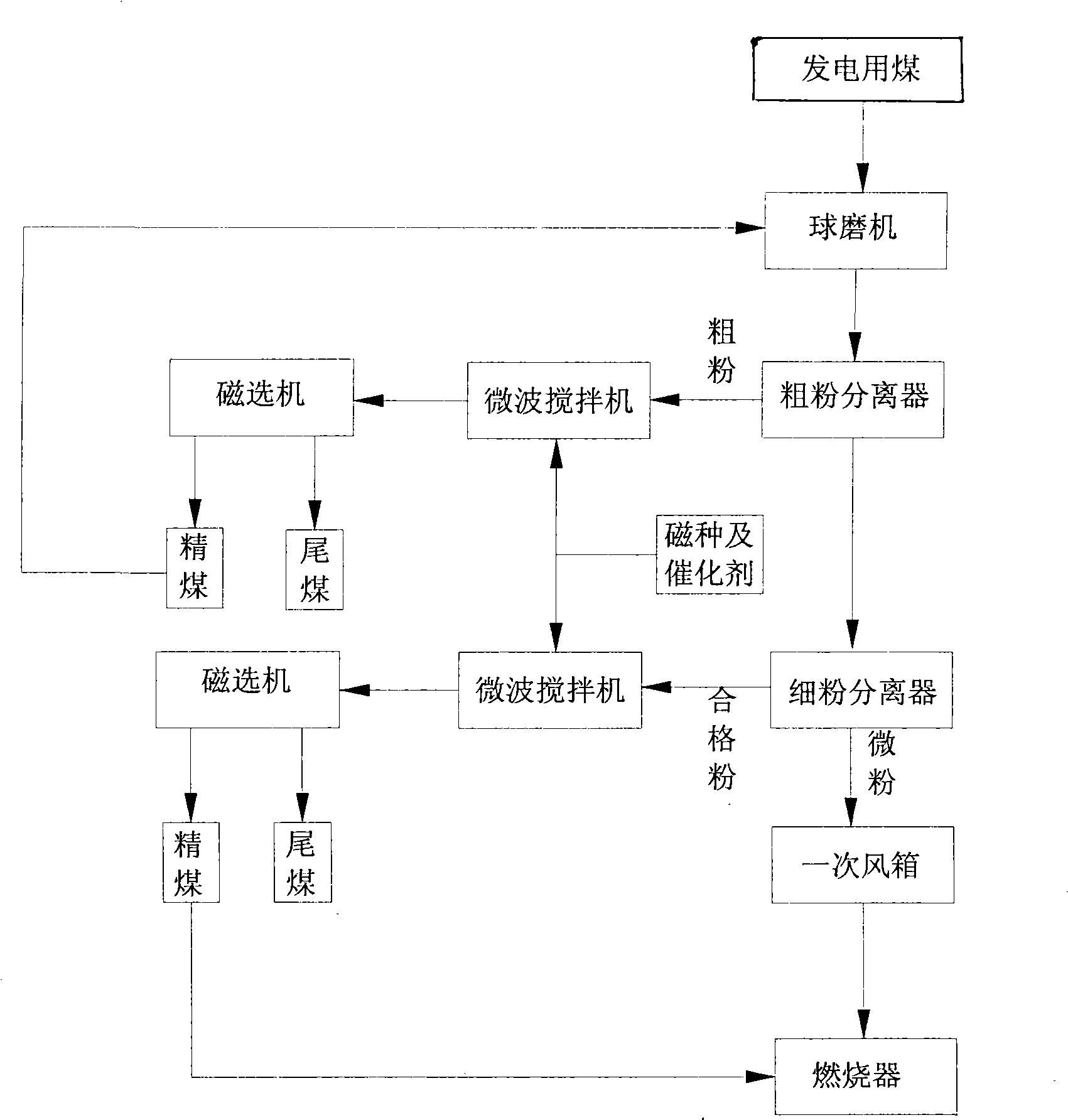

Two-section dry-type magnetic separation purification process before combustion of pulverized coal

A dry magnetic separation and purification process technology, applied in the field of pulverized coal desulfurization, can solve the problems of small equipment processing capacity and easy blockage of magnetic gathering media, and achieve the effect of clean, safe, automatic control and full and reasonable use of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Such as figure 1 As shown, after the coal for power generation is sampled by a ball mill, the particle size of the coal is controlled below 200 mesh, and it is first transported into the coarse separator. After passing through the coarse powder separator, the fine-grained coal powder that meets the requirements of combustion particle size directly enters the fine powder separator, while the coarse-powdered coal is sent to the microwave mixer for processing while adding magnetic seeds and catalysts. The magnetic seeds and catalyst components are Magnetite powder, processing time is 150-200 seconds. By controlling the parameters such as microwave irradiation atmosphere, microwave frequency and irradiation time, the pyrite sulfur and part of the organic sulfur are converted into strong magnetic iron-sulfur compounds (mainly pyrrhotite). After treatment, it is sent to the first-stage magnetic separator for desulfurization and ash reduction. The clean coal after magnetic se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com