Quick two-way stop valve

A stop valve, fast technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of high sealing body requirements, strong sealing surface pressure, long action time, etc., to ensure the shut-off effect and extend the service life The effect of life and acceleration improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

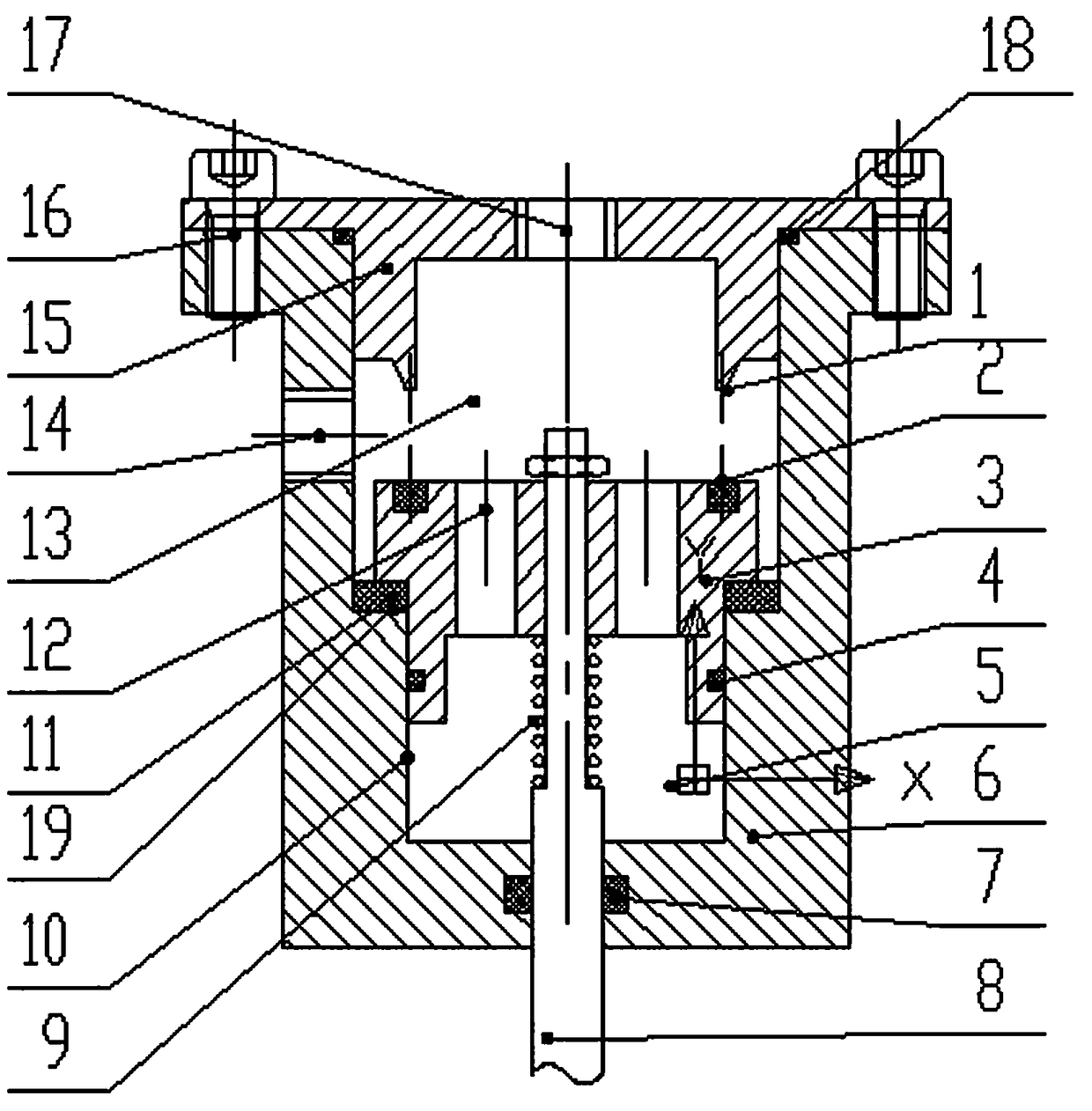

[0028] A fast two-way stop valve, including a valve body 6, an end cover 15 and a valve stem 8, wherein the positional relationship and connection relationship of each component are as follows (such as figure 1 shown):

[0029] The end cover 15 is fixed on the upper part of the valve body 6 by fastening bolts 16 , and a sealing ring 18 is arranged between the end cover 15 and the valve body 6 , so that an airtight air chamber is formed between the end cover 15 and the valve body 6 .

[0030] The end cover 15 is provided with an extending portion whose outer diameter matches the inner diameter of the valve body 6, and the outer diameter of the lower end of the extending portion decreases gradually. When the inner diameter of the inlet is close, the sealing lip 1 of the tapered structure is formed.

[0031]A valve plug 3 for dividing the inside of the valve body 6 into an upper air chamber 13 and a lower air chamber 5 is movable inside the valve body 6, and an air hole communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com