Patents

Literature

66 results about "Powder burn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A powder burn is a type of burn caused by exposure to the burning gases which are expelled from the muzzle of a firearm as it is fired. Powder burns only occur when the person or item to be burned is close to the discharging firearm, as the gases quickly dissipate. This can be an indicator on a corpse of whether the person was shot at point-blank range or not.

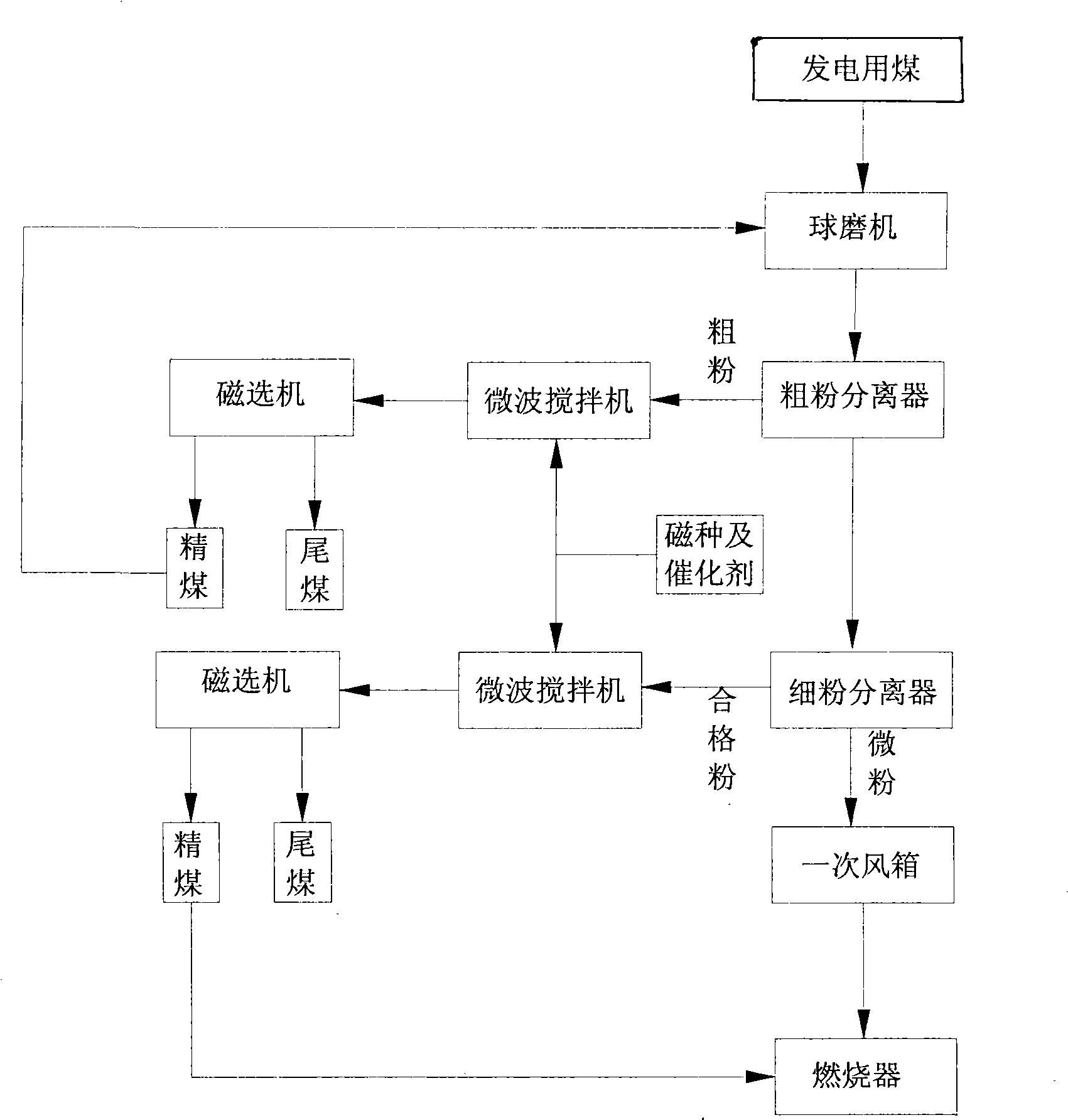

Two-section dry-type magnetic separation purification process before combustion of pulverized coal

InactiveCN101531938ASuitable for automatic controlSolid fuelsMagnetic separationEngineeringBall mill

The invention discloses a two-section dry-type magnetic separation purification process before the combustion of pulverized coal; the process comprises the step that after sampling is carried out by a ball mill, coal used for power generation firstly enters a coarse separator firstly and the process is characterized by also comprising the steps as follows: granule pulverized coal meeting the requirements of combustion granularity by the coarse separator directly enters a fine powder separator while the coarse powder burning coal is delivered to a microwave mixer, and treated simultaneously by adding a magnetic seed and a catalyst, and then conveyed to a first-section magnetic separator to carry out desulfurization and ash removal after treatment, later, cleaned coal after magnetic separation is returned to the ball mill again, and then tail coal is separated out; micro-powder fine coal which is separated out by the fine powder separator is directly conveyed to a burner while qualified pulverized coal which is separated out enters another microwave mixer, and also treated simultaneously by adding the magnetic seed and the catalyst, and then conveyed to a second-section magnetic separator to carry out desulfurization and ash removal after treatment, later, cleaned coal after magnetic separation is delivered to the burner for combustion, and then tail coal is separated out; and the process has the advantages of high efficiency, quick effect, energy conservation and electricity conservation, cleanness and safety, and good desulfurization effect.

Owner:HENAN POLYTECHNIC UNIV

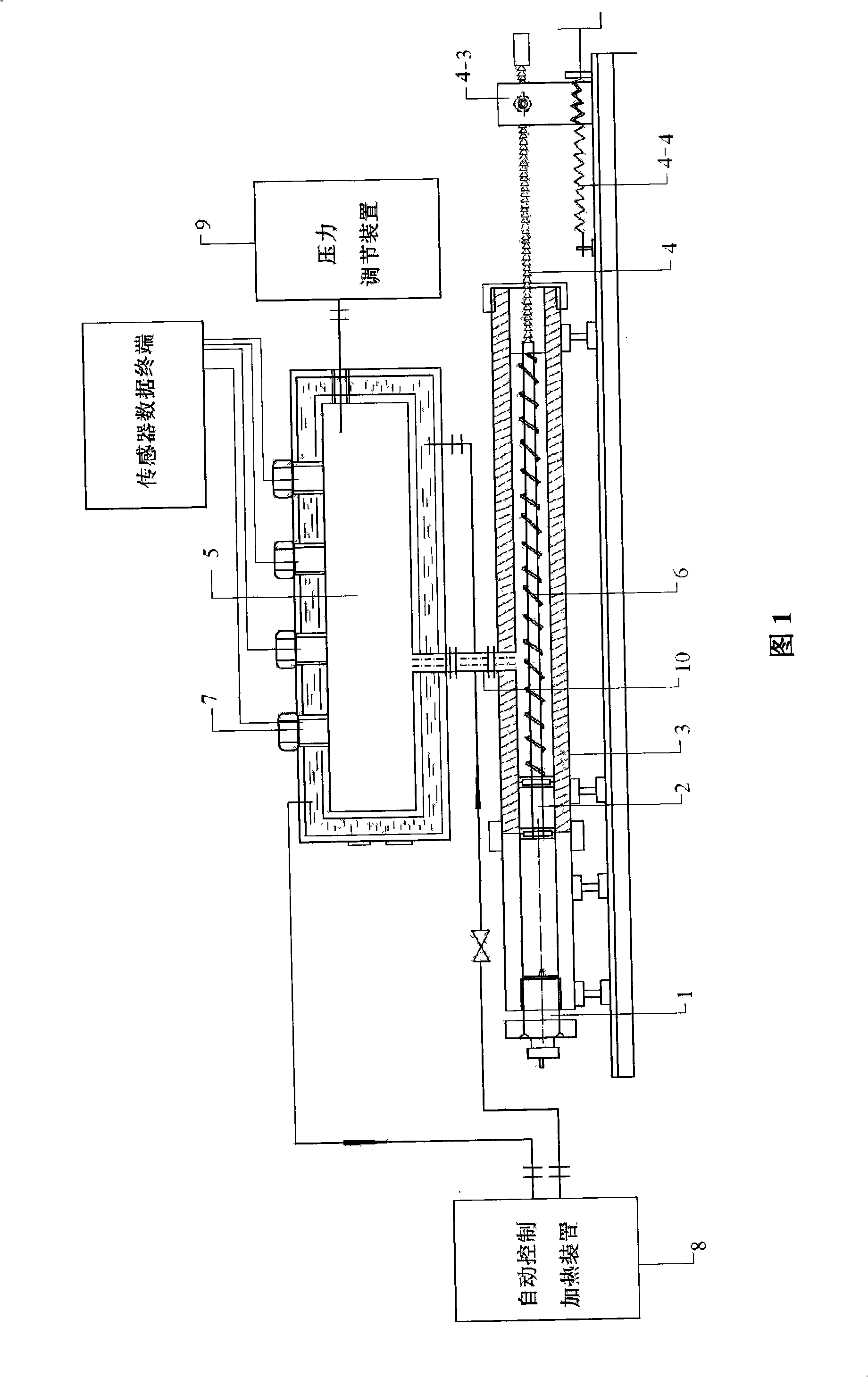

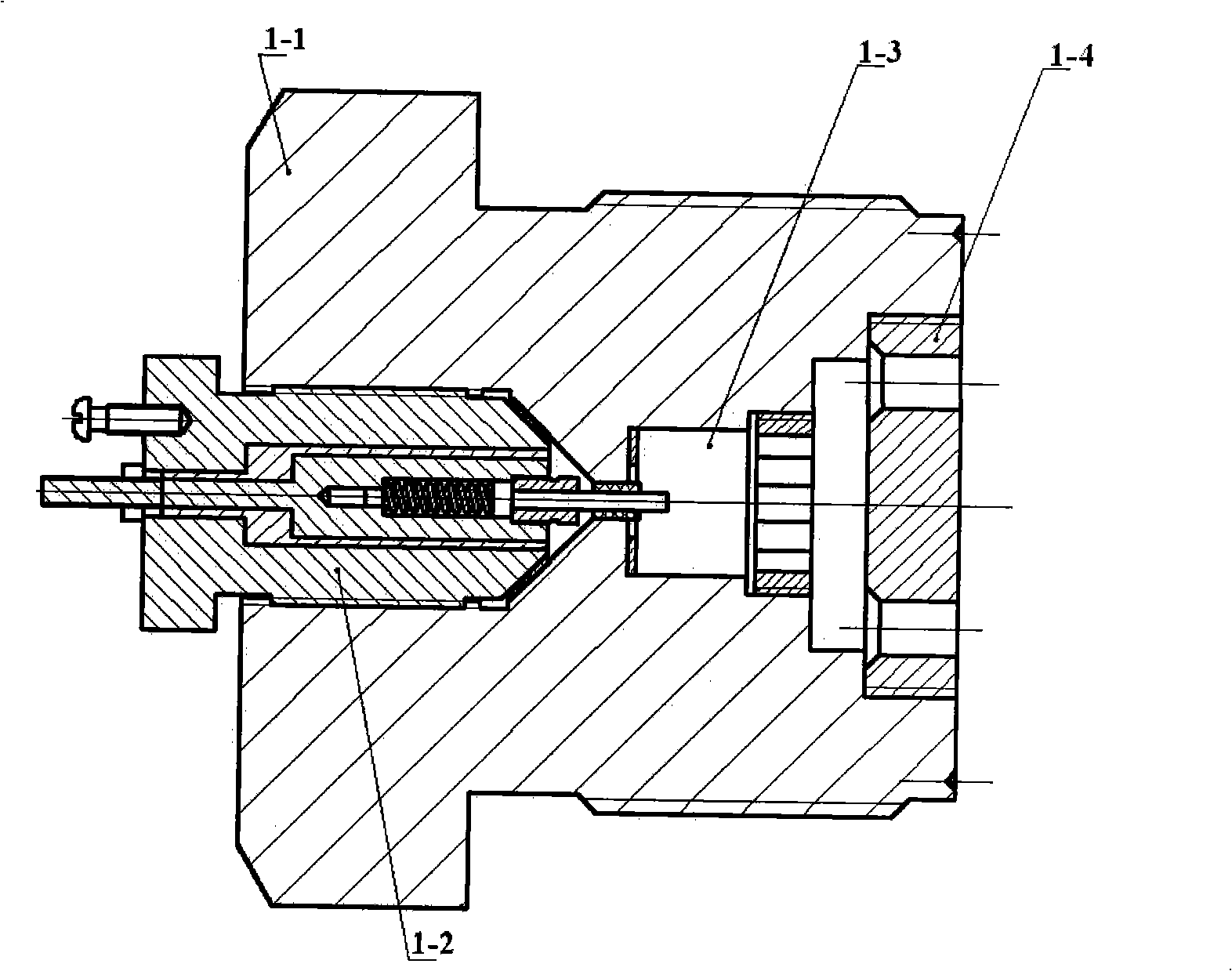

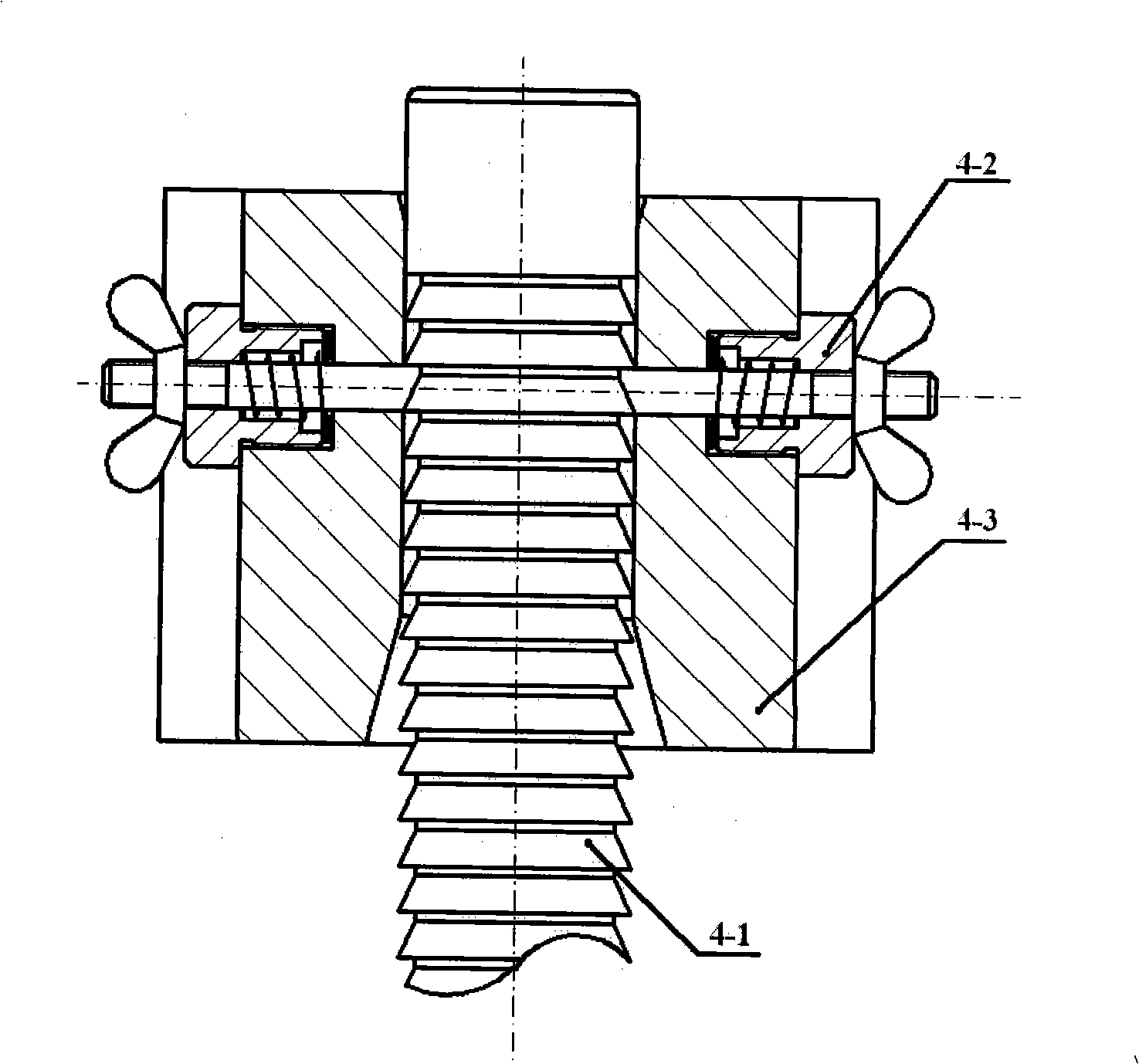

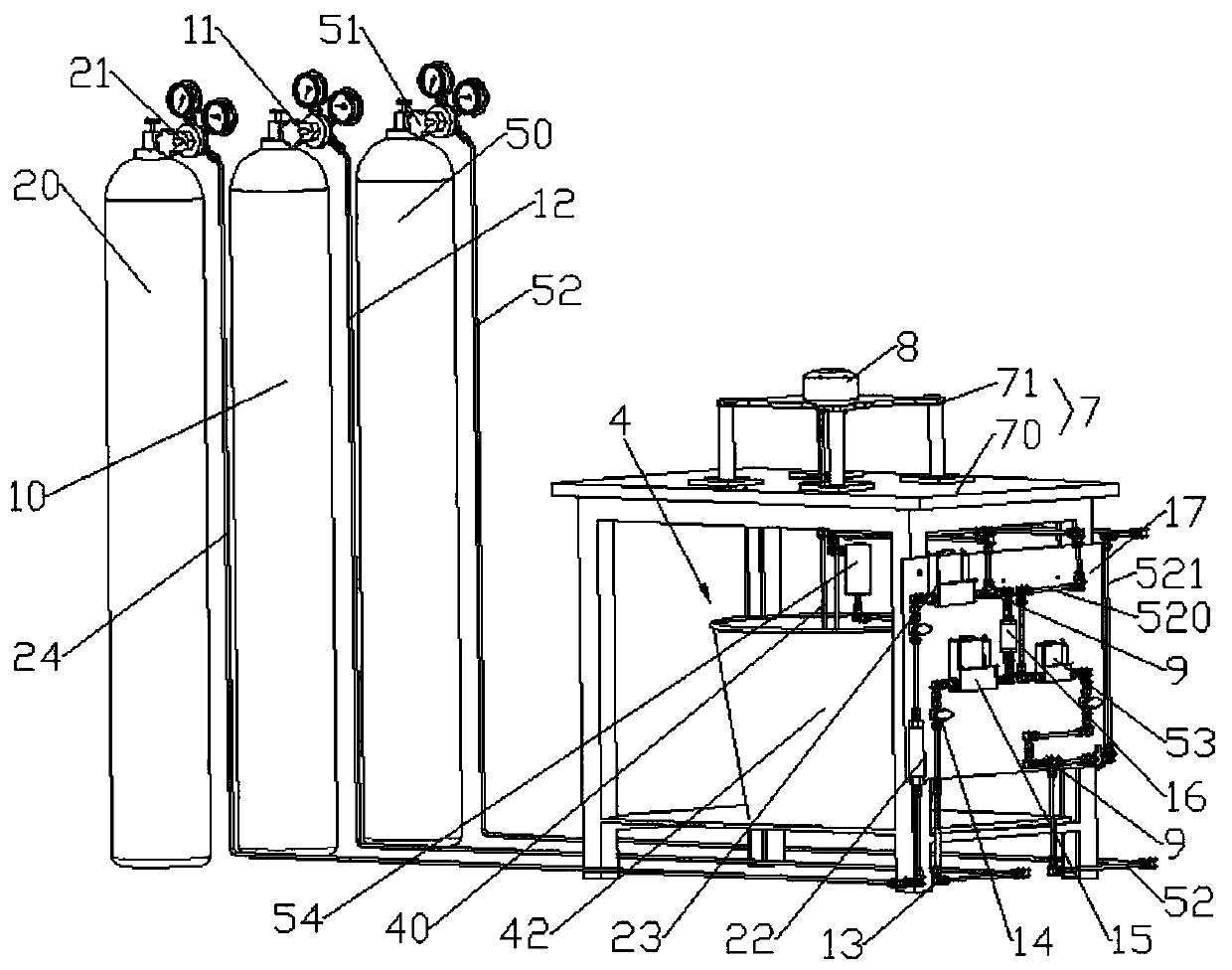

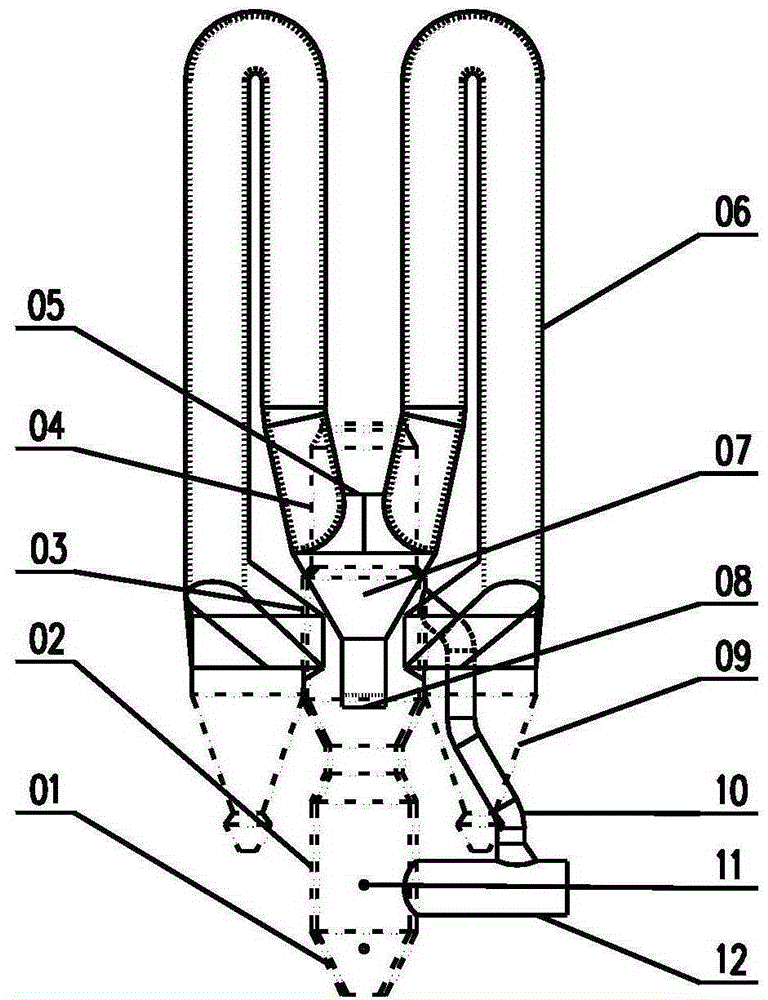

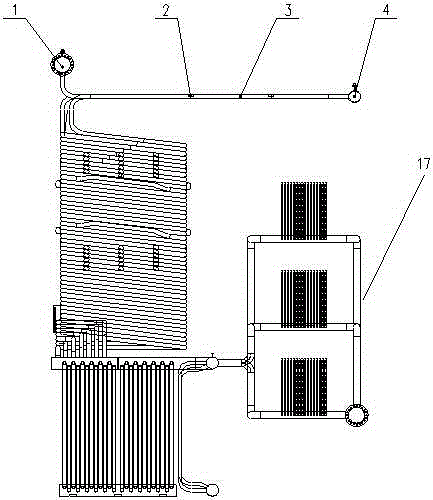

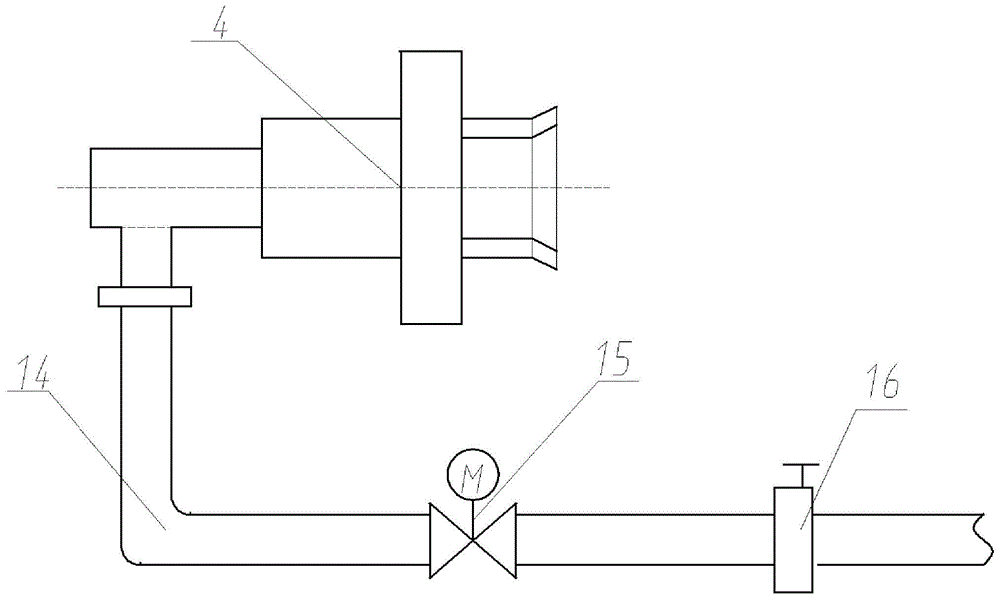

Propellant combustion tail gas quantitatively measuring device

ActiveCN101339182AGuaranteed measurementGuaranteed normal testFuel testingAutomatic controlMeasurement device

The invention discloses a quantitative measurement device of components of propellant powder burning tail gas, the device is characterized in that one end of a transmitting tube is connected with an electric ignition cable switch with an ignition groove; the big end of a piston is matched with the inner wall of the transmitting tube in a sliding way, while the small end of the piston is connected with a pawl arrester; an automatic control heating device and a pressure regulation device are adopted to ensure high constant temperature and stable air pressure of an air test chamber; an air outlet of the transmitting tube and an air inlet of the air test chamber are connected. When a measured propellant powder sample arranged on the ignition groove is burned, the burned gas of the propellant powder pushes the piston to move until the big end of the piston slides over the air outlet, the burned gas can enter the air test chamber; the above process truly simulates the whole process that a pill flies off a bouche from the ignition, when the piston moves to the position of maximum working stroke of the burned gas and then is locked. The burned gas entering the air test chamber is directly detected by a probe of a related sensor in real time; at last, each sensor gets the corresponding quantitative data of the components of the propellant powder burning tail gas. The quantitative measurement device has the advantages of accurate test result as well as good repeatability.

Owner:XIAN MODERN CHEM RES INST

Method of producing green fluorescent powder

InactiveCN101130689AImprove luminous performanceSmall particle size distributionCathode ray tubes/electron beam tubesLuminescent compositionsSolventCupric nitrate

The invention relates to a making method of green fluorescent powder, which comprises the following steps: mixing zinc blend as host material, cupric nitrate as activating agent, aluminum fluoride as coactivator, chlorauric acid, barium iodide as auxiliary solvent and sulfur in the blending machine to produce phosphor powder burning material; putting the phosphor powder firing material into the quartz container with the sulfur and active carbon to burn in the tunnel with protecting gas of N2; removing non-luminous or luminous abnormal powder and impurity from the phosphor powder under ultraviolet lamp to obtain the green emitting phosphor. The invention uses a fluxing agent material of the barium iodide and a new coactivator material of the aluminum fluoride, which improves luminous property of the phosphor powder with reducing particle size distribution and reduces usage of the coactivator of chlorauric acid at the same time.

Owner:CAIHONG GRP ELECTRONICS CO LTD

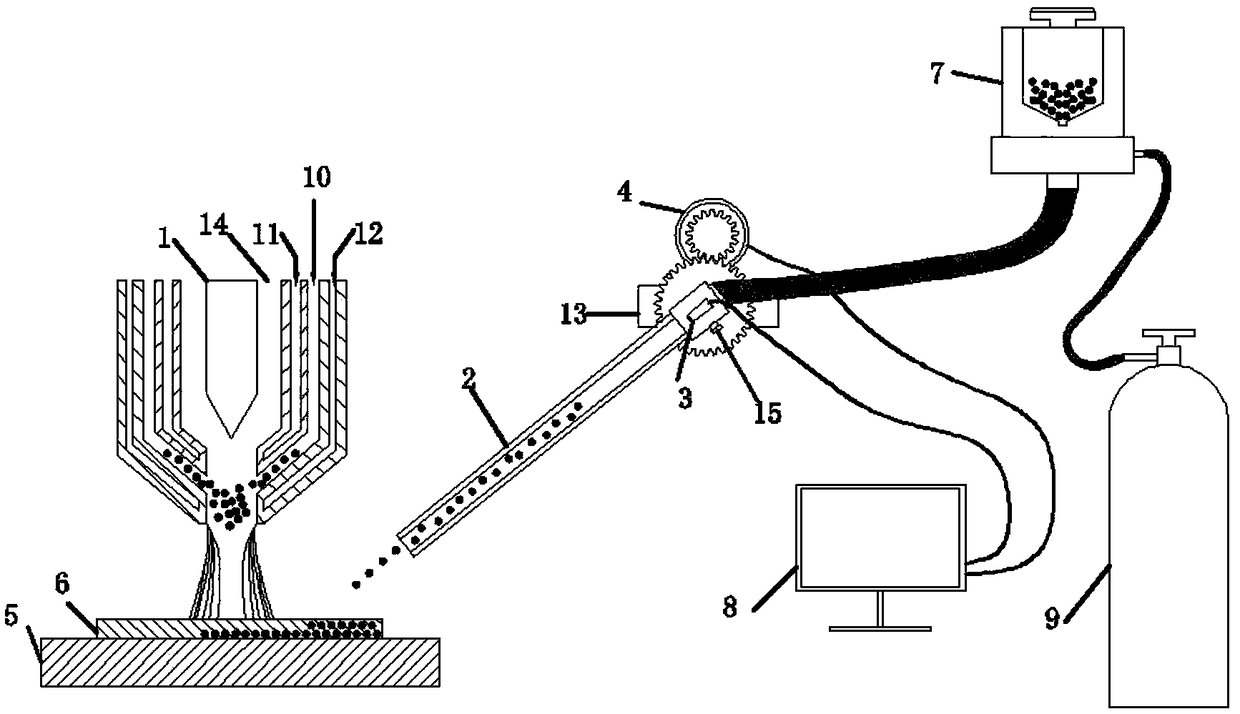

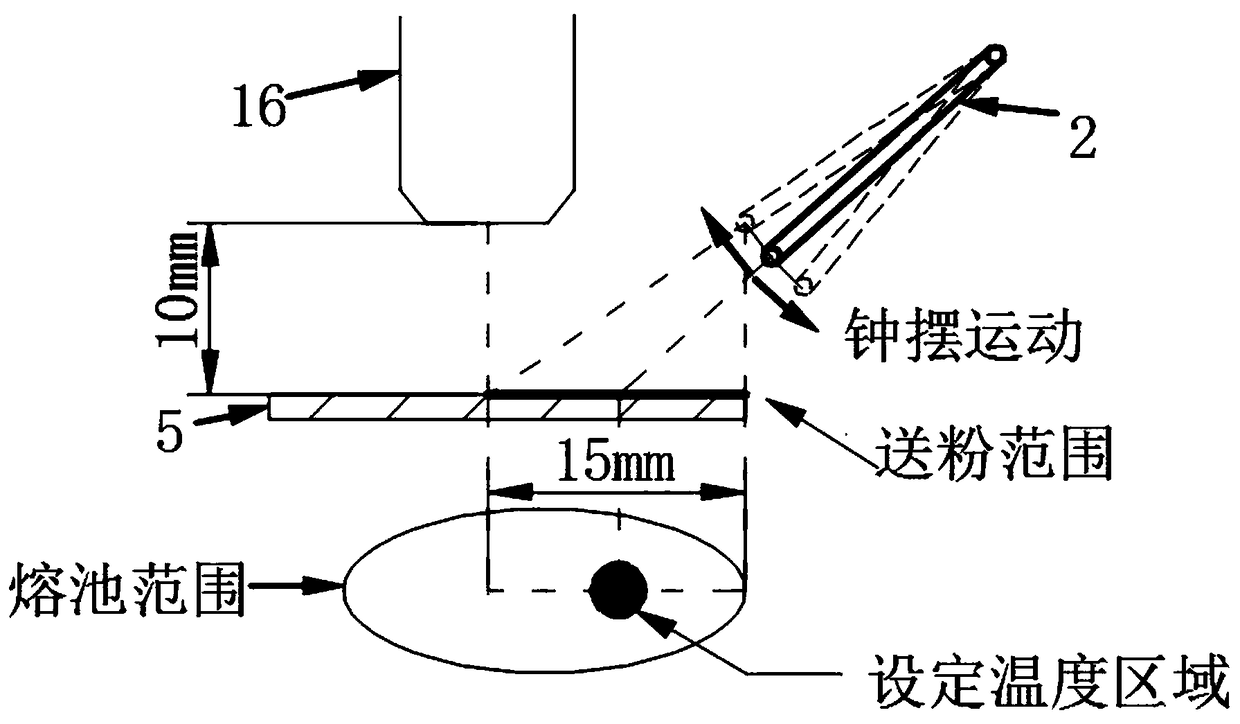

Preparation method for ceramic powder-reinforced metal-matrix welding layer, and powder feeding device thereof

The invention discloses a preparation method for a ceramic powder-reinforced metal-matrix welding layer. The preparation method for the ceramic powder-reinforced metal-matrix welding layer comprises the following steps: carrying out pretreatment on a metal matrix, an alloy powder and a ceramic powder; setting plasma surfacing process parameters according to the material of the metal matrix, and determining a powder feeding temperature of a powder feeding device; placing the metal matrix on a workbench, starting up a plasma surfacing machine and the powder feeding device, enabling the powder feeding device to automatically travel, detecting the temperature distribution of a metal molten pool and transmitting a temperature field to a control device for the powder feeding device by a temperature induction device, calculating the position of a set powder feeding temperature in the molten pool to determine the position of the powder feeding device by the control device, and enabling the ceramic powder to fall into a specified temperature area in the molten pool by adjusting the included angle of an outer powder feeding pipe; and controlling the outer powder feeding pipe of the powder feeding device to carry out pendular movement. According to the preparation method for the ceramic powder-reinforced metal-matrix welding layer, determination for a powder falling point of outer powderfeeding is facilitated; and meanwhile, the problems of serious powder burning loss and low powder utilization rate are solved.

Owner:WUHAN UNIV OF TECH

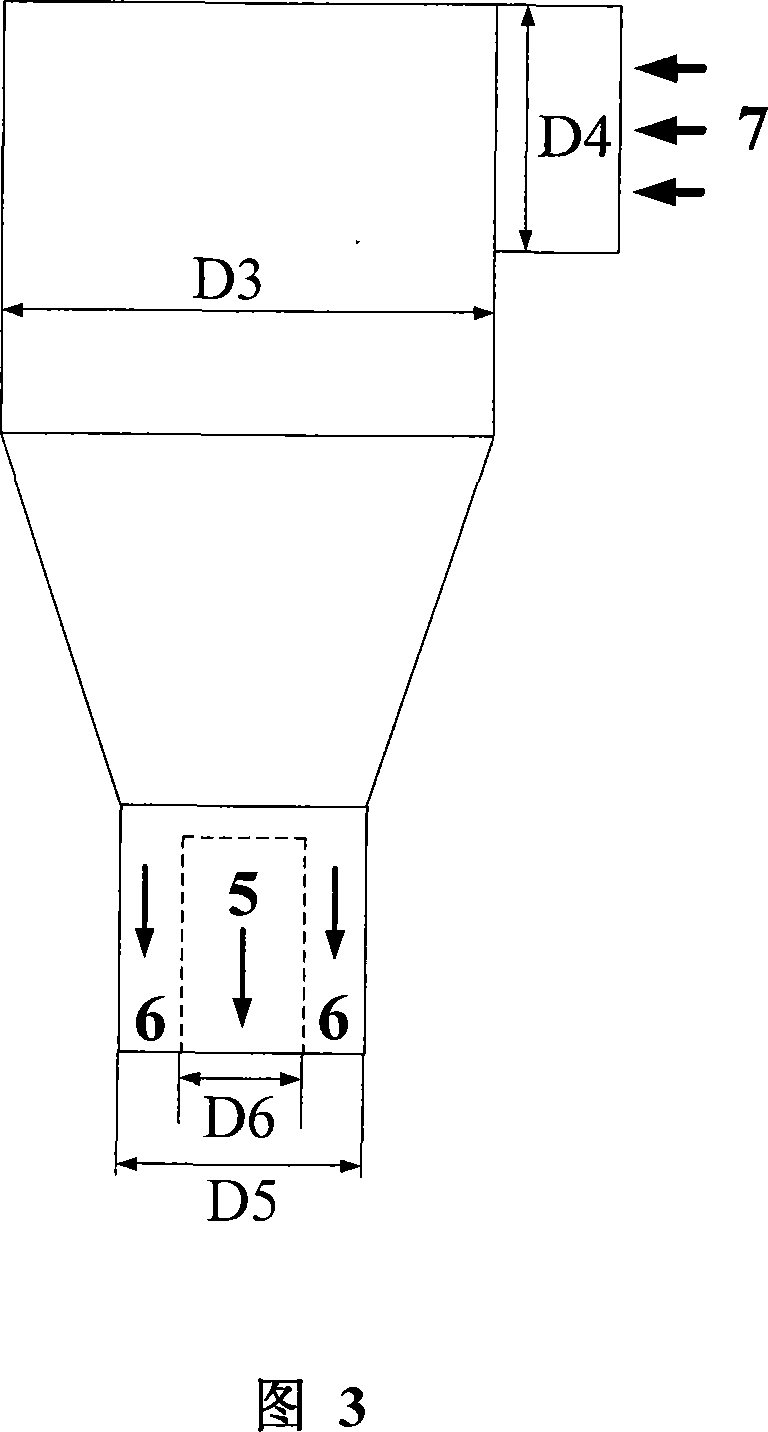

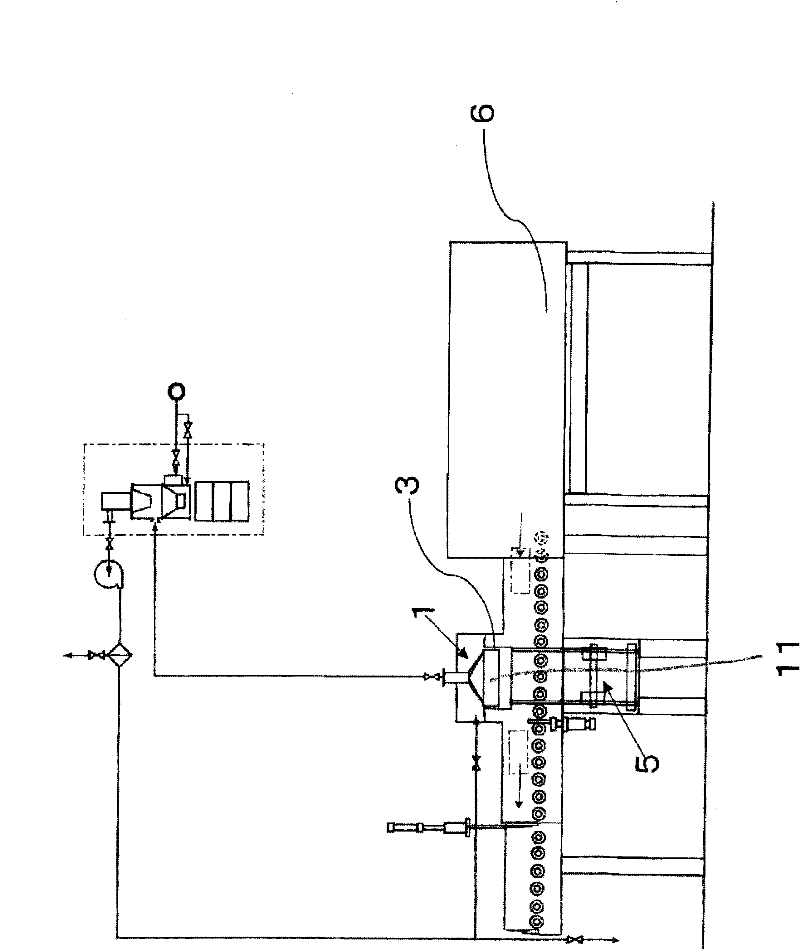

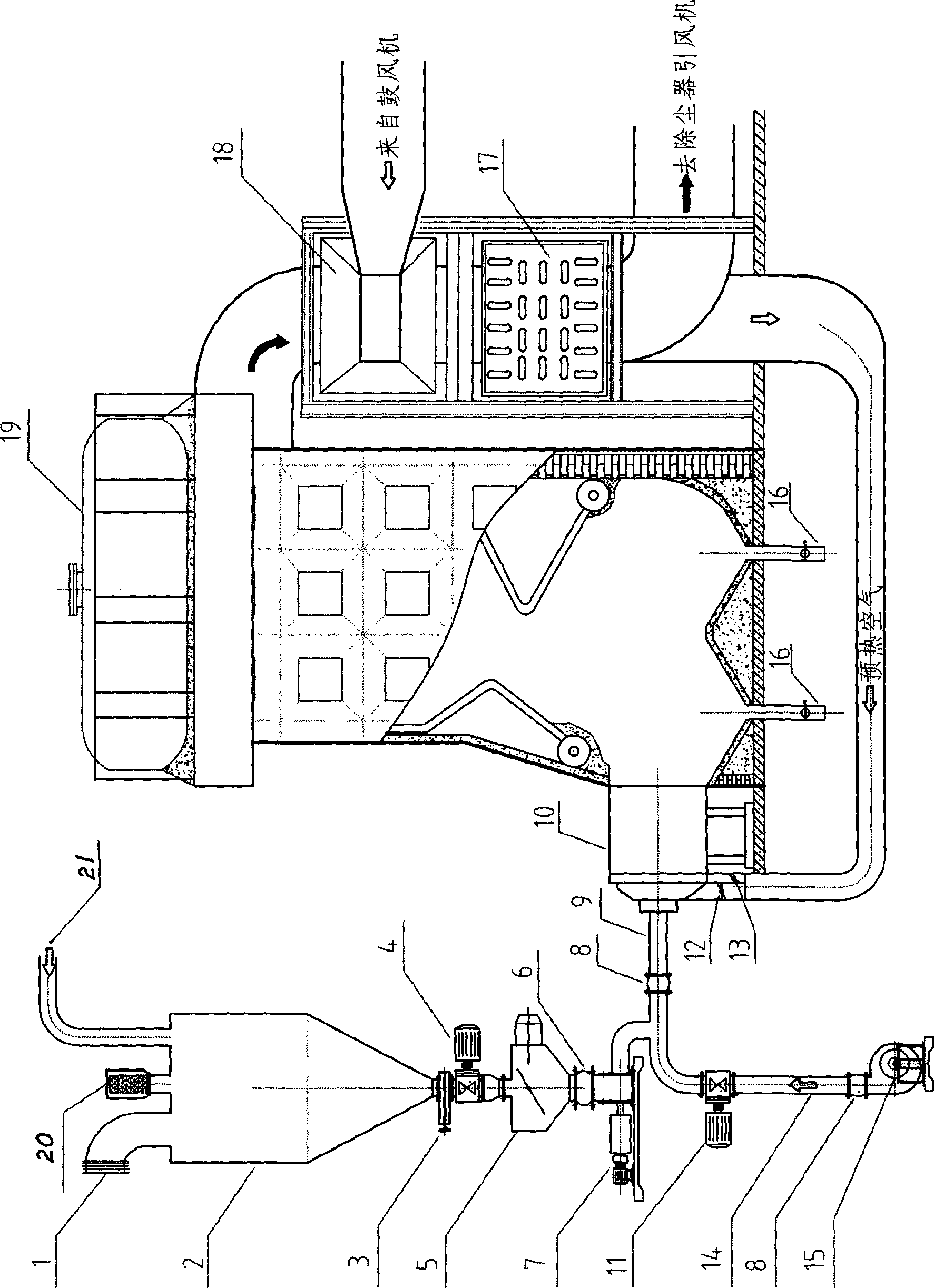

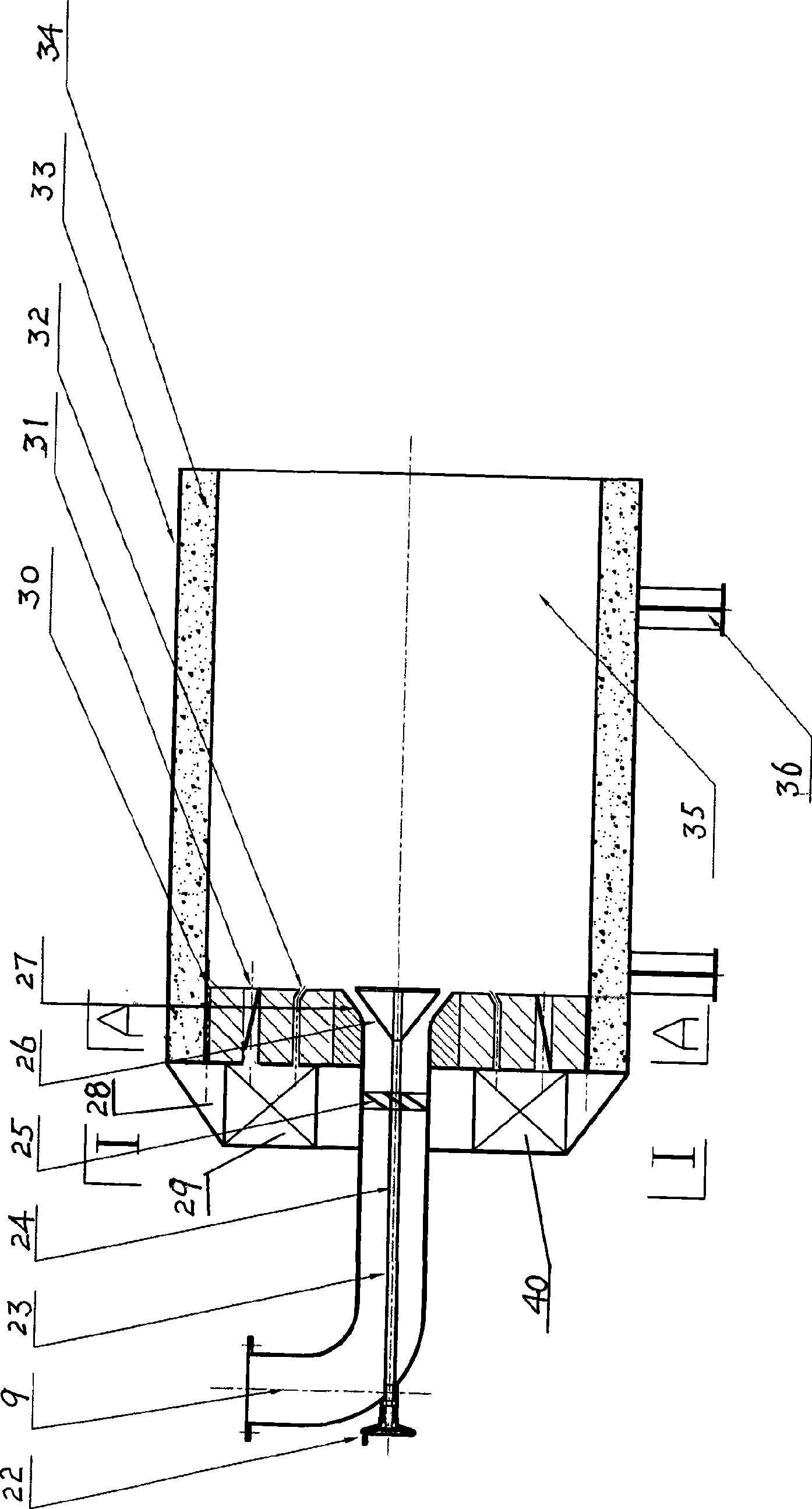

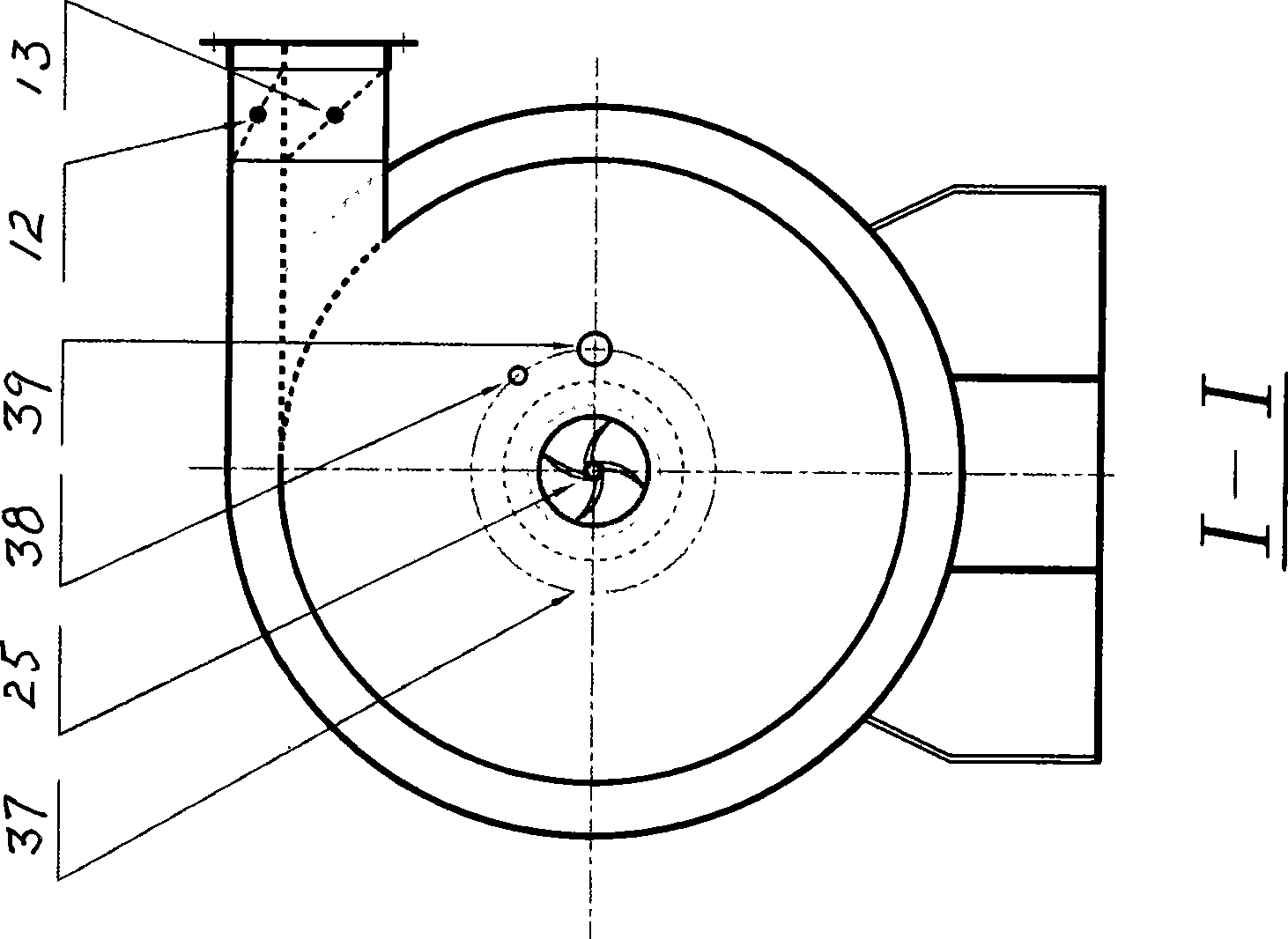

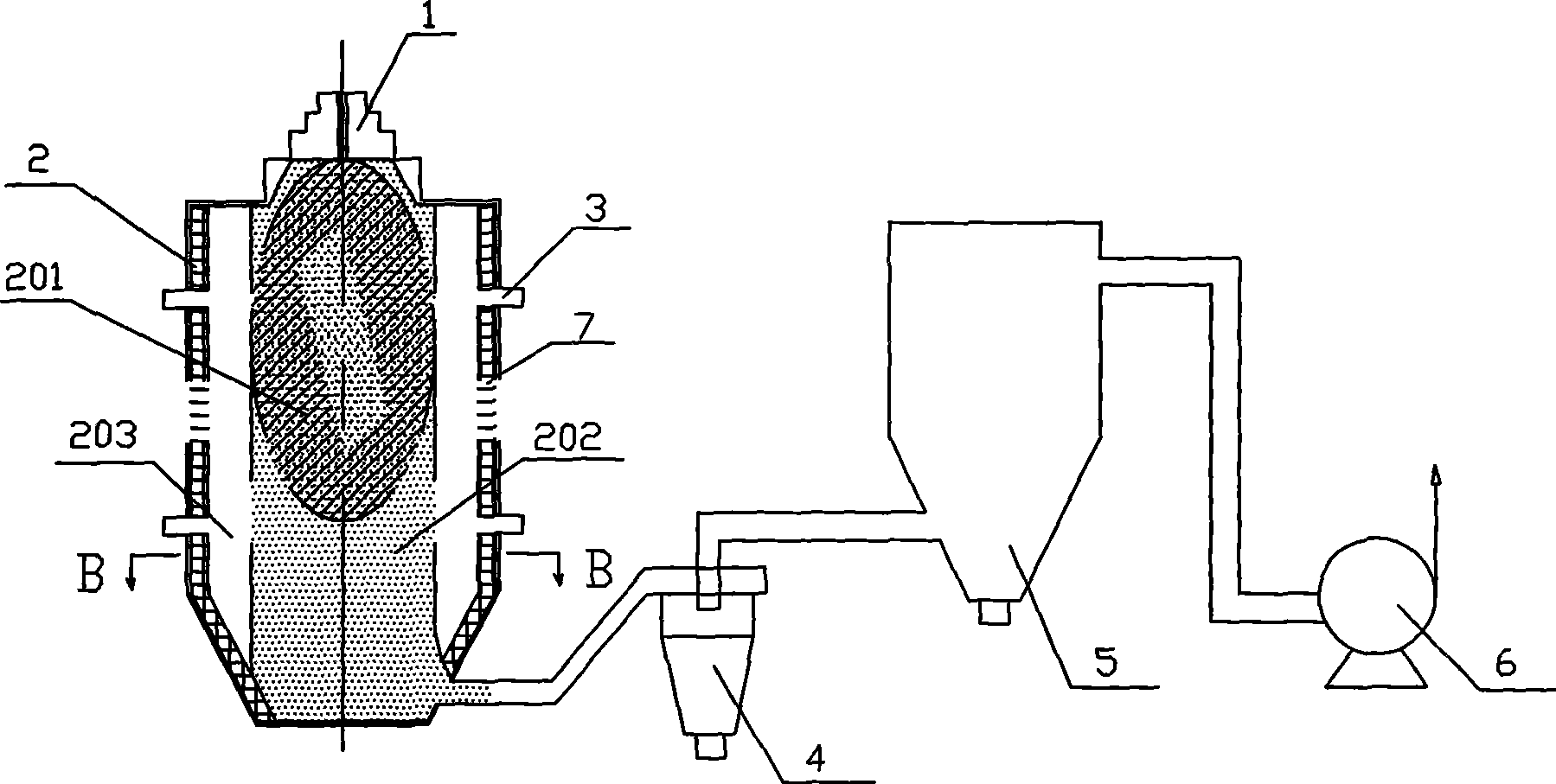

Crude and fine coal powder separation and burn method and device

InactiveCN101055077AImprove combustion stabilityPromote fireCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorJet flow

A coal powder thickness separation burning method and a device thereof belong to coal powder burning technology field and are adapted to coal powder burning boiler. The method includes: (1) separating step, separating the conventional coal powder to fine coal powder and thick coal powder; (2) flow lead burning step, setting the thick coal powder to the middle part of the burning jet flow, leading the fine coal powder to the external of the thick coal powder air flow to burn, forming a stable fire source around the thick coal powder air flow to strength the fire and stable burning for the thick coal powder air flow. The device of the invention is mounted with a cyclone separation apparatus on the front part of the main burner, the outlet of the cyclone separation apparatus is disposed with a double layer circular bushing, the inner pipe of the double layer circular bushing is connected to a hypo-wind circular tube outside of the main burner by a connection device, the outer pipe of the double layer circular bushing is connected to a hypo-wind circular tube in the main burner by a connection device. The invention has good fire characteristic, strong stable fire ability, high coal burnt rate, low NOx exhaust amount, strong adaptability for load and coal kinds and realizes high efficiency low-pollution combustion for coal powder.

Owner:HUAZHONG UNIV OF SCI & TECH

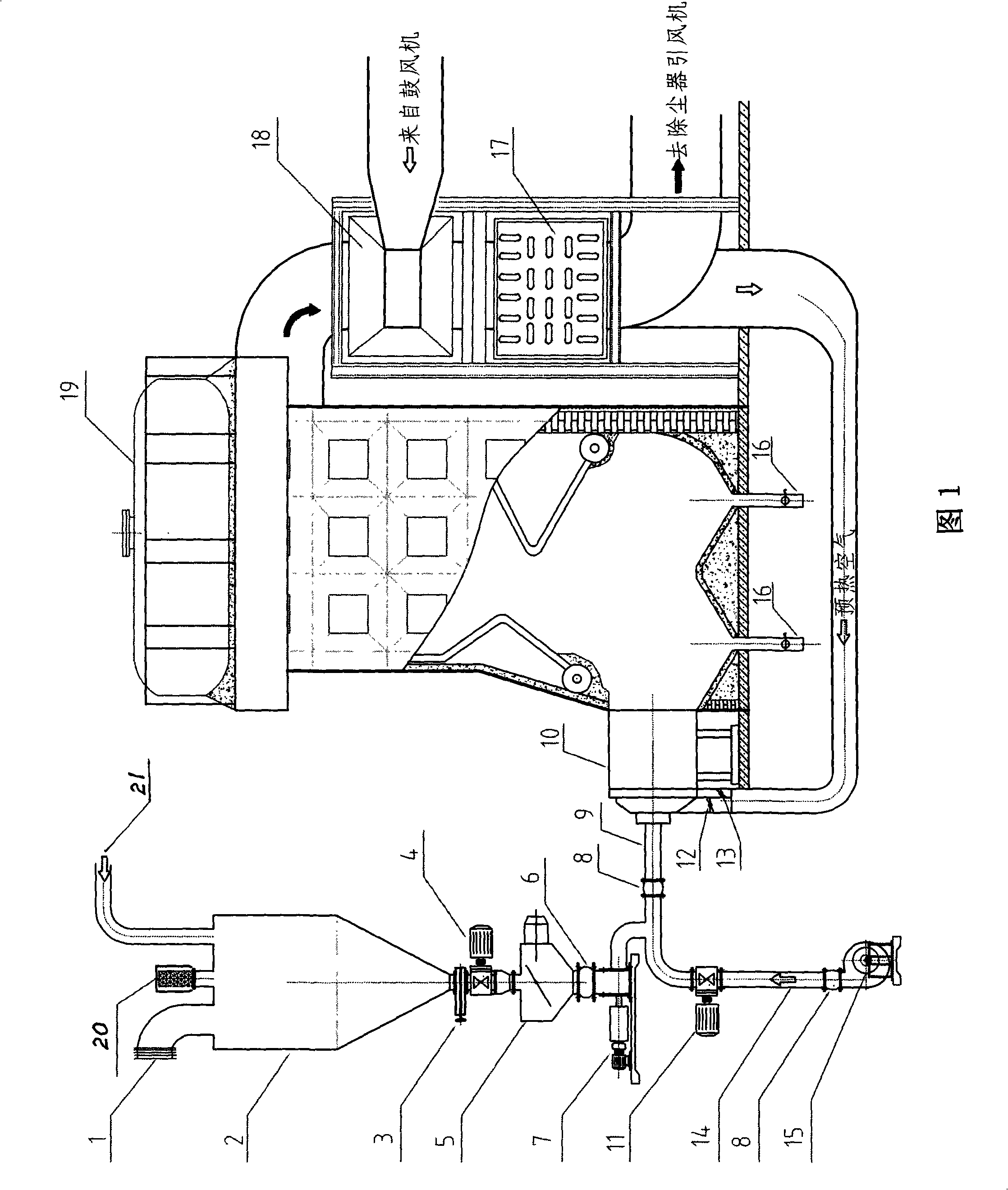

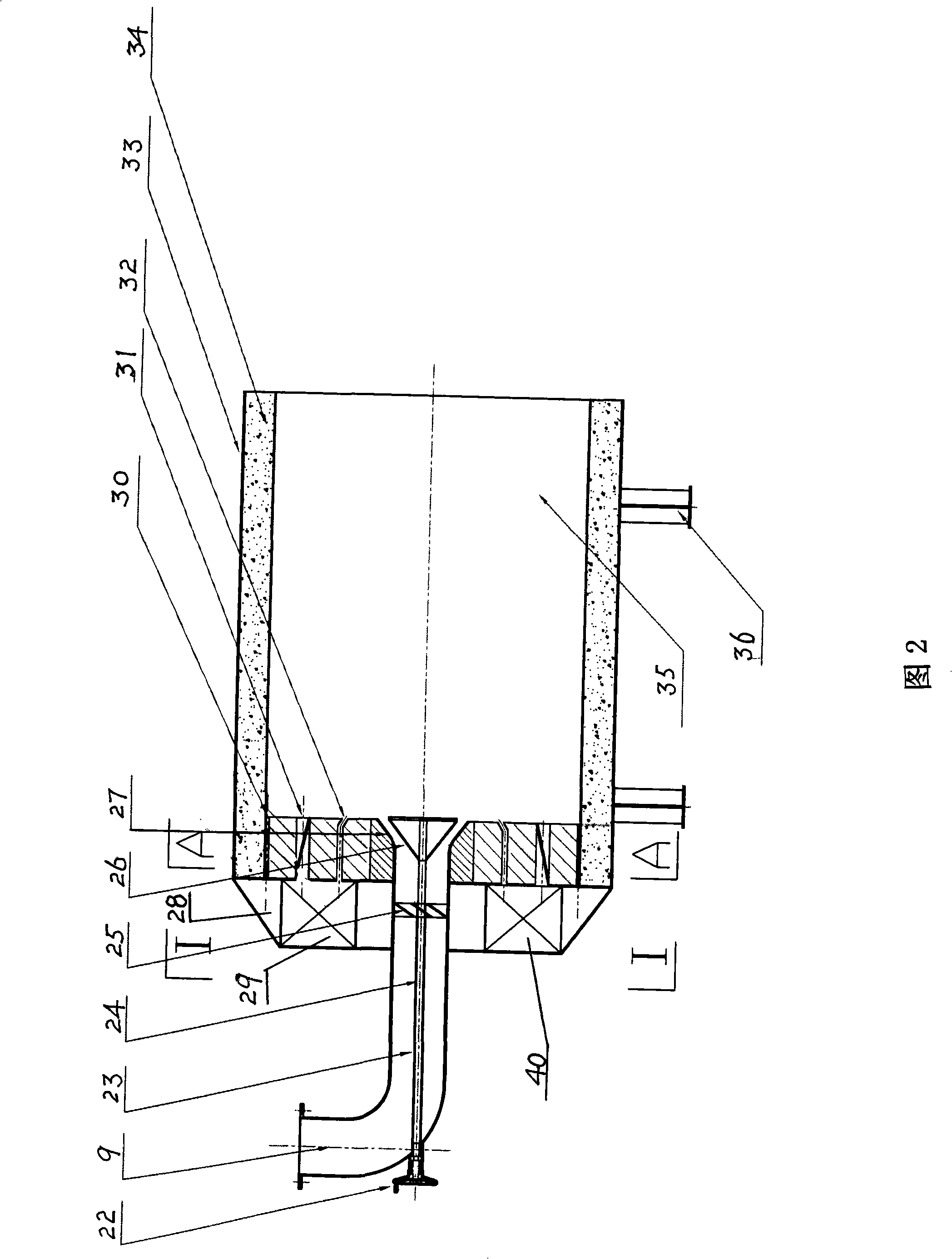

Biomass and powder coal mixed combustion and biomass recombusting and denitrating combustion apparatus

InactiveCN1673619AEmission reductionHigh volatile contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorRoom temperature

The present invention is one burning apparatus for the composite burning of biomass and coal powder and re-burning and denitrifying of biomass. The burning apparatus includes hearth, main coal powder burning area inside the hearth, main nozzles and biomass nozzles installed on the four corner of the hearth. The present invention has the following advantages: lower NOx exhaust rate, burning out of biomass fuel, large scale utilization of biomass, reduced room temperature CO2, and lowered SOx exhaust and simple apparatus structure.

Owner:HARBIN INST OF TECH

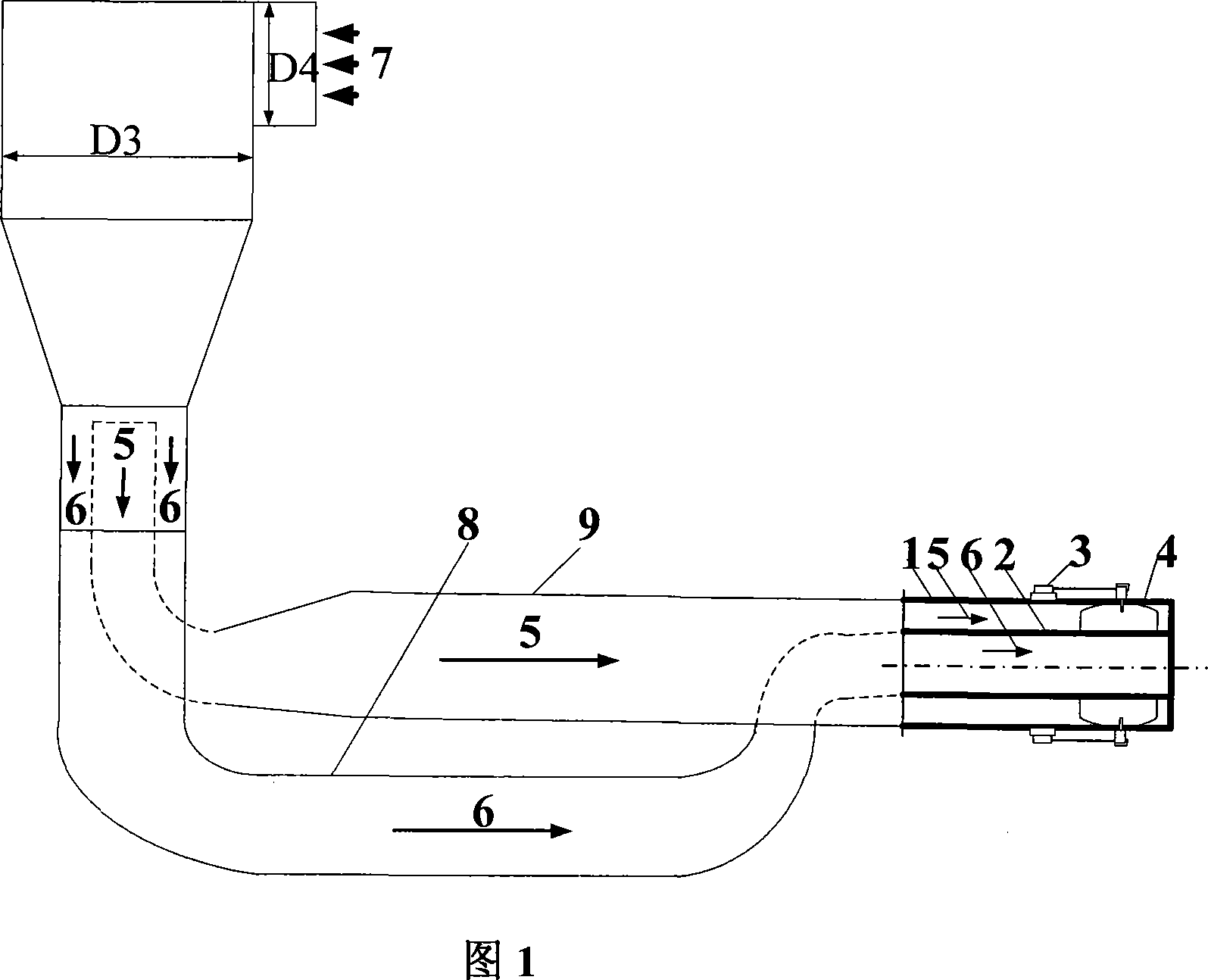

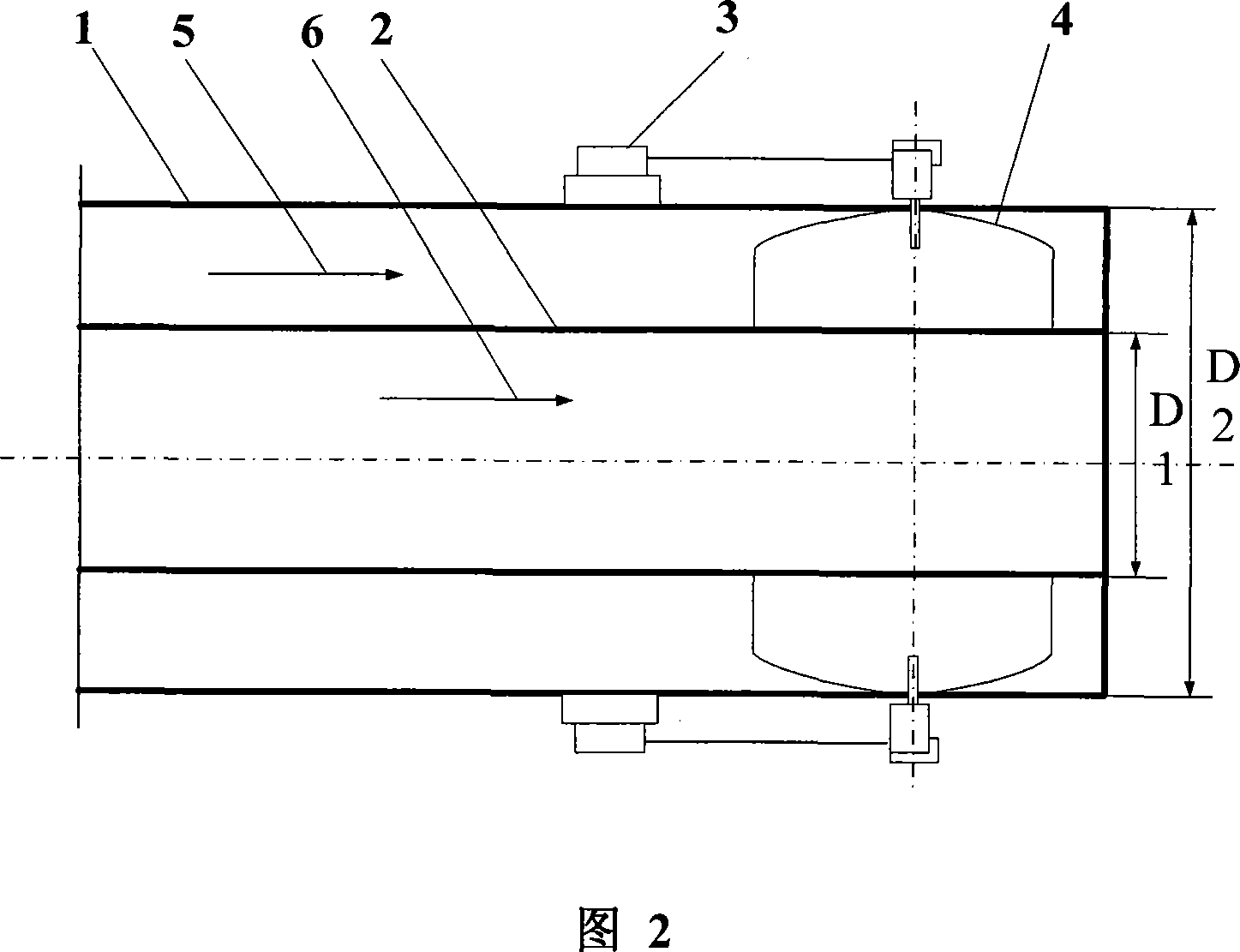

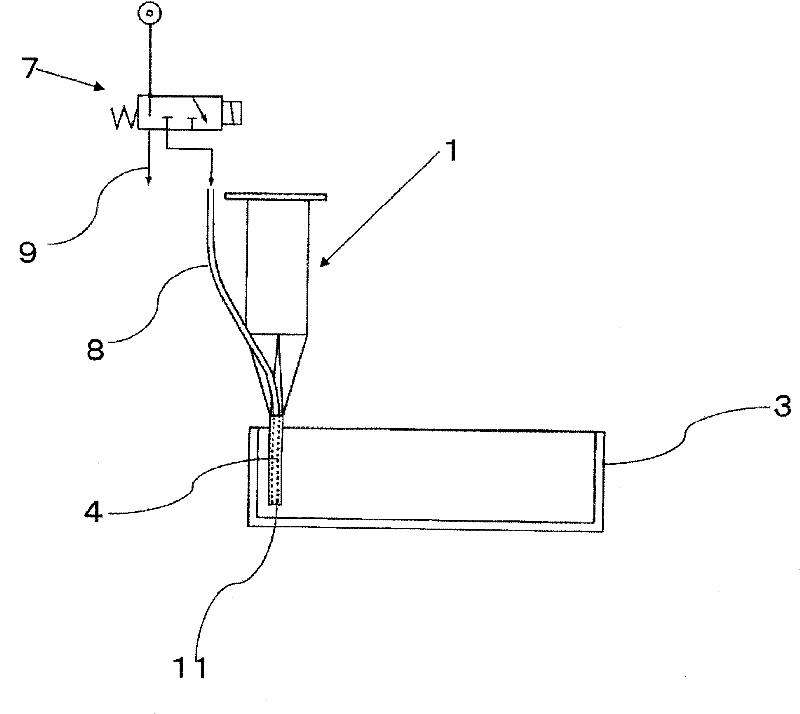

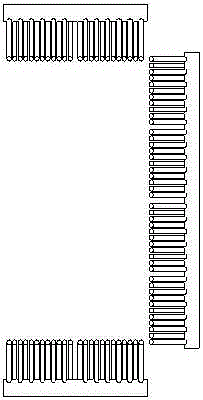

Cooling device for powder burned by saggar

InactiveCN102241395ACooling energy savingImprove cooling effectPhosphorus compoundsCooling effectSaggar

The invention provides a cooling device for powder burned by a saggar, where the cooling device without long and giant power cooling space has strong cooling effects, and cooling methods related. The powder cooling device comprises a powder nozzle (1) for sucking and recovering powder in the saggar, a powder conveying path (2) for conveying powder recovered by the powder nozzle (1), and a saggar moving unit (5) or a powder nozzle moving unit. The saggar moving unit (5) moves the saggar (3) under the powder nozzle (1) fixedly arranged, and the powder nozzle moving unit moves the powder nozzle (1) above the saggar (3) fixedly arranged. The saggar moving unit (5) or the powder nozzle moving unit has a moving mechanism which moves in segment on the vertical direction and moves continuously on the horizontal direction at a same height, so that powder in the saggar can be sucked in layers.

Owner:NGK INSULATORS LTD

Lime calcining rotary furnace

The lime calcining rotary furnace has one cylindrical furnace body, one calcining sieve barrel set concentrically inside the cylindrical furnace body, and several partition boards set homogeneously between the calcining sieve barrel and the cylindrical furnace body. During the rotation of the furnace body, crushed limestone is distributed in the channels the calcining sieve barrel and the partition boards form, heated homogeneously with the flame of the coal powder burning sprayer, and made to shift toward the relatively lower discharge port. The present invention has raised heat energy utilization and continuous operation and is superior to fixed kiln.

Owner:黄官禹

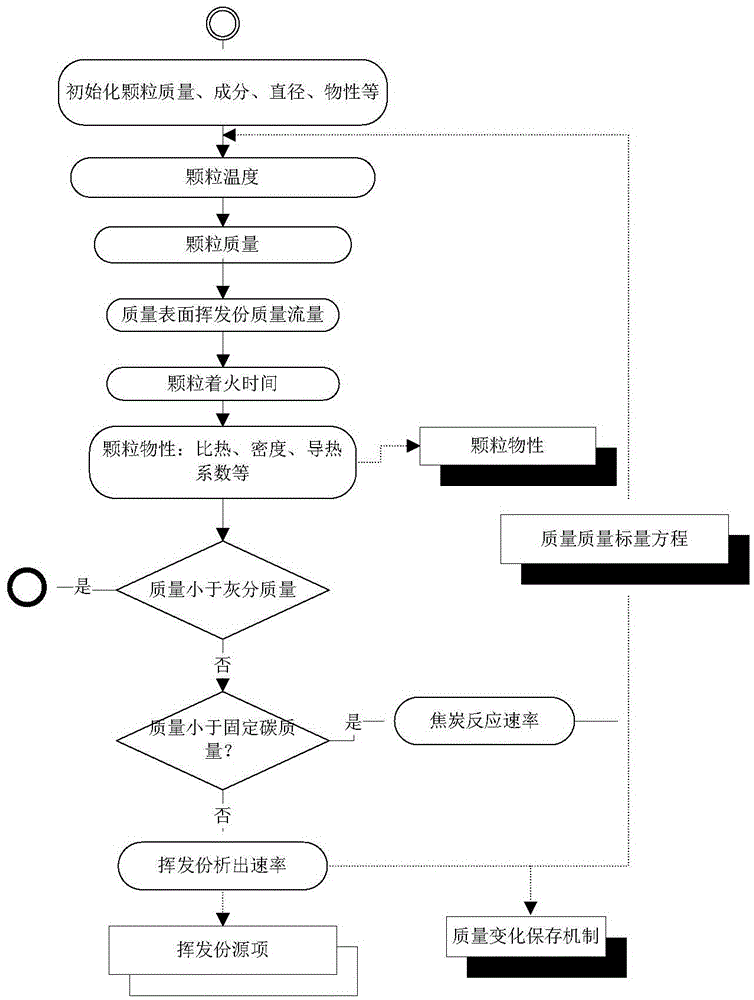

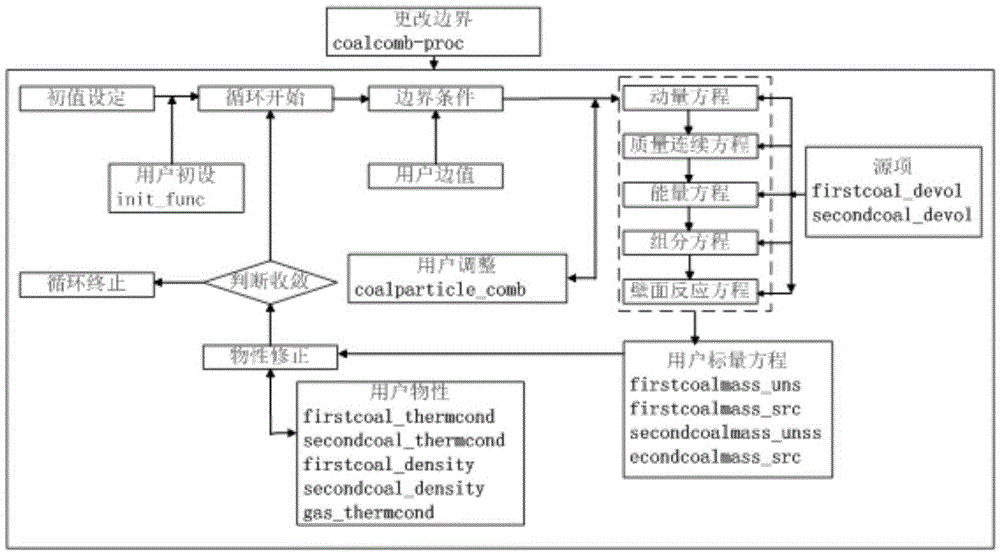

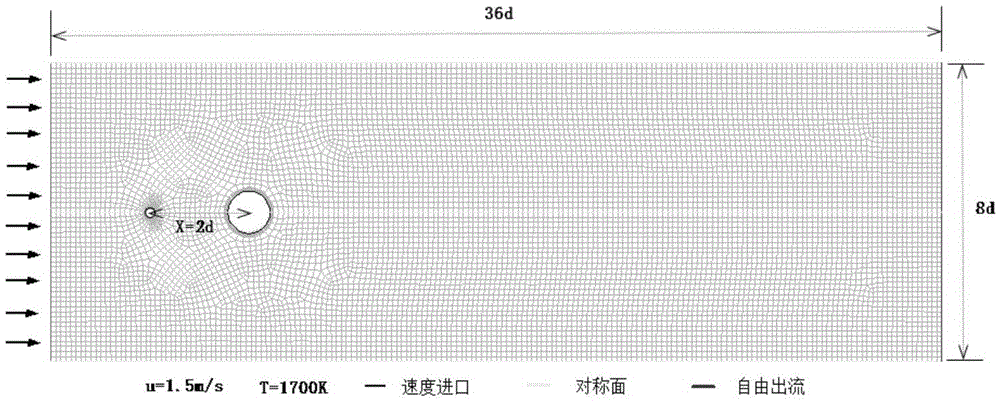

Numerical simulation method for interaction of coal powder particles in burning

ActiveCN105590005ARealize Holographic SimulationConvenient and efficient holographic simulationSpecial data processing applicationsPrillHybrid programming

The invention discloses a numerical simulation method for interaction of coal powder particles in burning, belonging to the technical field of computer numerical simulation. According to the characteristics of burning of the coal powder particles, the method is characterized in that on the basis of calculation of an existing mathematical model of fluid mechanics software FLUENT, FLUENT UDF and FLUENT Scheme are used for hybrid programming, and user-customized models, namely, a coal powder particles interaction model (a particle construction form, a particle mass change model, a particle size dynamic change model and a volatile element precipitation model) and a mass change storage mechanism, are coupled, so that numerical simulation of interaction of the coal powder particles in burning is realized. Experiments show that change rules of coal powder particle temperature and so on obtained through the numerical simulation method are generally consistent with experiment data. Through adoption of the method, a real, objective interaction mechanism of coal powder particles in burning is disclosed conveniently and efficiently, thereby providing powerful theoretical basis and technological support for improvement and optimization design of the coal powder burning technology.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

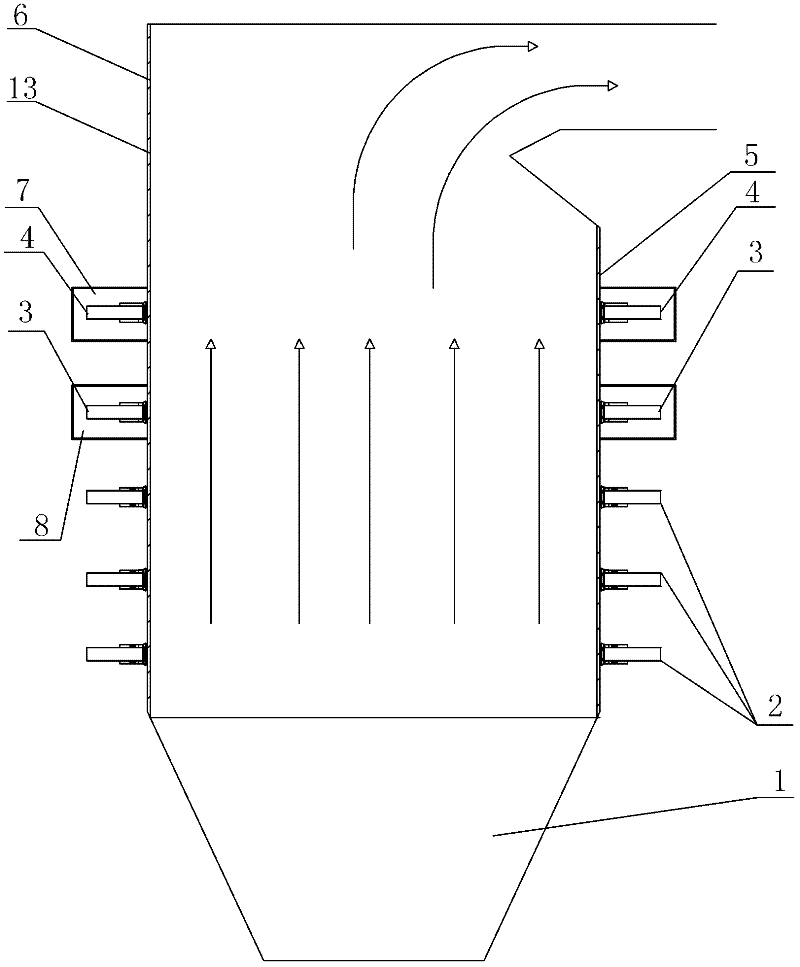

Wall-type arranged two-stage burn-up air device

InactiveCN102506419AStrong penetrating powerEnhanced turbulent mixingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSingle stageWater flow

A wall-type arranged two-stage burn-up air device relates to a wall-type arranged burn-up air device which can solve the problems of low coal powder burn-up degree, high fly ash carbon content and high attemperation water flow for existing wall-type arranged boilers caused by the adoption of a single-stage burn-up air device arrangement mode that does not adapt boiler loads and coal quality fluctuation. The device comprises a plurality of first-stage burn-up air, a plurality of second-stage burn-up air, a plurality of first-stage burn-up air bellows, a plurality of second-stage burn-up air bellows, a plurality of first-stage burn-up air doors, and a plurality of second-stage burn-up air doors; a lower end of a hearth wall body is connected with an upper end of a cold ash hopper; the plurality of swirl burners are arranged on the wall body in a multilayer mode; the plurality of first-stage burn-up air are arranged on the wall body and are located above the swirl burner at the top layer; the plurality of second-stage burn-up air are arranged on the wall body and are located above the first-stage burn-up air; the plurality of first-stage burn-up air are disposed in the first-stage burn-up air bellows. The invention is applicable to boilers.

Owner:HARBIN INST OF TECH

Production process with modified fly ash to replace cement clinker

The present invention discloses production process with modified fly ash to replace cement clinker. During power generation, coal powder is made to burn at 1300-1500 deg.c high temperature condition with oversaturated fine CaO powder, so that CaO can take part in the mineral recombination of coal powder burning remainder to activate the physical and chemical activity of aluminosilicate solid solution as the burning product and generate aluminosilicate mineral containing C3S, C2S, C3A and C4AF. The produced aluminosilicate mineral has the physical and chemical characteristics of cement clinker or high aluminum fly ash sintering base material, and may be used to replace common cement clinker or high aluminum fly ash sintering base material. The present invention can lower the slag treating cost in power generation and produce cement substitute.

Owner:葛东海

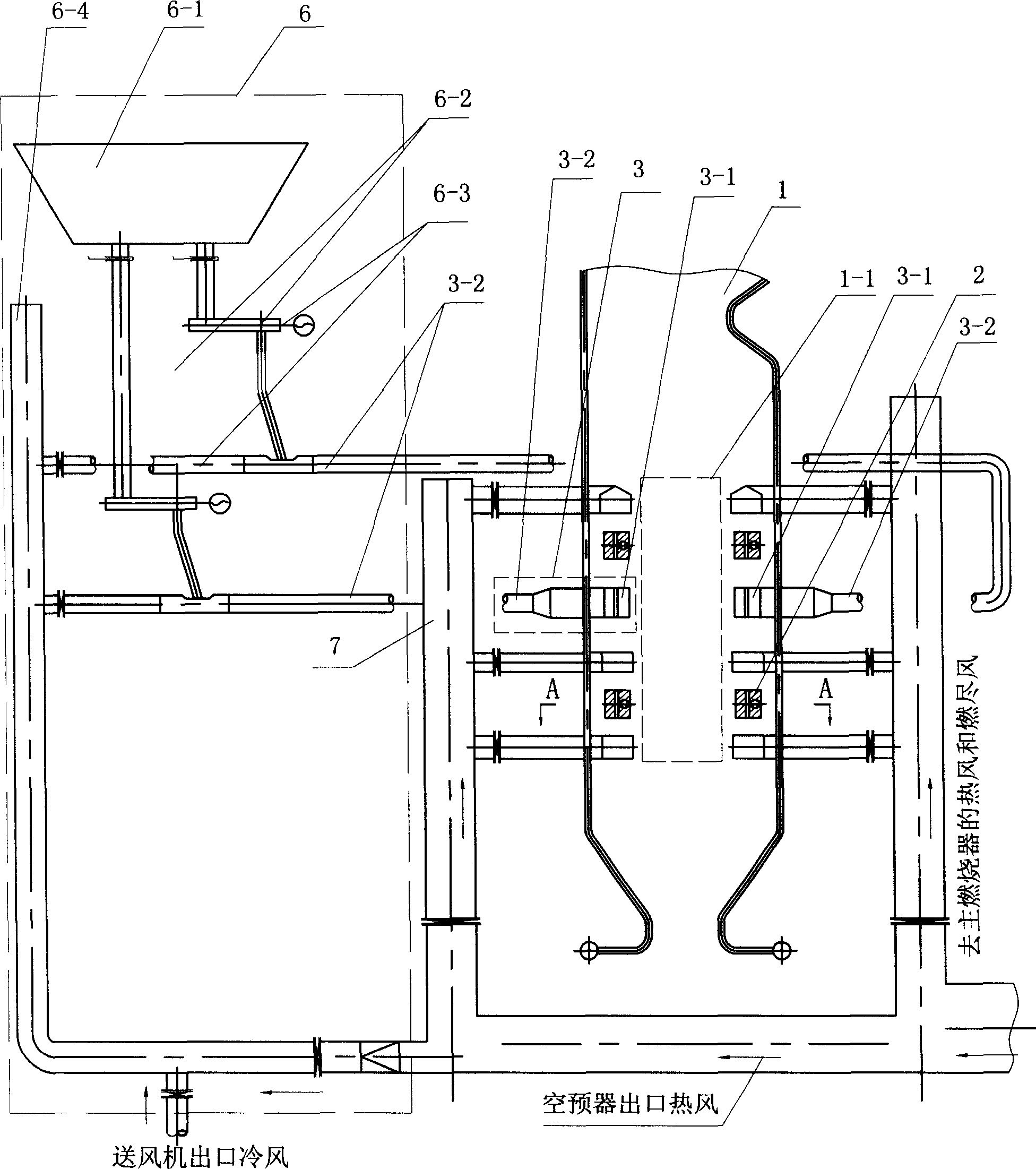

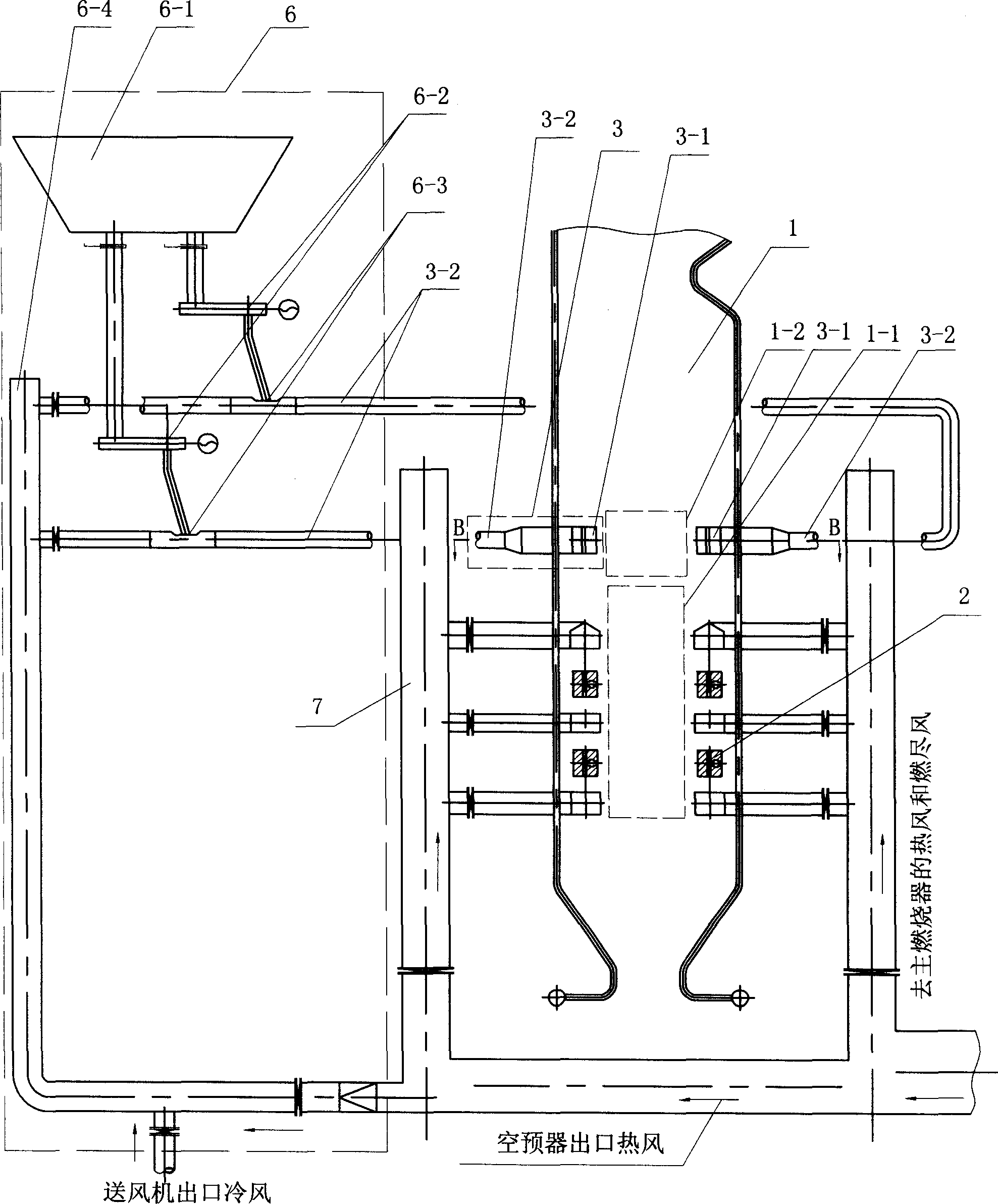

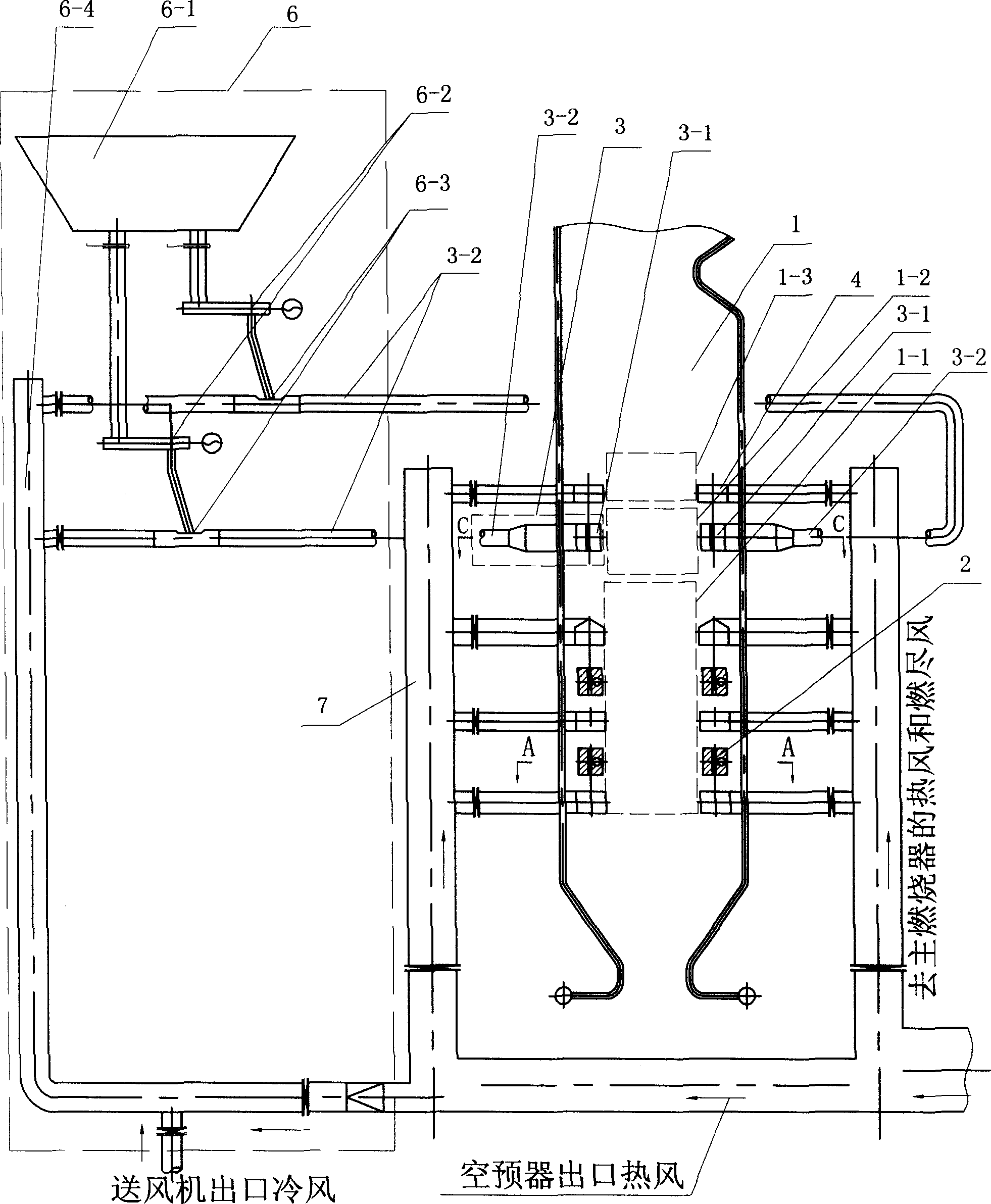

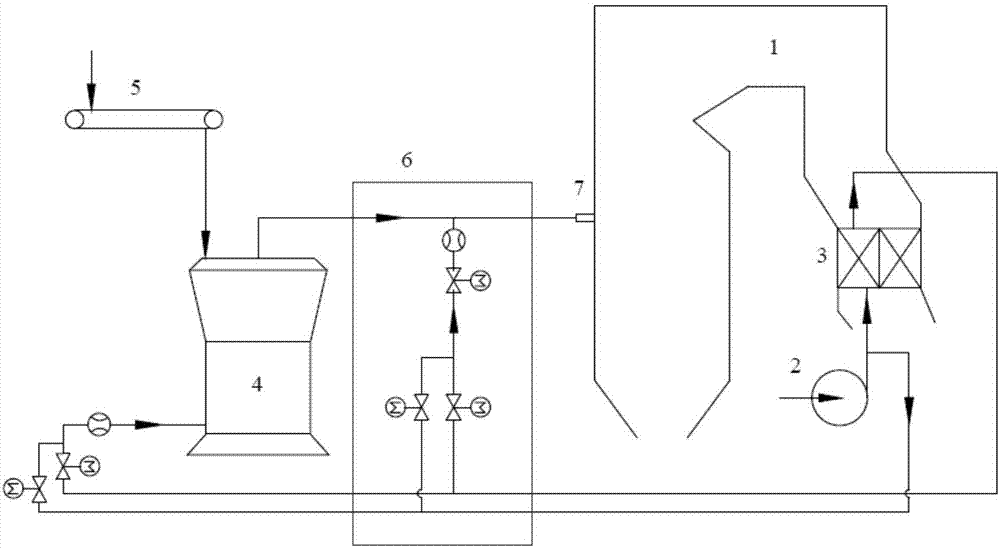

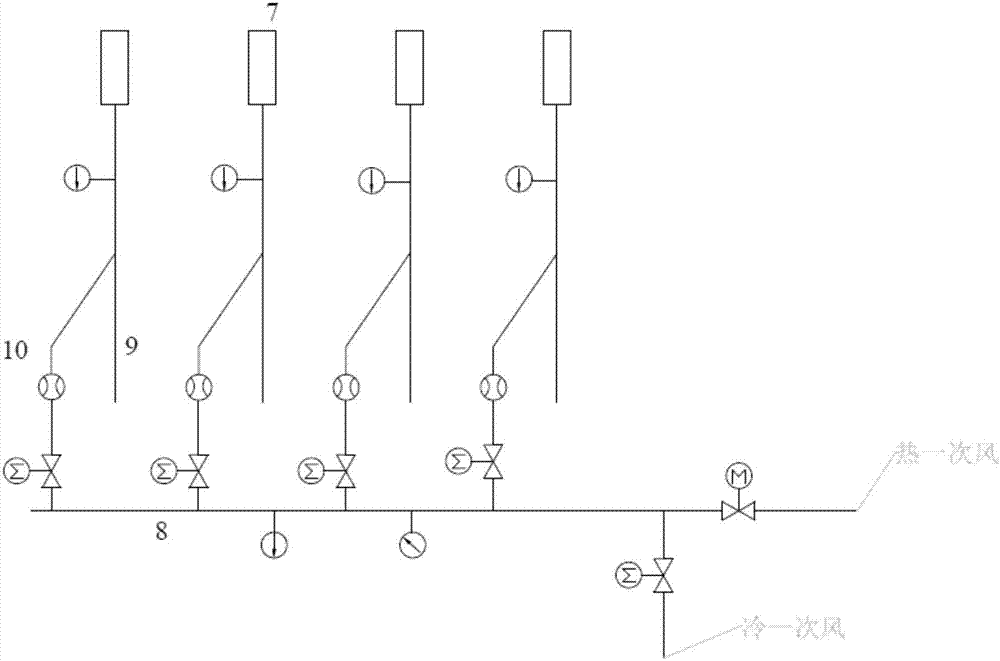

Wind powder mixing temperature and flow speed secondary adjusting system

PendingCN107238101AImprove burnoutImprove operational flexibilityFuel supply regulationIndirect carbon-dioxide mitigationAir preheaterCombustor

The invention discloses a wind powder mixing temperature and flow speed secondary adjusting system. A wind outlet of a primary fan is divided into two paths. One of the two paths communicates with a hot wind inlet of an adjusting system and an inlet of a first valve through an air preheating device. An outlet of the first valve communicates with a wind inlet of a coal mill. The other path of the two paths communicates with a cold wind inlet of the adjusting system and an inlet of a second valve. An outlet of the second valve communicates with the wind inlet of a coal mill. An outlet of a coal feeding device communicates with a coal inlet of the coal mill. An outlet of the coal mill, an outlet of a wind powder air-solid two-phase temperature and flow speed adjusting system and inlets of burners on a furnace communicate with one another. According to the wind powder mixing temperature and flow speed secondary adjusting system, secondary adjusting of wind coal mixing temperature and flow speed can be achieved, the problems of coal powder pipeline backfiring, burning loss of spraying nozzle, burner surrounding coking and overtemperature of the wall temperature of the water cool wall and the metal wall which are caused by once low wind speed are solved, safe and stable running of the system is ensured, and meanwhile, the coal powder burned-out performance, the furnace underload burning stability and the running flexibility of machine units are improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Low NOX dry ash extraction coal powder burning method

InactiveCN101487589AWell mixedAvoid sticking and cokingCombustion using gaseous and pulverulent fuelFuel supply regulationCombustion chamberCoal dust

The invention relates to a low NOX solid residue discharge coal dust combustion method which is characterized in that a fire grate at the bottom of an old boiler is dismounted, so that a pure hearth is formed, or a boiler provided with the pure hearth is manufactured; at least one inflamer is arranged at the bottom or one side of the pure hearth; when a primary air fan is started, primary air and coal dust enter the inflamer through a primary air / coal dust pipe, so that the primary air and the coal dust can burn sufficiently after entering a combustion chamber; meanwhile, a flame detector automatically enters a crust block prevention tertiary air curtain regulating valve which can monitor and has the function of linkage protection and regulation and a secondary air regulating valve, an air curtain is formed on the inner wall of a high temperature fire resistant layer by the wind sprayed out of a crust block prevention tertiary air curtain spray pipe, the secondary air enters the combustion chamber through a secondary air rotational flow guider and a secondary air flame stabilizing rotational flow guider, the rotational flow direction of the secondary air is consistent with that of an axial flow generator, and the secondary air is mixed with the coal dust burnt by the primary air again to be burnt, thus leading the coal dust to be burnt more fully. The invention has the advantage of burning the coals with low ash fusion point and high ash fusion point.

Owner:郑雯平

Gel ointment for treating burn and scald

InactiveCN101524328AWith hemostatic functionGrowth inhibitionAerosol deliveryCarbon active ingredientsCarboxymethyl celluloseTissue fluid

The invention relates to gel ointment for treating burn and scald, which is characterized in that sodium carboxymethyl cellulose and other gels are compounded into ointment matrix; and the ointment is carried with percolate miraculous for burn and carbon powder burned by residues. The gel ointment has the following advantages that the ointment has hemostasis function, has the function of inhibiting bacteria growth, can prolong the time for releasing medicament, generates biological adhesion to firmly adhere to an afflicted part, has the function of adsorbing tissue fluid generated after burning and scalding, has the function of inhibiting fibrocyte growth and reducing scars, forms a membrane shape at the afflicted part under the action of body temperature and natural condition, does not adhere to the skin, is easy to take off, does not cause twice bleeding and harm, is more stable, and is convenient to use.

Owner:大连永兴生物医药孵化器有限公司

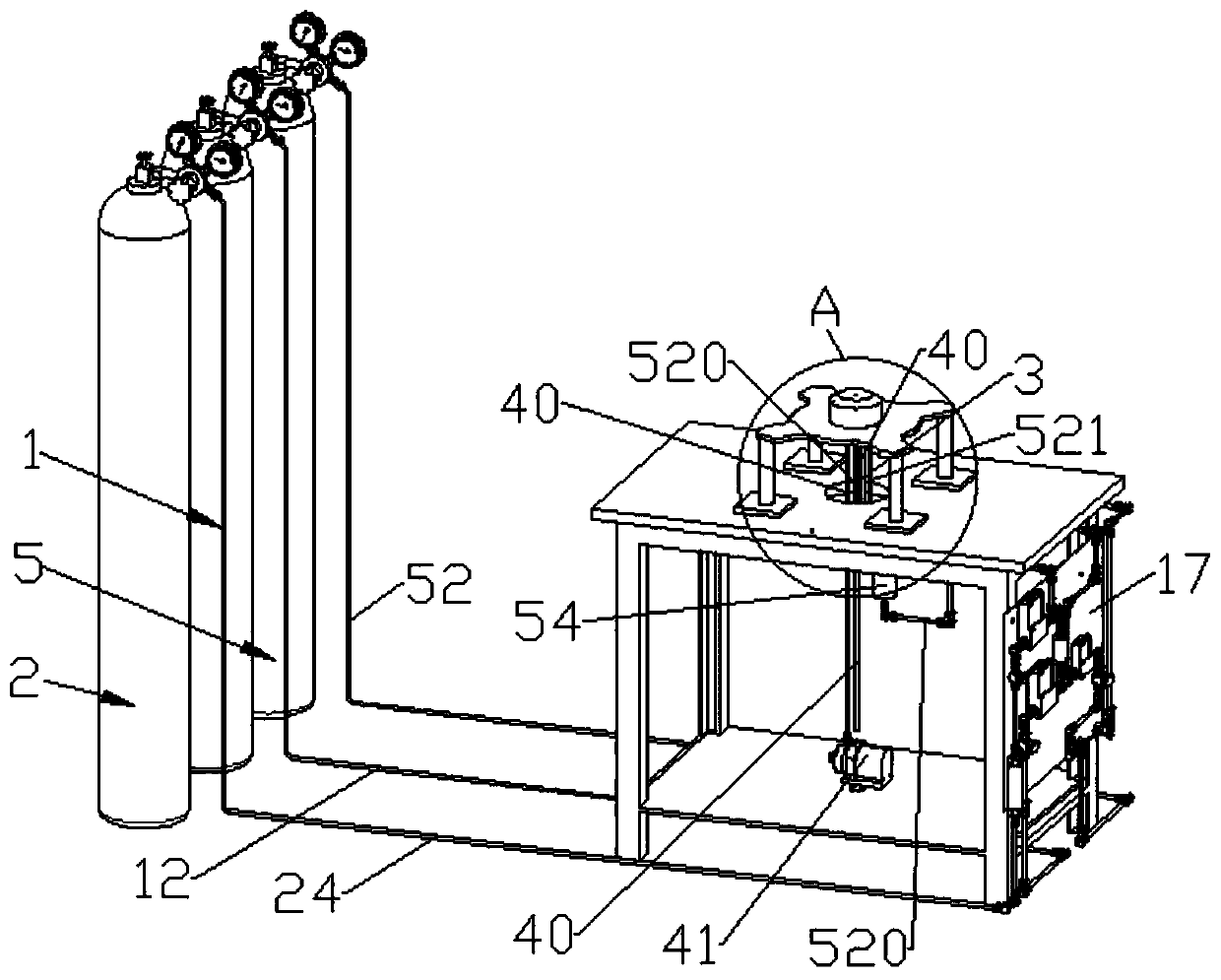

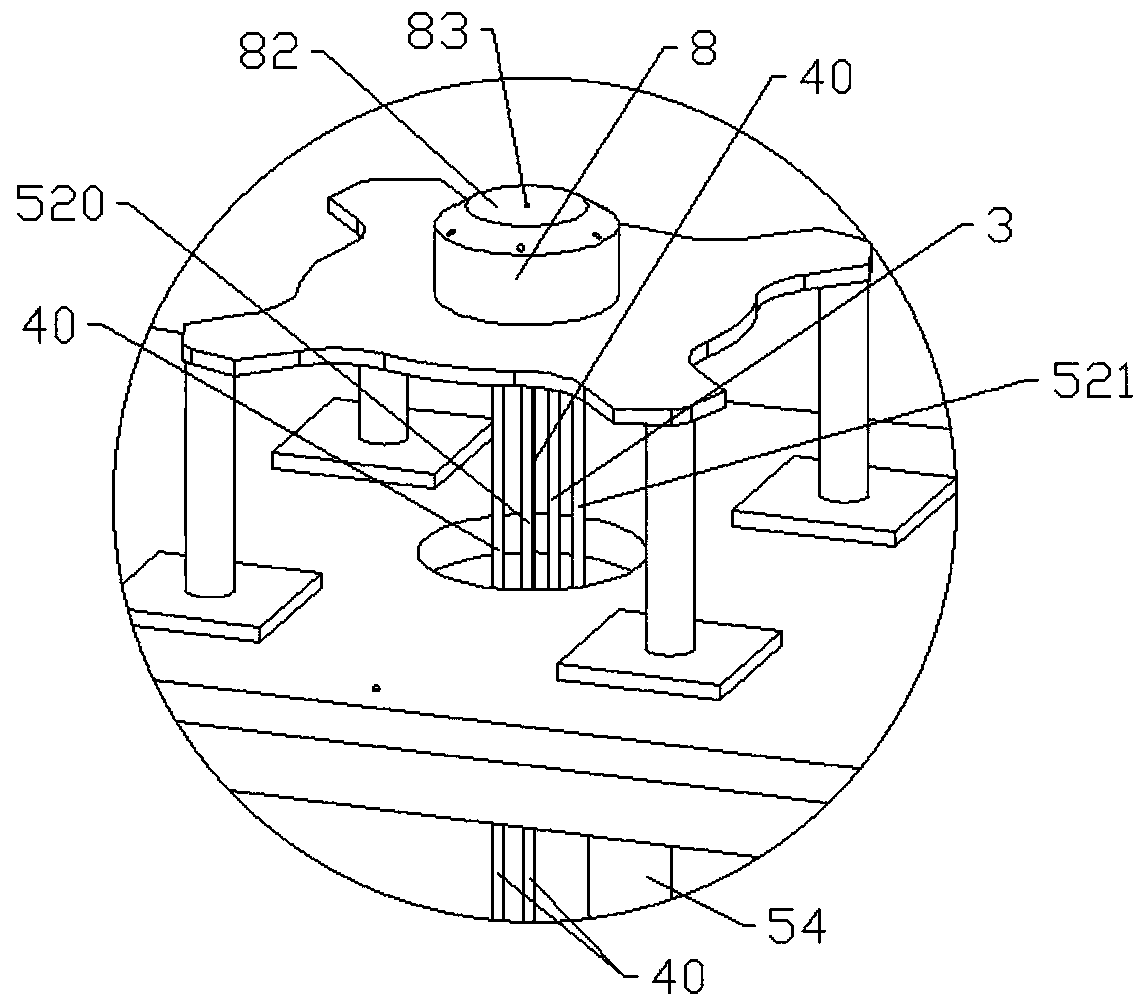

Powder combustion experiment platform

ActiveCN111323343AImprove combustion performanceObserve the performance of combustionChemical analysis using combustionNitrogen gasPowder burn

The invention provides a powder combustion experiment platform which mainly comprises a fuel gas conveying system, a water cooling circulation system, a nitrogen system, a test bed and a flat flame combustor, and the fuel gas conveying system comprises an air system, a methane system and a mixed fuel gas pipeline. By means of the powder combustion experiment platform, the powder combustion performance can be better observed.

Owner:XIAN MODERN CHEM RES INST

Energy conservation and emission reduction modification method for reducing emission load of nitric oxide of DDF decomposing furnace

ActiveCN105299625AIncrease volumeExtended dwell timeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelDecompositionNitric oxide

The invention discloses an energy conservation and emission reduction modification method for reducing the emission load of nitric oxide of a DDF cement decomposing furnace. By arranging an air gathering bellows and a gooseneck pipe on the DDF decomposing furnace with the small volume, the smoke standing time is prolonged; part of coal powder is distributed to the conical portion of the decomposing furnace, part of tertiary air is distributed to the upper middle portion of the decomposing furnace, the volume of the DDF decomposing furnace is enlarged, the position of part of coal powder entering the furnace is reduced, and the coal powder burn-off rate is improved. The coefficient of excess air in the lower middle portion of the decomposing furnace is smaller than 1.0. Under the condition of insufficient oxygen, CO of a large proportion is generated to become reducing agents for reducing and eliminating nitric oxide. An ash returning channel is arranged inside the air gathering bellows and feeds raw materials and coal powder particles subsided back to the position above a middle nozzle of the decomposing furnace, so that the problem of sintering blockage of accumulated ash is solved, the coarse particle processing capacity of the decomposing furnace is improved, the decomposition rate of raw materials entering the furnace is improved, and through the double effects of reducing emission of nitric oxide and reducing heat loss, the effective energy conservation and emission reduction of a cement calcining system are achieved.

Owner:BEIJING TRIUMPH INT ENG

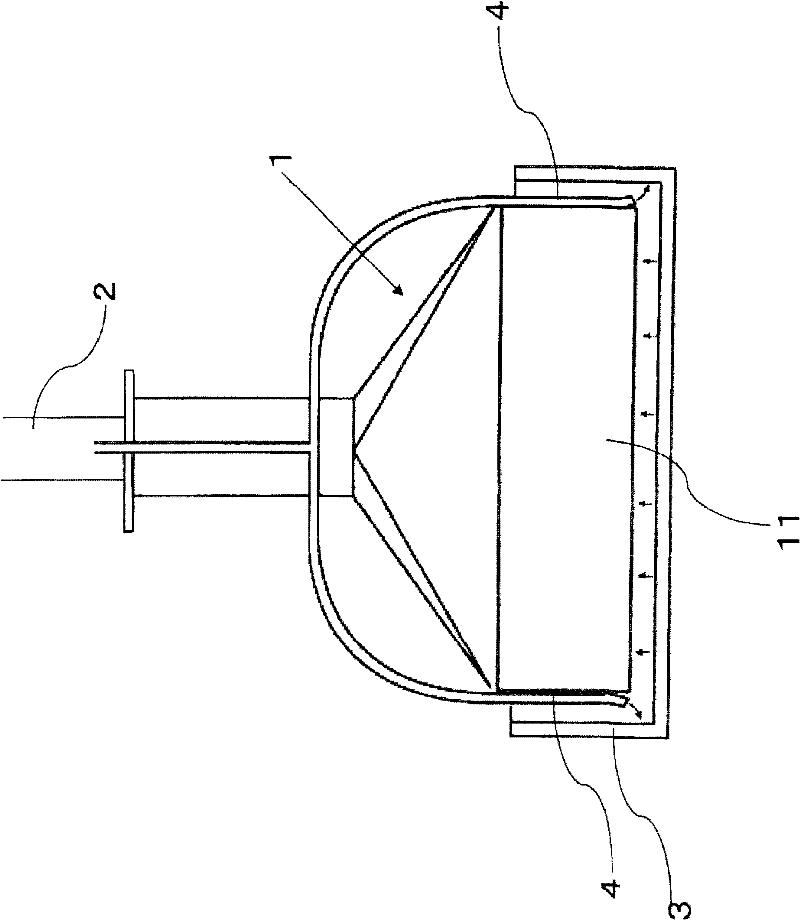

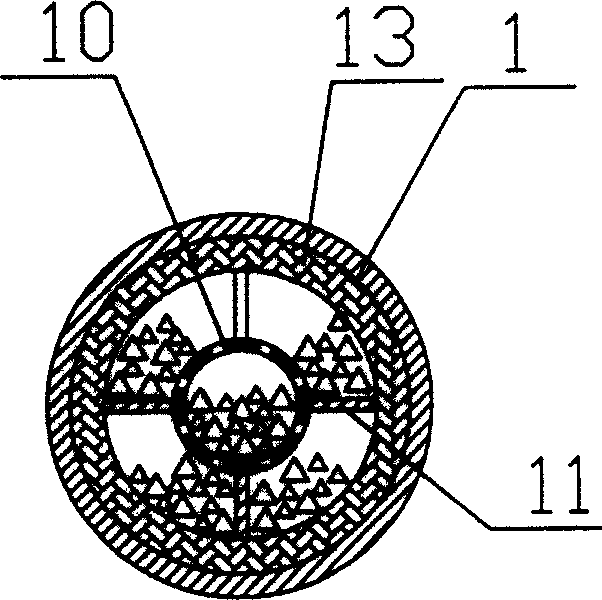

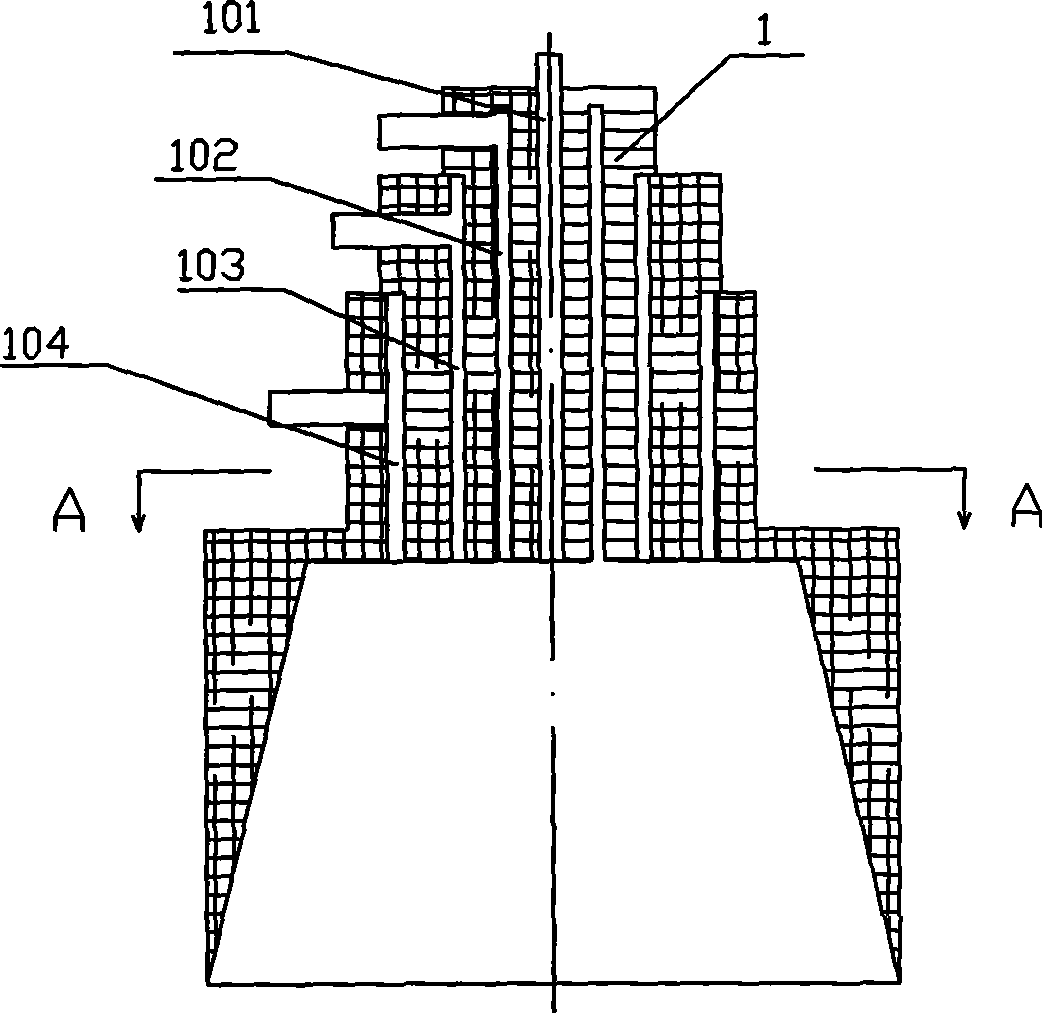

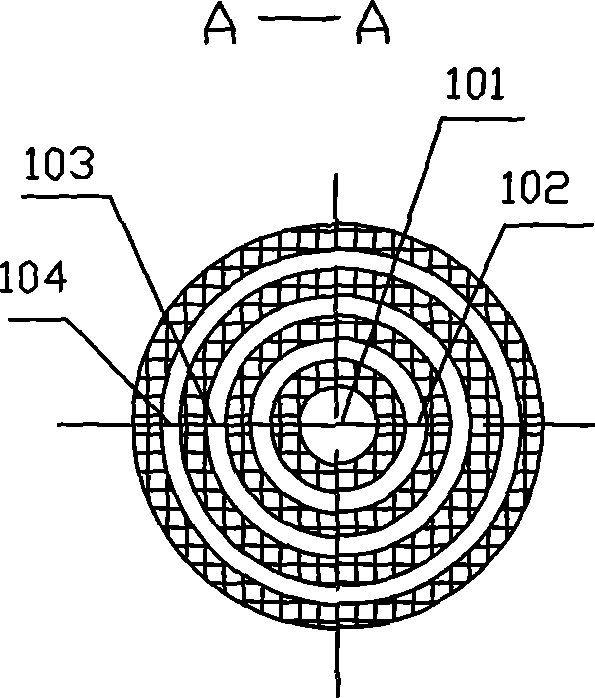

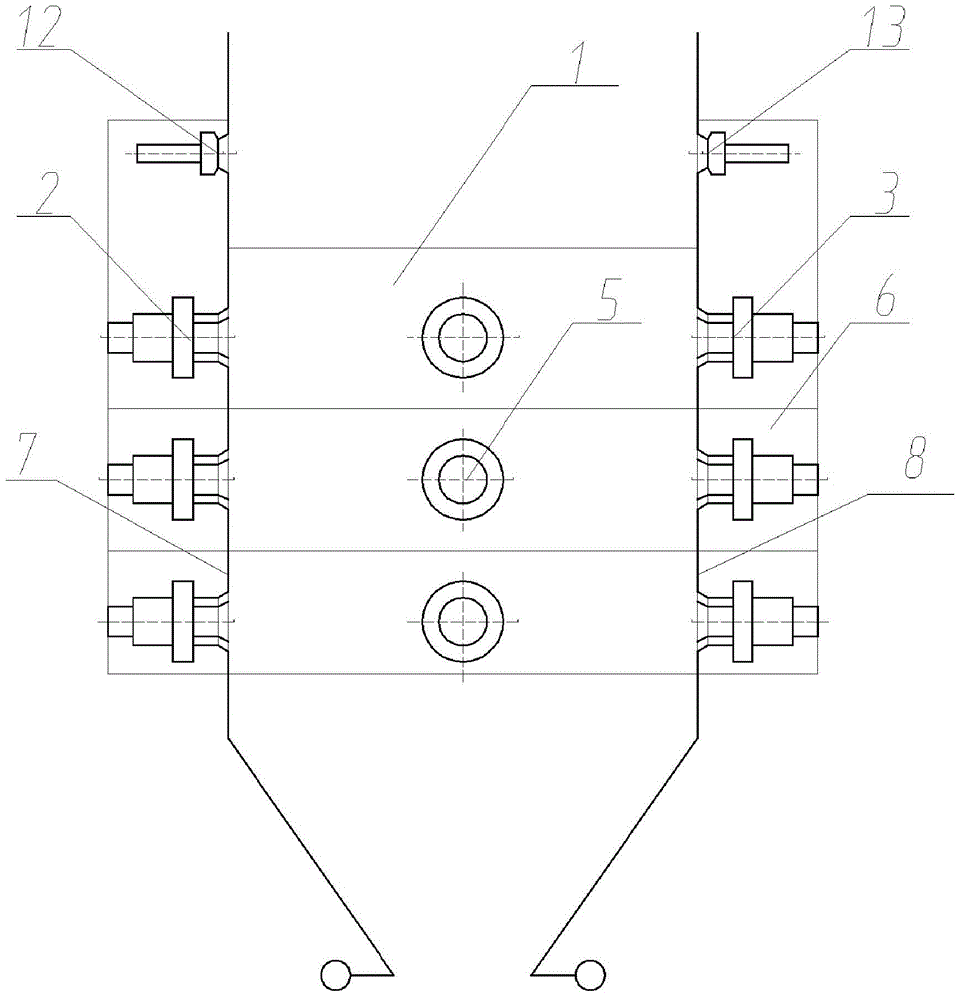

Powder burning furnace

InactiveCN101519207AProtect non-stick wallsReduce stressSilicaVery large scale integrated circuitsCombustor

The invention relates to a powder burning furnace which comprises a burner (1) and a spheroidizing furnace and is characterized in that the center of the burner (1) is provided with a gas orifice (101) and three layers of annular gas injection passages (102, 103 and 104). Inorganic powder and oxygen are injected from the gas orifice (101) after being mixed and mixedly burnt in a burning chamber together with natural gas and oxygen which are injected from the annular gas injection passages (102, 103 and 104). The invention has the advantages that the outer layer of annular protective oxygen can effectively protect powdery granules from sticking a fire wall and ensure oxygen rich burning, and spherical silica micro powder with excellent performances such as high dielectric property and filing ratio, low expansion and stress, high liquidity, and the like can be used, thereby the powder burning furnace can be applied to basal plates and packaged materials of large-scale and super large-scale integrated circuits.

Owner:赵娟

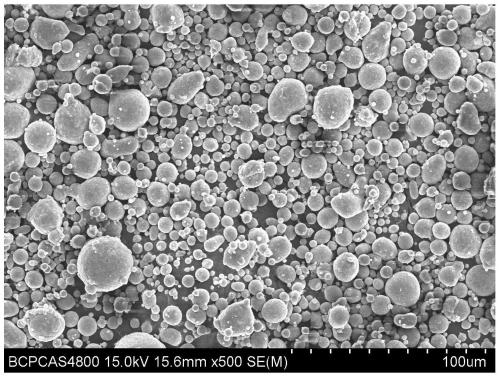

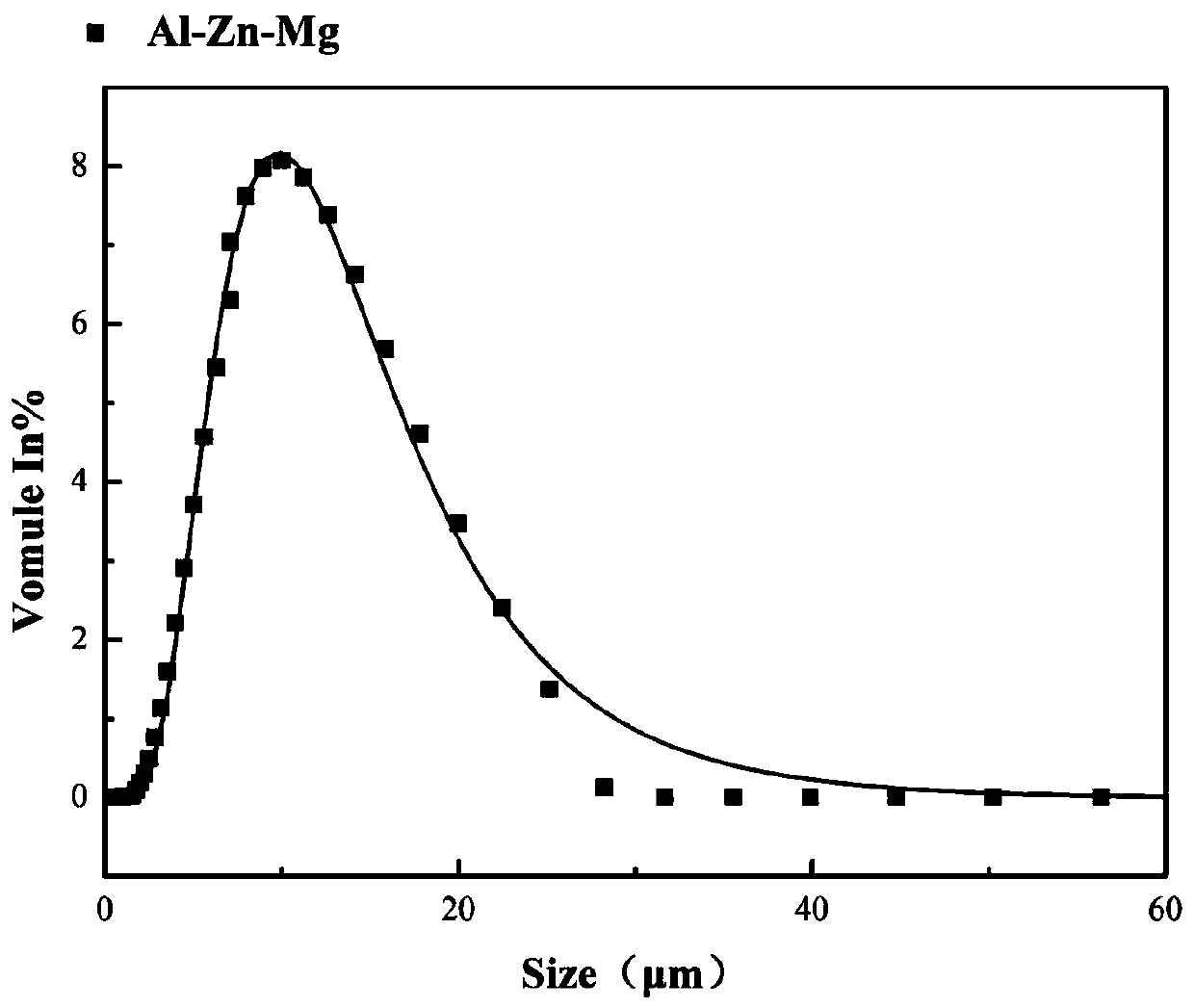

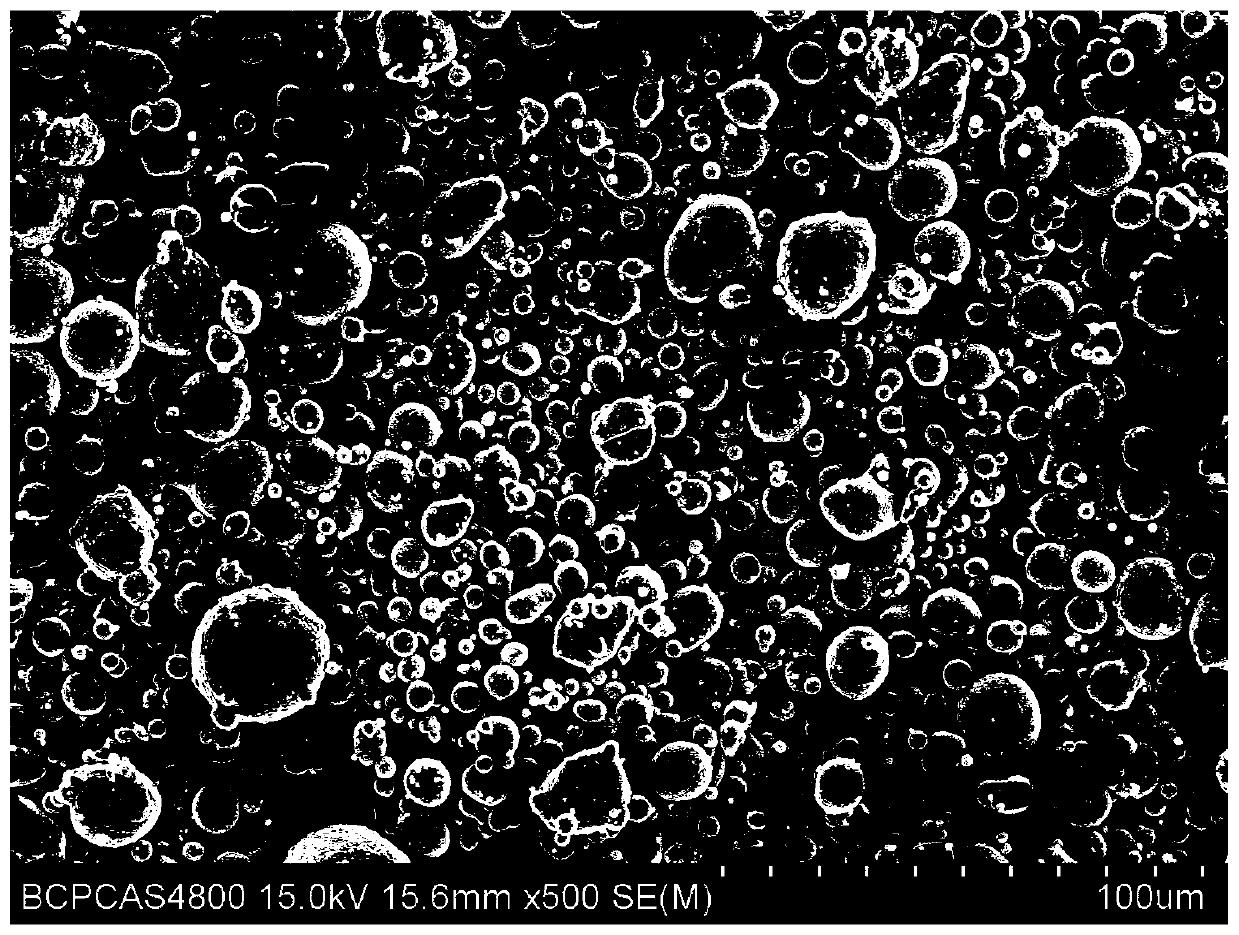

Aluminum zinc based multi-component alloy spherical powder and preparation method and application thereof

The invention provides aluminum zinc based multi-component alloy spherical powder and a preparation method and application thereof, and belongs to the technical field of alloy powder. The aluminum zinc based multi-component alloy spherical powder comprises aluminum, zinc and component metal elements, and the component metal elements comprise one or more of Li, Mg, Bi, Sb and Pb. The Li and the Mgin the component metal elements have lower melting and boiling points, are volatile and can form steam, and the steam can prevent the formation of oxides; when the Li and the Mg are burnt in a gas phase, a gas phase diffusion flame can be formed, the heating rate is high, and the opportunity for forming the oxides is less; and therefore, when the Mg and the Li are added into aluminum and zinc, thefuel activity of the aluminum and zinc can be improved, the firing temperature is lowered, and the burning performance is improved. The density of the Bi, the Sb and the Pb in the component metal elements is much greater than metal aluminum, due to the special performance of the oxides of the Bi, the Sb and the Pb, the burning efficiency of aluminum particles can be improved by increasing the high volume impulse quantity and energy density of the aluminum particles. The embodiment shows that the powder burning heat reaches 27kJ / g, the firing temperature is lowered to 960 DEG C, and the burning rate reaches 90%.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

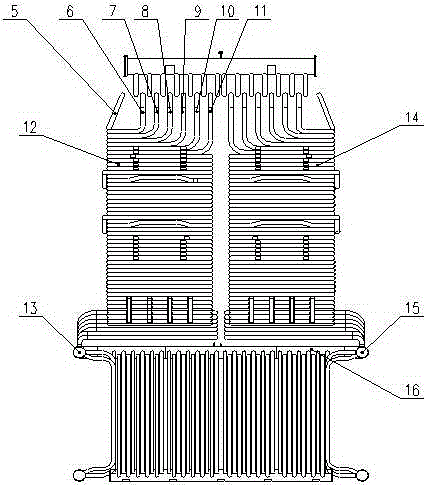

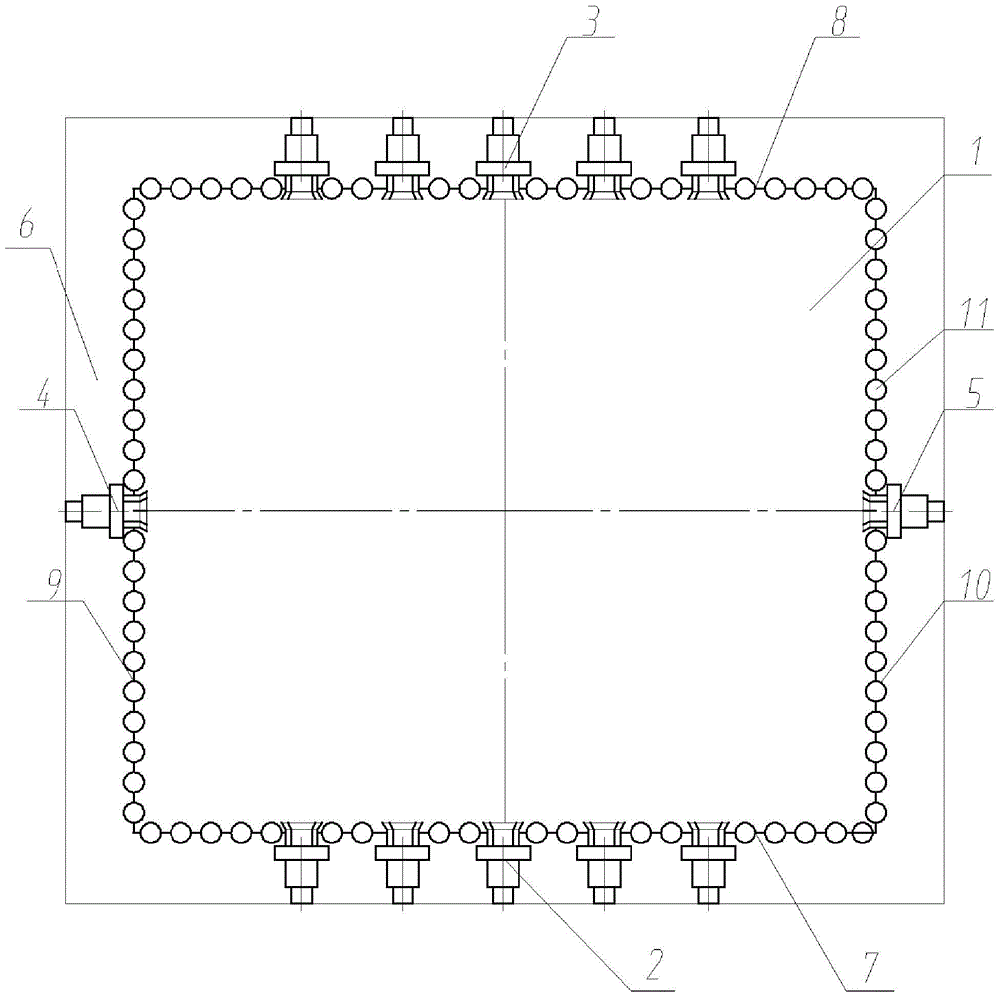

Coal powder burning organic heat carrier boiler

The invention provides a coal powder burning organic heat carrier boiler which comprises a lower hearth, an upper hearth, a convection region and a waste heat boiler. The coal powder burning organic heat carrier boiler is characterized in that the length of the lower hearth is smaller than the length of flame of a burning region, one side of the lower hearth is provided with an air feeding device, the flame of the burning region is bent to be in an L shape, the cross section of a heat exchange region of the lower hearth is in a U shape, a double-rectangular-coil structure is adopted for the upper hearth, the upper hearth is provided with two rectangular coil assemblies of the same shape and size, the convection region is formed by connecting three sets of coils in parallel, the upper portion of the waste heat boiler is provided with a flue gas collection region, and the cross section of the flue gas collection region is circular and gradually increased from top to bottom.

Owner:ZHEJIANG TUFF BOILER

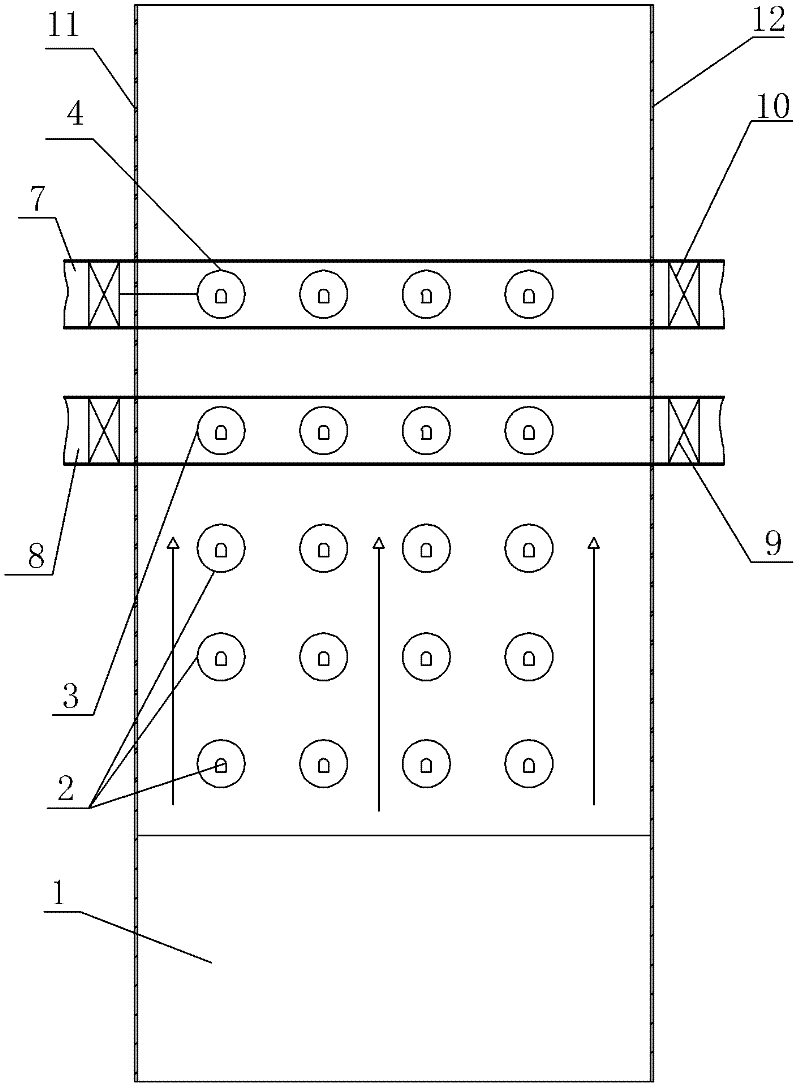

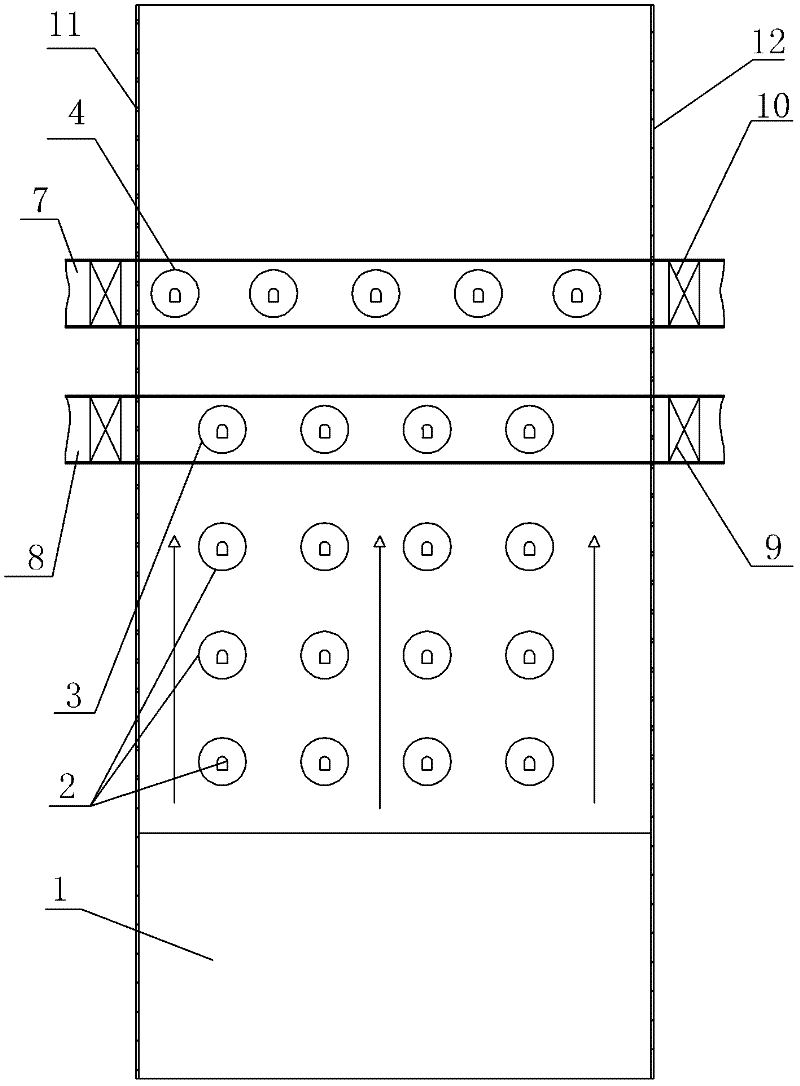

Opposed firing structure of boiler

ActiveCN104595891AIncrease oxygen contentReduce oxygen contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorStructural engineering

The invention discloses an opposed firing structure of a boiler. The opposed firing structure comprises a hearth, wherein the hearth is formed by enclosing of a boiler left-side wall, a boiler right-side wall, a boiler front wall and a boiler rear wall; left-side wall burners are distributed on the middle line of the boiler left-side wall along the height direction of the hearth; right-side wall burners are distributed on the middle line of the boiler right-side wall along the height direction of the hearth; a plurality of rows of front-wall burners are distributed on the boiler front wall; a plurality of rows of rear-wall burners are distributed on the boiler rear wall; and the peripheries of the boiler left-side wall, the boiler right-side wall, the boiler front wall and the boiler rear wall are provided with bellows for providing secondary air and over-fired air for the hearth. The opposed firing structure disclosed by the invention has the advantage that on the basis of not influencing the original coal-powder burning mode, the problem of corrosion caused by high temperature of water cooling walls of the side walls is thoroughly solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

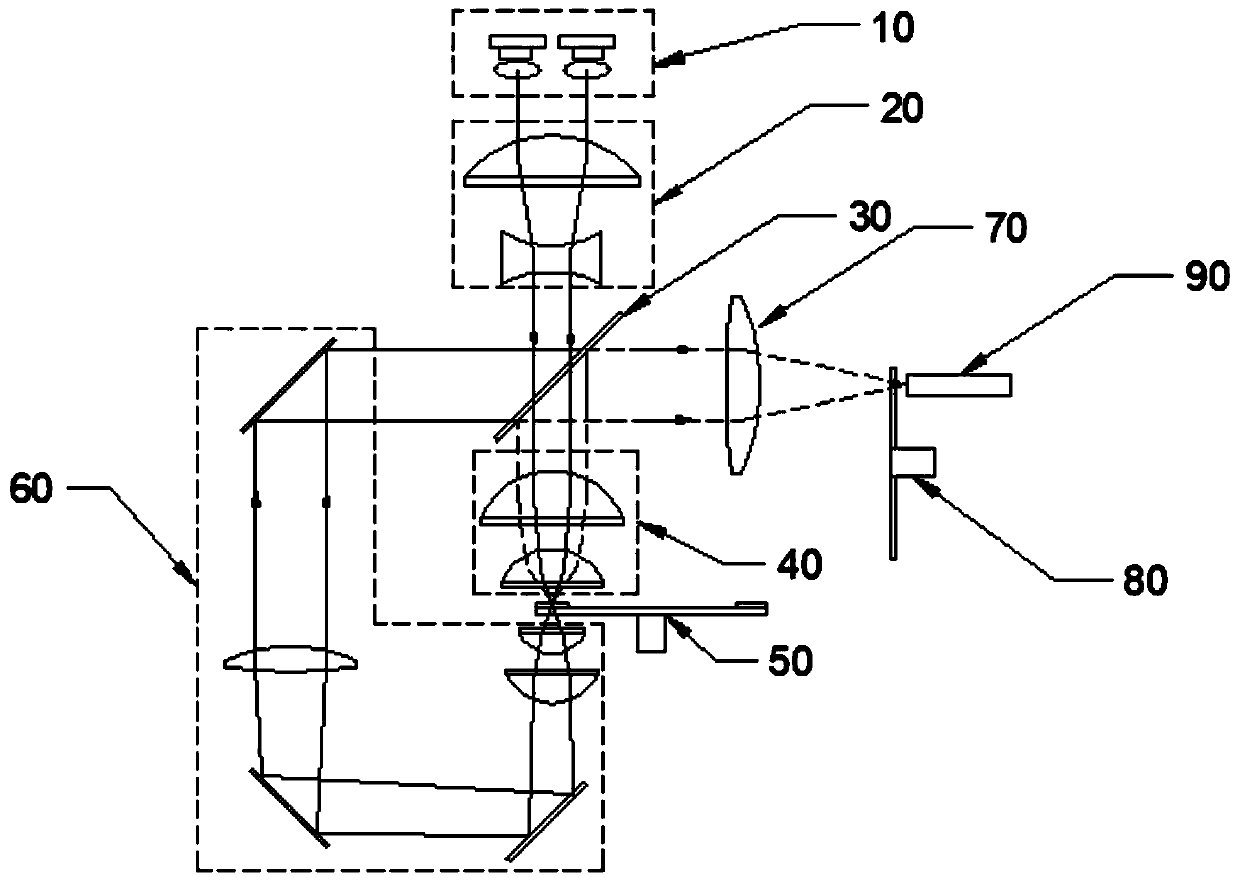

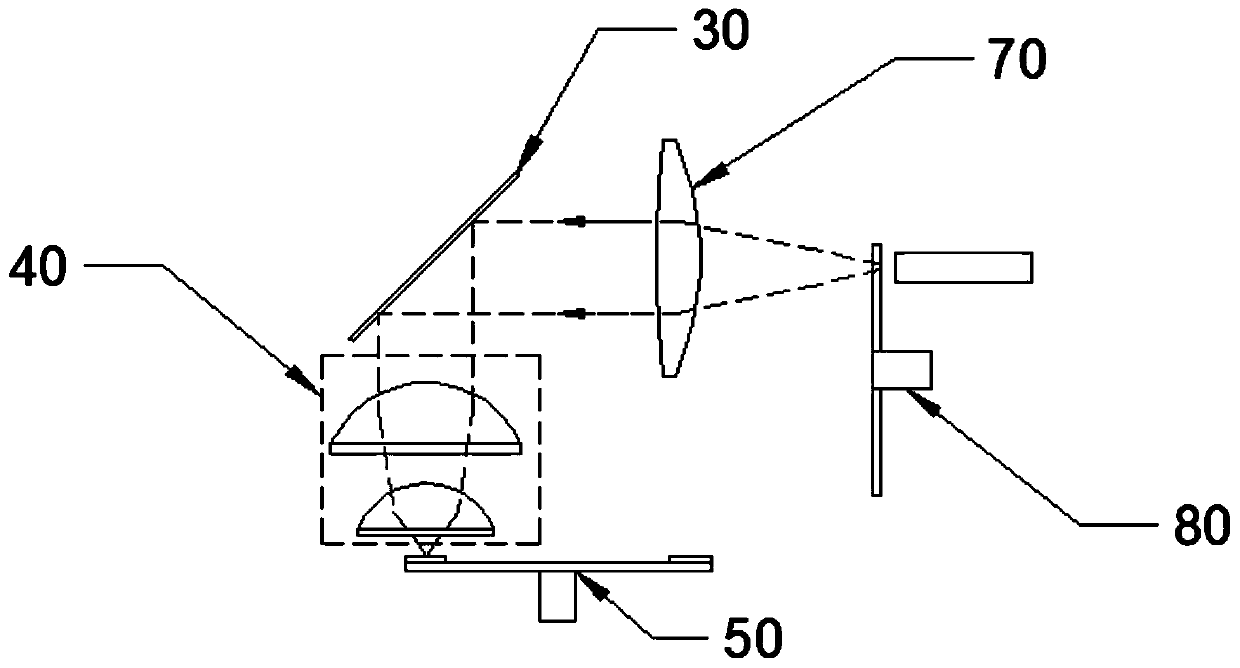

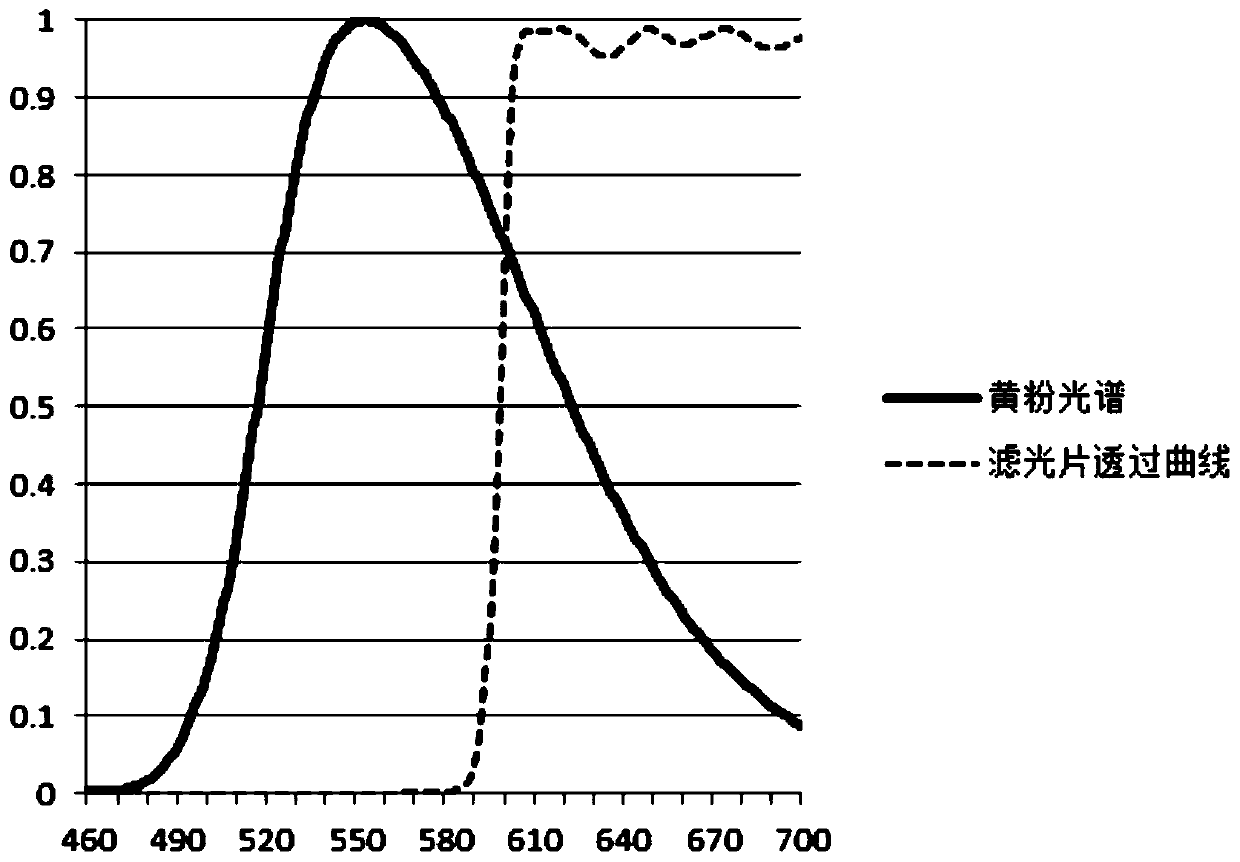

Laser projection light source

ActiveCN110376835ASolve the risk of burning powderUniform energyProjectorsLaser arrayOptoelectronics

The invention discloses a laser projection light source, which comprises a laser array, a telescopic assembly, a dichromatic assembly, a light receiving assembly, a fluorescent powder wheel device, ablue light path, a light gathering assembly, a color wheel device and a light bar assembly, wherein a laser beam emitted by the laser array penetrates through the telescopic assembly, the dichromaticassembly and the light receiving assembly and is then focused on the surface of the fluorescent powder wheel device. The first surface of a red filter area of the color wheel device is a scattering surface, the second surface is a long-wave-pass filter film, and light in a reflected wave band penetrates through a diffuse scattering surface twice, so that the energy is more uniform when a reflectedlight spot irradiates the surface of the surface of fluorescent powder, and the energy density at the center point is reduced; and the powder burning risk of the high-brightness laser projection system can be simply and effectively solved.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Coal burning catalyzing and inducing activator for cement industry and its use

The present invention belongs to the field of fuel coal activator, and is especially one kind fuel coal catalyzing and inducing activator for cement industry. The fuel coal catalyzing and inducing activator consists of iron powder 30-60 wt%, carbide slag 20-50 wt% and modifying leftover 10-30 wt%. The modifying leftover is obtained with hydrocarbon leftover from food and petrochemical industry and aerated concrete powder in the weight ratio of 60-90 to 10-40 and through pulverizing for 0.5-1.0 hr. The present invention can lower coal powder igniting temperature, raise coal powder burning-out degree and speed burning of coal, and has the features of low cost and no negative effect on cement clinker performance, and is suitable for bituminous coal with high ash content, anthracite coal with low volatile component content and other kind of coal.

Owner:WUHAN UNIV OF TECH

Low NOX dry ash extraction coal powder burning method

InactiveCN101487589BWell mixedBurn fullyCombustion using gaseous and pulverulent fuelFuel supply regulationCombustion chamberCoal dust

The invention relates to a low NOX solid residue discharge coal dust combustion method which is characterized in that a fire grate at the bottom of an old boiler is dismounted, so that a pure hearth is formed, or a boiler provided with the pure hearth is manufactured; at least one inflamer is arranged at the bottom or one side of the pure hearth; when a primary air fan is started, primary air andcoal dust enter the inflamer through a primary air / coal dust pipe, so that the primary air and the coal dust can burn sufficiently after entering a combustion chamber; meanwhile, a flame detector automatically enters a crust block prevention tertiary air curtain regulating valve which can monitor and has the function of linkage protection and regulation and a secondary air regulating valve, an air curtain is formed on the inner wall of a high temperature fire resistant layer by the wind sprayed out of a crust block prevention tertiary air curtain spray pipe, the secondary air enters the combustion chamber through a secondary air rotational flow guider and a secondary air flame stabilizing rotational flow guider, the rotational flow direction of the secondary air is consistent with that ofan axial flow generator, and the secondary air is mixed with the coal dust burnt by the primary air again to be burnt, thus leading the coal dust to be burnt more fully. The invention has the advantage of burning the coals with low ash fusion point and high ash fusion point.

Owner:郑雯平

Preparation method of magnetic ferrite

The invention discloses a preparation method of magnetic ferrite. The method comprises the following steps: putting ingredients into a ball mill, performing coarse grinding, wherein the coarse grinding time is controlled to 5 h, and the powder particle size is controlled at 2-5 [mu]m, and after the coarse grinding is finished, performing heating drying, wherein the drying temperature is controlledat 55-60 DEG C, and the drying time is controlled to 1 h; and performing mixed combustion: putting the dried raw material powder into a crucible, and dispersedly introducing a pure oxygen gas into the raw material; and igniting the carbon powder until combustion heat is completely discharged. The preparation method of the magnetic ferrite provide by the invention innovates the step of mixed combustion, replaces a pre-sintering step in a conventional process, and can save a large amount of fuel; the method creates a process of aluminum powder burning heating, and can provide a large amount ofheat; and a large amount of introduced oxygen gas can oxidize and cool the burned aluminum powder and iron powder in time to prevent metals from being molten and accumulated together, and the metals are oxidized in time, so that the strength of an oxide can be reduced, and the processing difficulty of the ball milling step is reduced.

Owner:滁州市博瑞特工贸有限公司

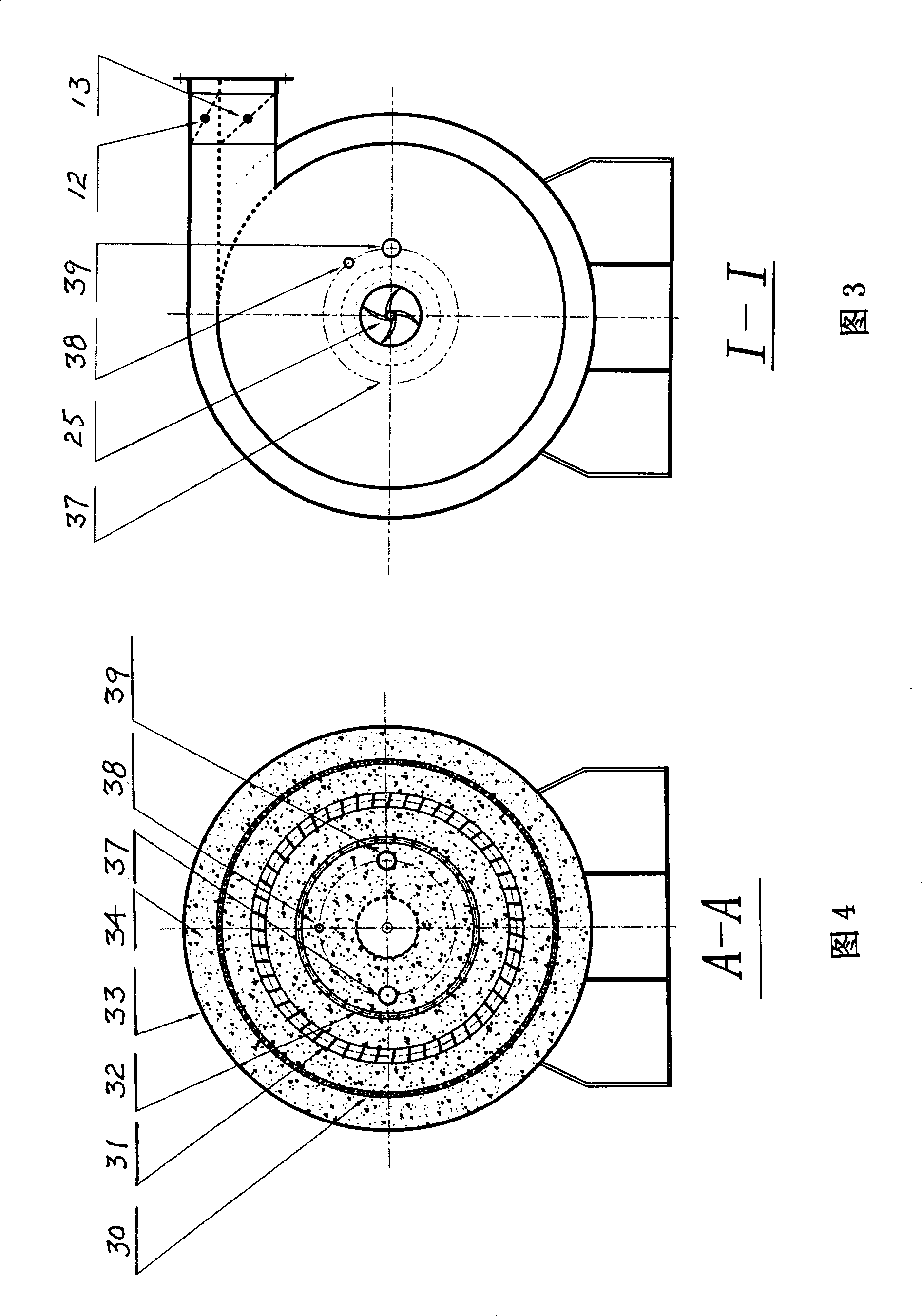

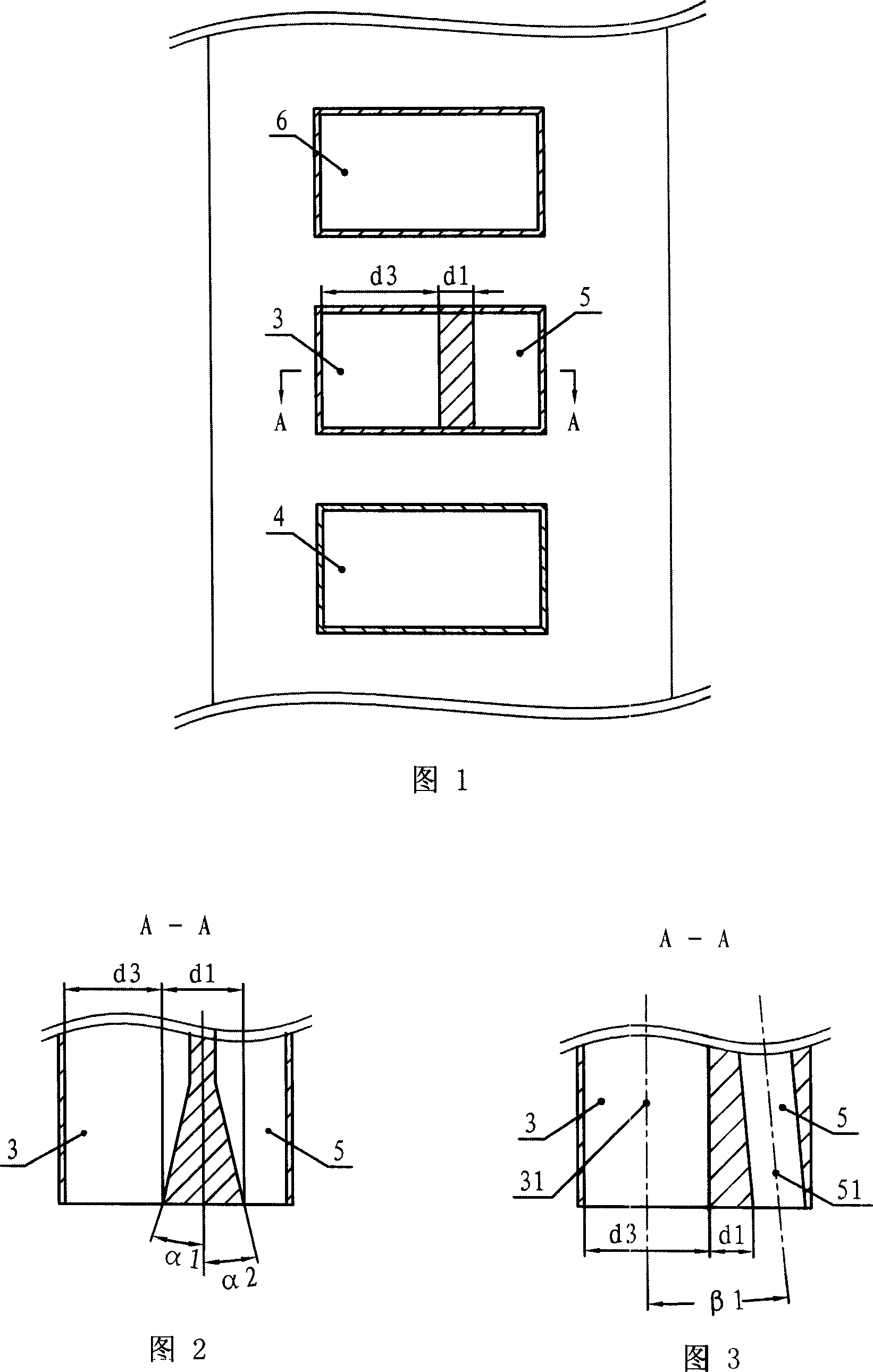

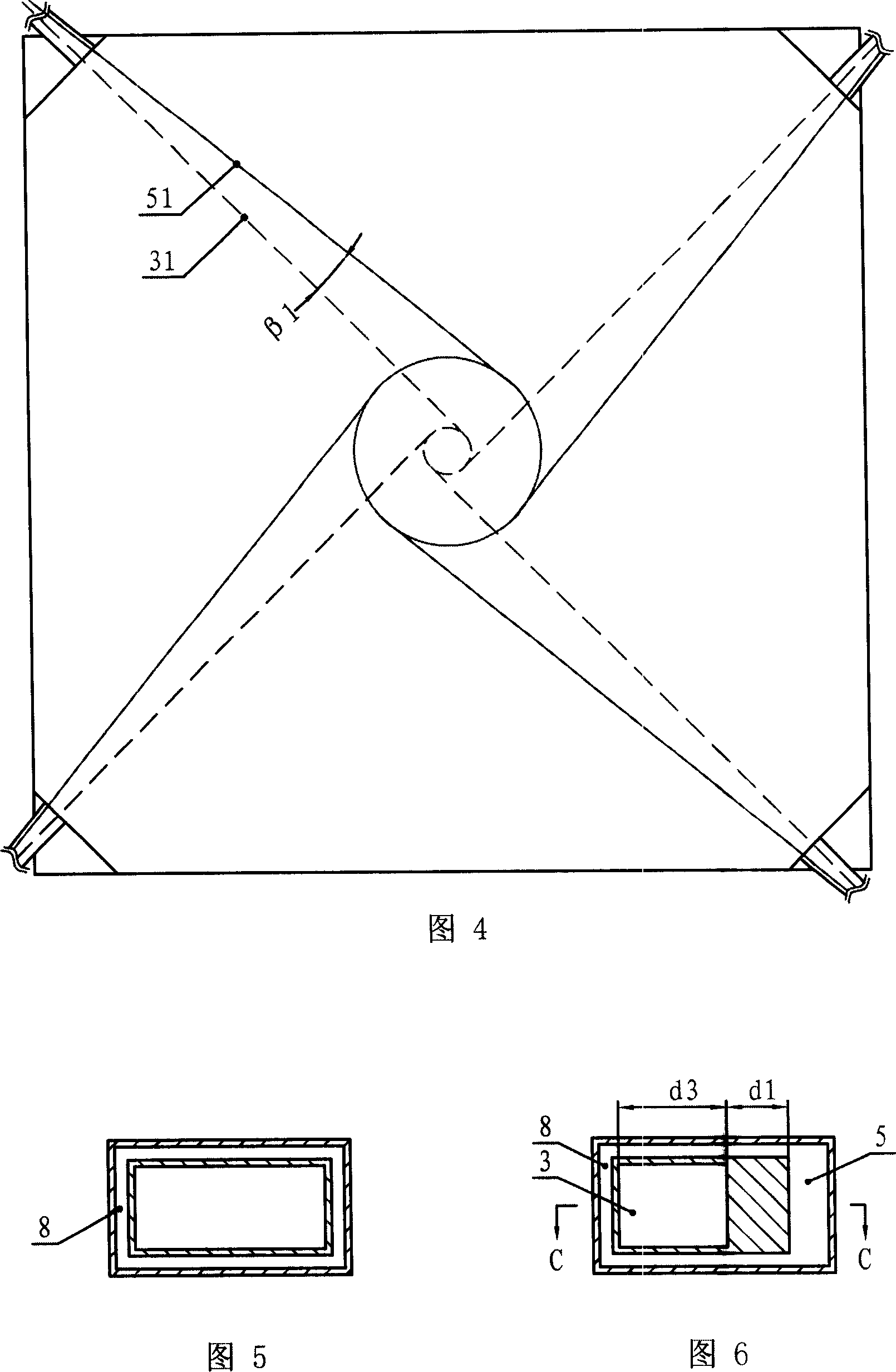

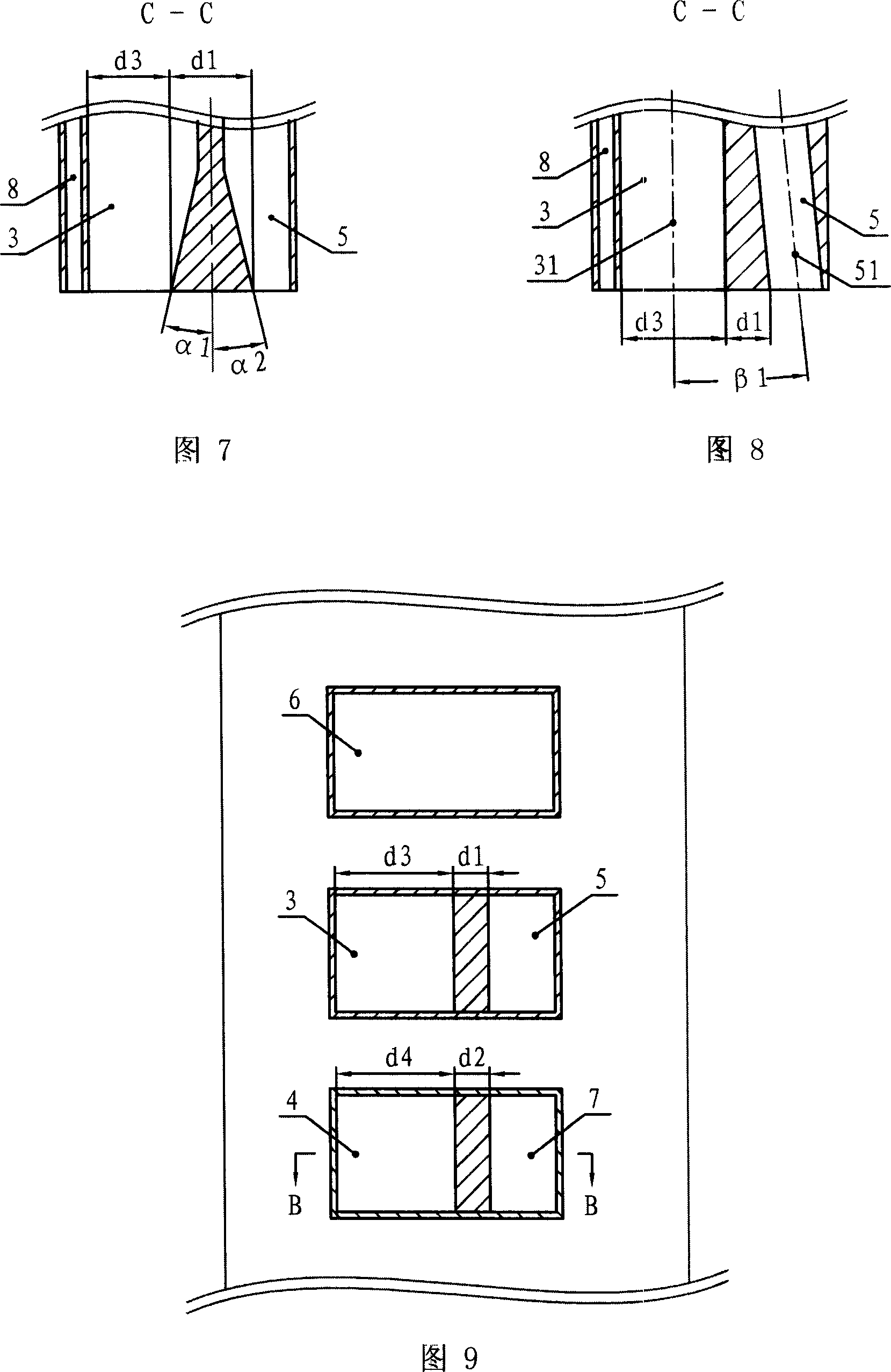

Slagging-resistance and high temperature resistance coal powder burning device used in vertical strong/weak combustion boiler

InactiveCN101016988AImprove air supply conditionsAvoid skewPulverulent fuel combustion burnersAir/fuel supply for combustionVertical gradientEngineering

A coal powder burner can avoid scale and high-temperature corrosion in vertical gradient burning boiler, wherein a back side d1 of dense first injector is fixed with a dense secondary injector, the dense first airflow and the axis of the dense second airflow have a corner at beta 1, a dilute second airflow can be arranged at the back of the dilute first injector. The two airflows can improve the injection rigidity to confirm the oxidization condition near the water cooling wall and reduce the temperature near the water cooling wall, to avoid scale and high-temperature corrosion. The invention can arrange space or baffle between the dense first injector and the dense secondary injector, to reduce the mixing between the dense first airflow and the dense secondary airflow.

Owner:HARBIN INST OF TECH

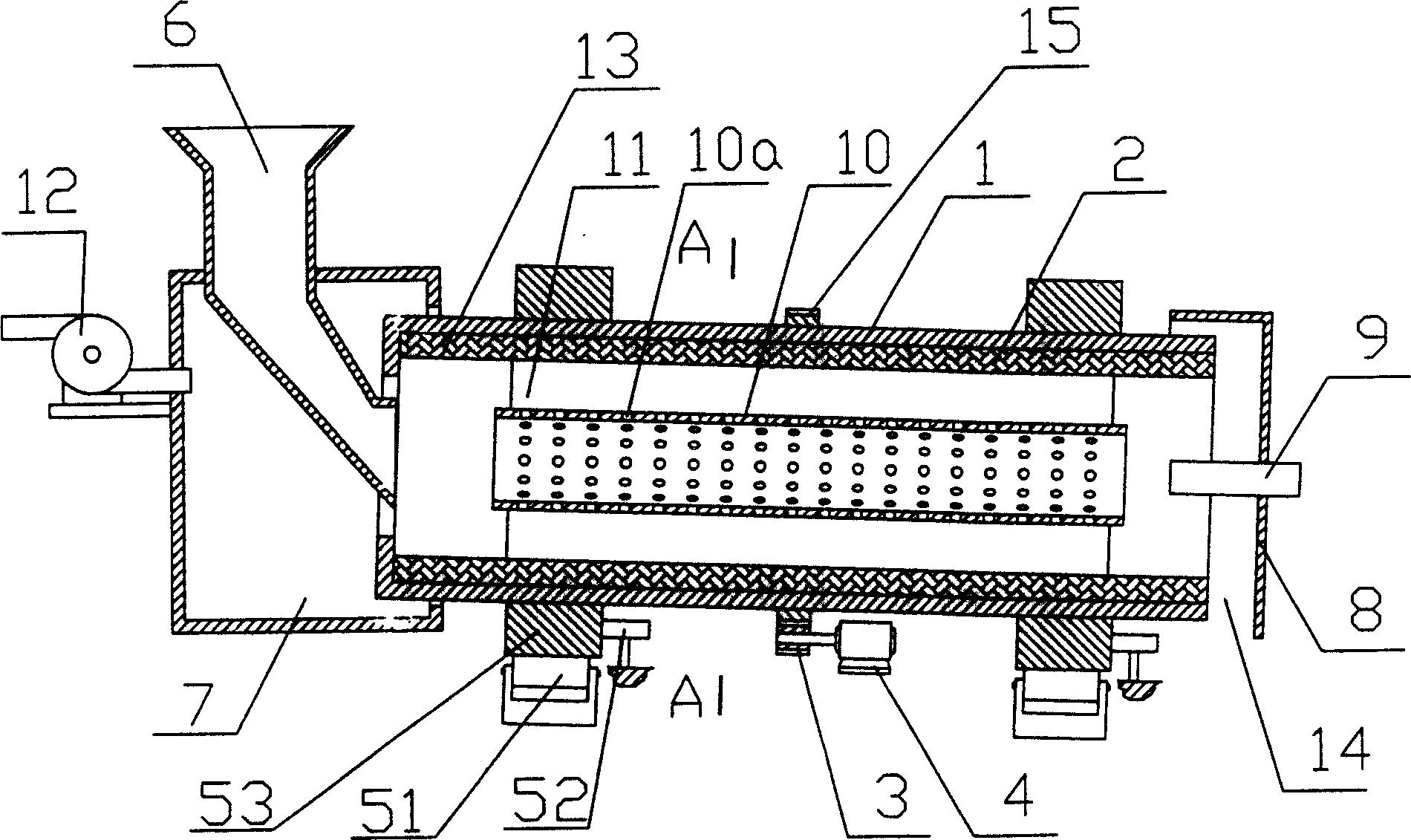

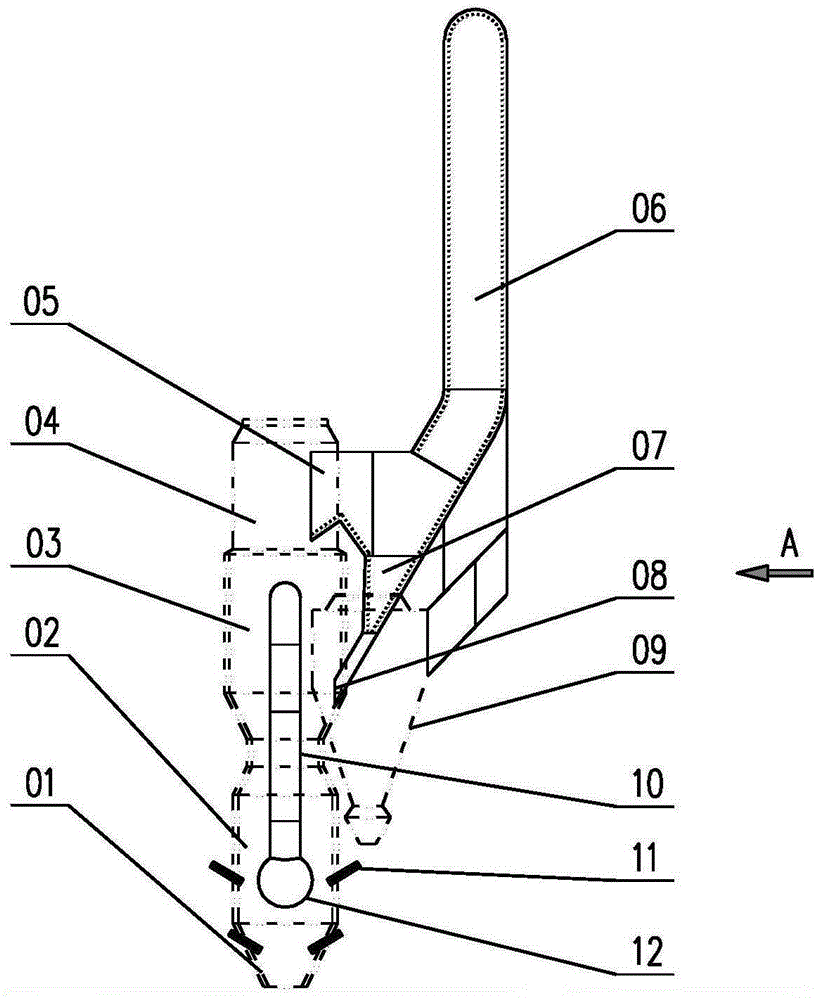

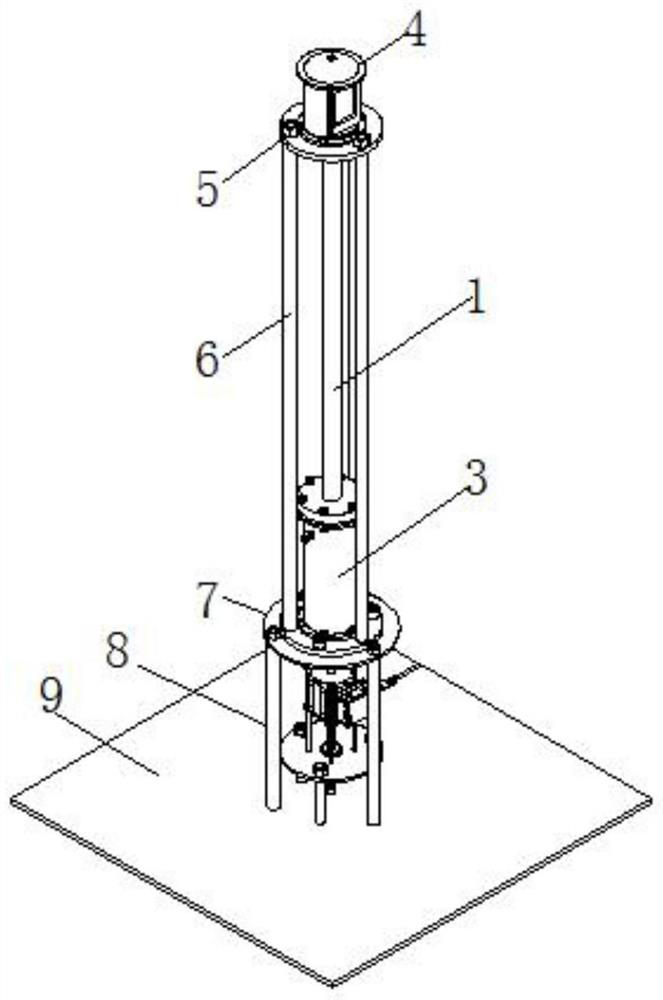

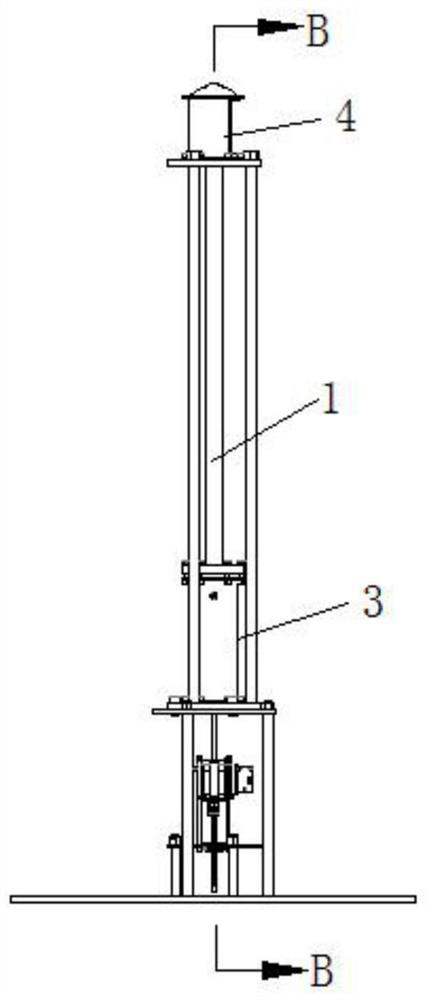

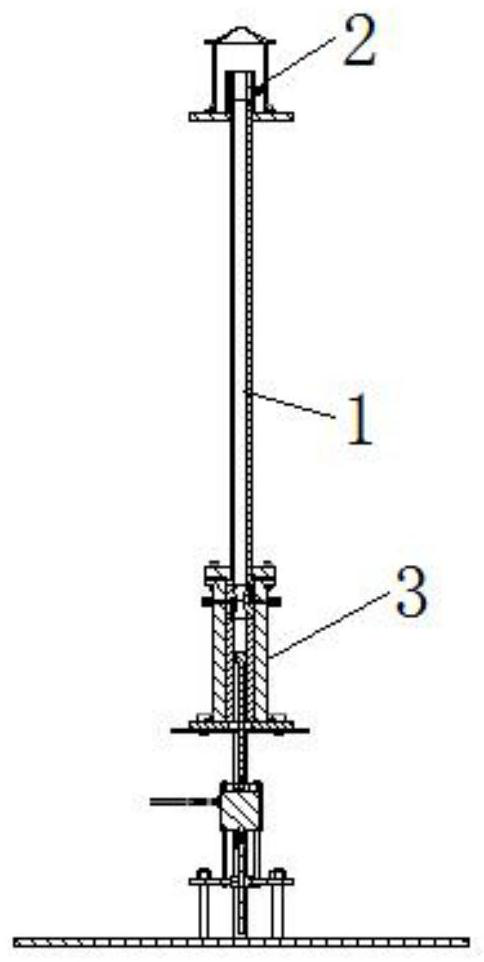

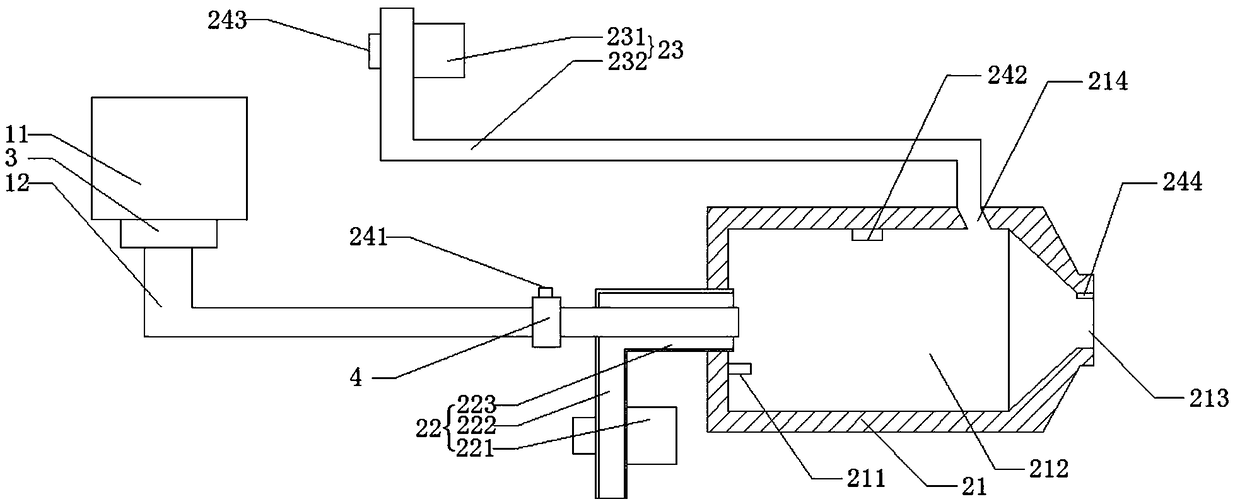

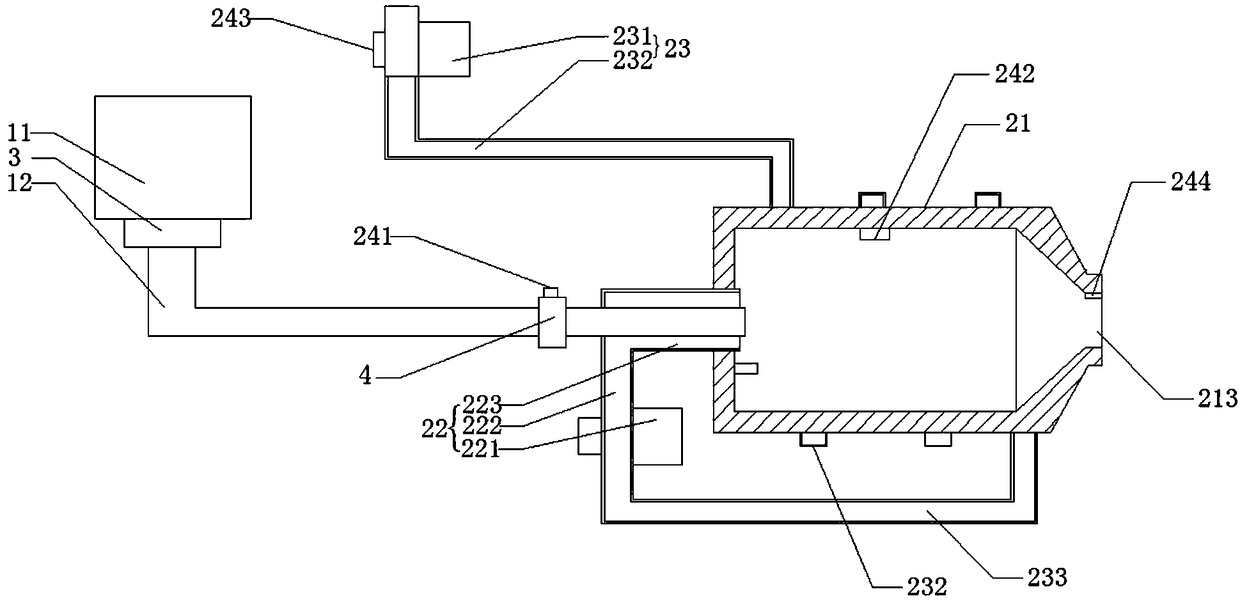

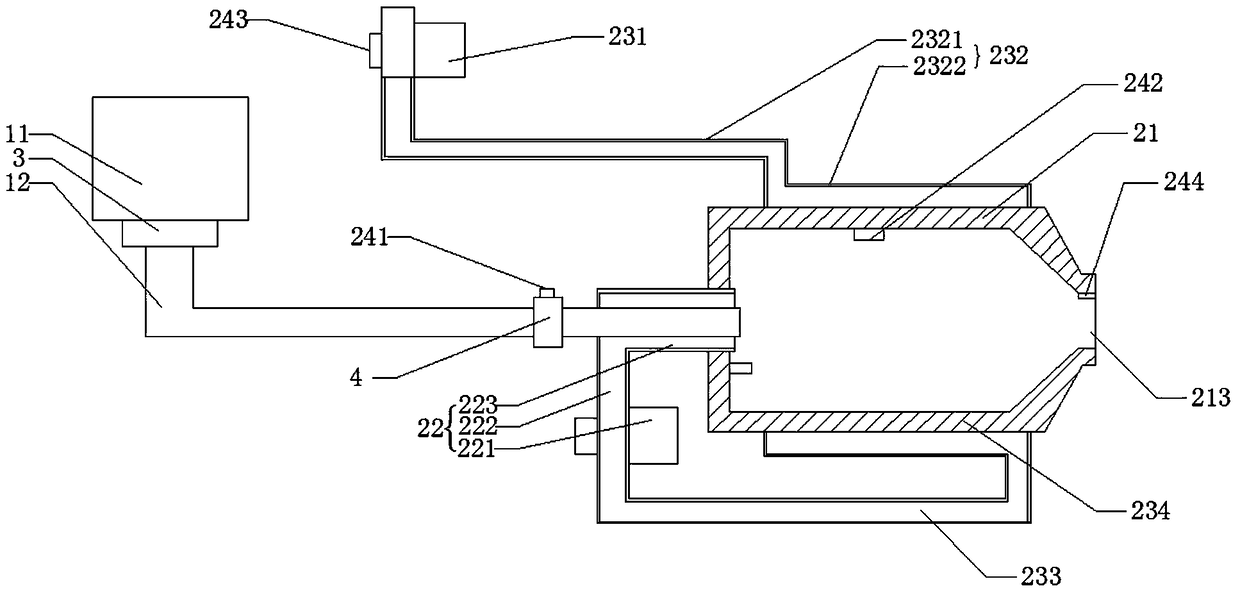

Metal powder combustion device

ActiveCN113266821ASimple and safe operationReduce processing costsTransportation and packagingMetal-working apparatusCombustorEngineering

The invention discloses a metal powder combustion device. The metal powder combustion device comprises a flow guide pipe, a combustion device is arranged at the top of the flow guide pipe, and a metal powder fluidization conveying device is arranged at the bottom of the flow guide pipe. The combustion device is a laminar flow combustor or a turbulent flow combustor. The metal powder fluidization conveying device comprises a powder storage device, a through powder storage cavity is formed in the powder storage device, a piston capable of moving up and down is arranged in the powder storage cavity, a piston rod at the bottom of the piston is connected with a telescopic driving device, and a fluidizer is arranged at the top of the powder storage device. A through fluidization cavity is formed in the fluidizer. According to the combustion device, good experimental equipment is provided for studying metal powder, the characteristics of laminar flames can be studied, the characteristics of turbulent flames can further be studied with the help of the combustion device, and a foundation is laid for further studying the combustion phenomenon of metal powder fuel.

Owner:NORTH CHINA INST OF AEROSPACE ENG

Biomass wood powder burning engine

PendingCN109404898AIncrease volumeImprove combustion efficiencyPulverulent fuel combustion burnersCombustion regulationCold airCombustor

The invention discloses a biomass wood powder burning engine and relates to the technical field of burning equipment. According to the biomass wood powder burning engine, the burning engine can be cooled through air cooling, and the material inlet amount and the air input of the burning engine can be automatically controlled. The main technical scheme of the biomass wood powder burning engine includes that the biomass wood powder burning engine comprises a feeding portion and a burning portion, wherein a burner is connected to a feeding pipe, an oxygen supply component is arranged at one end of the burner, one end of a cooling pipe is connected to a cooling fan, the other end of the cooling pipe communicates with the burner mutually, and a first detector is arranged in the burner and connected to a first controller; when the temperature in the burner is smaller than a preset value, the first controller closes the feeding pipe; and a second detector is arranged in the position of a spray outlet of the burner and connected to a second controller, and when the temperature in the position of the spray outlet of the burner is greater than a preset value, the second controller controls the cold air inlet amount of the cooling fan to be increased. The biomass wood powder burning engine is mainly used for burning biomass wood powder.

Owner:昌吉州锐通木业有限公司

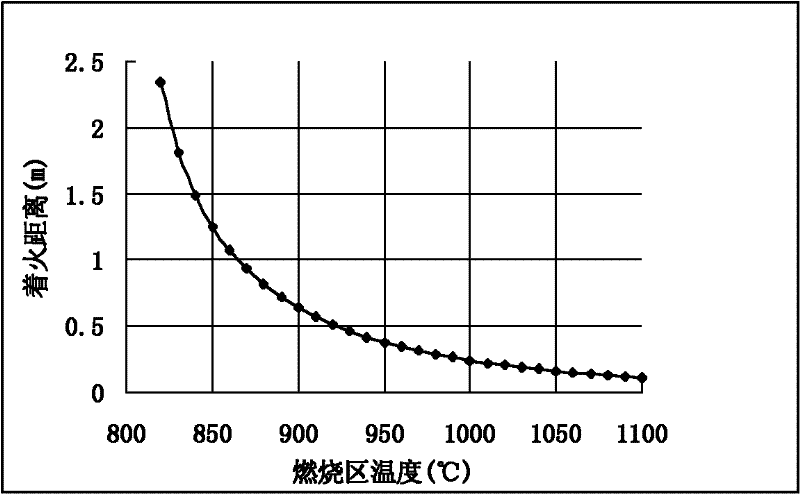

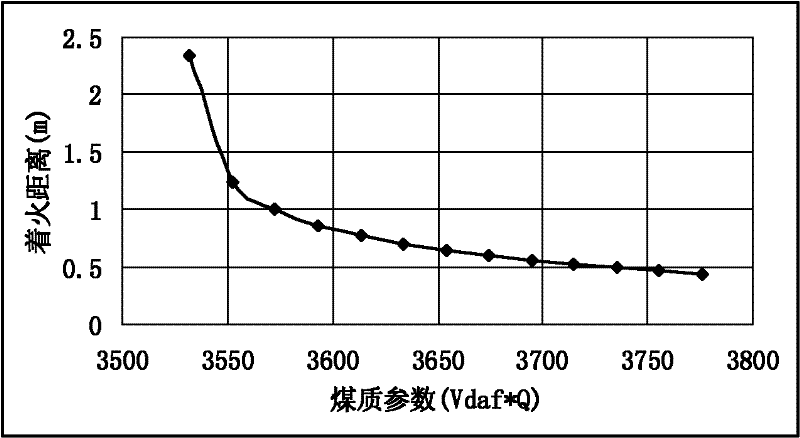

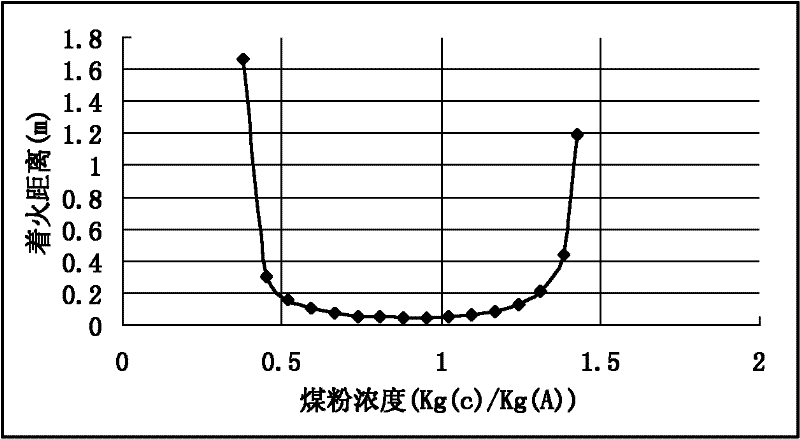

Method for measuring primary air-coal powder burning distance and coals for DC (direct current) burner of coal-fired boiler

InactiveCN102230792AImprove combustion efficiencyEmission reductionFuel testingAir velocityCombustor

The invention relates to a method for measuring the primary air-coal powder burning distance and coals, comprising the following steps: firstly, segmenting a primary air channel, measuring the length li of each section of air channel, the primary air temperature Ti of each section of air channel and the primary air temperature Tn of a burning distance section; measuring the primary air velocity Vi of each section of air channel, and the primary air velocity Vn of the burning distance section; measuring the coal powder concentration coali of the section of air channel and the coal powder concentration coaln of the burning distance section; measuring the coal powder fineness R90 of each section of air channel, that is, the percentage of coal powder which dose not pass through a 90mu m sieve is measured; measuring oxygen content Oi in the primary air of each section of air channel and oxygen content On in the primary air of each section of burning distance; measuring a coal quality parameter M of each section of the air channel; and substituting the measured parameters into a formula for computing, and obtaining the burning distance ln by computing the final section of air channel. Compared with the prior art, the method is utilized to collect the primary air channel length, the primary air temperature, the primary air velocity, the coal powder concentration, the coal powder fineness, the oxygen content, the coal quality parameters, the temperatures of the burner areas around a nozzle and other real-time parameters, thus computing the actual burning distance more accurately, which has significance on reasonable design of the boiler and safe running of changing the coals. Meanwhile, if the burning distance is known, online monitoring on the coal changes can be realized, thereby carrying out reasonable air distribution, improving the burning efficiency of the boiler and reducing pollutant emission.

Owner:ZHEJIANG ELECTRIC POWER TEST & RES INST +1

Gel film agent for treating burn and scald

InactiveCN101524338AWith hemostatic functionGrowth inhibitionDermatological disorderMacromolecular non-active ingredientsCarboxymethyl celluloseMedicine

The invention relates to a gel film agent for treating burn and scald, which is characterized in that sodium carboxymethyl cellulose and other gels are compounded into film agent matrix; and the film agent is carried with percolate miraculous for burn and carbon powder burned by residues. The gel film agent has the following advantages that the film agent has hemostasis function, has the function of inhibiting bacteria growth, can prolong the time for releasing medicament, generates biological adhesion to firmly adhere to an afflicted part, has the function of adsorbing tissue fluid generated after burning and scalding, has the function of inhibiting fibrocyte growth and reducing scars, does not adhere to the skin, is easy to take off, does not cause twice bleeding and harm, has good ventilation property, is more stable, and is convenient to use.

Owner:大连永兴生物医药孵化器有限公司

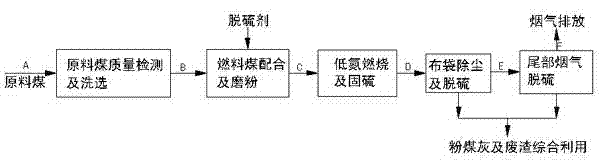

Application of multi-section composition pollutant removing technology in novel coal powder industrial boilers

InactiveCN103203177AImprove efficiencyHigh removal rateDispersed particle filtrationCycloneLow nitrogen

The invention discloses the technology for removing pollutants in coal powder burning, in particular to application of multi-section composition pollutant removing technology in novel coal powder industrial boilers. The application includes steps of reducing sulfur content and ash content of fuel coal by washing raw coal, burning by low-nitrogen cyclone burner, realizing low-nitrogen combustion of coal powder, completing efficient dust extraction after burning by adopting cloth bag dust extraction technology, desulfurizing smoke, and desulfurizing tail smoke by the smoke desulfurizing technology after a cloth bag deduster. Pollutant removal technologies before, during and after burning are combined to use, and since the multi-section composition pollutant removing technology is adopted from raw coal to tail smoke purifying, high smoke and sulfur dioxide removal efficiency is realized on the premise of low burden of the single technology.

Owner:王民发

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com