Enameled wire hot wax automatic coating device

An automatic coating and enameled wire technology, which is applied in the field of enameled wires, can solve the problems of uneven coating, lower temperature, and lower fluidity of adsorption felts, and achieve the effect of accelerating air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

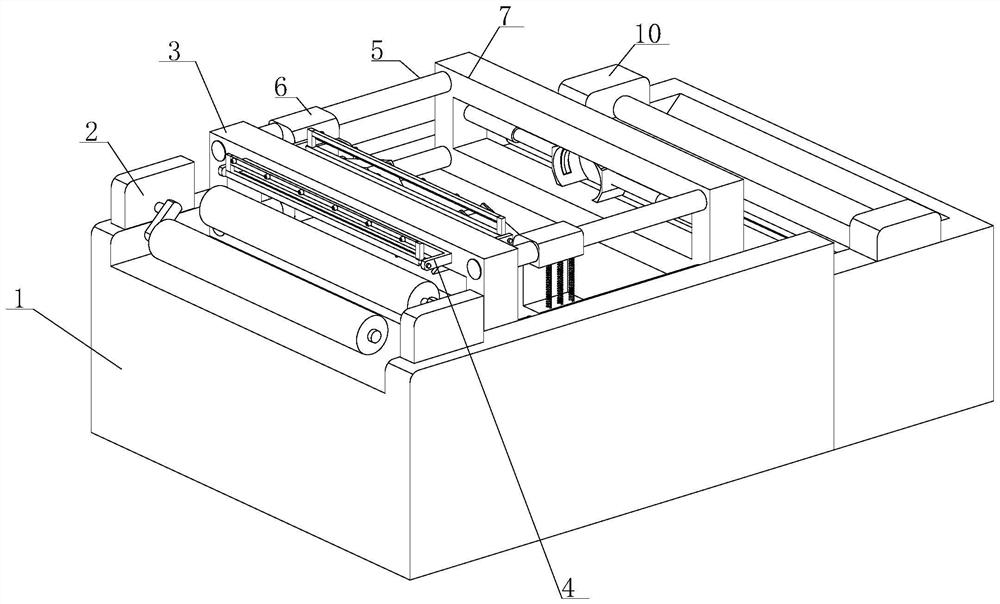

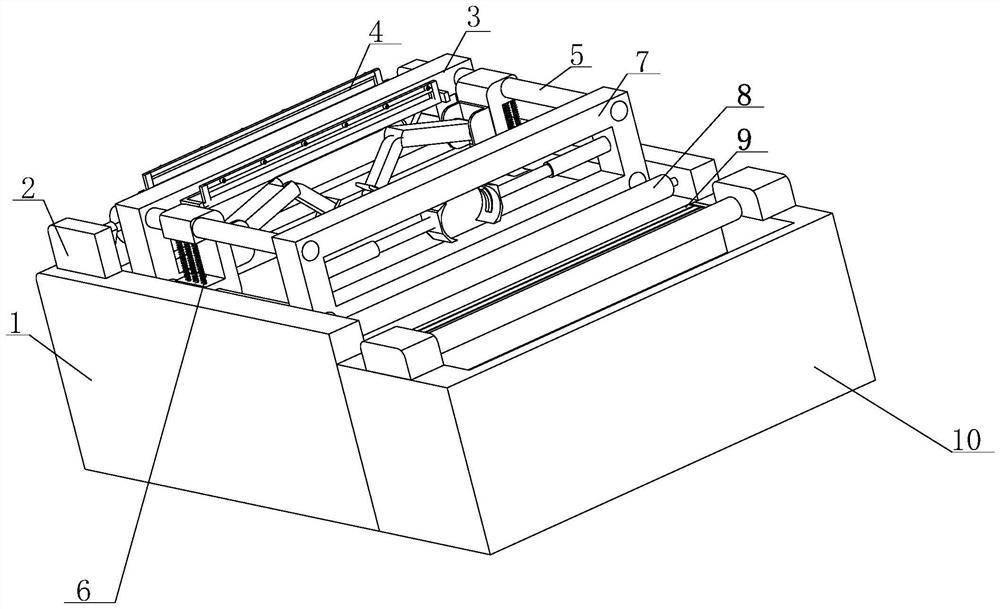

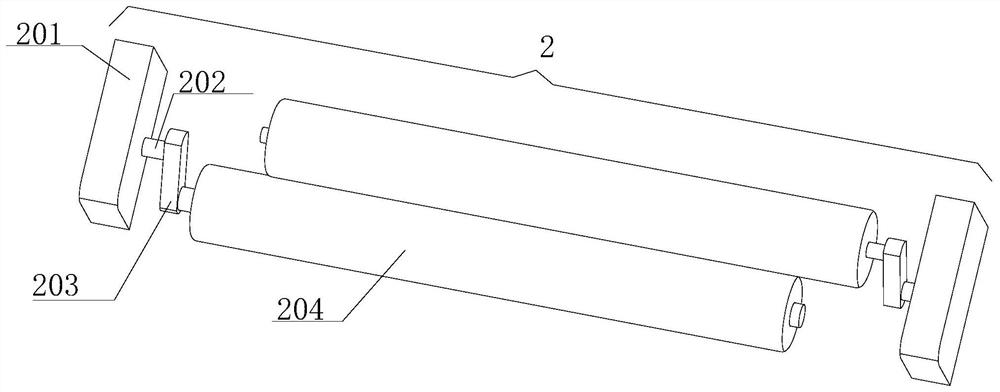

[0039] see Figure 1-3, the present invention provides a technical solution: an enameled wire hot wax automatic coating device, including a machine platform 1, an adjustment device 2 is fixedly installed on the top of the machine platform 1, and the inside of the adjustment device 2 includes a fixed platform 201, the fixed platform 201 A rotating shaft 202 is arranged inside, and one end of the rotating shaft 202 is movably connected with the inner wall of the fixed table 201, and the other end of the rotating shaft 202 is fixedly connected with an adjusting plate 203, and the end of the adjusting plate 203 away from the rotating shaft 202 is provided with an adjusting shaft, and the adjusting shaft One end of one end is movably connected with one end of the regulating plate 203, and the outer wall of the regulating shaft is movably connected with a heating roller 204.

[0040] In this embodiment, two adjustment devices 2 are arranged on the top of the machine table 1, the rot...

Embodiment 2

[0042] see Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the top of the machine platform 1 is provided with a front fixed plate 3, the bottom of the front fixed plate 3 is fixedly connected with the top of the machine platform 1, and the front fixed plate 3 The outer wall of the spraying device 4 is fixedly installed with a spraying device 4. The inside of the spraying device 4 includes a connecting frame 401. The outer wall of the connecting frame 401 is fixedly connected with the outer wall of the front fixed plate 3. The inside of the connecting frame 401 is provided with a control shaft 402. The two sides of the control shaft 402 The end is movably connected with the inner wall of the connecting frame 401, and the outside of the control shaft 402 is provided with a movable rod 403. Both ends of the plate 404 are fixedly connected with the outer wall of the movable rod 403 , and the outer wall of the mounting plate ...

Embodiment 3

[0045] see Figure 1-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the inside of the front fixing plate 3 is fixedly equipped with an electric screw 5, and the outer wall of the electric screw 5 is movably connected with a coating arm 6 , the inside of the coating arm 6 includes a movable concave platform 601, the outer wall of the movable concave platform 601 is fixedly equipped with a spring 602, one end of the movable concave platform 601 is fixedly installed with a movable concave platform 601, and the inner wall of the movable platform 603 is provided with a connecting arm 604 One end of connecting arm one 604 is movably connected with the inner wall of movable table 603, the other end of connecting arm one 604 is movably installed with connecting arm two 605, and the end of connecting arm two 605 away from connecting arm one 604 is fixedly connected with L-shaped frame 606, The interior of the L-shaped fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com