Tunnel kiln environment conditioning method and device of automatically adjusting temperature in kiln

A technology of environment regulation and tunnel kiln, which is applied in temperature control, control/regulation system, non-electric variable control, etc. It can solve the problems of large temperature difference between upper and lower, difficult turbulent flow of gas and air, and insufficient combustion, so as to increase the mixed combustion of gas area, solve the problem of temperature difference between upper and lower, and achieve a more complete combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

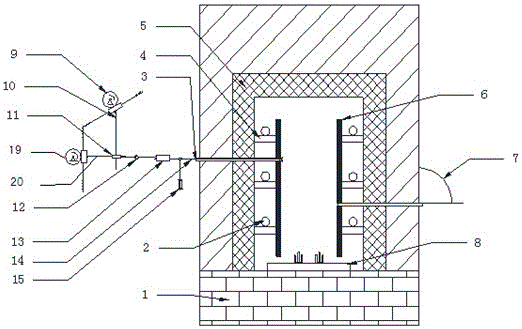

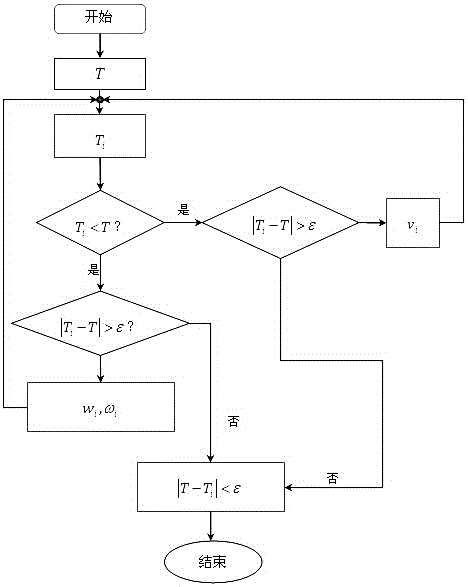

[0038] A tunnel kiln environment regulation method, comprising the following steps:

[0039] S1. Install environmental information collection equipment in the tunnel kiln, the environmental information collection equipment is used to collect environmental parameters of the environment to be adjusted in the tunnel kiln, and send the environmental parameters to the controller;

[0040] S2. The controller adjusts system parameters according to the environmental parameters collected by the environmental information collection device, generates an environment adjustment instruction, and sends the environment adjustment instruction to an environment adjustment actuator;

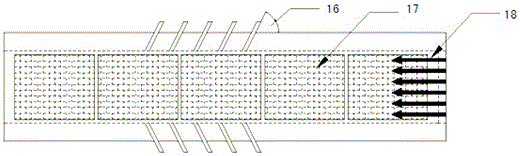

[0041] S3. The environment adjustment actuator adjusts the environment in the tunnel kiln according to the environment adjustment instruction sent by the controller; the environment adjustment actuator includes: temperature adjustment burners arranged on both sides of the kiln body and blower at the rear of the bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com