Steel wire rope overload automatic falling-off lifting sling

An automatic shedding and wire rope technology, applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve problems such as heavy objects falling, wire rope breakage, inaccurate estimation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

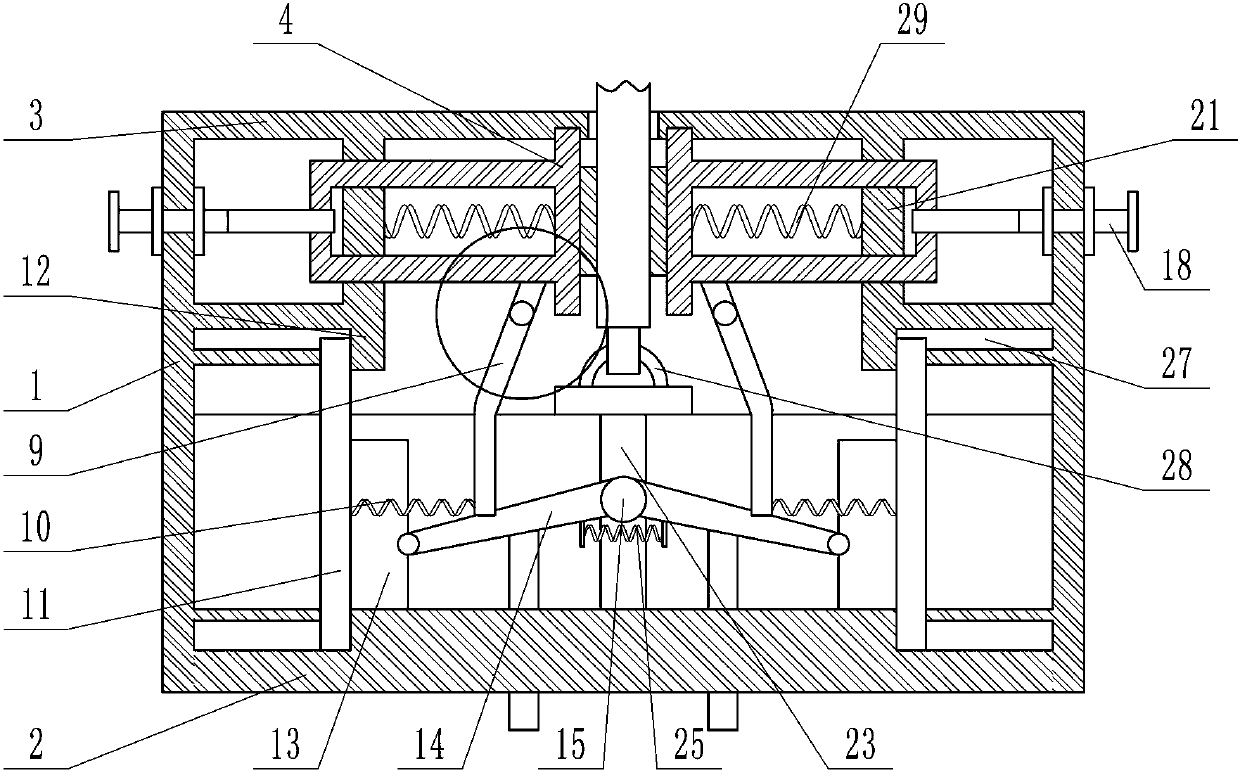

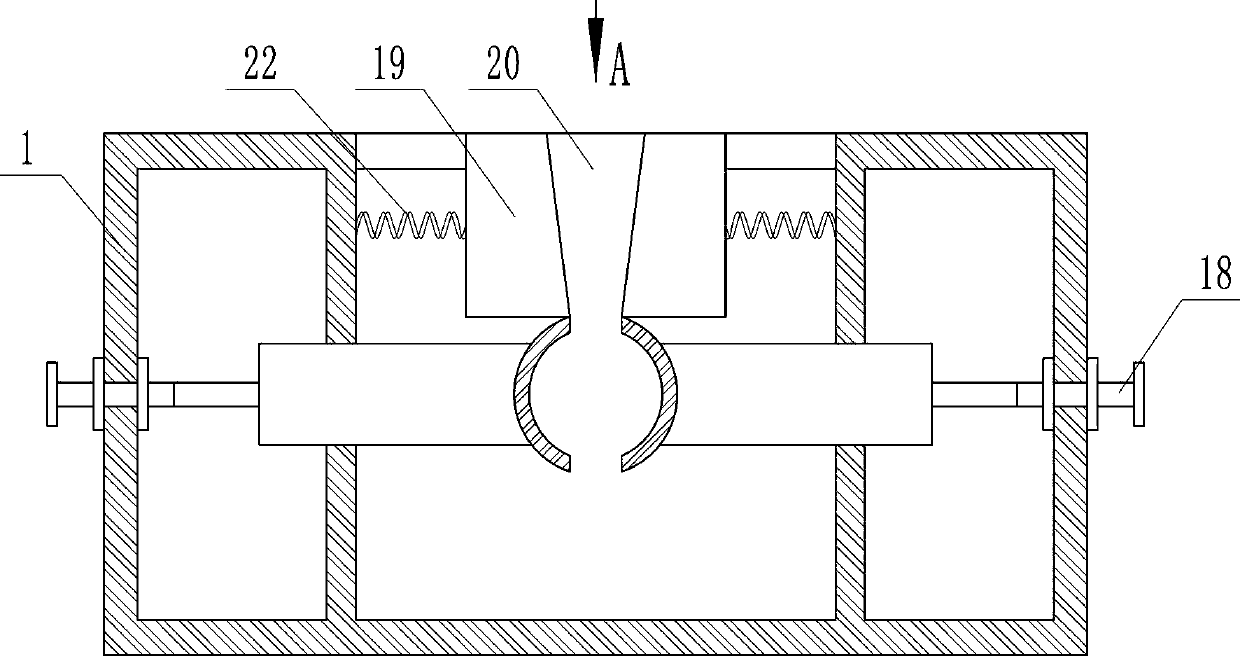

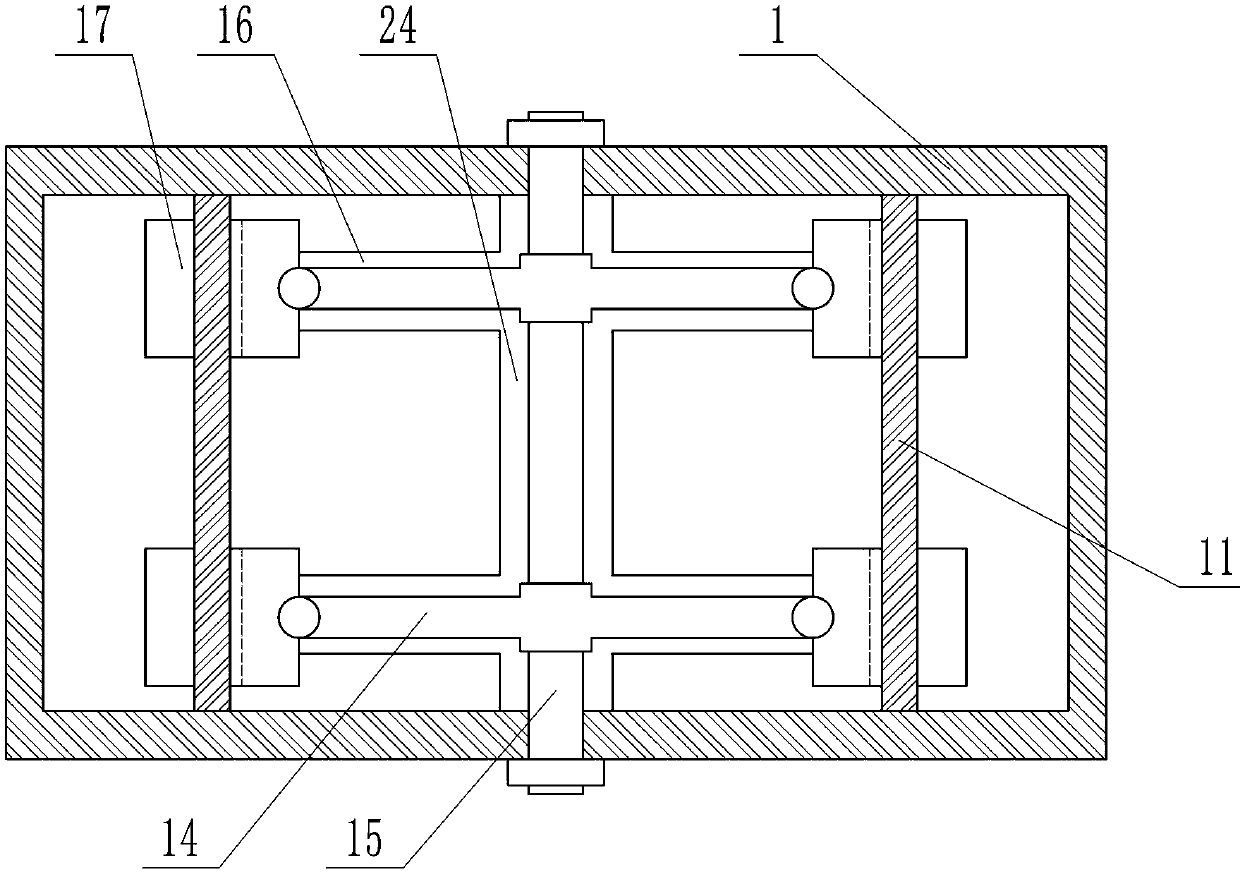

[0017] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] Depend on Figure 1-7 It can be seen that the present invention includes a supporting frame 1, the lower end of the supporting frame 1 is provided with a bottom plate 2, the upper end of the supporting frame 1 is provided with a cover plate 3, and the inner upper part of the supporting frame 1 is provided with a clamping device placed below the cover plate 3, and the clamping device is placed At the central position of the support frame 1 in the left and right direction, the clamping device is composed of two blocks 4 that can move left and right, and the two blocks 4 are symmetrically arranged left and right, and each block 4 includes a semicircular arc block 5, The semicircular inner surfaces of the two arc-shaped blocks 5 are opposite, and the outer surface of each arc-shaped block 5 is connected with two horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com