Primary Air Distribution Method for Circulating Fluidized Bed Boiler

A circulating fluidized bed and boiler technology, which is applied in the directions of fluidized bed combustion equipment, combustion methods, and fuels burned in a molten state, can solve problems such as poor economy, reduced power supply efficiency, and increased plant power consumption. The effect of optimizing the combustion state of the furnace, improving the fluidization of materials, and reducing the power consumption rate of the plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

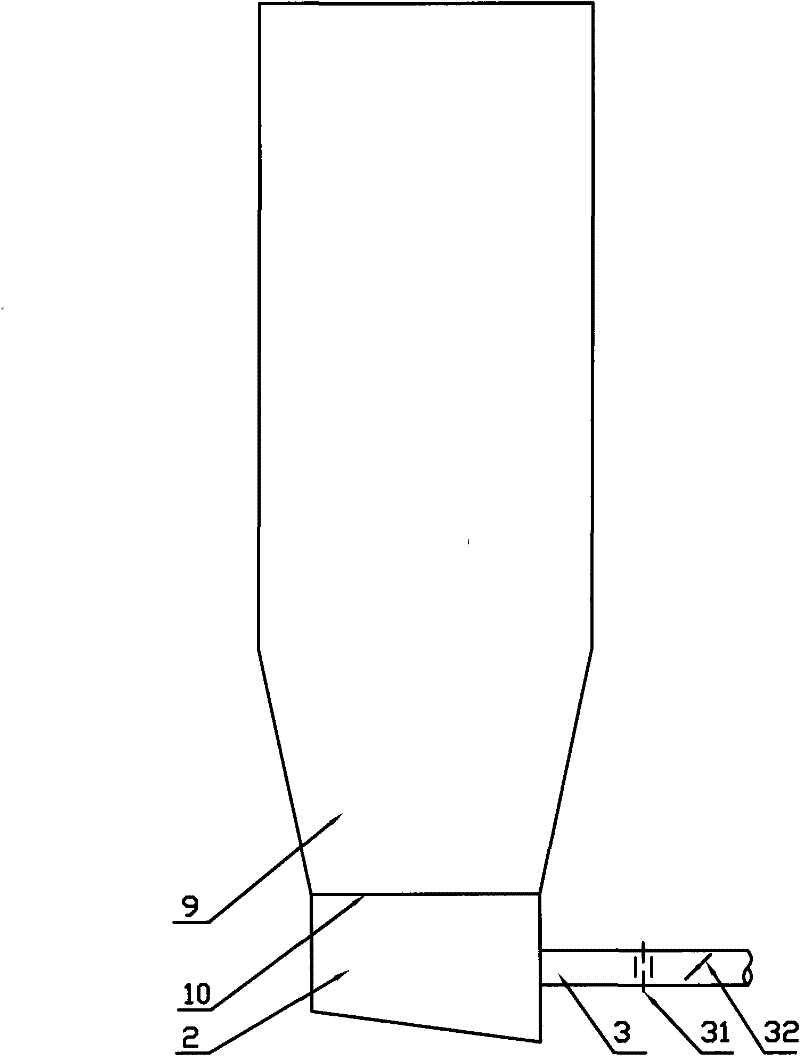

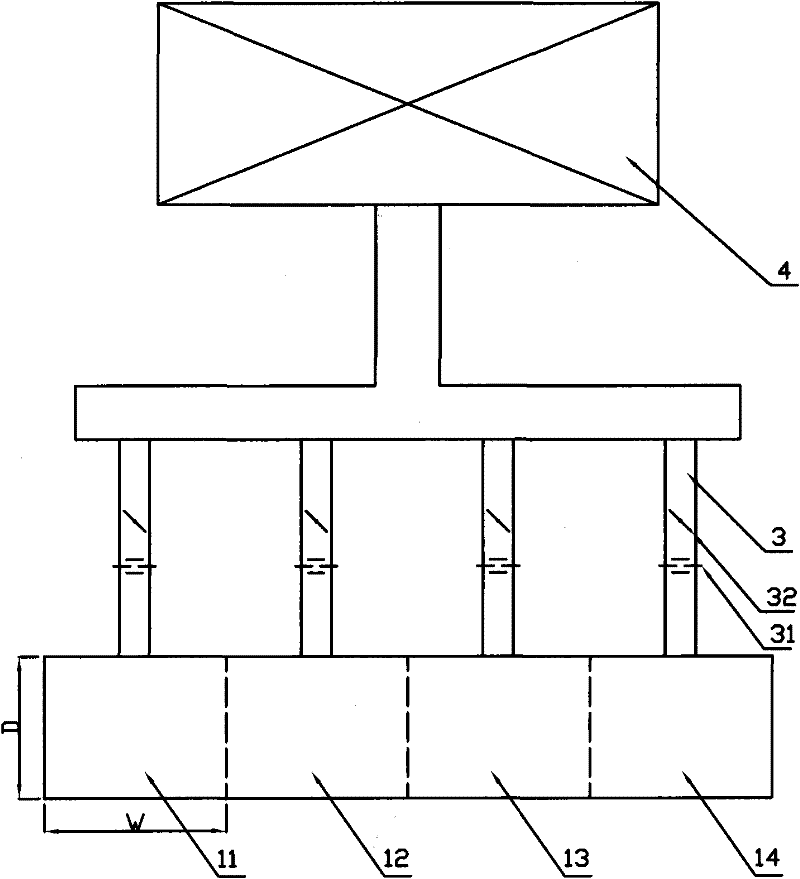

[0020] figure 1 and figure 2 It is a top view diagram of a 670t / h circulating fluidized bed boiler in Example 1 of the present invention. The bottom of the furnace 9 is provided with an air distribution plate 10 with a width of 22.7 meters and a depth of 4.5 meters. The air distribution plate 10 is divided into successive phases along the width direction. The four adjacent air distribution panel partitions 11, 12, 13, and 14, and each air distribution panel partition is provided with an air chamber ( figure 1 The label 2 in represents these 4 air chambers), each air chamber is not connected to each other; each air chamber is connected with the air preheater 4 of the boiler through the air pipe 3, when the air pipe 3 is drawn out from the air preheater 4 It is a main pipe, which is divided into 4 branch pipes before passing into each air chamber, and each branch pipe is equipped with an air flow measuring device 31 and a regulating device 32 . The branch pipes of the air duc...

Embodiment 2

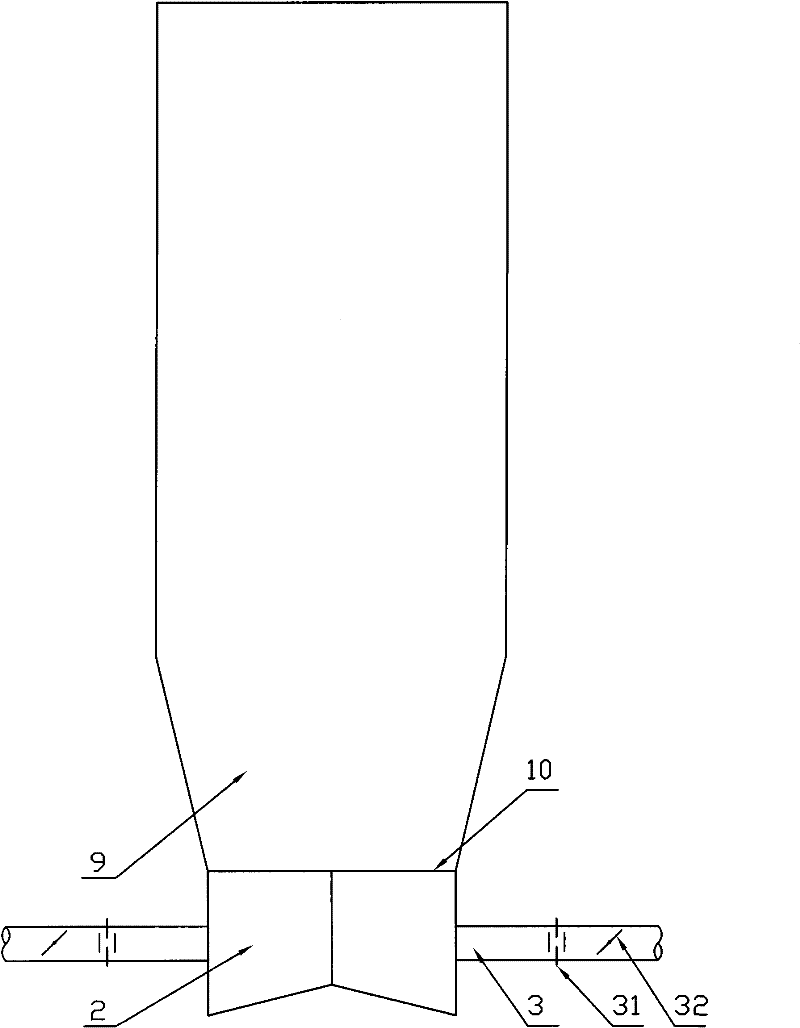

[0024] image 3 and Figure 4 It is a schematic diagram of a 600MW circulating fluidized bed boiler in Example 2 of the present invention. The boiler has a single furnace and a single air distribution plate. The bottom of the hearth 9 is provided with an air distribution plate 10 of 32 meters x 6.6 meters. Close to the air preheater 4 is the rear wall of the furnace, and opposite to it is the front wall of the furnace. Standing in front of the furnace faces the boiler, the left side is the left side wall, and the right side is the right side side wall.

[0025] Divide the air distribution board 10 into 2 rows, 4 in each row, a total of 8 air distribution board partitions (11-18), each air distribution board partition is provided with an equal pressure air chamber ( image 3 The middle mark 2 represents these 8 air chambers), and each air chamber is not connected to each other.

[0026] Each air chamber 2 is connected to the air preheater 4 of the boiler through the air pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com