Patents

Literature

98results about How to "Improve the state of combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

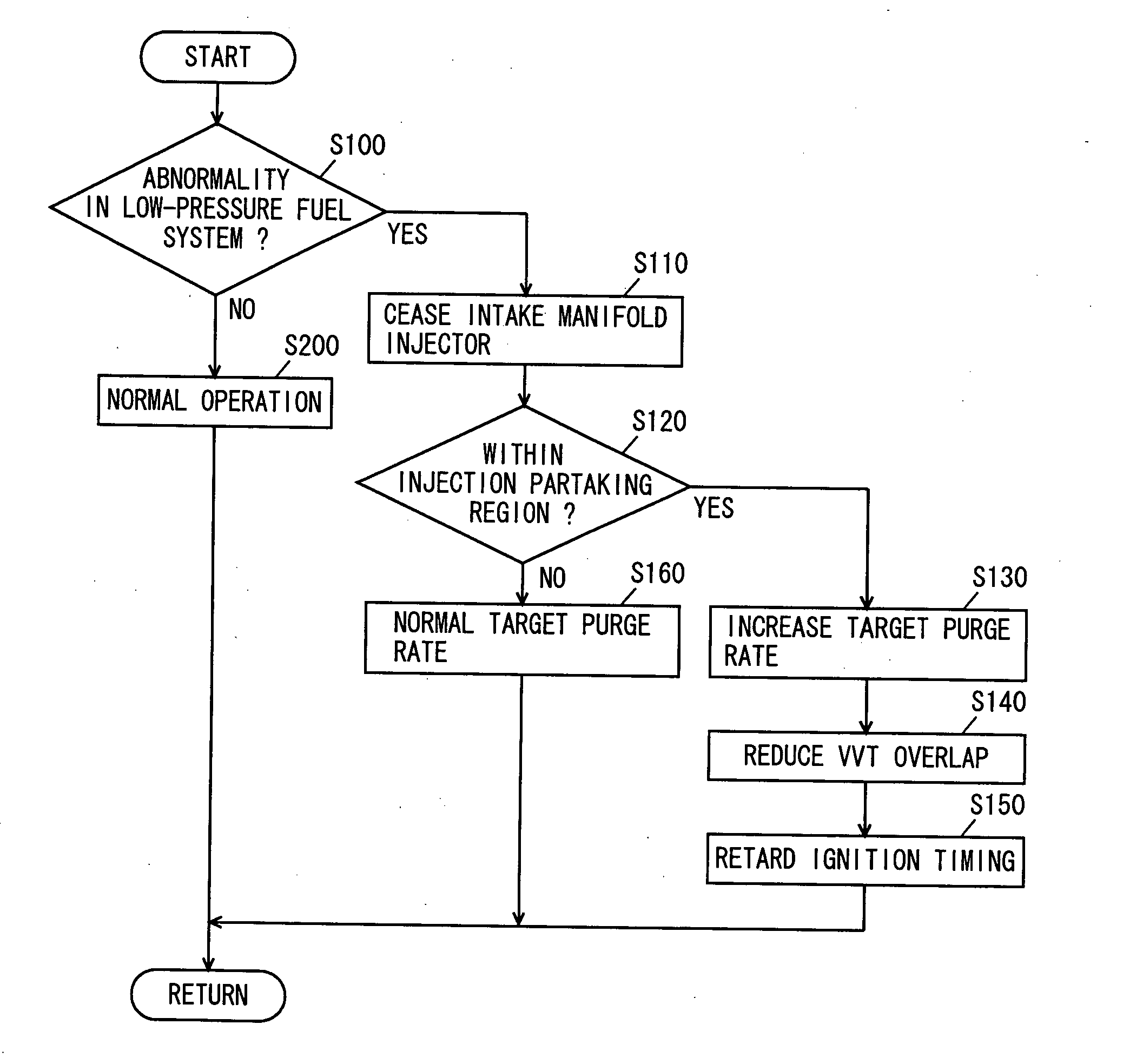

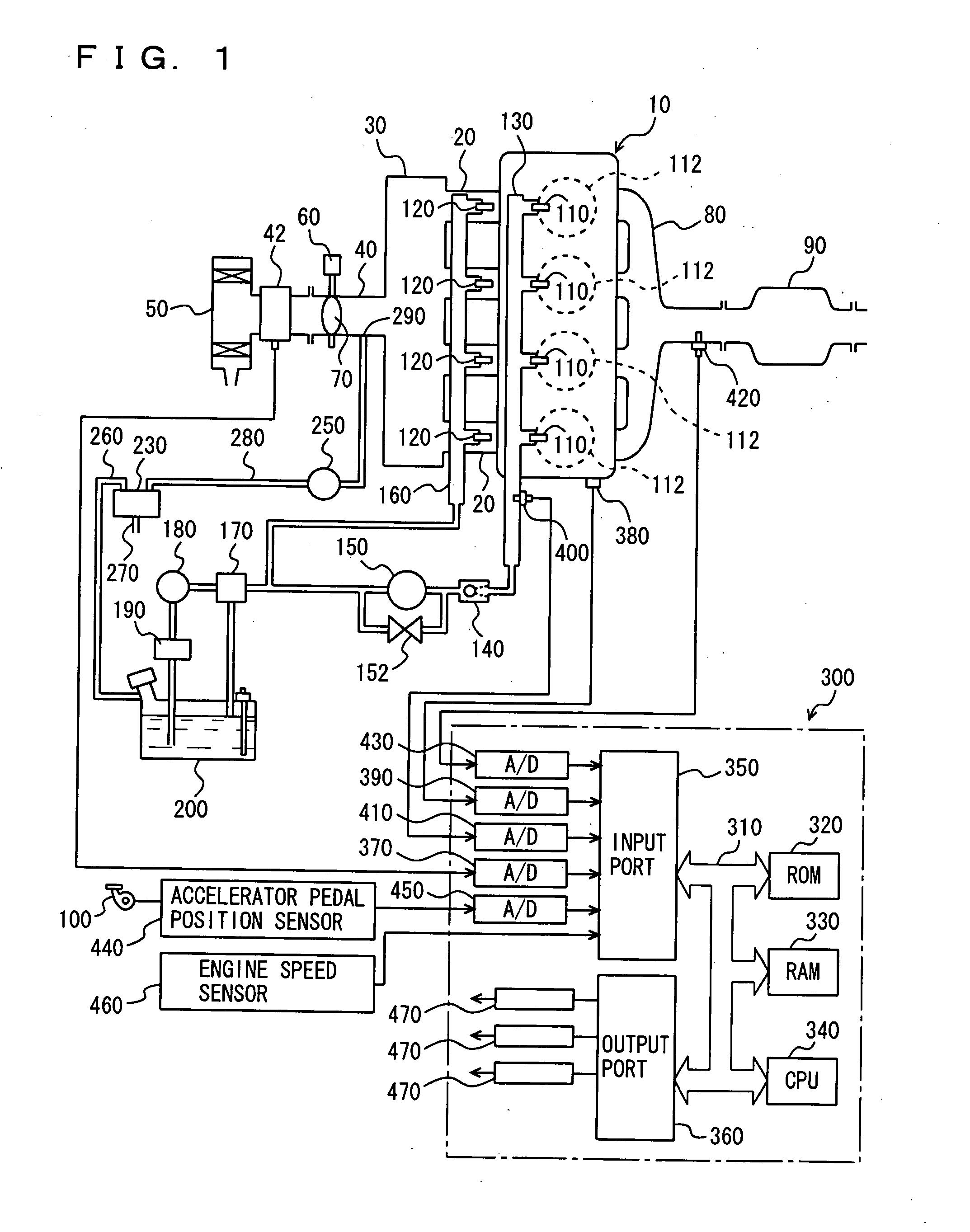

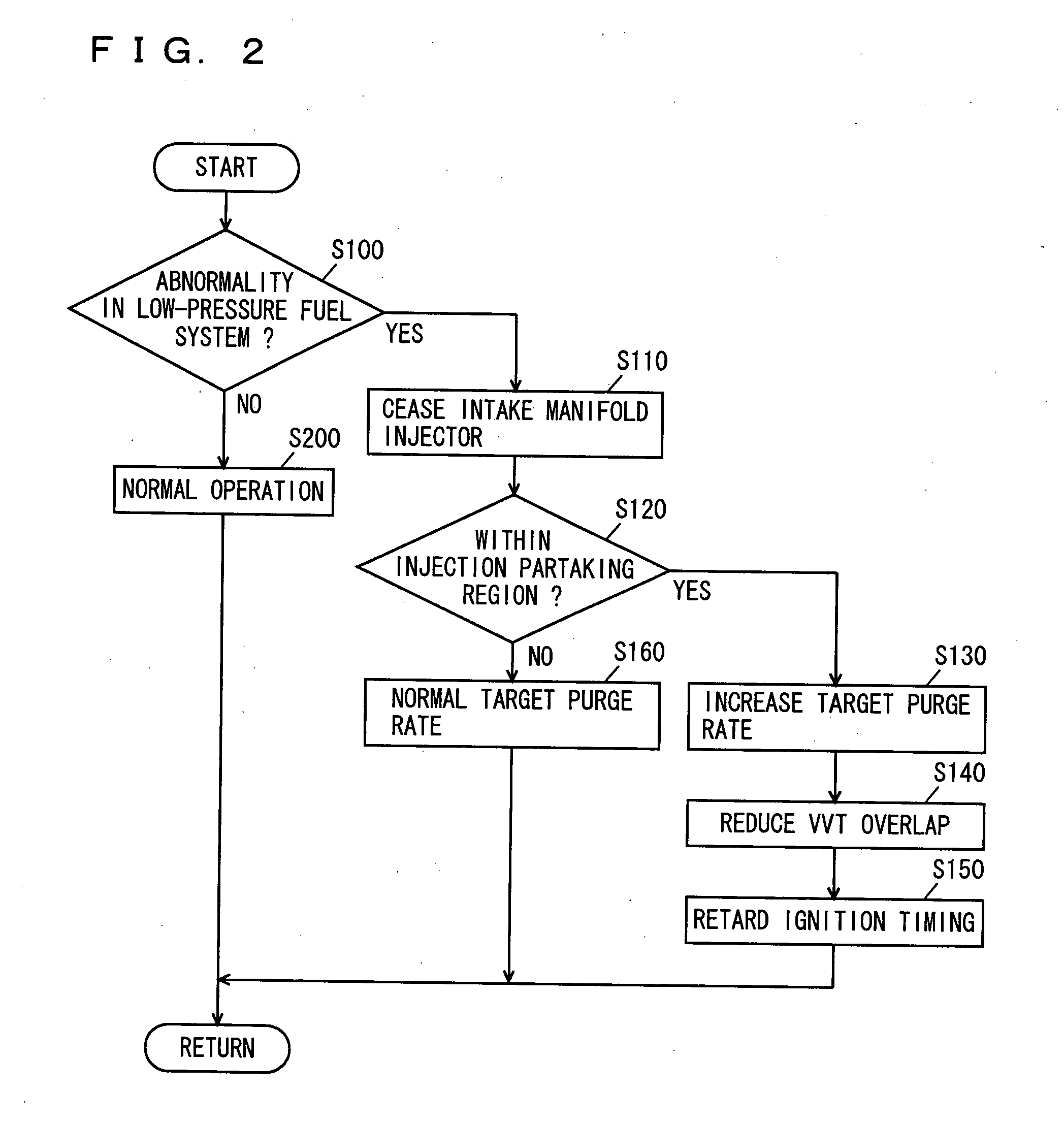

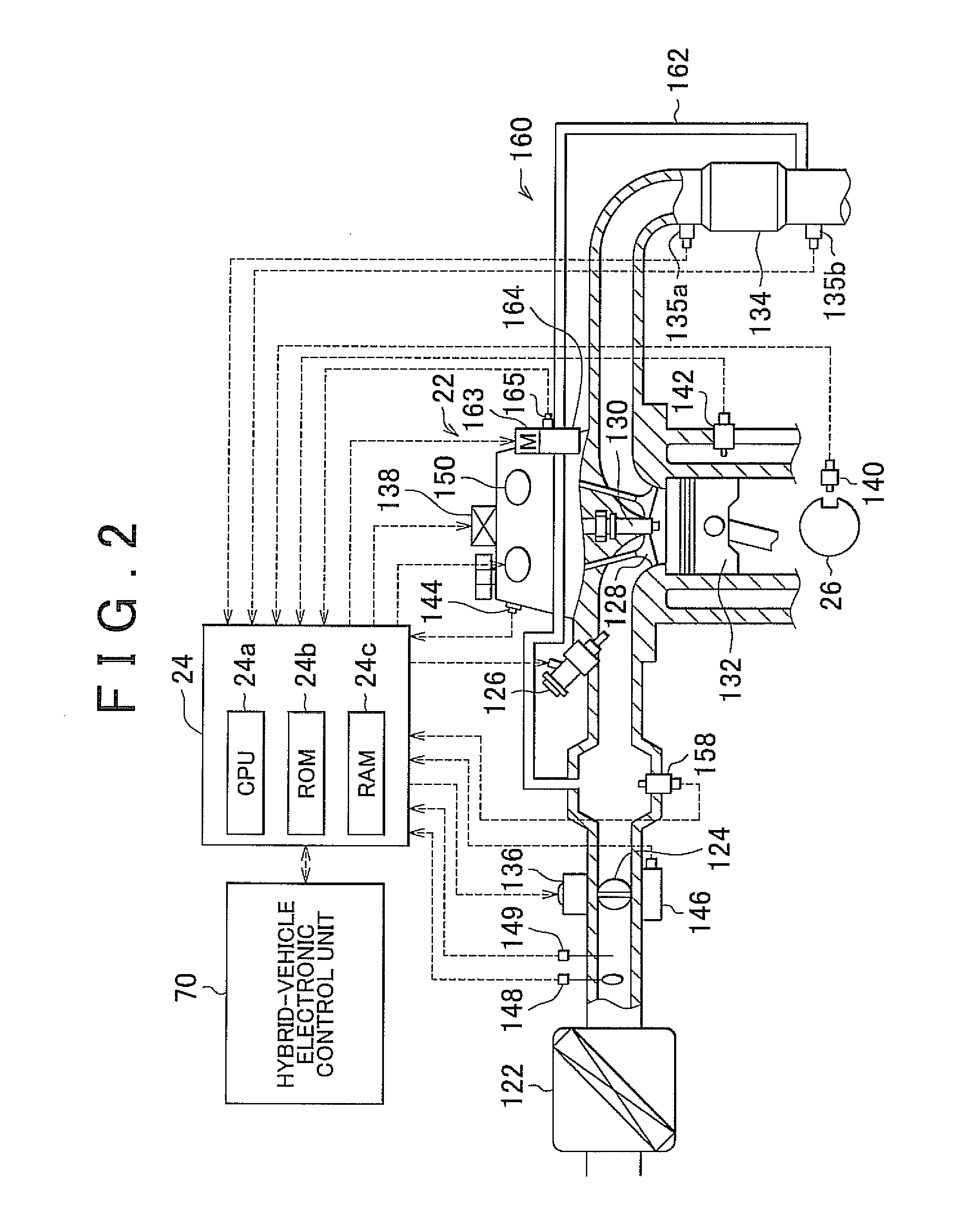

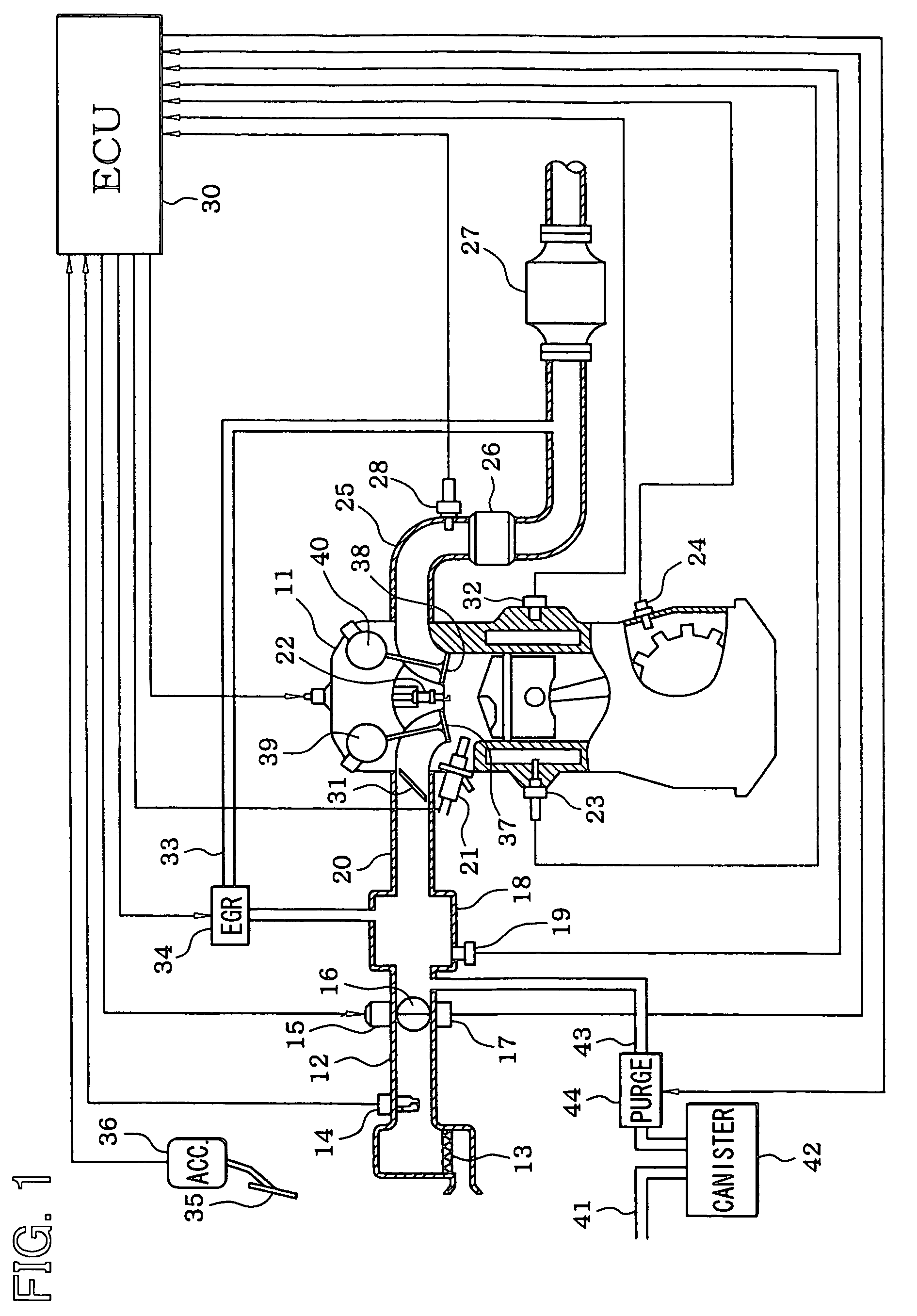

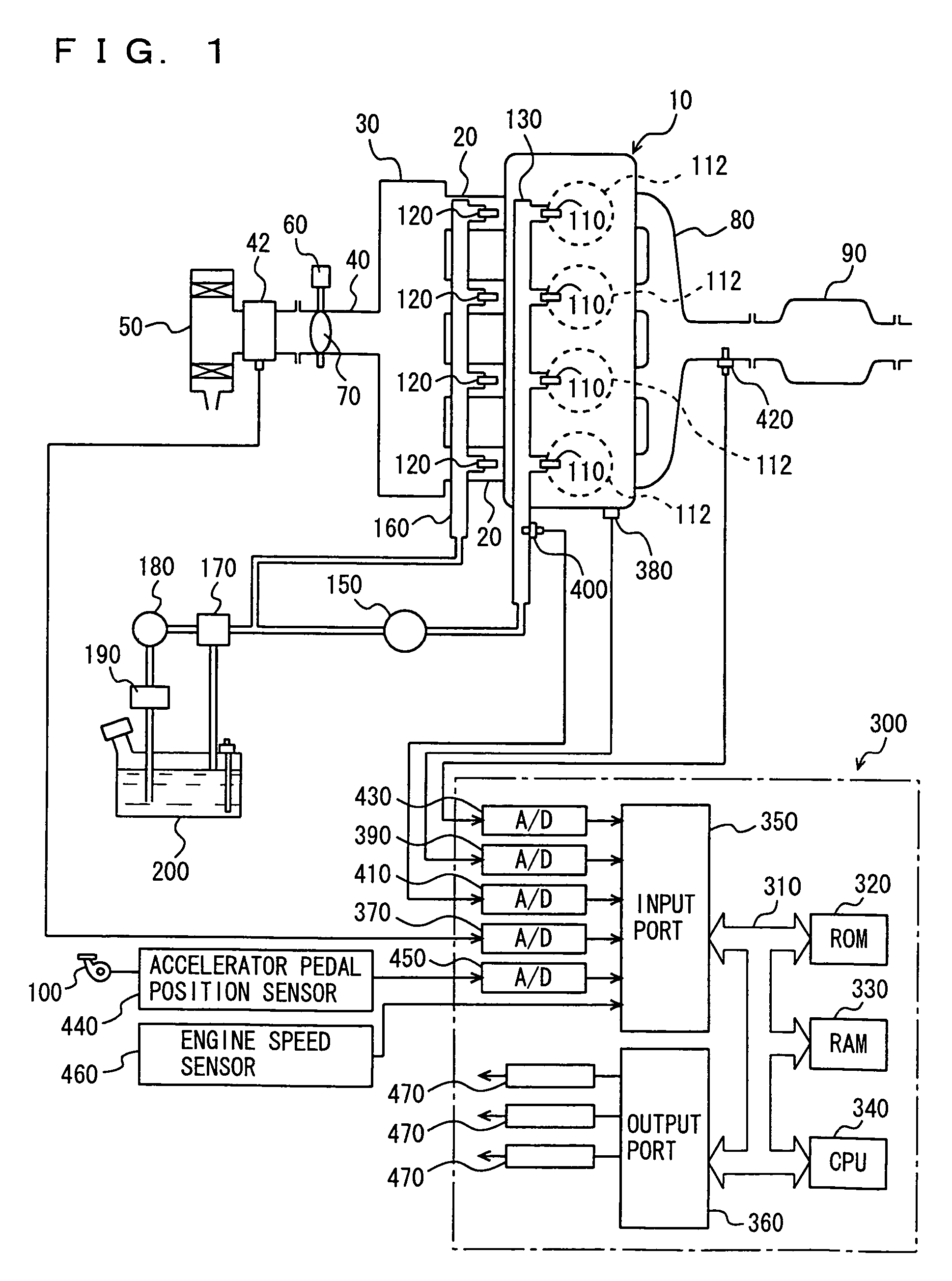

Control apparatus for internal combustion engine

InactiveUS20060090732A1Increasing purge rateVariation can be suppressedValve arrangementsElectrical controlIgnition timingInlet manifold

An engine ECU executes a program including the steps of: determining presence of abnormality in a low-pressure fuel system; ceasing an intake manifold injector when determination is made of abnormality in the low-pressure fuel system; increasing the target purge rate when the engine operation state attains an injection partaking state between an in-cylinder injector and an intake manifold injector; reducing the VVT overlap; and retarding the ignition timing.

Owner:TOYOTA JIDOSHA KK

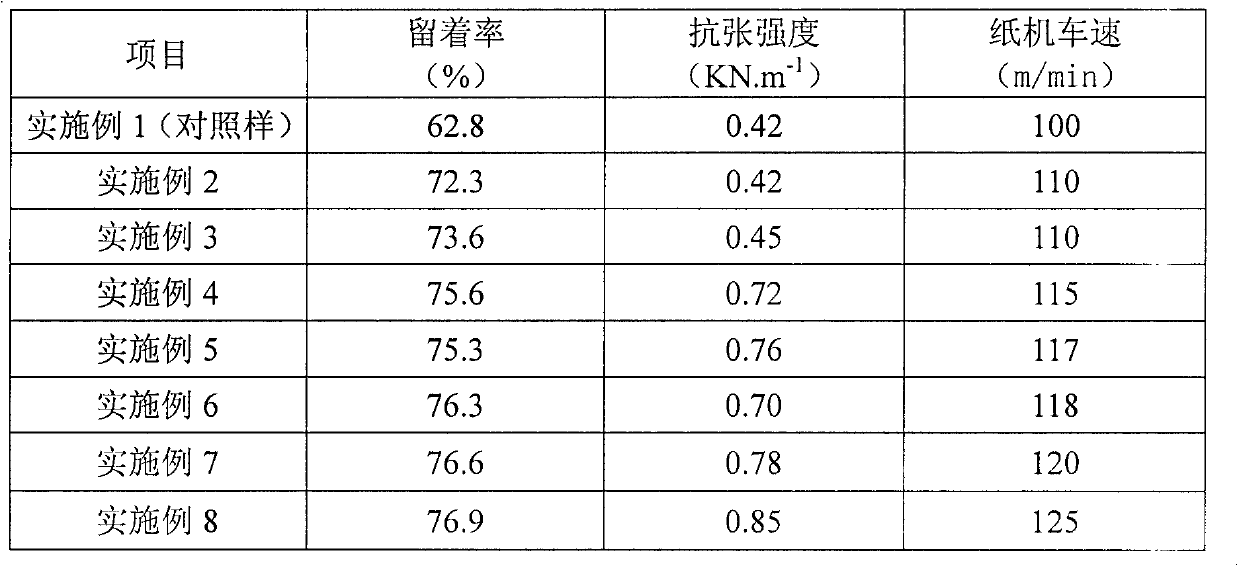

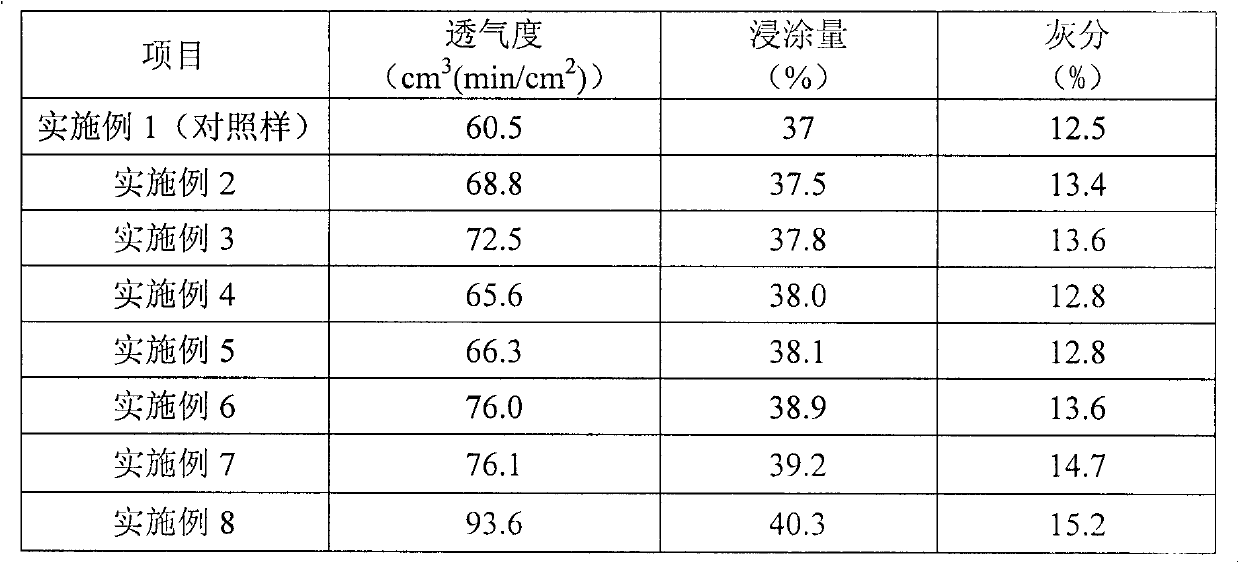

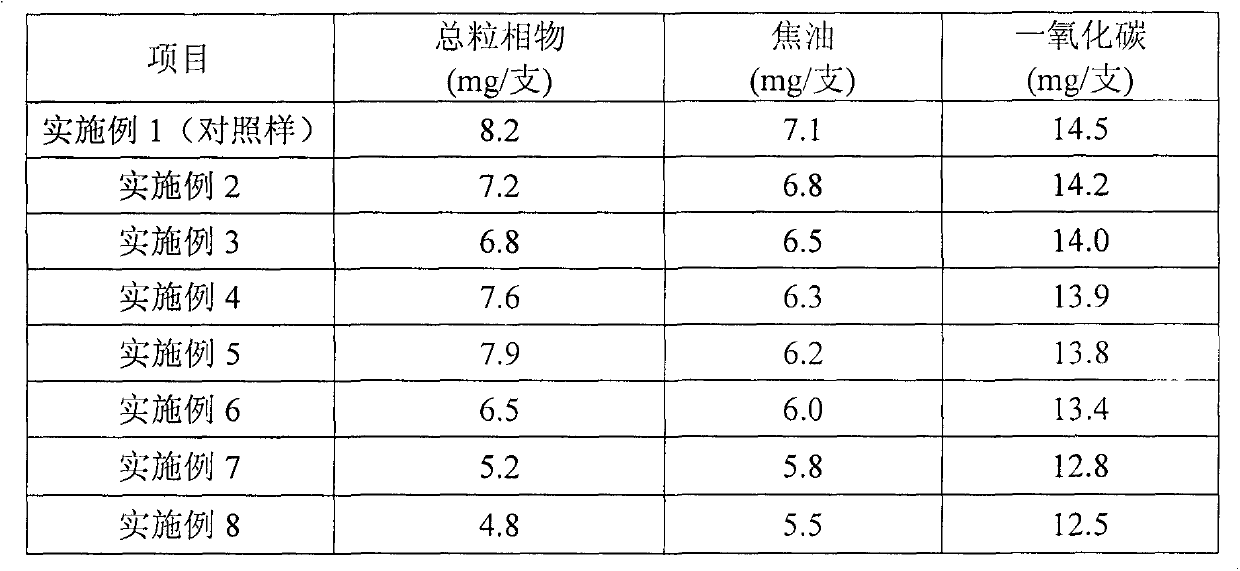

Preparation method for paper-making process tobacco sheet and finished product of paper-making process tobacco sheet

ActiveCN103141928AImprove single layer retentionImprove breathabilityTobacco preparationPlant fibrePaper based

The invention belongs to the field of tobacco industry and relates to a preparation method for a functional harm-reduction and tar-reduction paper-making process tobacco sheet and a finished product of the paper-making process tobacco sheet. The preparation method for the paper-making process tobacco sheet comprises the following steps of extracting and concentrating effective components of tobacco; mixing formulas; pulping and blending fibers; manufacturing paper with pulp; dipping, drying and tearing and shaping. The blending process comprises the following steps of: adding non-tobacco plant fiber pulp of which the beating concentration is 3-4 percent and the Schopper-Riegler (SR) beating degree is 18-28 to tobacco mixed fiber pulp, adding filling to a machine chest, regulating the pulping concentration to 2-3 percent by water, and evenly mixing. By the use or the combine use of the filling and the non-tobacco plant fiber pulp, the combustion state of the sheet can be improved while physical properties, such as the air permeability, the retention and the tensile strength of a paper base, are improved, i.e., harmful ingredients of smoke, such as tar and carbon monoxide of the paper-making process tobacco sheet, can be effectively reduced, and hazard indexes of cigarettes are reduced. Meanwhile, technical-economic indicators, such as the speed and the input- output efficiency of a paper machine, also can be improved.

Owner:杭州利群环保纸业有限公司

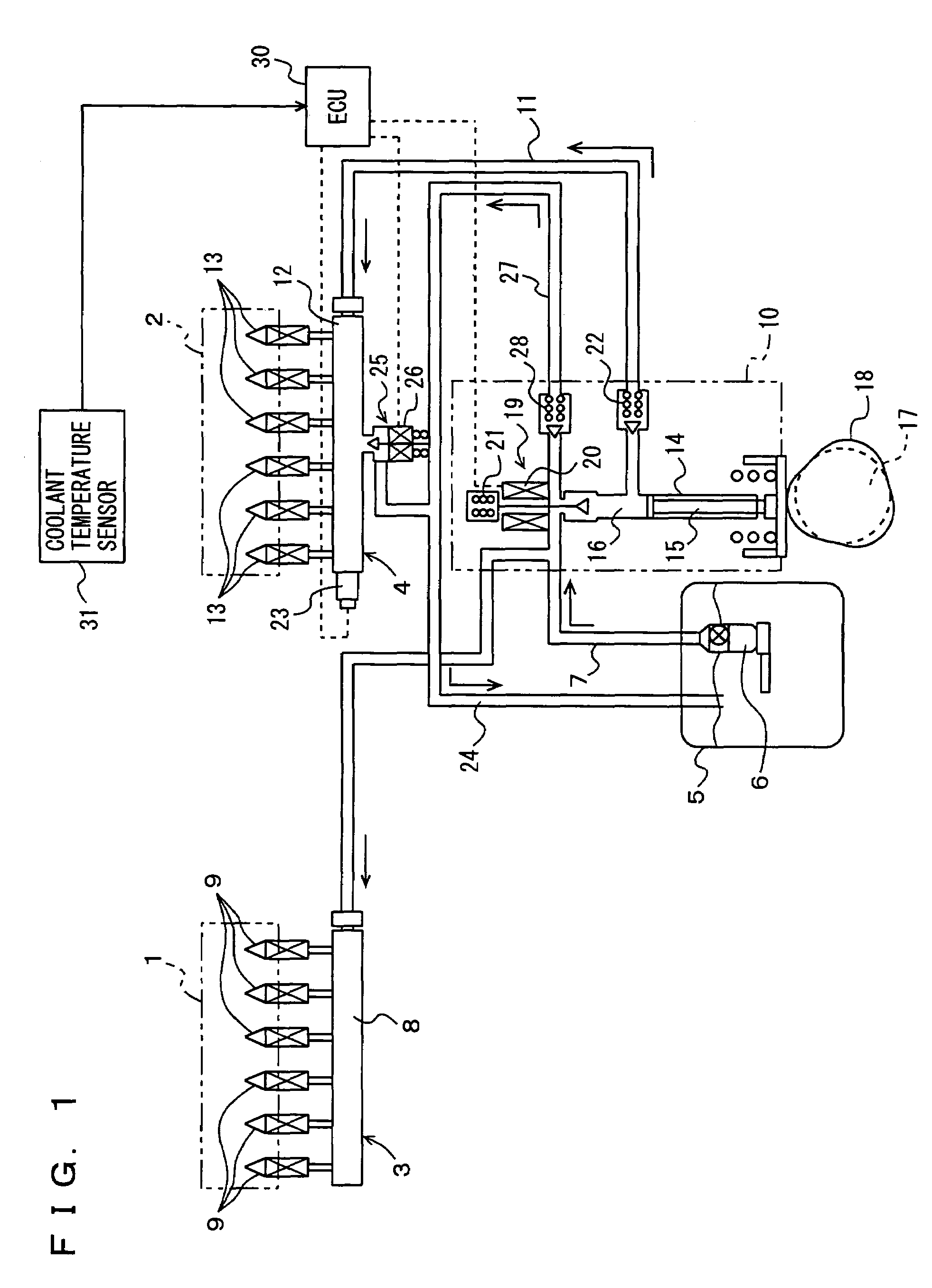

Control apparatus for internal combustion engine

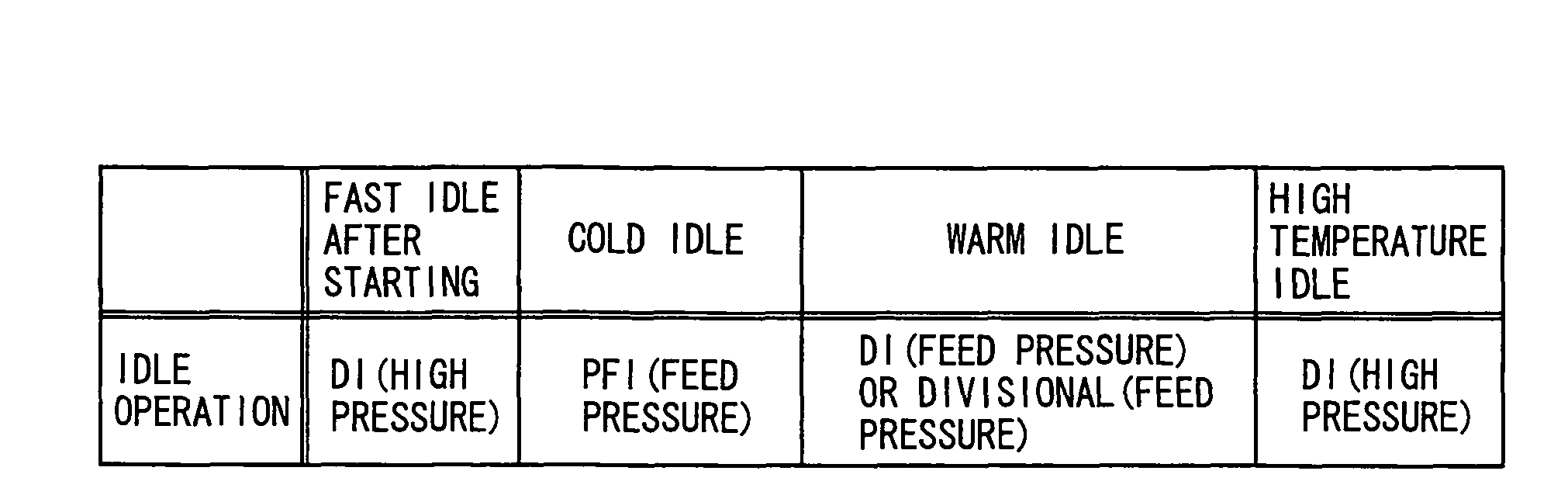

InactiveUS20070000478A1Suppress generationStable combustionElectrical controlDigital data processing detailsTransitional RegionIdle speed

An engine ECU executes a program including the steps of: detecting an engine speed NE, engine load, and engine coolant temperature (S100, S110, S115); when determination is made of being in an idle region (YES at S120), determining whether in a cold idle region, a transitional region, or a warm idle region (S130); injecting fuel from an intake manifold injector alone when in the cold idle region (S140); injecting fuel from the intake manifold injector and injecting fuel from an in-cylinder injector at the feed pressure when in the transitional region (S150); and injecting fuel from the in-cylinder injector at the feed pressure when in the warm idle region (S160).

Owner:TOYOTA JIDOSHA KK

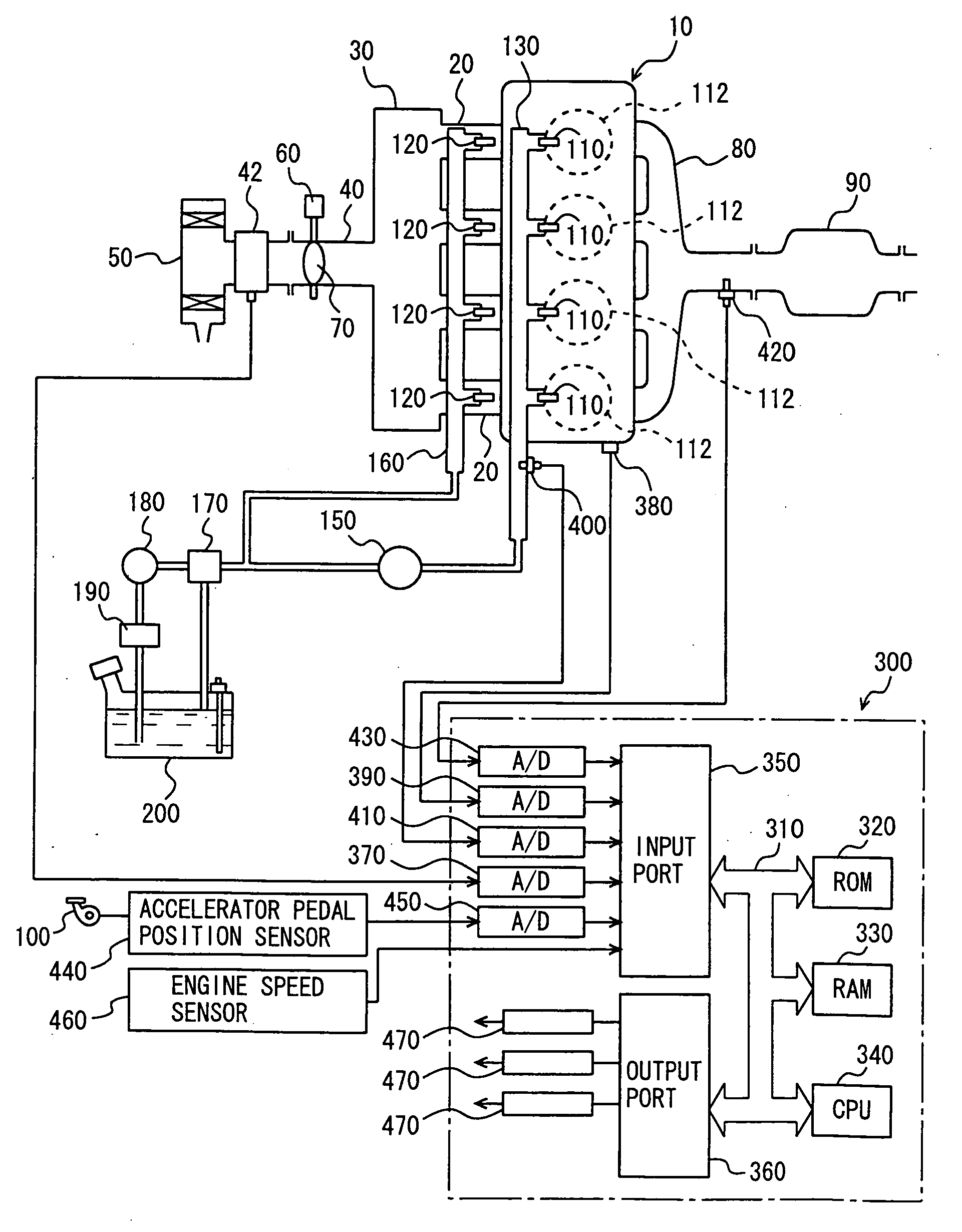

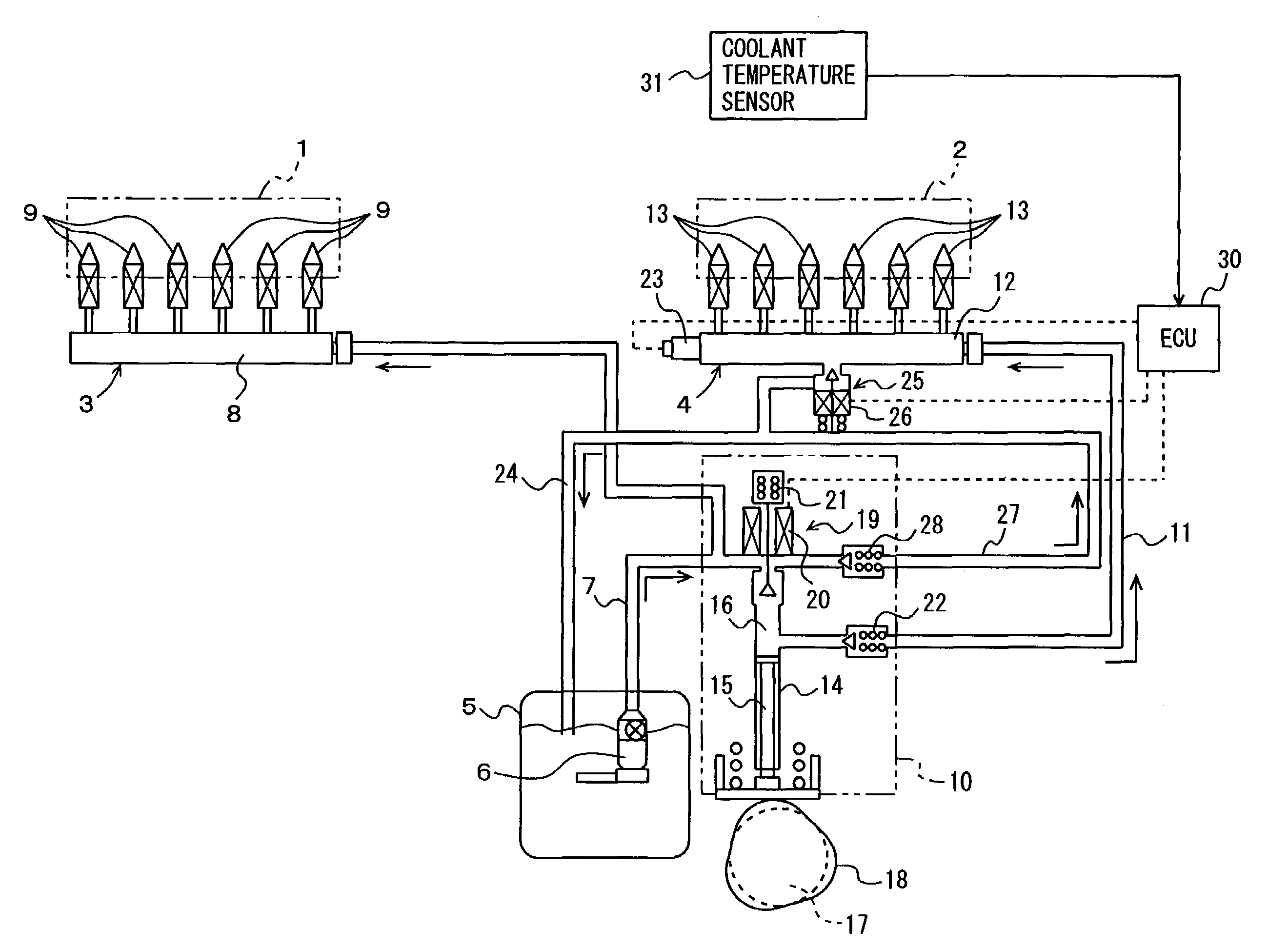

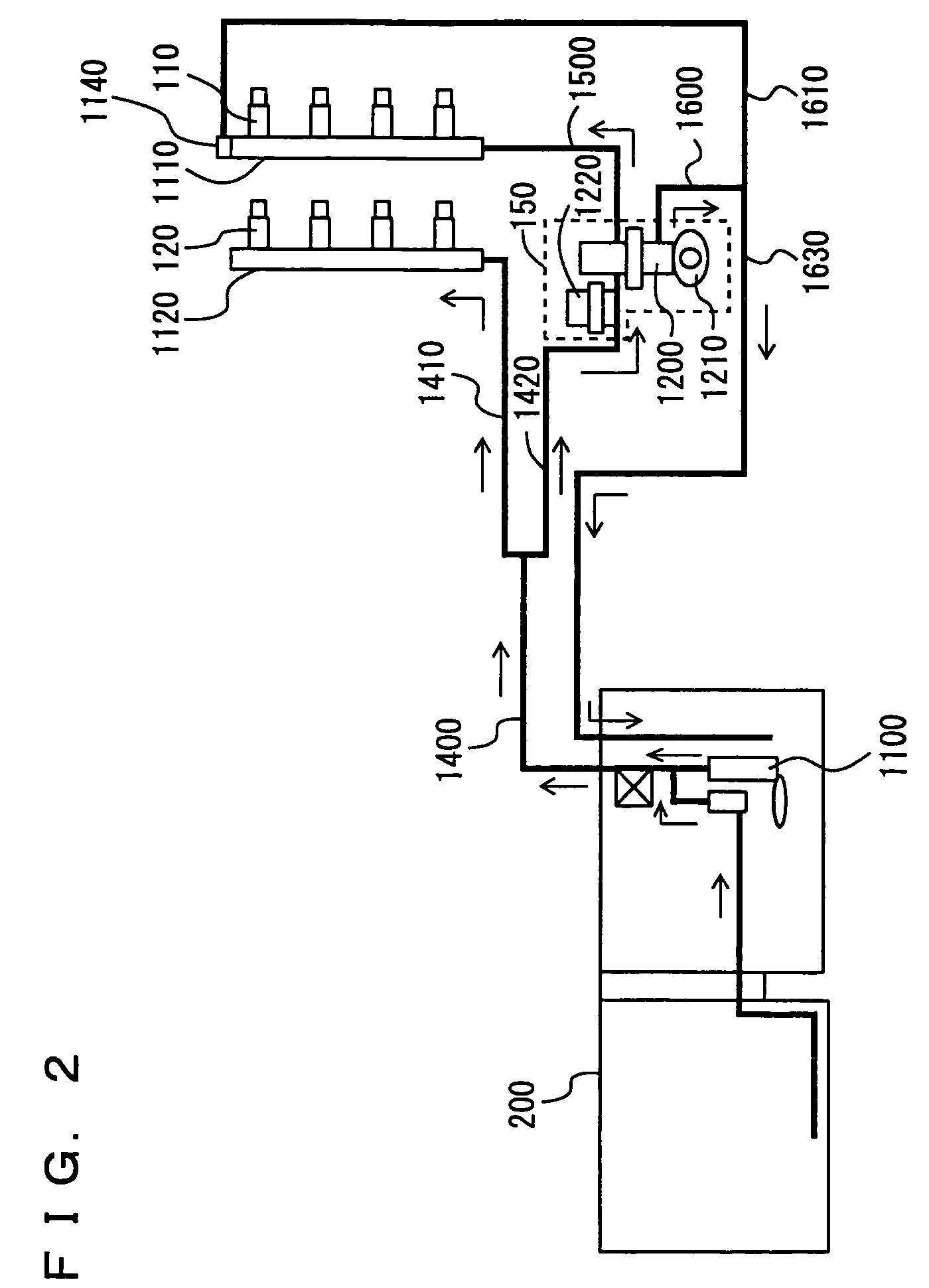

Fuel supply apparatus for internal combustion engine

InactiveUS7263973B2Suppress mutationImprove the state of combustionElectrical controlInternal combustion piston enginesExternal combustion engineHigh pressure

The engine ECU executes a program including the step of detecting an engine coolant temperature, the step of detecting an engine speed and an engine load, the step of estimating a temperature at a tip end of an in-cylinder injector based on the engine coolant temperature, the engine speed and the engine load, and, when the temperature at the tip end is greater than a guaranteed temperature, the step of calculating a drive duty of a high-pressure fuel pump that ensures a decrease of the temperature at the tip end of the in-cylinder injector to the guaranteed temperature, and the step of controlling the high-pressure fuel pump using the drive duty.

Owner:TOYOTA JIDOSHA KK

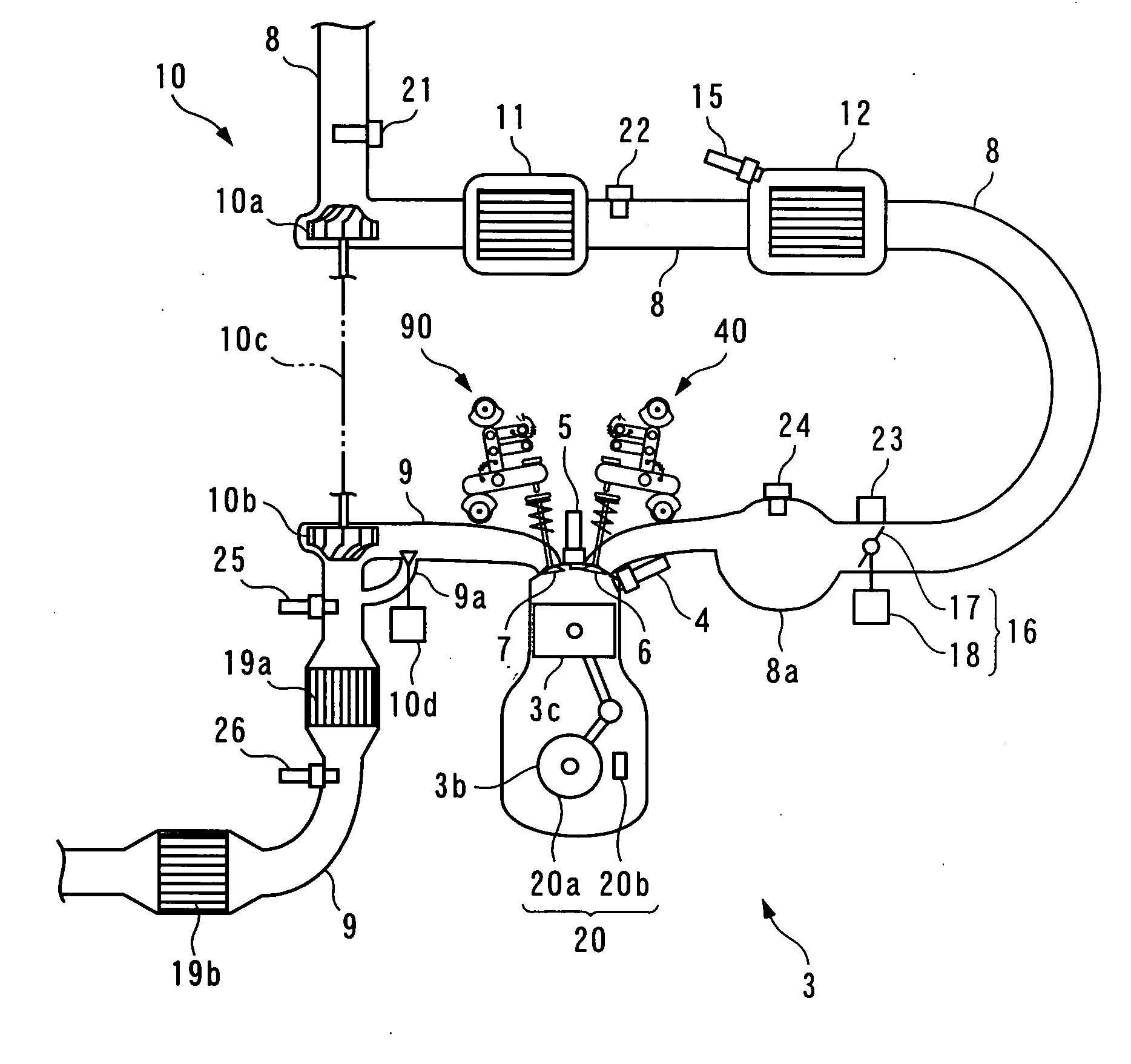

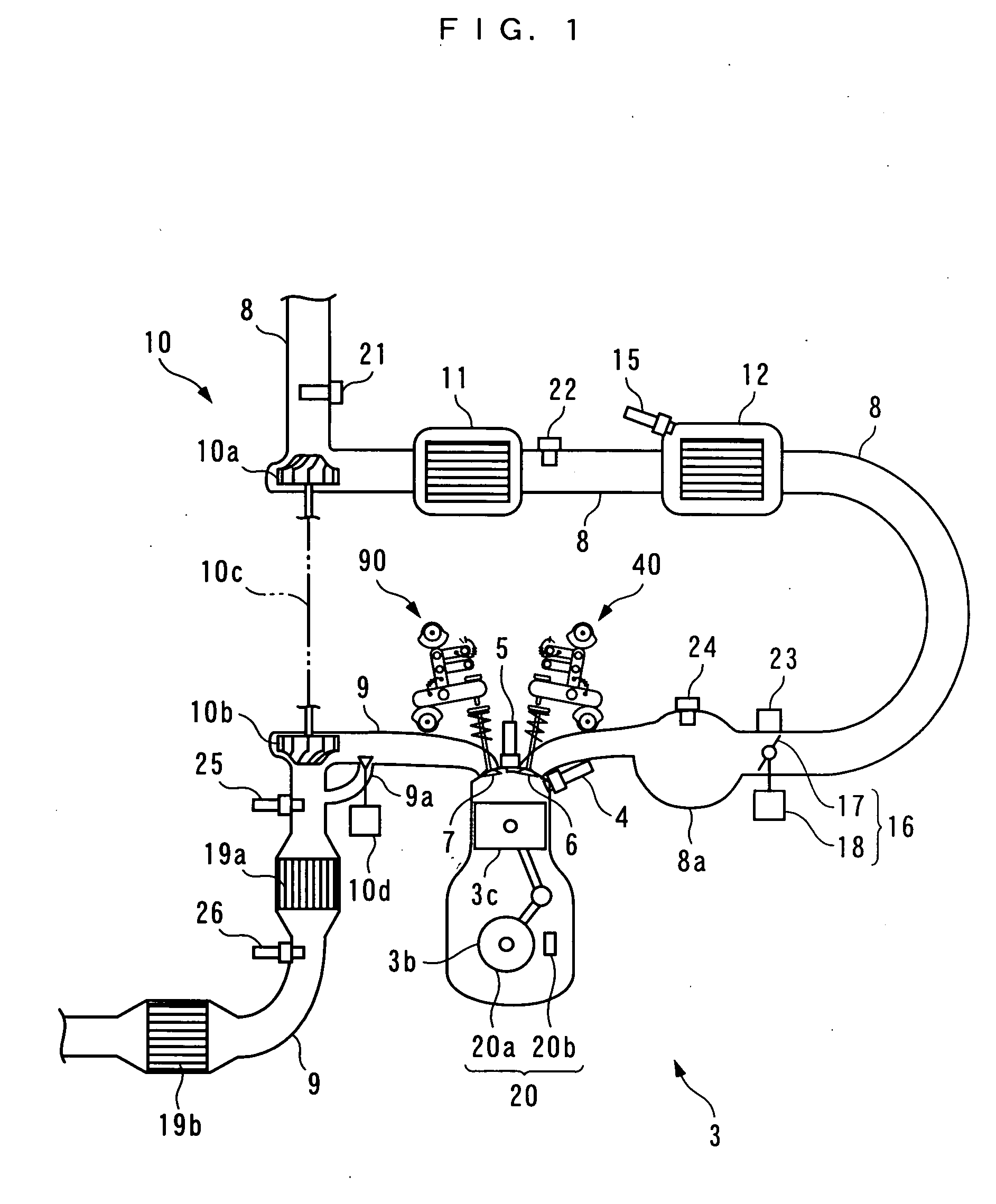

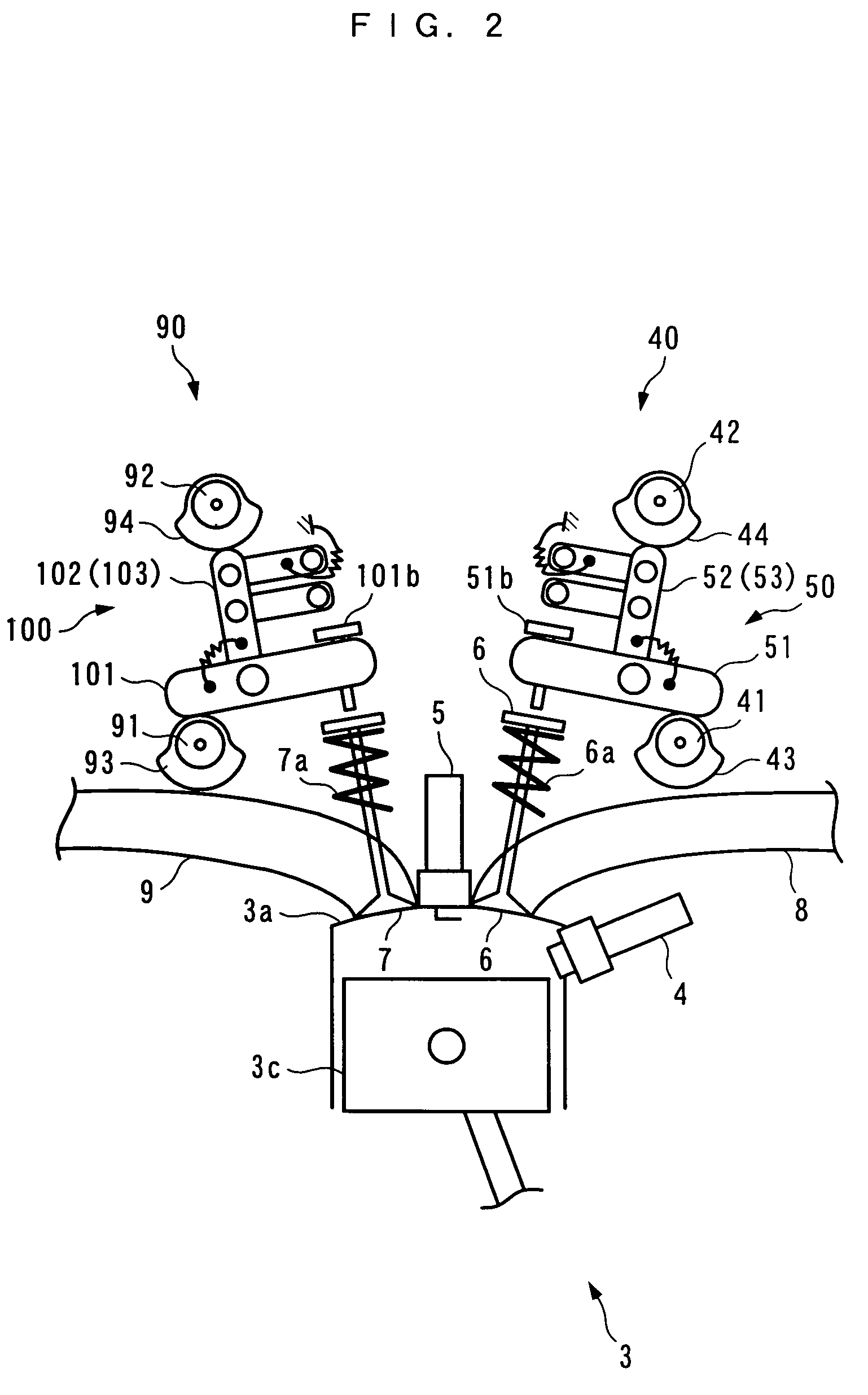

Intake Air Amount Control System for Internal Combustion Engine and Control System

InactiveUS20080051979A1Fast convergenceShort timeElectrical controlInternal combustion piston enginesControl systemInlet valve

An intake air amount control system for an internal combustion engine, which is capable of ensuring high robustness and improving controllability in intake air amount control, to thereby improve drivability and reduce exhaust emissions. A control system 1 of an internal combustion engine 3, which variably controls the amount of intake air drawn into cylinders #1 to #4 as desired via a variable intake valve actuation assembly 40 includes an ECU 2. The ECU 2 calculates a cylinder intake air amount Gcyl and a target intake air amount Gcyl_cmd (step 16), identifies, based on a controlled object model [equation (2)], a vector θs of all model parameters of the controlled object model with an identification algorithm [equations (8) to (13)], calculates a target auxiliary intake cam phase θmsi_cmd based on the vector θs with a sliding mode control algorithm [equations (15) to (21)] (step 80), and controls the variable intake valve actuation assembly 40 according to the target auxiliary intake cam phase θmsi_cmd.

Owner:HONDA MOTOR CO LTD

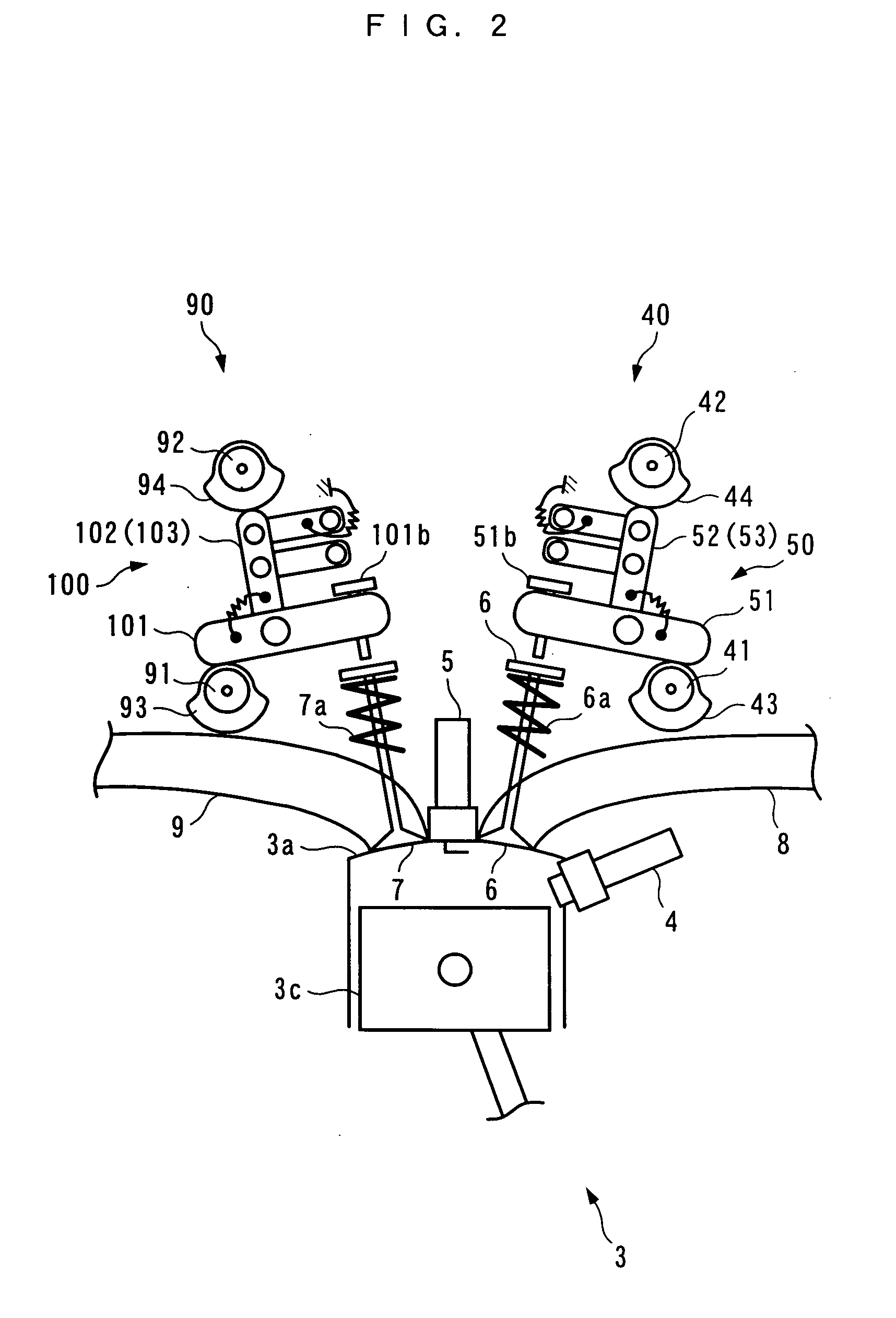

Filter paper of air filter for saving fuel and method for manufacturing same

ActiveCN101392703AReduce resistanceEasy to useWater-repelling agents additionMachines/enginesWater basedFuel conservation

The invention provides filter paper of an air filter of fuel conservation and a manufacture method thereof. The filter paper consists of base paper and a sizing agent which is coated on a single side or double sides of the base paper gram weight of between 110 and 160 gram / meter<2>, and water-base resin (butt) is 5 to 30 percent of mass of the base paper. The sizing agent comprises the following components in weight percentage: 2 to 20 percent of the water-base resin (butt), 1 to 20 percent of powder functional material, and 60 to 80 percent of water. The powder functional material is more than one of tourmaline ore powder with far infrared emitting property and releasing anion property, molten mass powder of rare-earth zirconium oxide and alumina, molten mass powder of rare-earth zirconium oxide, titanium oxide or rare-earth zirconium oxide, zinc oxide and the like. With the filter paper, fuel can be saved by 3 to 10 percent, but power of the engine is increased by 5 to 20 percent; noise of the engine is reduced by over 10 decibels, and exhaust emission pollutants are reduced by over 10 to 30 percent.

Owner:湖北国鼎华明纳米新材料有限公司

Vehicle and control method therefor

InactiveUS20100235070A1Improve energy efficiencyAvoid discomfortHybrid vehiclesElectrical controlExhaust gas recirculationAcceleration Unit

A vehicle includes: an internal combustion engine; an exhaust gas recirculation device; and a controller that controls the internal combustion engine and the exhaust gas recirculation device. When acceleration of the vehicle is greater than or equal to zero and is less than or equal to a predetermined acceleration, an ignition performed with a predetermined energy and a predetermined number of times of performance that enable the internal combustion engine to efficiently operate for one event of explosion and combustion of the internal combustion engine. When the acceleration of the vehicle is greater than the predetermined acceleration, the ignition performed with an energy that is greater than the predetermined energy and / or a number of times of performance that is greater than the predetermined number of times of performance for one event of explosion and combustion of the internal combustion engine.

Owner:TOYOTA JIDOSHA KK

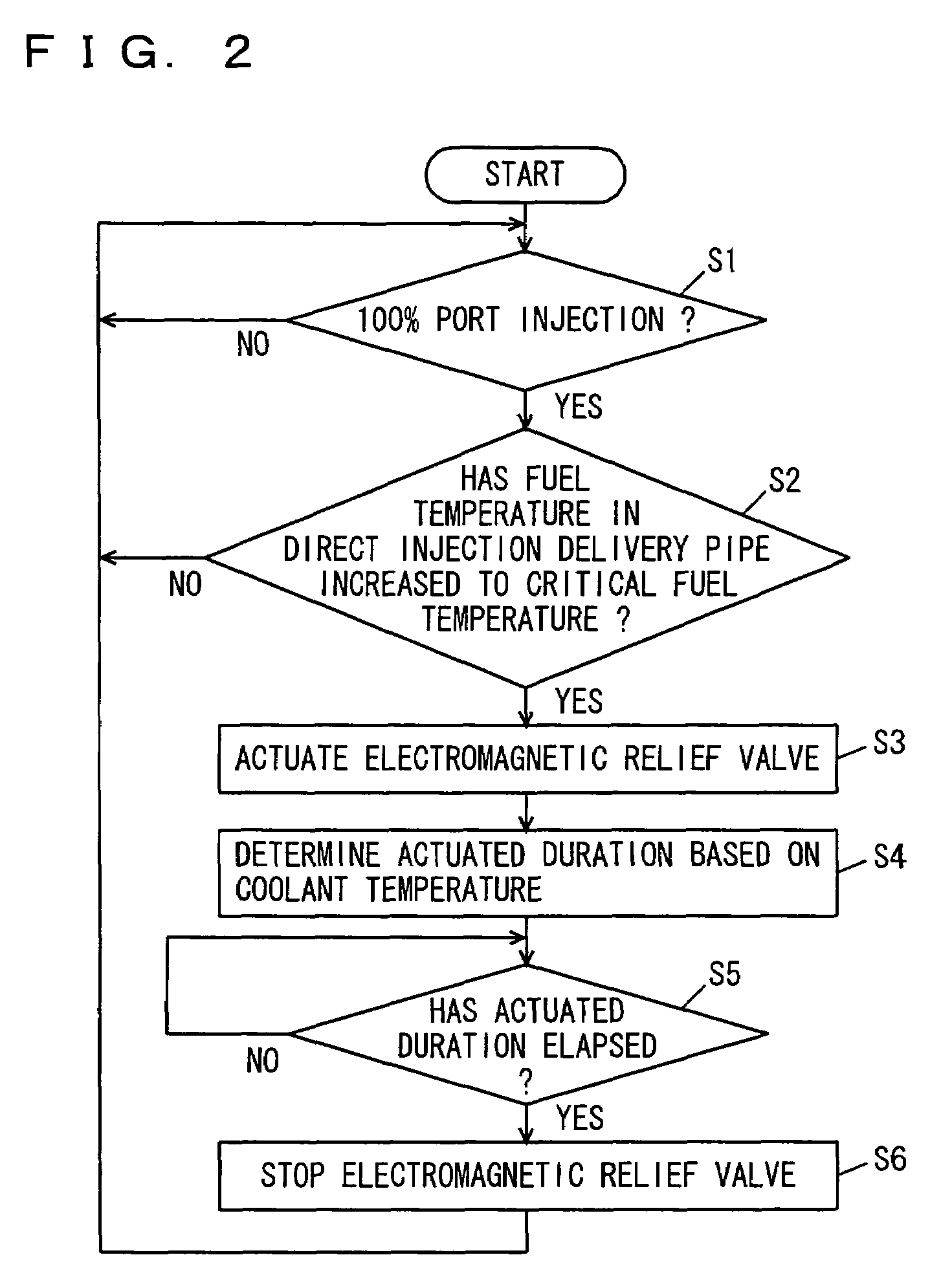

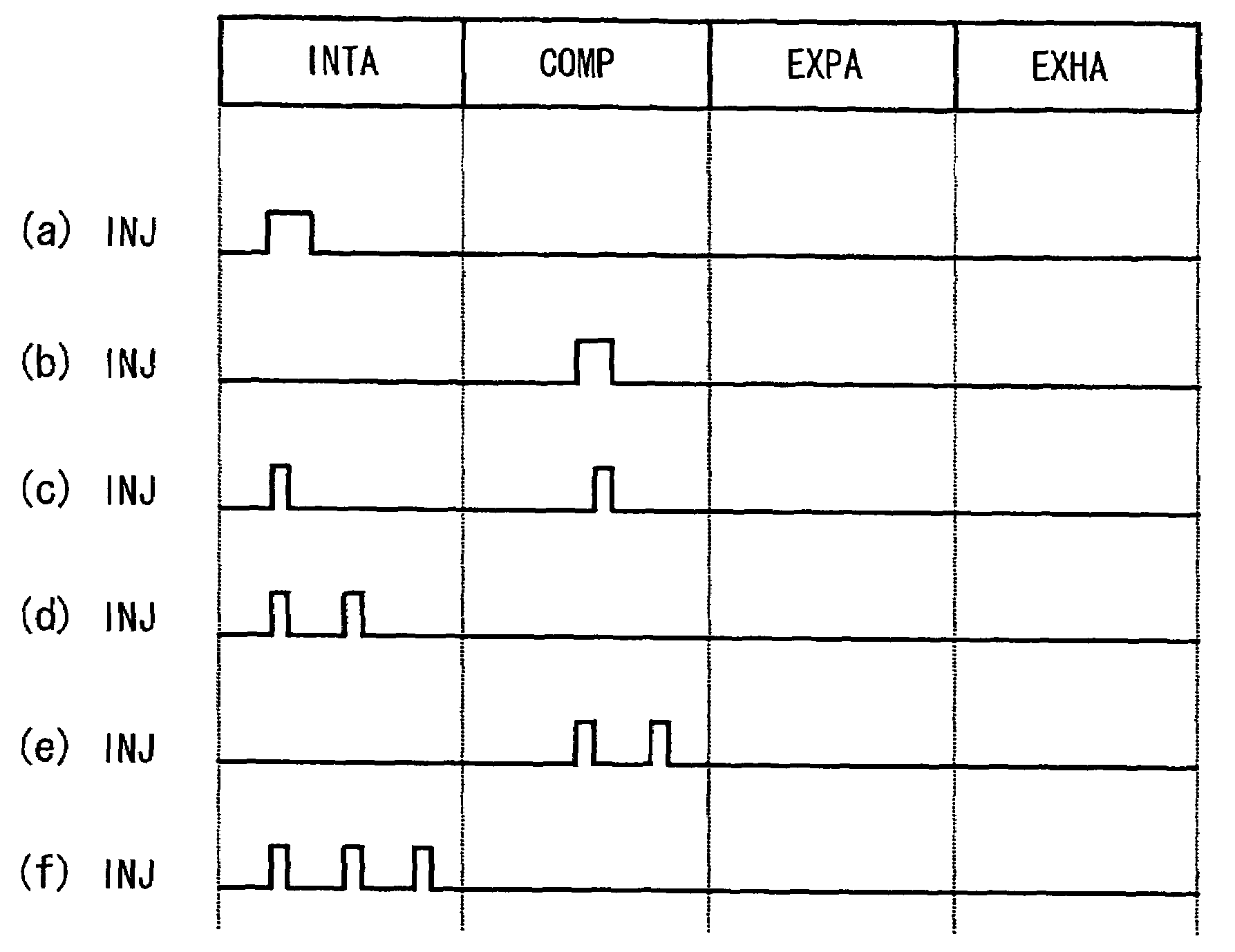

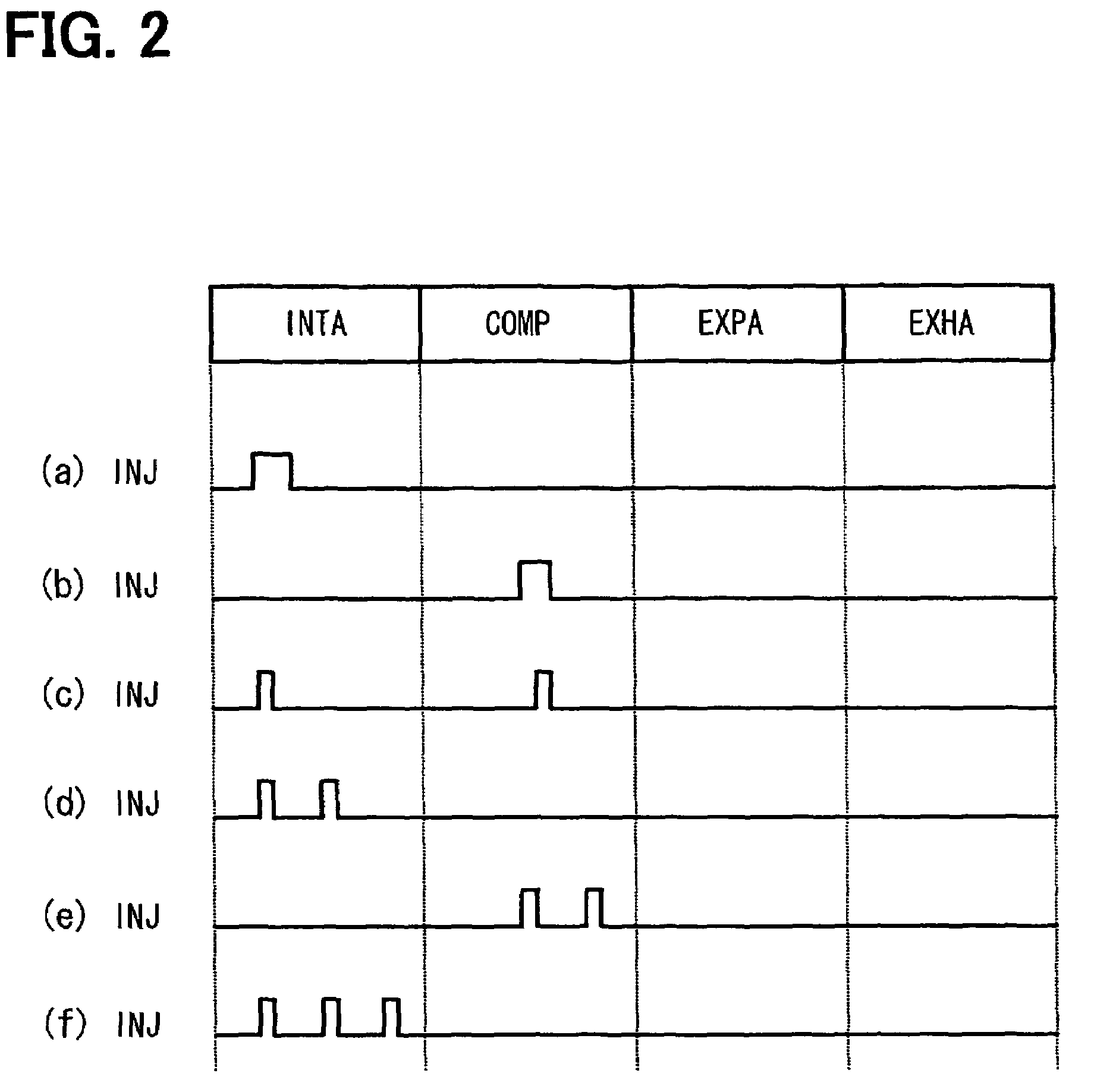

Fuel injection controller for in-cylinder injection engine

InactiveUS7222602B2Improve the state of combustionEmission reductionElectrical controlNon-fuel substance addition to fuelMultiple injectionCombustion

A fuel injection controller of an in-cylinder injection engine determines that a combustion state has deteriorated and executes a split injection for injecting fuel in split amounts into each cylinder in multiple injection events in a cycle of the cylinder if it is determined that a combustion fluctuation is greater than a predetermined determination value during operation of the engine. The fuel injection controller increases a ratio of an injection amount of the first injection event in the split injection and lengthens an injection interval between the injection events as the combustion fluctuation increases. Thus, a wet amount of the injected fuel is reduced to expedite atomization of the injected fuel and to homogenize an in-cylinder mixture gas. As a result, the combustion state is improved.

Owner:DENSO CORP

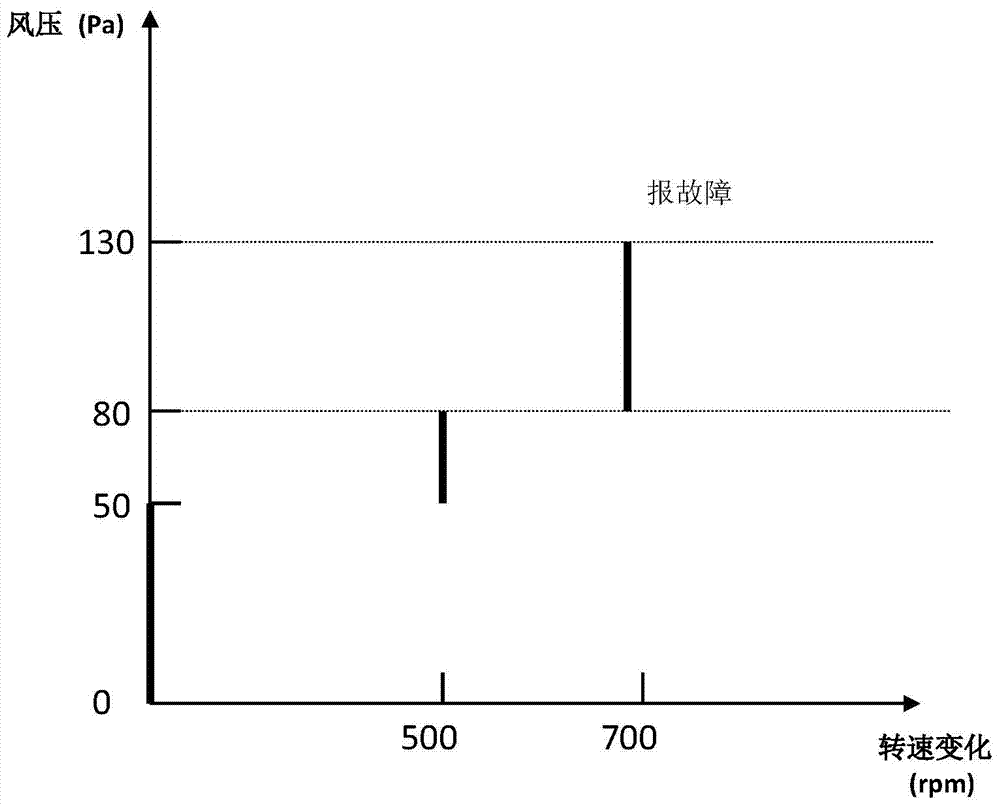

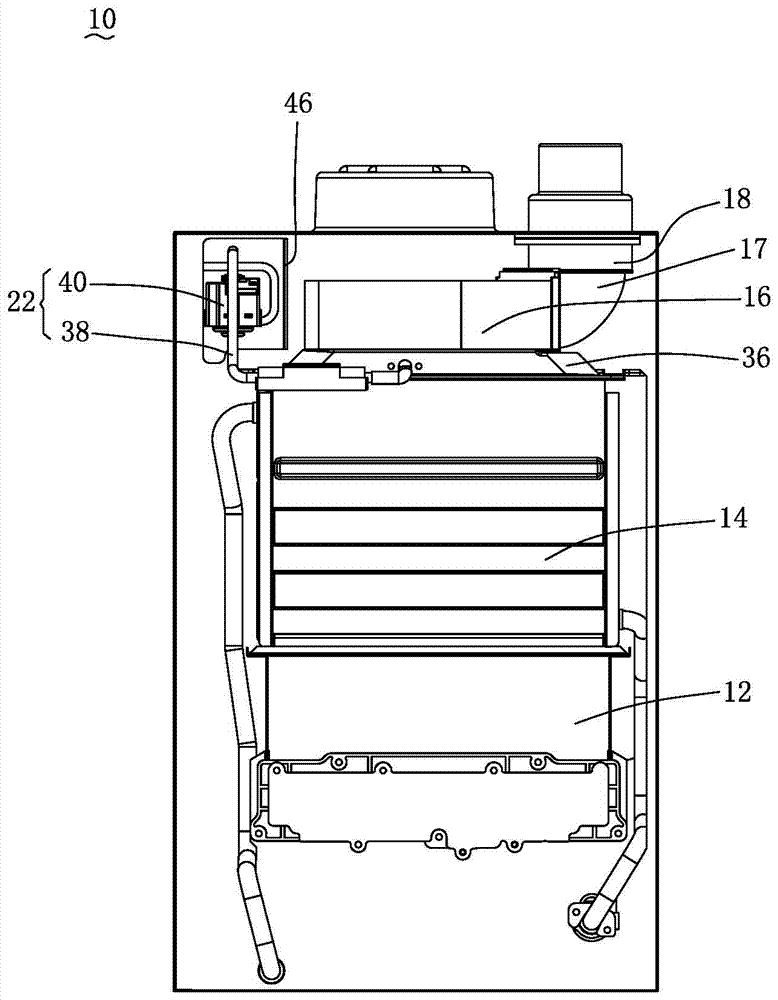

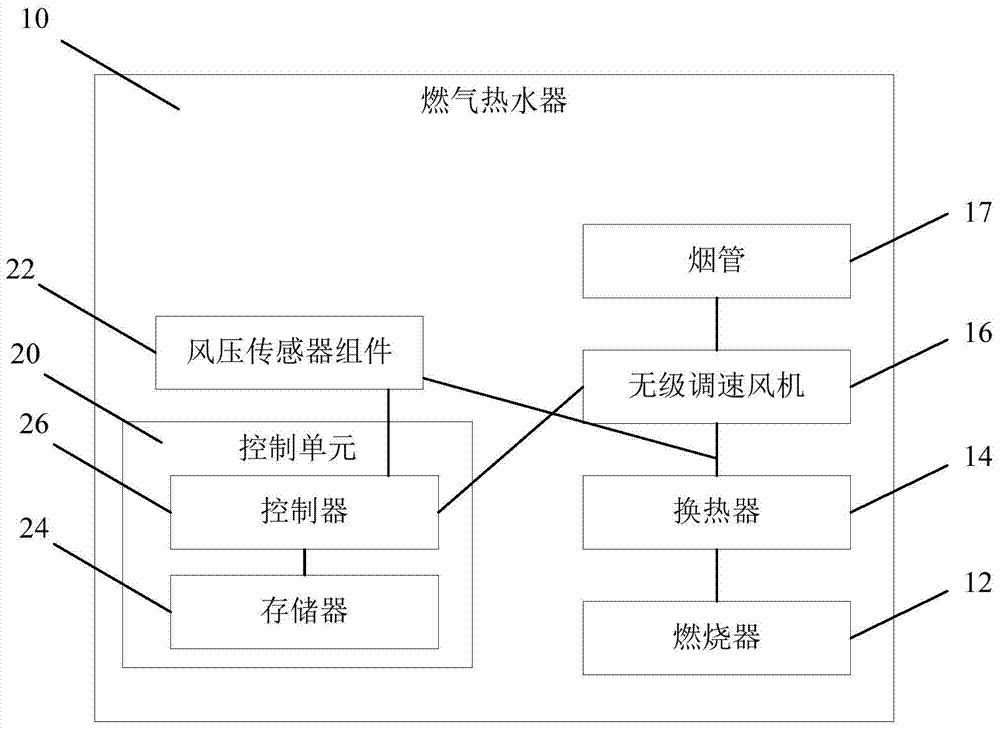

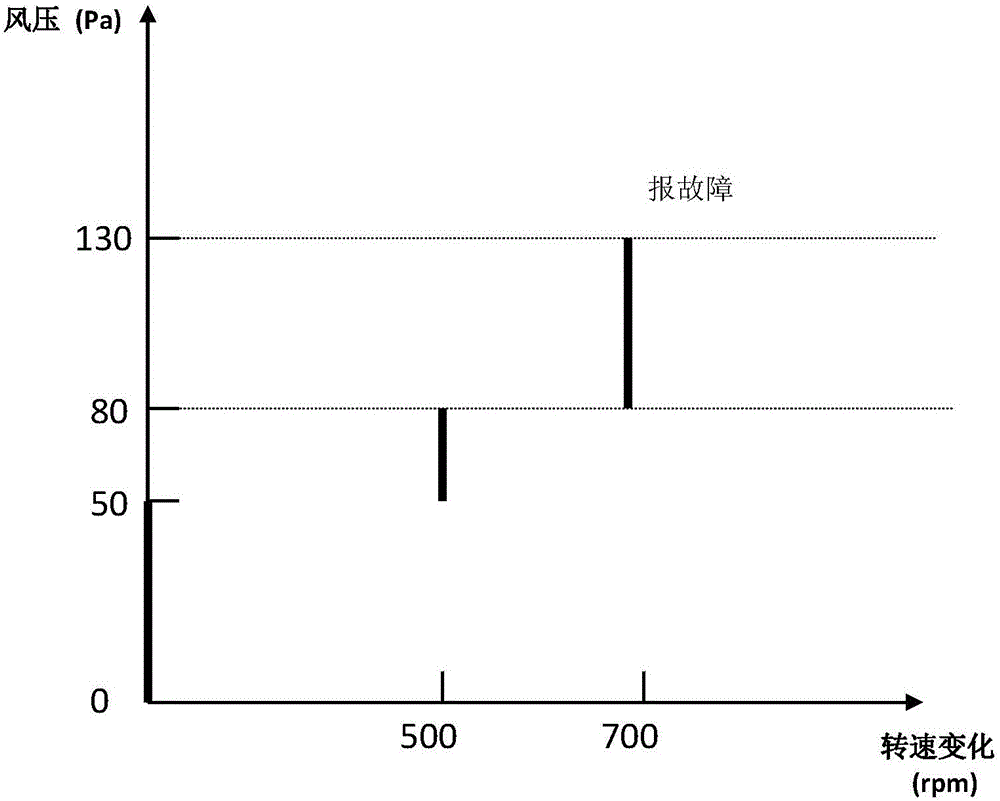

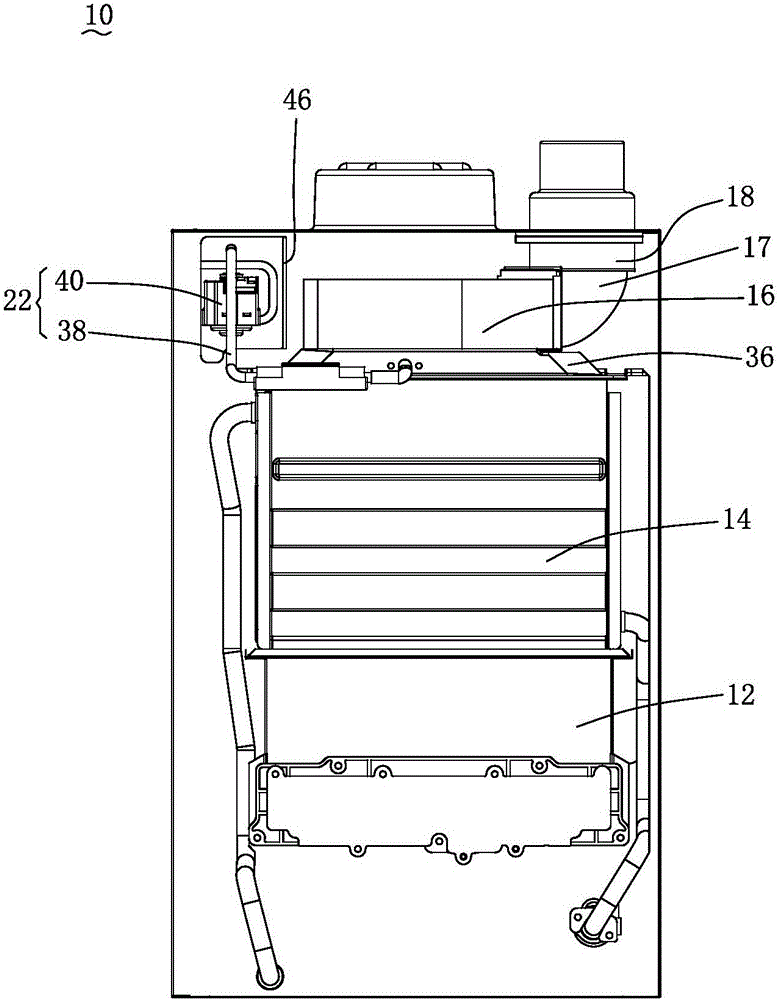

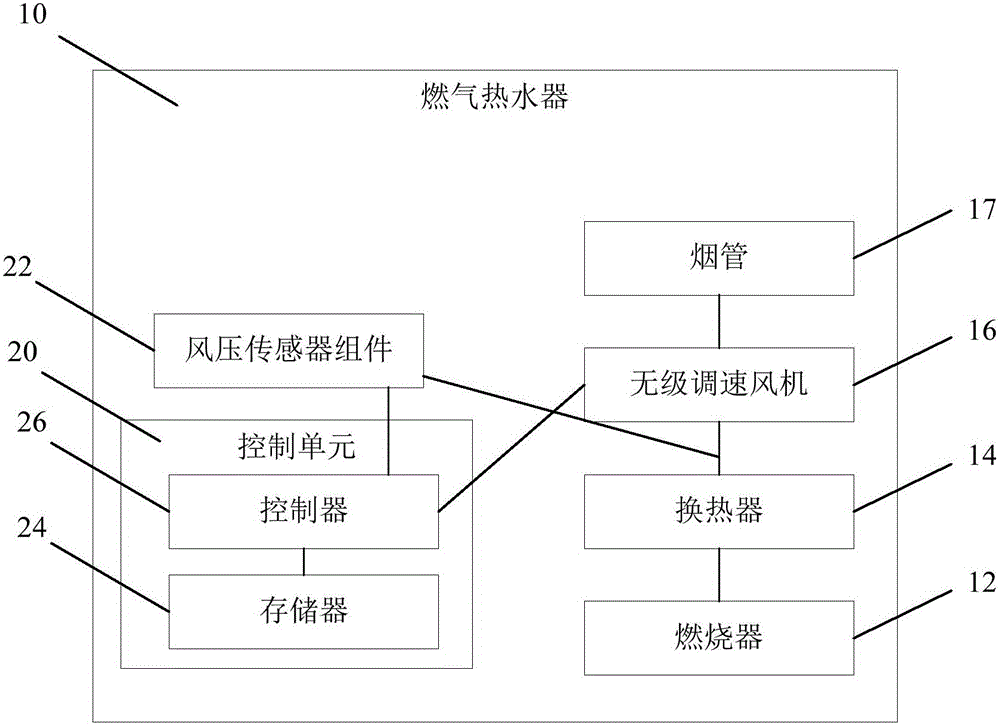

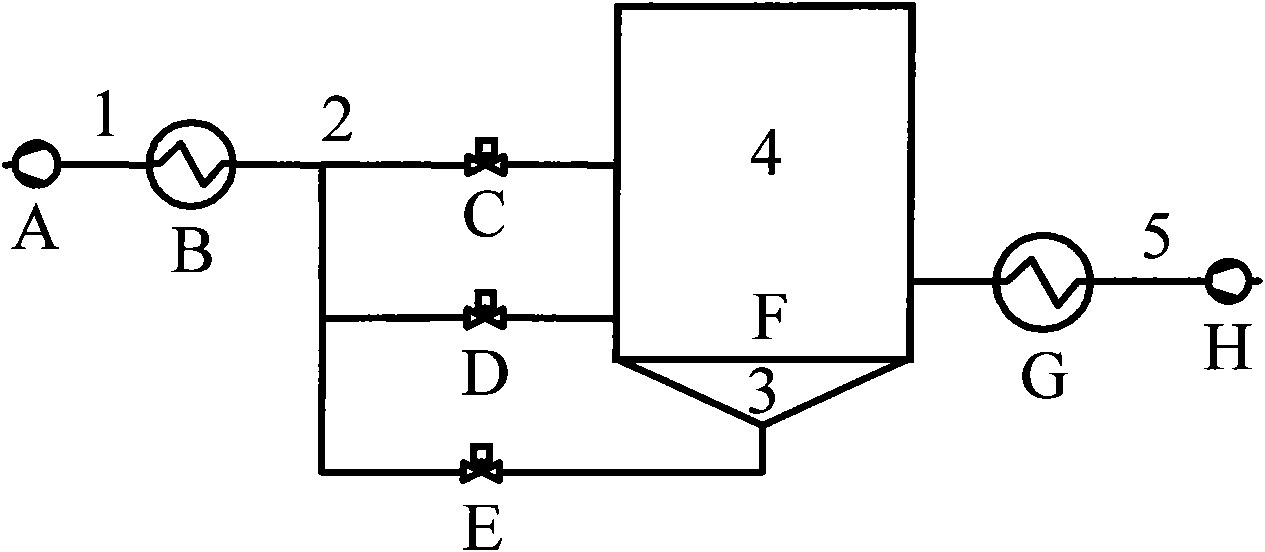

Combustion control system for gas water heater or wall-hanging stove and control method thereof

ActiveCN104729101AExact matchImprove wind pressure resistanceAir supply regulationWater heatersCombustorControl system

The invention discloses a combustion control system for a gas water heater or a wall-hanging stove and a control method thereof. The system comprises a flue gas channel composed of a combustor, a heat exchanger, a stepless variable speed fan and a smoke pipe which are sequentially connected, a control unit connected with the signal input end of the stepless variable speed fan and an air pressure sensor assembly for detecting pressure signals of the upstream of the stepless variable speed fan, and the signal output end of the air pressure sensor assembly is connected with the control unit. The control unit comprises a storage and a controller, the storage is used for storing the corresponding relation between the pressure signals of the upstream of the stepless variable speed fan and heating loads of the combustor, and the controller is used for controlling operation of the stepless variable speed fan according to the corresponding relation. By detecting the pressure signals of the upstream of the stepless variable speed fan, the rotating speed of the upstream of the stepless variable speed fan is further adjusted, and the combustion control system has high wind-resistant performance.

Owner:A O SMITH CHINA WATER HEATER CO LTD

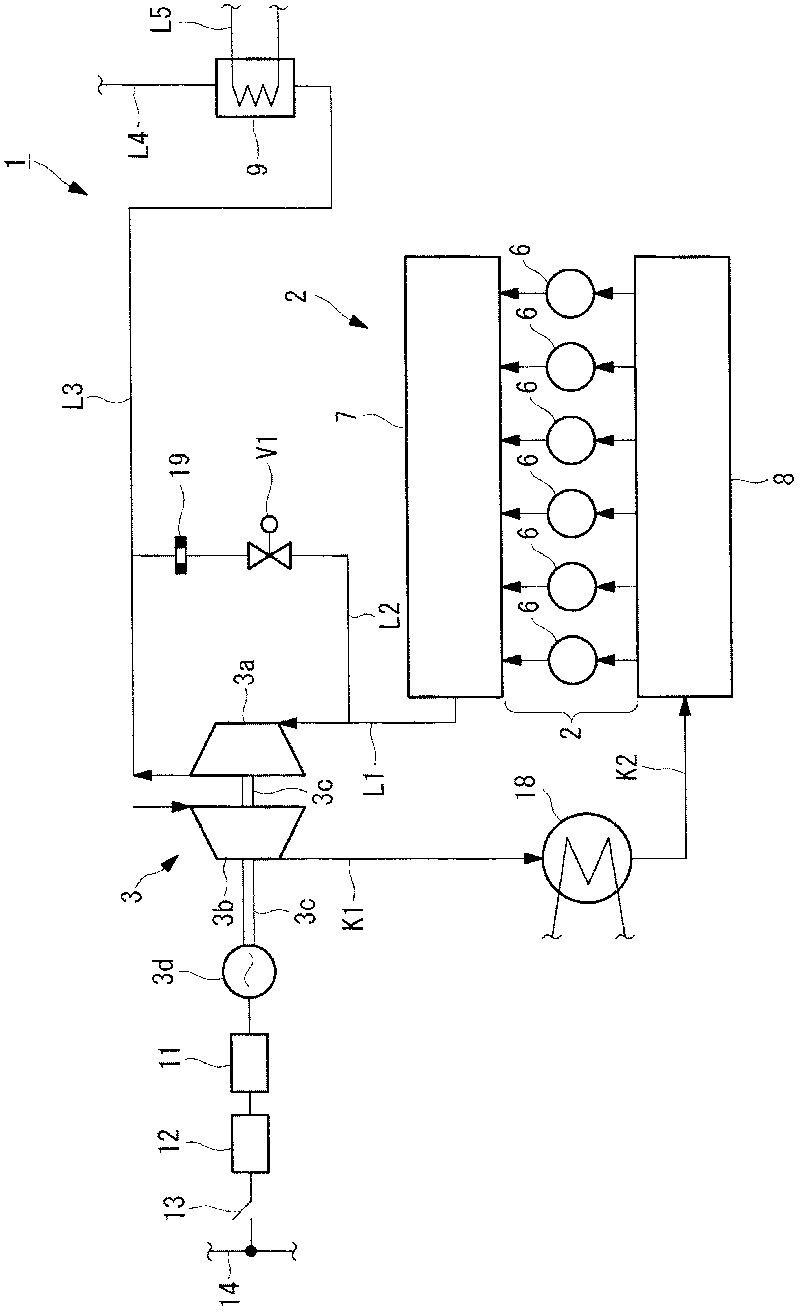

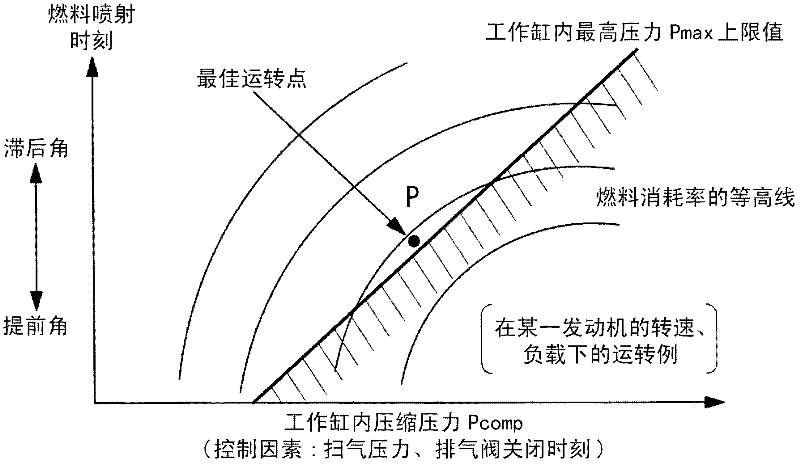

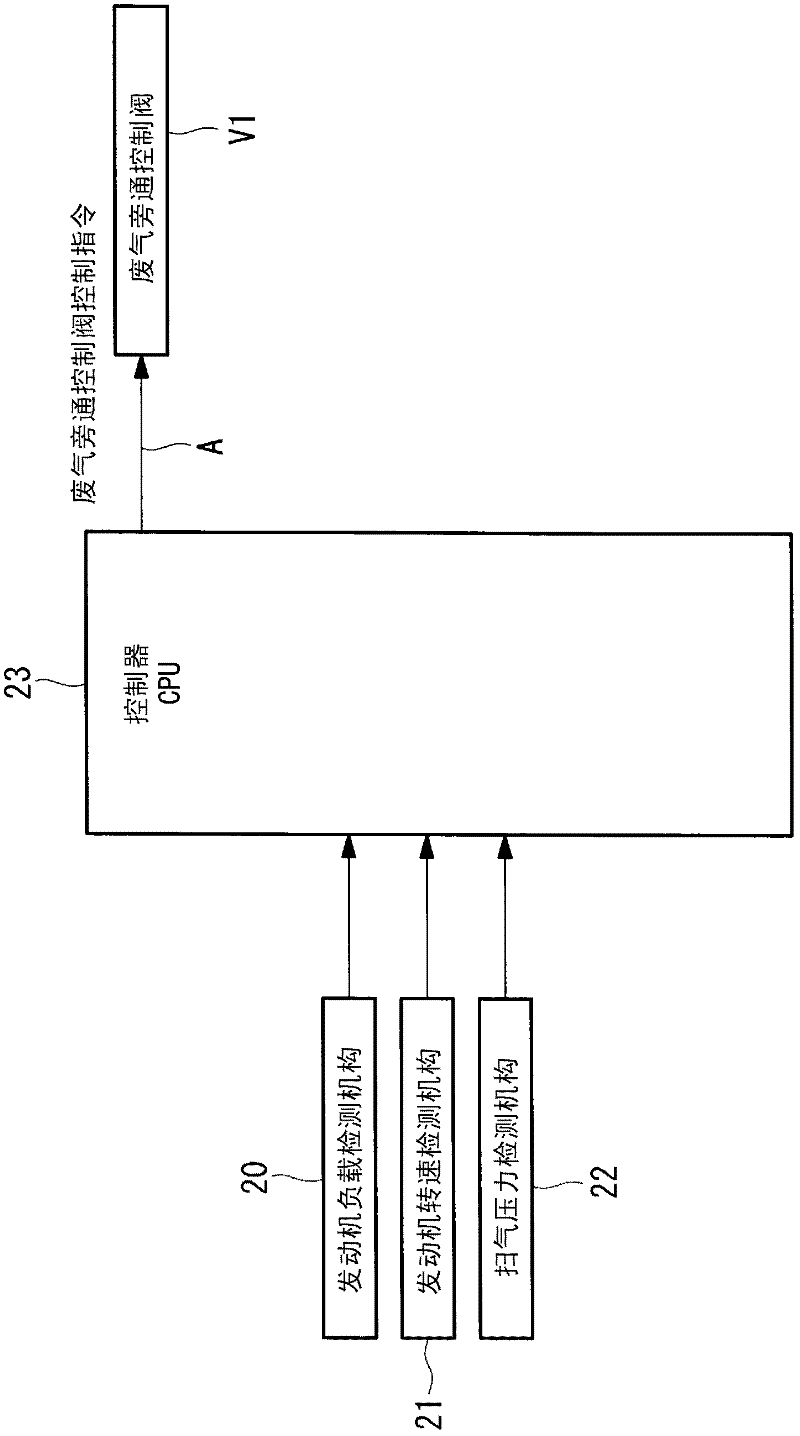

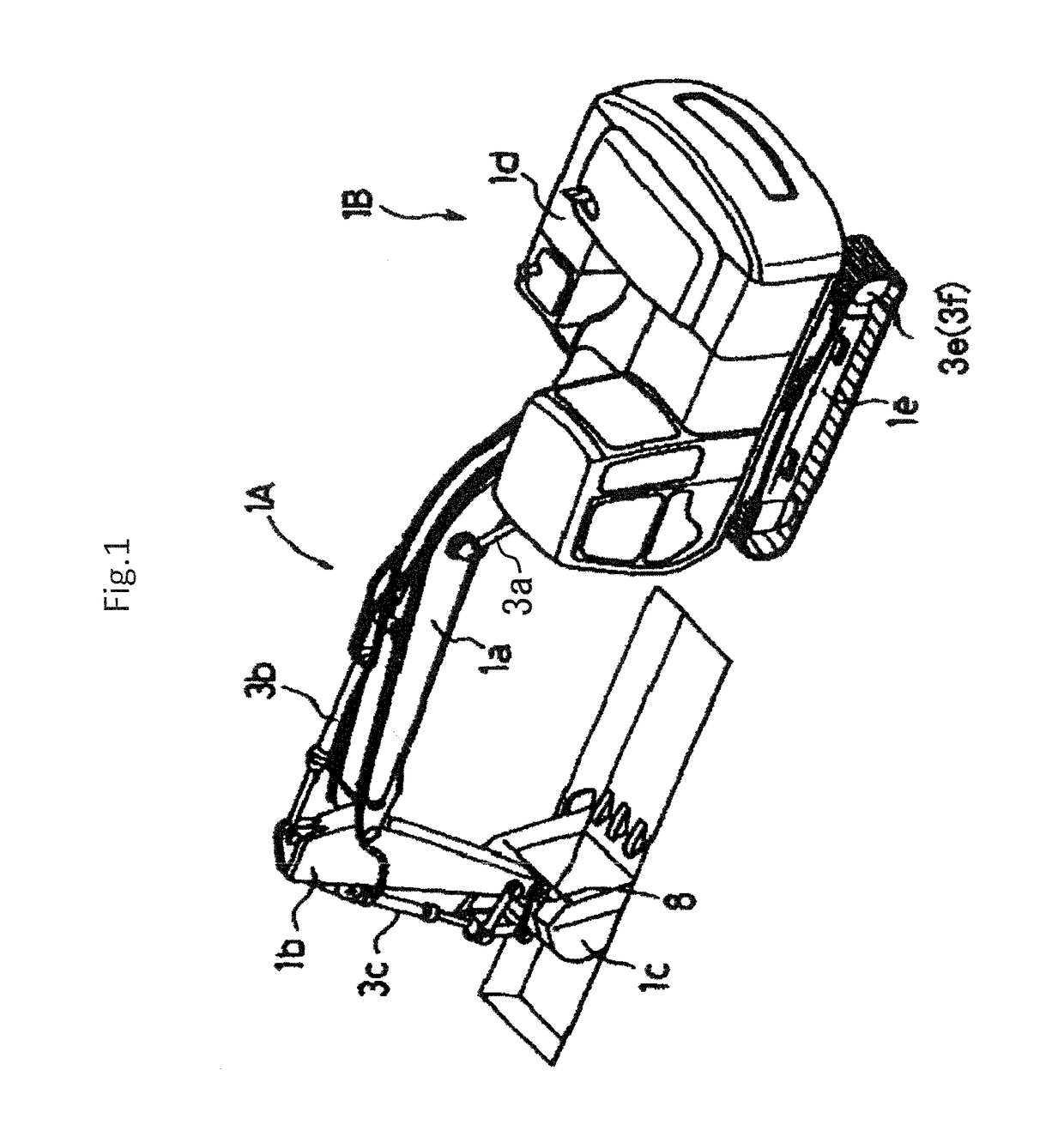

Engine exhaust energy recovery device, ship provided therewith, and power generation plant provided with said engine exhaust energy recovery device

InactiveCN102472161AFuel consumption rate suppressionLow running costElectrical controlInternal combustion piston enginesExhaust fumesEnergy recovery

Provided is an engine exhaust energy recovery device wherein it is possible to reduce the fuel consumption rate of an engine to a predetermined level or lower in relation to the various engine loads and the number of revolutions of the engine, and to effectively use the exhaust gas which is emitted from the engine. The engine exhaust energy recovery device is provided with: a hybrid supercharger (3) which has a turbine section (3a) to which the exhaust gas emitted from an engine (2) is supplied, a compressor section (3b) which compresses and transfers a scavenging pressure to the engine (2), and a power generator / electric motor section (3d) which generates power when the turbine (3a) is driven; a bypass path (L2) which bypasses the exhaust gas that is supplied to the hybrid supercharger (3); and a control device which has a database for calculating the scavenging pressure, in which the fuel consumption rate of the engine (2) is at a predetermined level or lower, on the basis of the detection values obtained from the detection means including an engine load detection means, an engine revolution number detection means, and a scavenging pressure detection means. The control device controls an exhaust gas bypass control valve (V1) in order to control the scavenging pressure of the engine (2).

Owner:MITSUBISHI HEAVY IND LTD +1

Intake air amount control system for internal combustion engine and control system

InactiveUS7469180B2Quickly and stably convergeImprove robustnessElectrical controlInternal combustion piston enginesControl systemInlet valve

An intake air amount control system for an internal combustion engine, which is capable of ensuring high robustness and improving controllability in intake air amount control, to thereby improve drivability and reduce exhaust emissions. A control system of an internal combustion engine, which variably controls the amount of intake air drawn into cylinders as desired via a variable intake valve actuation assembly includes an ECU 2. The ECU 2 calculates a cylinder intake air amount Gcyl and a target intake air amount Gcyl_cmd based on a controlled object model, a vector θs of all model parameters of the controlled object model with an identification algorithm, calculates a target auxiliary intake cam phase θmsi_cmd based on the vector θs with a sliding mode control algorithm, and controls the variable intake valve actuation assembly according to the target auxiliary intake cam phase θmsi_cmd.

Owner:HONDA MOTOR CO LTD

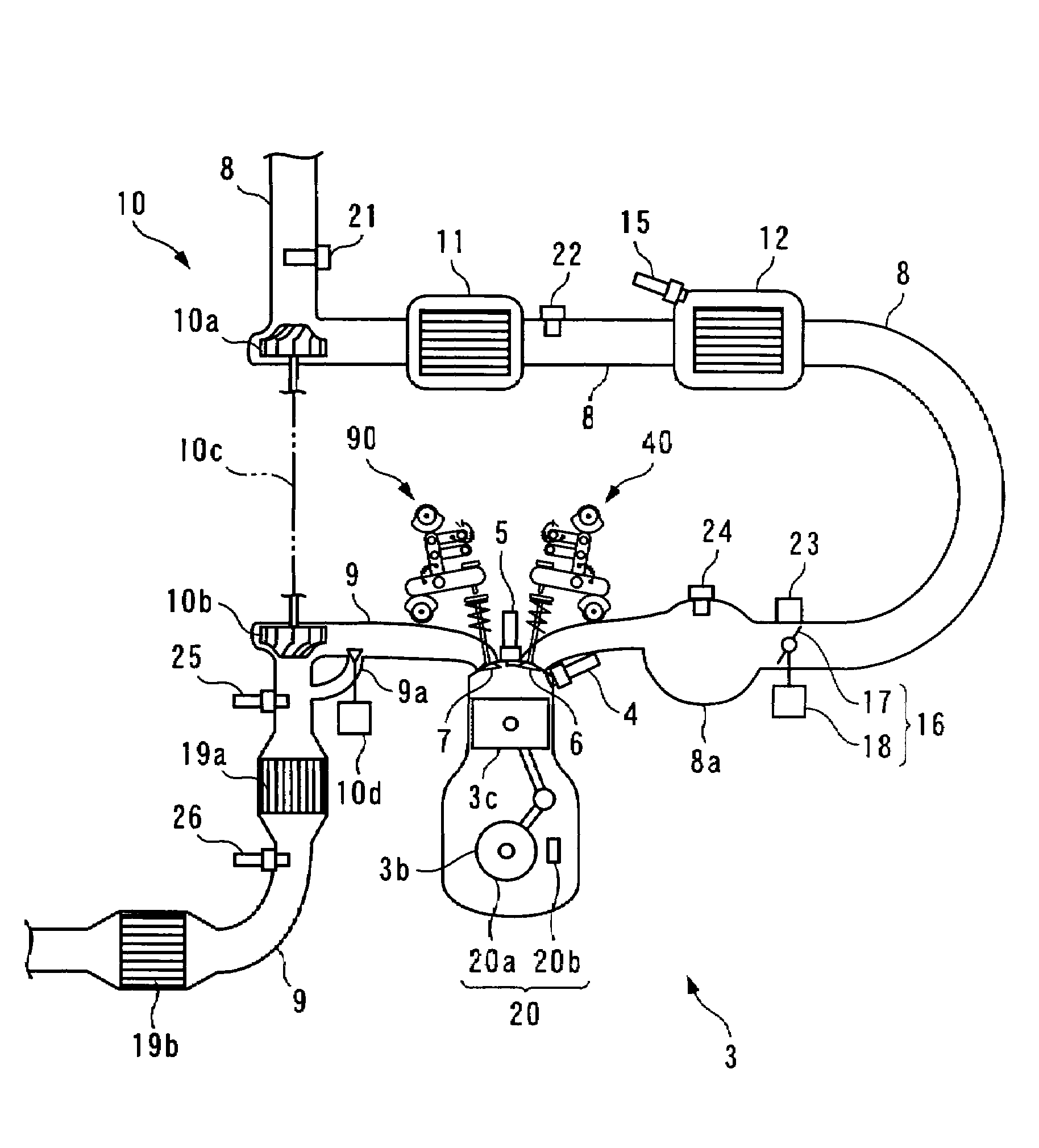

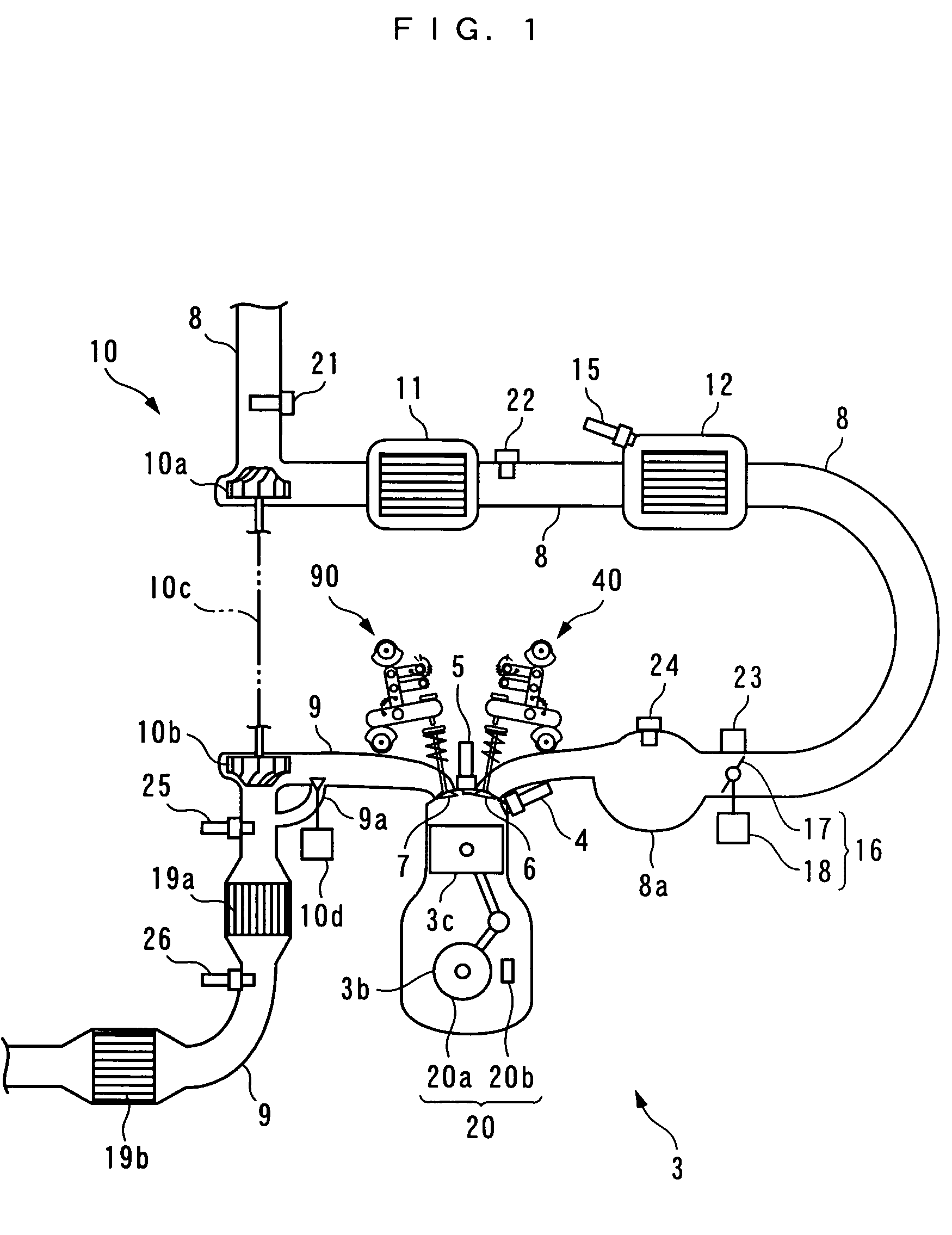

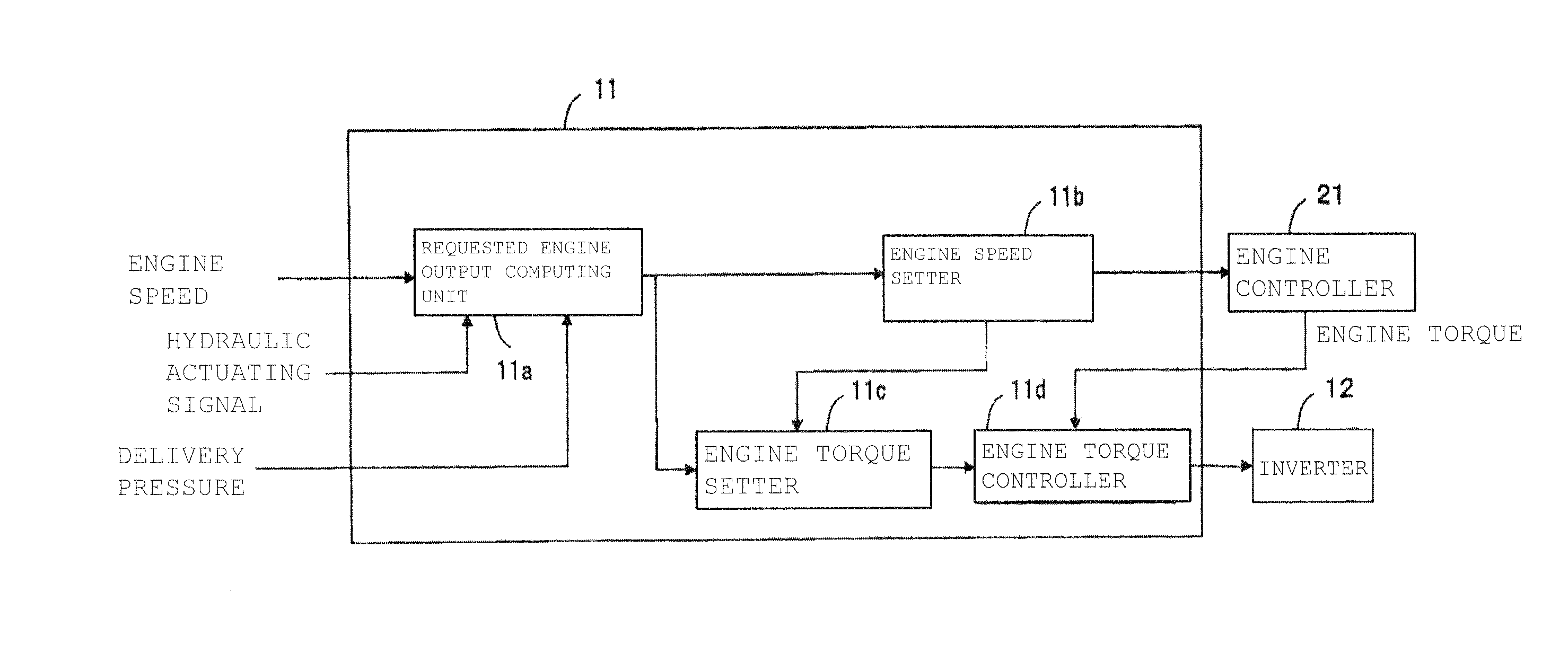

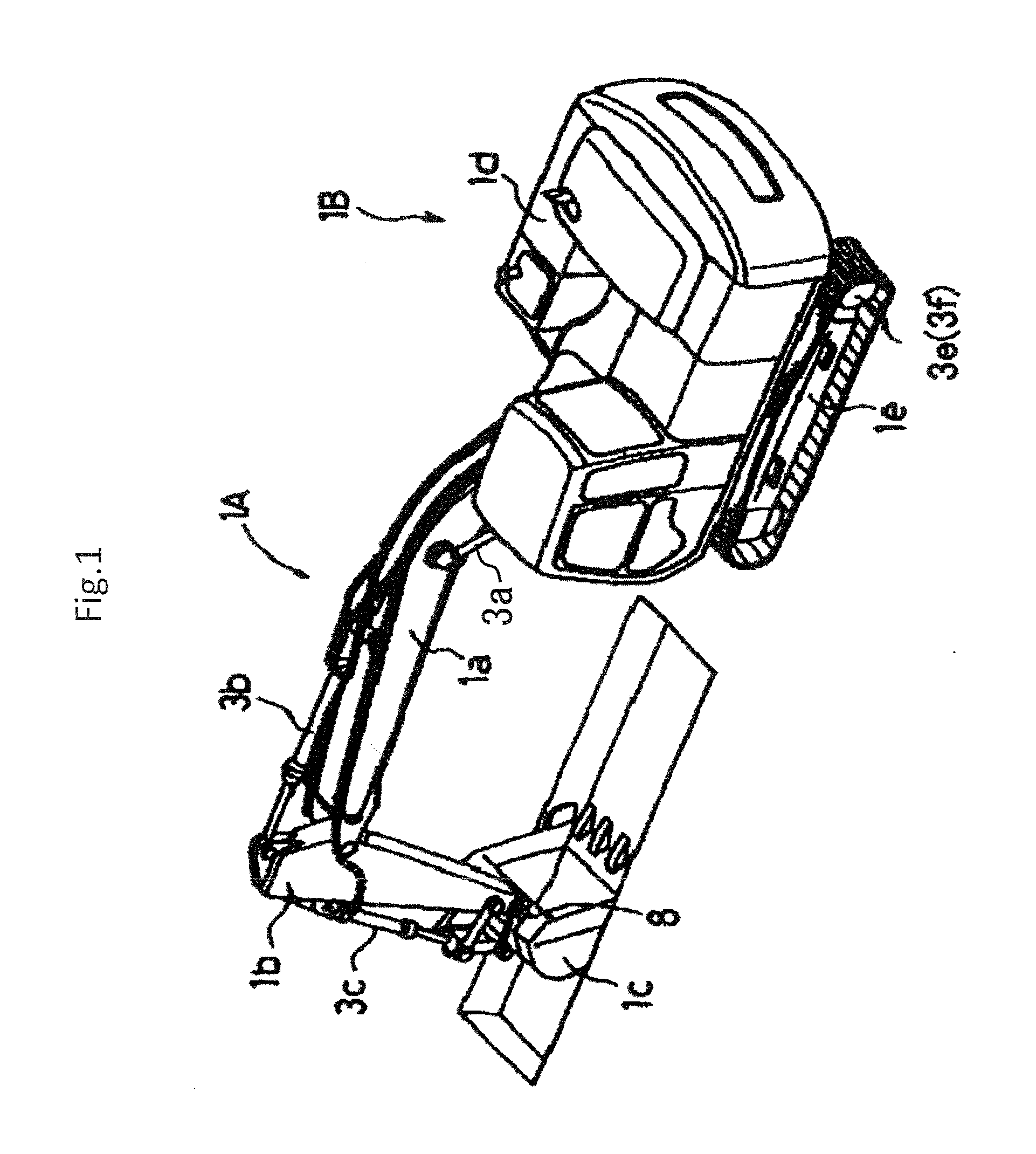

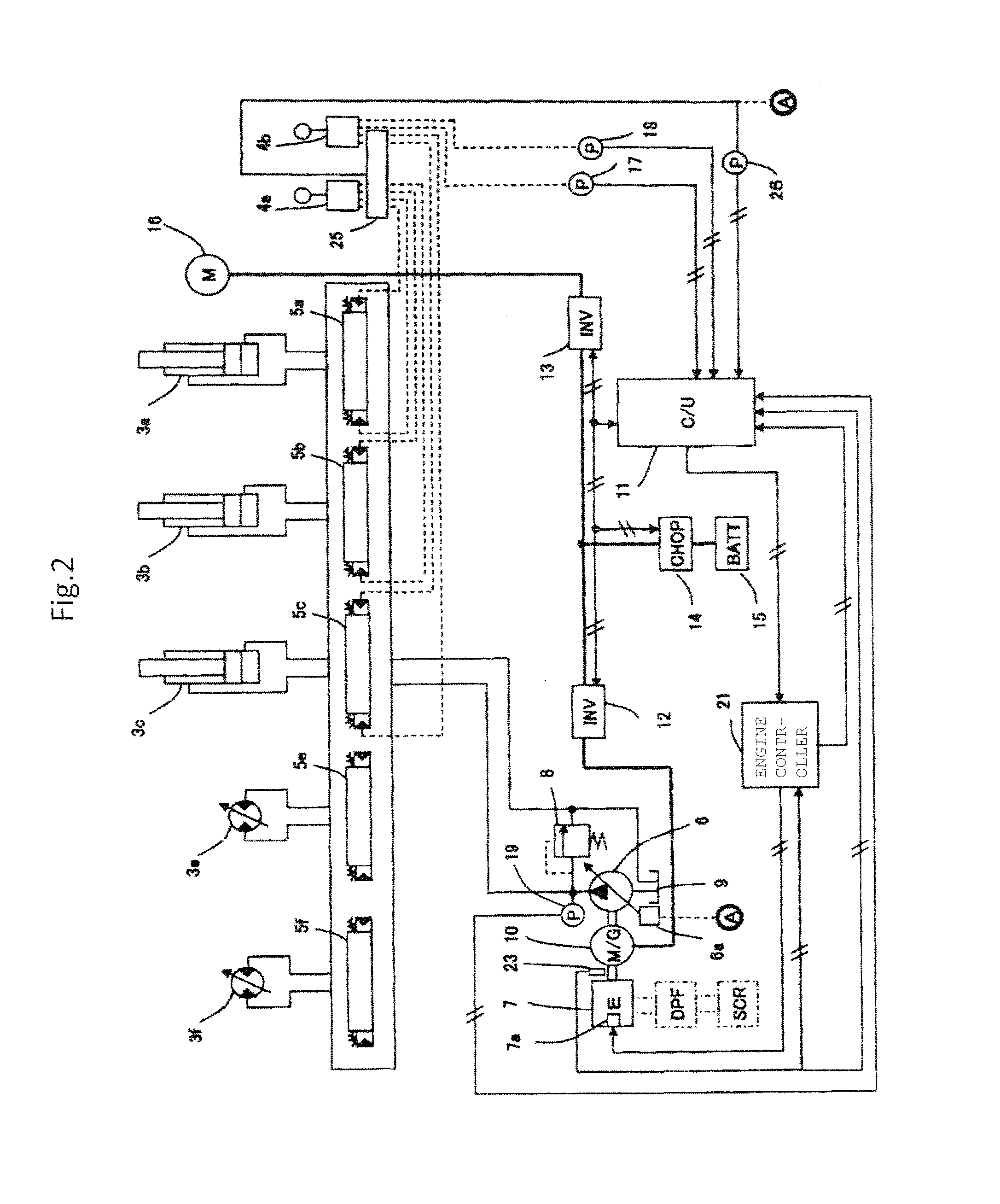

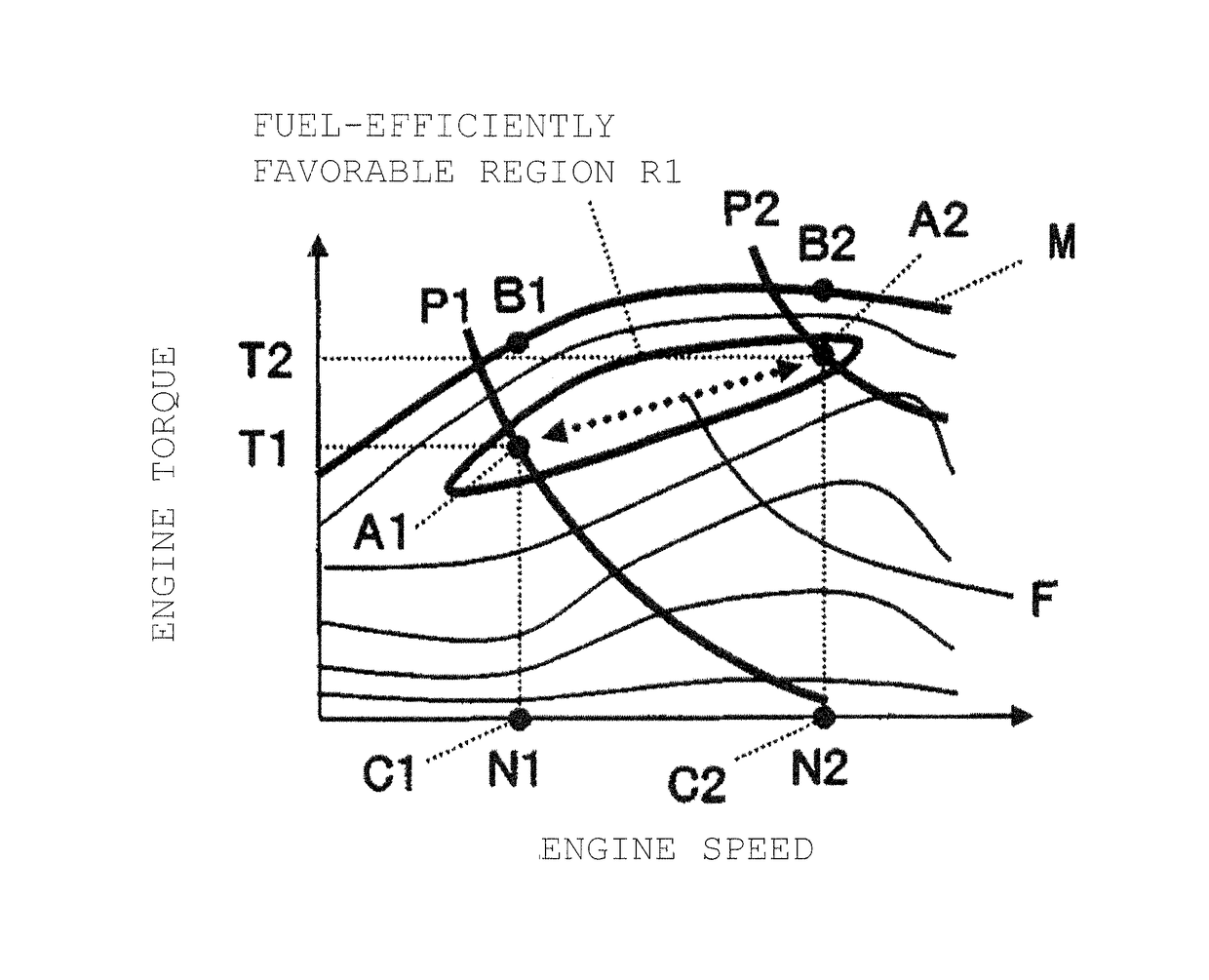

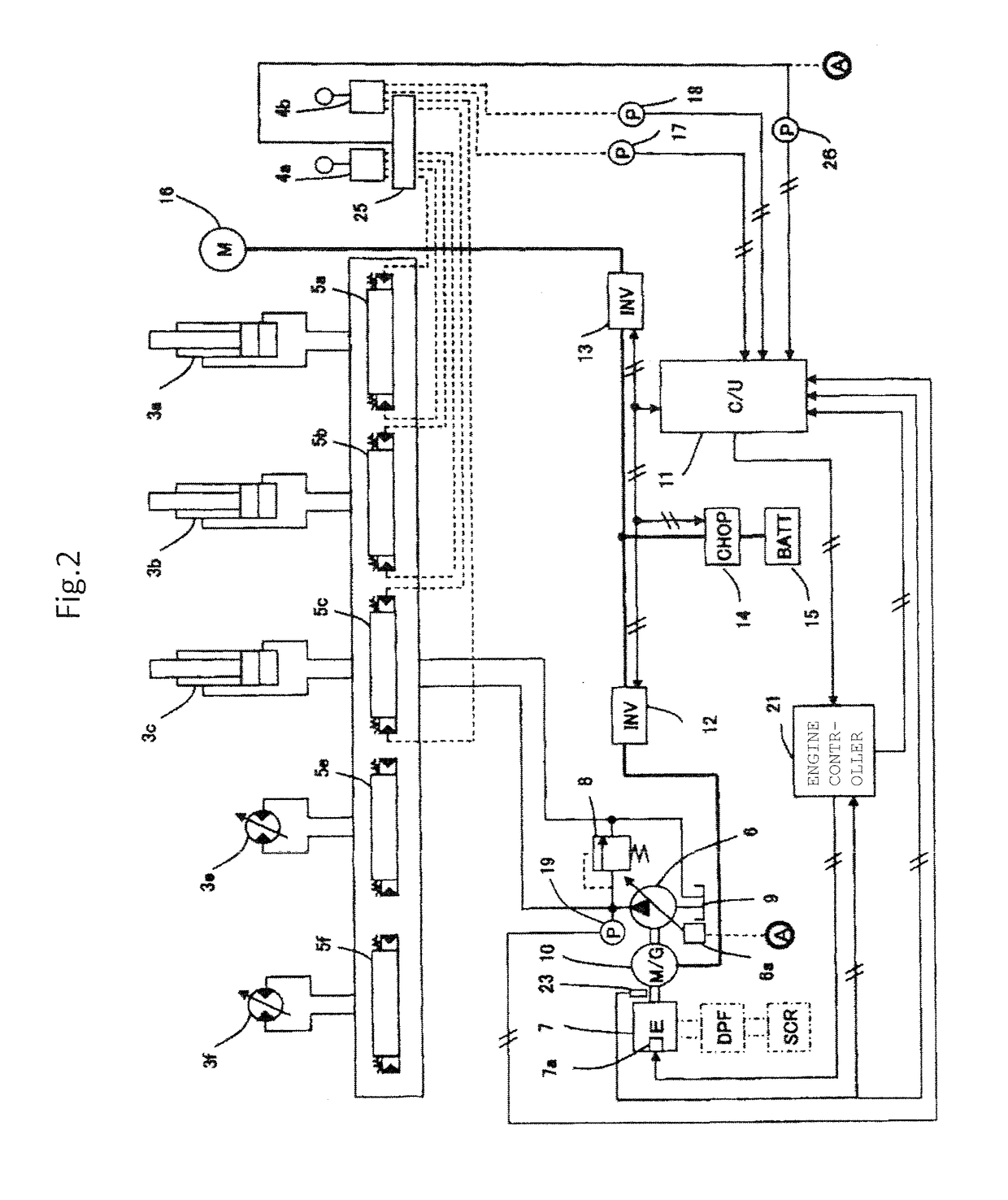

Hydraulic work machine

ActiveUS20150225927A1Improve the state of combustionPrevent the operating point from moving tooHybrid vehiclesAnalogue computers for trafficTransient stateOperating point

This invention is a hydraulic work machine having an electric assist motor coupled to an engine and a hydraulic pump, in the hydraulic work machine of which, a rotational speed and torque of the engine are controlled so that an operating point of the engine moves along a predetermined route for yielding a combustion state of the engine under a transient state that the engine changes in speed and torque. A target speed and torque of the engine 7 are set so that the rotational speed and torque of the engine 7 will change along a predetermined route F in a running region of the engine, respective rates of change of the target rotational speed and torque of the engine 7 are limited, and the engine 7 is controlled to yield the target engine speed. In addition, torque of the assist motor 10 is controlled to yield the target torque of the engine.

Owner:NIHON KENKI CO LTD

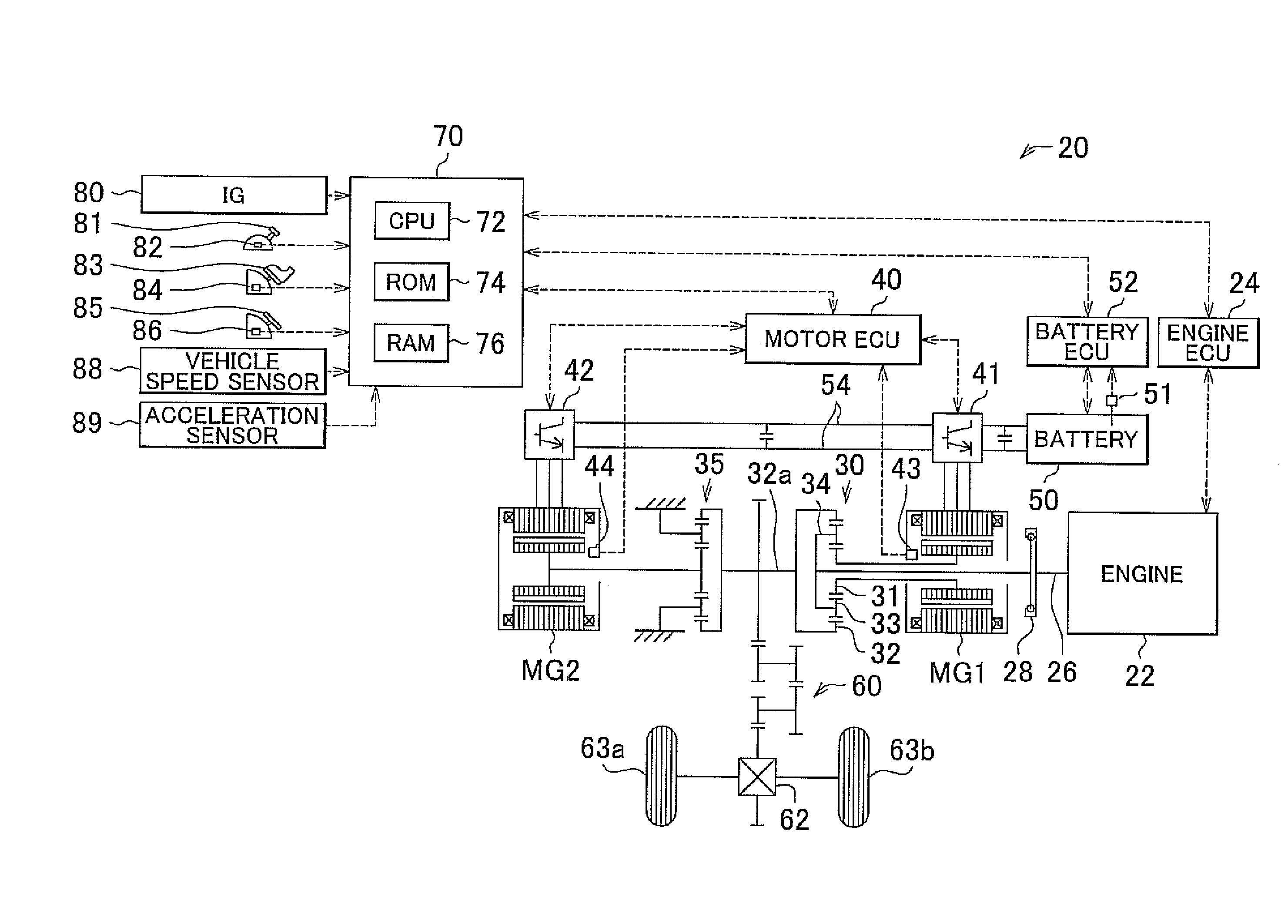

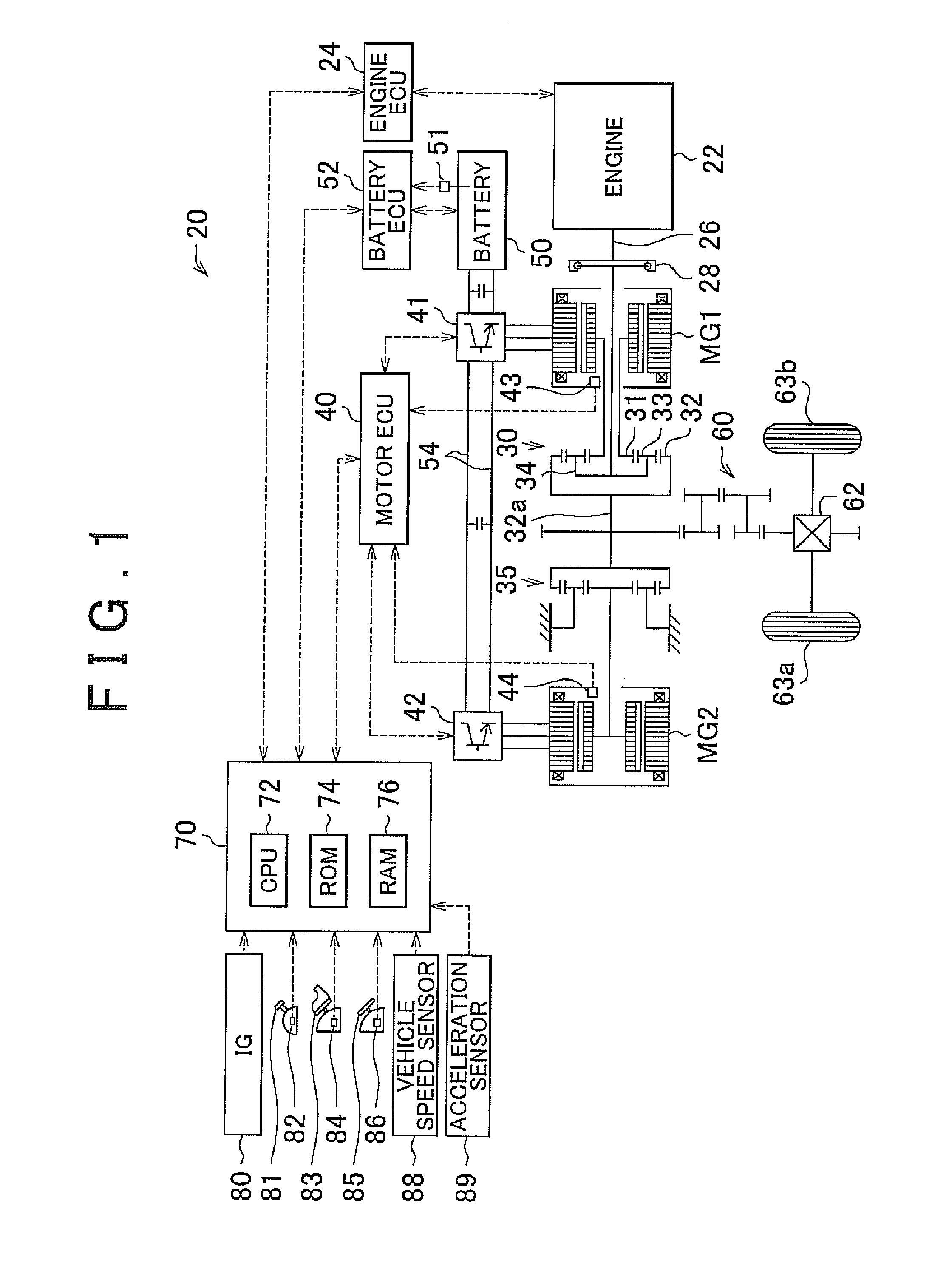

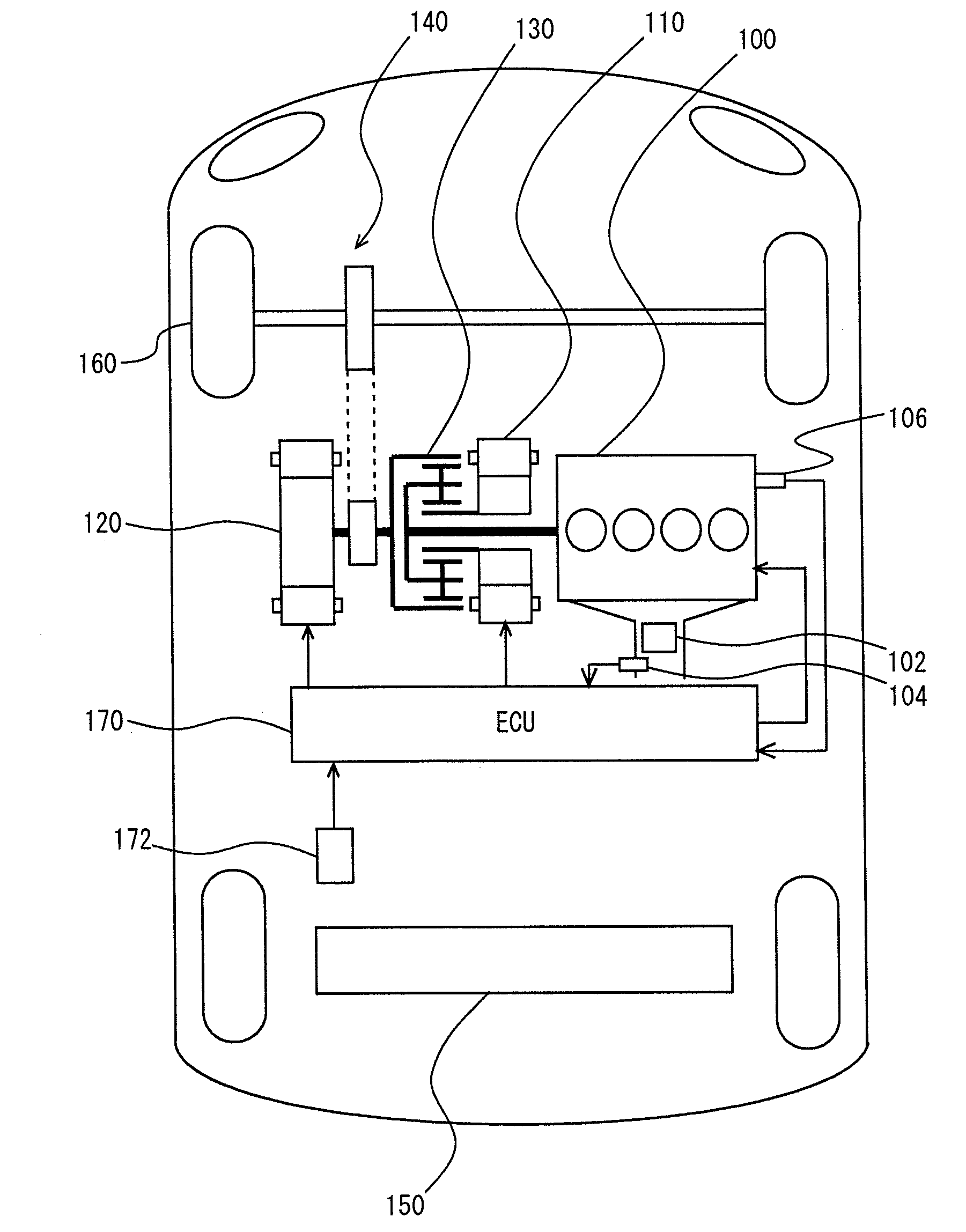

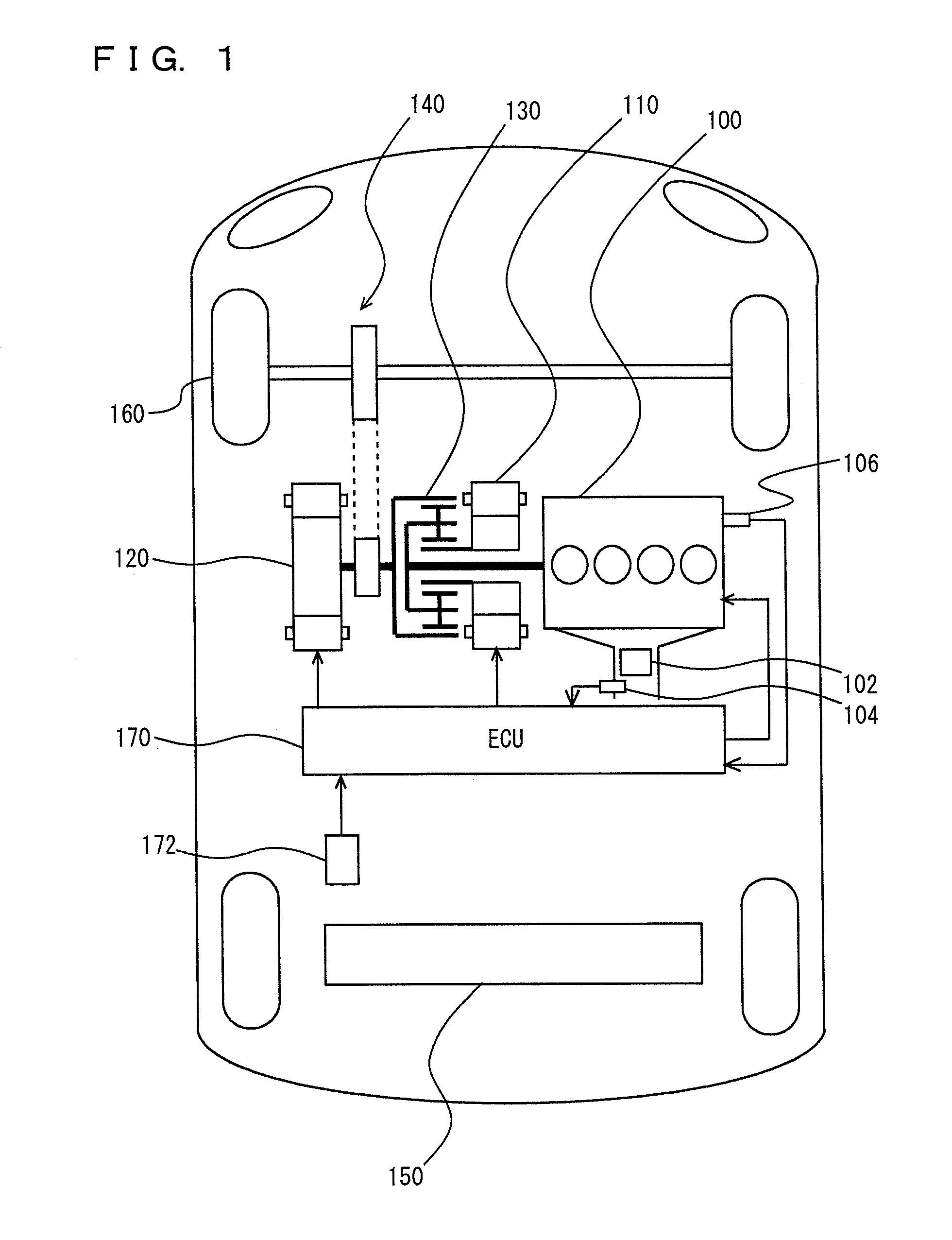

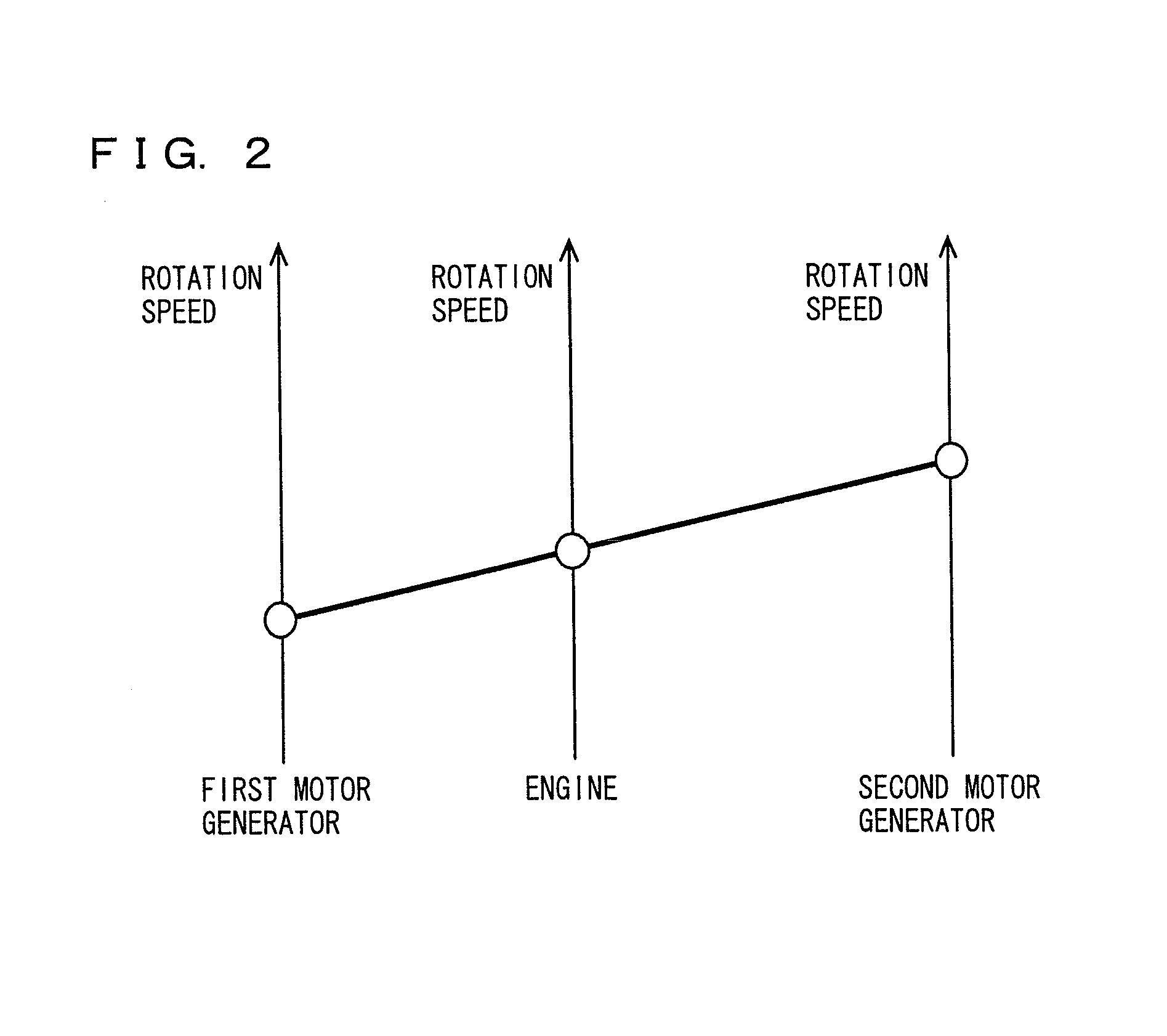

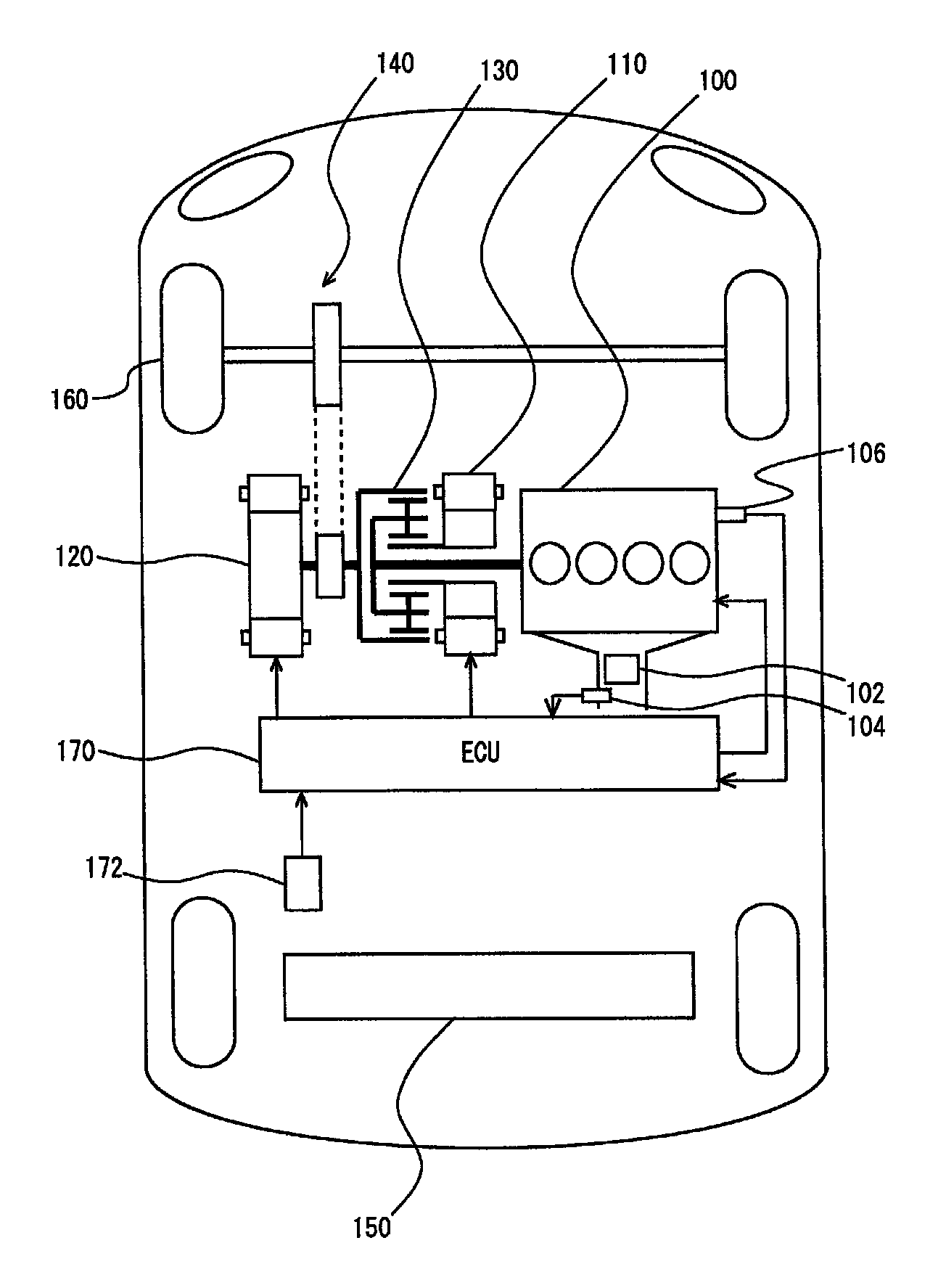

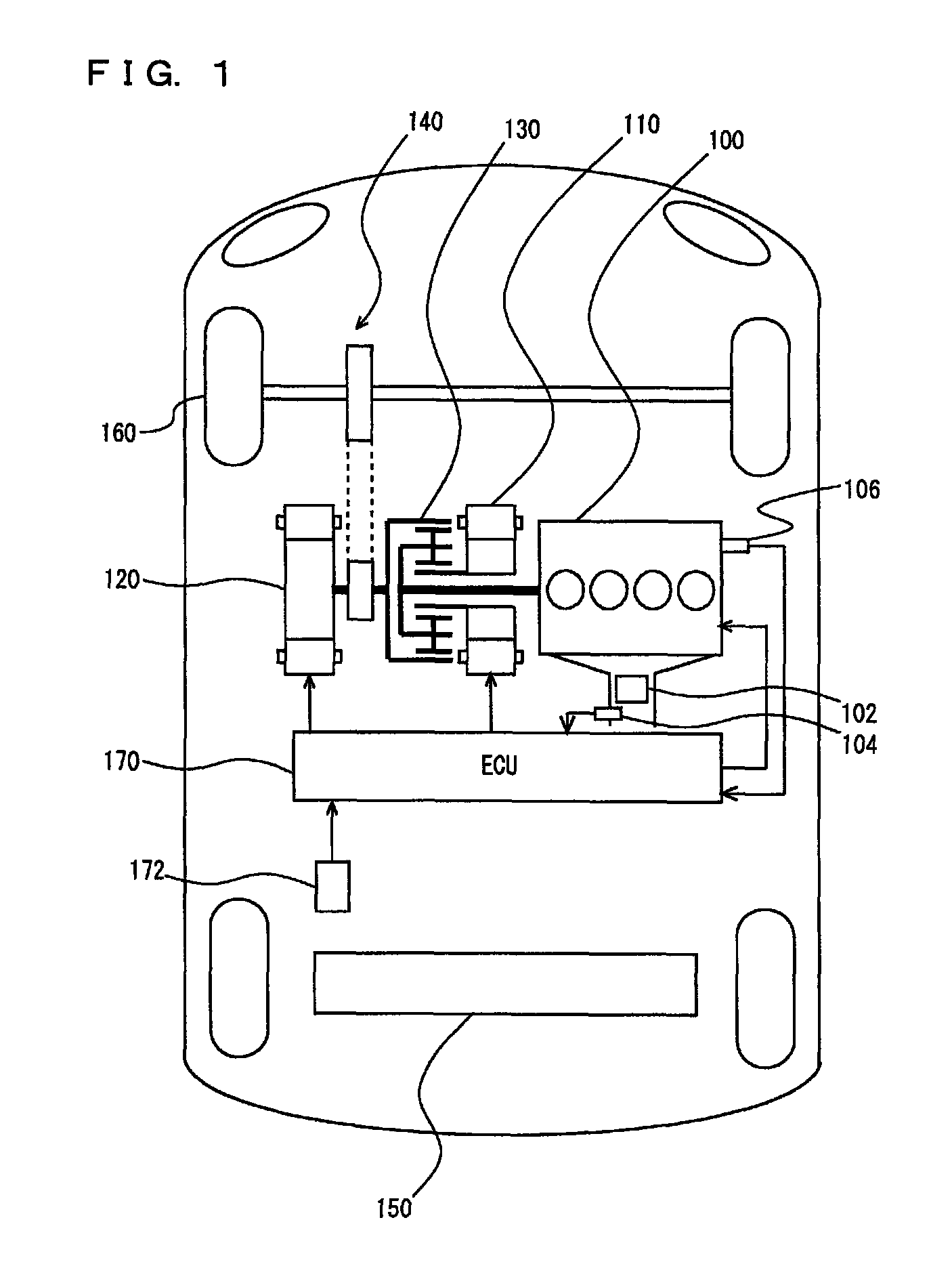

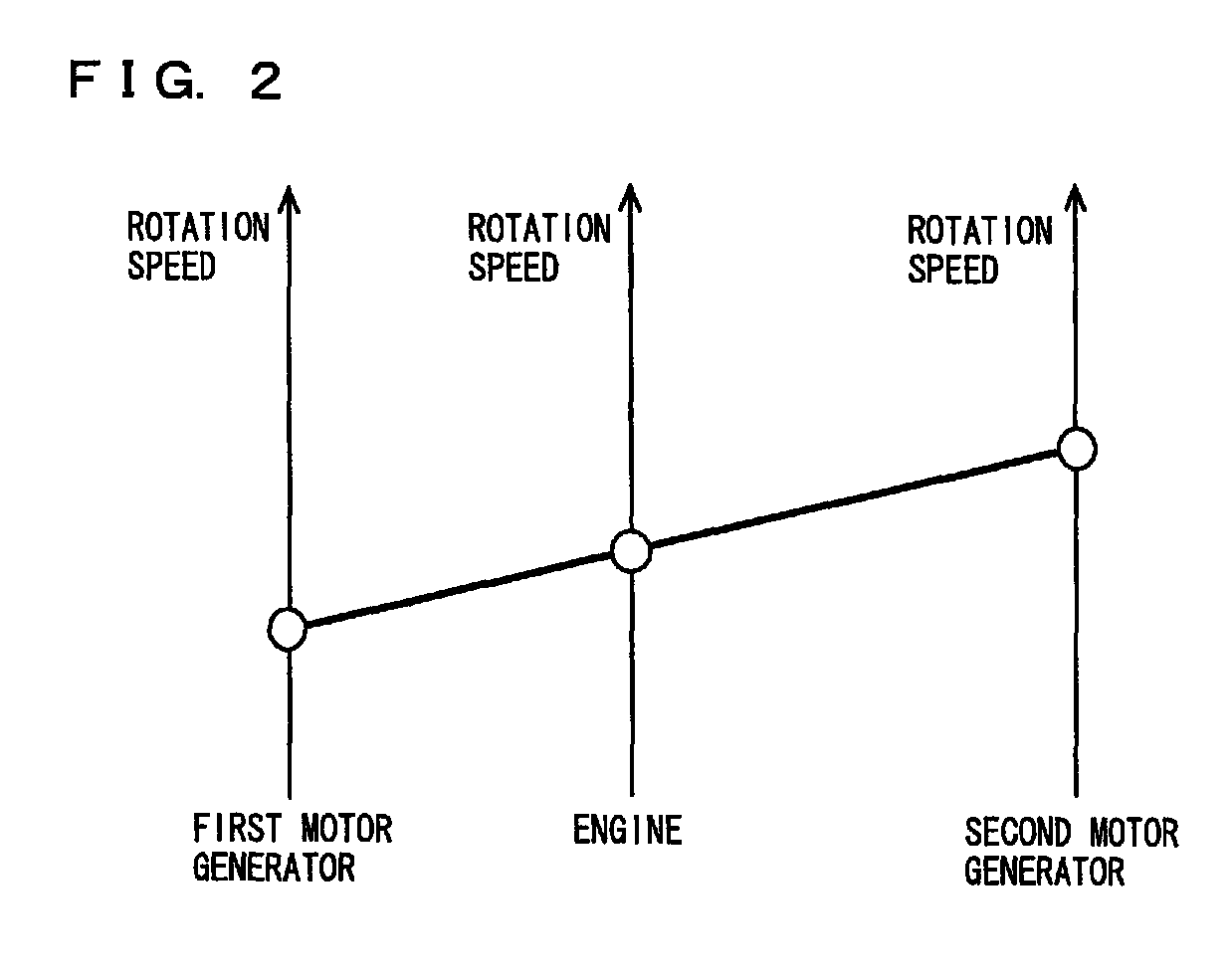

Vehicle, method and device for controlling engine

InactiveUS20120310458A1Improve the state of combustionIncrease opportunitiesHybrid vehiclesInternal combustion piston enginesState of chargeDynamo

A vehicle provided with a motor generator as a driving source includes a battery to supply electric power to the motor generator, an engine, and an ECU to control the vehicle in one of a CS mode and a CD mode in which opportunity for operation of the engine is limited compared to in the CS mode. The ECU controls the engine in accordance with a condition different from a condition used to control the engine in the CS mode, if the engine is started at least due to decrease in a state of charge of the battery while the vehicle is controlled in the CD mode.

Owner:TOYOTA JIDOSHA KK

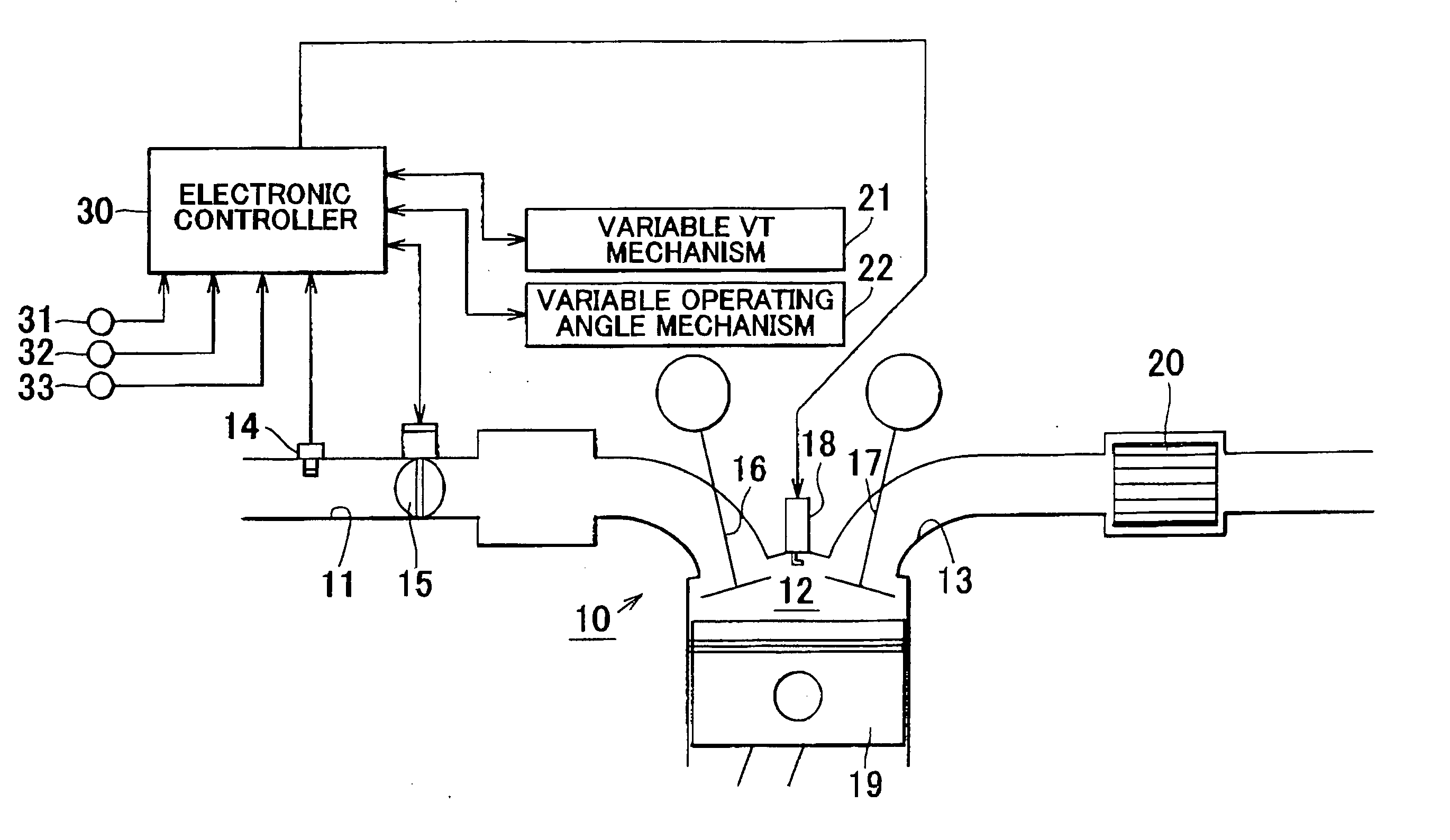

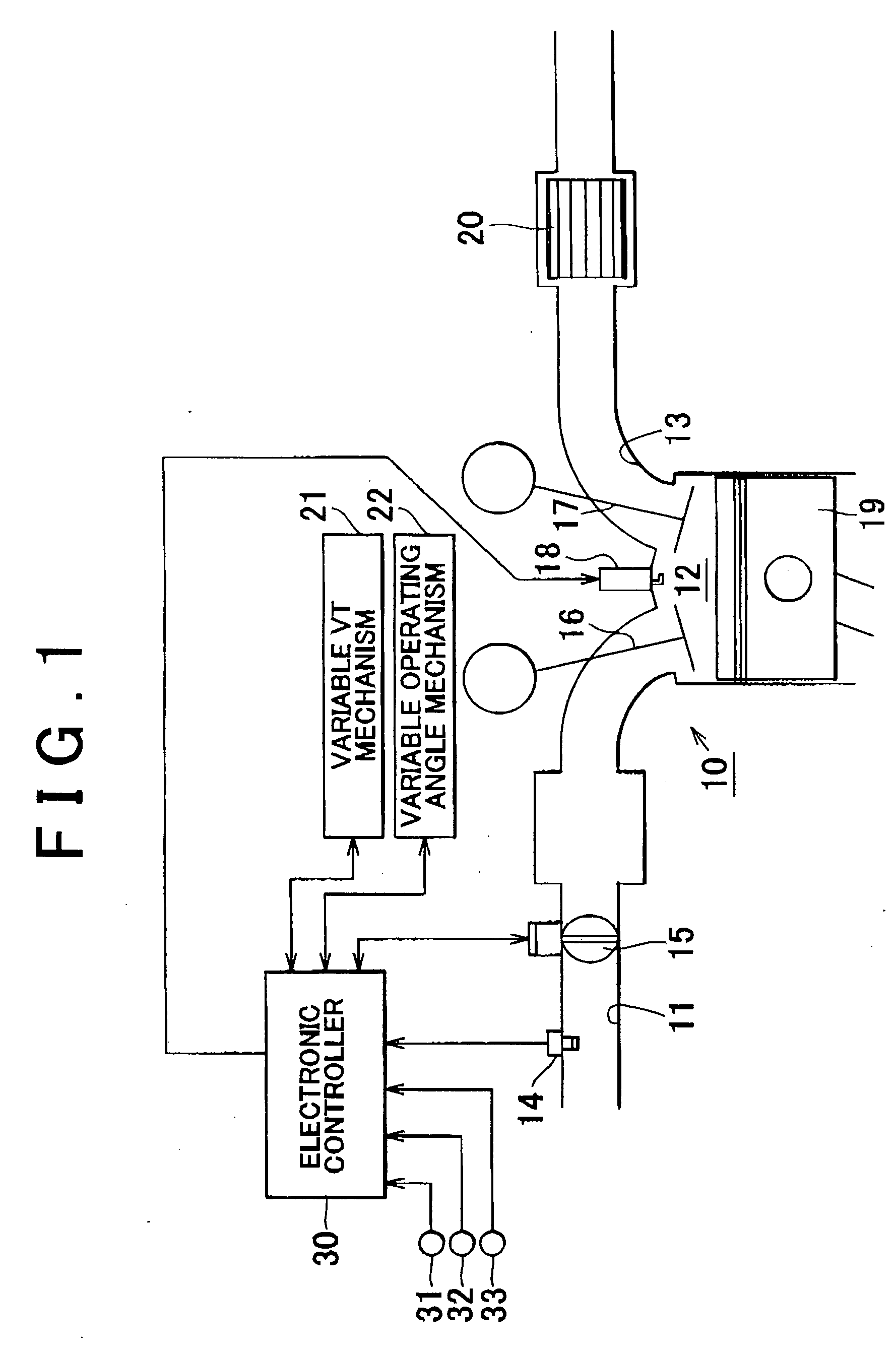

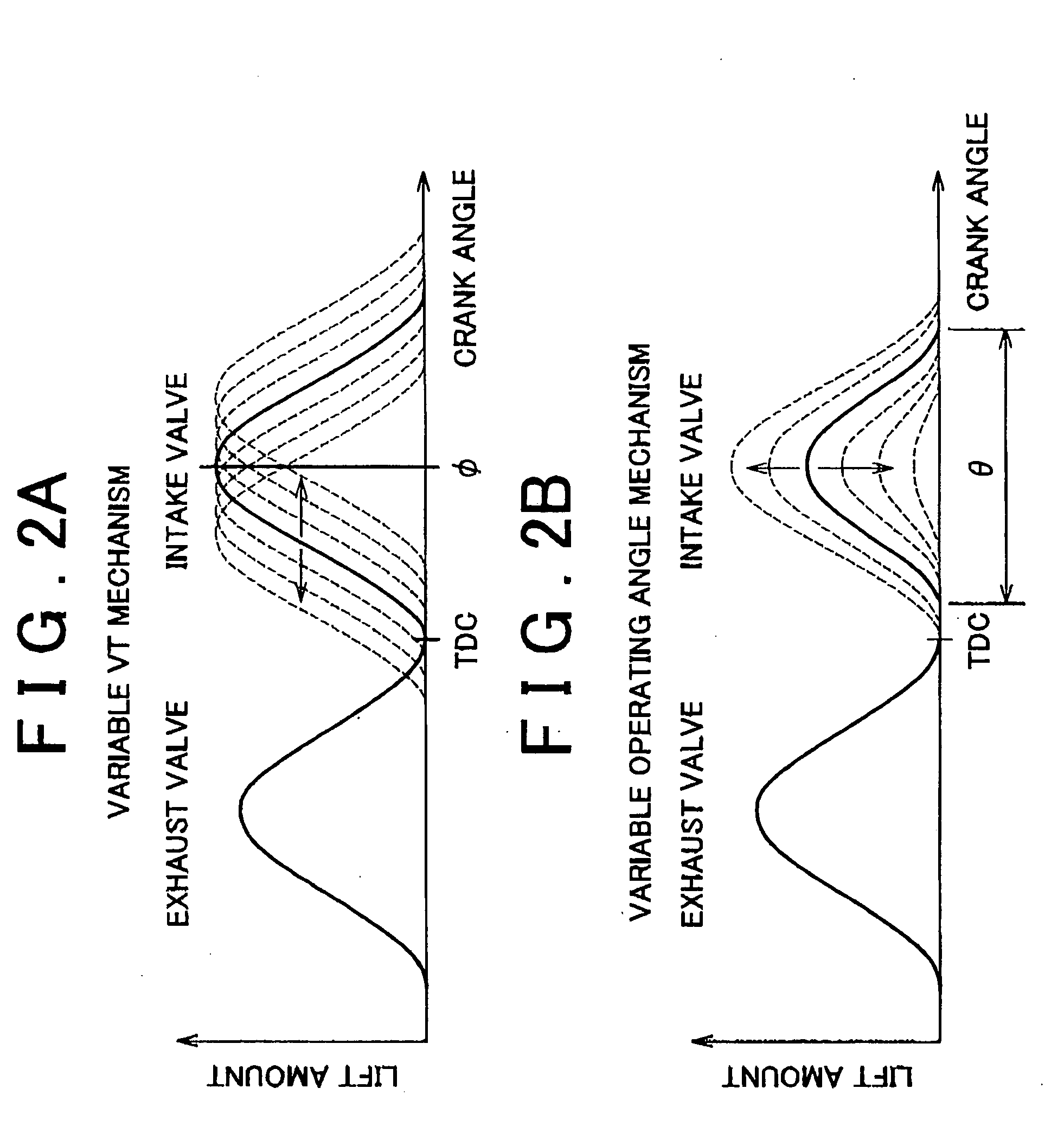

Valve characteristic controlling apparatus and method for internal combustion engine

ActiveUS20060090730A1Increase flow rateReduce opening timeValve arrangementsInternal combustion piston enginesLow loadInternal combustion engine

An electronic controller variably controls the center of an operating angle of an intake valve as follows: when an engine load factor is equal to or higher than a threshold in a low load operation, the electronic controller advances the center of the operating angle with a decrease in the engine load factor. When the engine load factor is lower than the threshold in the low load operation, the electronic controller retards the center of the operating angle with a decrease in the engine load factor.

Owner:TOYOTA JIDOSHA KK

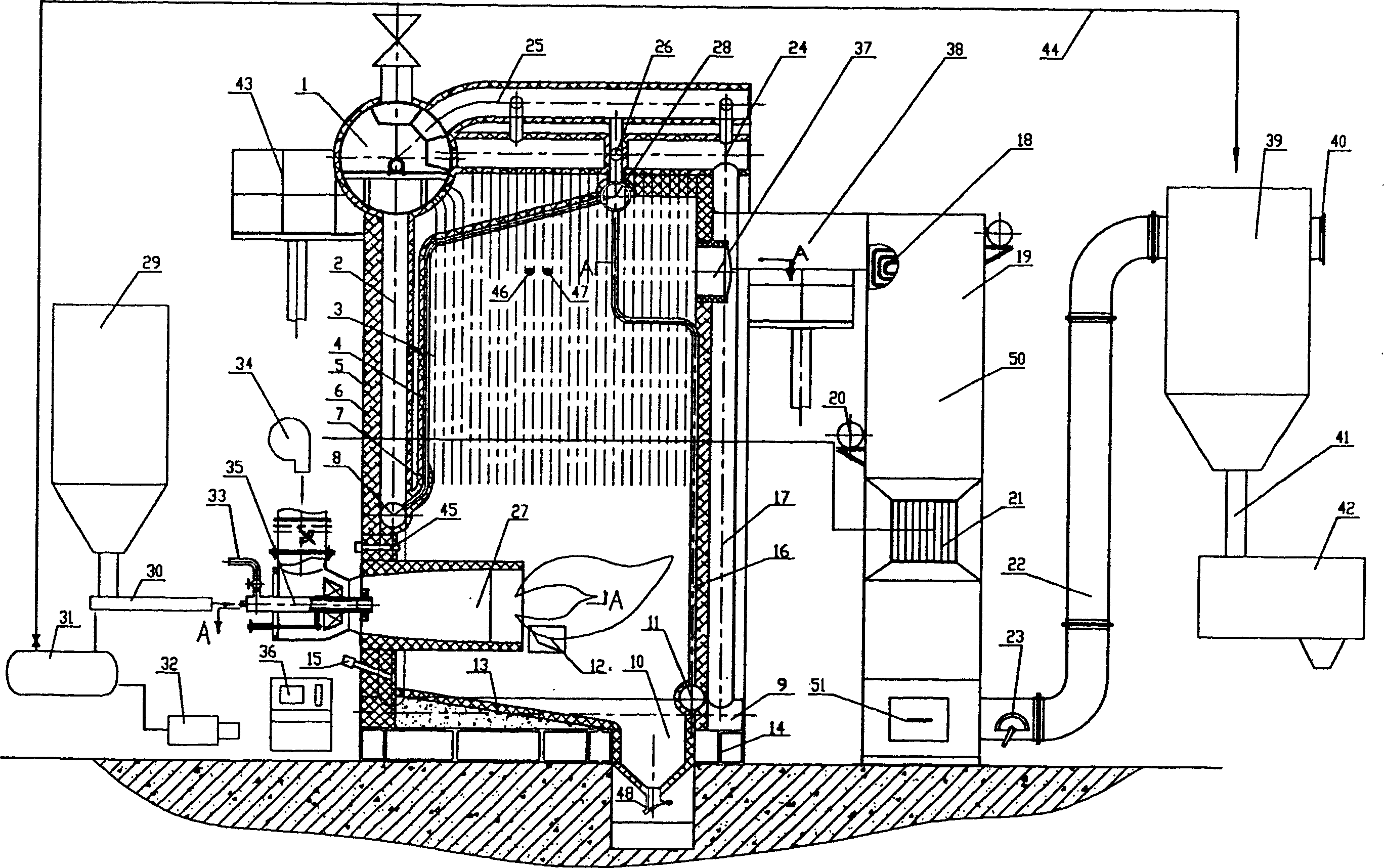

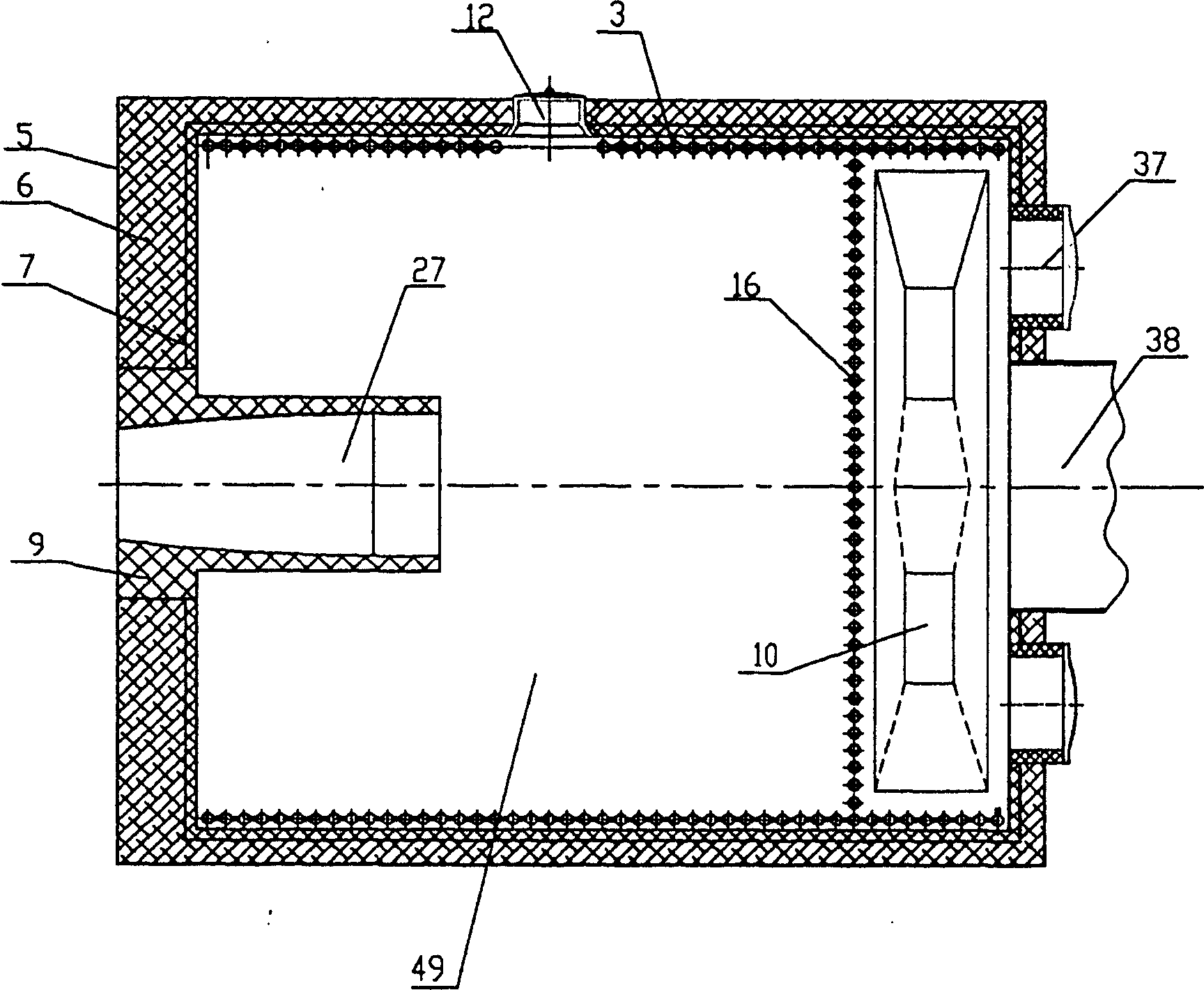

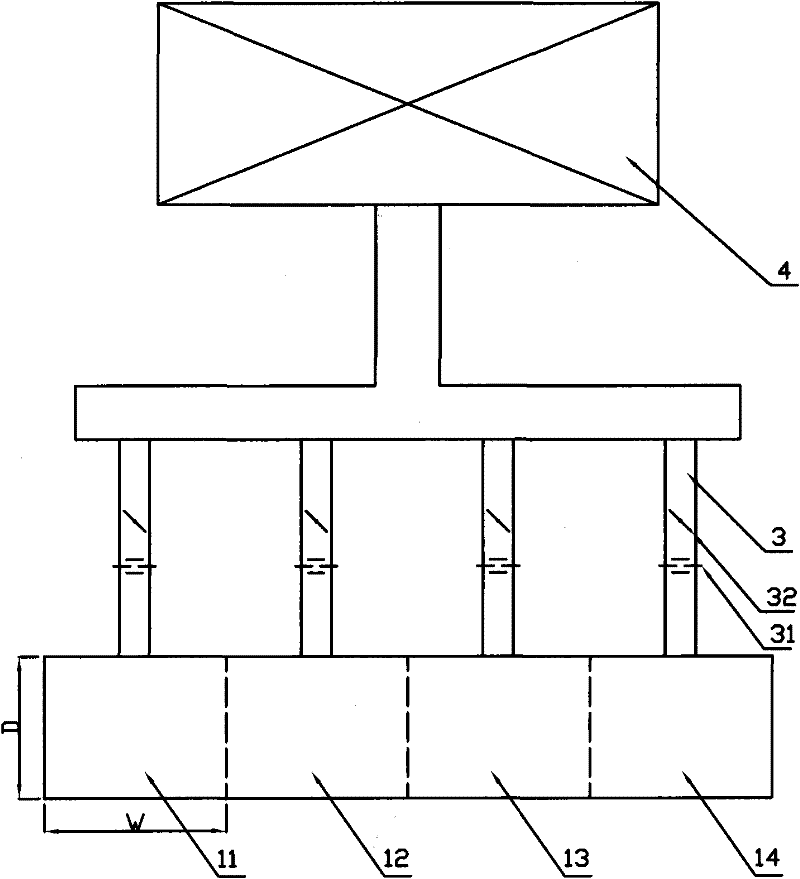

Industrial boiler of multi-fuel burning using ultrafine coal dust as main fuel

InactiveCN1724928AImprove burnout rateFully mixed combustionBurnersCombustion using multiple fuelsMultifuelCoal dust

The invention discloses an industrial boiler fired by multiple mixed fuels with superfine powder coal(water coal slurry) as the primary and natural gas or oil products as the auxiliary, and it is an industrial boiler with the advantages of high firing efficiency, low cost, auto control and reduction of environmental pollution, especially applied to middle-small scale industrial boilers.

Owner:姜政华

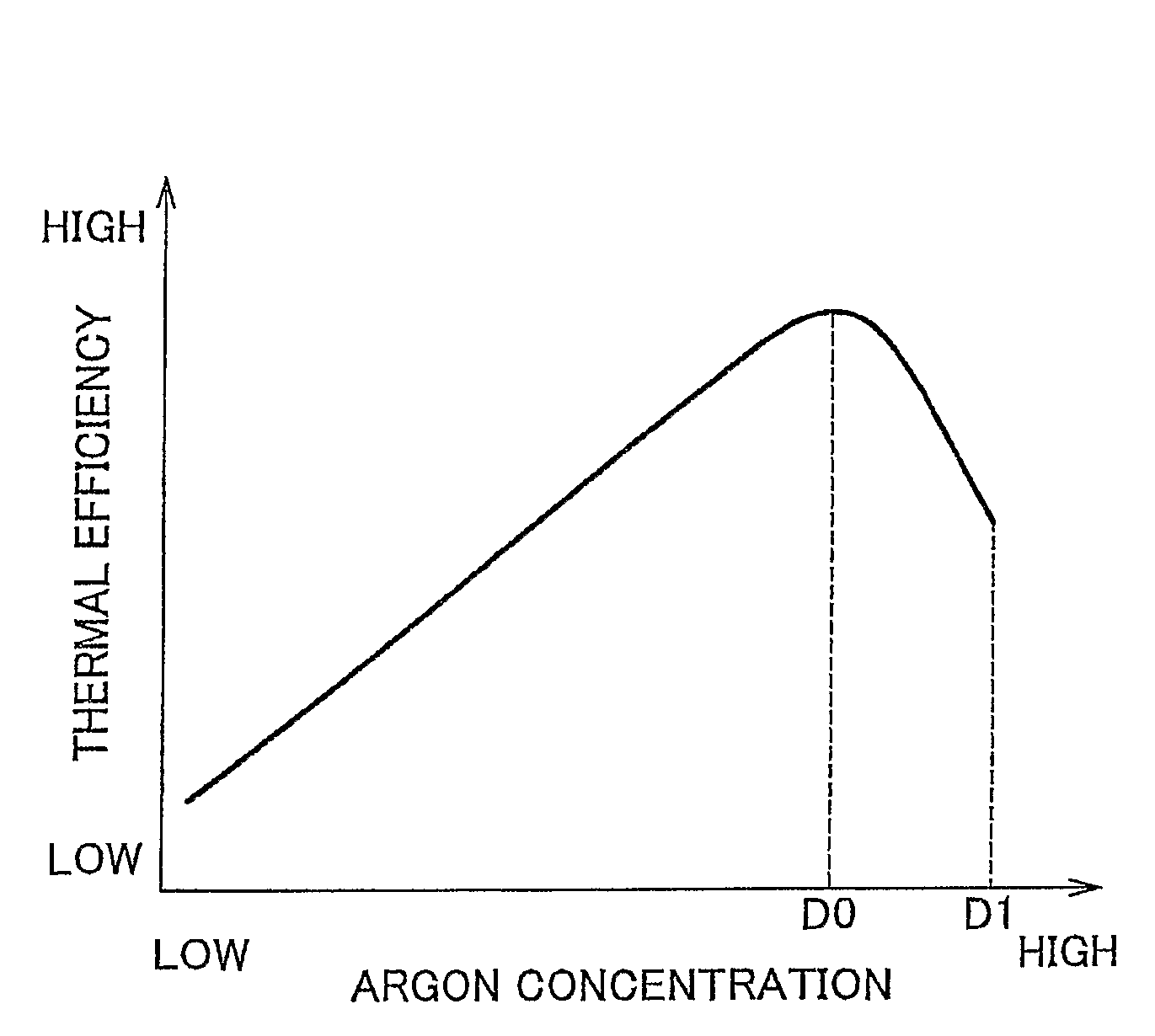

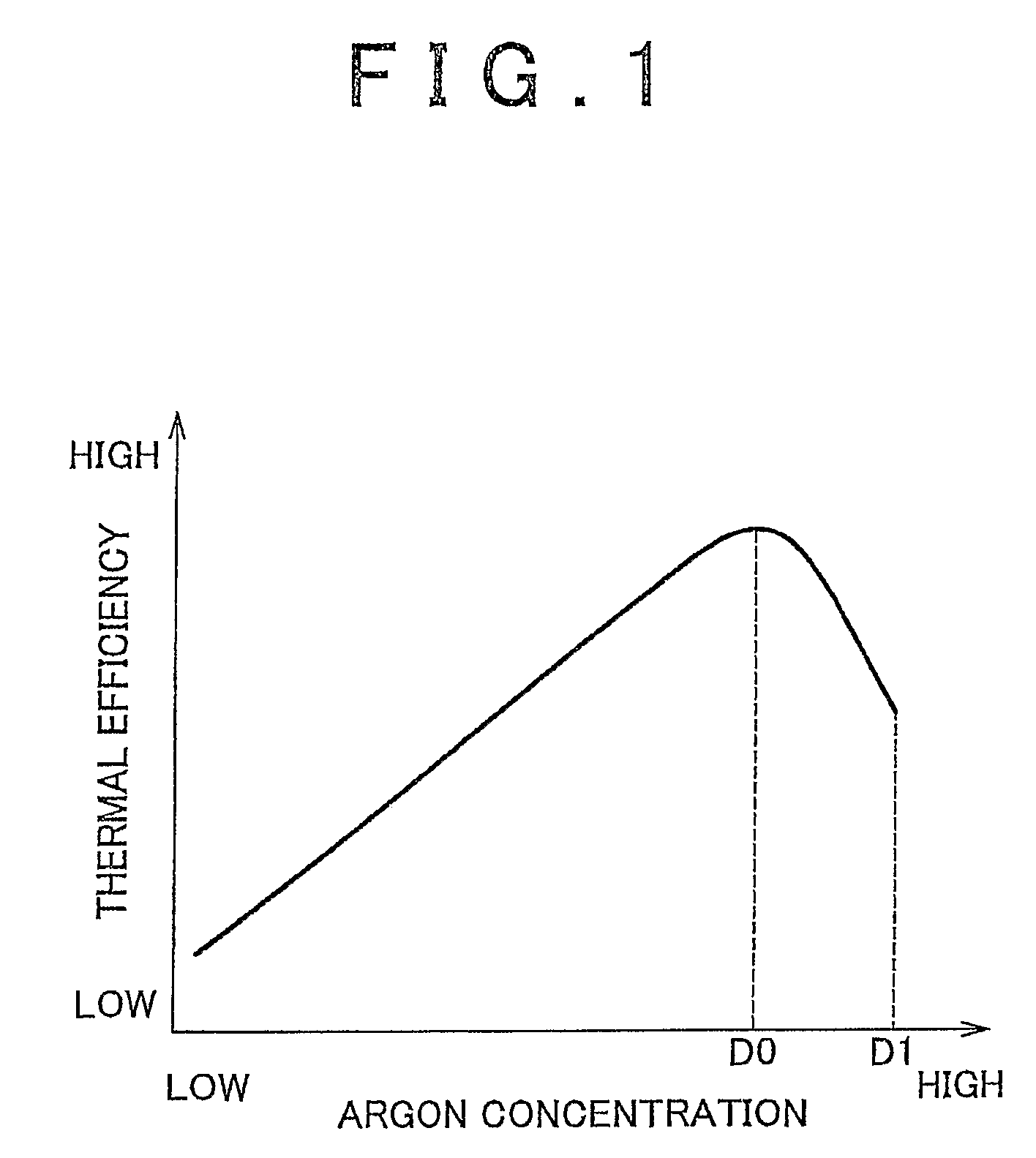

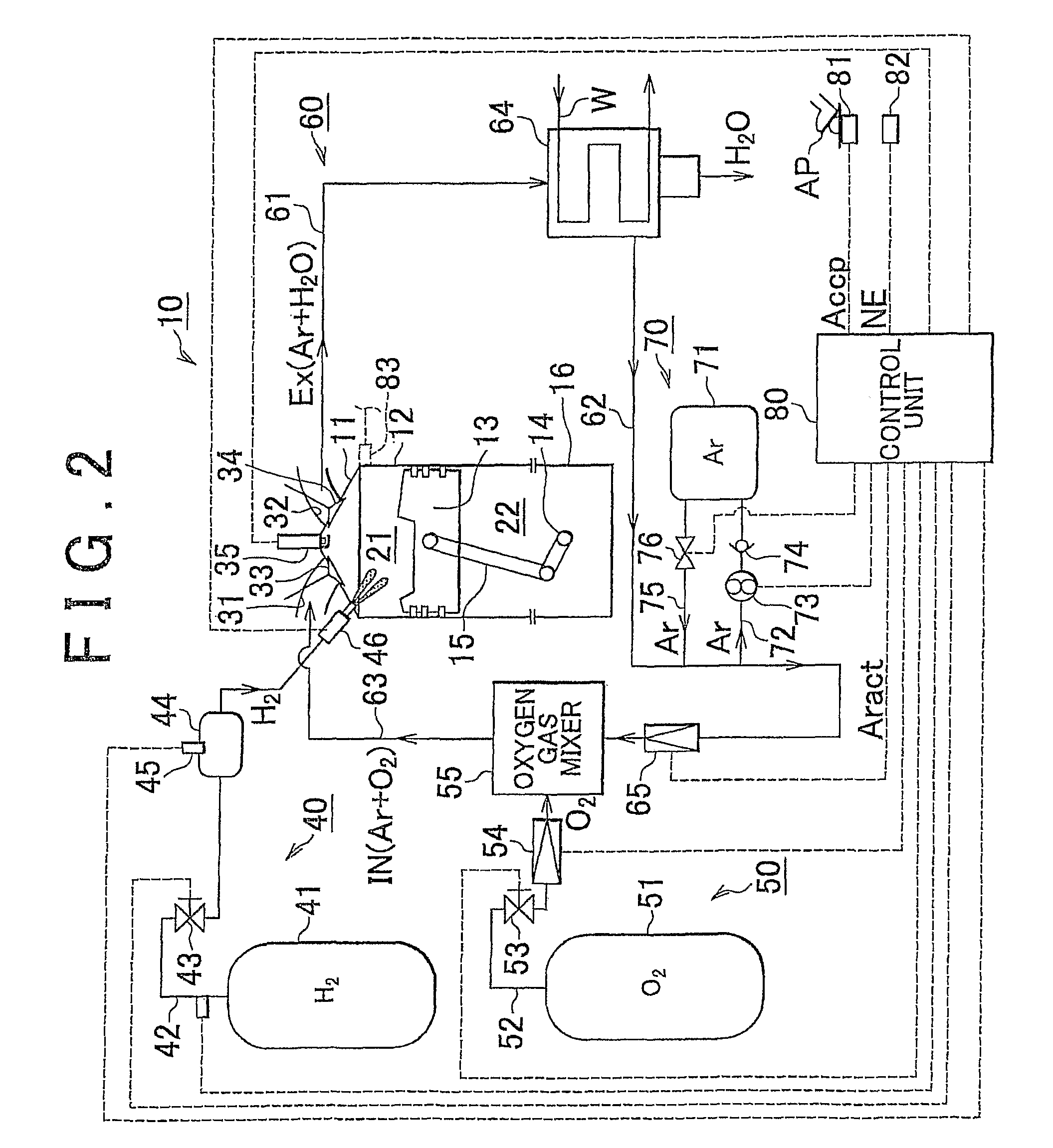

Internal combustion engine and control method thereof

InactiveUS7621260B2Improve internal efficiencyImprove the state of combustionElectrical controlInternal combustion piston enginesExternal combustion engineElectrical control

An operating gas circulation type internal combustion engine that uses argon as the operating gas, for example, and includes a hydrogen and oxygen supply portion, an argon supply amount regulating portion, and an electric control unit. The electric control unit determines the amount of hydrogen and oxygen to be supplied to a combustion chamber based on a required torque, which is the torque required of the internal combustion engine, and supplies the determined amounts of hydrogen and oxygen to the combustion chamber using the hydrogen supply portion and the oxygen supply portion. Further, the electric control unit determines an amount of operating gas to be supplied to the combustion chamber according to the required torque, and controls the argon supply amount regulating portion such that the determined amount of operating gas is supplied to the combustion chamber.

Owner:TOYOTA JIDOSHA KK

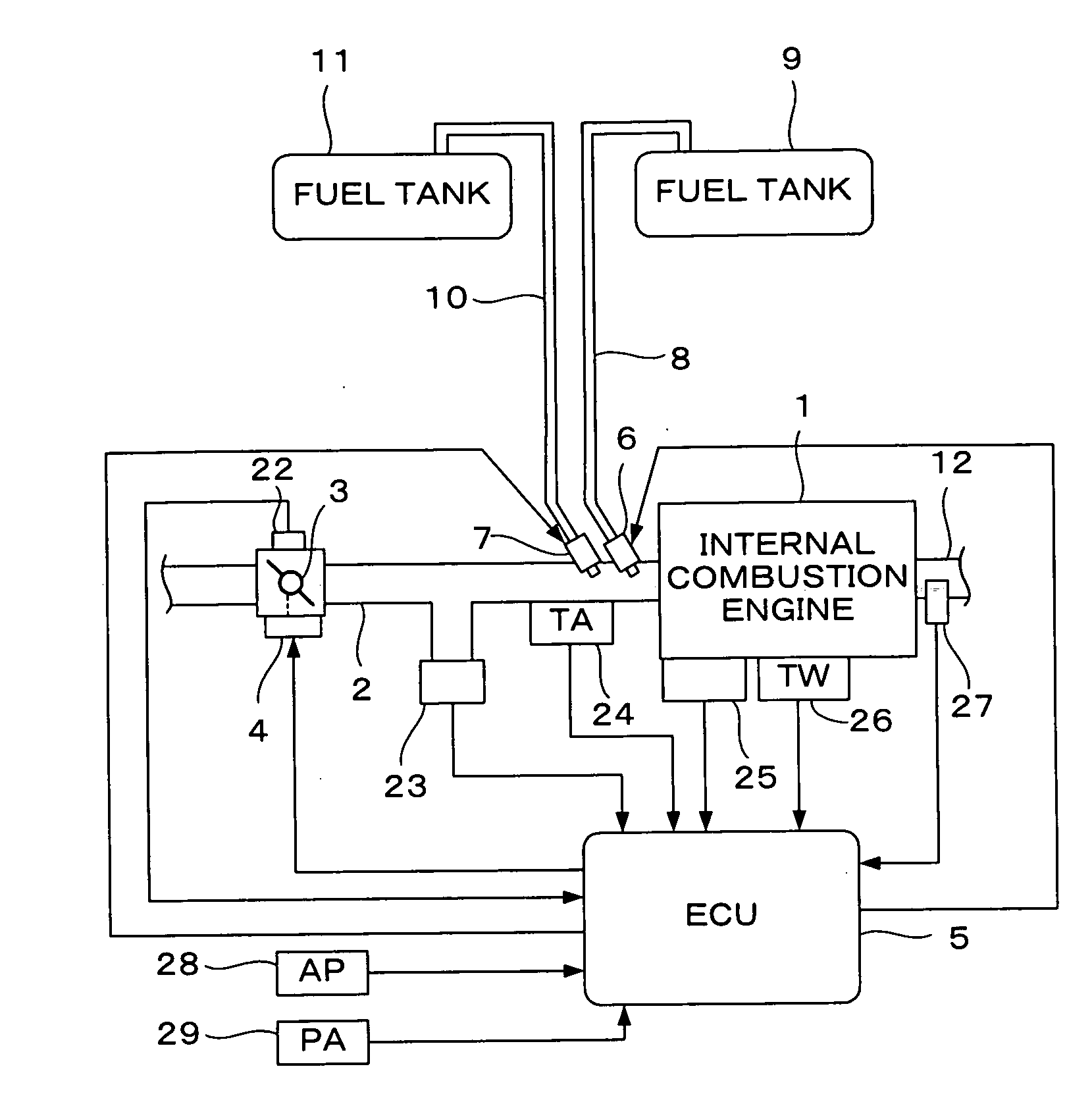

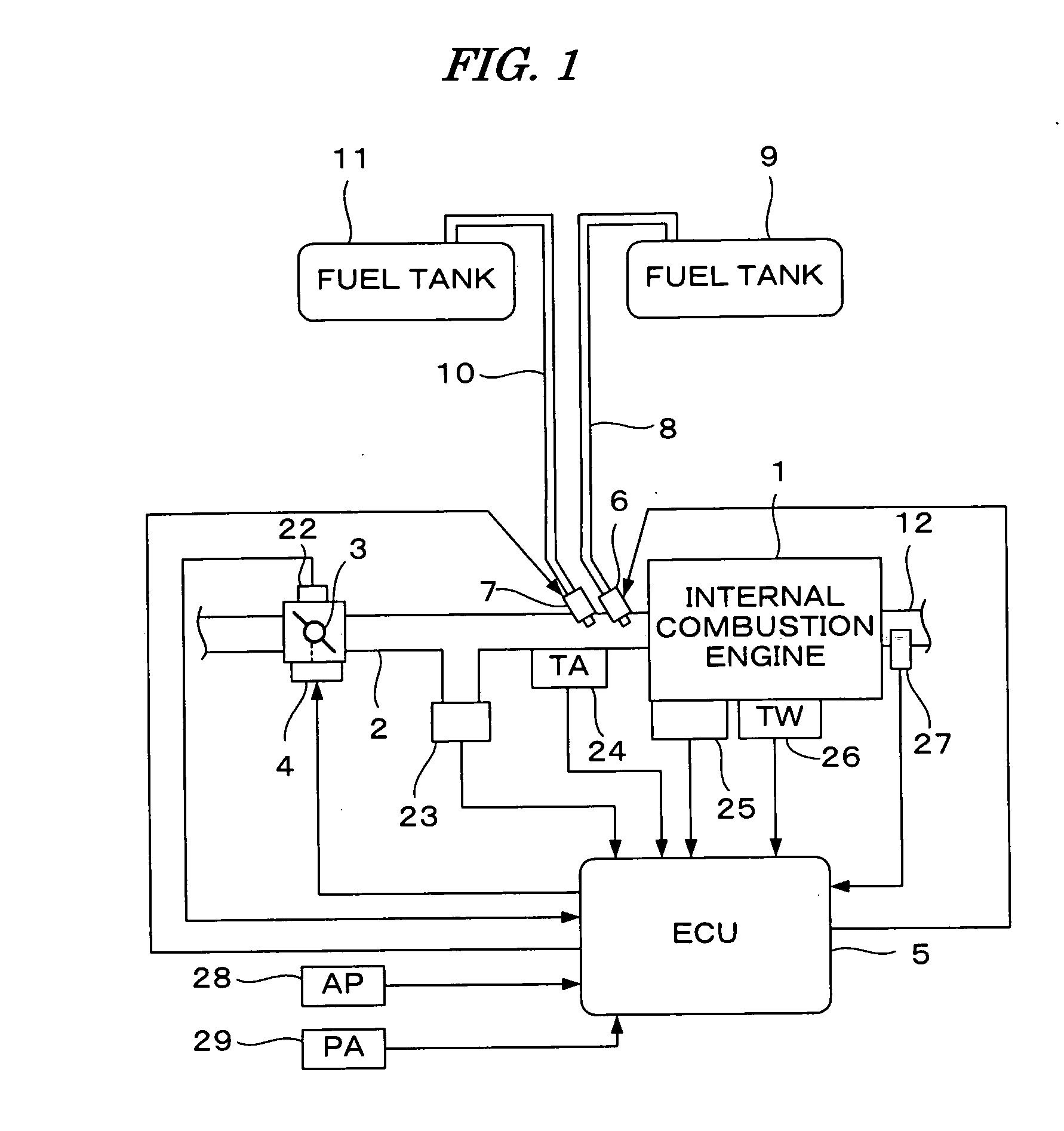

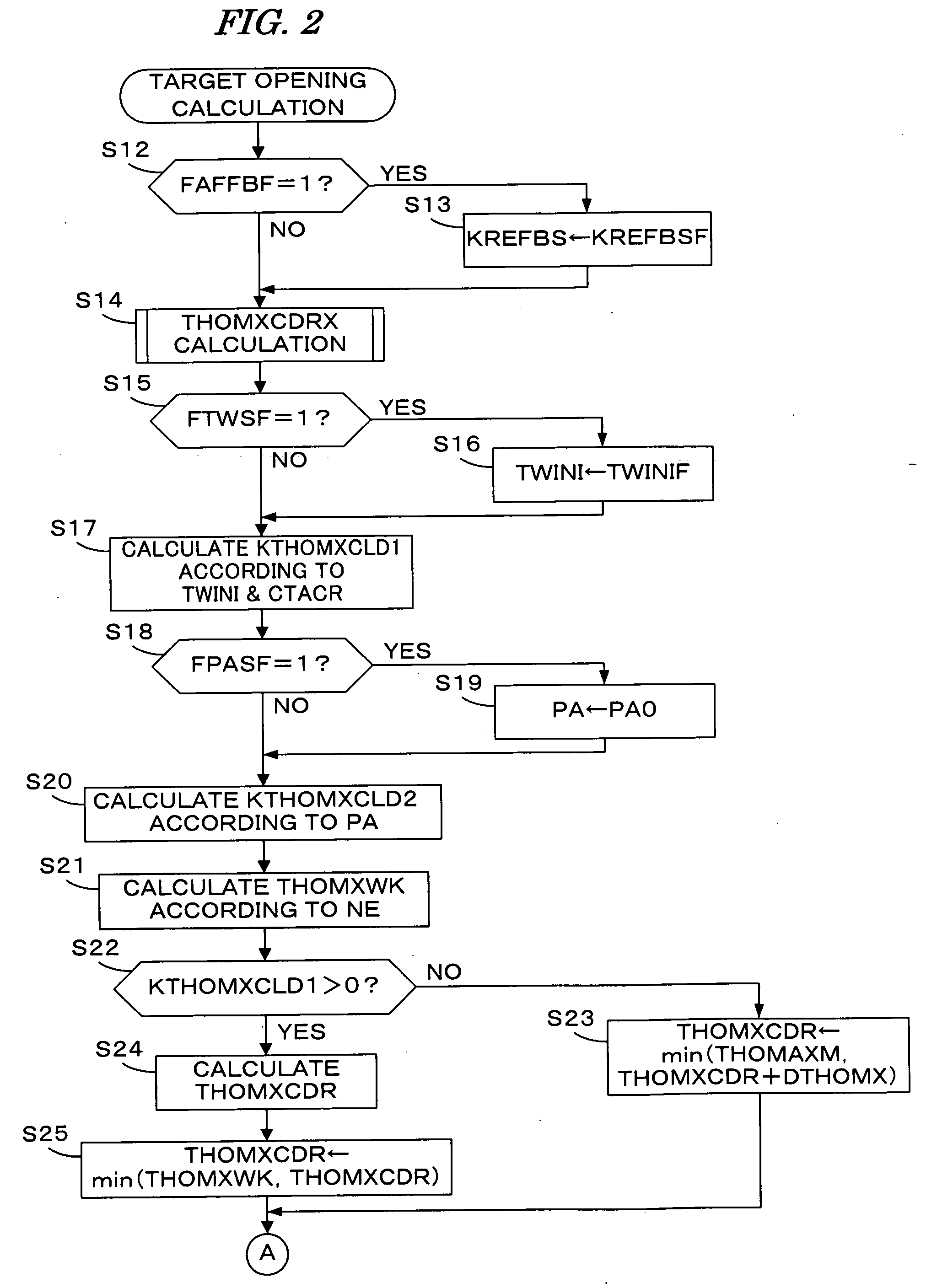

Control system for internal combustion engine

InactiveUS20090112443A1Avoid inconvenienceSuppresses deterioration of drivabilityAnalogue computers for vehiclesElectrical controlControl systemExternal combustion engine

A control system for an internal combustion engine in which fuel containing alcohol is used. In the control system, a maximum opening of a throttle valve of the engine is set, and a target opening of the throttle valve is set to a value which is equal to or less than the maximum opening. An opening of the throttle valve is controlled so as to coincide with the target opening. The maximum opening is according to a concentration parameter indicative of a concentration of alcohol in the fuel, a temperature parameter indicative of a temperature of the engine, and a number of ignitions performed after start of the engine.

Owner:HONDA MOTOR CO LTD

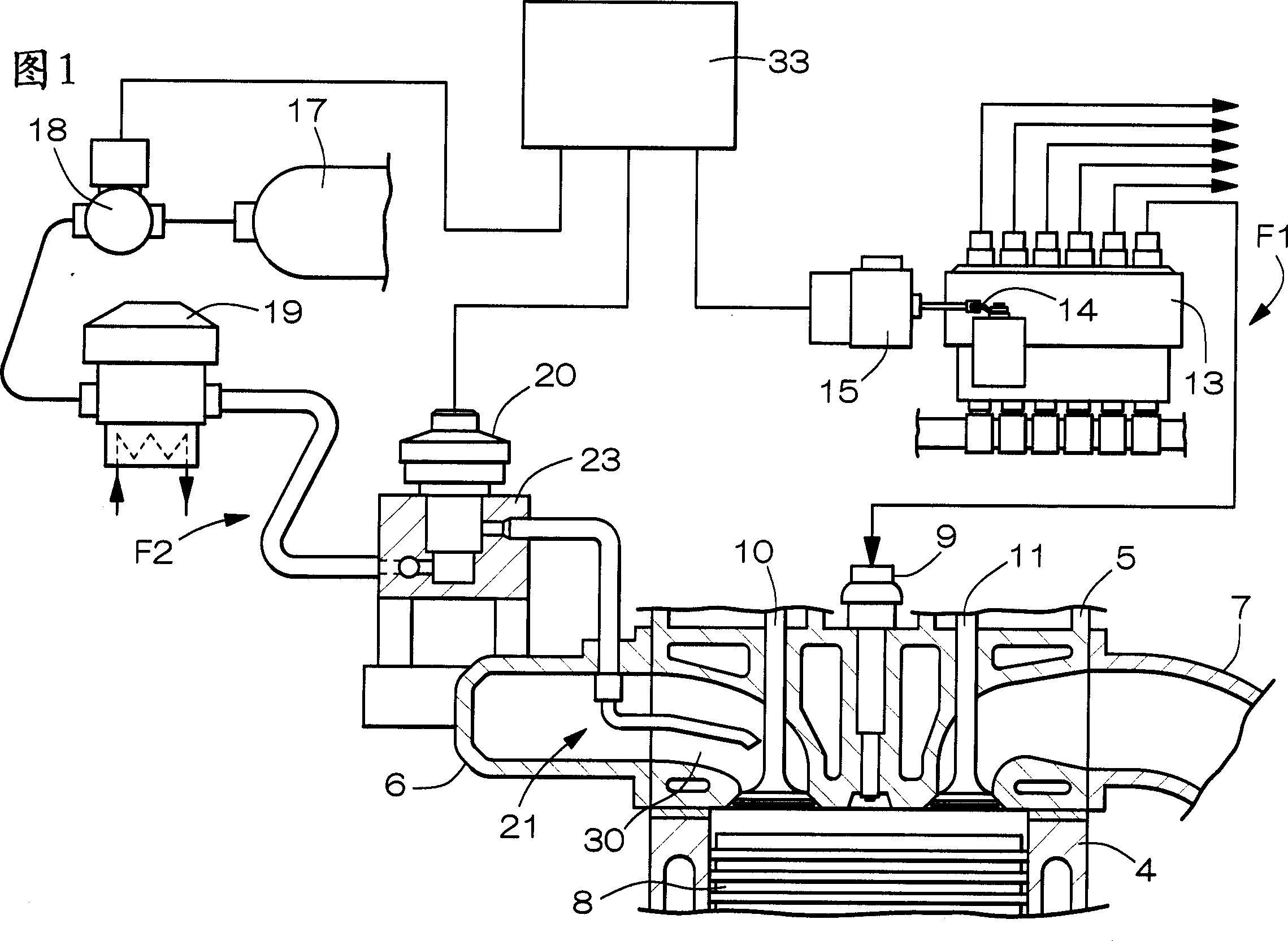

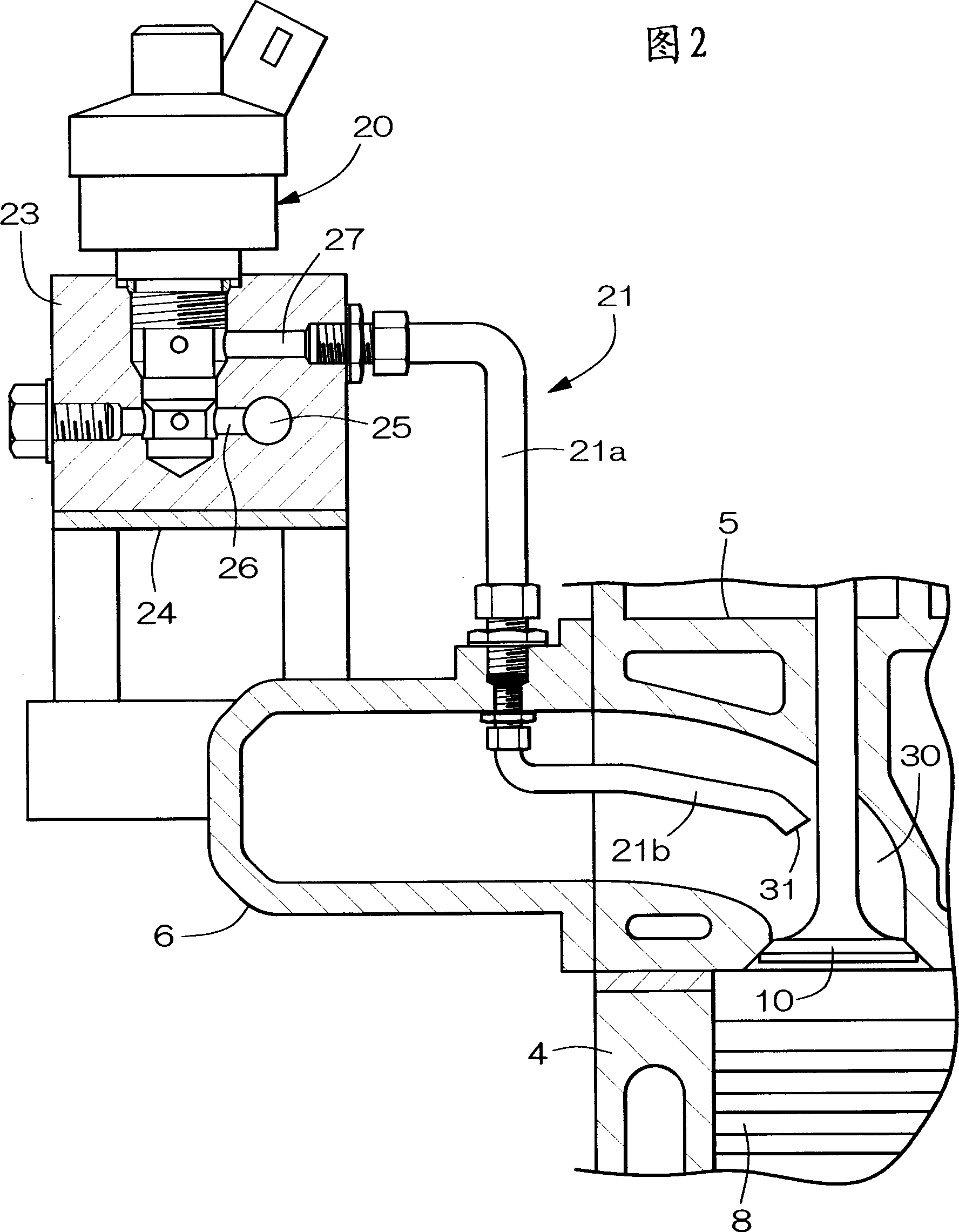

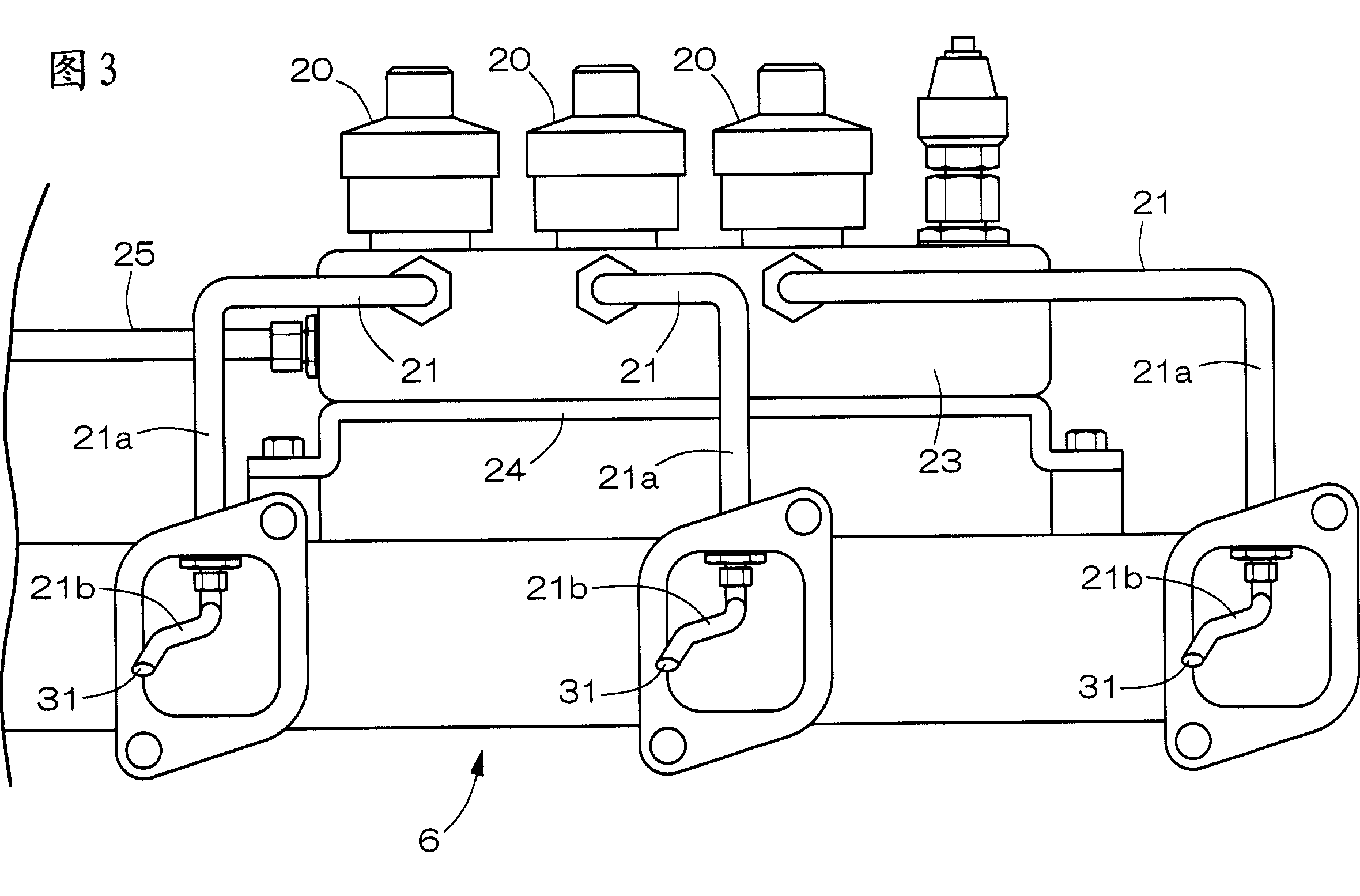

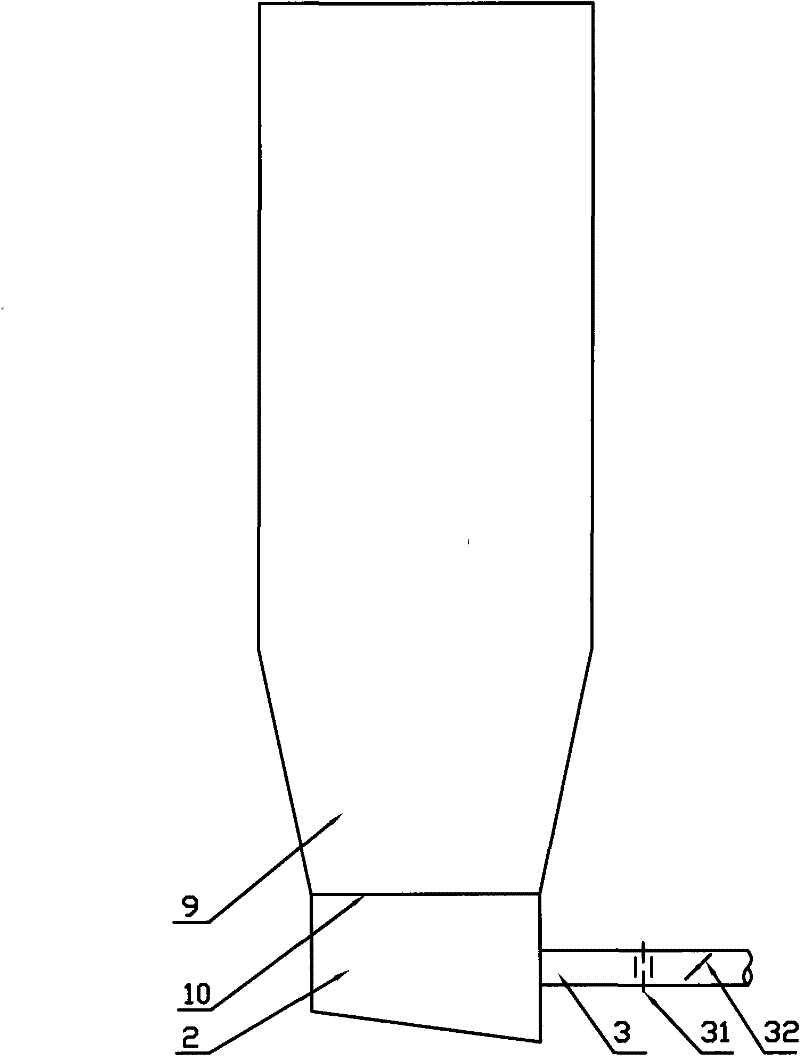

Dual-fuel internal cobustion engine using gas fuel at the same time

InactiveCN1428501APrevent outflowRealize low pollutionInternal combustion piston enginesFuel supply apparatusExhaust valveExhaust fumes

A duel fuel diesel engine combining gas fuel, which comprises a first fuel supply system F1 for supplying a liquid fuel and a second fuel supply system F2 for supplying a gas fuel. The second fuel supply system F2 consists of a gas supply source 17, a pressure controller 19 for controlling the supply pressure of the gas and a gas injector 20 for injecting and supplying the gas fuel to an intake port 30. The gas injector 20 is arranged on the outer face of the engine, with its injection passage 21 having an exit 31 facing to the intake port 30. In a second intake stroke S2 after closing an exhaust valve 11, the gas fuel is injected and supplied to the intake port 30 by the gas injector 20. This makes it possible to achieve lower exhaust gas pollution by preventing the occurrence of unburnt gas or black smoke.

Owner:NIPPON EKOSU

Control apparatus for internal combustion engine

InactiveUS7806104B2Suppress generationStable combustionElectrical controlDigital data processing detailsTransitional RegionCoolant temperature

An engine ECU executes a program including the steps of: detecting an engine speed NE, engine load, and engine coolant temperature (S100, S110, S115); when determination is made of being in an idle region (YES at S120), determining whether in a cold idle region, a transitional region, or a warm idle region (S130); injecting fuel from an intake manifold injector alone when in the cold idle region (S140); injecting fuel from the intake manifold injector and injecting fuel from an in-cylinder injector at the feed pressure when in the transitional region (S150); and injecting fuel from the in-cylinder injector at the feed pressure when in the warm idle region (S160).

Owner:TOYOTA JIDOSHA KK

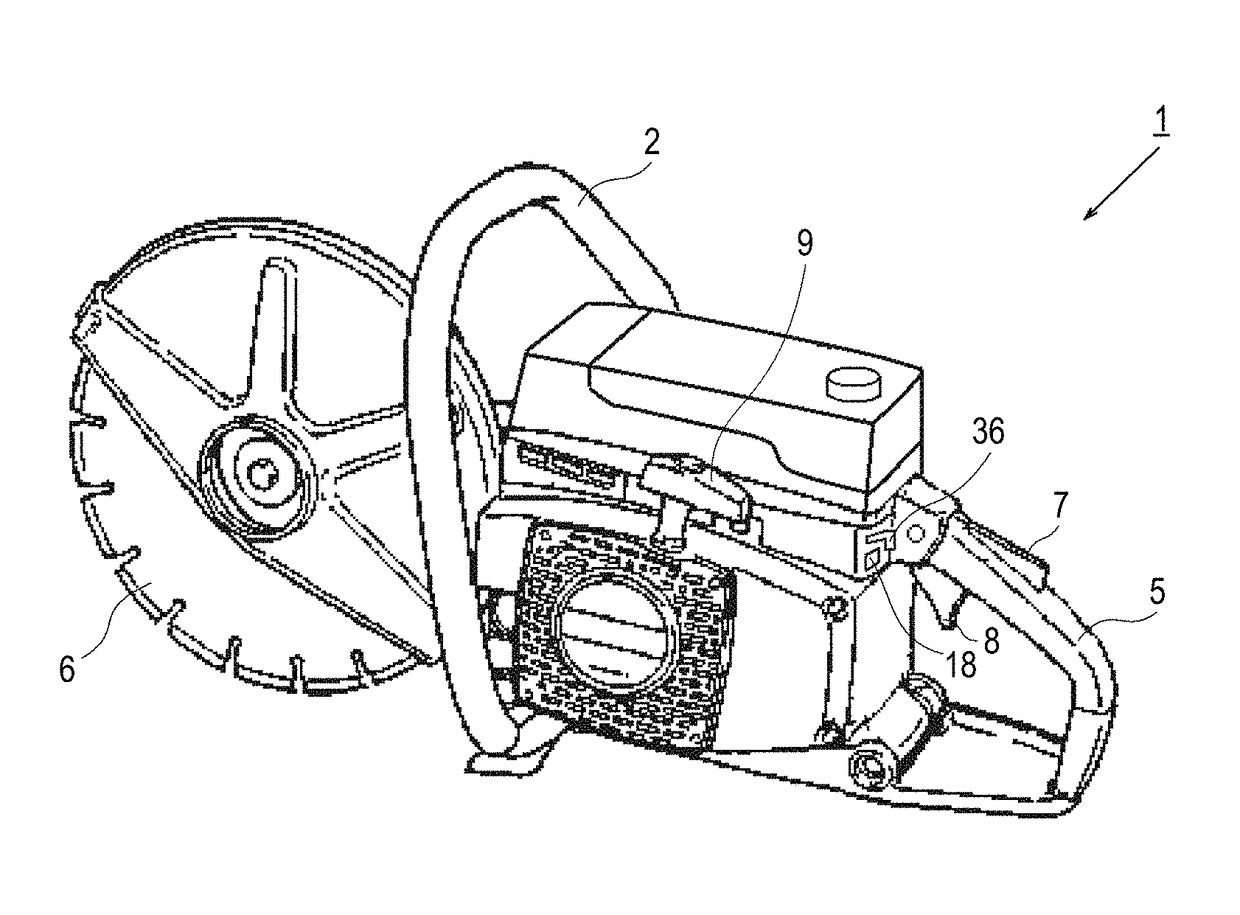

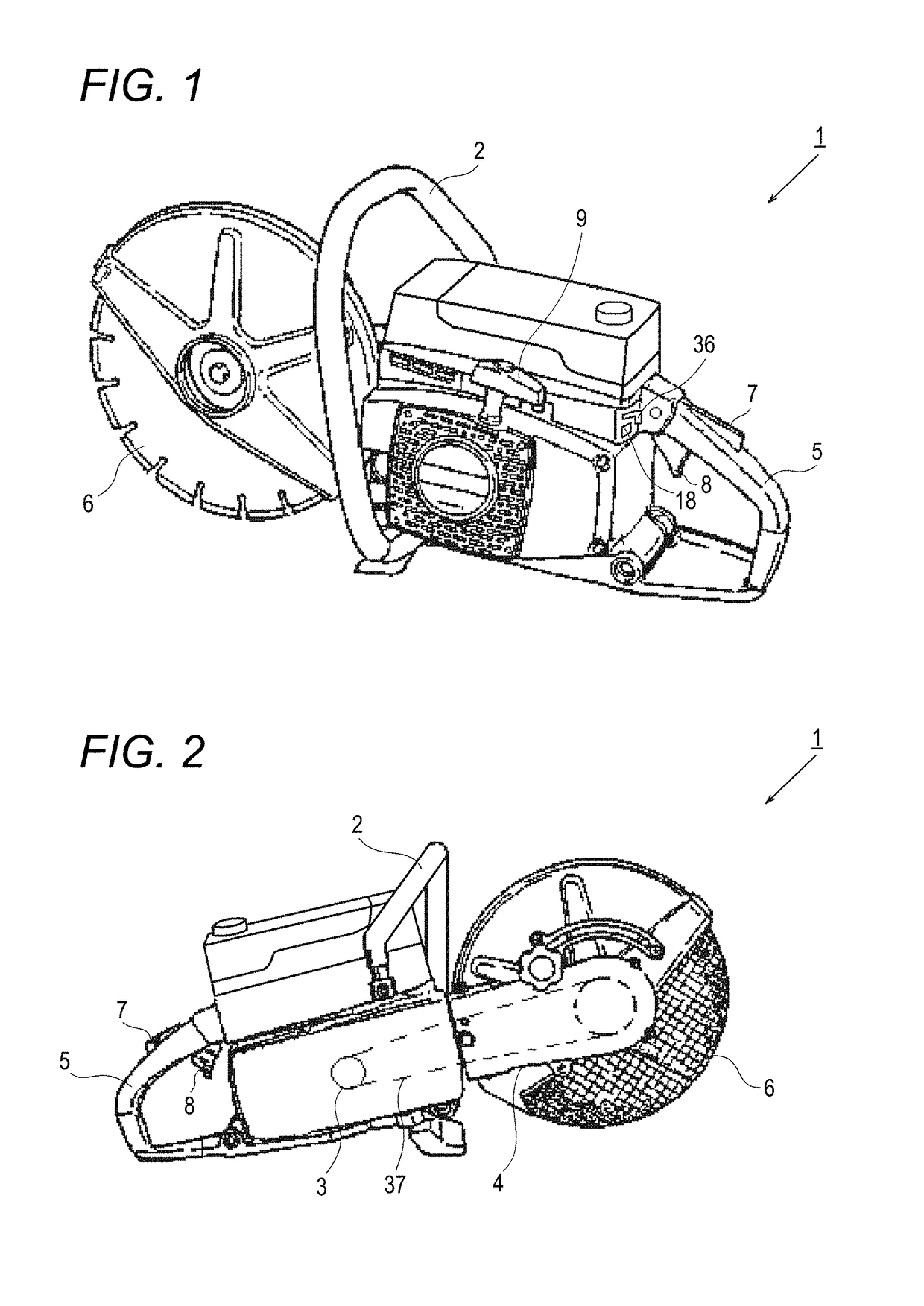

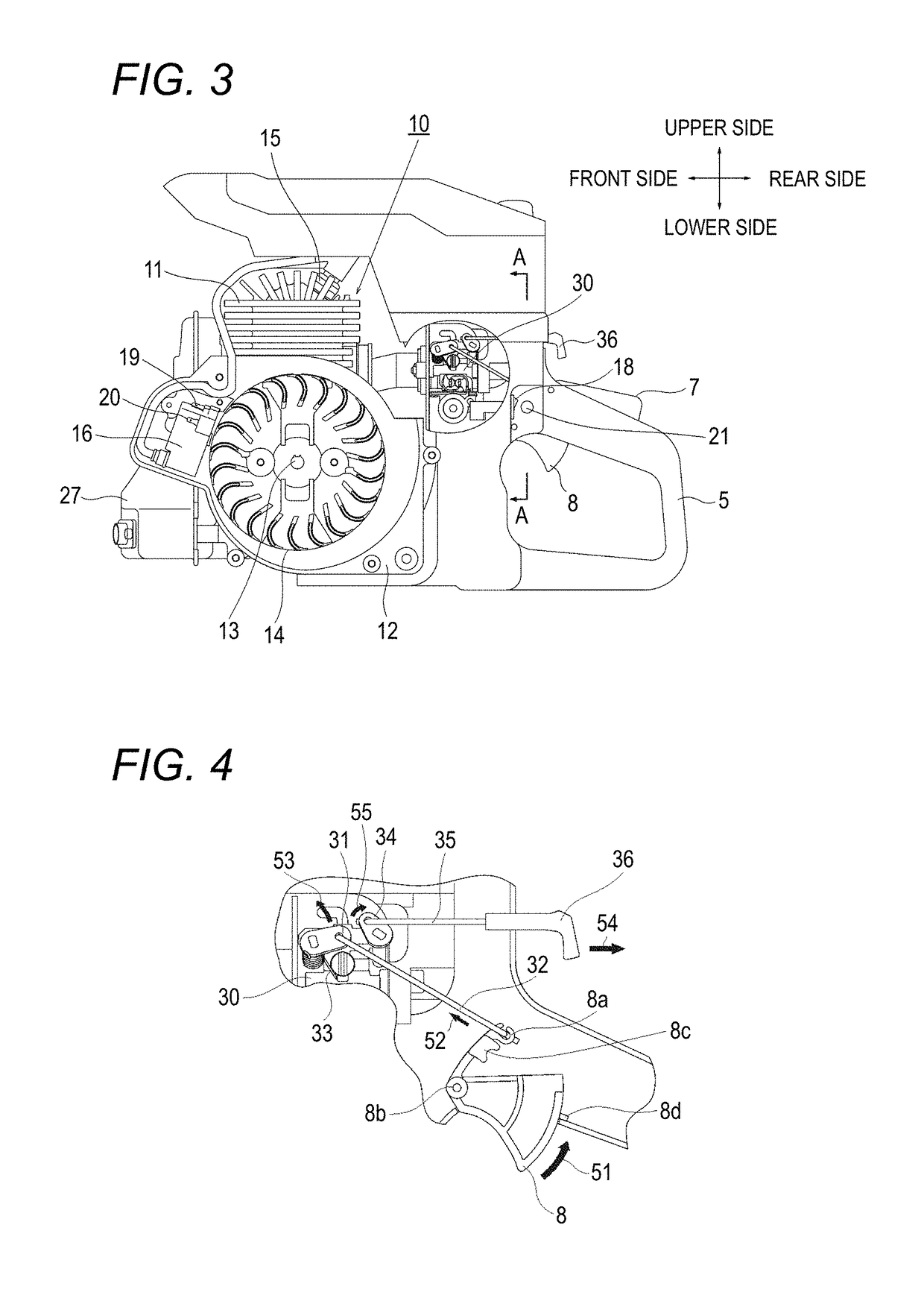

Engine and engine-operated working machine

ActiveUS9759176B2Prevent the engine from stoppingIncrease engine speedInternal combustion piston enginesMuscle operated startersEngineeringIgnition timing

Owner:KOKI HLDG CO LTD

Oil sludge-containing moulded coal

The invention relates to sludge-containing coal. China is a country with serious energy resource shortage. By calculating based on proved reserves and production capacity, the productive age limit of coal, oil and natural gas in China are 80 years, 15 years and 30 years. Recent years, the energy consumption is increased rapidly, therefore, the imbalance between supply and demand is increasingly outstanding. The composition of the sludge-containing coal comprises raw coal, sludge, coal slurry and sulfur-fixing smoke eliminating agent, the weight portion of the raw coal is 20 to 50, the weight portion of the sludge is 2 to 35, the weight portion of the coal slurry is 10 to 40, and the weight portion of the sulfur-fixing smoke eliminating agent is 3 to 8. The sludge-containing coal can be used as vicarious combustion material for coal.

Owner:于群龙 +1

System and method for controlling combustion of gas water heater or wall-hanging stove

ActiveCN105042871AExact matchImprove wind pressure resistanceAir supply regulationWater heatersImpellerCombustor

The invention discloses a combustion control system for a gas water heater or a wall-hanging stove and a control method thereof. The system comprises a flue gas channel composed of a combustor, a heat exchanger, a stepless variable speed fan and a smoke pipe which are sequentially connected, a control unit connected with the signal input end of the stepless variable speed fan and an air pressure sensor assembly for detecting pressure signals of the upstream of the stepless variable speed fan, and the signal output end of the air pressure sensor assembly is connected with the control unit. The control unit comprises a storage and a controller, the storage is used for storing the corresponding relation between the pressure signals of the upstream of the stepless variable speed fan and heating loads of the combustor, and the controller is used for controlling operation of the stepless variable speed fan according to the corresponding relation. By detecting the pressure signals of the upstream of the stepless variable speed fan, the rotating speed of the upstream of the stepless variable speed fan is further adjusted, and the combustion control system has high wind-resistant performance.

Owner:A O SMITH (CHINA) WATER HEATER CO LTD

Vehicle, method and device for controlling engine

InactiveUS8972148B2Improve the state of combustionIncrease opportunitiesHybrid vehiclesAnalogue computers for vehiclesState of chargeDynamo

A vehicle provided with a motor generator as a driving source includes a battery to supply electric power to the motor generator, an engine, and an ECU to control the vehicle in one of a CS mode and a CD mode in which opportunity for operation of the engine is limited compared to in the CS mode. The ECU controls the engine in accordance with a condition different from a condition used to control the engine in the CS mode, if the engine is started at least due to decrease in a state of charge of the battery while the vehicle is controlled in the CD mode.

Owner:TOYOTA JIDOSHA KK

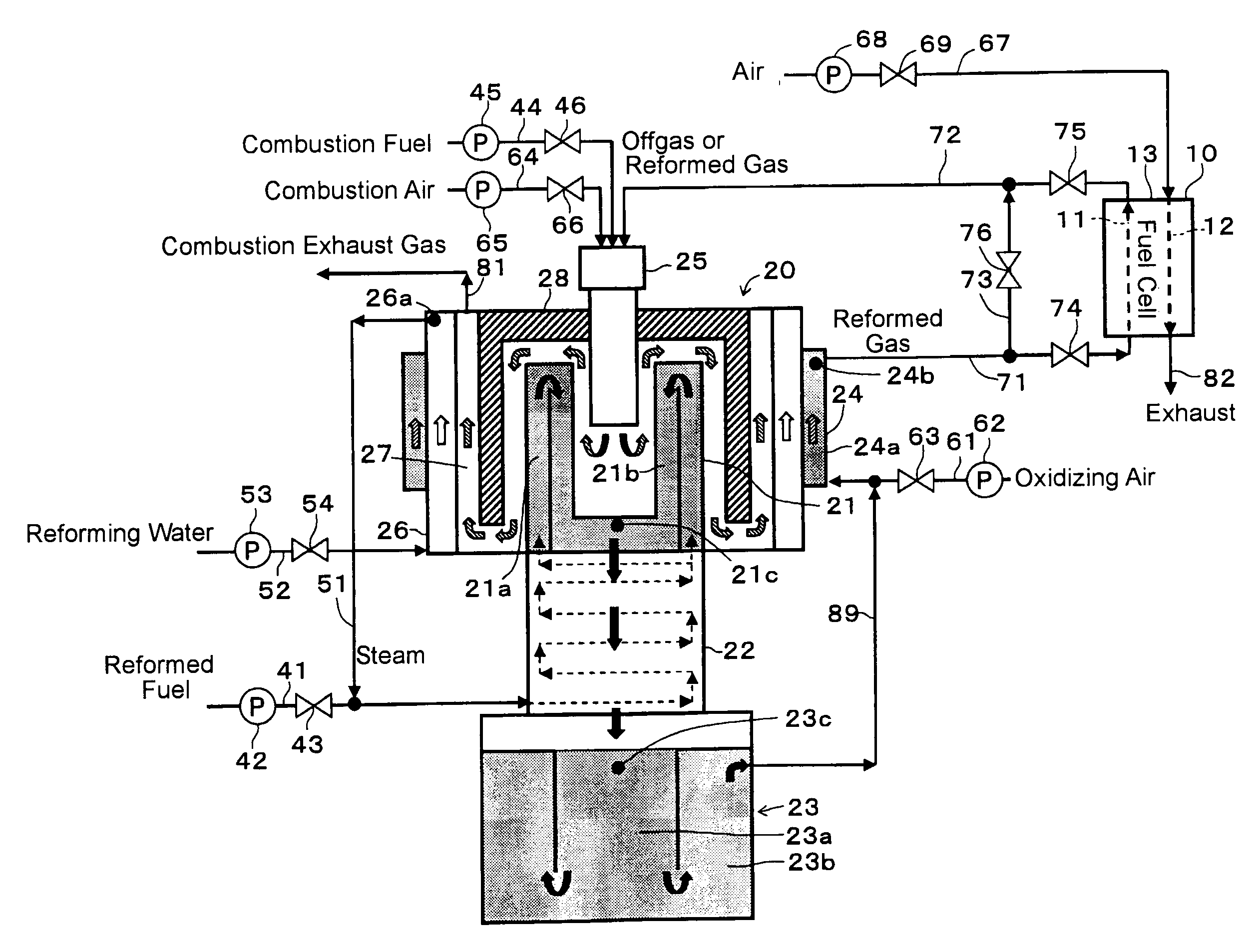

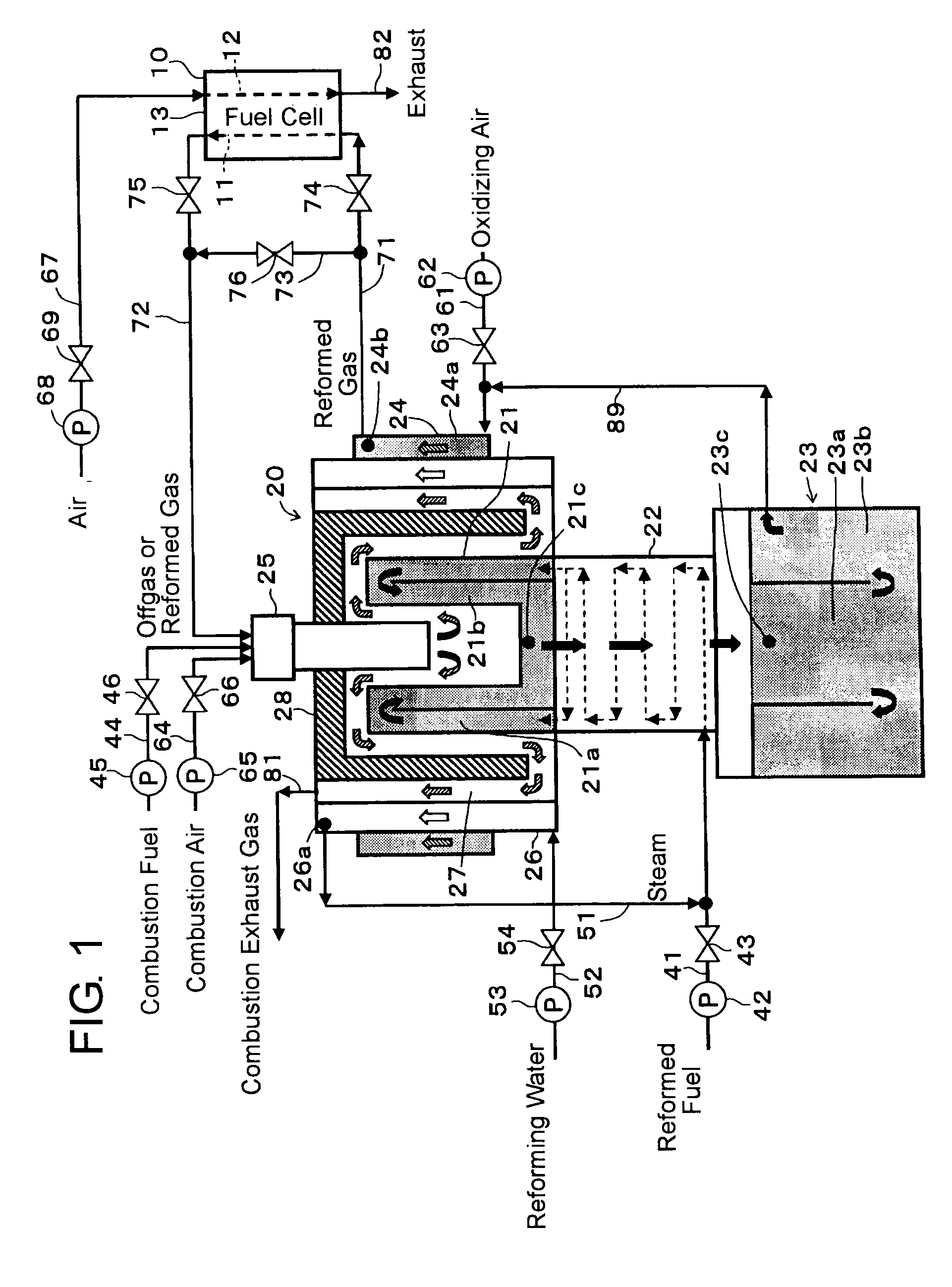

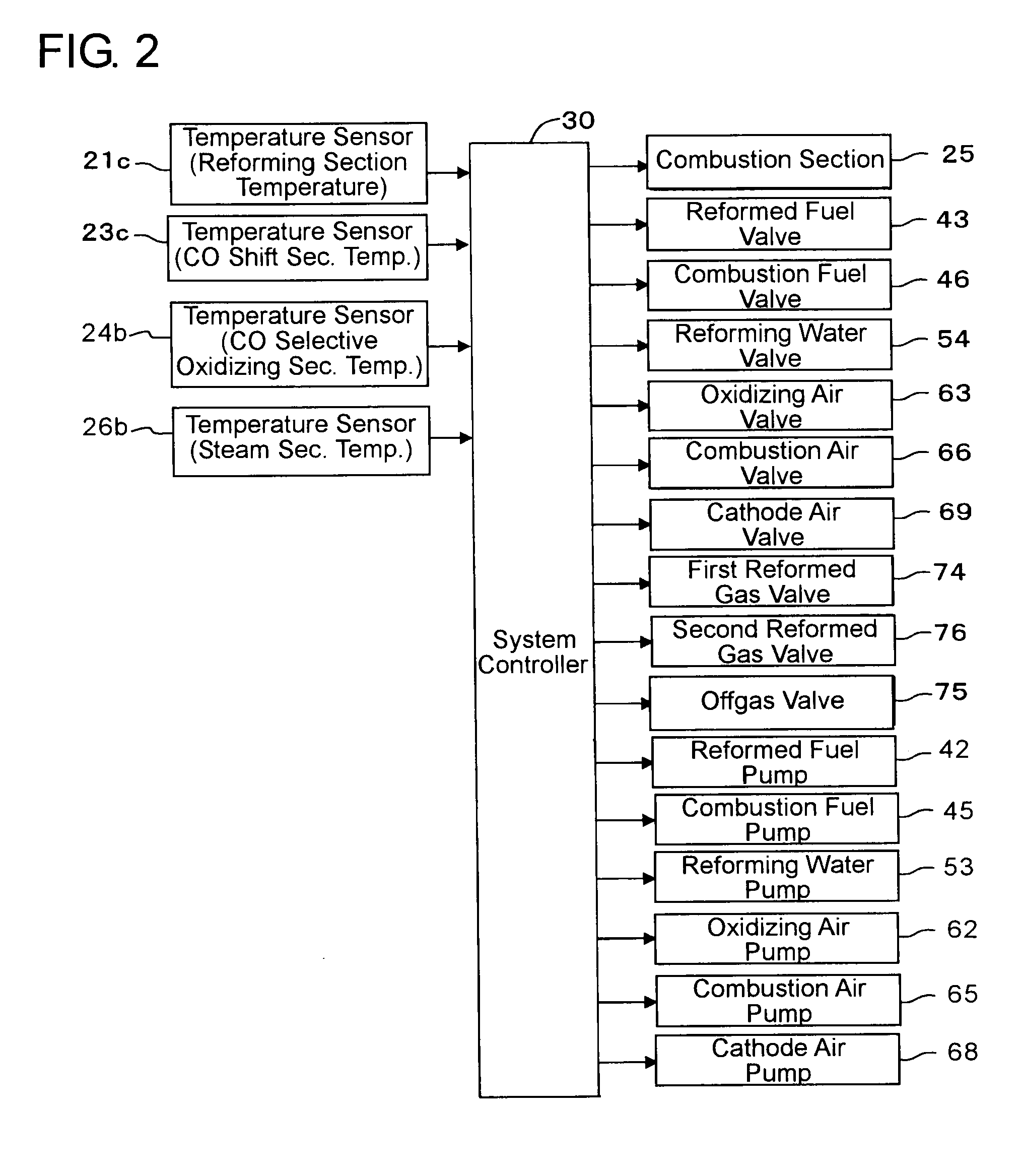

Reformer and fuel cell system incorporating the same

InactiveUS20080268309A1Low costReliable judgmentExhaust apparatusElement comparisonFuel cellsCombustible gas

A controller for a reformer includes supply quantity changing means for changing the supply quantity of at least either one of combustible gas and combustion oxidizing gas supplied to a combustion section, a combustion state change detecting means for detecting a change which is caused in the combustion state of the combustion section as a result that the change of the supply quantity is brought by the supply quantity changing means, based on a detection result from the combustion state detecting means, and combustion state checking means for checking the combustion state which arose at the combustion section before the change brought by the supply quantity changing means, based on a detection result from the combustion state change detecting means. Thus, the gone-out state of the combustion section can be reliably judged with the construction of a low cost, and the combustion state of the combustion section in the reformer of a fuel cell system can be adjusted to an optimum combustion state.

Owner:TOYOTA JIDOSHA KK

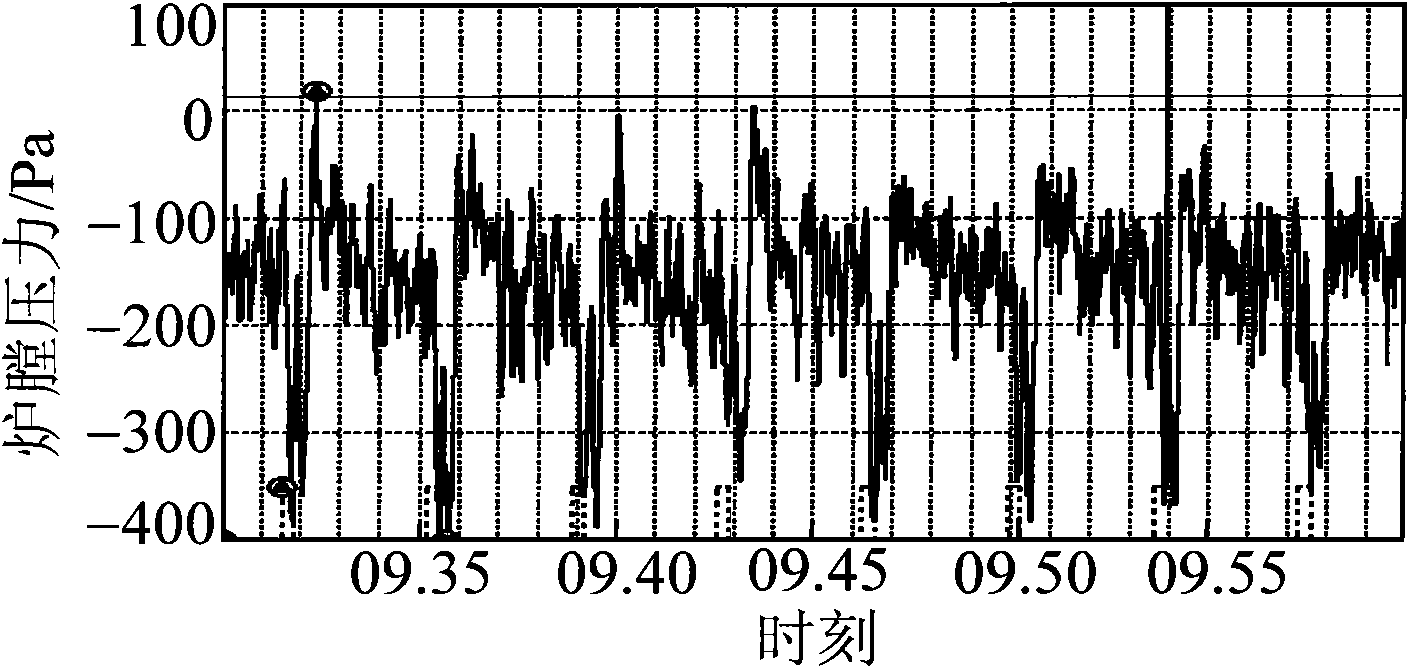

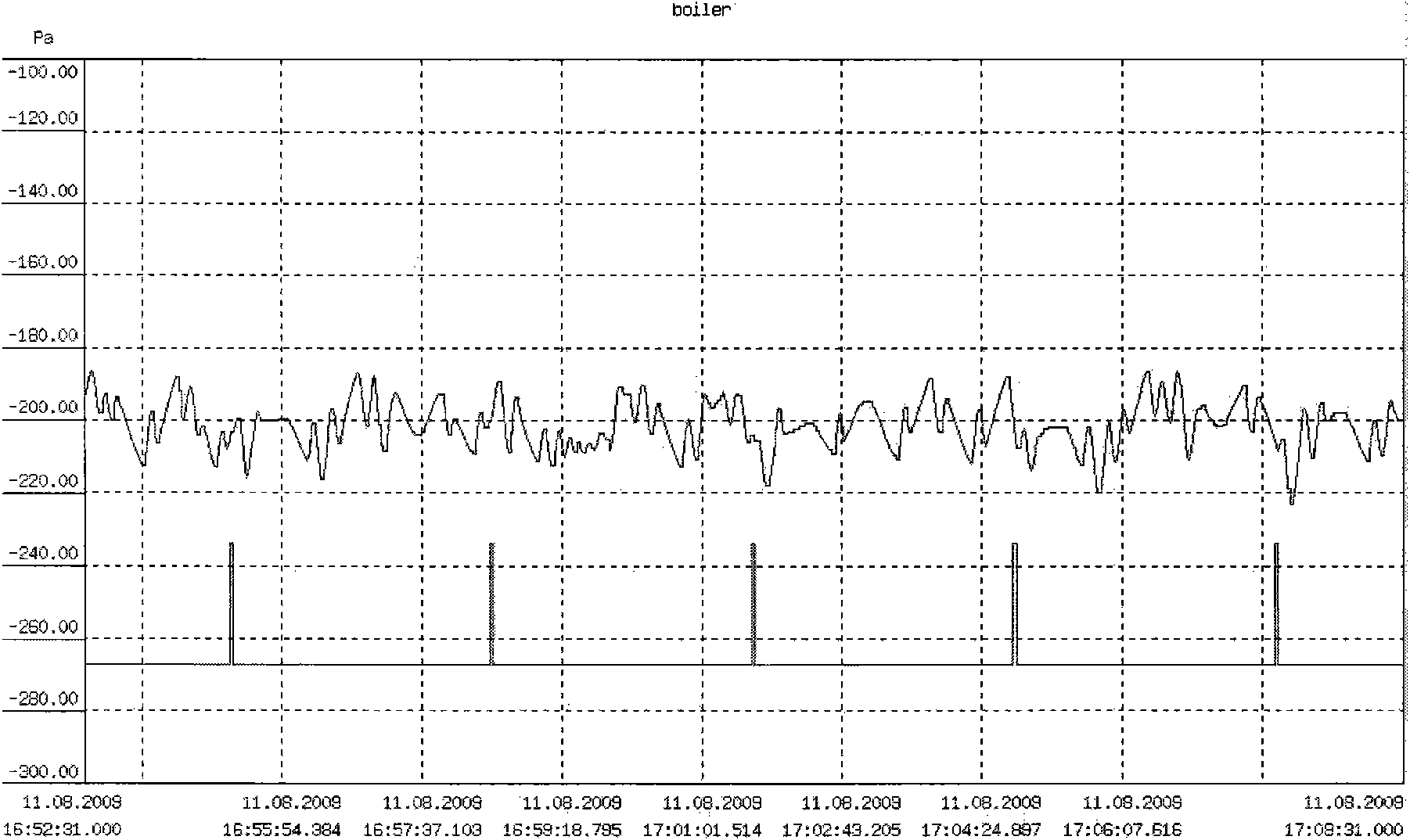

Hearth pressure control method of vibrating grate boiler

InactiveCN101660766AImprove efficiencyCombustion state is stableCombustion regulationCombustionAir volume

The invention relates to a hearth pressure control method of a vibrating grate boiler, which is an assistant adjusting method aiming at grate vibrating on the basis of an original hearth pressure control system, and can judge the hearth pressure change according to the influence of the grate vibrating on the flow of all the parts of an air and flue system, reduce grate air flow in due time and increase secondary air flow through advanced adjustment of all the executing mechanisms of the air and flue system, and provide guarantee for the safe combustion of the fuel while realizing the stable control of the hearth pressure. The method well solves the problems of raising, oscillating and the like of the hearth pressure along with the grate vibrating, improves the efficiency of the control system, improves the control effect, and is beneficial to the stabilization of the boiler burning state, and the improvement of the economical and safe operation level of the boiler.

Owner:CHINA ELECTRIC POWER RES INST +1

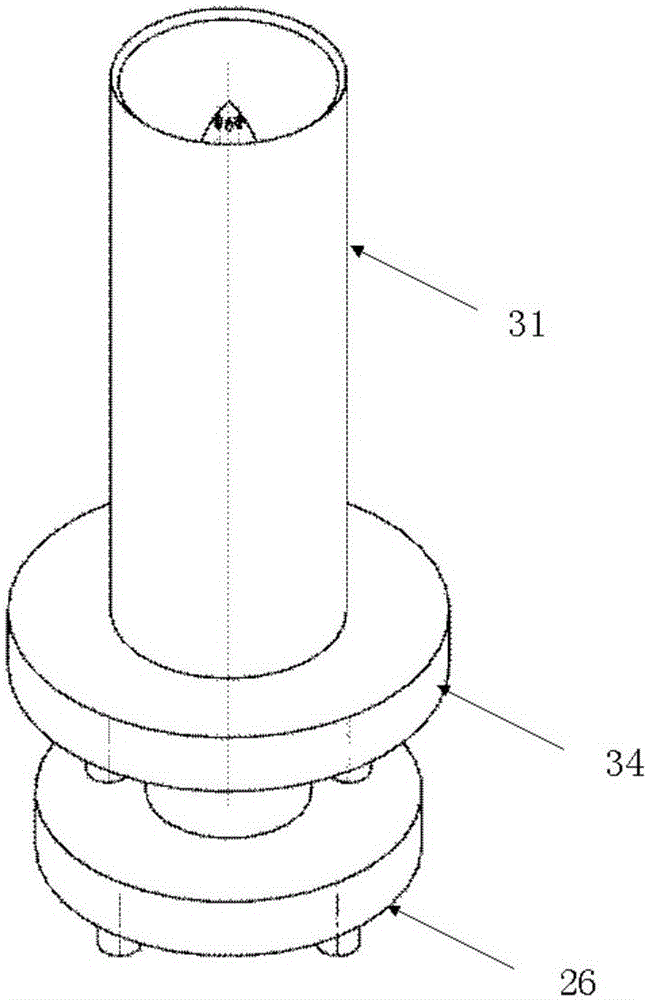

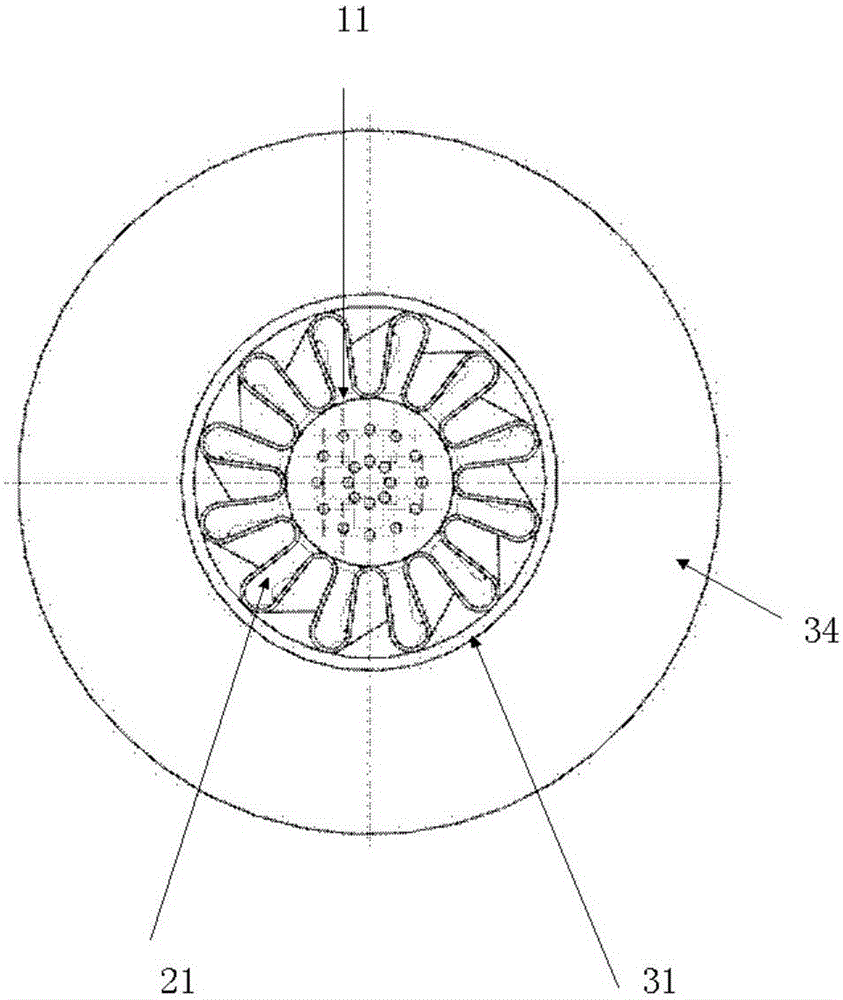

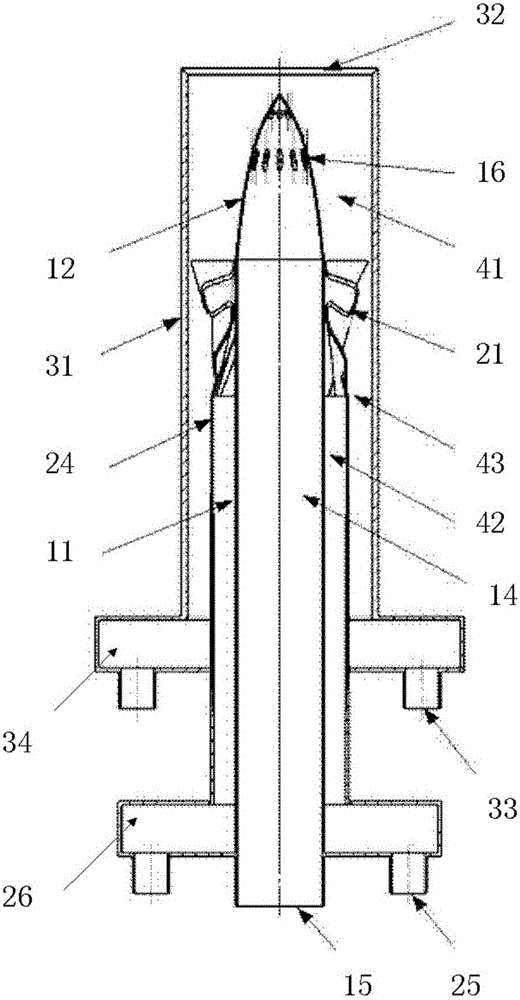

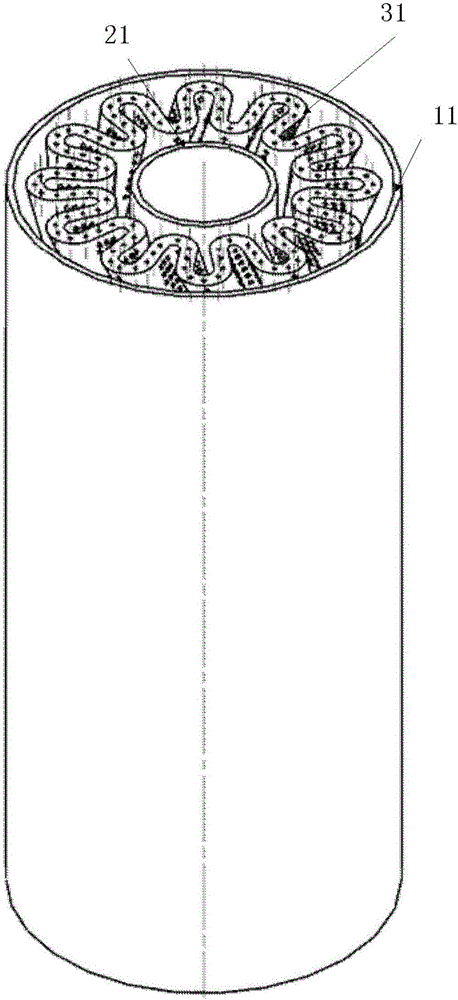

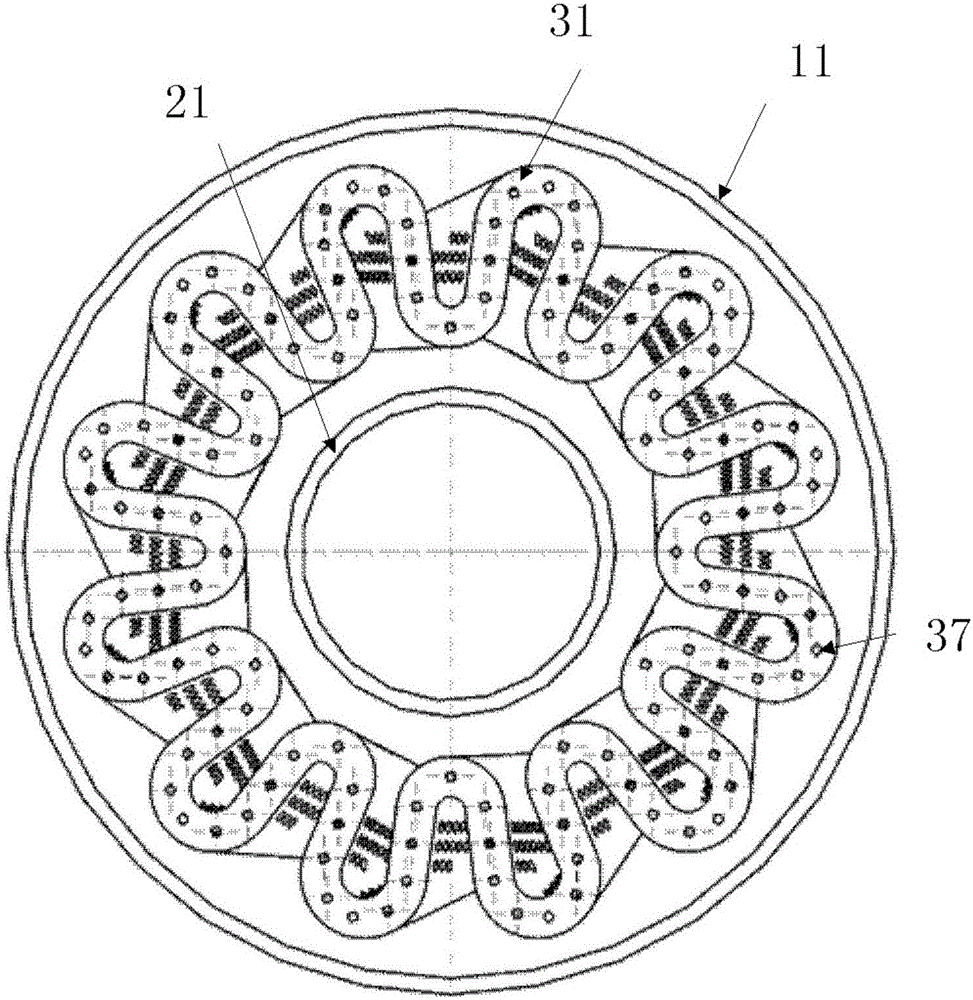

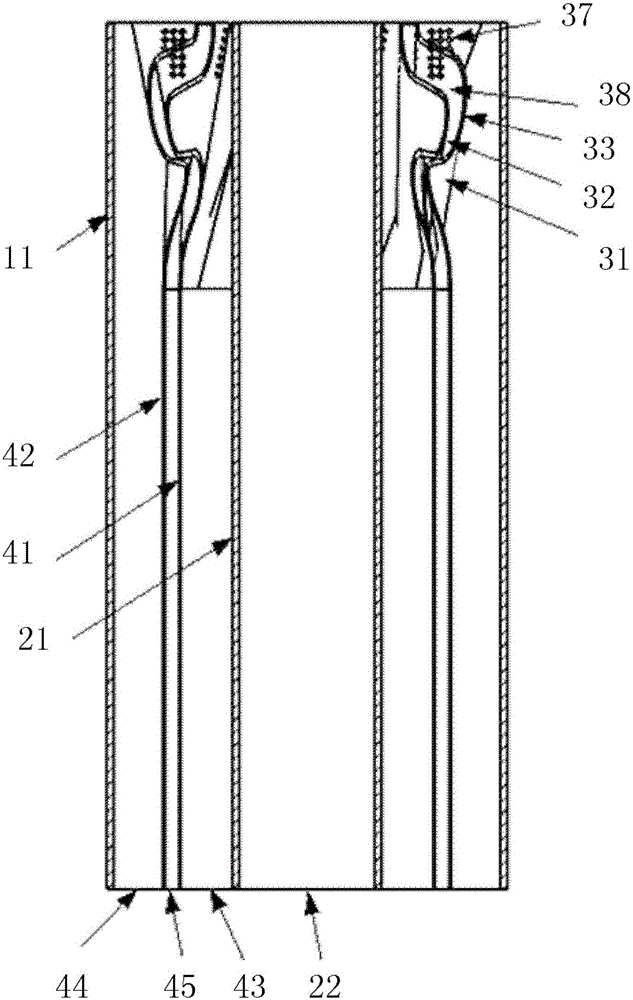

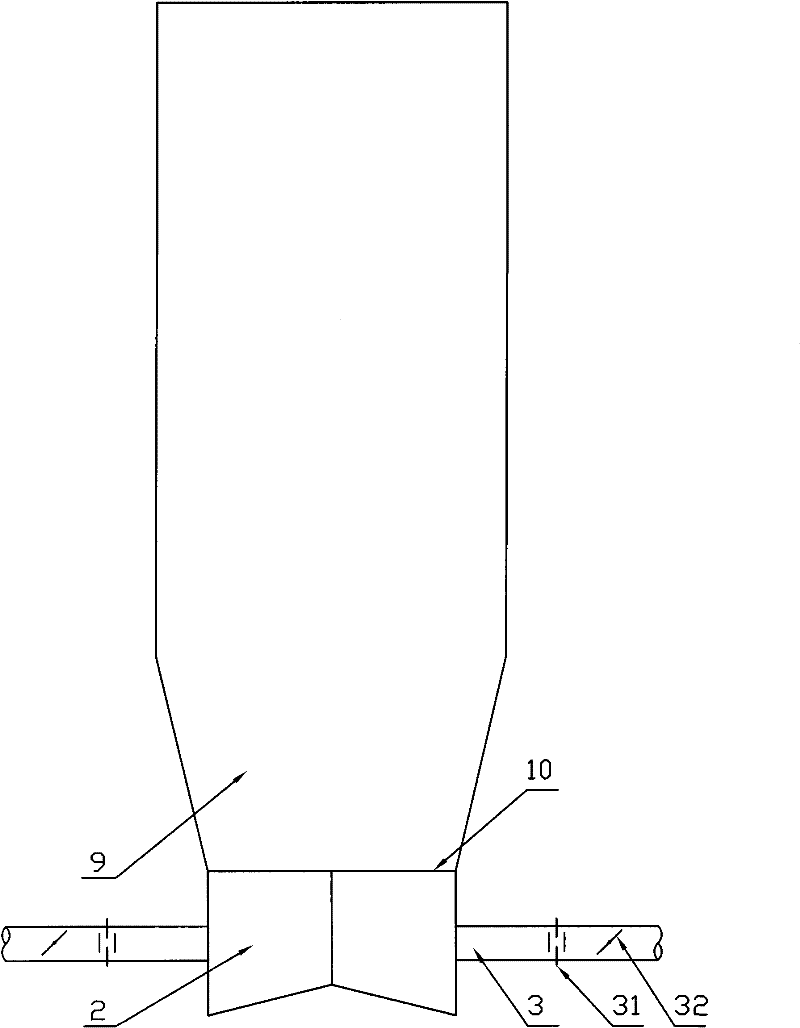

Nozzle for premixed combustion, nozzle array and combustor

ActiveCN105757716AReduce the impactIncrease tempering marginContinuous combustion chamberCombustorFlameout

The invention provides a nozzle for premixed combustion.A dilution zone is formed among the fluid outlet end of an inner-layer gas inflow structure, an outer-layer cylinder of an outer-layer gas inflow structure and the top ends of M layers of middle gas inflow structures, the influence of tempering on the nozzle and a combustor is lowered, and the tempering margin is increased.Oblique flow channels are formed between two adjacent wave rotational structures, between the corresponding wave rotational structure and an inner-layer cylinder and between the corresponding wave rotational structure and the outer-layer cylinder, combustion efficiency is improved, emissions of pollutants are reduced, flameout and flame pulsation are avoided, and the stability of combustion is improved.A drainage channel, an inner-side passageway and an outer-side passageway are formed by a supporting cylinder, the inner-layer cylinder and the outer-layer cylinder, and the stability, completeness and efficiency of combustion are further improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Atomizing nozzle, nozzle array and combustor

ActiveCN105737200AEmission reductionImprove the state of combustionContinuous combustion chamberCycloneCombustor

The invention provides an atomizing nozzle, a nozzle array and a combustor. Fuel is atomized through an atomizing wave cyclone and is fully mixed with air, the combustion state is improved, the combustion stability is improved, the stable operation range is enlarged, the combustion efficiency is improved, and the effect of reducing pollutant emission is achieved. Due to an oblique flow channel, a low-speed area is generated near a center shaft of an outlet of the nozzle, the flame combustion rate and the rate of a reaction fluid flow field are balanced, and the phenomena of flameout and flame pulsation are avoided. Due to the adoption of a supporting cylinder, the fuel and air flowing speed can be more stable, the flow field is more stable, and the stability, completeness and efficiency of combustion can be further improved. The atomizing nozzle is switched between a diffusion combustion mode and a premixed combustion mode according to combustion conditions so as to be suitable for various working conditions and various kinds of fuel, and the combustion performance is greatly improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Primary Air Distribution Method for Circulating Fluidized Bed Boiler

InactiveCN102278744AUniform fluidizationEasy to fluidizeFluidized bed combustionApparatus for fluidised bed combustionAir preheaterFluidized bed

The invention discloses a method for distributing primary air of a circulating fluidized bed boiler, and relates to the technology of a circulating fluidized bed boiler. There is an air chamber at the bottom, and the air chambers are not connected to each other; each air chamber is connected to the air preheater of the boiler through an air pipe; each air pipe is equipped with an air flow measuring device and an adjustment device. device; when the boiler is running, adjust the air flow regulating device to control the primary air volume flowing into each air chamber. The method of the invention can improve the uniformity of the primary air distribution of the circulating fluidized bed boiler, especially the large capacity circulating fluidized bed boiler.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Hydraulic work machine

ActiveUS9816252B2Improve the state of combustionPrevent the operating point from moving tooElectric machinesGas pressure propulsion mountingTransient stateOperating point

This invention is a hydraulic work machine having an electric assist motor coupled to an engine and a hydraulic pump, in the hydraulic work machine of which, a rotational speed and torque of the engine are controlled so that an operating point of the engine moves along a predetermined route for yielding a combustion state of the engine under a transient state that the engine changes in speed and torque. A target speed and torque of the engine 7 are set so that the rotational speed and torque of the engine 7 will change along a predetermined route F in a running region of the engine, respective rates of change of the target rotational speed and torque of the engine 7 are limited, and the engine 7 is controlled to yield the target engine speed. In addition, torque of the assist motor 10 is controlled to yield the target torque of the engine.

Owner:NIHON KENKI CO LTD

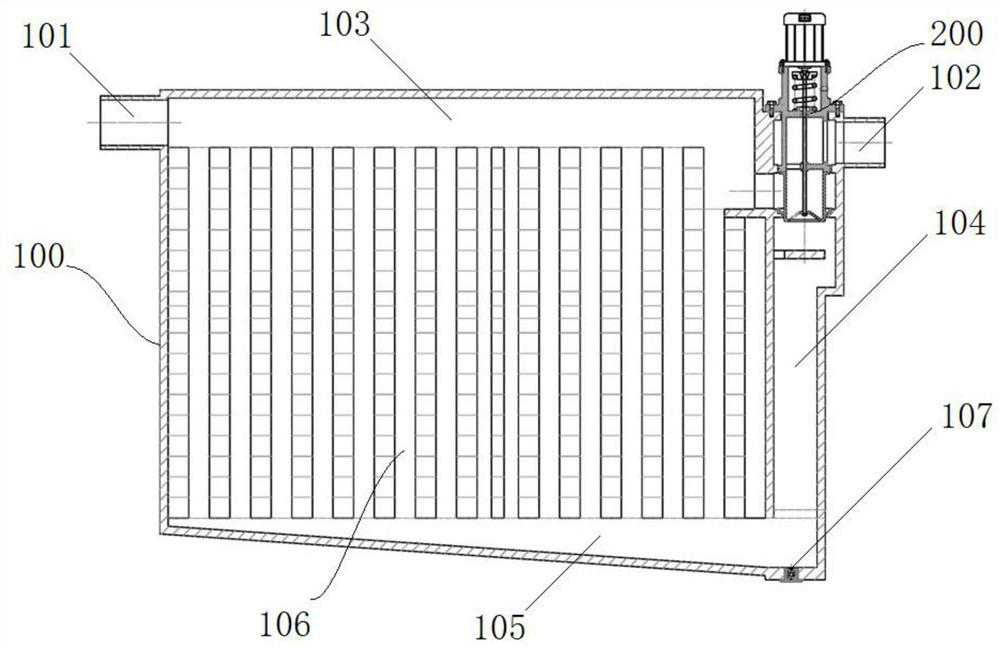

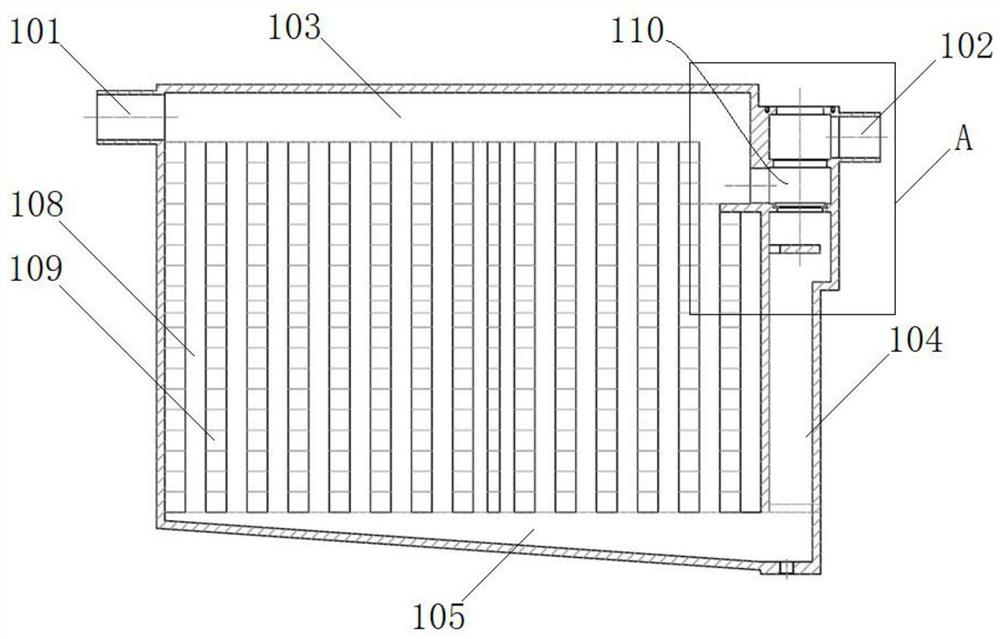

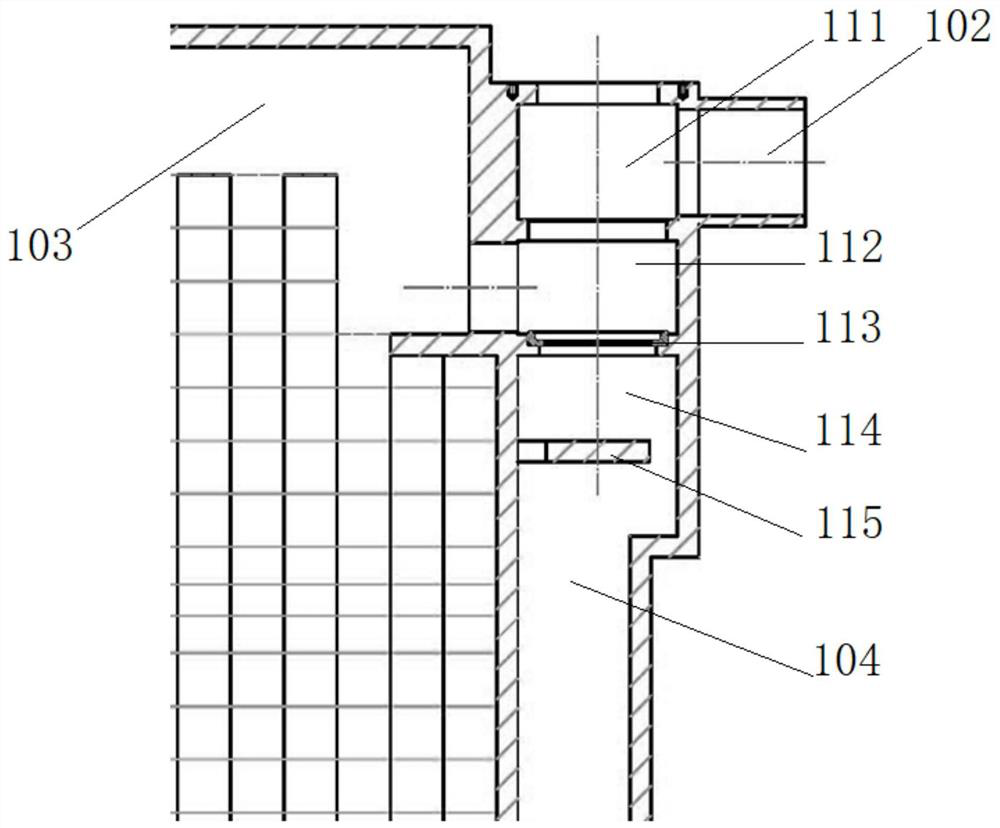

Cooling-temperature-controllable-type engine intercooler assembly

ActiveCN111810288AAdjustable temperatureImprove combustion thermal efficiencyInternal combustion piston enginesThermodynamicsGas passing

The invention relates to a cooling-temperature-controllable-type engine intercooler assembly, and belongs to the technical field of supercharged engine intercoolers. The cooling-temperature-controllable-type engine intercooler assembly comprises an intercooler, a front gas channel, a rear gas channel and a temperature adjusting valve; the intercooler is provided with a gas inlet hole and a gas outlet hole; the front gas channel is connected between the gas inlet hole and the gas outlet hole and used for circulating gas not passing through the interior of a cooling device; the rear gas channelis connected between the gas inlet hole and the gas outlet hole and used for circulating gas passing through the interior of the cooling device; and the temperature adjusting valve adjusts the gas temperature in the gas outlet hole by adjusting the opening degree of a gas outlet of the front gas channel and / or the rear gas channel. The interior of the intercooler is arranged into a cooling and non-cooling double-gas-channel form, and the temperature adjusting valve is arranged at the common outlet of the front gas channel and the rear gas channel; the temperature adjusting valve can control the mixing ratio of the gas in the front gas channel to the gas in the rear gas channel to meet the control requirement of the gas inlet temperature of an engine, and the gas inlet temperature of the engine is automatically controlled; and the temperature adjusting valve can adjust the temperature after intercool to enable gas inlet temperatures of all operating points of the engine to be controlledin the optimal state.

Owner:DONGFENG COMML VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com