Crude and fine coal powder separation and burn method and device

A combustion method and pulverized coal technology, which is applied in the coal pulverized separation combustion, pulverized coal combustion boiler field, can solve the problems of increased carbon content in fly ash, reduced combustion efficiency, unstable combustion, etc., to achieve load and coal type adaptation Strong performance, suppression of NOx formation, and low NOx emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

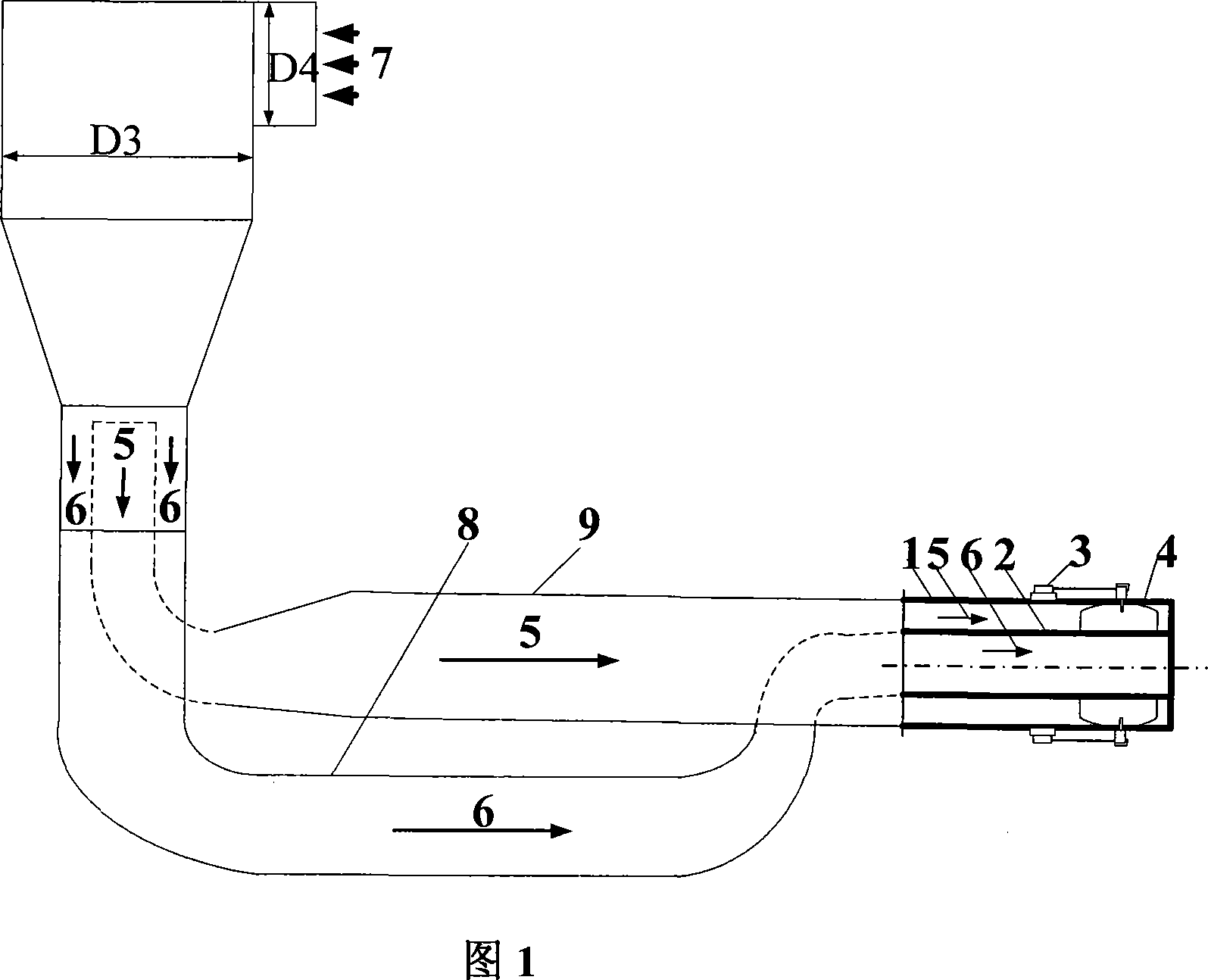

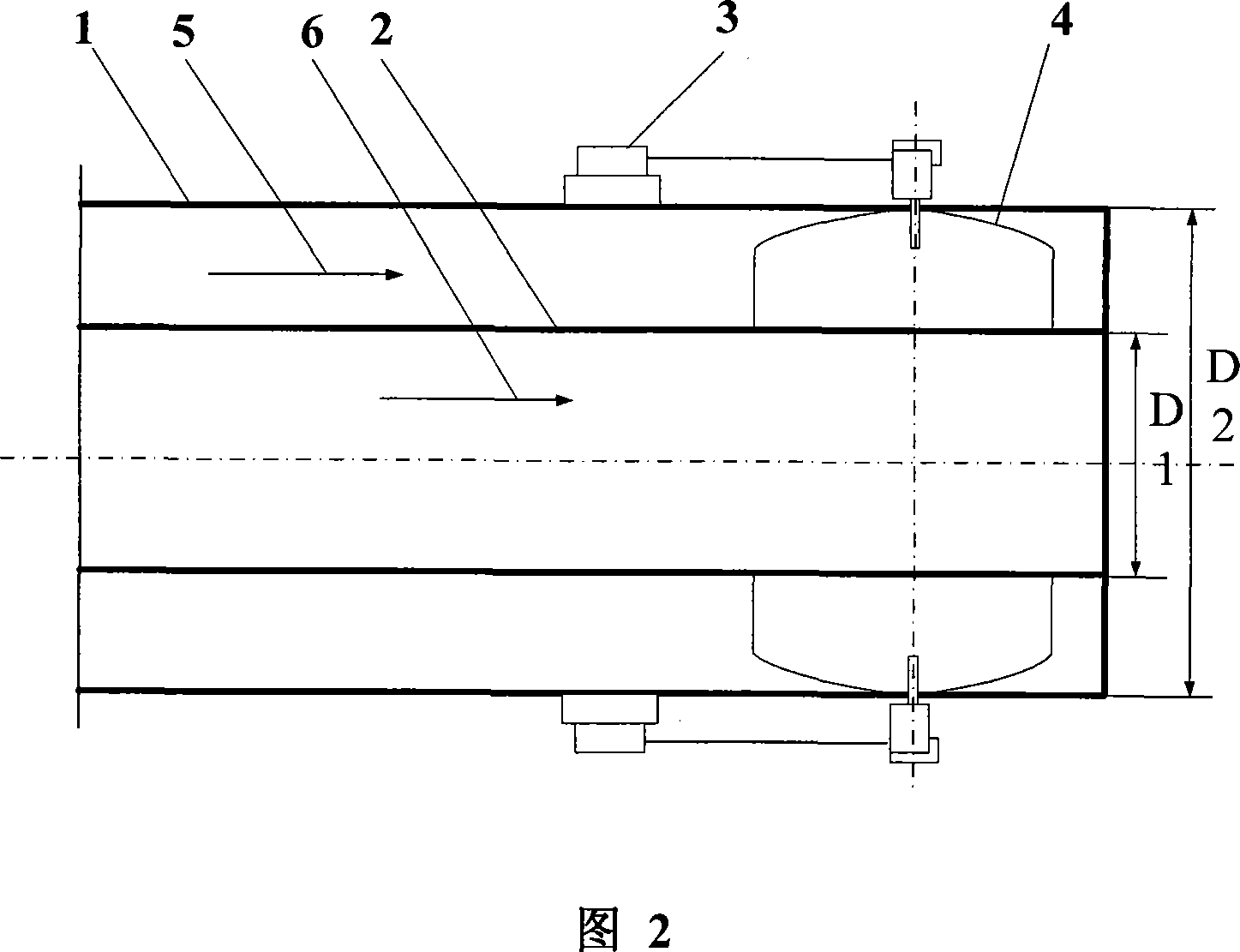

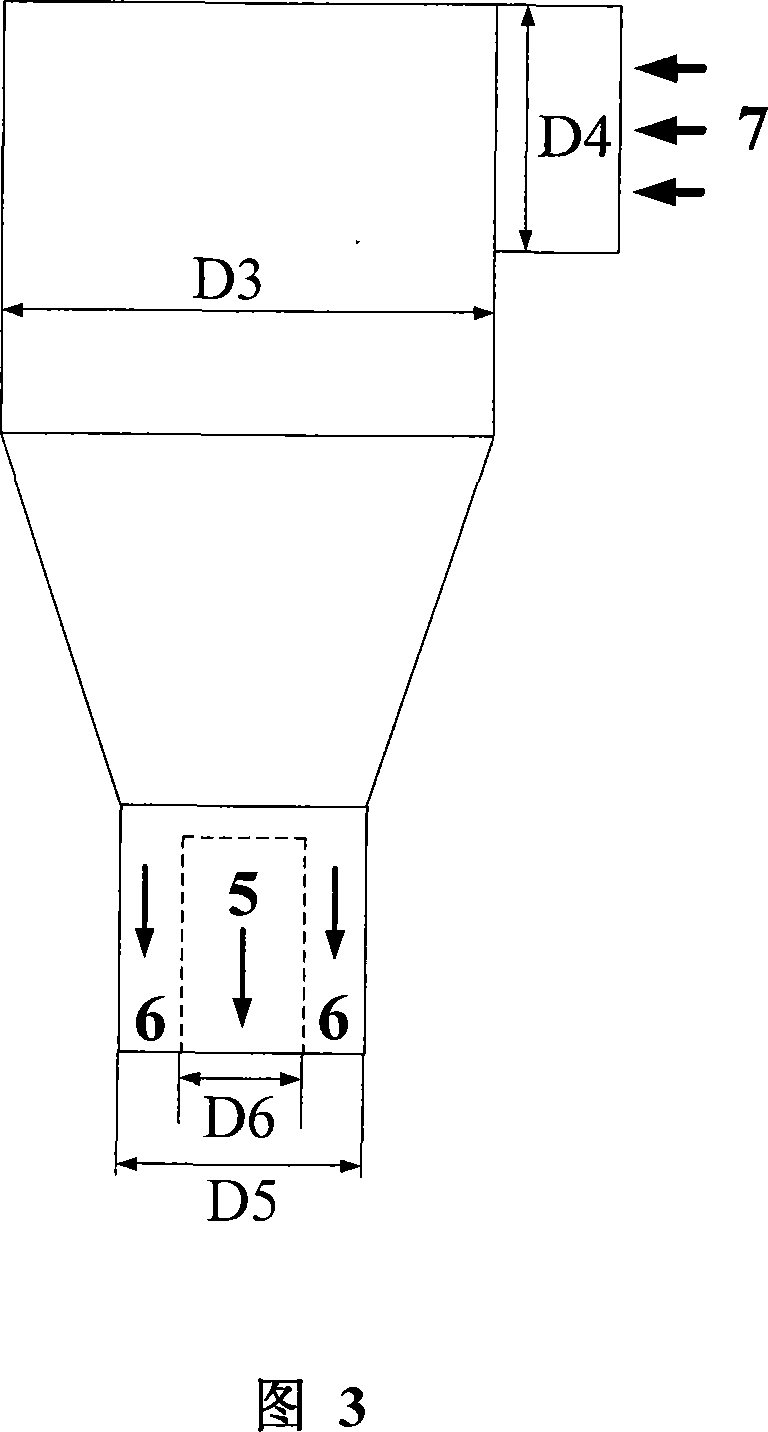

[0027] The marks in Fig. 1, 2, 3 and Fig. 4 are: outer primary air pipe 1 of the main burner, inner primary air round pipe 2, electric adjustment device 3, blade 4, fine pulverized coal airflow 5, coarse pulverized coal airflow 6 , Conventional primary air pulverized coal airflow 7, coarse pulverized coal airflow conveying connecting pipeline 8, fine coal pulverized airflow conveying connecting pipeline 9.

[0028] In the device of the present invention, blades 4 are provided between the outer primary air circular pipe 1 and the inner primary air circular pipe 2 of the main burner, and the axial direction is adjustable; It is connected with the axially adjustable blade 4 by a drive shaft; a cyclone separation device is installed at the front of the main burner, and the outlet of the cyclone separation device is a double-layer circular casing, and the inner pipe of the double-layer circular casing passes through the connecting device. The fine pulverized coal airflow conveying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com