Hearth pressure control method of vibrating grate boiler

A technology of vibrating grate and pressure control, which is applied in the direction of controlling combustion, lighting and heating equipment, etc., and can solve problems such as incomplete combustion of fuel, reduction of secondary air, and reduction of boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

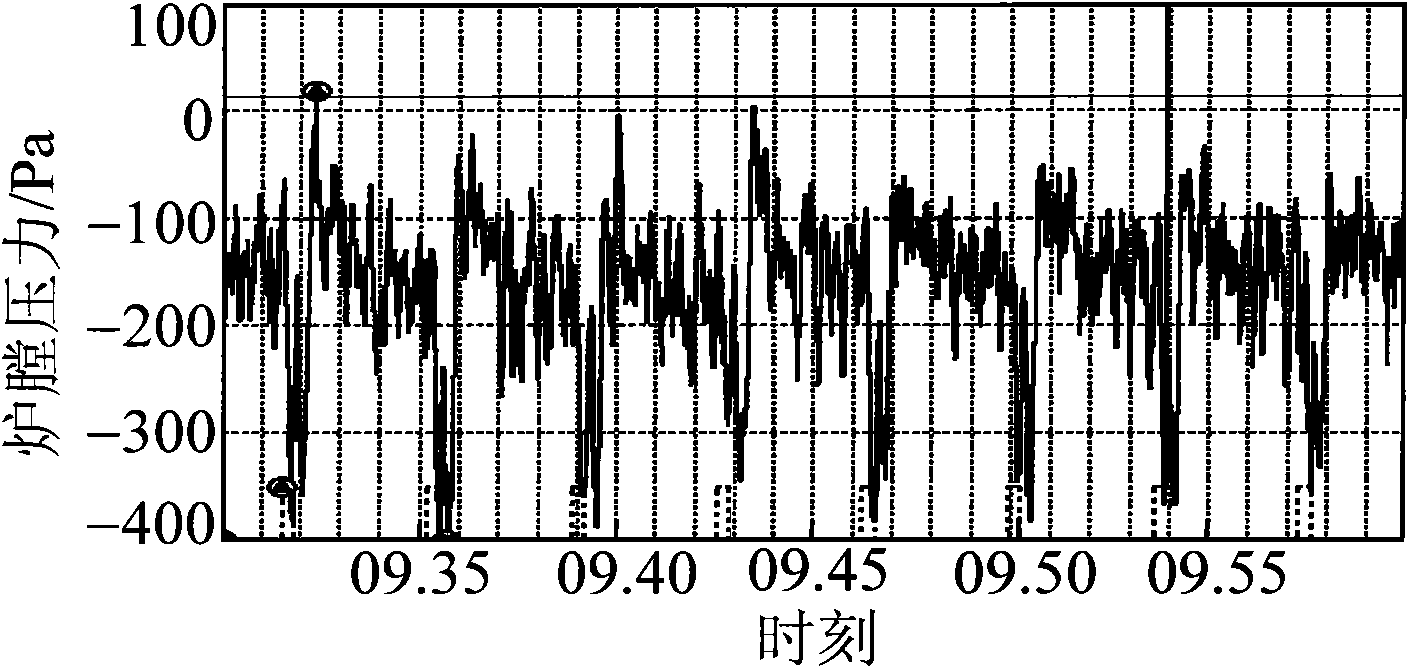

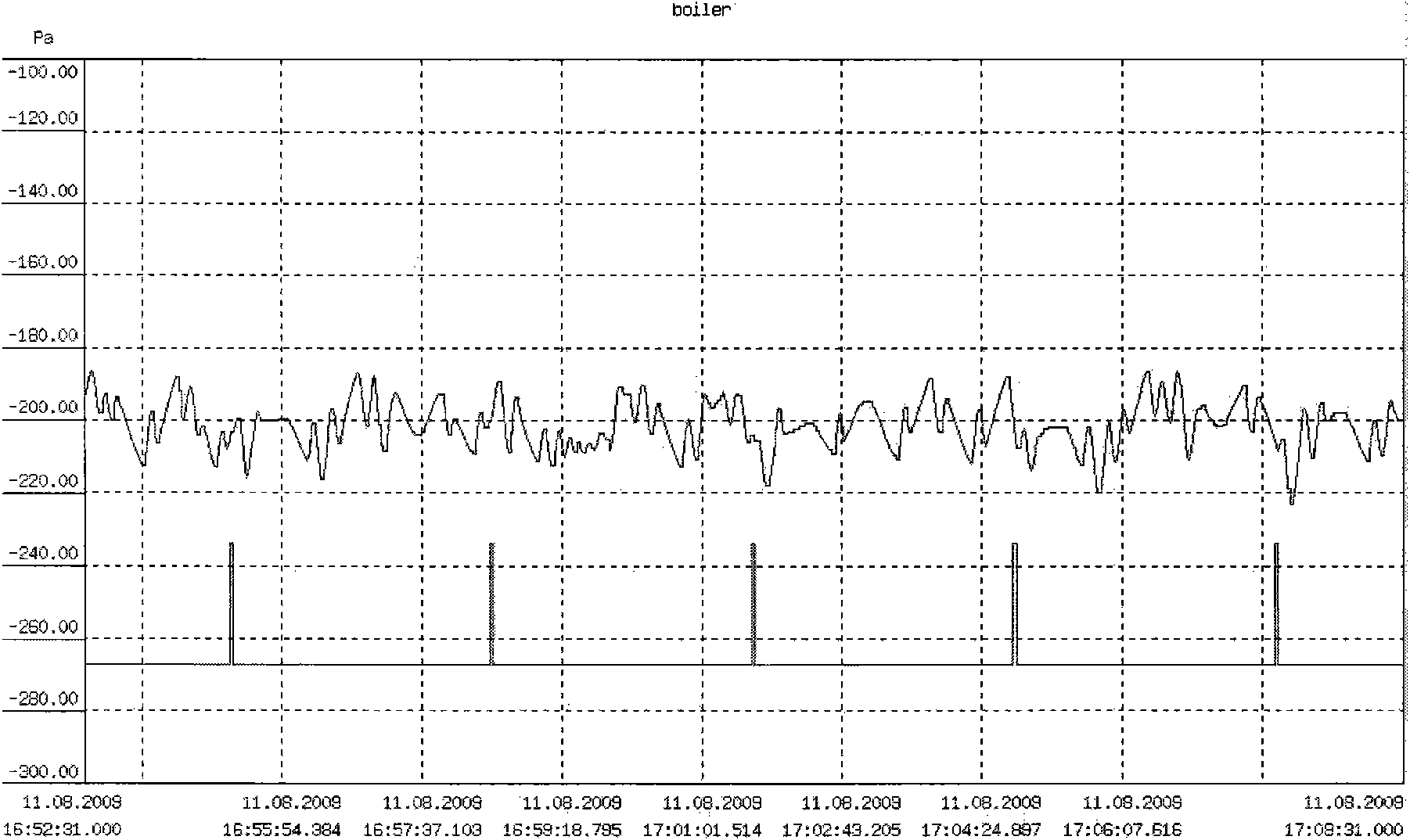

[0039] 1. Model analysis of furnace pressure

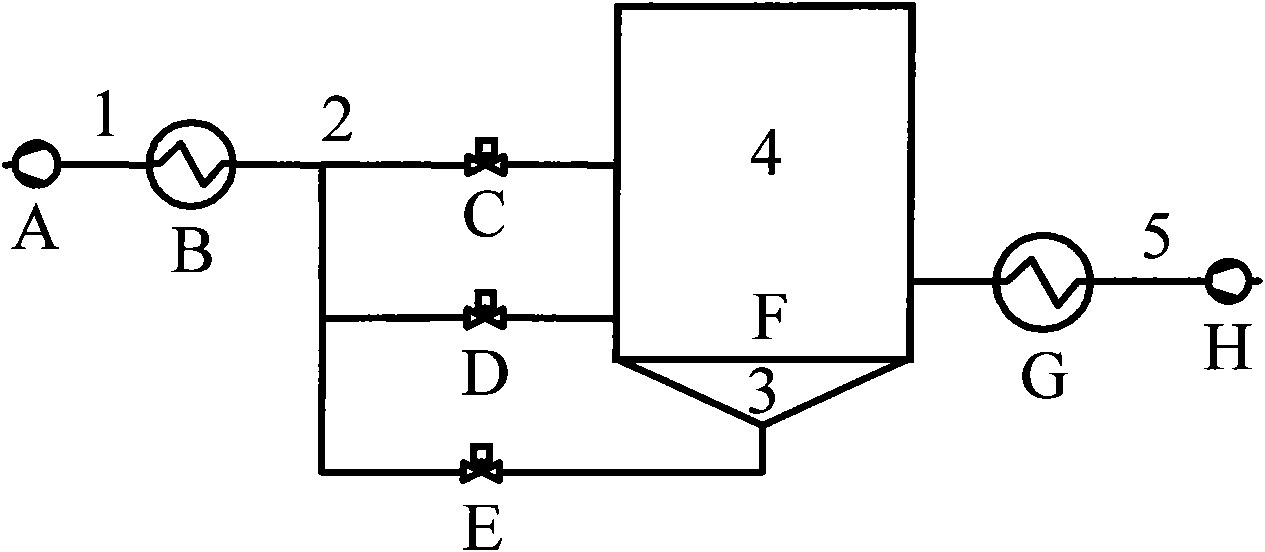

[0040] The vibrating grate biomass boiler has periodic disturbances to the boiler control due to the periodic vibration of its grate. On the basis of the original furnace pressure control system, a set of auxiliary control methods for grate vibration is designed to control the boiler air and smoke. The system performs rapid adjustment. By adjusting the amount of grate air volume, secondary air volume and induced air volume, the air and smoke system can overcome the disturbance caused by the grate vibration and realize the stable control of the furnace pressure. A schematic diagram of the flue gas system of a vibrating grate biomass boiler figure 2 As shown, the blower sends air into the system. The air is heated to about 190°C by the air preheater, and is divided into three parts: grate air, ignition air and secondary air. The grate air enters the air chamber through the grate air door. Pass through the grate and enter the furnace, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com