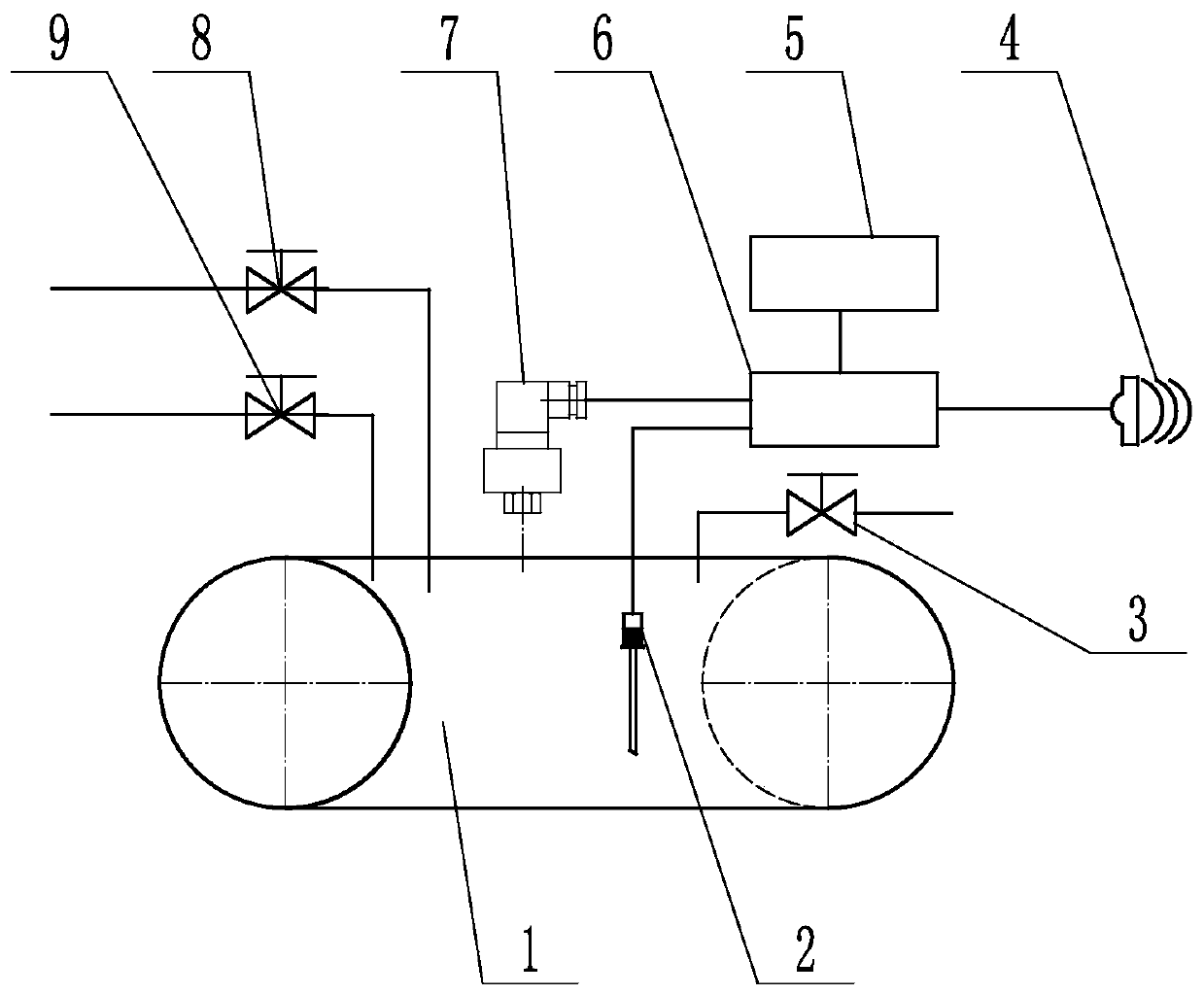

[0031] Such as figure 2 As shown, the precise control method of the shape of the transfusion product of the present invention after sterilization comprises the following steps:

[0032] (1) According to the characteristics of the product to be sterilized, divide the sterilization heating section and the sterilization cooling section into multiple subsections, for example, the sterilization heating section is divided into 12 subsections, and the sterilization cooling section is divided into 12 subsections;

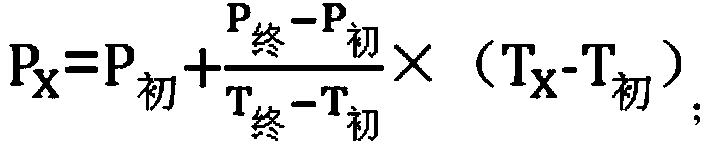

[0033] (2) In the HMI system 5, correspondingly input the starting temperature T of each segment 初 and end temperature T 终 , set the starting pressure P 初 and end pressure P 终 , and then input the temperature rise rate △T in this temperature range. As the Tx temperature continues to rise, the pressure Px that needs to be added to the sterilized product will continue to increase. According to the relationship of a linear function, it can be obtained:

[0034]

[0035] ...

Embodiment 2

[0080] On the basis of Embodiment 1, in the unit time of N consecutive sections; the temperature sensor detects that the temperature change rate T per unit time is greater than the set temperature change rate ΔT, or the temperature sensor detects the temperature change rate per unit time T is less than the set temperature change rate △T; alarm reminder. 2≤N≤25. The value of N is set according to the required sterilization temperature change, that is, the accuracy of regulating the temperature change rate is determined. N can be 2, 3, 4, 5, 6, 10, 15, 20 or 25. Preferably, N is 5, 10 or 20.

[0081] Pressure sensor: refers to the device that uses a diaphragm device (stainless steel diaphragm, silicone diaphragm, etc.) as a medium to measure the pressure of gas and liquid with a pressure-sensitive element, and converts it into an electrical signal output.

[0082] Temperature sensor: refers to a sensor that can sense temperature changes and convert them into usable output sig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com