Aluminum zinc based multi-component alloy spherical powder and preparation method and application thereof

A spherical powder, aluminum-zinc technology, applied in the field of alloy powder, can solve the problem of limited improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing the aluminum-zinc-based multi-element alloy spherical powder described in the above technical solution, comprising the following steps:

[0029] (1) Under an inert atmosphere, sequentially melting and mixing aluminum ingots, zinc ingots and component metal elements to obtain a smelting solution;

[0030] (2) Under an inert atmosphere, atomize and rapidly condense the smelting liquid obtained in the step (1) to obtain the aluminum-zinc-based multi-element alloy spherical powder.

[0031] The invention melts and mixes aluminum ingots, zinc ingots and component metals sequentially under an inert atmosphere to obtain a smelting solution. In the present invention, the aluminum in the aluminum-zinc-based multi-element alloy spherical powder is added in the form of aluminum ingots; the zinc is added in the form of zinc ingots; and the component metal elements are preferably added in the form of corresponding metal elem...

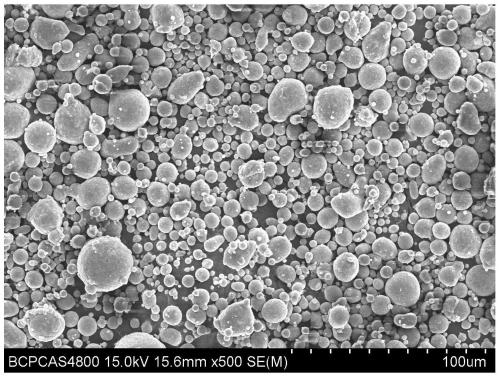

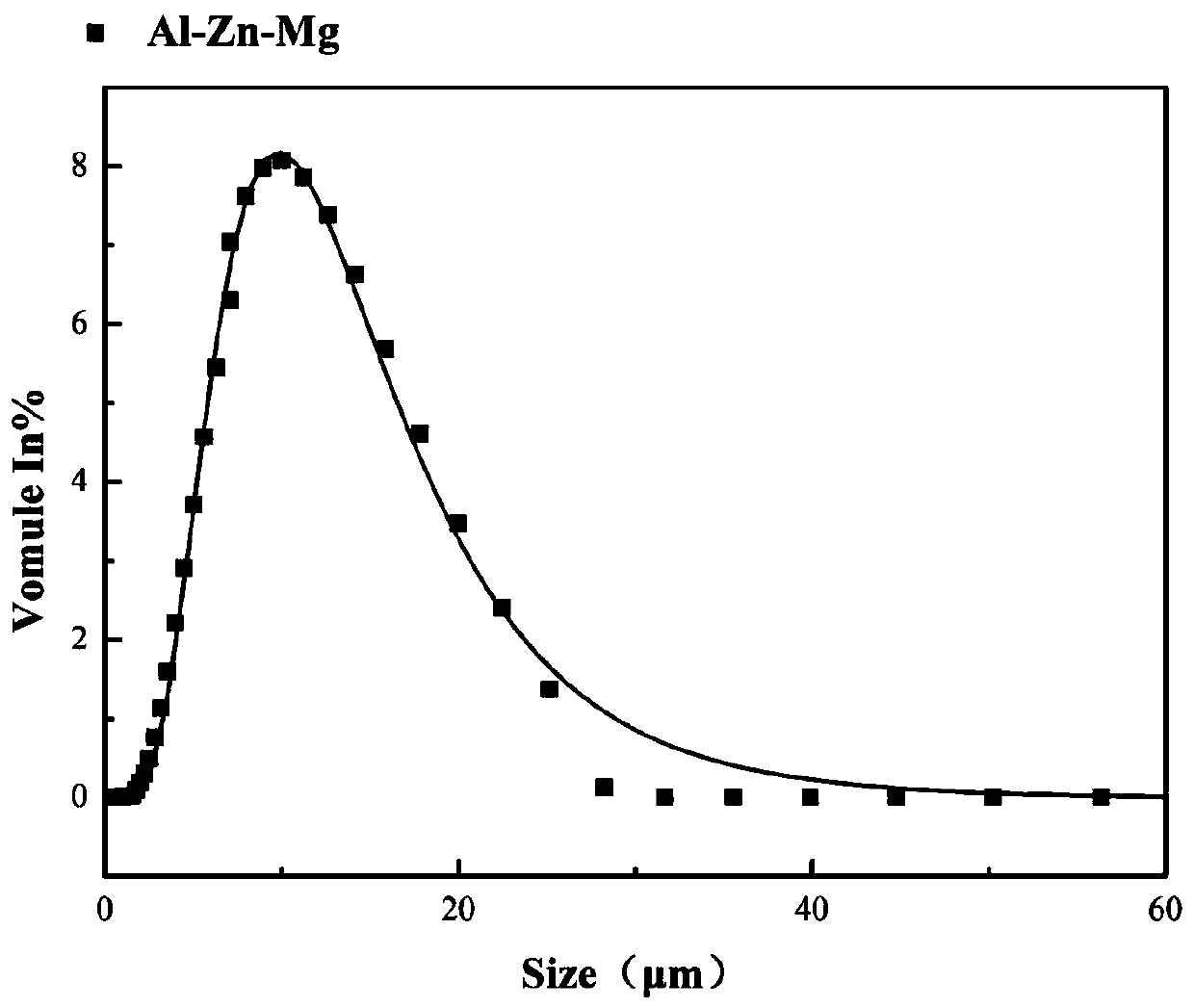

Embodiment 1

[0044] An aluminum-zinc-based multi-element alloy spherical powder, including the following elements by mass fraction: aluminum 87%, zinc 10%, magnesium 3%;

[0045] Preparation methods include:

[0046] (1) First weigh aluminum ingots, zinc ingots and magnesium ingots with a mass ratio of 87:10:3, and use high-temperature nitrogen to purge the aluminum ingots, zinc ingots and magnesium ingots; In the melting furnace, use the intermediate frequency heating ring to heat the furnace body to 680-730°C to melt the aluminum ingots, then add zinc ingots; finally add magnesium ingots to melt and mix to obtain a smelting solution;

[0047] (2) Under an inert atmosphere, pass the smelting liquid into an atomization furnace for gas atomization treatment; use a 325 mesh vibrating sieve to carry out particle size classification on the gas atomization treatment product to obtain the spherical powder of the aluminum-zinc-based multi-element alloy, and then carry out Sealed packaging; where...

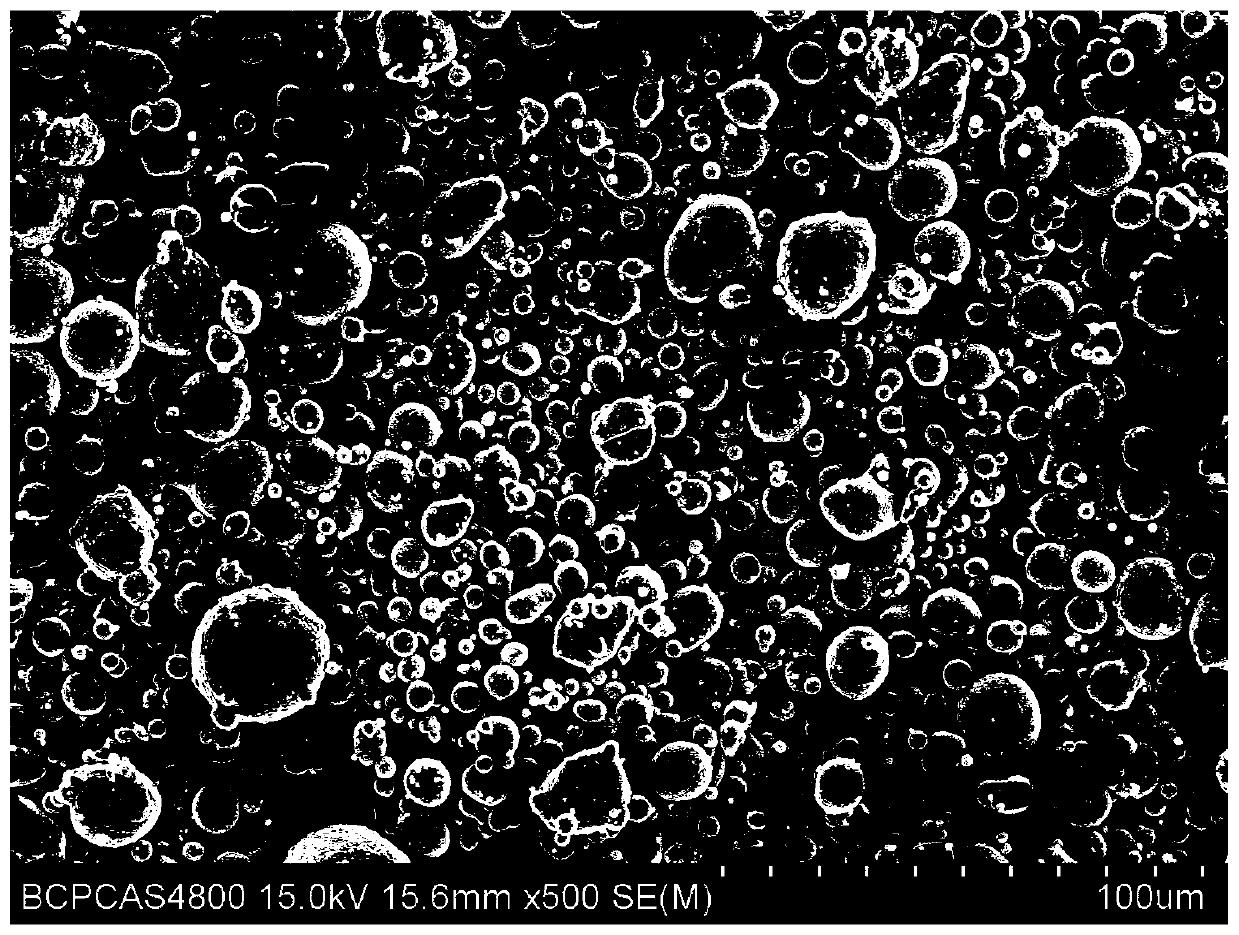

Embodiment 2

[0053] An aluminum-zinc-based multi-element alloy spherical powder, including the following elements in mass fractions: 80% aluminum, 15% zinc, 3% lead, and 2% bismuth;

[0054] Preparation methods include:

[0055] (1) First weigh aluminum ingots, zinc ingots, lead ingots, and bismuth ingots with a mass ratio of 80:15:3:2, and use high-temperature nitrogen to purge the aluminum ingots, zinc ingots, lead ingots, and bismuth ingots; Next, add aluminum ingots to the pre-melting furnace, use the intermediate frequency heating ring to heat the furnace body to 680-730 °C to melt the aluminum ingots, then add zinc ingots to melt and mix, then add lead ingots and bismuth ingots to melt and mix in turn to obtain smelting liquid;

[0056] (4) Under an inert atmosphere, pass the smelting liquid into an atomization furnace for gas atomization treatment; after the gas atomization treatment, use a 325-mesh vibrating screen to carry out particle size classification on the gas atomization t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com