Industrial boiler of multi-fuel burning using ultrafine coal dust as main fuel

A fuel co-firing, industrial boiler technology, applied in the field of boilers, can solve the problems of limited application of pulverized coal combustion, high gas and oil costs, environmental pollution, etc., and achieve the effects of stable combustion, improved combustion efficiency, and improved burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

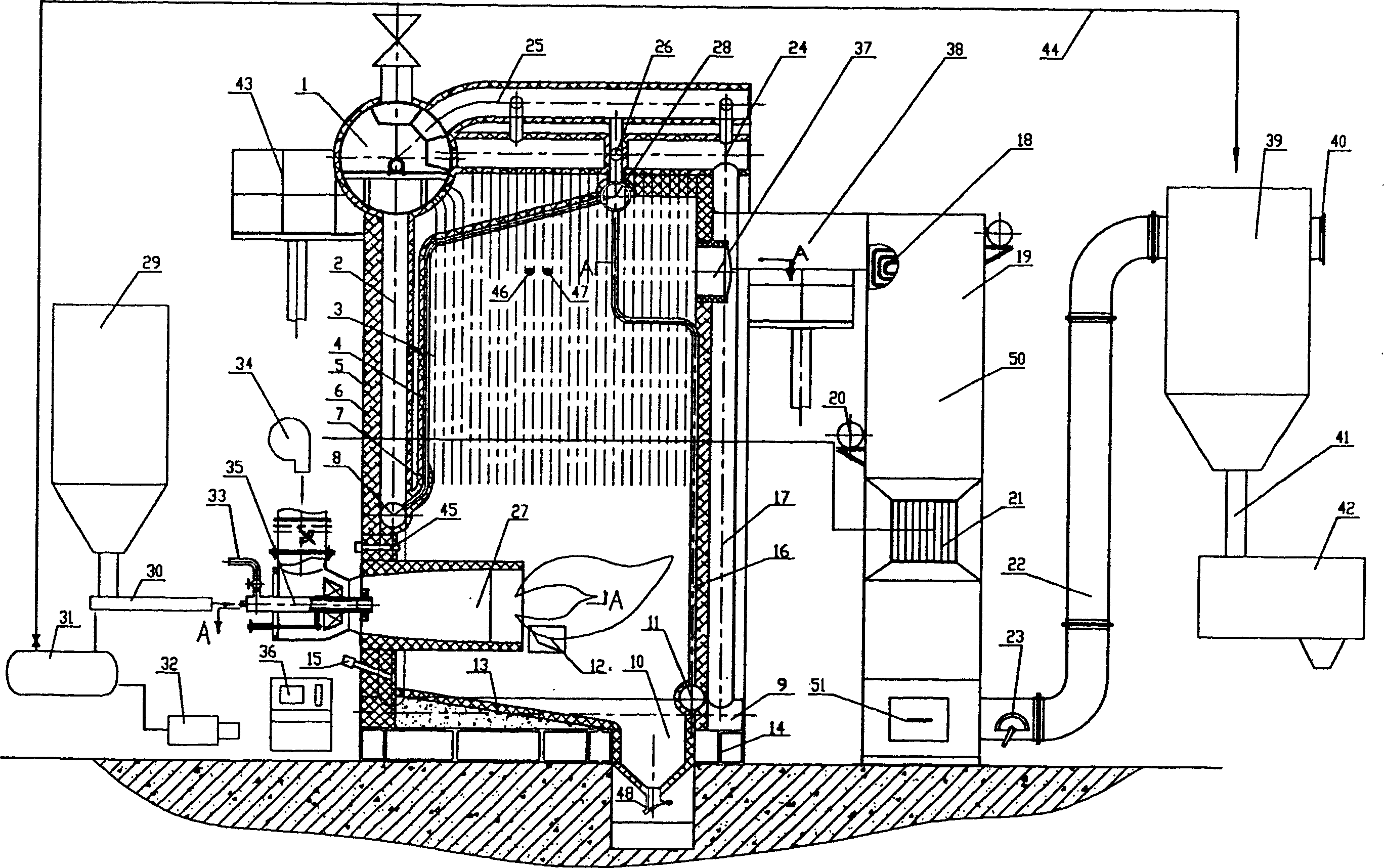

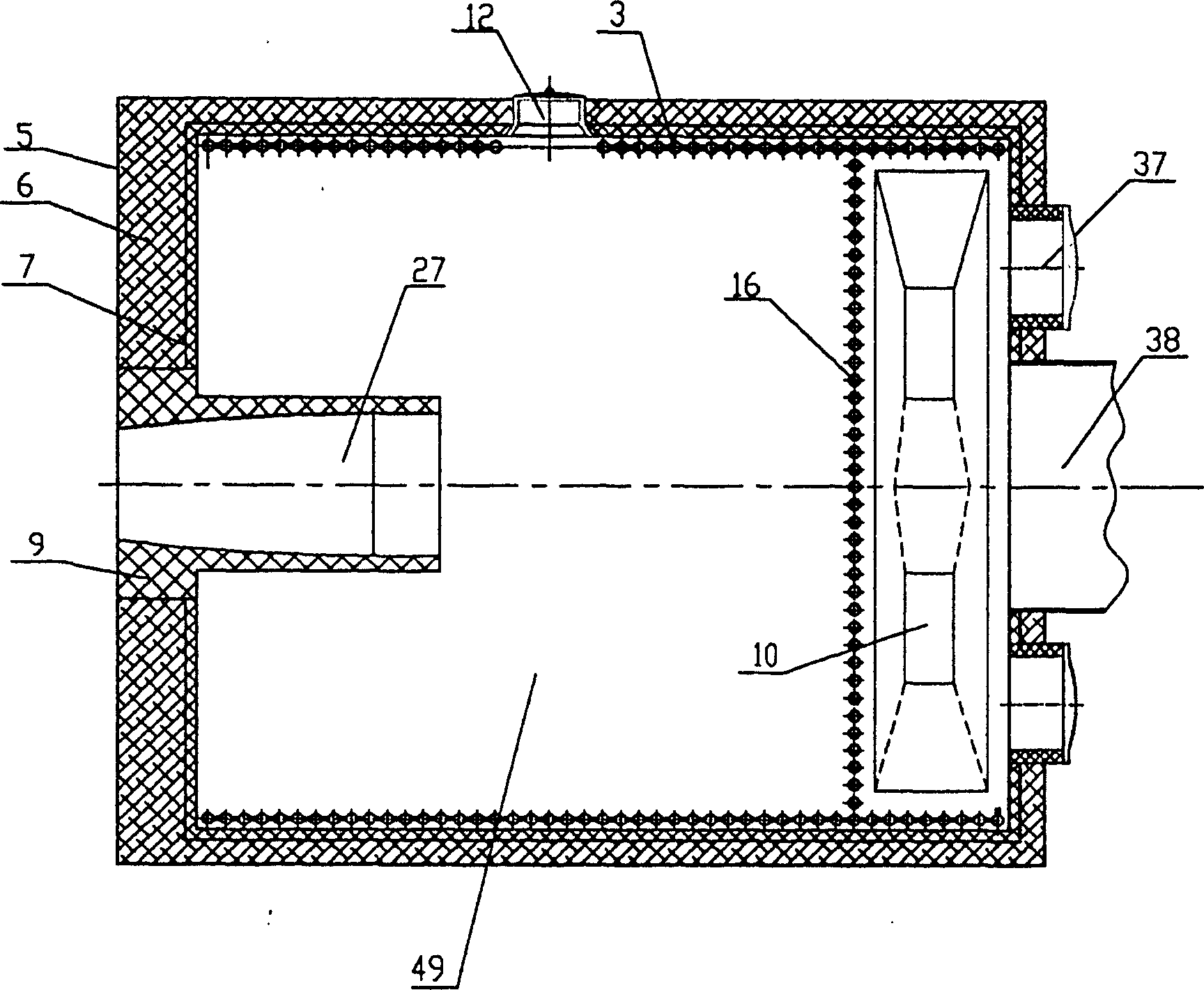

Embodiment 1

[0013] Example 1, see figure 1 , 2 , Processed into the boiler shell 5, install the insulation layer 6 and the furnace wall 7 in the shell 5, install the left and right membrane water wall 3 and the front membrane water wall 4 in the furnace wall 7, the left and right membrane water wall 3, the front Membrane water wall 4 adopts a corner tube type full water wall structure. Drum 1 is installed at the upper left of shell 5, front drop tube 2 is installed at the lower part of drum 1, and front header 8 is installed at the lower part of front drop tube 2. The middle part of the right side is connected to the connecting pipe 24 and the upper connecting pipe 25, the lower part of the upper connecting pipe 25 is connected to the connecting pipe 26, the upper header 28 is installed at the lower part of the connecting pipe 26, the rear membrane type water wall 16 is installed at the lower part of the upper header 28, the rear membrane type The water wall 16 adopts a corner tube type full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com