Permanent Magnetic Separator

A technology of permanent magnet iron remover and magnetic steel, which is applied in the fields of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of large power consumption, hidden danger of safety accidents, large energy consumption, etc., so as to reduce energy loss and use. Convenience and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

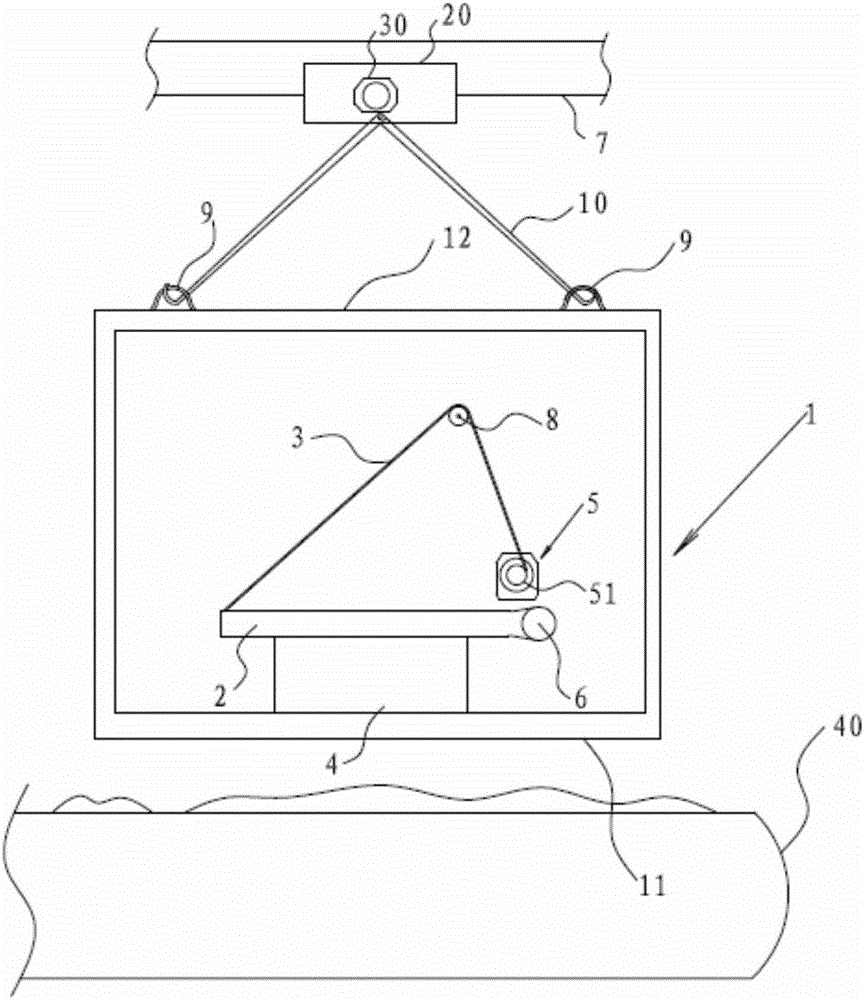

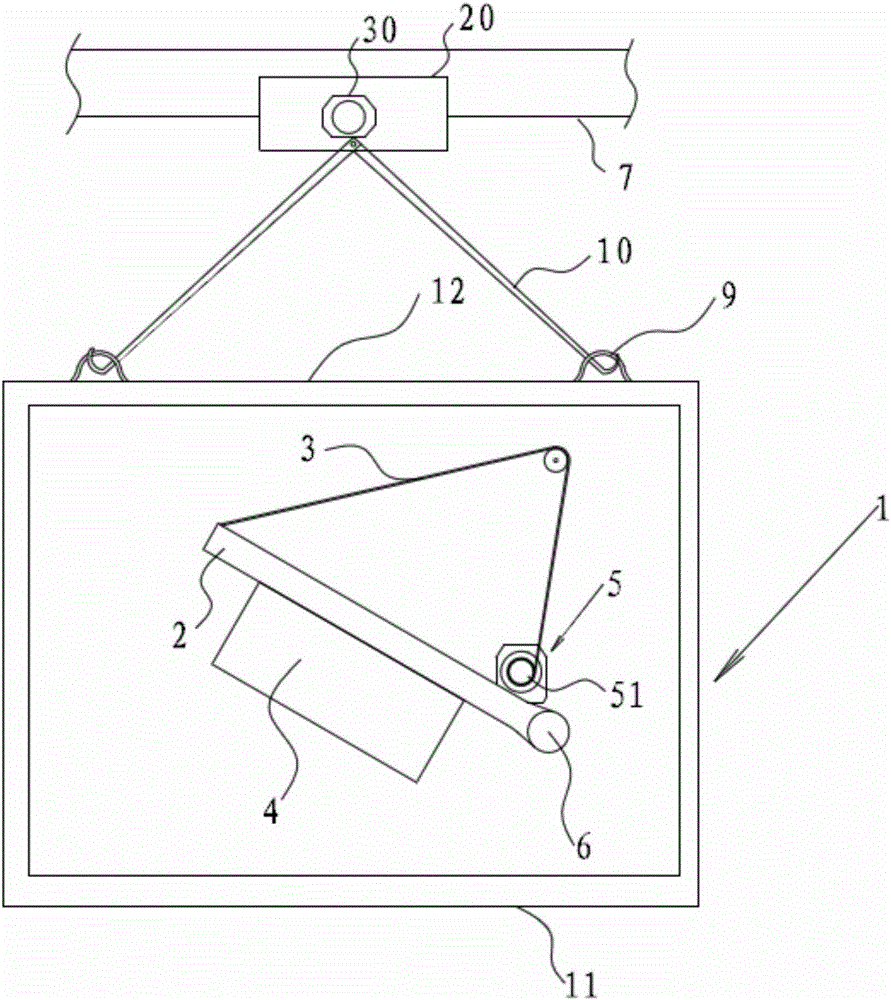

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] refer to figure 1 and figure 2 . The permanent magnet iron remover of the present invention includes a casing 1, a rotating shaft 6, a magnetic steel 4 and a driving device, the driving device is arranged in the casing 1, the casing 1 includes a bottom plate 11, the rotating shaft 6 is connected with the driving device, and the magnetic steel 4 is connected with the rotating shaft 6, the rotating shaft 6 and the magnetic steel 4 are both arranged in the box body 1, and the magnetic steel 4 is arranged correspondingly to the bottom plate 11. The driving device drives the rotating shaft 6 to rotate, and the magnetic steel 4 rotates along with the rotating shaft 6 . Therefore, it can be realized that after the magnetic force of the magnet 4 makes the iron filings outside the base plate 11 adsorb, with the rotation of the magnet 4, the magnetic force l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com