Composting method using rectorite as accessory material

A composting method and rectorite technology, applied in the field of sludge aerobic composting, can solve the problems of poor air permeability and porosity of materials, failure to reduce heavy metal content, high amount of auxiliary materials, etc., to achieve uniform composting fermentation process and low operating costs Inexpensive, improves air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

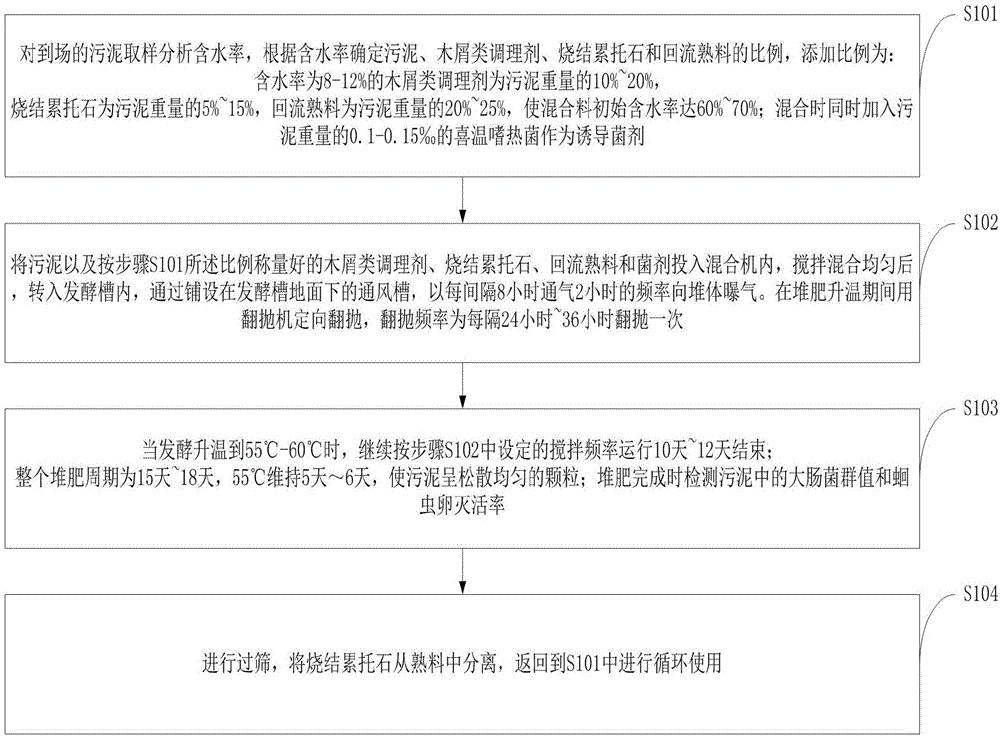

Method used

Image

Examples

Embodiment l

[0041] Sampling and analysis of dewatered sludge from a sewage plant (domestic sewage) in a city in Hubei shows that the basic properties of the sludge are: moisture content 78%, total organic matter 540g / kgDM, water-soluble total nitrogen 3.1g / kgDM, coliform value ≥ 23,000MPN / kgDM. Then add sawdust with a water content of about 10% and vermiculite with a specification of 3.1-3.5 cm as auxiliary materials, and the added amount is 20% and 5% of the weight of the sludge respectively. Put the above materials into the automatic mixing system. Control the weight of the return material to be 25% of the weight of the sludge. Then stir, so that the fermentation dominant bacteria are evenly mixed into the material system. Pour it into the fermentation tank, stack it in the form of strips and stir it directionally for 30 minutes every 12 hours, and discharge it after 18 days of treatment, and the weight of the material is reduced by 39.5%. The value of the coliform group in the detec...

Embodiment 2

[0043] Sampling and analysis of dewatered sludge from a sewage plant (domestic sewage) in a city in Hubei shows that the basic properties of the sludge are: moisture content 77%, total organic matter 590g / kgDM, water-soluble total nitrogen 3.3g / kgDM, coliform value ≥ 23,000MPN / kgDM. Then add wood chips with a moisture content of about 10% and sintered rectorite with a specification of 3.1-3.5 cm as auxiliary materials, and the addition amounts are 20% and 10% of the weight of the sludge respectively. Put the above materials into the automatic mixing system. Control the weight of the return material to be 20% of the weight of the sludge. Then stir, so that the fermentation dominant bacteria are evenly mixed into the material system. Pour it into the fermentation tank, stack it in the form of strips and stir it directionally for 30 minutes every 12 hours, and discharge it after 18 days of treatment, and the weight of the material is reduced by 41.3%. The value of the coliform...

Embodiment 3

[0045] Sampling and analysis of dewatered sludge from a sewage plant (domestic sewage) in a city in Hubei shows that the basic properties of the sludge are: moisture content 80%, total organic matter 550g / kgDM, water-soluble total nitrogen 3.2g / kgDM, coliform value ≥ 24,000MPN / kgDM. Then add sawdust with a moisture content of about 10% and two conditioners such as the sintered rectorite of Example 1 as auxiliary materials, and the additions are respectively 15% and 15% of the weight of the sludge. Put the above materials into the automatic mixing system. Control the weight of the return material to be 20% of the weight of the sludge. Then stir, so that the fermentation dominant bacteria are evenly mixed into the material system. Transfer to the fermentation tank and pile up in the form of strips. Directional stirring for 30 minutes every 12 hours, after 18 days of treatment, the material was discharged, and the weight of the material was reduced by 40.5%. The value of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com