Internally circulating fluidized reburning device for fly ash based on high temperature separation

A technology of fly ash and fluidization, which is applied in the direction of fluidized bed combustion equipment, fuel for combustion in a molten state, and combustion methods, etc., can solve the problems of weak capture of fly ash, improve combustion efficiency and boiler thermal efficiency, and improve burnout The effect of low efficiency and transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

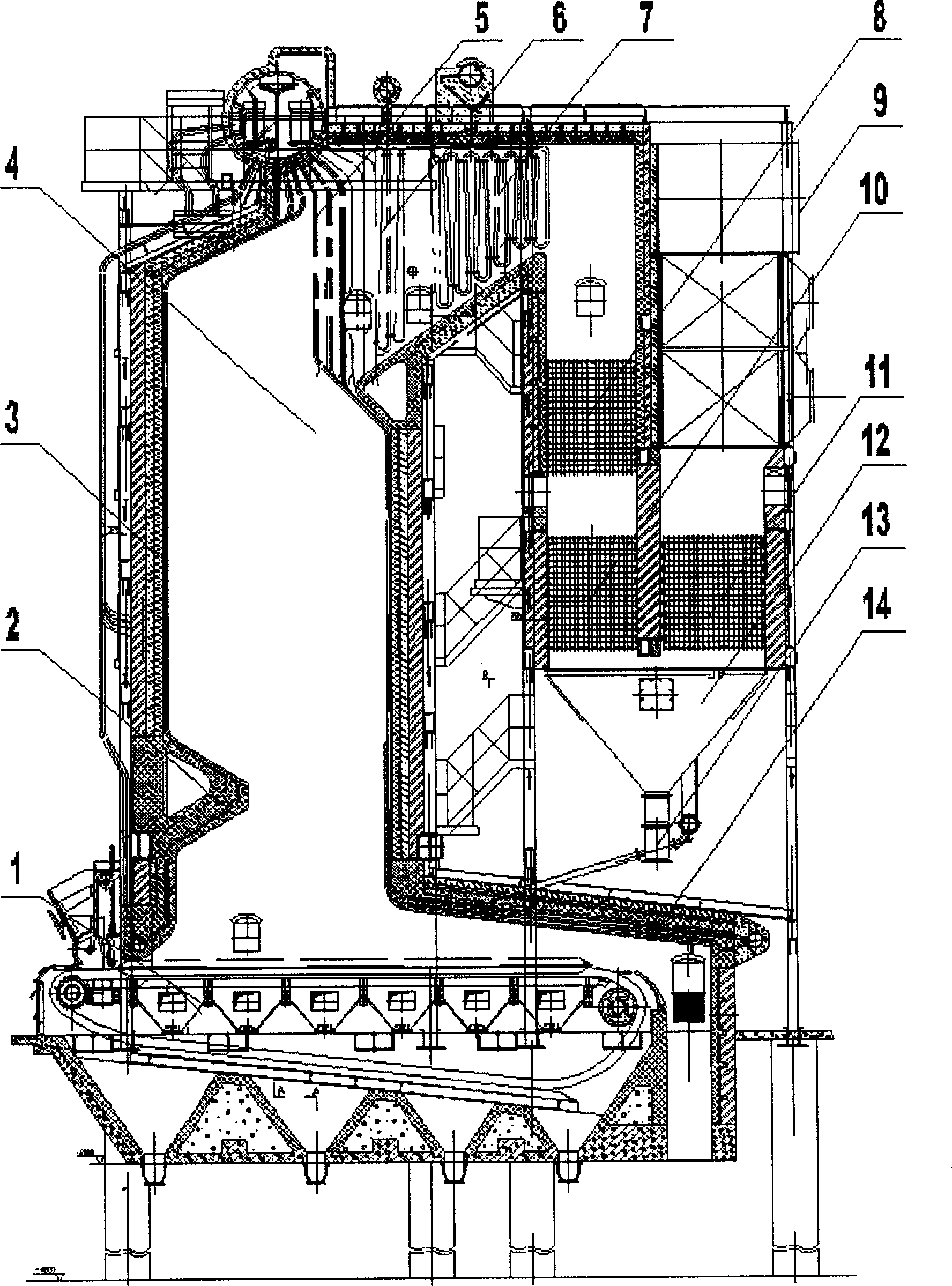

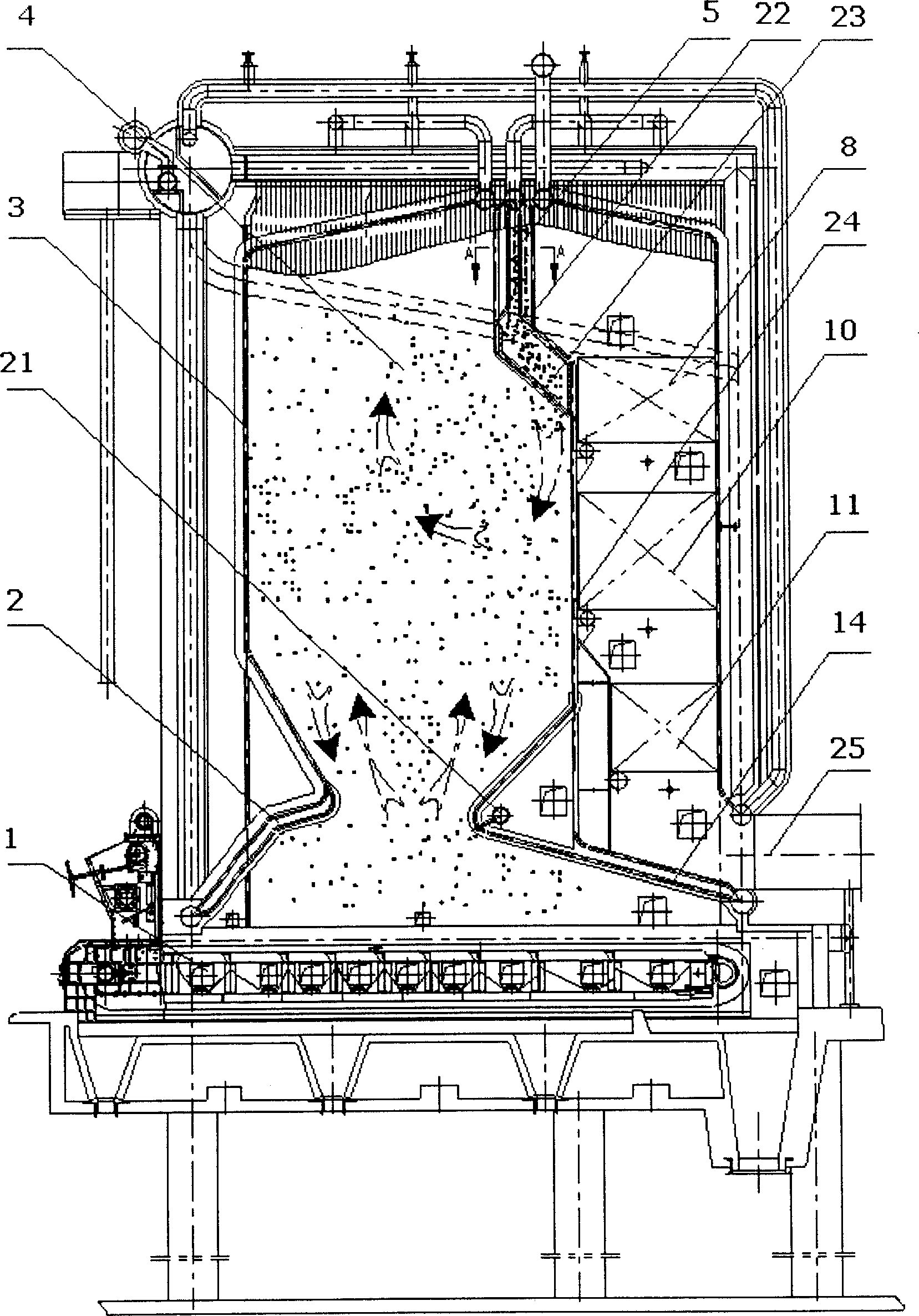

[0026] A fly ash internal circulation fluidized reburning burnout device based on high temperature separation of the present invention, for different boiler types, it at least includes a furnace, a front wall water cooling wall and a rear wall water cooling wall, a front wall water cooling wall and a rear wall The water-cooled wall extends into the front and rear arches inside the furnace and the combined structure of the secondary air arranged in the rear arch, as well as the heating surface of the water-condensed slag tube bundle. A combined water-cooled separator is arranged on the heating surface of the water-condensed slag tube bundle at the furnace outlet. The fly ash separated by the combined water-cooled separator is naturally returned to the high temperature zone of the furnace for reburning by gravity.

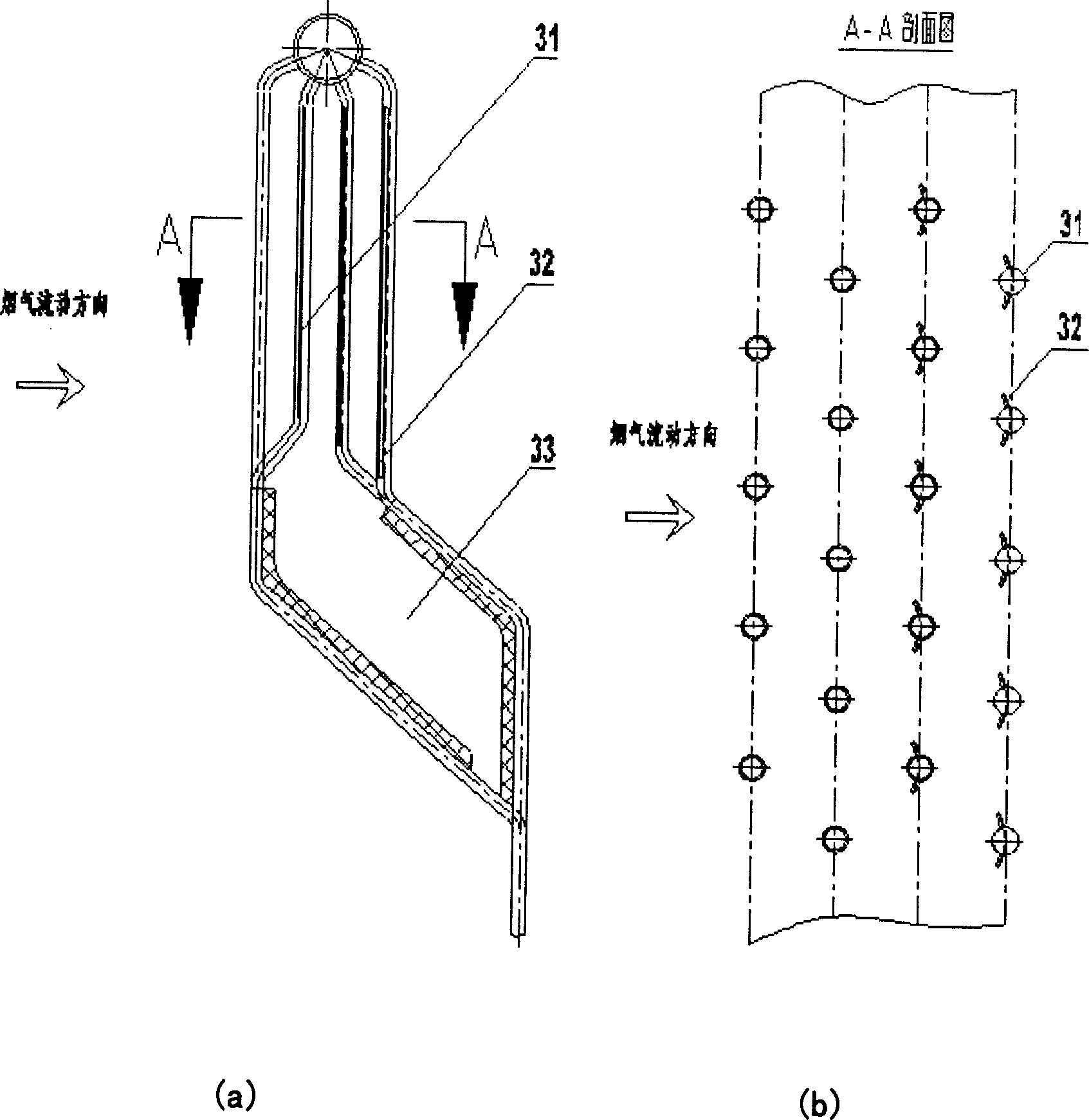

[0027] see figure 2 , image 3 , figure 2 It is an embodiment of the present invention, it includes fire grate 1, front arch 2, secondary air 21, front wall wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com