Bidirectional self-prove rated force measuring device

A force-measuring device and rated technology, applied in the direction of measuring devices, elastic testing, machine/structural component testing, etc., can solve problems such as instability, accuracy doubts, damage, etc., to achieve convenient program operation, accurate pressure control, The effect of low cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

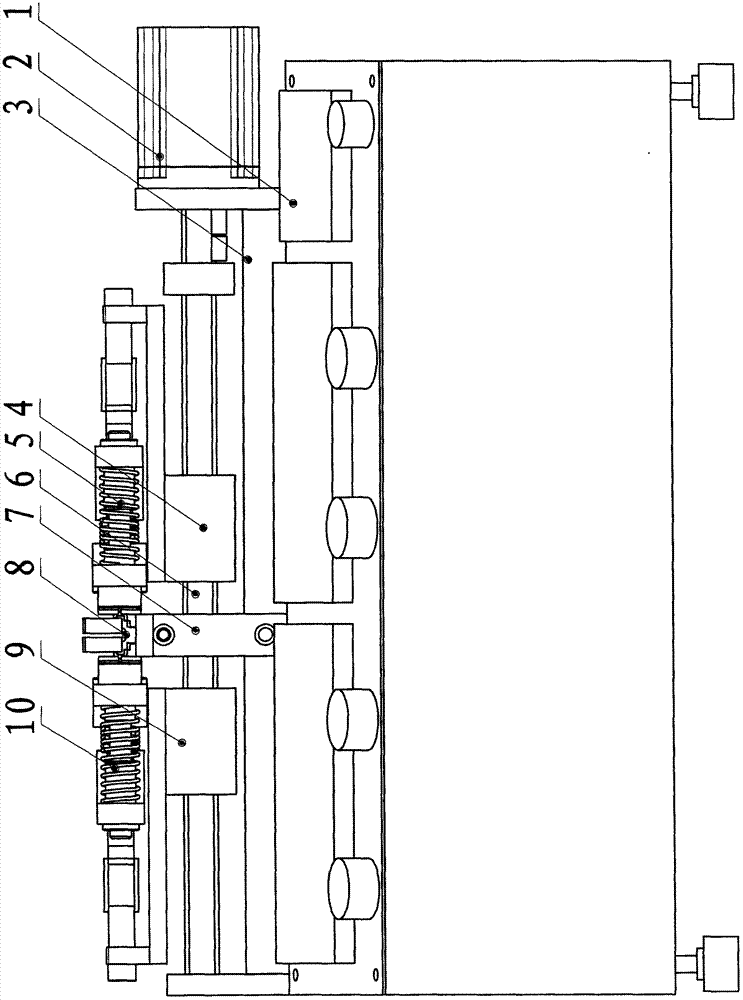

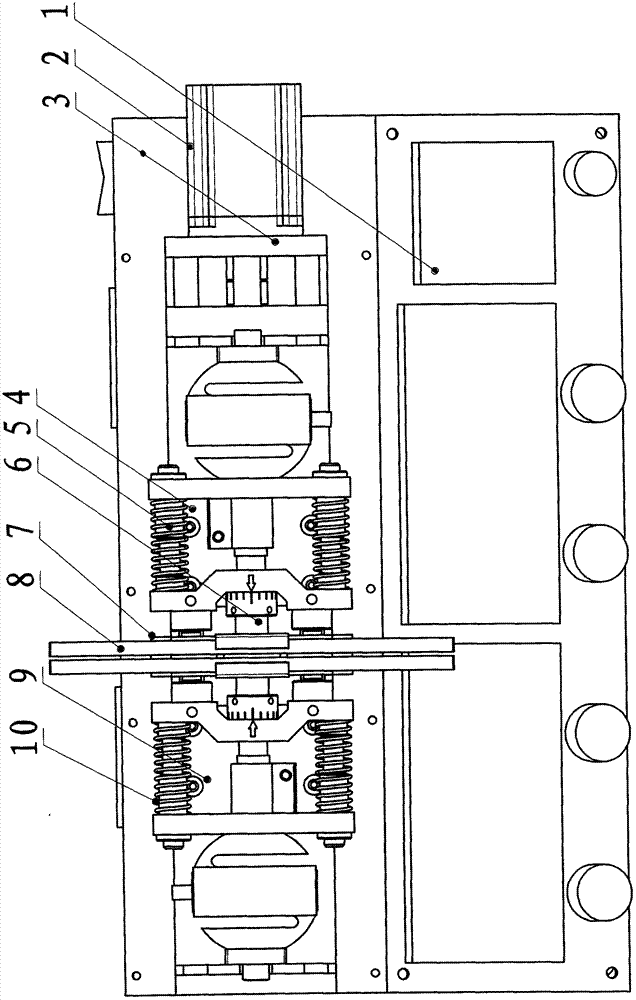

[0009] refer to figure 1 , figure 2 , the two-way self-certified rated force measuring device of the present invention comprises a frame 3 (comprising a slide table), a connected motor 2 and a transmission rod 6 are installed on the frame 3, and on the frame 3 and on the transmission rod 6 Fixtures 7 are installed between the front and rear of the clamp 7, and left slider 9 and right slider 4 are respectively installed on the transmission rod 6 and at the corresponding positions on both sides of the clamp 7, and the left and right sliders 9, 4 are respectively connected with one end of the left pressure regulator 10 and the right pressure regulator 5, and the left and right pressure regulators 10, 5 are respectively installed on the left and right sliders 9, 4 and are connected with the microcomputer controller 1 (including display screen, red light, green light, etc.) electrical connection.

[0010] Working principle of the present invention: the workpiece 8 to be tested (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com