Patents

Literature

220results about How to "Automatic disengagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reamer

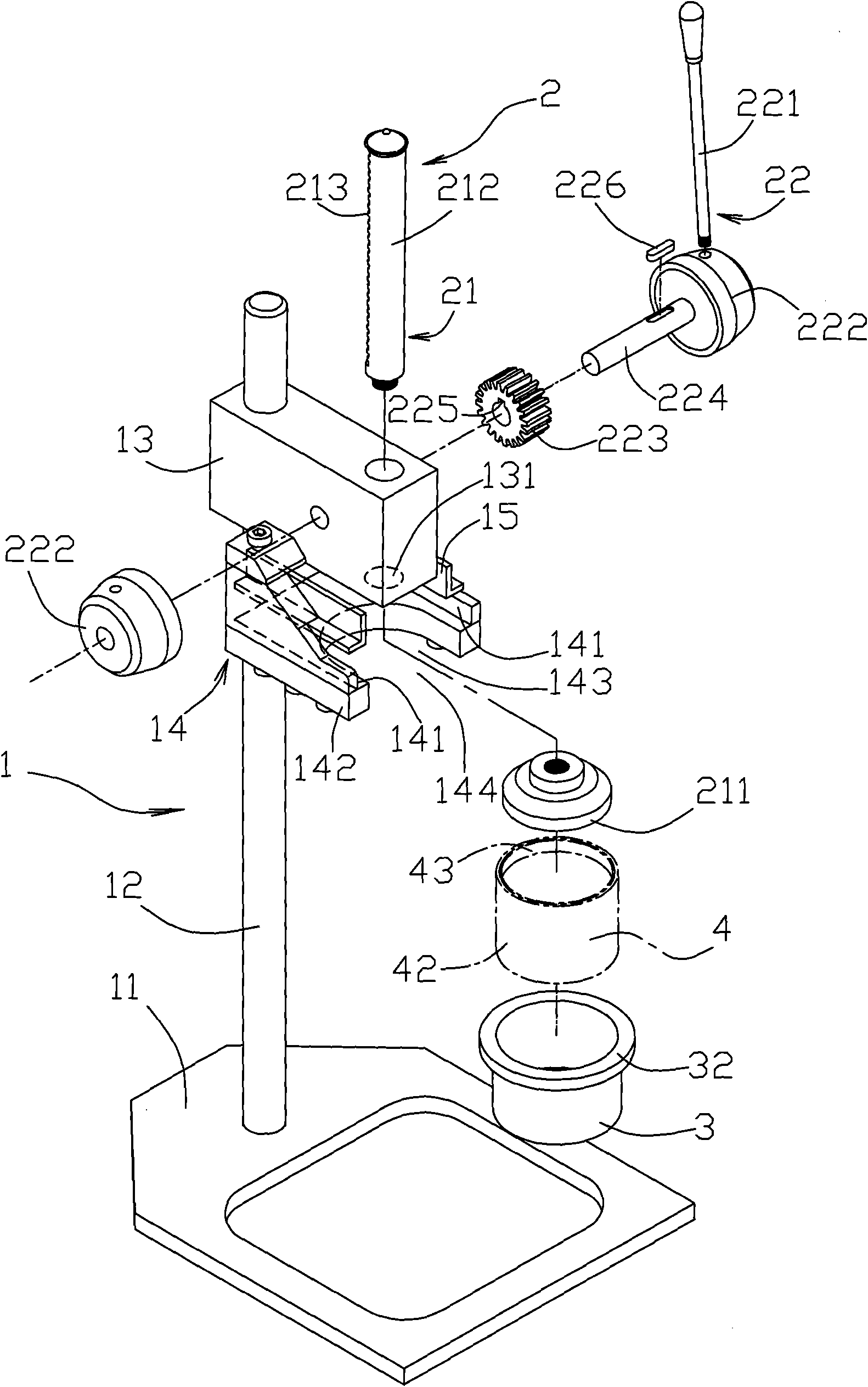

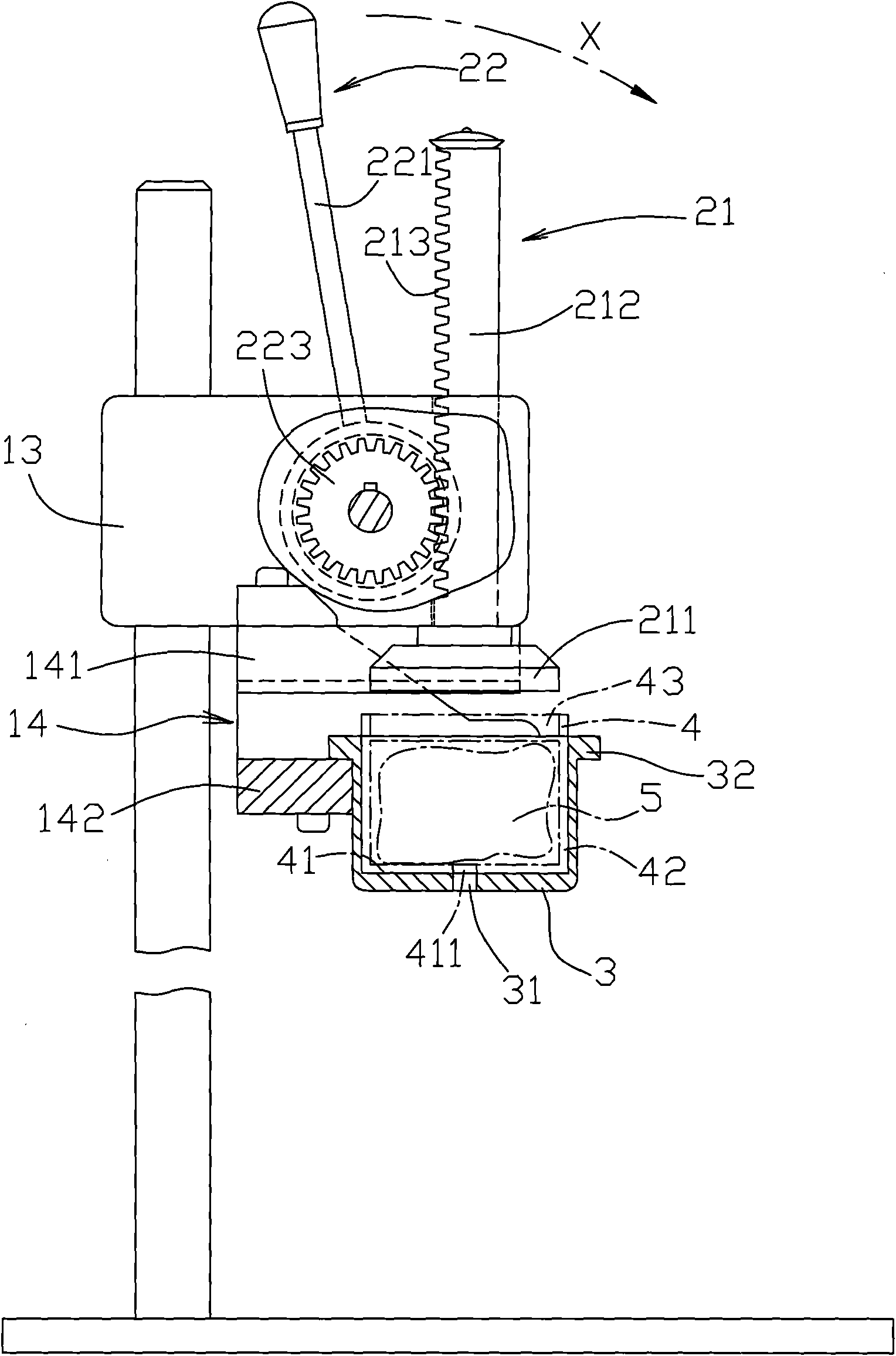

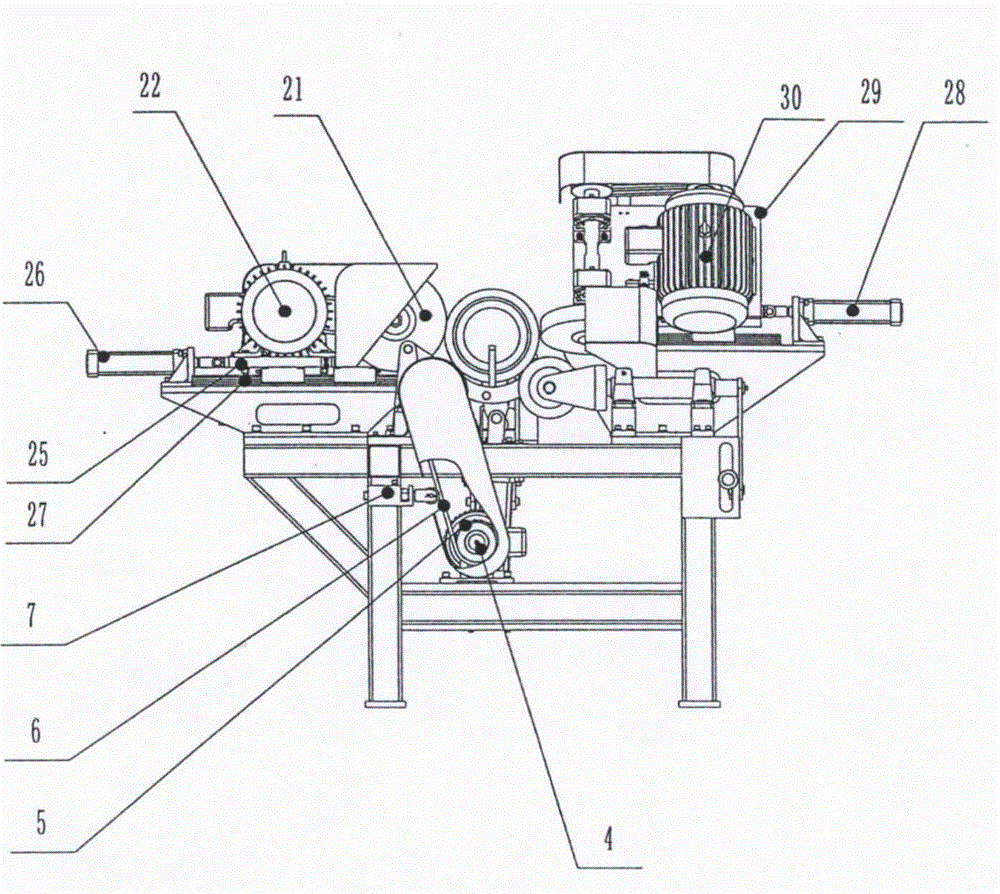

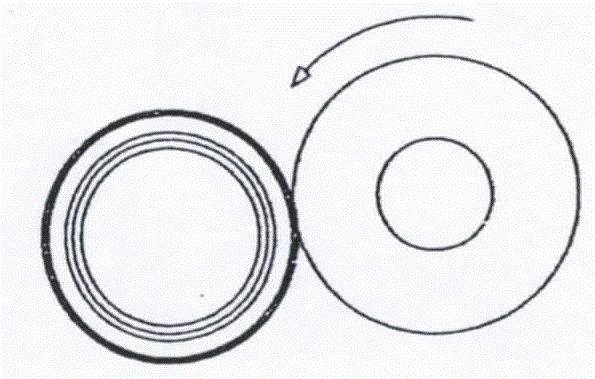

ActiveCN104492988AIncrease productivitySave energyShaping toolsMetal-working feeding devicesReamerSmall footprint

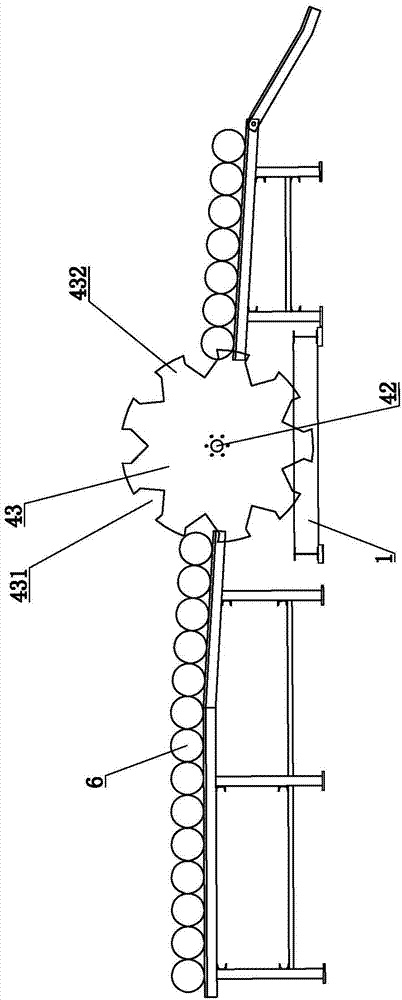

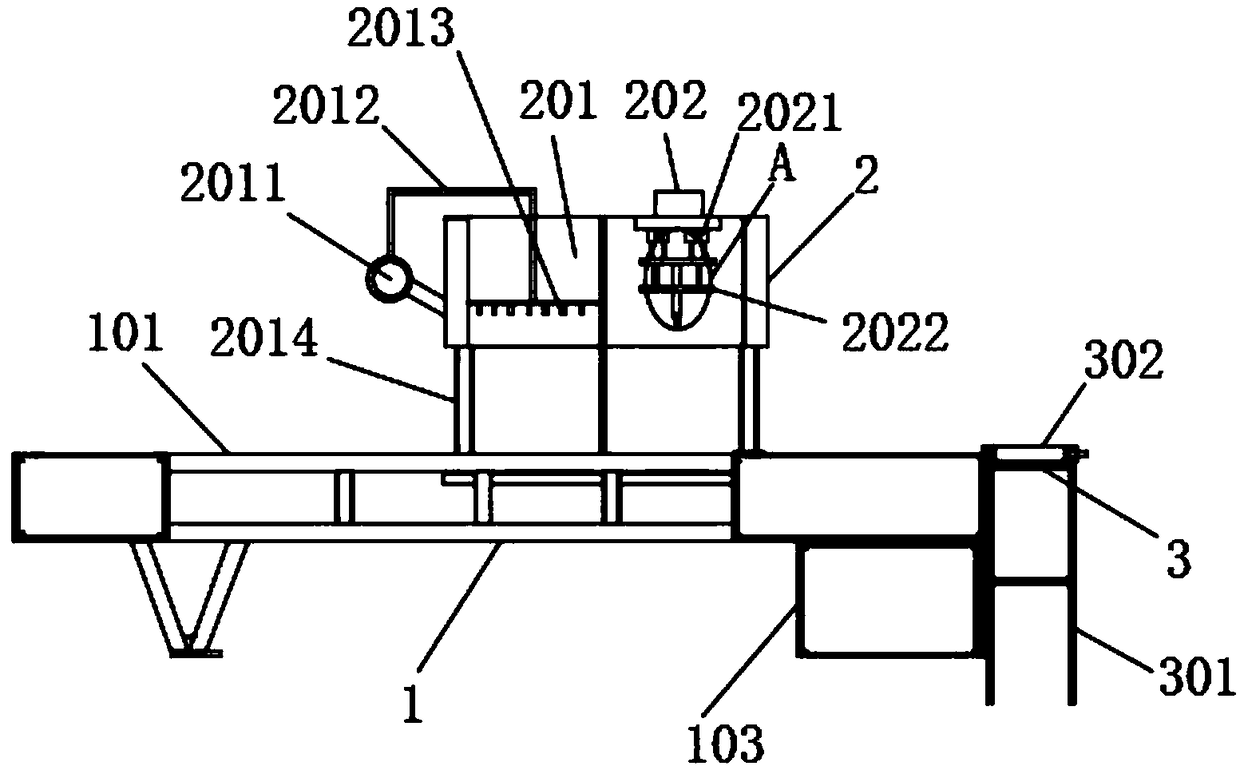

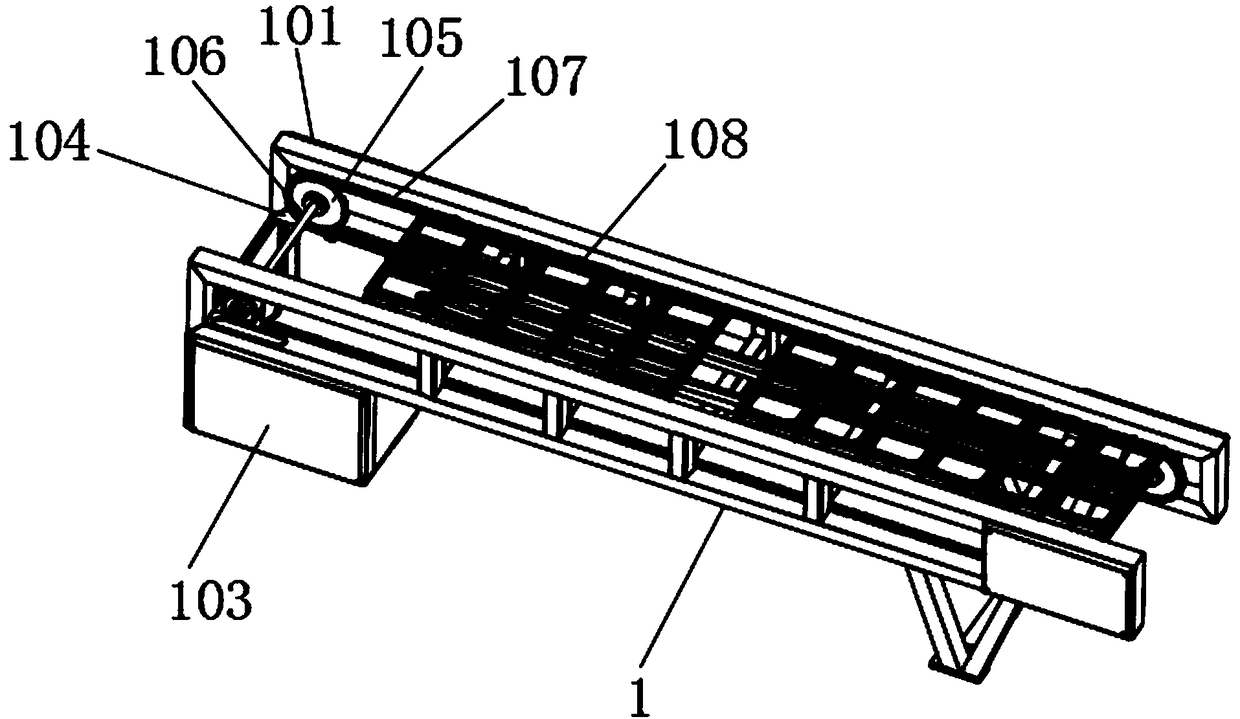

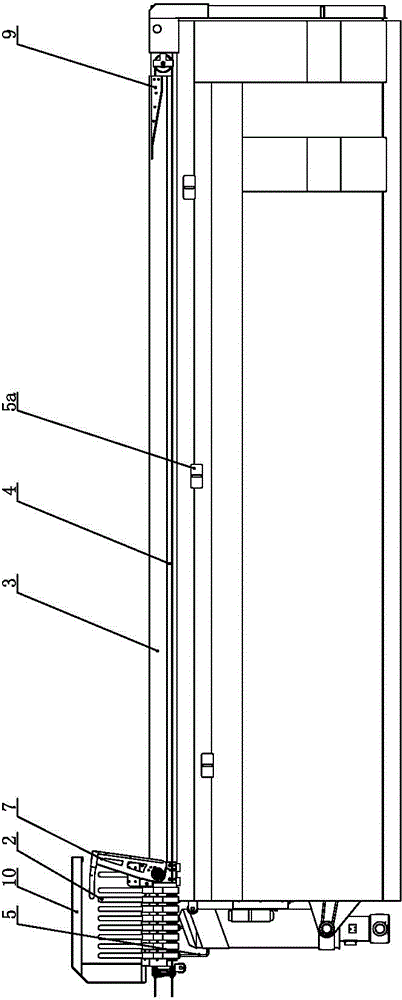

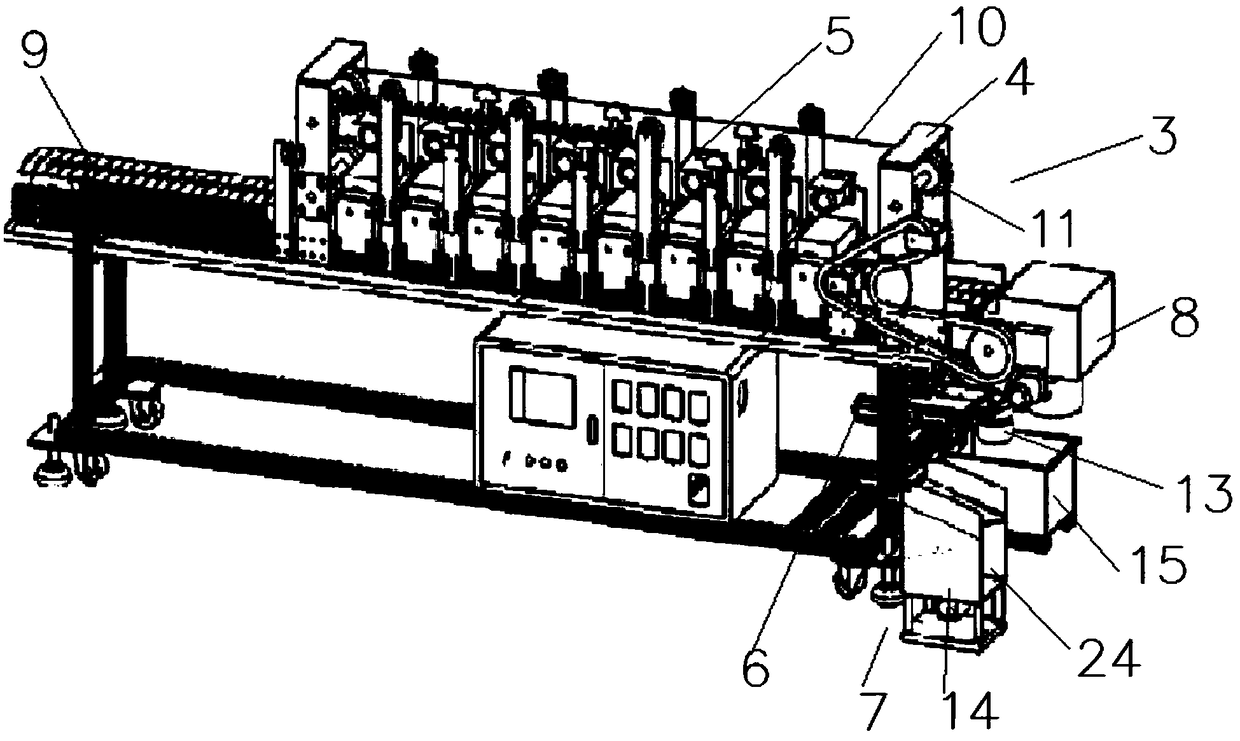

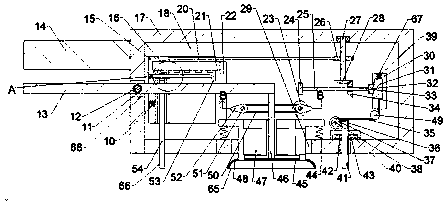

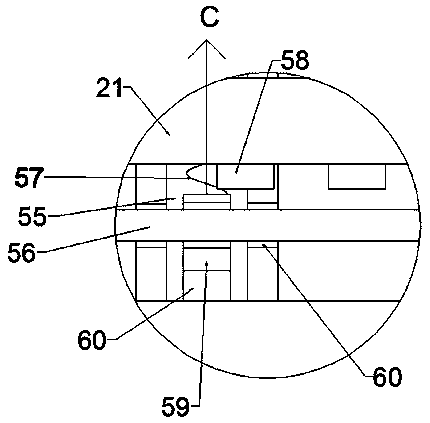

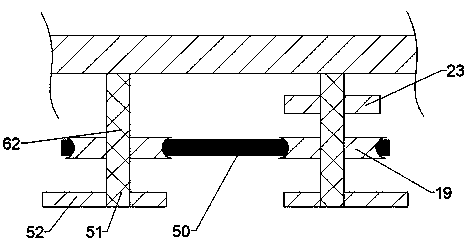

The invention discloses a reamer. The reamer comprises a rack, wherein the rack is provided with an electromagnetic heating device and a reaming device which are arranged from front to back in sequence; the electromagnetic heating device comprises an electromagnetic heating coil; the reaming device comprises a reaming hole driven by a first power device; the rack is provided with a poking plate feeding device; the poking plate feeding device comprises a rotating shaft connected with a second power device; the rotating shaft is transversely arranged on the rack; the two ends of the rotating shaft are fixedly provided with circular poking plates; the peripheral parts of the poking plates are provided with at least three feeding fork entries for conveying metal pipes; poking plates are formed between adjacent feeding fork entries and can rotate to the positions, corresponding to the electromagnetic heating coil and a reaming head, on every two adjacent feeding fork entries respectively. The reamer has the advantages of high production efficiency, small floor area and low power consumption.

Owner:高密天一机械科技有限公司

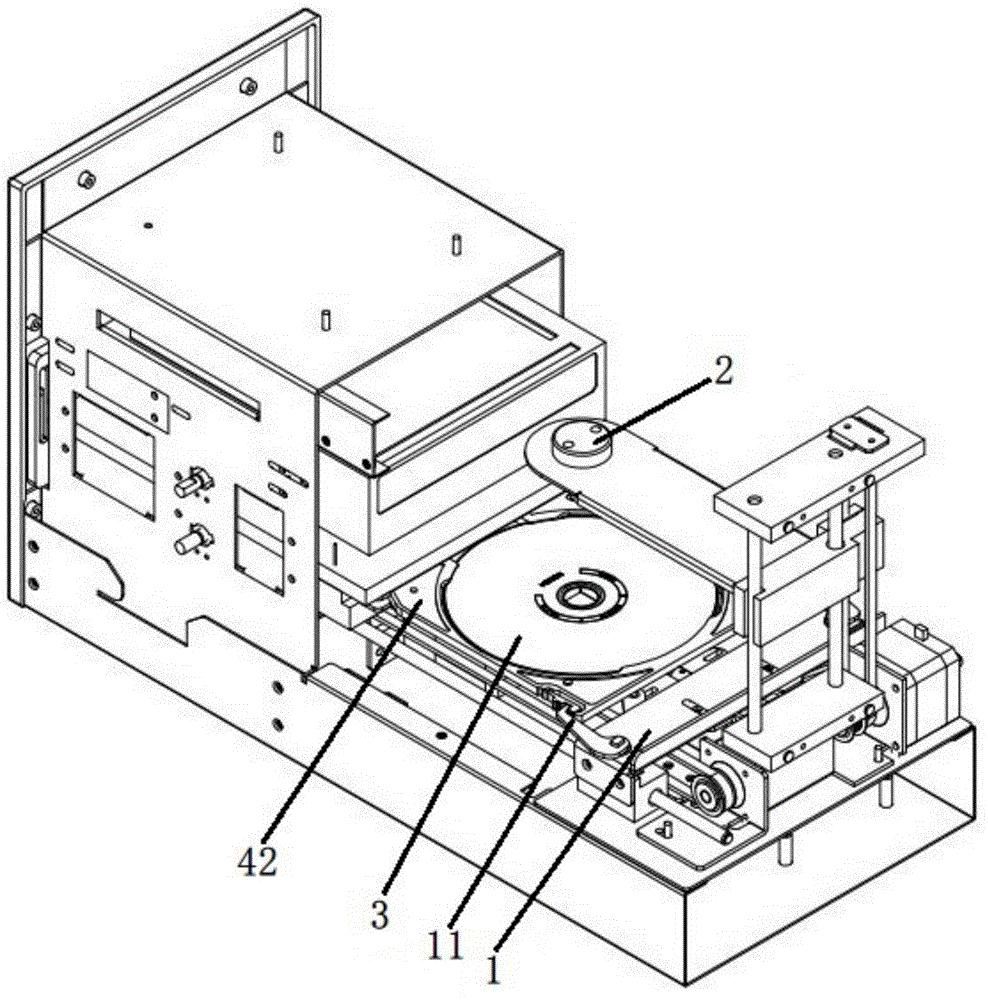

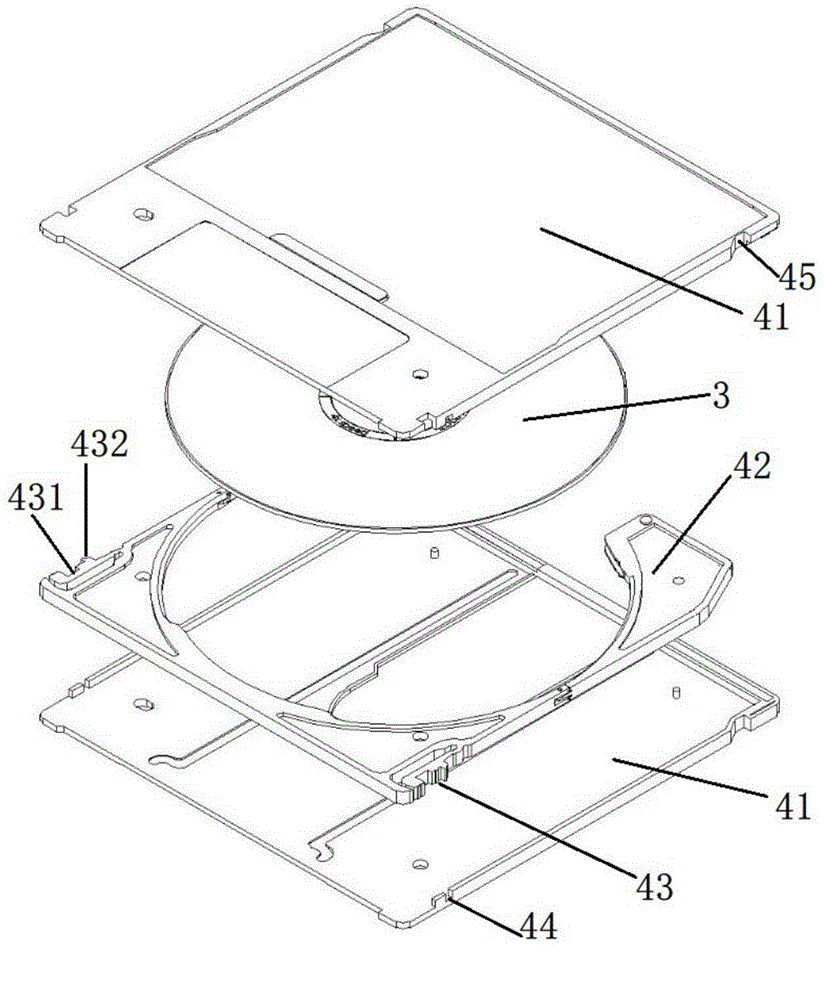

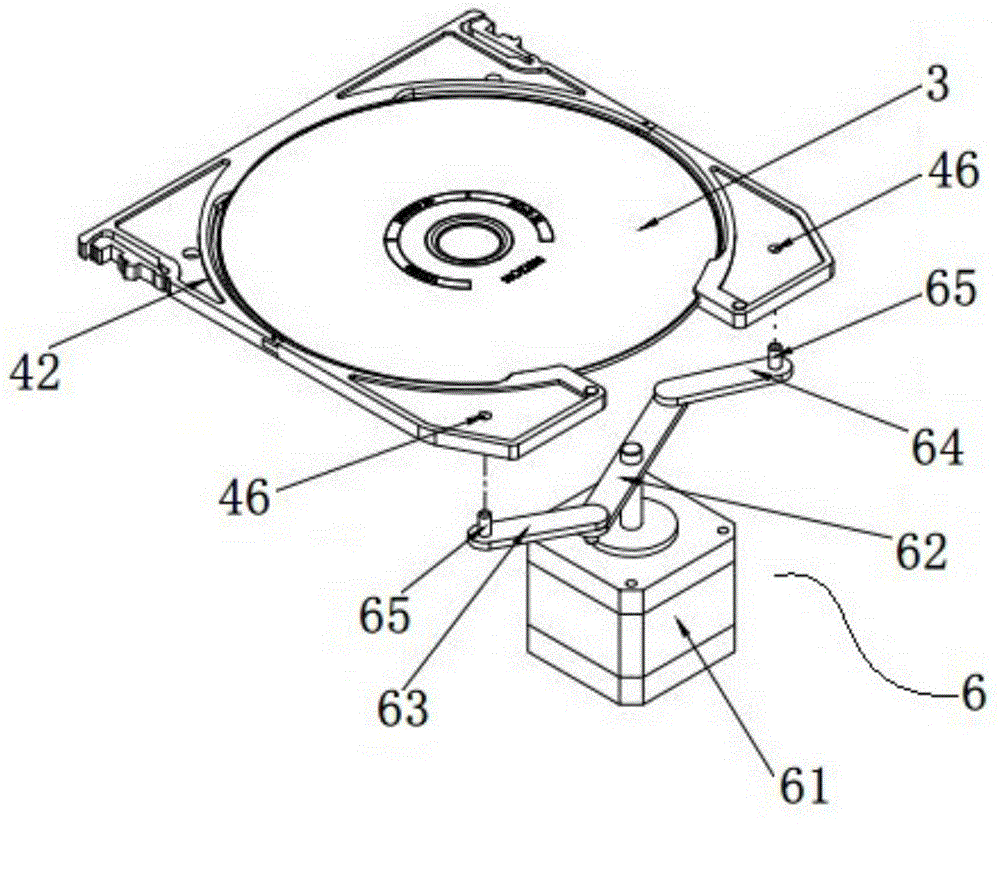

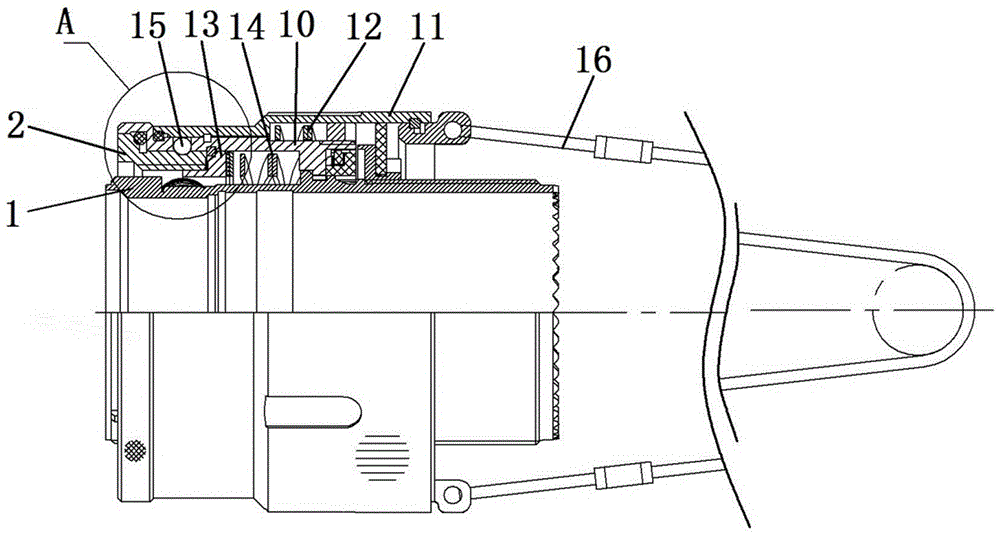

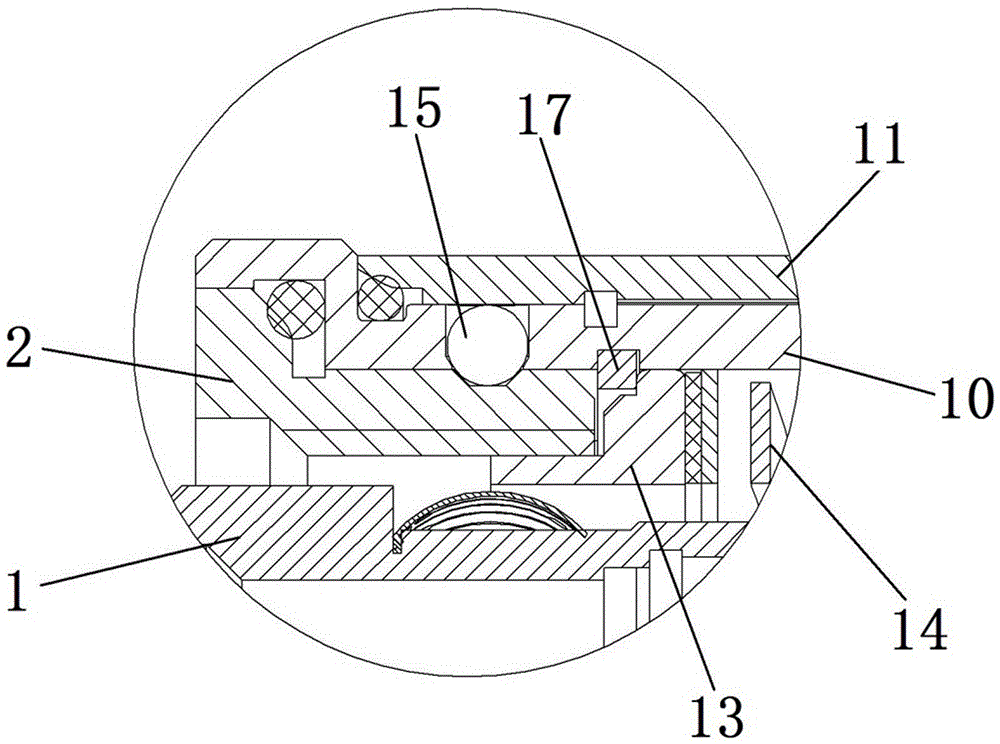

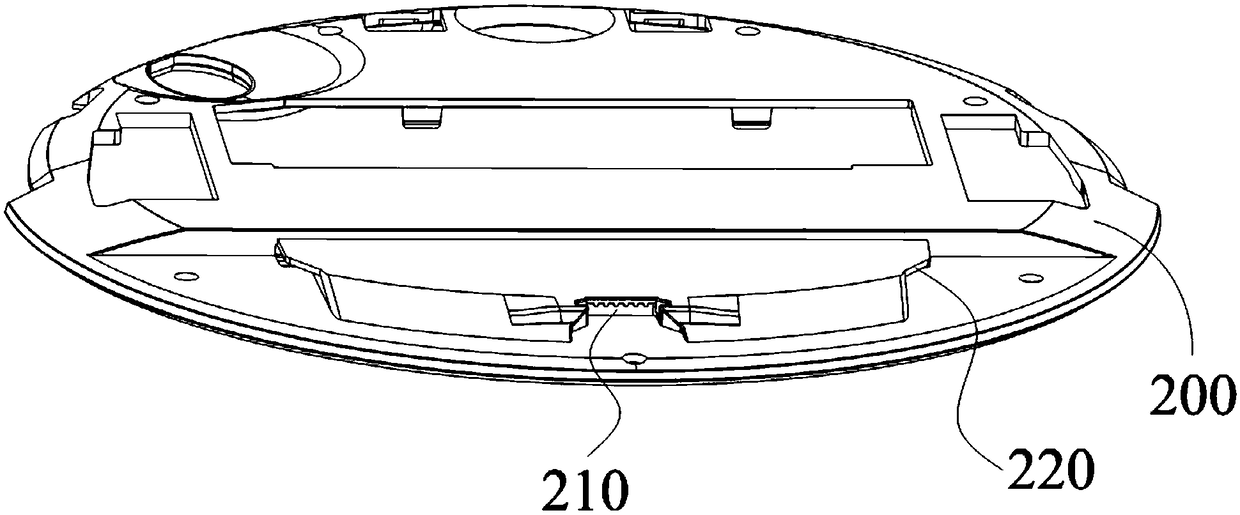

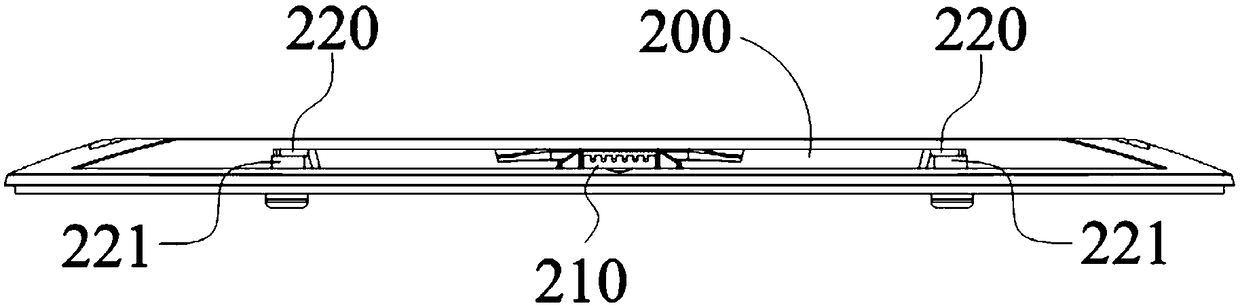

Automatic read-write device for double-sided disc

ActiveCN104575534ASo as not to damageAutomatic disengagementRecord information storageMechanical engineeringOptical disc

Owner:SUZHOU NETZON INFORMATION STORAGE TECH

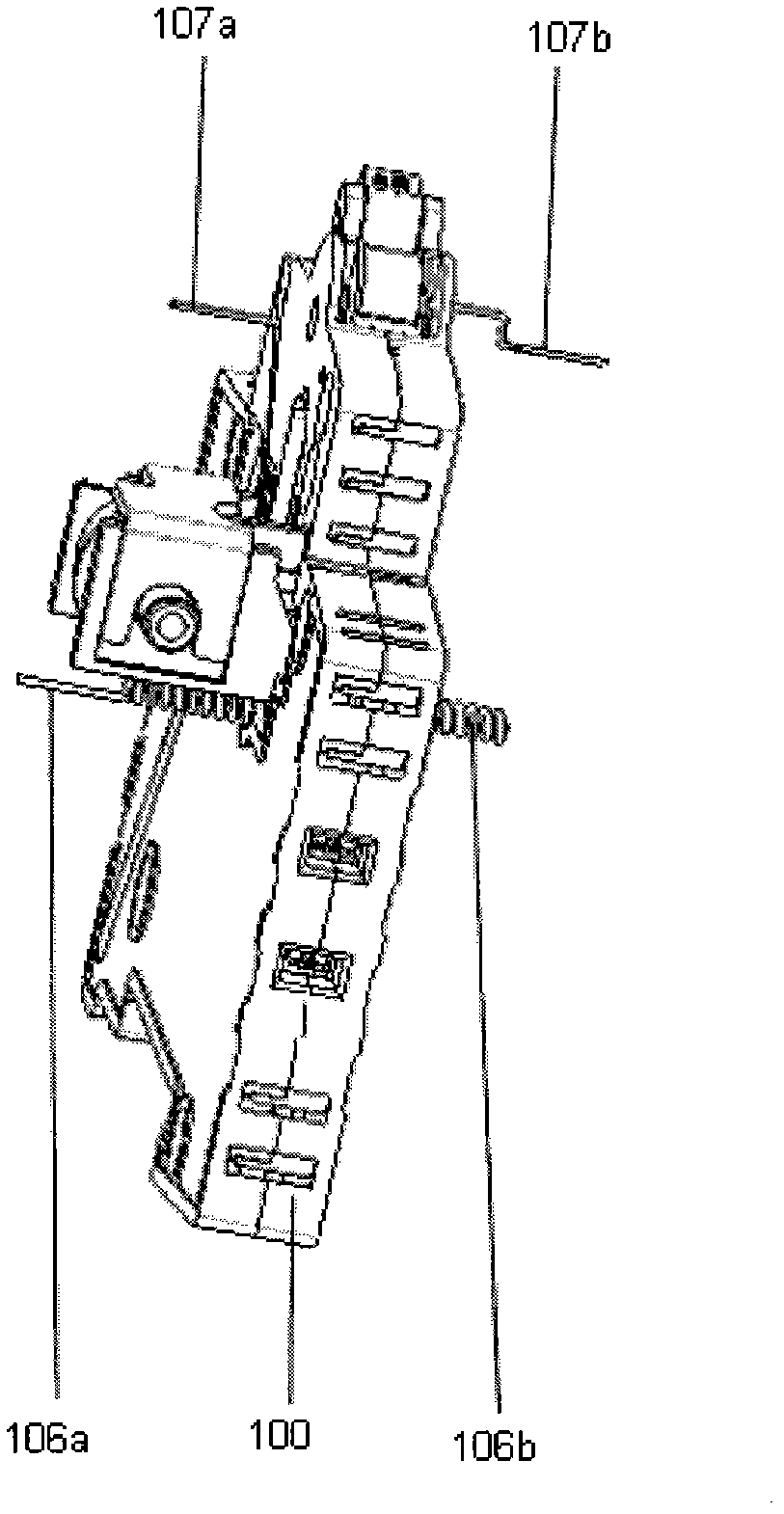

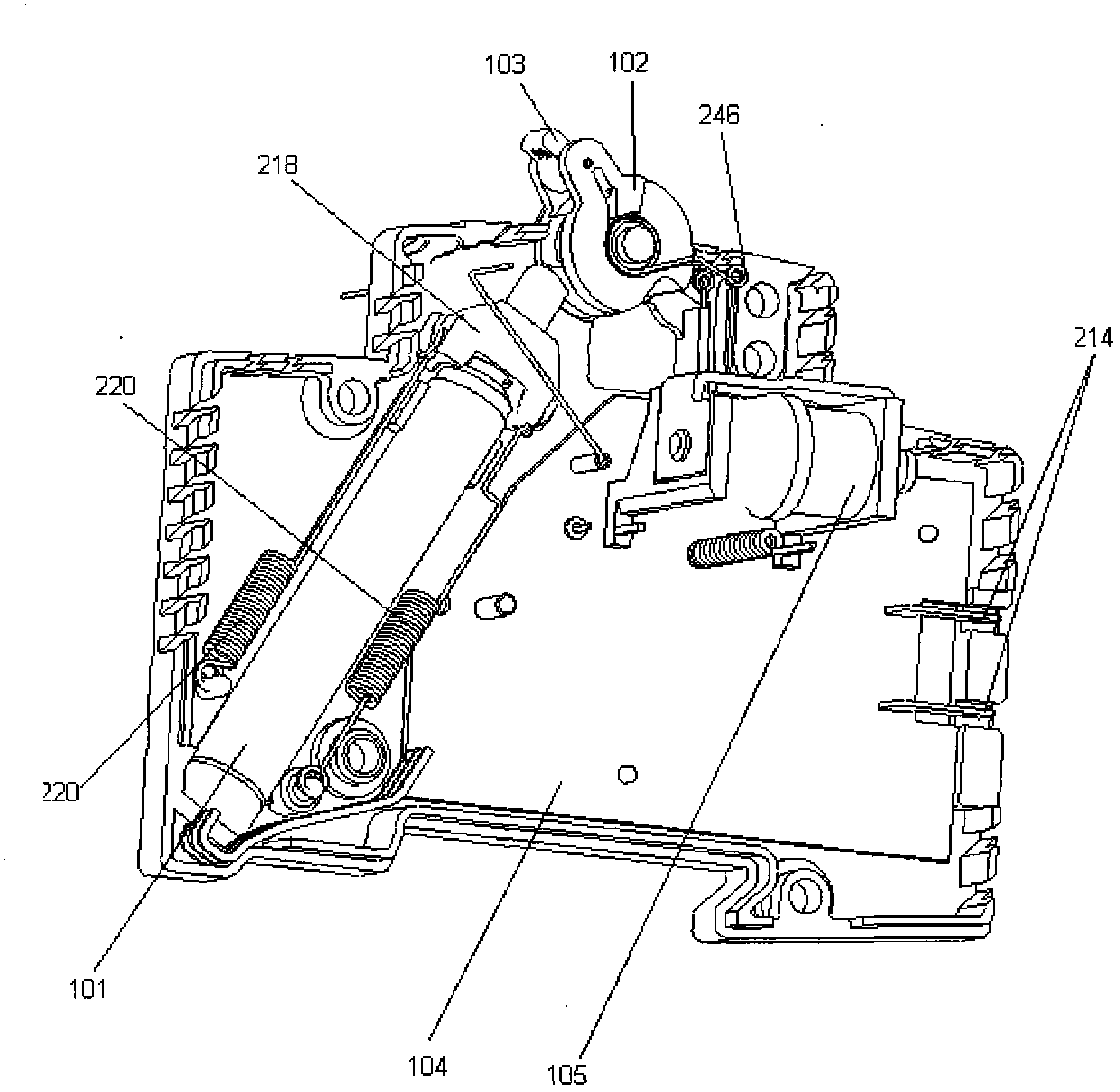

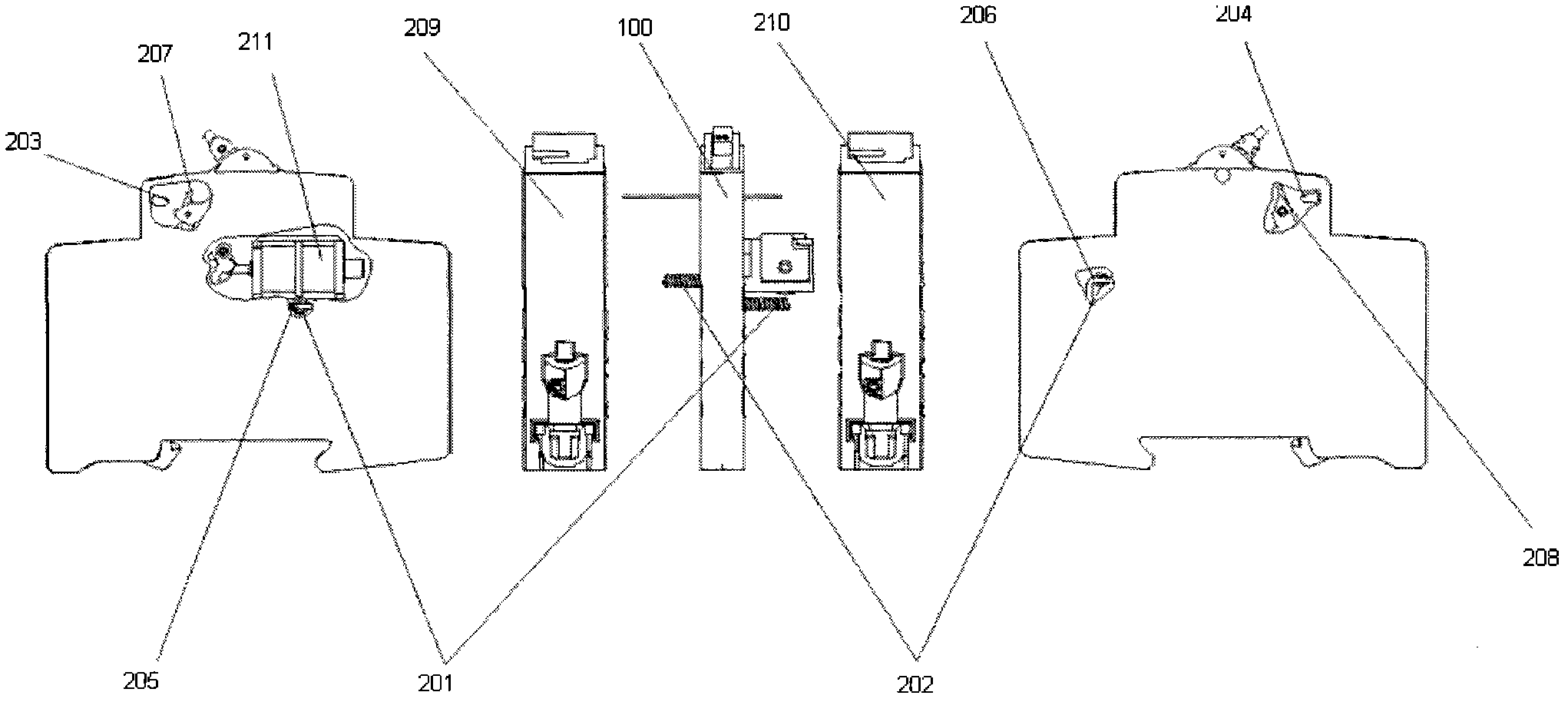

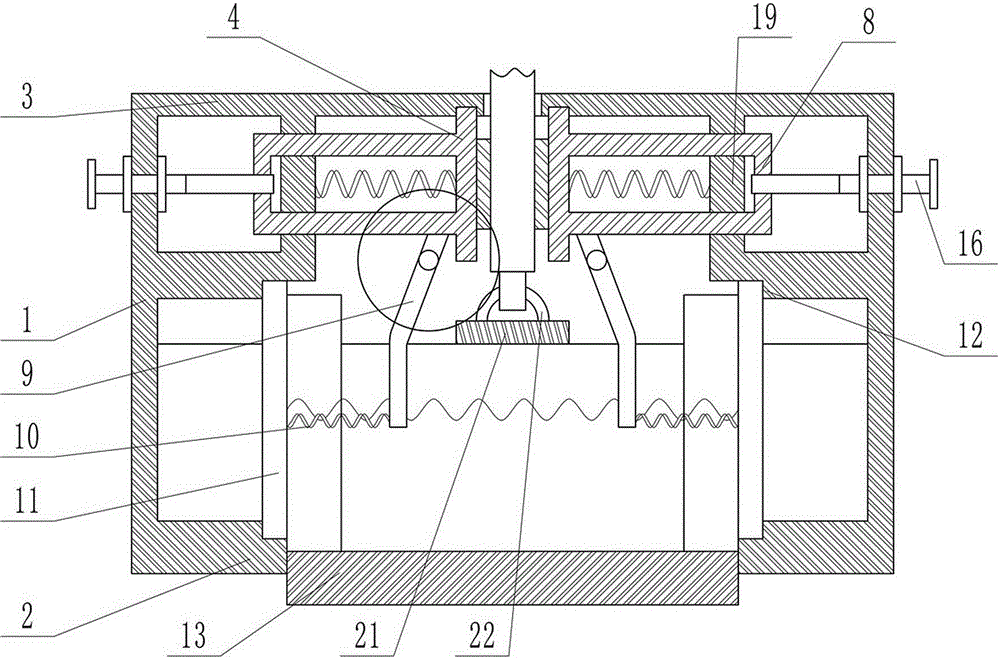

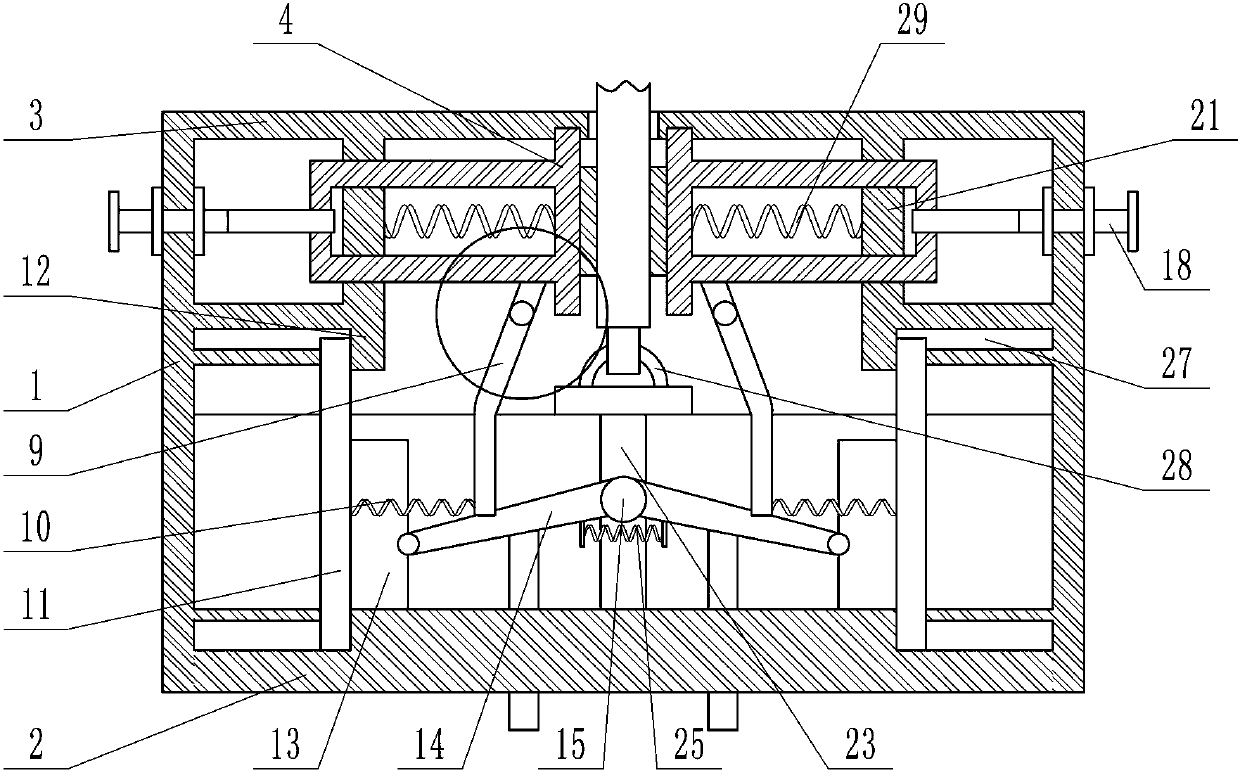

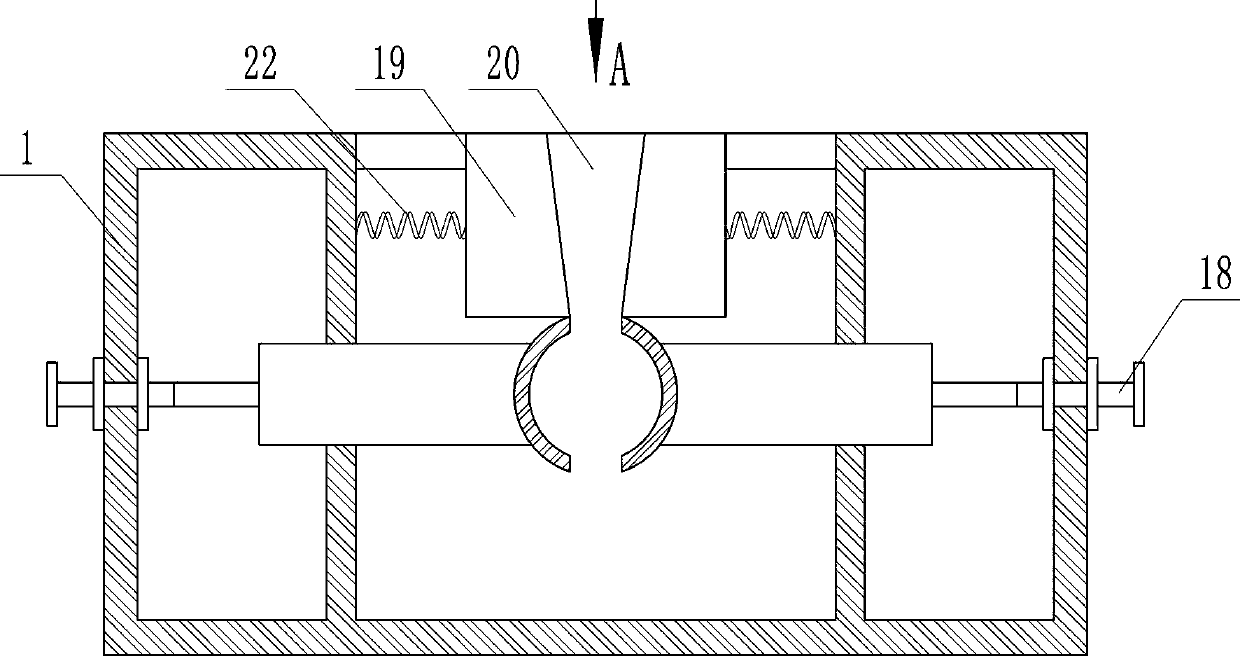

Intelligent operation device capable of closing and separating brake automatically according to front voltage and miniature circuit breaker of same

ActiveCN102568952AFit closelyCompact structureProtective switch operating/release mechanismsOvervoltageToggle switch

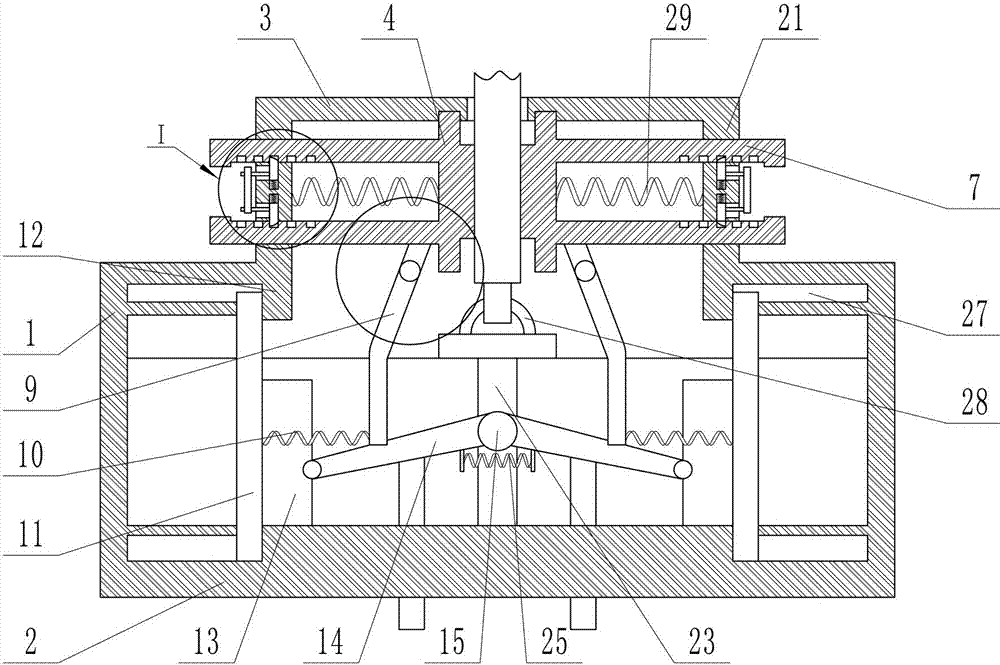

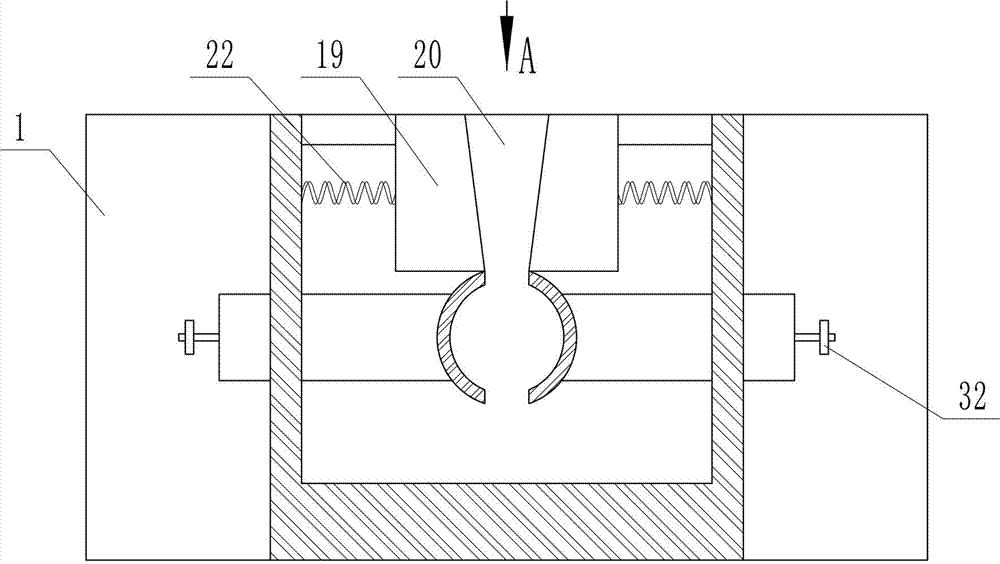

The invention discloses an intelligent operation device for detecting front voltage and closing and separating a brake automatically according to the front voltage, as well as an automatic-reset abnormal voltage protection intelligent miniature circuit breaker comprising the intelligent operation device. The intelligent operation device comprises an automatic closing power device, an automatic closing power track switch assembly, an automatic closing shield toggle switch assembly, a multifunctional logic control circuit board, an abnormal voltage tripping device (shunt tripping device), a power spring, a power needle and auxiliary contacts. After the intelligent operation device is combined with N pole and L pole of a standard MCB (memory control block), the formed automatic-reset abnormal voltage protection intelligent miniature circuit breaker has overvoltage protection and low-voltage protection functions expect the functions like manual brake closing or separating of a common MCB, overload protection, overcurrent protection and so on; after the abnormal voltage protection is automatically separated, the breaker has automatic-reset and automatic closing functions when the voltage of the system recovers normally; and the automatic closing action meets with that of the safety logic stipulations. With the advantages of simple and compact structure, economical lost, reliable function and wide suitable current range, the intelligent operation device can solve the bottleneck problem that the current abnormal voltage protection products cannot realize closing brakes automatically, or a various production combination scheme for realizing brake closing automatically has high cost, complex structure and large volume.

Owner:北京ABB低压电器有限公司

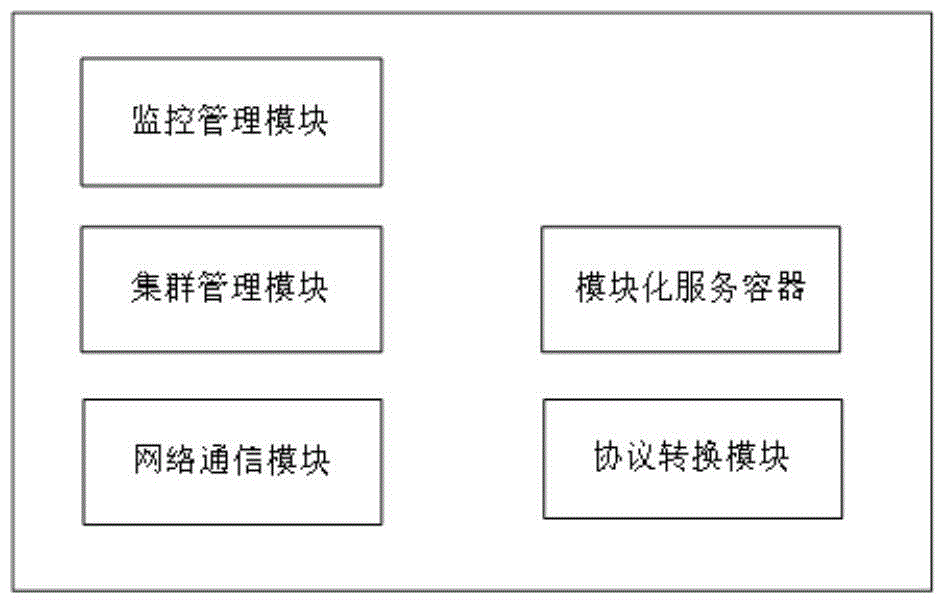

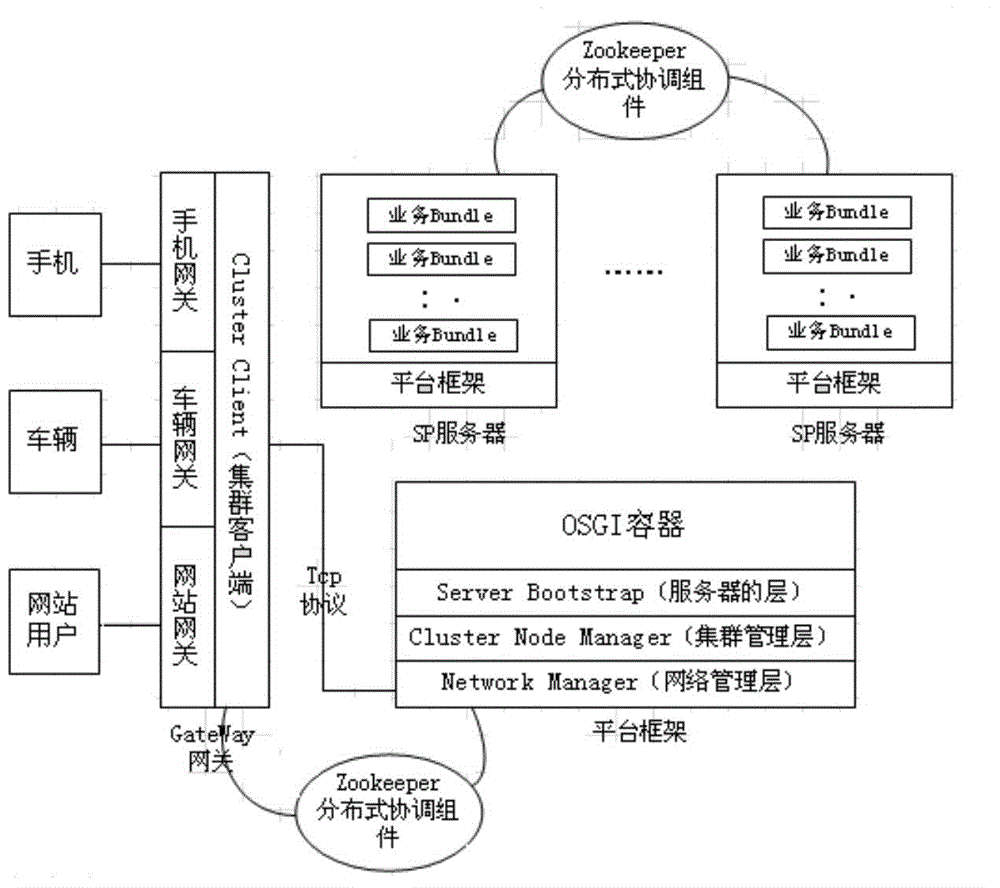

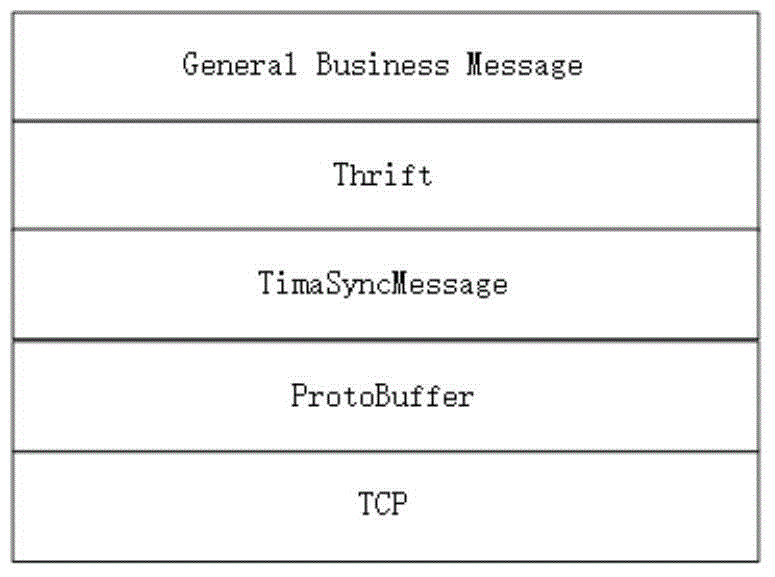

OSG-based parallel extendable application server

The invention discloses an OSG-based parallel extendable application server, which comprises a network communication module, a protocol conversion module, a cluster management module, a modularized service container and a monitoring management module. The network communication module is used for connecting the application server with terminal equipment. The protocol conversion module is used for achieving protocol conversion between a client and the server. The cluster management module is used for integrating a Zookeeper assembly into the application server so that the application server has a dynamic cluster capability. The modularized service container is used for making all network requests from the network communication module enter a thread pool, the requests will be distributed to different service processors after tasks in the thread pool are carried out, and the service processors search corresponding services in an osgi container to finish associated service processing. The monitoring management module is used for monitoring a service module. The application server can be clustered, is parallel extendable, and meets high concurrency demands of automobile data acquisition of Internet-of-Vehicles.

Owner:钛马信息网络技术有限公司

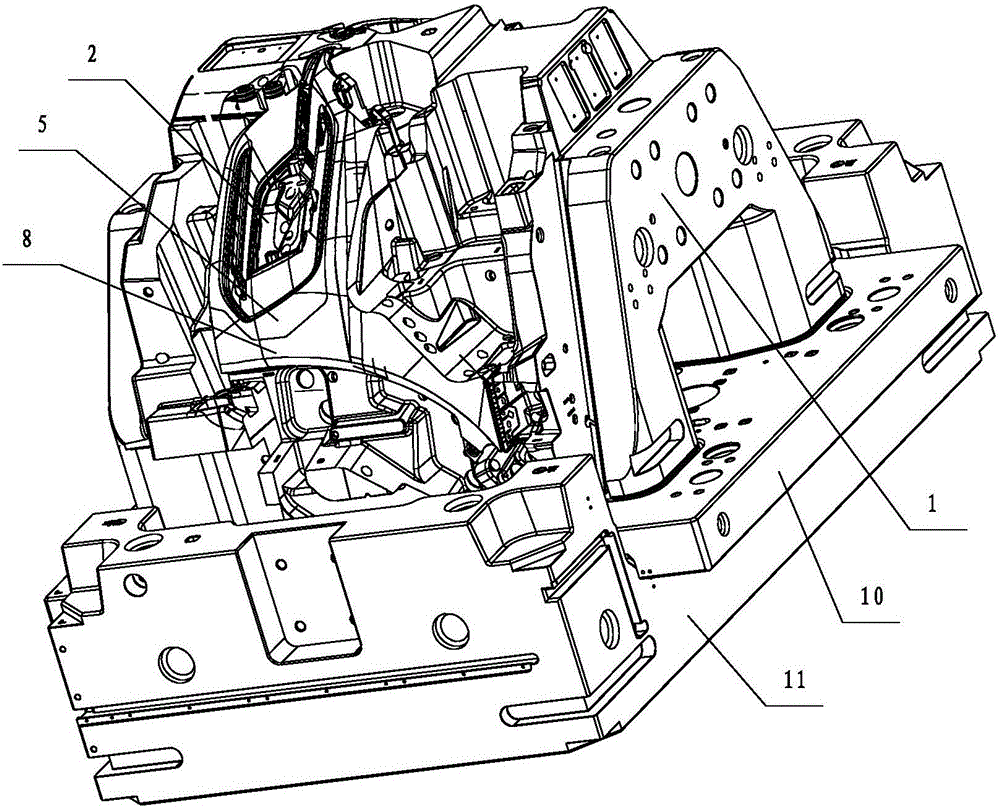

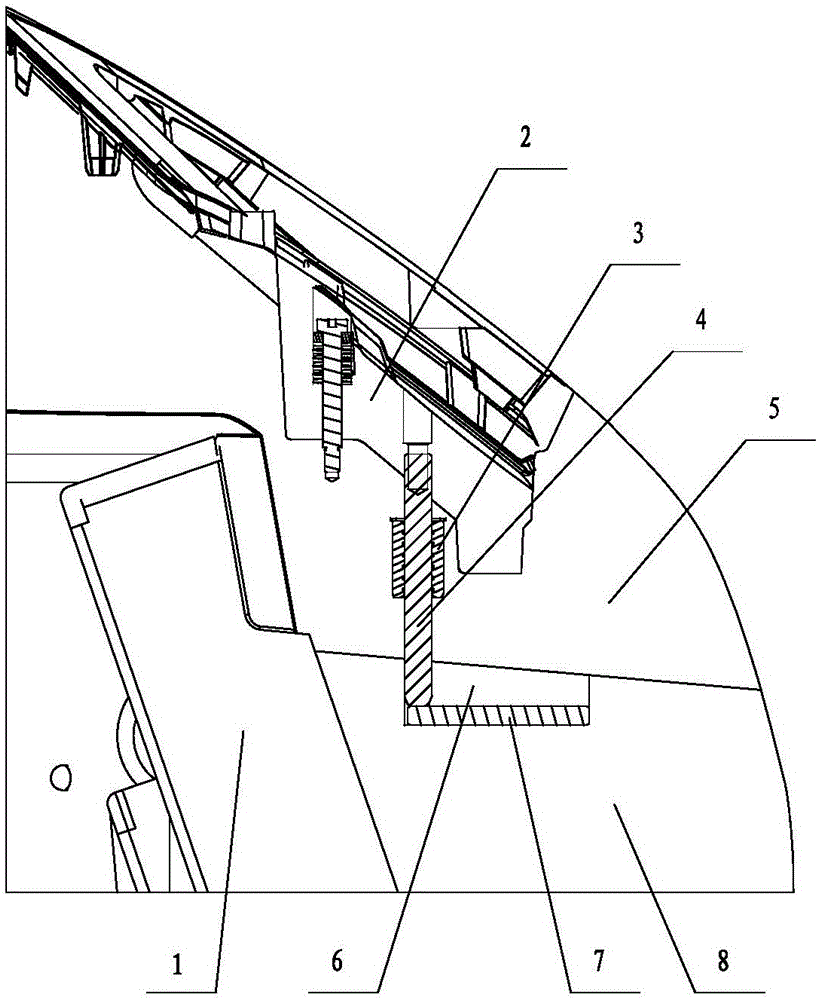

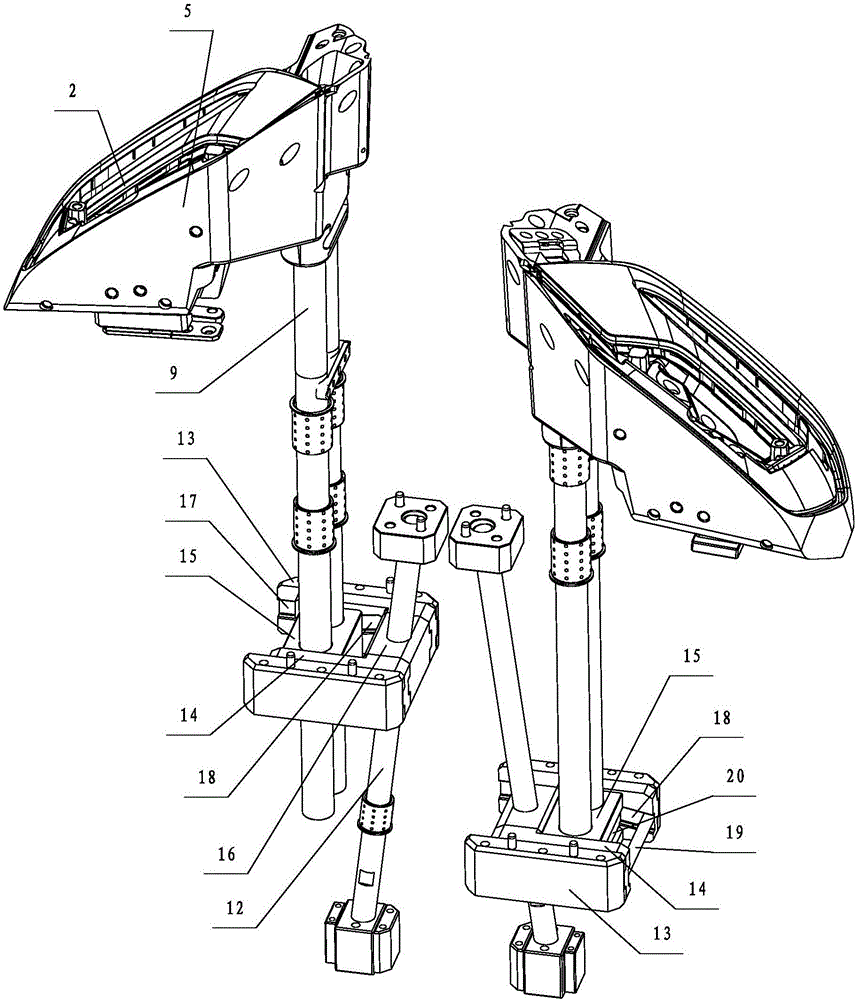

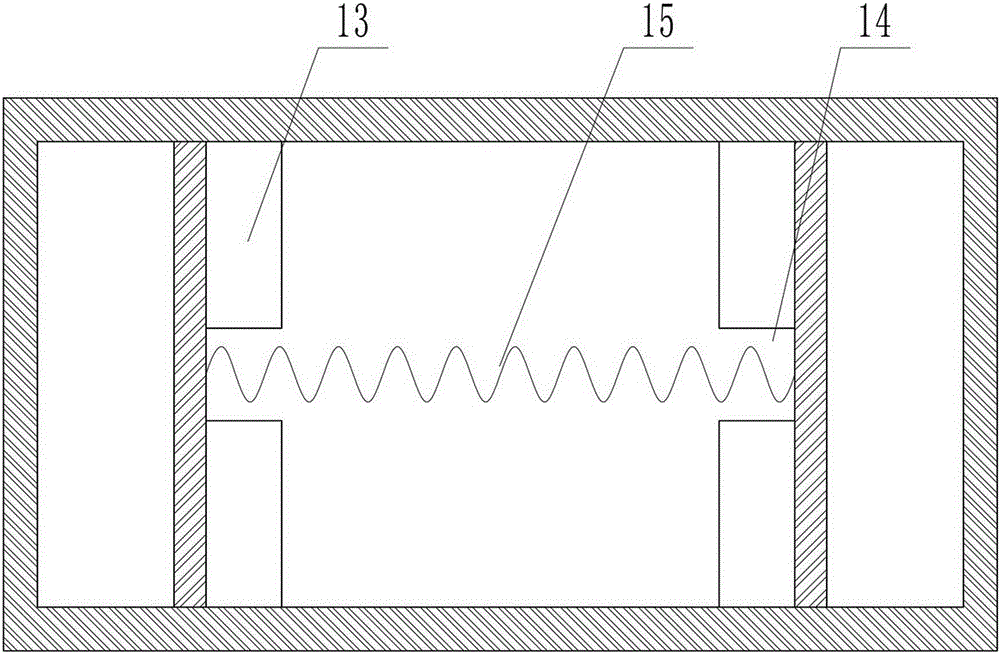

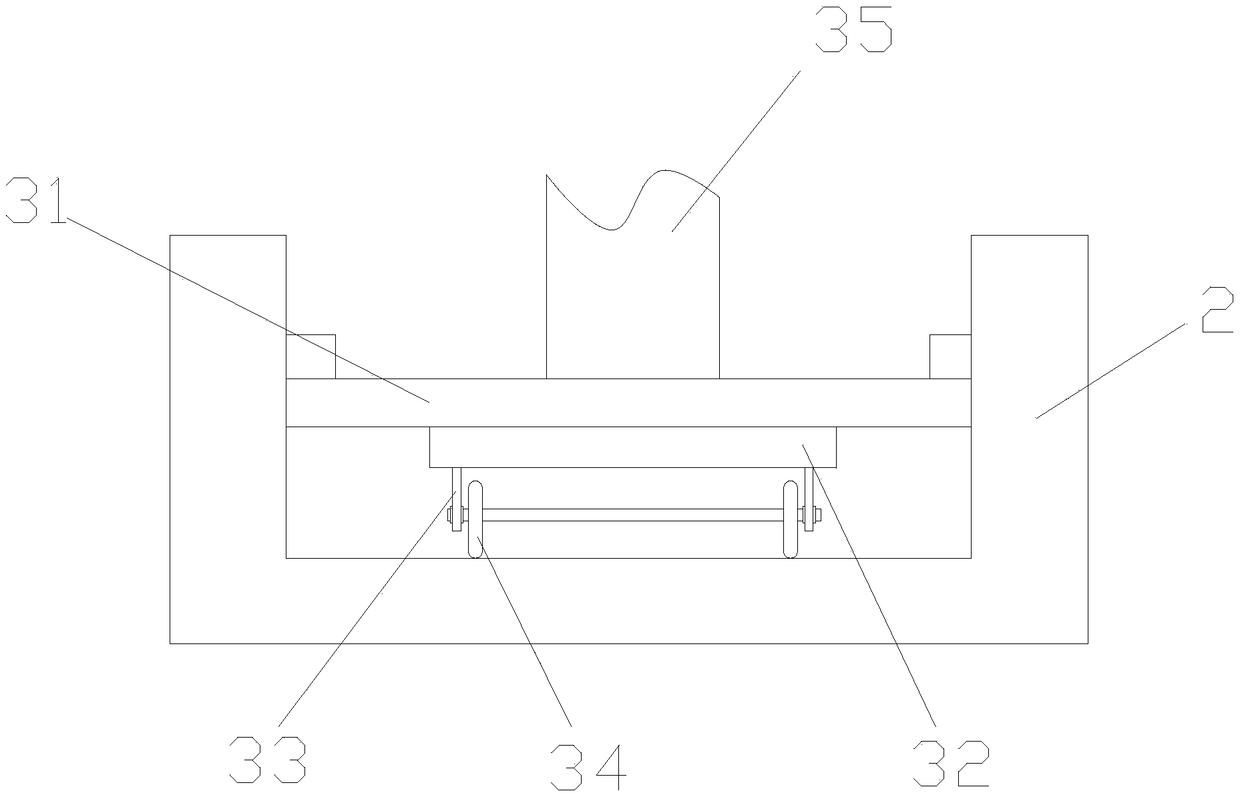

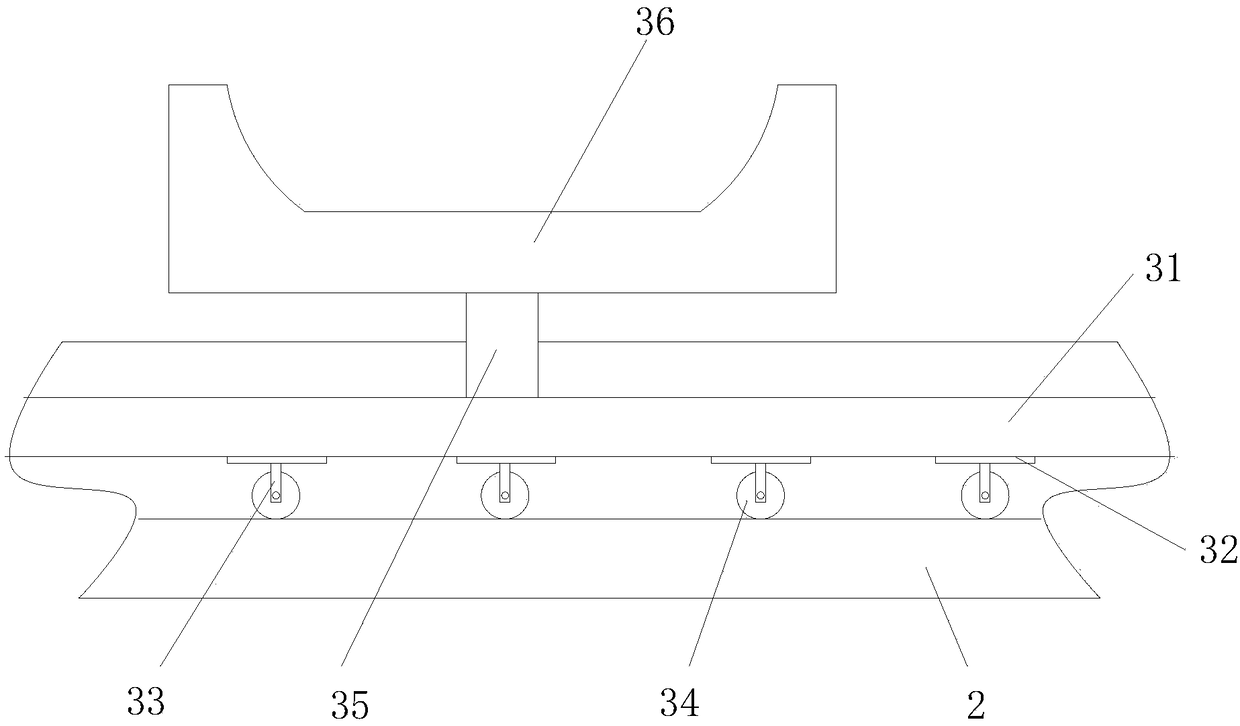

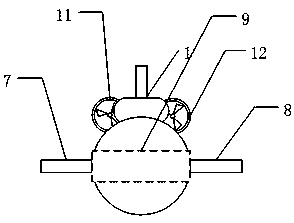

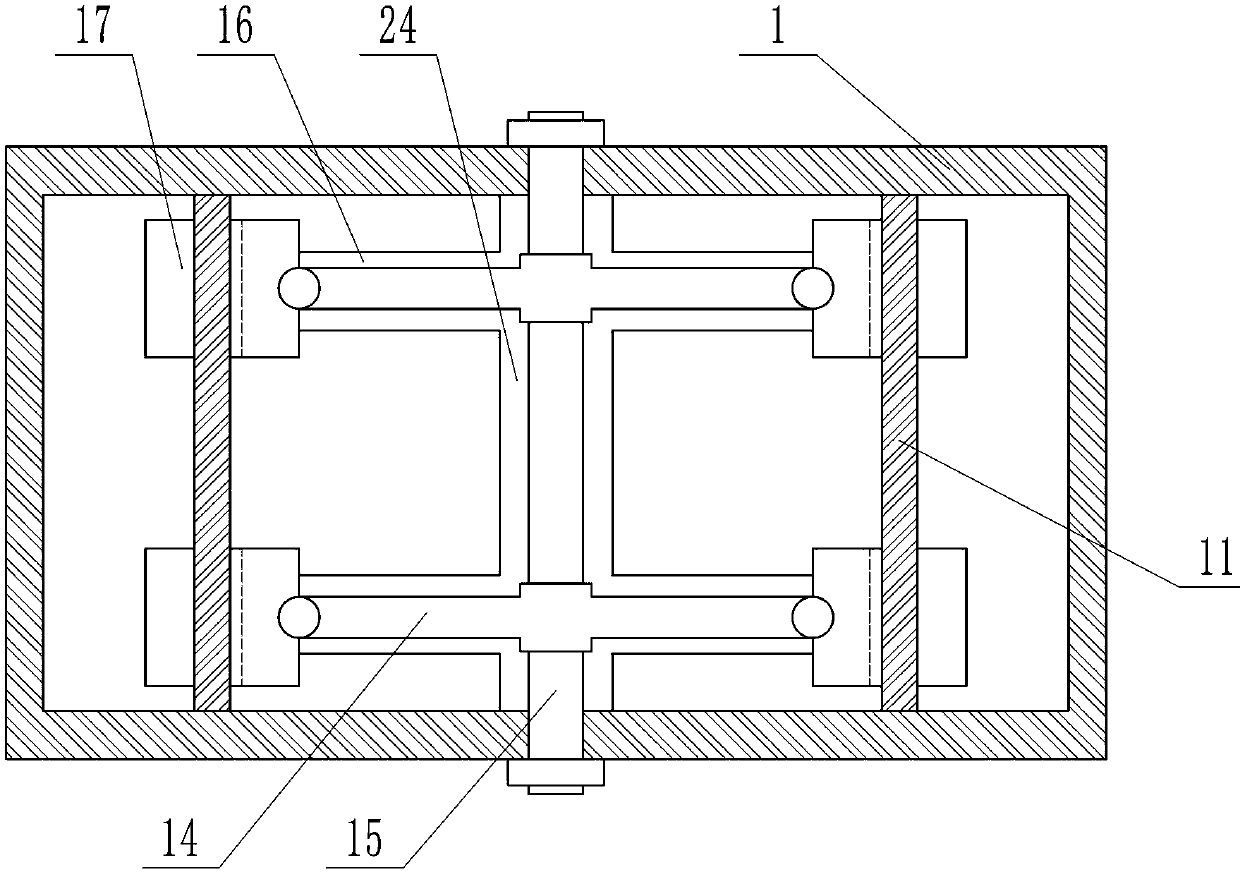

Ejection device for bumper mould

ActiveCN106393602ACompact structureAchieve step-by-step demouldingDomestic articlesEngineeringMechanical engineering

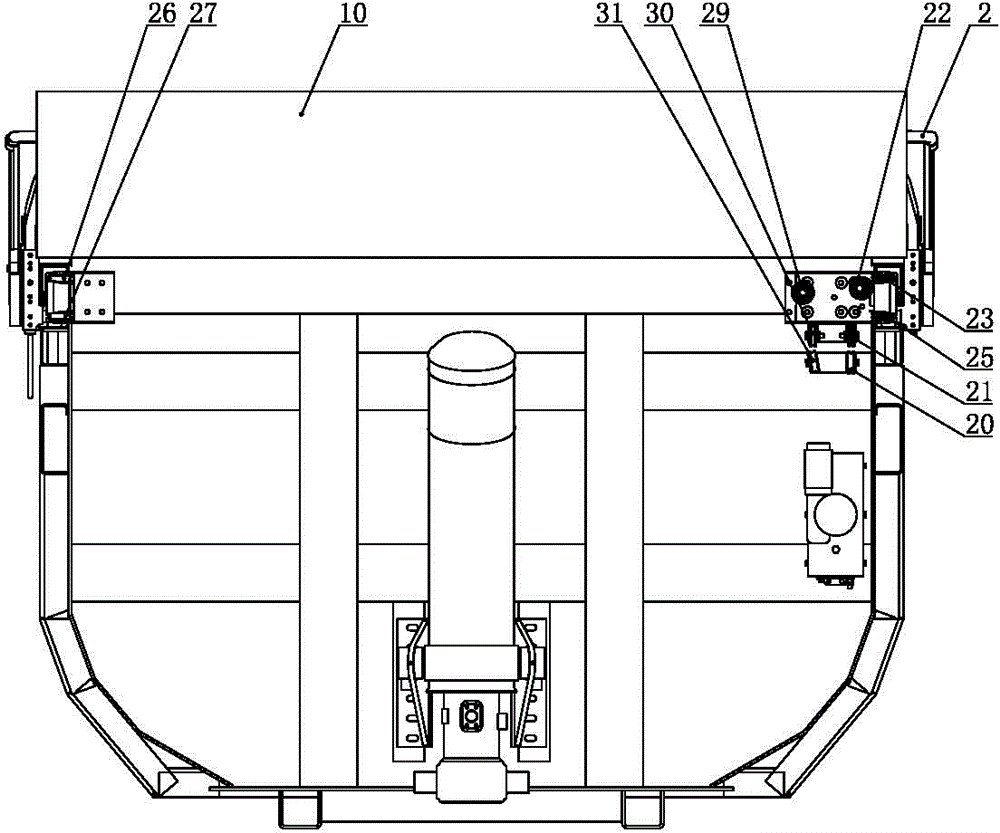

The invention discloses an ejection device for a bumper mould. The ejection device for the bumper mould comprises a small straight ejection mechanism, a big straight ejection mechanism, an inclined ejection mechanism and a movable mould insert core (1). Small straight ejection blocks (2) are embedded in big straight ejection blocks (5); inclined ejection blocks (8) are slidably connected with the big straight ejection blocks (5); the lower ends of big straight ejection guide rods (9) are slidably connected into the movable mould insert core (1) through sliding foot components; inclined ejection guide rods (12) are slidably connected with the sliding foot components; small straight ejection guide rods (4) and the big straight ejection blocks (5) are slidably connected in a vertical direction; the lower ends of the small straight ejection guide rods (4) and the big straight ejection blocks (5) are slidably connected with the inclined ejection blocks (8) in a horizontal direction; and return stroke structures for automatically separating the small straight ejection blocks (2) and the big straight ejection blocks (5) are arranged in the sliding components. By adopting the structure, the ejection device for the bumper mould is simple and compact in structure, and can accurately realize each demoulding action without damaging a product.

Owner:NINGBO FANGZHENG TOOL

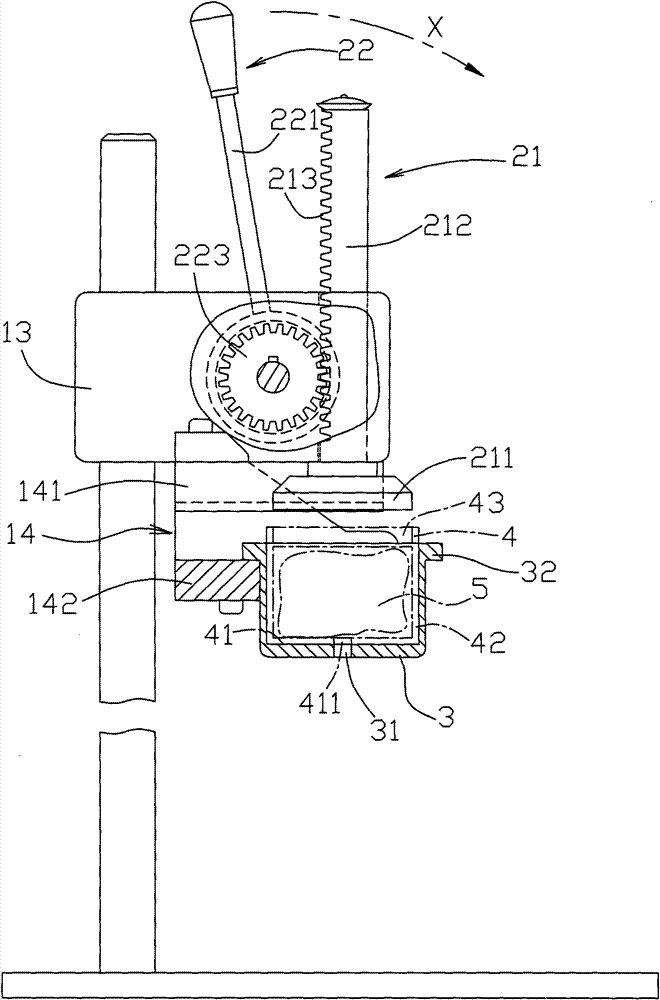

Ice cram machine

The invention discloses an ice cream machine for extruding an ice cream cup, which comprises a supporting device and an extruding device. The supporting device comprises an upper frame, a bearing frame and a cup detaching assembly, wherein the upper frame is arranged at the top end, the bearing frame is used for arranging the ice cream cup, and the cup detaching assembly is arranged between the upper frame and the bearing frame. The extruding device comprises an extruding unit and an actuating unit, wherein the extruding unit penetrates through the upper frame, and the actuating unit can drive the extruding unit to move up and down between a nonextrusion position far away the bearing frame and an extrusion position close to the bearing frame. The extruding unit extrudes the ice cream cup to force ice cream to flow out at the extrusion position, the extruded and deformed ice cream cup can be detachably adhered on the extruding unit and returns to the nonextrusion position through the extruding unit, and the top edge of the ice cream cup props against the cup detaching assembly to make the ice cream cup to separate from the extruding unit.

Owner:LUCKY ROYAL

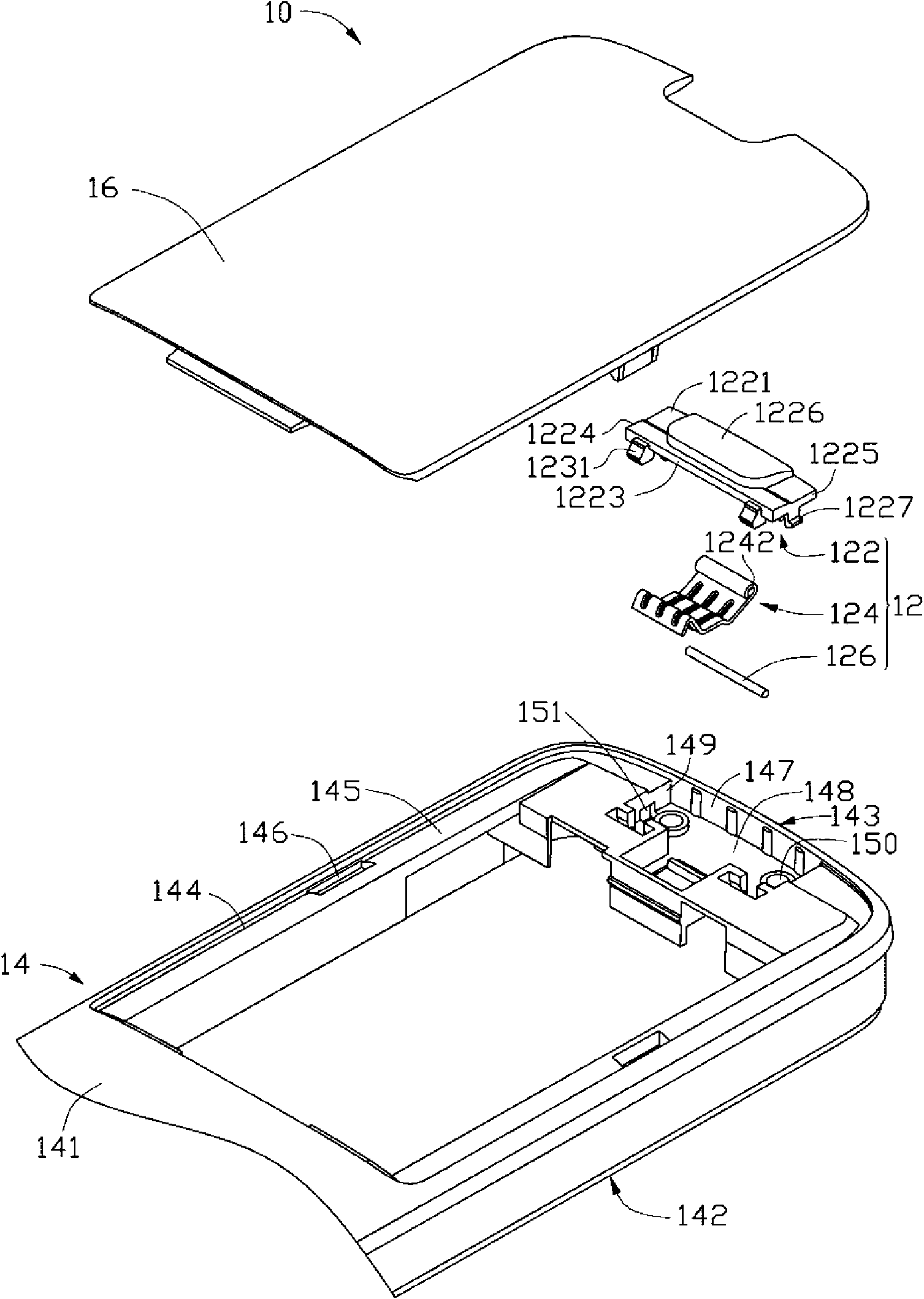

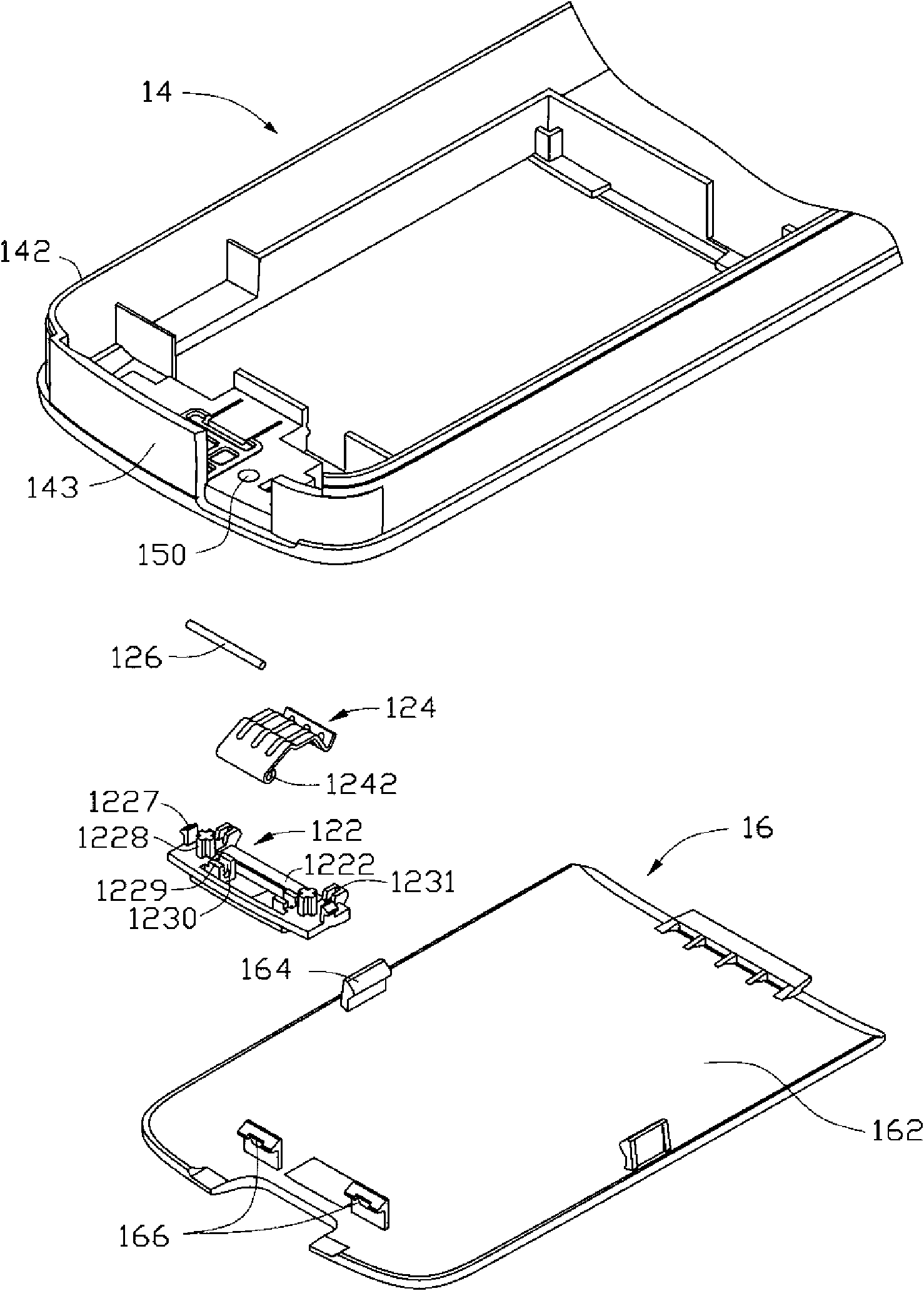

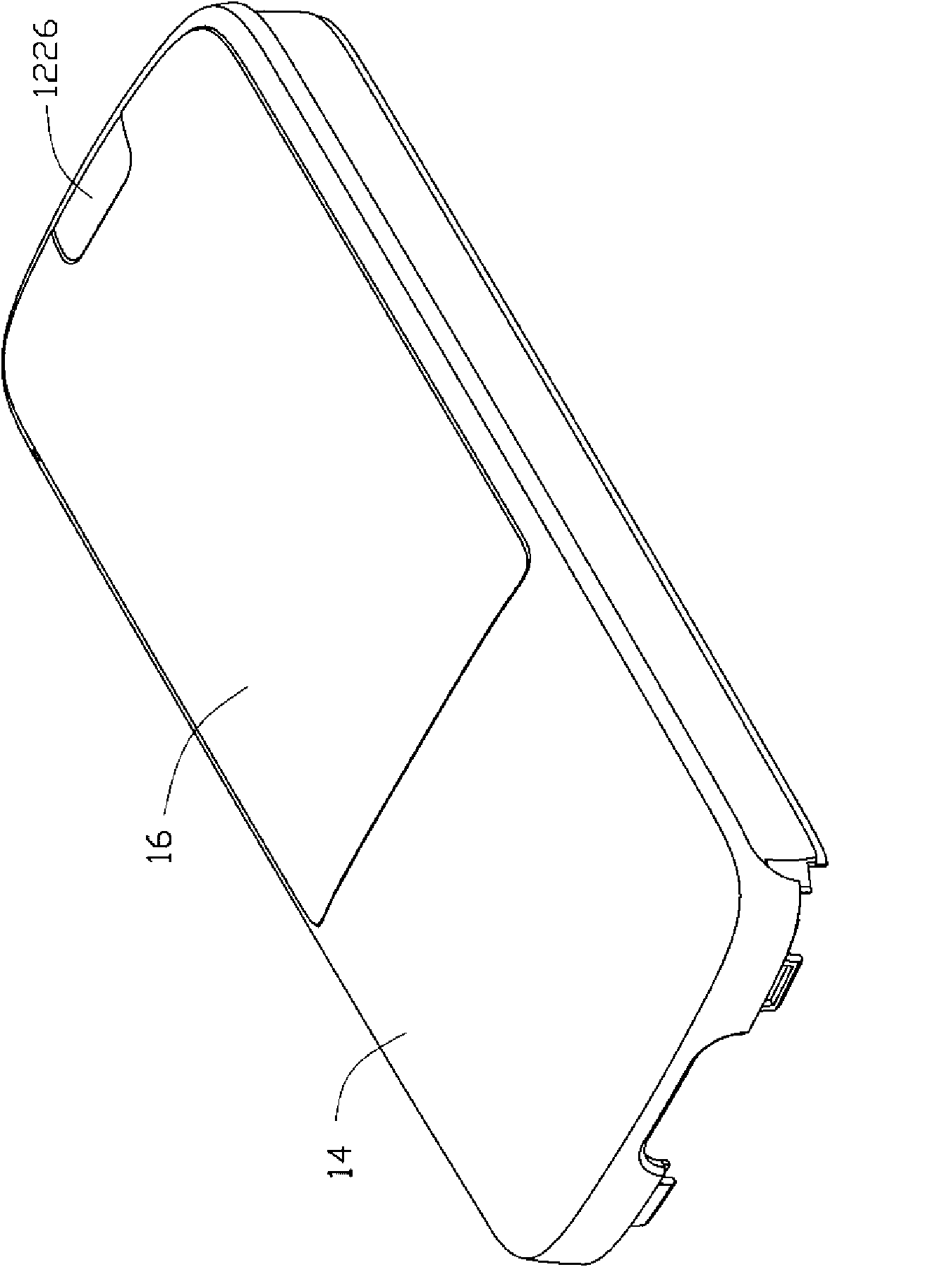

Cell cover locking structure

InactiveCN101556994AAutomatic disengagementDigital data processing detailsCasings/cabinets/drawers detailsElastomerEngineering

Owner:南通恒信精工机械有限公司

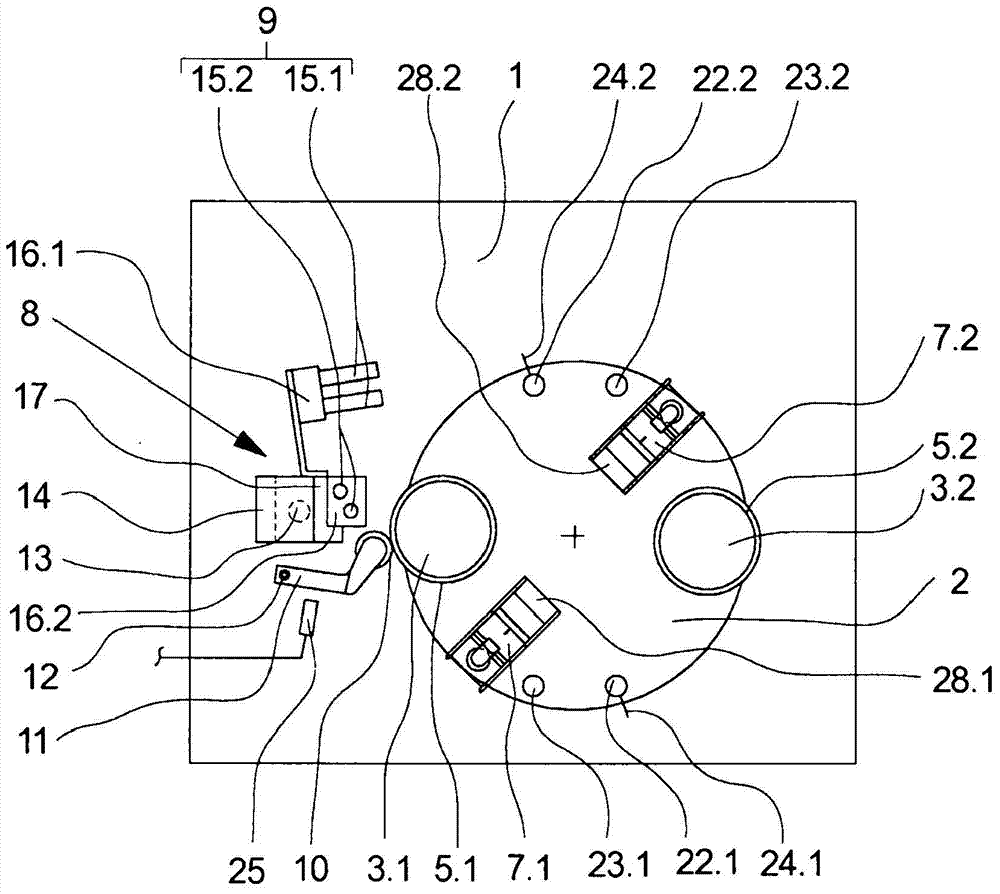

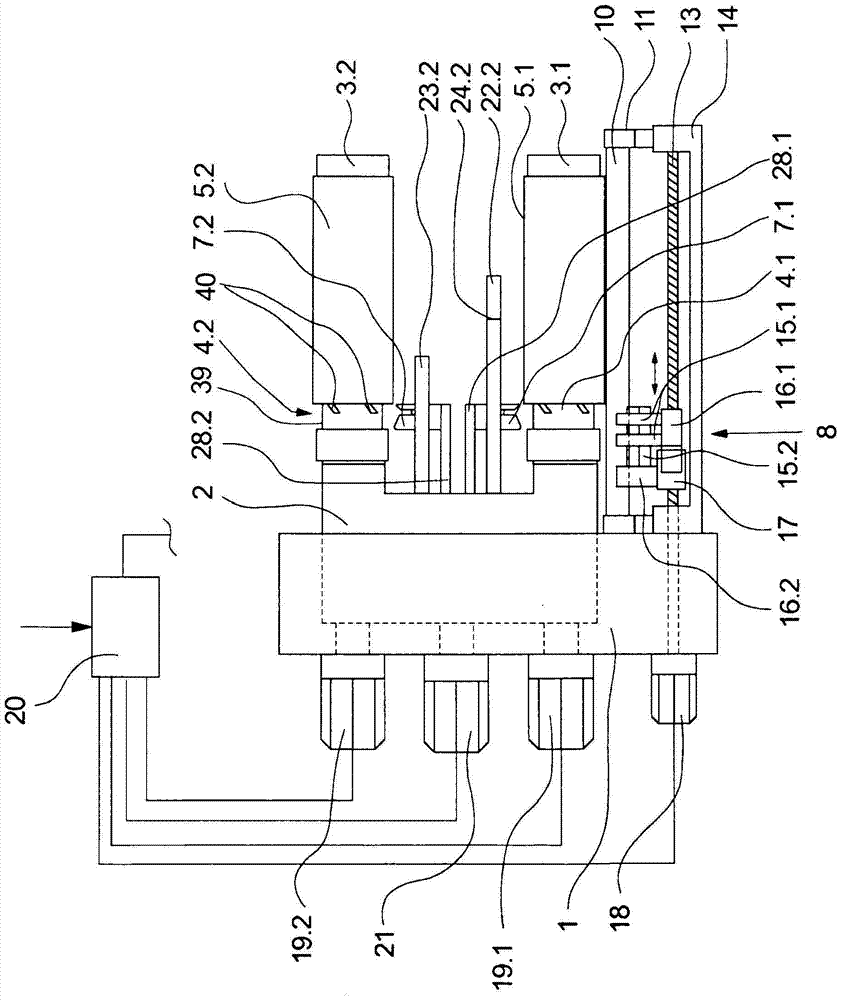

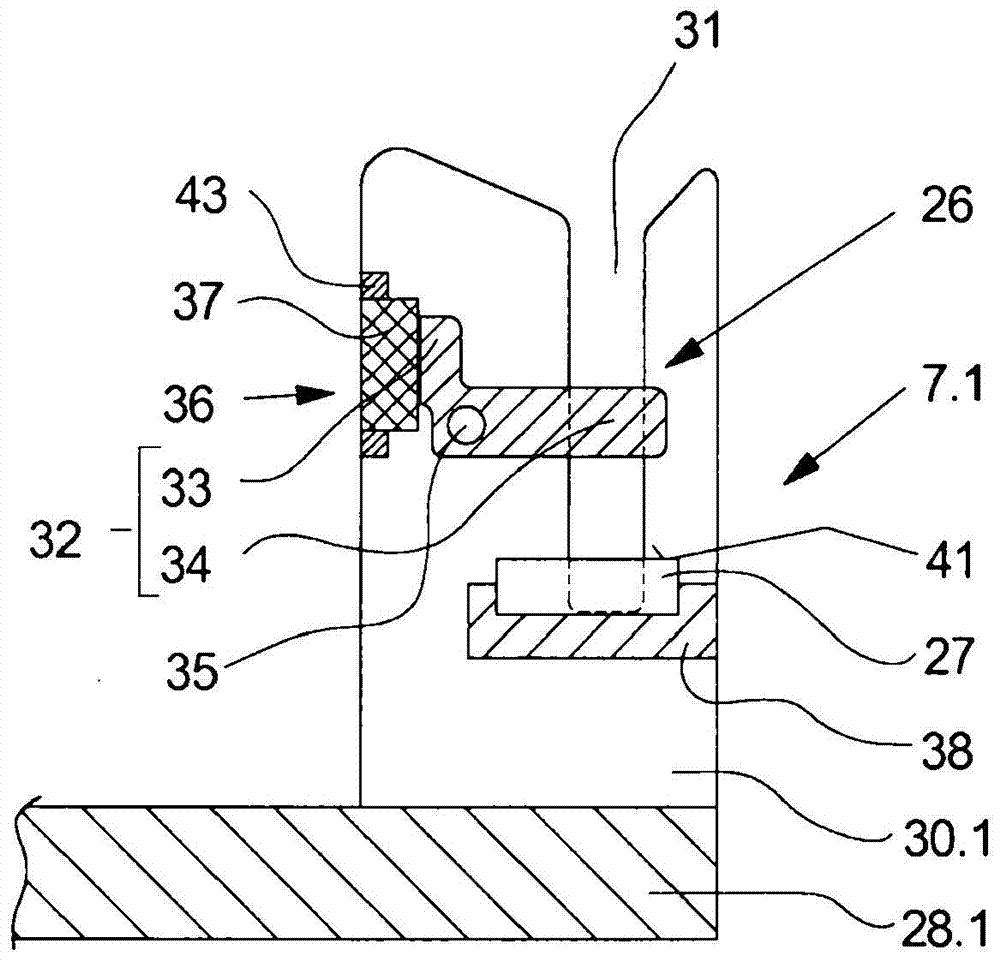

Winding device

The invention relates to a winding device for continuously winding a fiber strand. The winding device has a rotatably supported winding revolver (2) having two rotationally drivable winding spindles (3.1, 3.2), which are retained on the winding revolver in a protruding manner and which each have a winding sleeve (5.1, 5.2) and a catching apparatus (4.1, 4.2) On the winding revolver (2), two severing apparatuses (7.1, 7.2) are associated with the winding spindles (3.1, 3.2). The severing apparatuses cause the fiber strand to be severed when the fiber strand is transferred from one of the winding spindles having a wound full spool to other winding spindles. A traversing apparatus (8) is arranged upstream of the winding spindles and has a traversing thread guide (9), which can be moved parallel to the winding spindles and which can be positioned outside of a traversing stroke in order to transfer the fiber strand. In order to obtain defined severing of the fiber strand at relatively slow process speeds, each severing apparatus (4.1, 4.2) has a blade (27) and a locking means (26) associated with the blade, wherein the fiber strand (42) is guided by the blocking means (26) before the severing and wherein the fiber strand (42) causes a release of the locking means (26) when a minimum tensile force is reached and can be fed to the blade (27).

Owner:OERLIKON TEXTILE GMBH & CO KG

Water body automatic sampling device

ActiveCN109632393ALong sampling periodAvoid affecting test resultsWithdrawing sample devicesImpellerMotor drive

The invention relates to a water body automatic sampling device. The problems that manual sampling is inconvenient and automatic sampling cannot fully reflect the actual situation of a water body andis not accurate enough are effectively solved. According to the technical scheme, the rotation of an impeller is driven by river water; the impeller drives a first reel to receive a rope and drives asecond reel to release the rope, so that the time interval for sample collecting is proportional to the flow rate of the river water; a signal transmitted by a Hall sensor is used to control the startand stop of a motor; when the motor drives a second rotation shaft to rotate, sample collecting is started; the second reel receives the rope, and the first reel releases the rope; the impeller rotates in the opposite direction; the nearby river water is stirred, so that the river water is not stratified; a floating object entangled on the impeller automatically break away from the impeller; eachtime the motor starts and stops, a planetary gear train drives a first sleeve to rotate at a certain angle to collect a bottle of sample.

Owner:山东中成环境技术服务有限公司

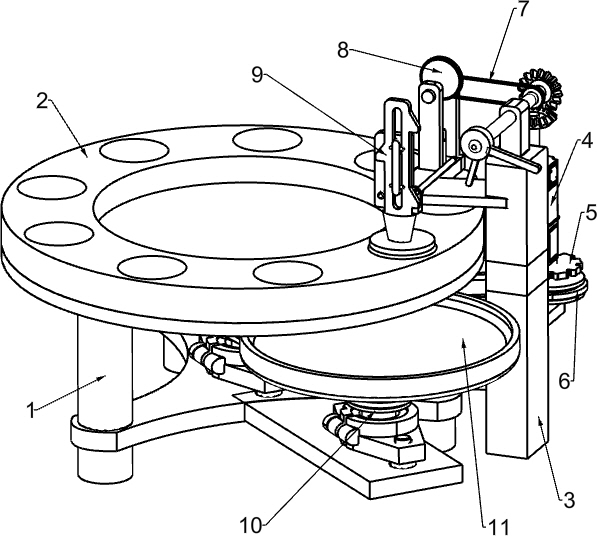

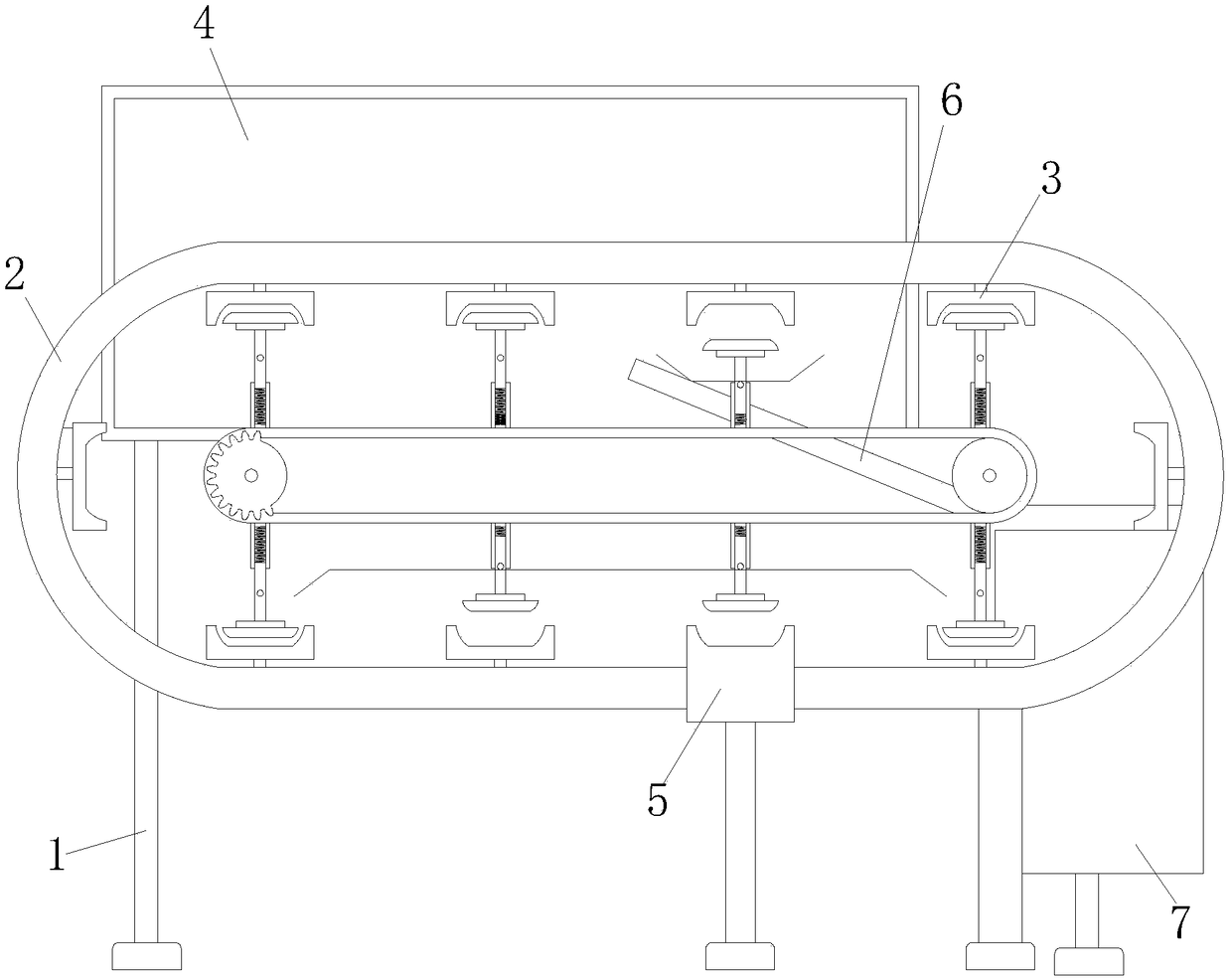

Tengxian rice cake pressing device

The invention relates to a pressing device, in particular to a Tengxian rice cake pressing device. The technical problem is to provide a Tengxian rice cake pressing device which can automatically press rice cakes, collects prepared rice cakes, and reduces manual operations. According to the technical scheme the Tengxian rice cake pressing device comprises a base and a support frame, wherein the top part of the base is rotationally provided with a worktable; the top part of the worktable is evenly provided with a plurality of circular grooves for holding the rice cakes; the support frame is arranged on one side of the base; and the upper part of the side part of the support frame is provided with a dual-axis motor. According to the Tengxian rice cake pressing device, through an intermittentrotating mechanism, the worktable automatically rotates intermittently; without manually replacing and taking the rice cakes repeatedly during pressing, through a pressing mechanism, automation of rice cake pressing is realized, manual operation steps are reduced, and the efficiency of rice cake pressing is increased; and through a poking mechanism, after being pressed, the rice cakes on the worktable can automatically separate from the worktable without manually taking out the rice cakes.

Owner:董永辉

Ice cram machine

The invention discloses an ice cream machine for extruding an ice cream cup, which comprises a supporting device and an extruding device. The supporting device comprises an upper frame, a bearing frame and a cup detaching assembly, wherein the upper frame is arranged at the top end, the bearing frame is used for arranging the ice cream cup, and the cup detaching assembly is arranged between the upper frame and the bearing frame. The extruding device comprises an extruding unit and an actuating unit, wherein the extruding unit penetrates through the upper frame, and the actuating unit can drive the extruding unit to move up and down between a nonextrusion position far away the bearing frame and an extrusion position close to the bearing frame. The extruding unit extrudes the ice cream cup to force ice cream to flow out at the extrusion position, the extruded and deformed ice cream cup can be detachably adhered on the extruding unit and returns to the nonextrusion position through the extruding unit, and the top edge of the ice cream cup props against the cup detaching assembly to make the ice cream cup to separate from the extruding unit.

Owner:LUCKY ROYAL

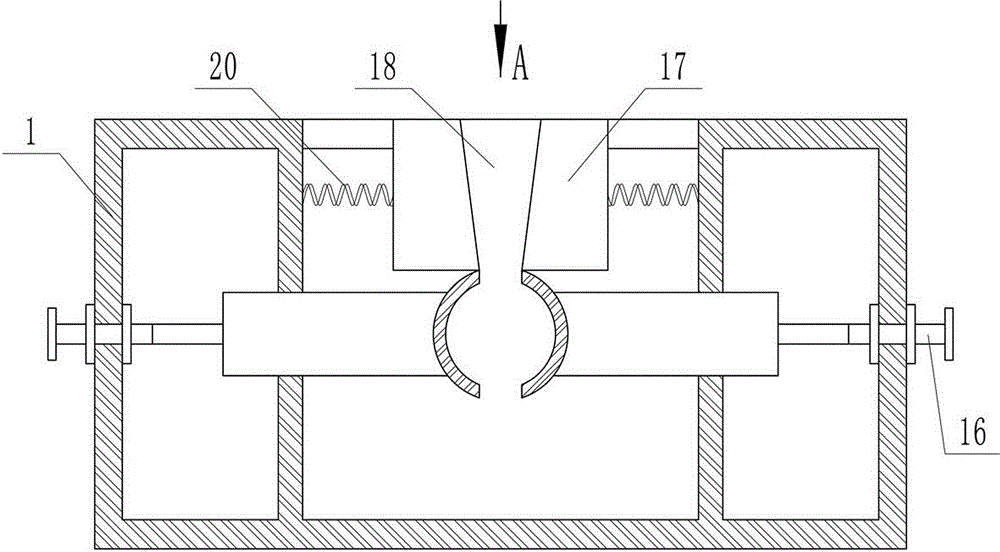

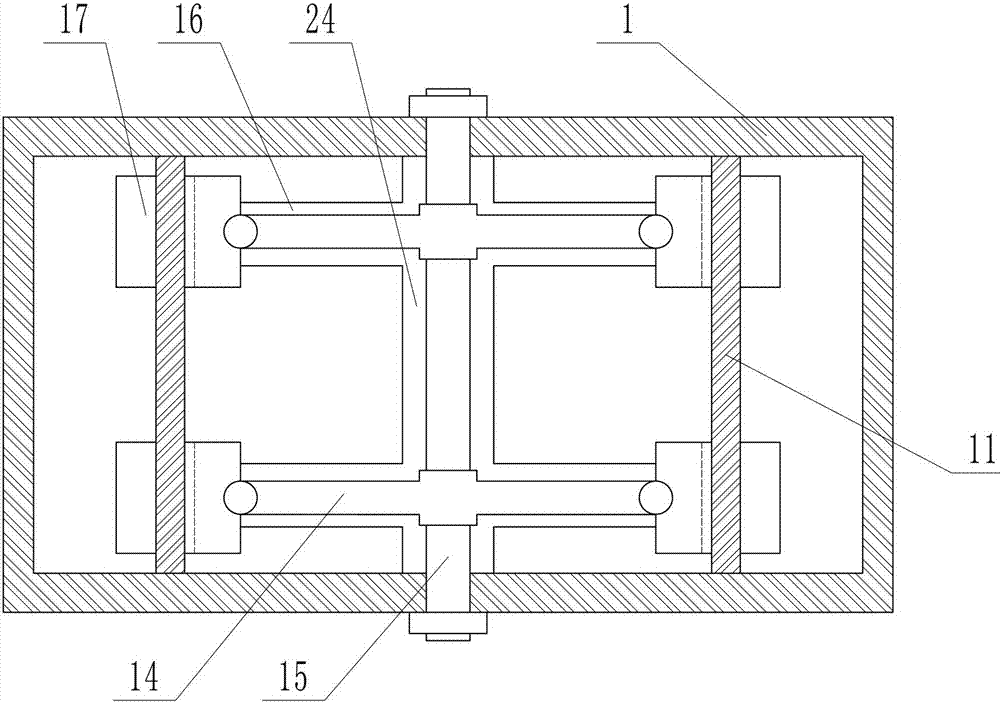

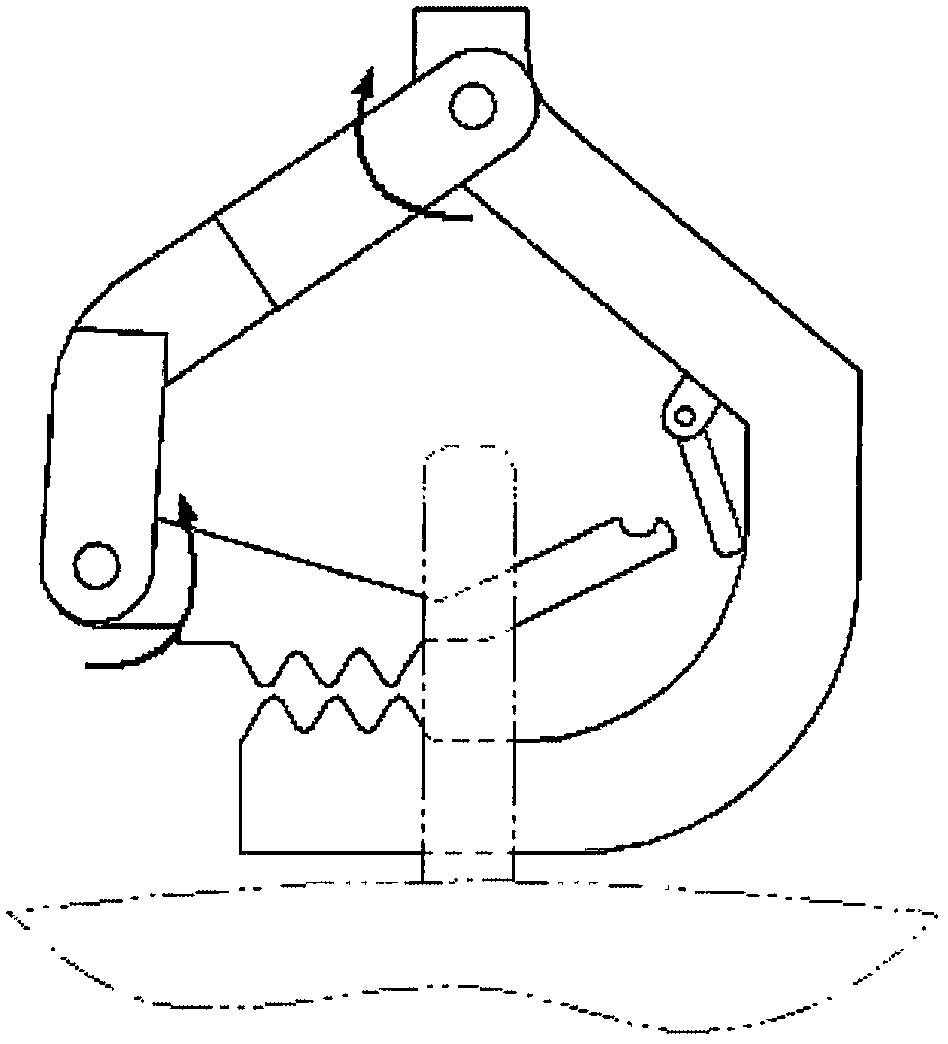

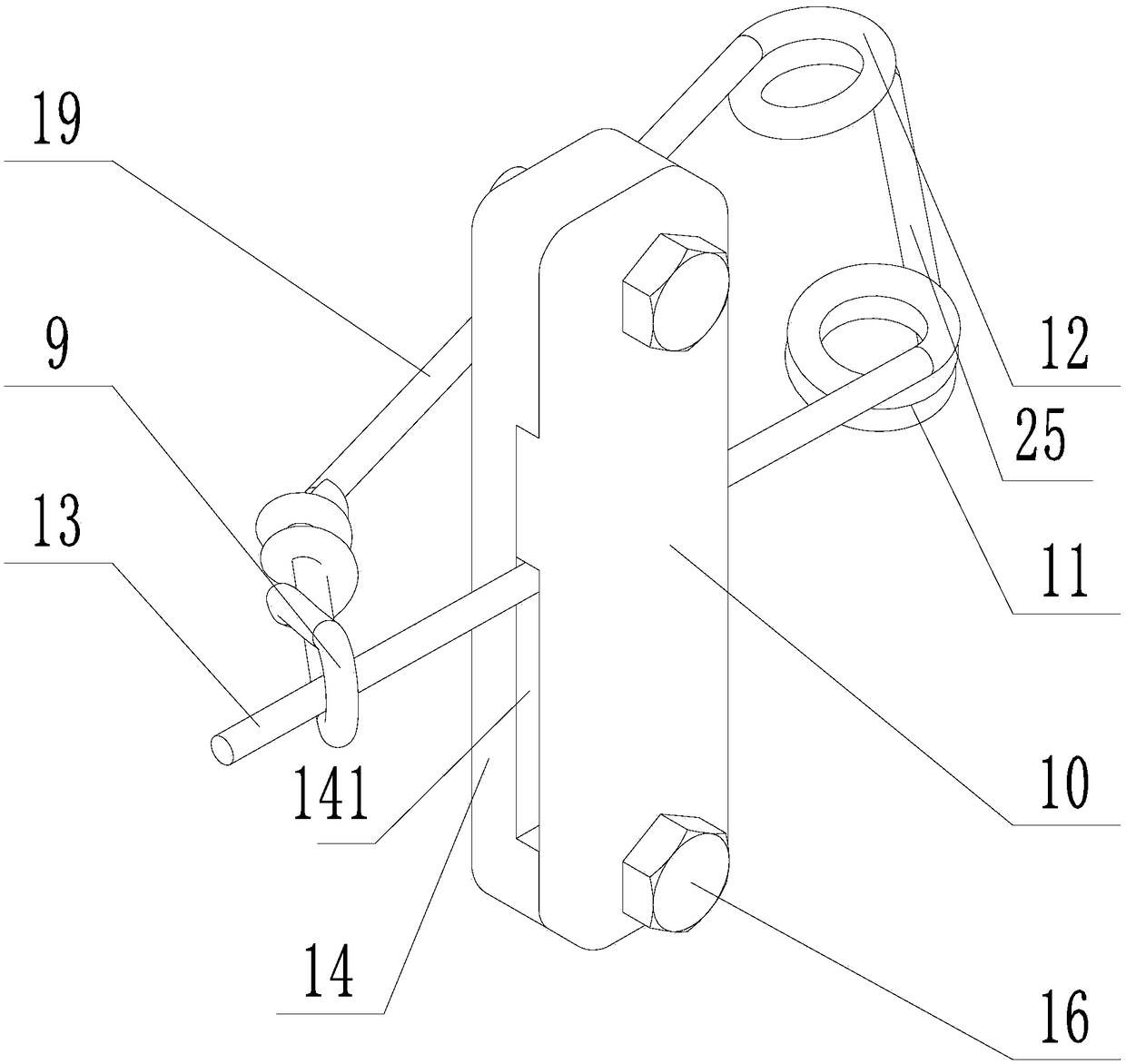

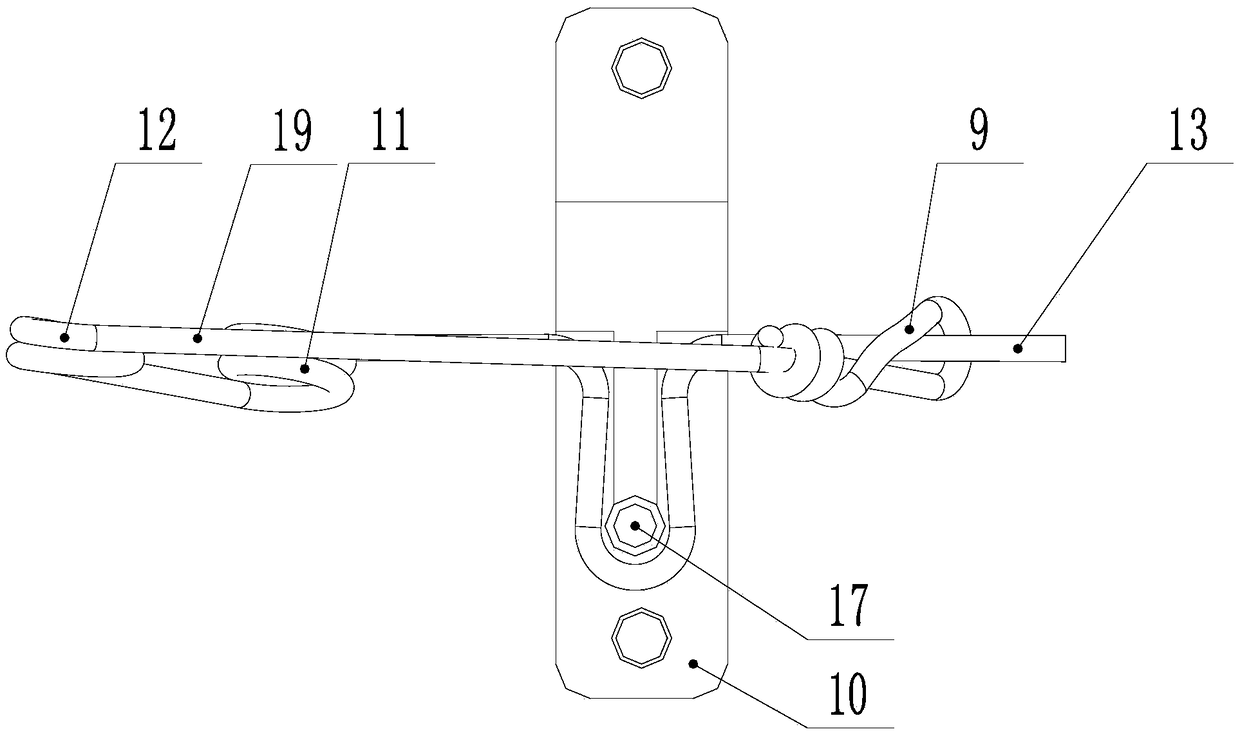

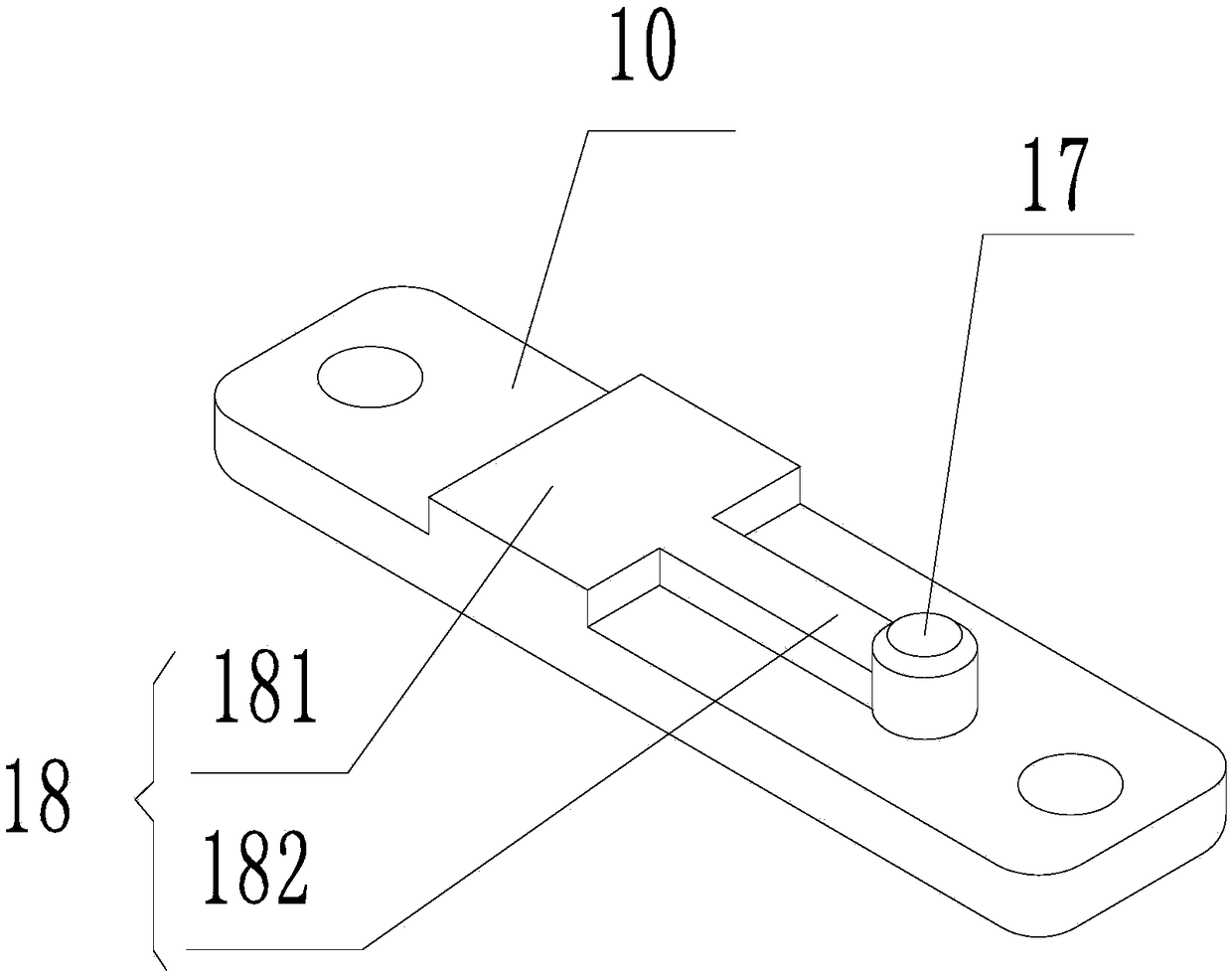

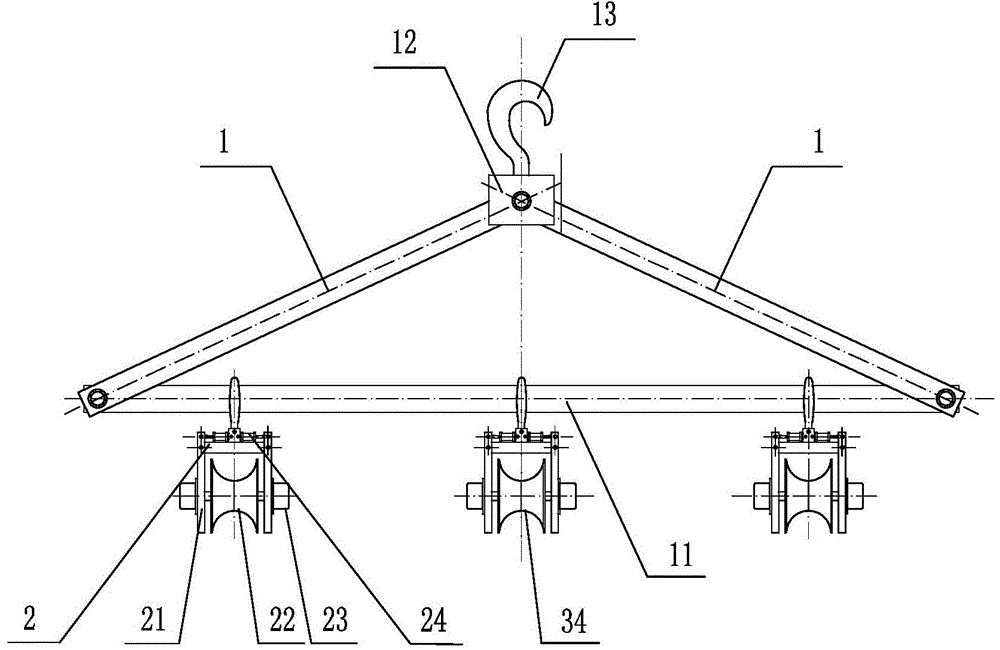

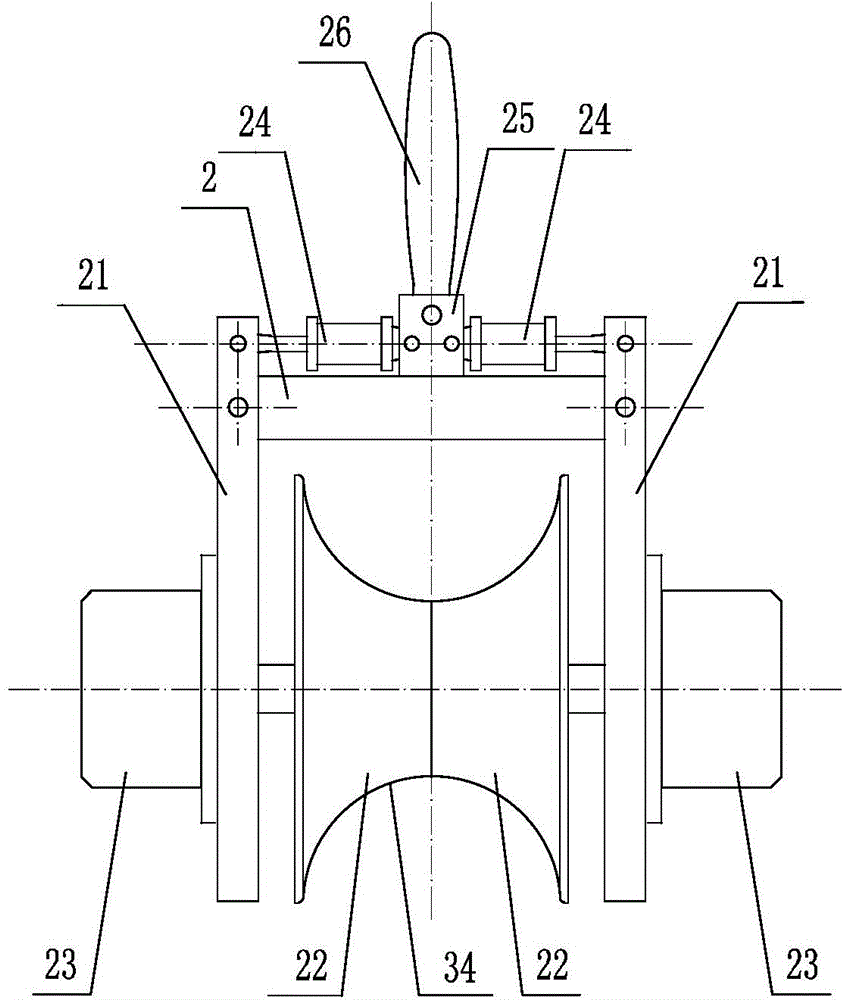

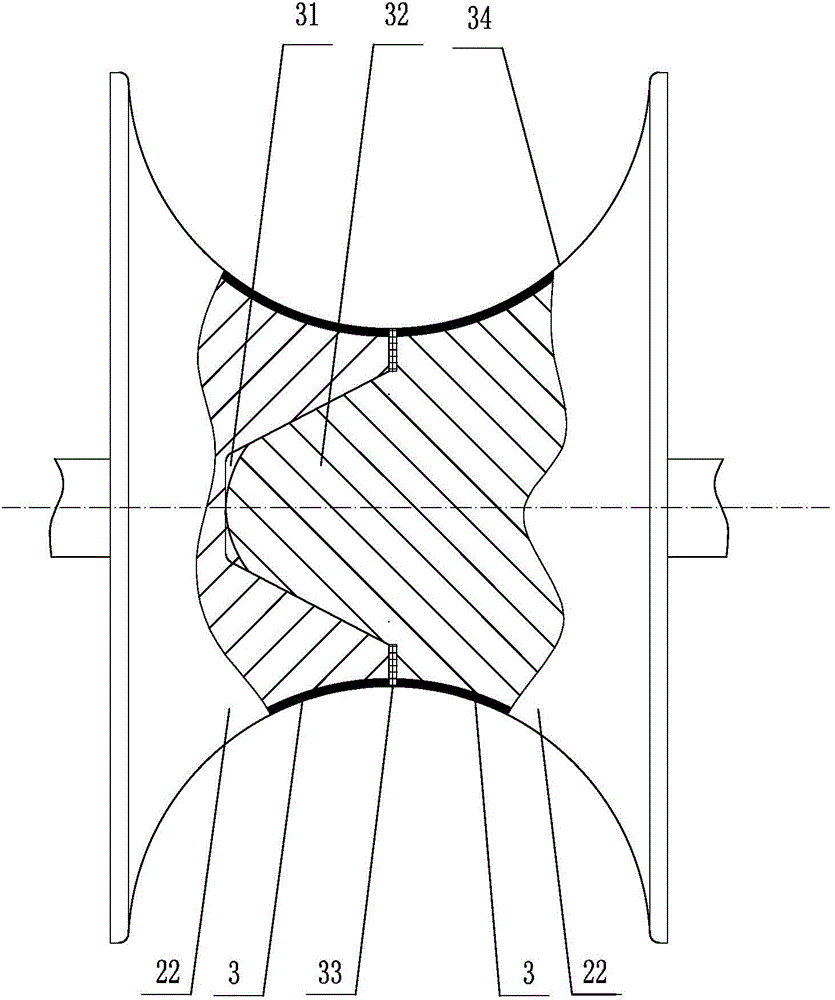

Friction type overload automatic disengaging sling

The invention provides a friction type overload automatic disengaging sling. The danger that the heavy object falls after being hoisted is avoided. According to the solved technical scheme, the friction type overload automatic disengaging sling comprises a supporting frame, and a clamping device is arranged at the upper portion in the supporting frame and is composed of two clamping blocks. Each clamping block comprises an arc block, wherein the outer circle of the arc block is connected with a horizontal plate, a first connecting rod and a first pin shaft are arranged below the horizontal plate, the first connecting rod is arranged on the first pin shaft in a sleeving manner through a sliding groove, a baffle is arranged on the outer side of the first connecting rod, a strong spring is connected between the first connecting rod and the baffle, the upper end of the first connecting rod is hinged to the horizontal plate, and a limiting step is arranged in the supporting frame. A U-shaped frame is arranged under the clamping device and comprises a left vertical plate and a right vertical plate, a tension spring is connected between the inner side walls of the two baffles, and the friction force to the U-shaped frame from the left baffle and the right baffle under the action of the tension spring is larger than the gravity of the U-shaped frame, and adjusting screws are fixed to the left side and the right side of the supporting frame correspondingly. The friction type overload automatic disengaging sling is ingenious in concept and safe in usage.

Owner:HENAN DAFANG HEAVY MACHINERY

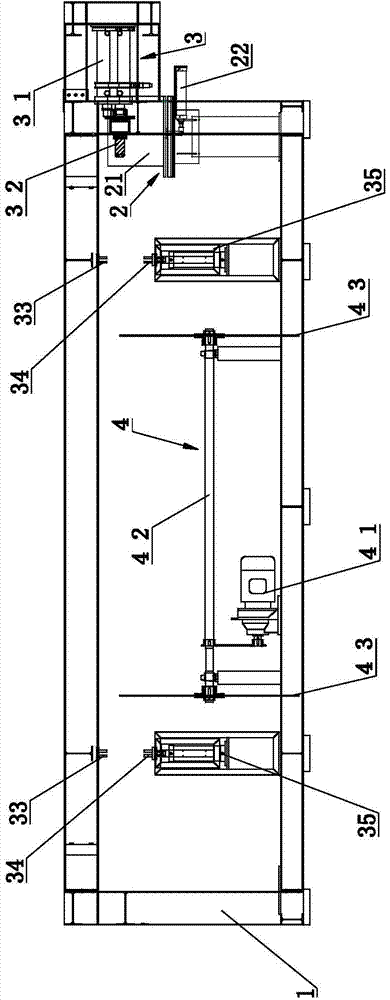

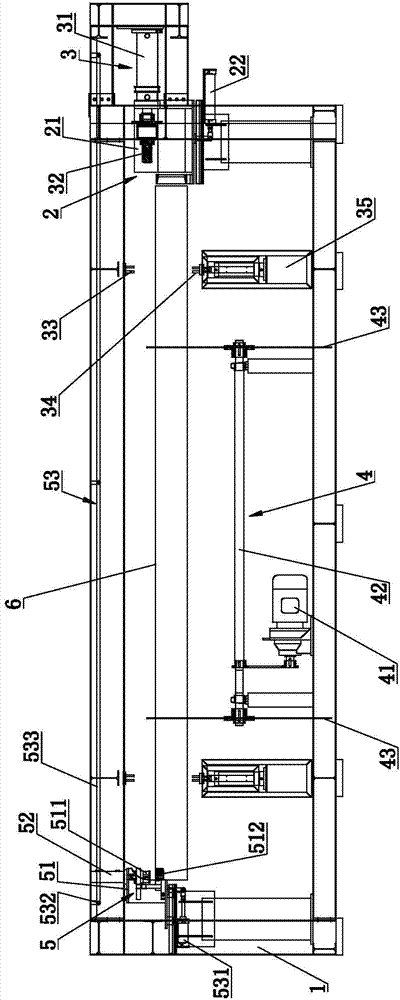

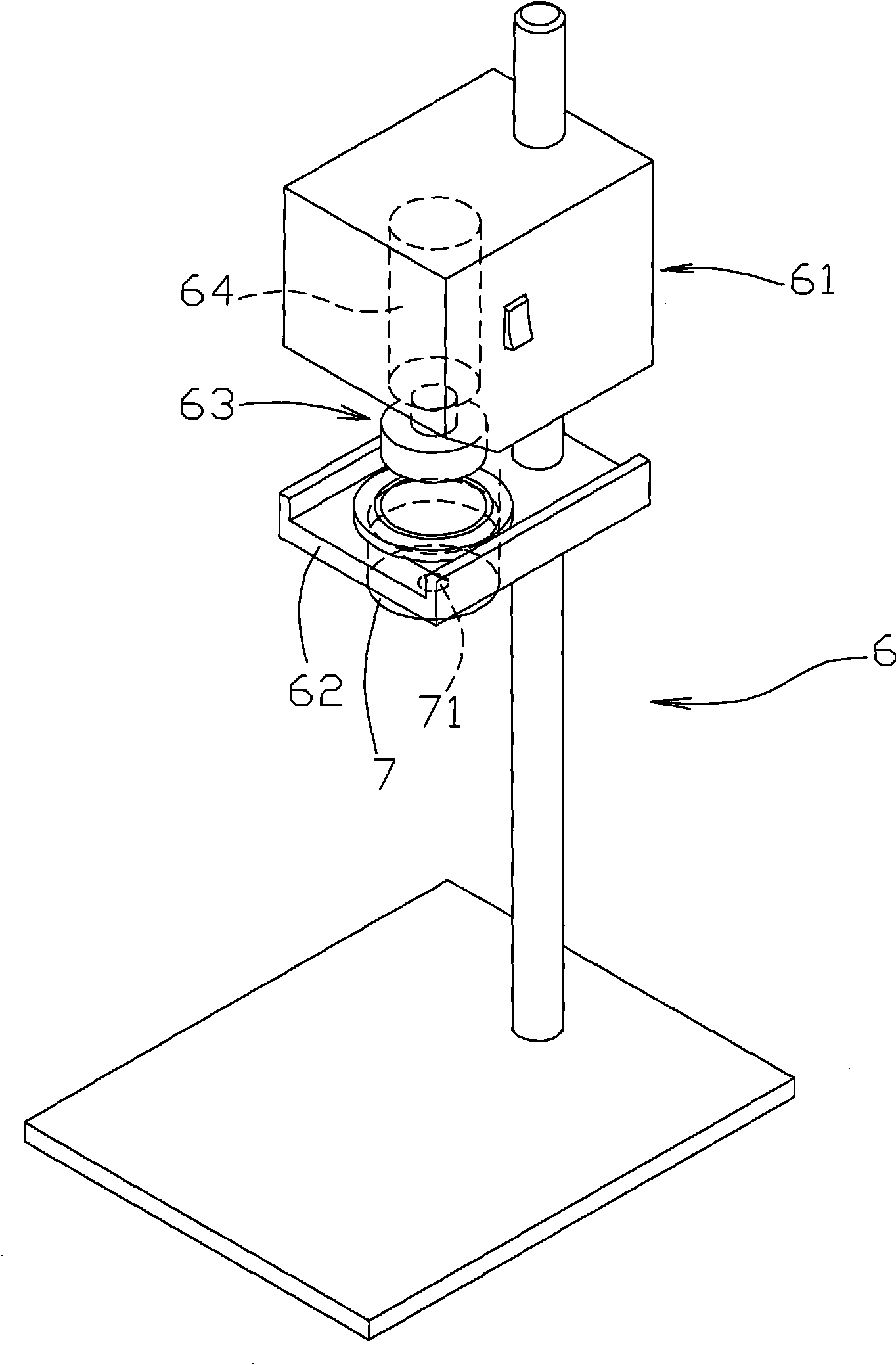

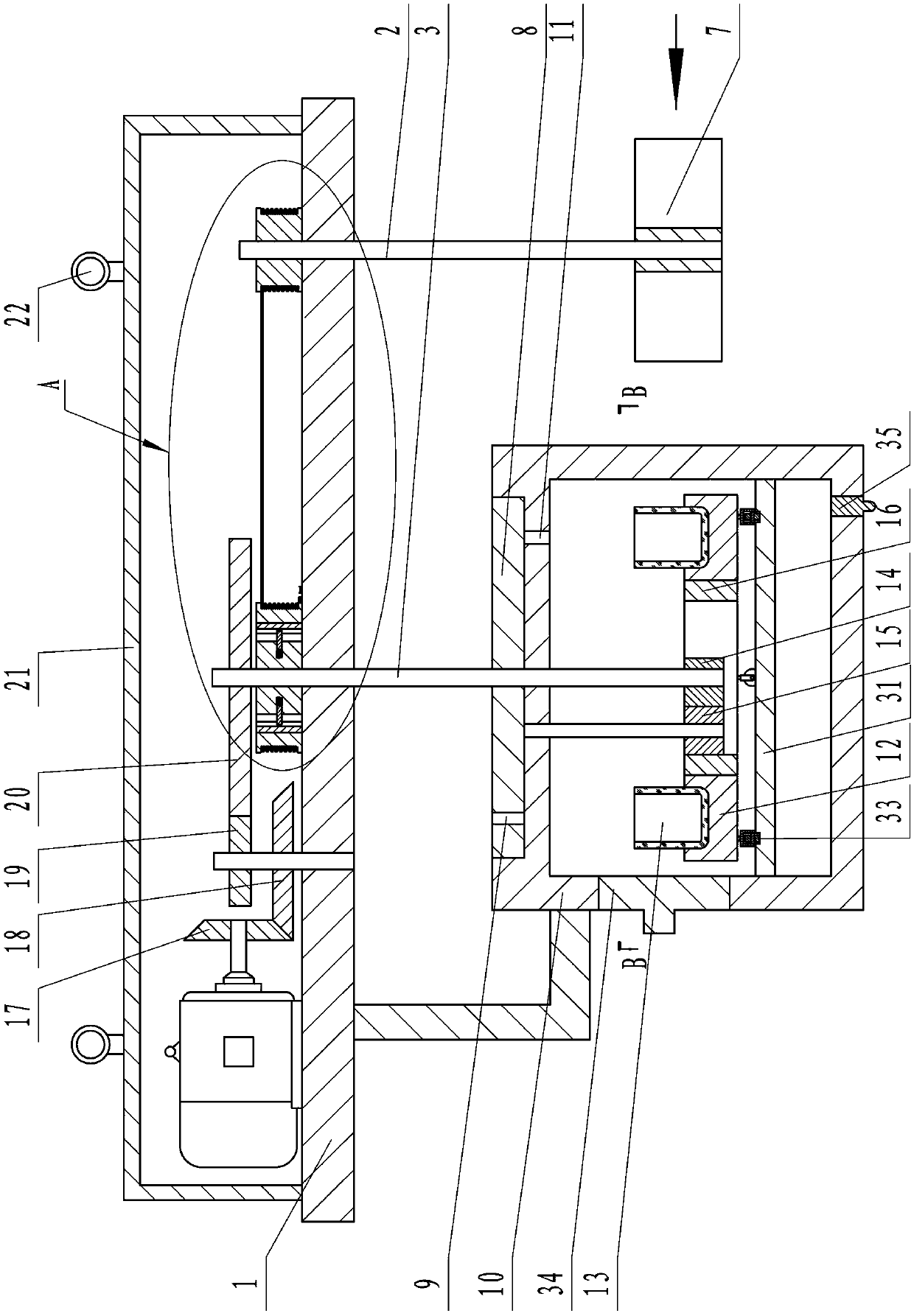

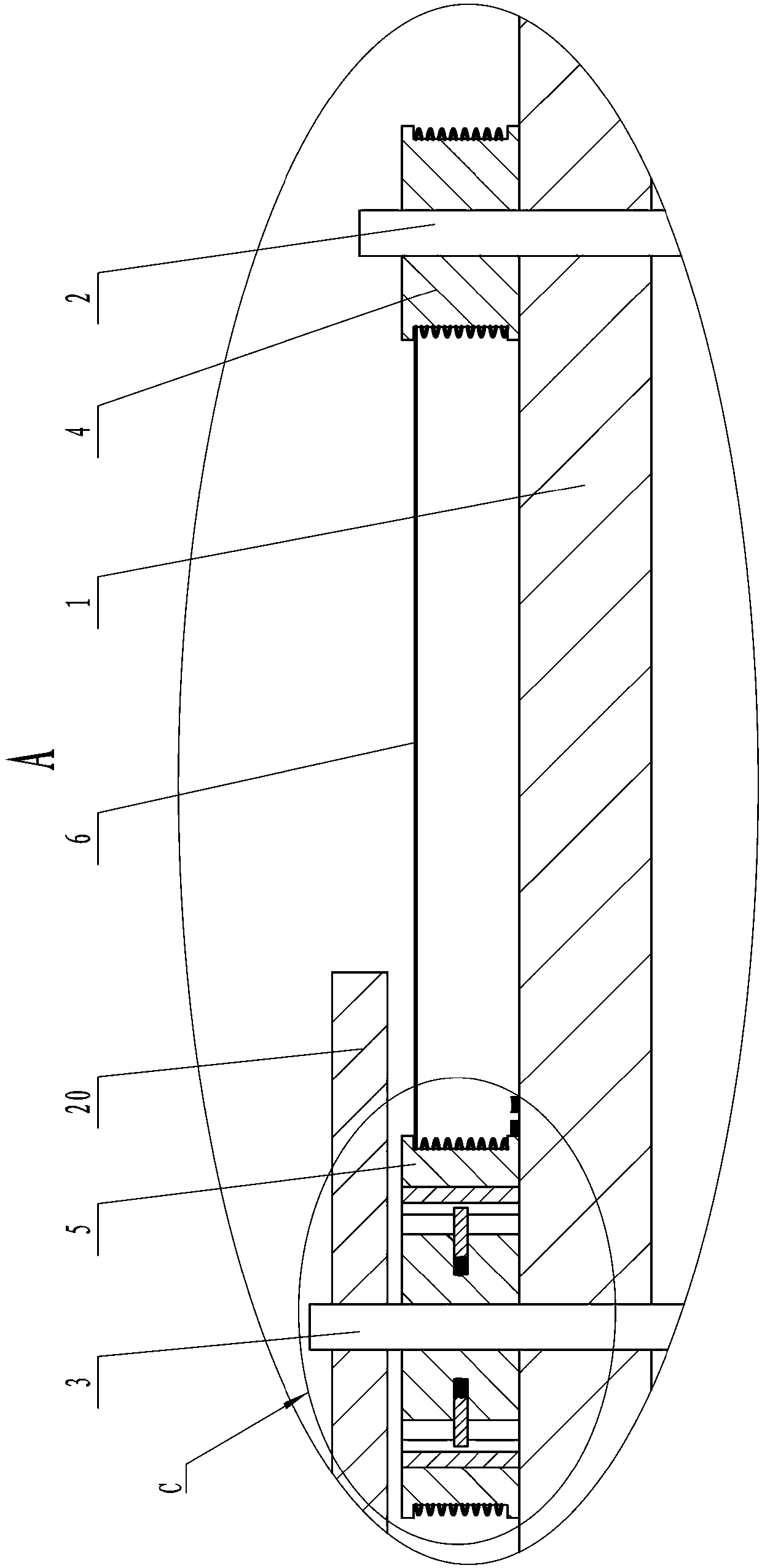

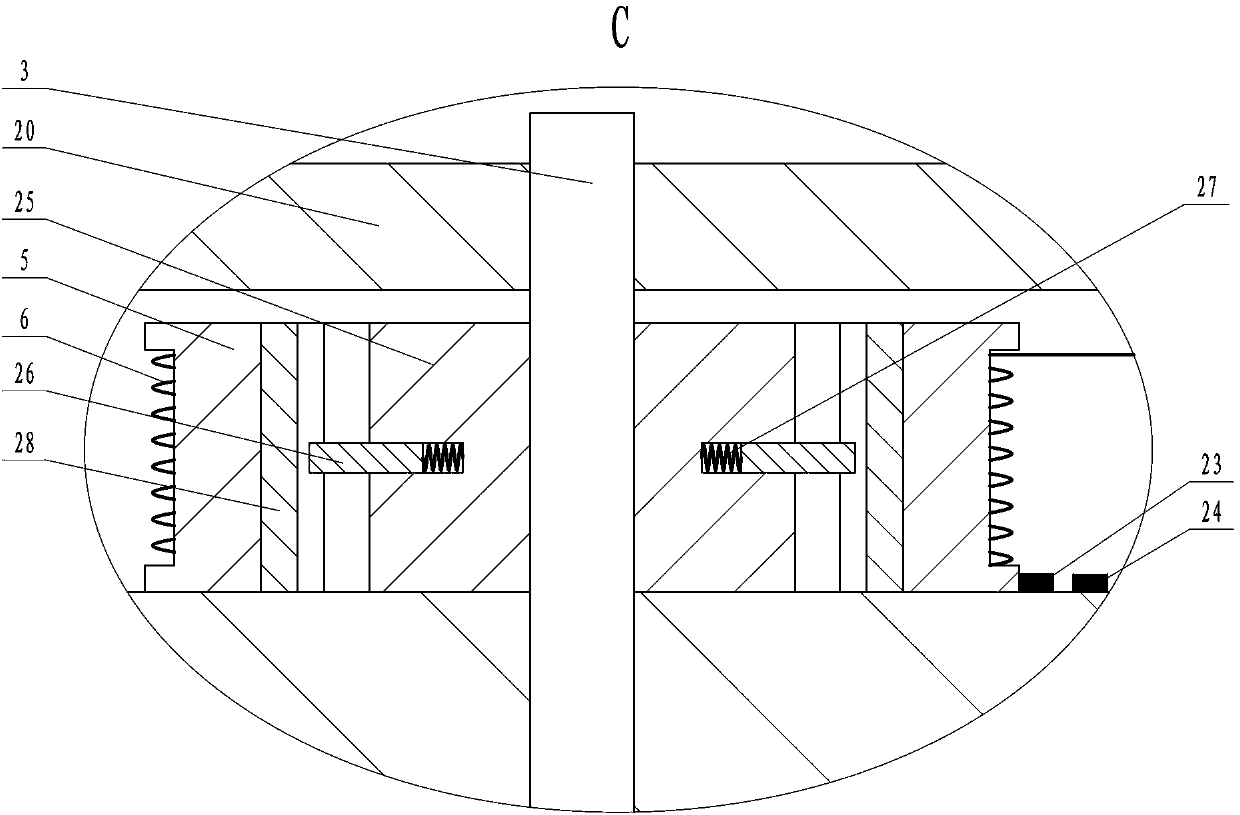

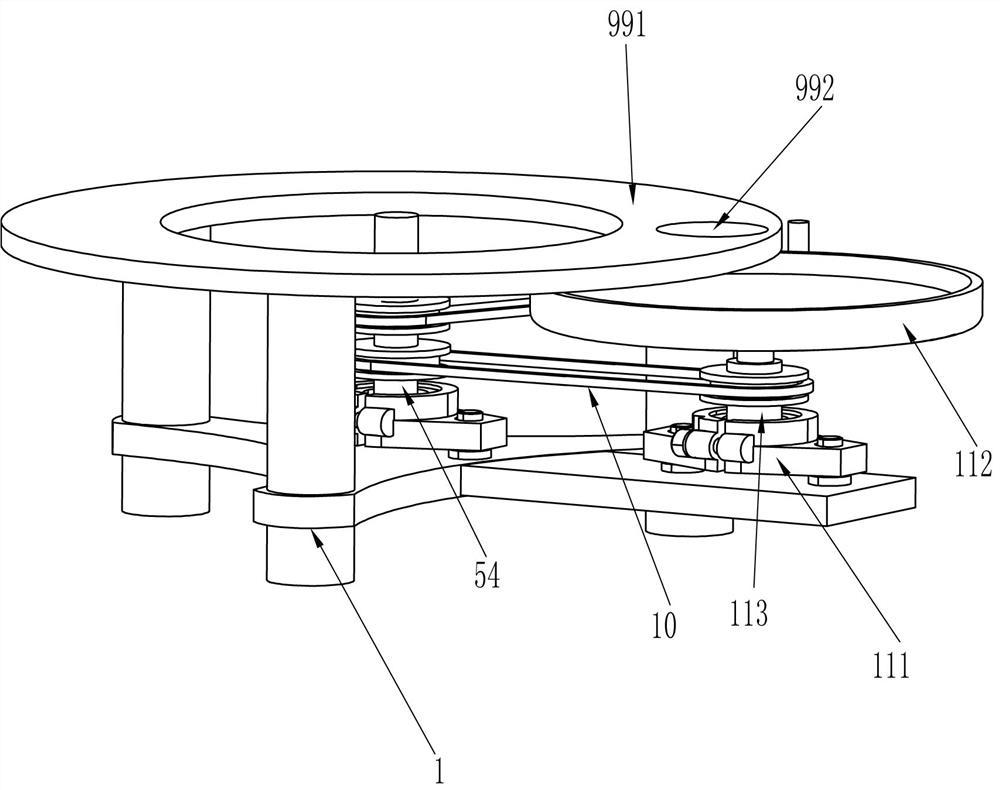

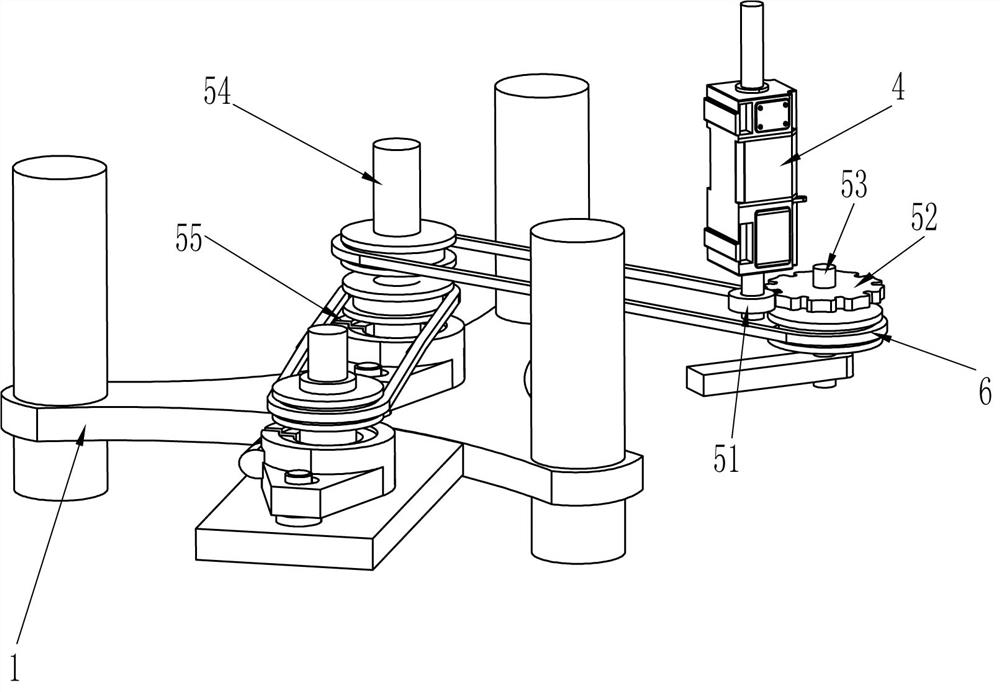

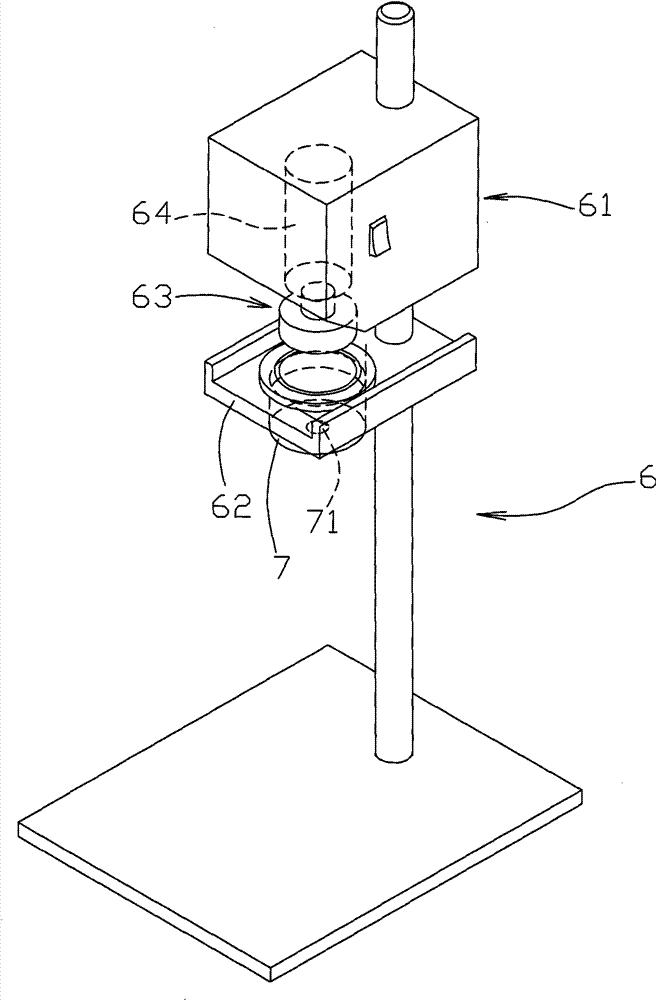

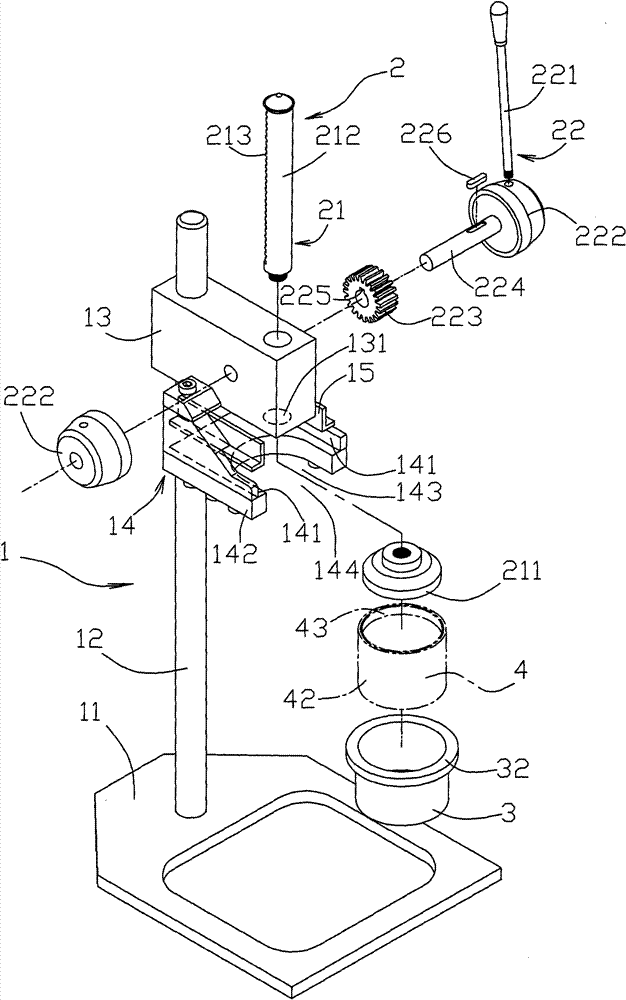

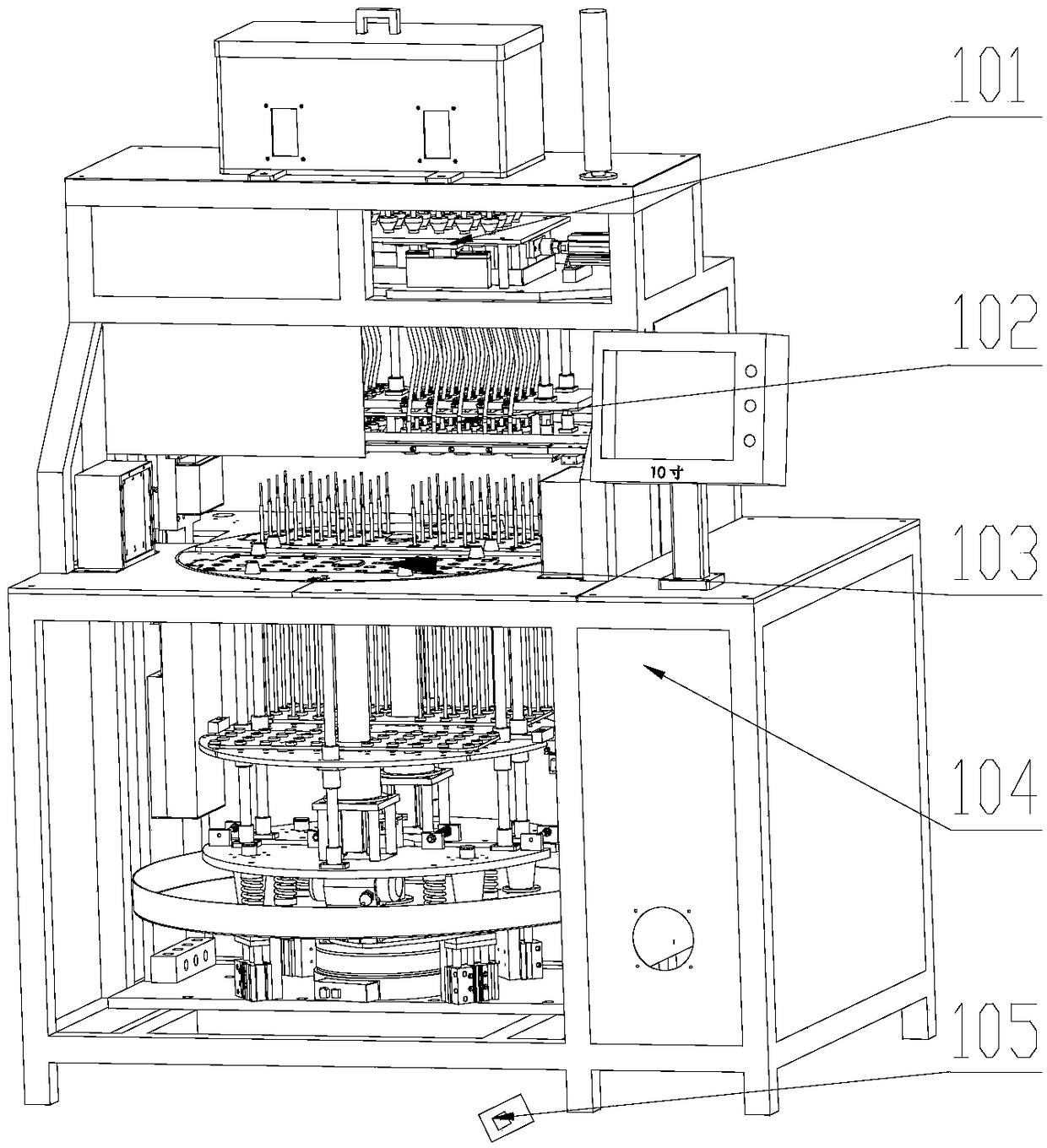

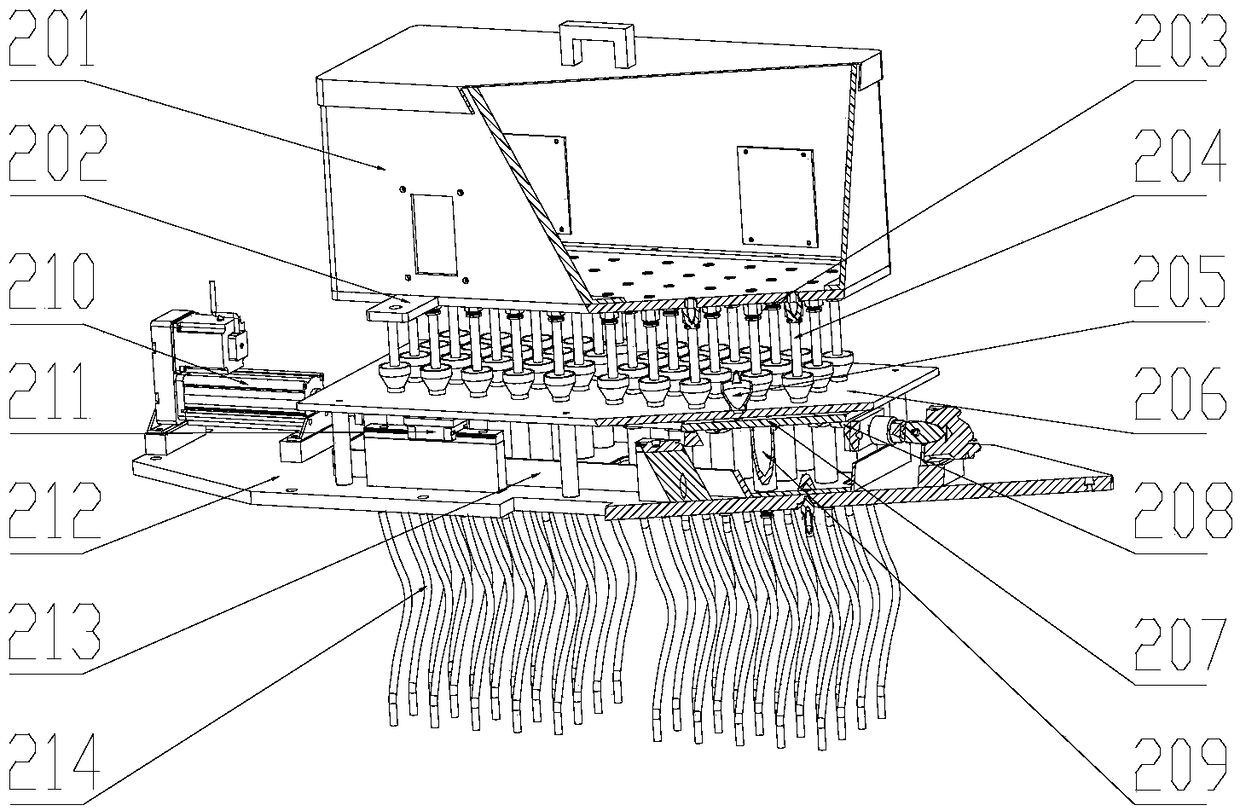

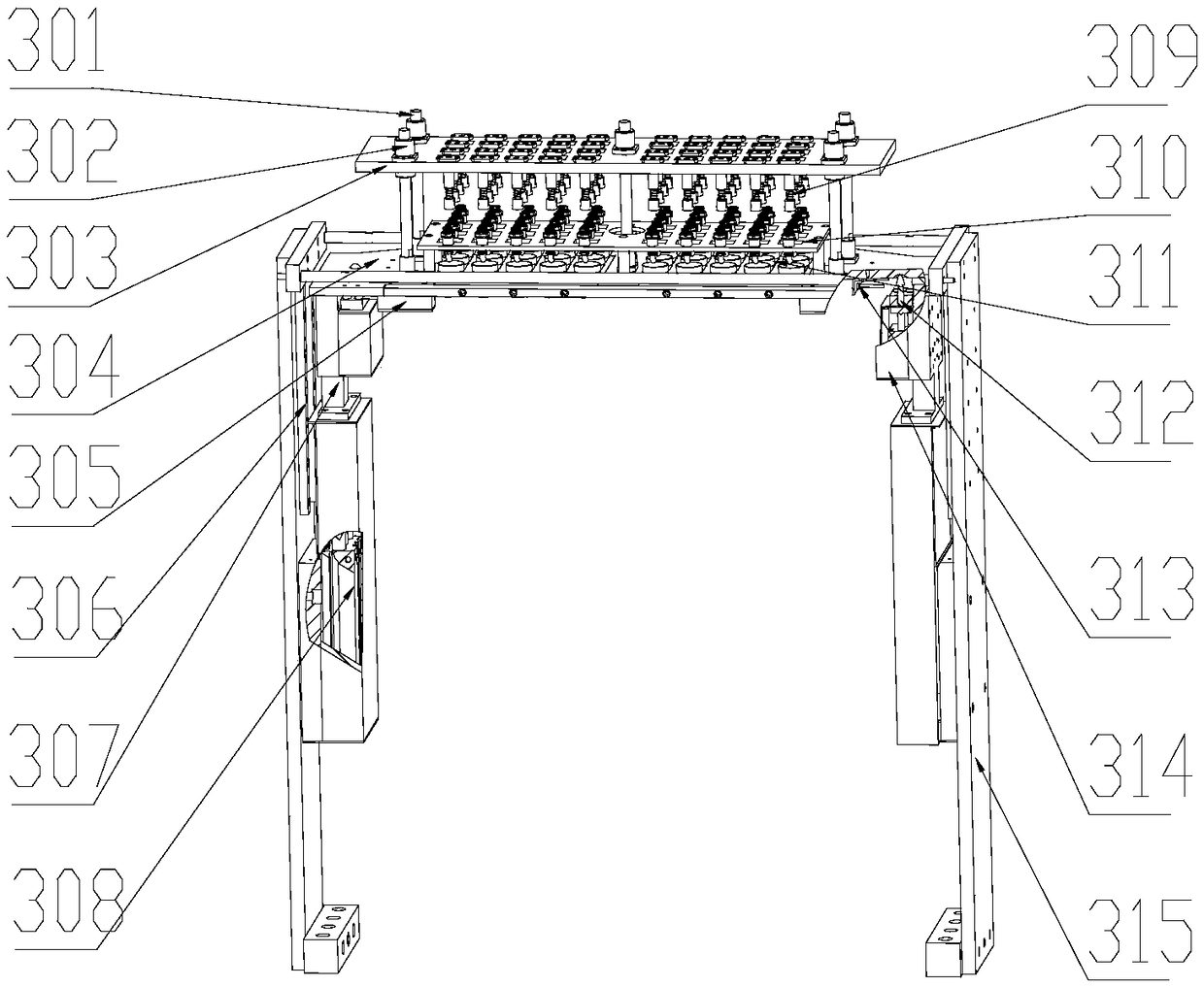

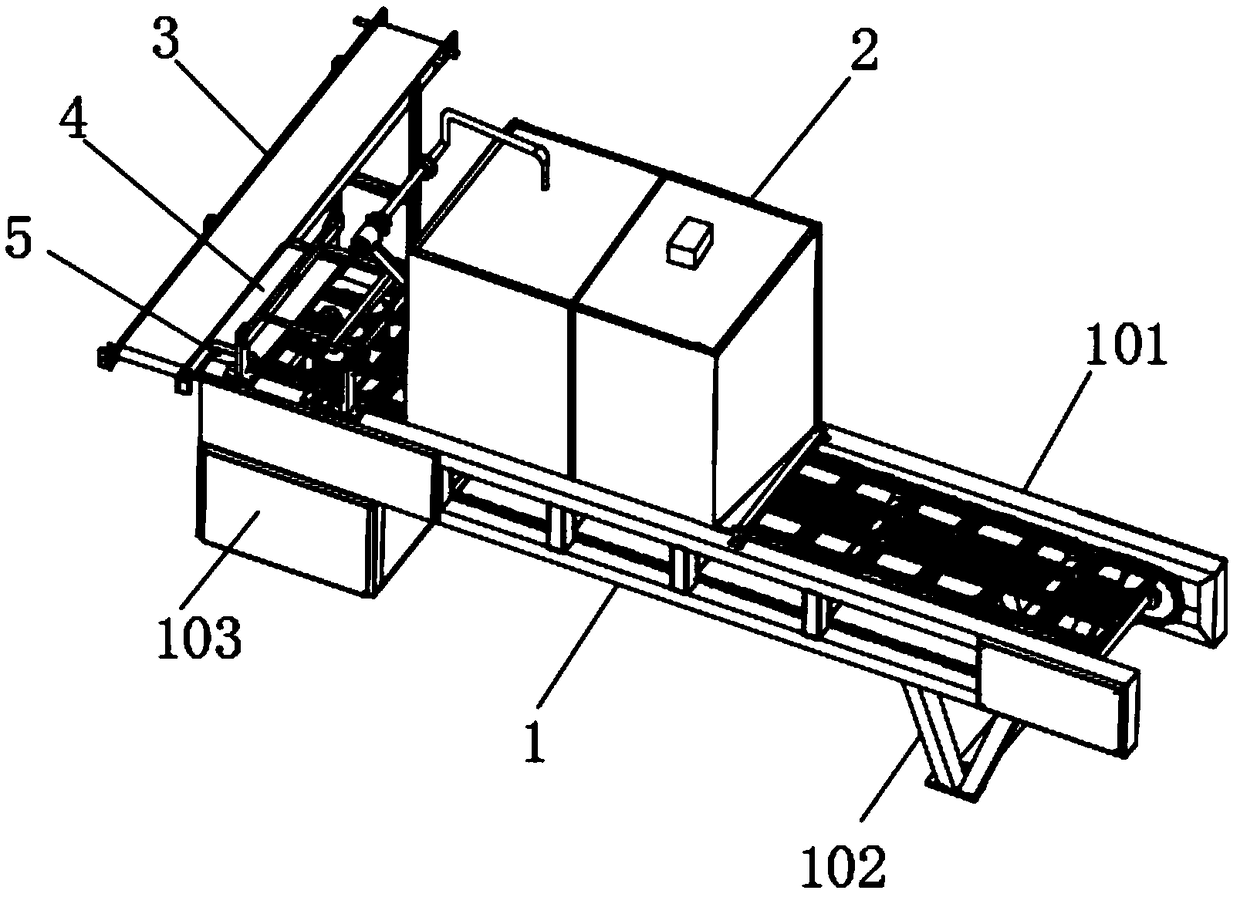

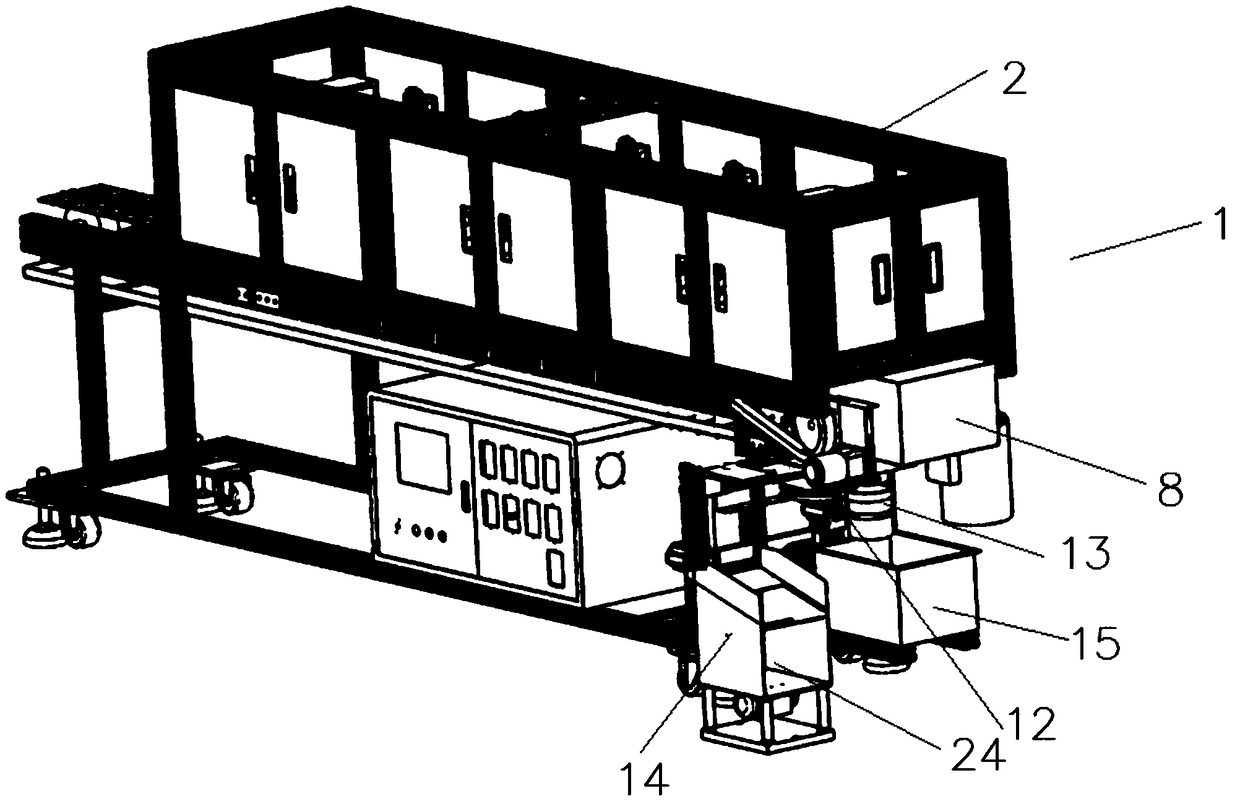

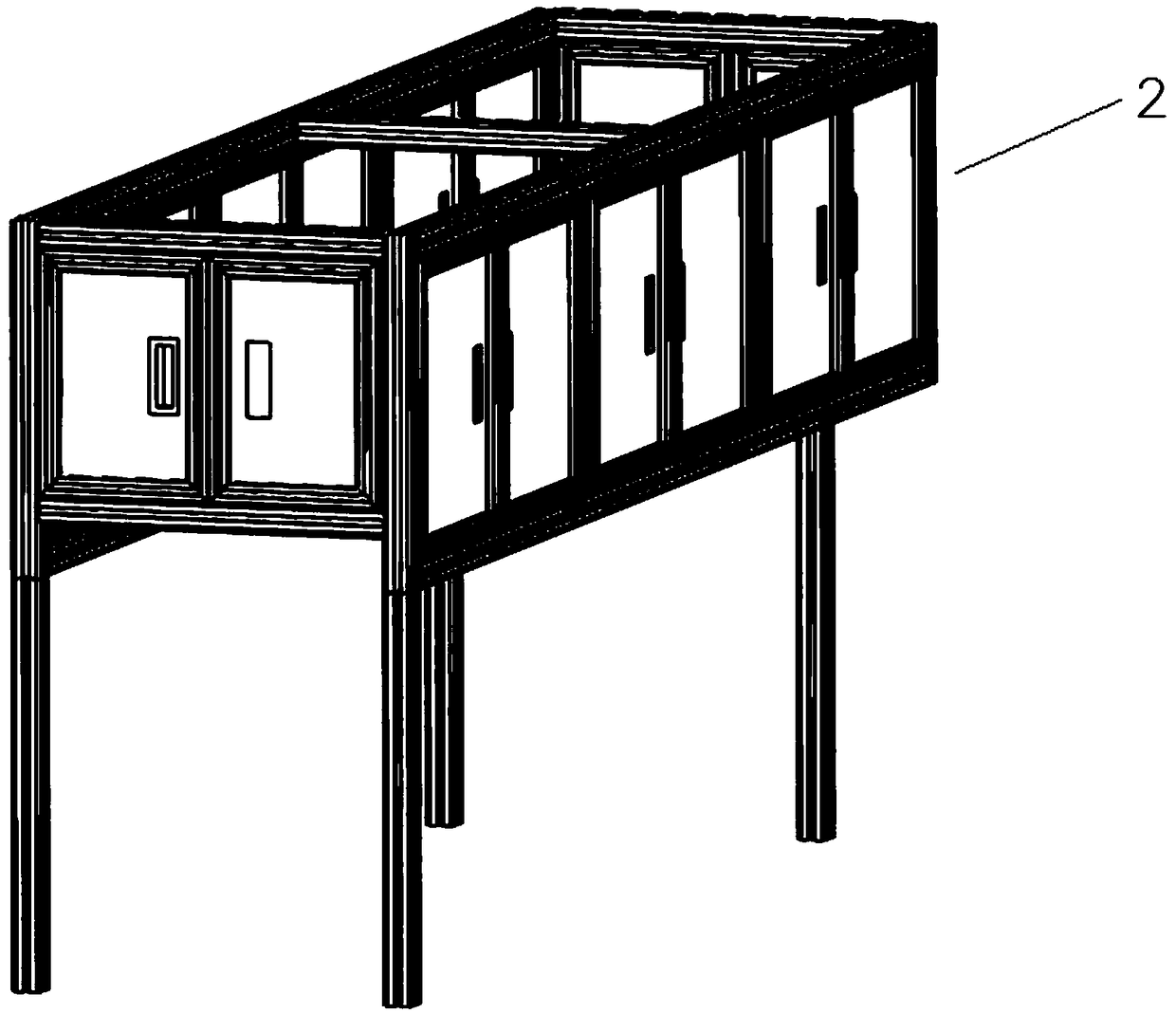

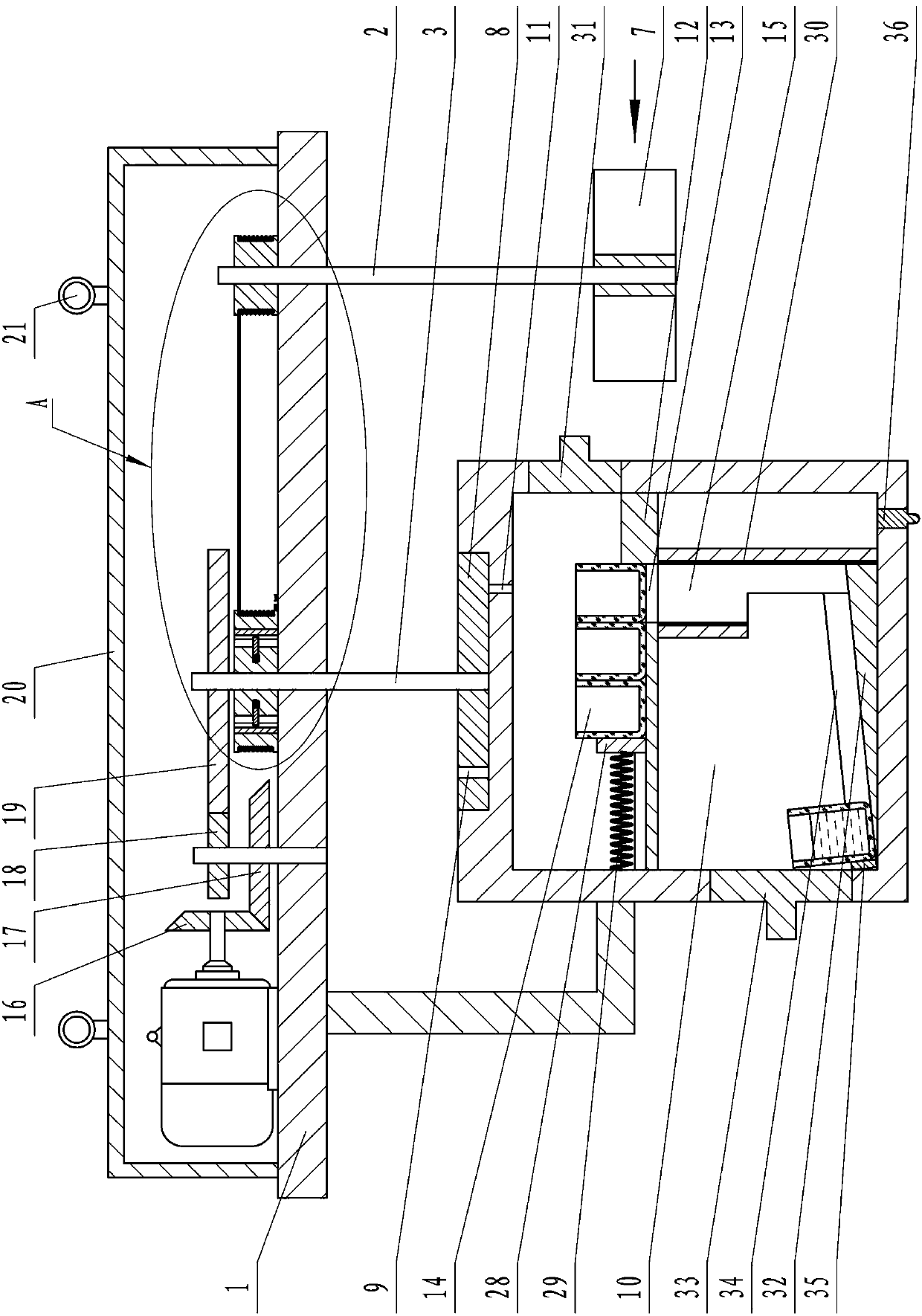

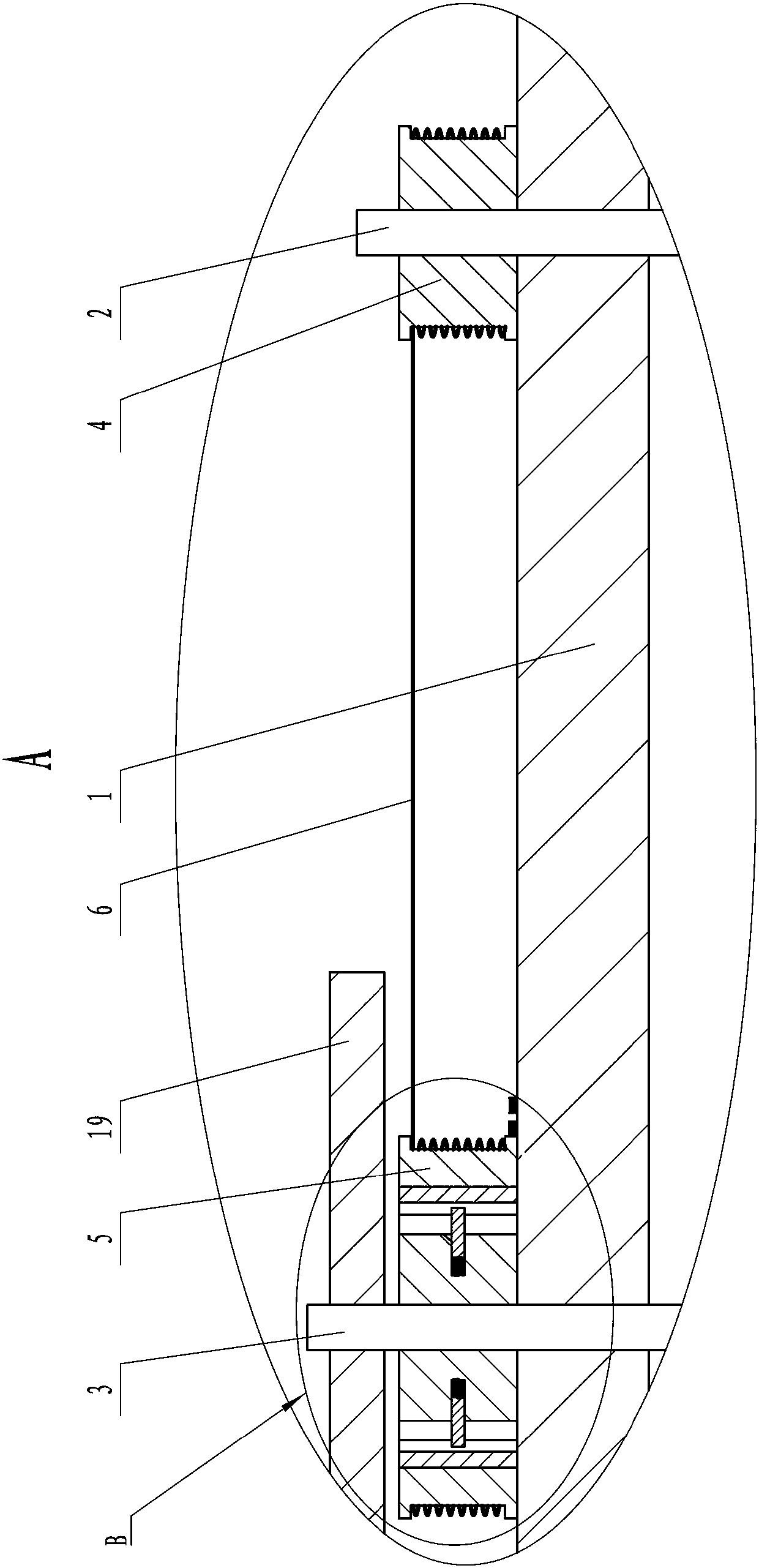

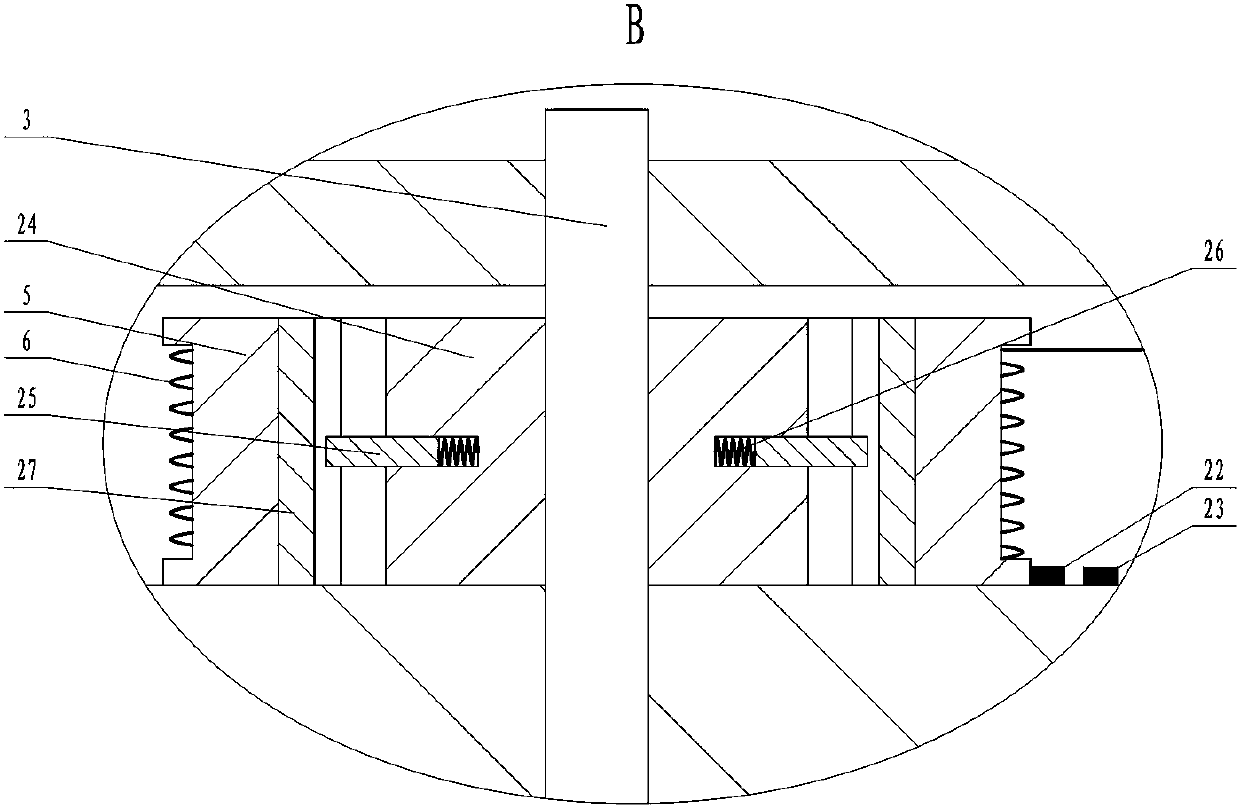

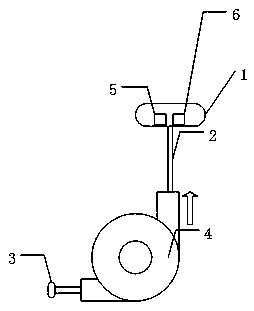

Automatic quantitative power filling equipment for novel heat tube

PendingCN109277564AAchieve precise quantitationAvoid stratificationIndirect heat exchangersEngineeringCopper

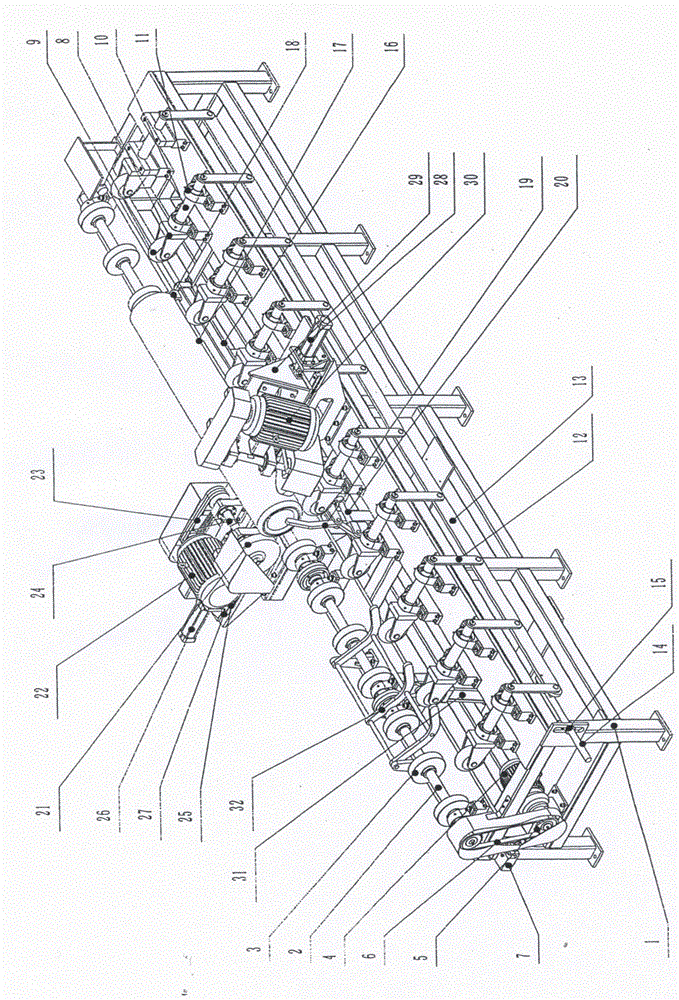

The invention discloses automatic quantitative power filling equipment for a novel heat tube. The automatic quantitative power filling equipment comprises a rack, a control device, a precise power quantifying mechanism, a lifting power filling mechanism and a rotating worktable mechanism; the precise power quantifying mechanism comprises a power storage box, a power storage box baseplate, hollow cylindrical tubes, power quantifying funnels, an upper fixing plate, middle movable plates, a plurality of powder storage measuring cylinders, a lower fixing plate and the like; the lifting power filling mechanism comprises a compression bar assembly fixing disk, mandrel compression bar assemblies, a copper powder tube fixing disk, replaceable powder cup assemblies, a lifting platform baseplate, alocating cylinder, a lifting cylinder and the like; the rotating worktable mechanism comprises powder filling worktables, lifting worktables, vibration baseplates, damping spring components, a power storing plate and the like; and the control device is connected to the precise power quantifying mechanism, the lifting power filling mechanism and the rotating worktable mechanism. The automatic quantitative power filling equipment has the advantages of high quality, precision, power filling efficiency, automation degree and universality, easy operation, low labor intensity and small dust.

Owner:SOUTH CHINA UNIV OF TECH +1

Wet tissue processing combined mechanism and processing technique thereof

ActiveCN109505077AAvoid twisting or even breakingIncrease productivitySevering textilesTextile treatment machine arrangementsPulp and paper industryCross-cutting

The invention discloses a wet tissue processing combined mechanism and a processing technique thereof. The wet tissue processing combined mechanism comprises a processing platform, wherein side platesare mounted on both sides of the processing platform, bracket legs are mounted at the positions of corners of the bottom end of the processing platform, a motor box is mounted at the bottom of the processing platform, a processing chamber is fixedly mounted on the outer surface of the upper end of the processing platform, a conveying table is disposed on one side of the processing platform, a connecting plate is mounted at a connecting position between the processing platform and the conveying table, and a supporting plate is mounted under the connecting plate. The whole combined mechanism isscientific and reasonable, the wet tissue immersion and cross-cutting process can be achieved, the transportation of a wet tissue after the immersion and cross-cutting is facilitated, the automated processing production greatly improves work efficiency and saves labor cost, a bolt can be pushed out of a through hole between chain shafts, so that a carrier is automatically detached from a slidingchain, a processing blade can be protected from distortion and breakage caused by vertical overpressure, and the wet tissue processing combined mechanism has a better protection effect.

Owner:铜陵麟安生物科技股份有限公司

Overload protection device for steel wire rope

ActiveCN107986164AAvoiding the danger of fallingIngenious ideaWinding mechanismsSafety gearEngineeringCam

The invention provides an overload protection device for a steel wire rope. The overload protection device can effectively solve the problem that a heavy object is prone to fall after the heavy objectis lifted. The overload protection device comprises a supporting frame; a clamping device is arranged in the supporting frame; clamping blocks are arranged in a bilateral symmetry mode and arc-shapedblocks; the outer circle surfaces of the arc-shaped blocks are connected with horizontal plates; first connecting rods and first pin shafts are arranged below the horizontal plates; the first connecting rods are arranged on the first pin shafts in a sleeving mode through sliding grooves; baffles are arranged on the outer sides of the first connecting rods; strong springs are connected between thefirst connecting rods and the baffles; a limiting step is arranged in the supporting frame; a lifting unit is arranged right below the clamping device; clamping grooves are formed in the opposite endsurfaces of the horizontal plates; elastic blocks are arranged between every two horizontal plates; the inner side surface of each elastic block is an arc surface; every two elastic blocks can move up and down and can be clamped into the clamping grooves; the outer sides of every two elastic blocks are connected to one cam; and the rotation of each cam can drive the corresponding two elastic blocks to move up and down. The overload protection device has the advantages of being ingenious in concept and safe to use.

Owner:HENAN DAFANG HEAVY MACHINERY

Agricultural rice threshing device with automatic feeding function

The invention discloses an agricultural rice threshing device with an automatic feeding function. The device comprises a rack, an arc outer frame is installed on the rack, rice clamping assemblies isinstalled in the arc outer frame, and a rice threshing assembly is installed at one side of the arc outer frame; a feeding assembly is installed at the side, away from the rice threshing assembly, ofthe arc outer frame, and matched with the rice clamping assemblies to complete uninterrupted feeding of rice, an inclined slide plate is installed between the rice threshing assembly and the arc outerframe, and a rice straw collecting box is connected to the lower portion of the inclined slide plate. According to the device, rice straw is automatically clamped and separated, and the situation that the rice straw is manually held for threshing operation is avoided; through the arrangement of a driving gear and a conveying wheel, the working time difference exists between the feeding assembly and the rice clamping assemblies, uninterrupted feeding of the rice is achieved, uninterrupted running of a driving motor and a conveying motor is achieved at the same time, the situation that the driving motor and the conveying motor are frequently started up and shut down is avoided, and the service life of the driving motor and the conveying motor is prolonged.

Owner:JIXI YUANDAO AGRI IND TECH

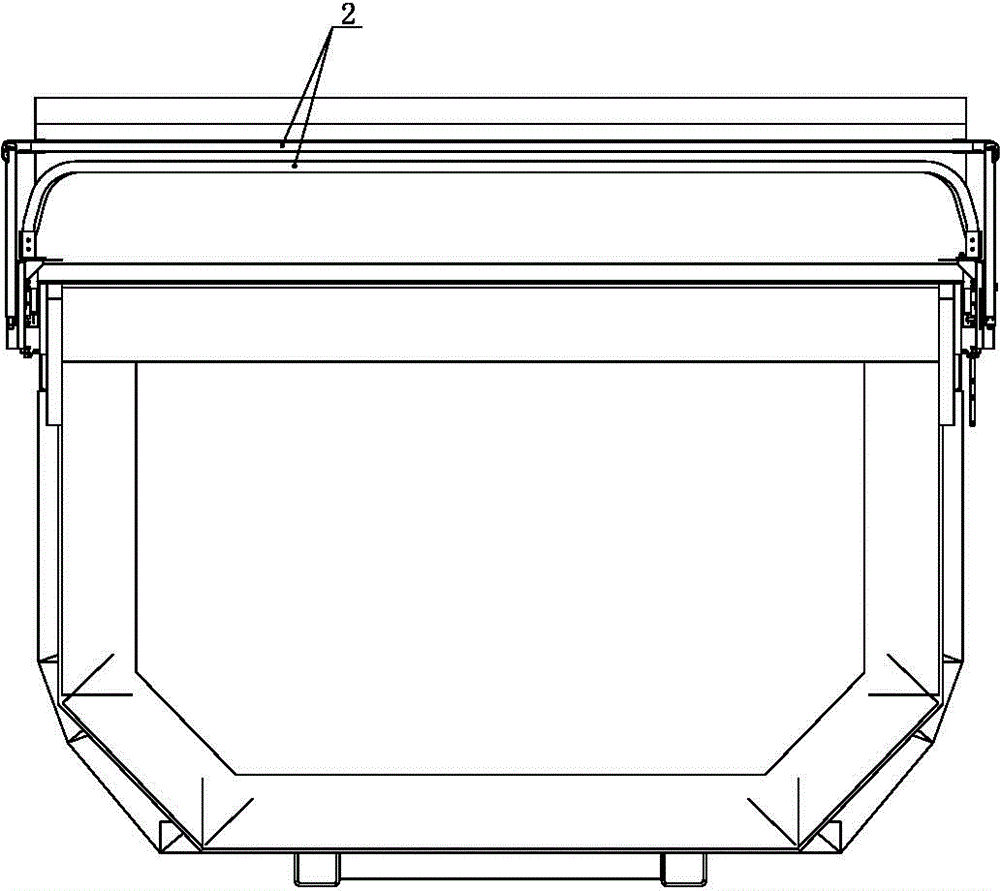

Carriage with awning

The invention relates to a carriage with an awning. A plurality of awning rods are uniformly arranged along the length direction of the carriage and are respectively connected below the awning, the upper ends of the left and the right of the carriage are respectively provided with an upper beam, slide grooves are arranged below the upper beams, each awning rod crosses over the carriage along the width direction and two ends of each awning rod are respectively inserted into awning rod sliders respectively sliding along the upper beams or the slide grooves. The awning rod sliders are capable of meeting mounting requirements of various states, the awning rods close to the rear portion of the carriage are mounted on a tail oscillating bar device, and slope racks are respectively fixed on two sides of the upper beams of the tail of the carriage. When the tail oscillating bar device moves to the rear portion of the carriage, the slope racks enable an oscillating bar to oscillate to the horizontal state, so that the tail of the carriage is closed. A single steel wire is capable of driving slide seats at the tails of the two sides, and the sliders on two sides are kept synchronized. A steel wire dragging device adopts a duplex wheel with coaxial gear and rope sheave, is large in wrap angle and high in traction force and slipping of the steel wire is avoided.

Owner:HYVA MECHANICS (CHINA) CO LTD

Steel seamless cylinder outer surface polisher

ActiveCN103551936AStable rotation speedControl travel speedRevolution surface grinding machinesGrinding feedersGas cylinderEngineering

The invention discloses the technology of a steel seamless cylinder outer surface polisher. A machine body is fixed with a motor, a shaft is fixed by a bearing, and a tensioner, a cross seat, a longitudinal seat, a D cylinder, an E cylinder, a material overturning device, an A cylinder, a guide sleeve and a bearing are all fixed; the motor is fixed with a chain wheel, the shaft is fixed with a driven chain wheel, the shaft is fixed with a roller, the bearing is fixed with a swing shaft fixed with a swing arm and a support, a connecting plate is fixed with a screw rod, the E cylinder is fixed with the material overturning device, the cross seat is fixed with a C cylinder and a guide track, a cross motor seat is fixed with a cross motor and a sand wheel shaft seat, a sand wheel shaft is fixed with a cross sand wheel, a longitudinal motor seat is fixed with a longitudinal motor and a longitudinal sand wheel shaft seat, a longitudinal sand wheel shaft is fixed with a longitudinal sand wheel, and the longitudinal seat is fixed with a B cylinder and a track; the chain wheel and the driven chain wheel are movably connected by a chain, the tensioner is movably connected with the chain, the support is movably connected with a driven roller, the swing arm is movably connected with the connecting plate, the guide track is movably connected with the cross motor seat, the cross motor is movably connected with the sand wheel shaft by a belt, the C cylinder is movably connected with the cross motor seat, the track is movably connected with the longitudinal motor seat, the longitudinal motor is movably connected with the longitudinal sand wheel shaft by a plate belt, a B cylinder is movably connected with the longitudinal motor seat, the A cylinder is movably connected with a push rod movably connected with the guide sleeve, and the D cylinder is movably connected with a hook member; the screw rod penetrates through the machine body to be in threaded connection with a nut. The steel seamless cylinder outer surface polisher is used for polishing a cylinder and has good effect.

Owner:宽城天海压力容器有限公司

Automatic stiff aphid processing system

PendingCN109042549AFacilitate automatic collectionLabor savingAnimal husbandryEngineeringTobacco leaf

The invention discloses an automatic stiff aphid processing system which comprises an automatic stripping assembly and a split charging assembly. The automatic stripping assembly comprises a first conveying device, the first conveying device comprises a first conveying belt, and a tobacco leaf feeding position, a washing-brushing module, a collecting module and a tobacco leaf discharging positionare sequentially arranged on the first conveying belt; the split charging assembly comprises a second conveying device, the second conveying device comprises a second conveying belt, and an upper boxposition, a stiff aphid split charging module and a lower box position are sequentially arranged on the second conveying belt; the collecting module comprises a discharging port, and the direction ofthe discharging port faces the stiff aphid split charging module of the split charging assembly. By means of automatic operation of a production line, labor can be saved, stiff aphids can be efficiently and economically stripped from tobacco leaves, and then drying, impurity removal and collection are performed; stiff aphids which are not stripped from leaves are small in number and low in damagerate; in addition, the stiff aphids adjustable in number can be efficiently split-charged.

Owner:YUNNAN TOBACCO CO LTD KUNMING BRANCH +1

Tile well fixing device for decoration

ActiveCN110318521AEasy to operateAutomatic disengagementBuilding constructionsEngineeringMechanical engineering

The invention discloses a tile well fixing device for decoration. The tile well fixing device for decoration comprises a machine body; a working chamber is arranged in the machine body; a limiting rodis arranged in the working chamber; the limiting rod includes a vibration block; a measuring mechanism is arranged on the left side of the limiting rod; the measuring mechanism comprises a measuringrod; the rear end wall of the working chamber is provided with a moving chamber; the right side of the measuring mechanism is provided with a lifting mechanism; and the lifting mechanism comprises a motor. The tile well fixing device for decoration is easy to operate; after the tile is manually sucked onto the device, the motor is started, and the tile well fixing device for decoration can automatically compact the cement between the tile and the wall to remove the air; and the tile well fixing device for decoration can detect whether the tile surface is horizontal or not; if the tile surfaceis horizontal, the tile well fixing device for decoration automatically separates from the tile; and if the tile surface is not horizontal, the tile well fixing device for decoration does not automatically separate from the tile.

Owner:YIWU AOLI MASCH TECH CO LTD

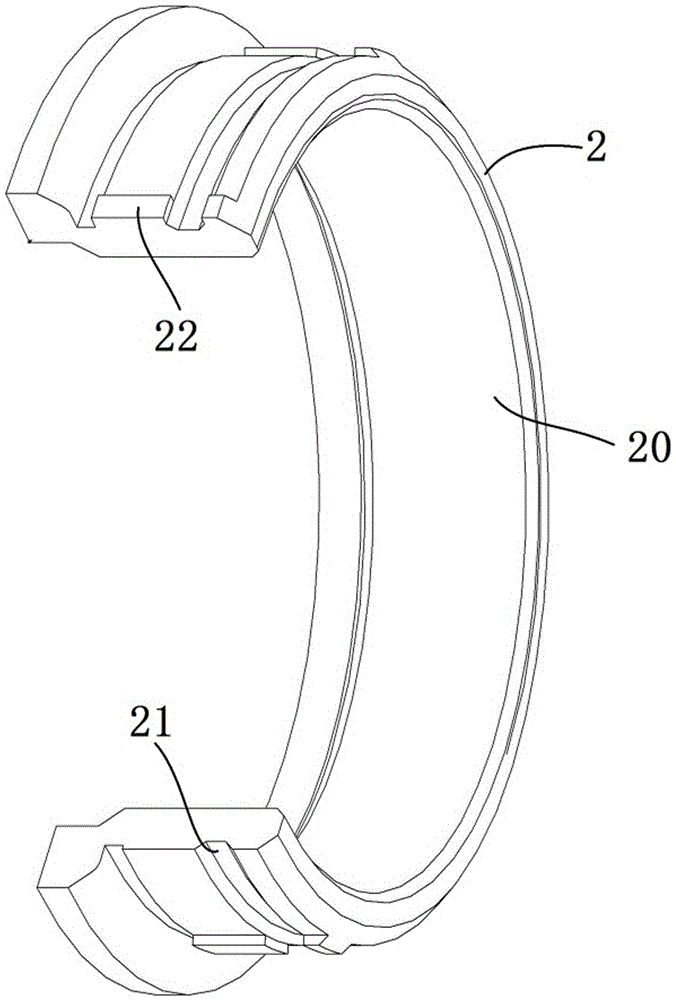

Connecting ring and socket as well as pulling and separating connector

ActiveCN106099539AAutomatic disengagementStable and smooth disengagementCoupling device detailsSteel ballEngineering

The invention provides a connecting ring and a socket as well as a pulling and separating connector. The pulling and separating connector comprises a socket shell. A connection sleeve is axially and fixedly installed on the socket shell. The connection sleeve is locked with a connecting ring through a steel ball locking structure. A plug connection structure connected with a plug shell is arranged on the connecting ring. A removing and separating spring is arranged in the socket shell and provides acting forces for the connecting ring or provides the acting forces towards a direction breaking away from the plug shell when the plug shell is connected to the connecting ring for the plug shell. The connection sleeve of the pulling and separating connector is locked with the connecting ring through the steel ball locking structure. The connecting ring is connected with the plug shell through the plug connection structure. The removing and separating spring is also arranged in the socket shell. When the steel ball locking structure is unlocked, the removing and separating spring can provide the plug shell or the connecting ring with an elastic force, and a plug and a socket can be automatically separated. Thus the plug and the socket can be stably and smoothly separated, and the usage is convenient.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

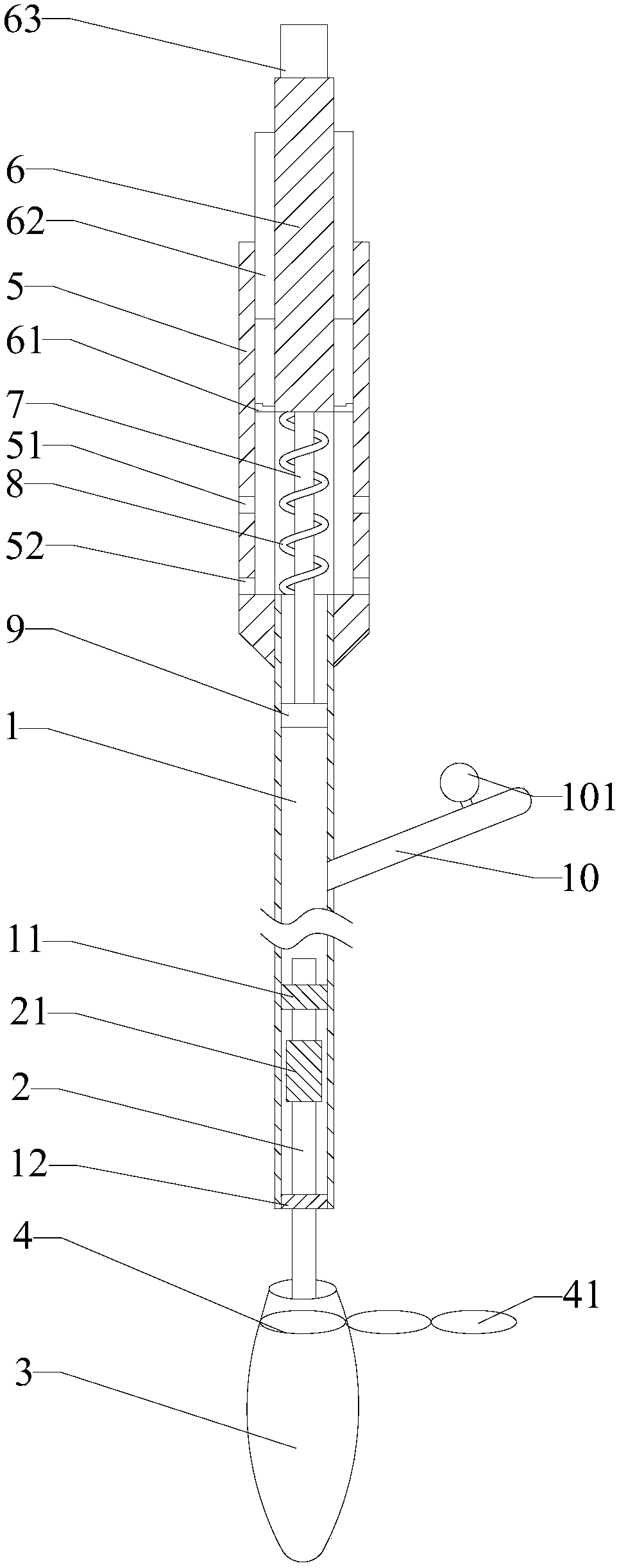

Enteroscope balloon

PendingCN108498062AReduce peristalsisAutomatic disengagementSuture equipmentsInternal osteosythesisRubber ringMedical equipment

The invention relates to the technical field of medical equipment, in particular to an enteroscope balloon. The enteroscope balloon comprises a longitudinally arranged fixed tube, a movable sleeve sleeved with the fixed tube, a first rubber piston, a dilation balloon, a sealing rubber ring and a push-pull device; the fixed tube and the movable sleeve are each of a hollow structure, the extended end of the movable sleeve stretches into the dilation balloon, the sealing rubber ring is used for making the movable sleeve and the dilation balloon connected, the upper end of the fixed tube is connected with the push-pull device, retraction and stretching of the movable sleeve are controlled by means of vertical movement of the second rubber piston in the push-pull device, the movable sleeve retracts, the sealing rubber ring and the dilation balloon achieve automatic separation from the movable sleeve, the dilation balloon is left in the colon, a dilation balloon physically blocks port side intestine peristaltic wave to be transmitted to the anorectal colon, large intestine peristalsis is weakened, and by means of the physical supporting effect of the dilation balloon, an operation spaceand clear vision are provided for endoscopic treatment.

Owner:郑由周

Sampling device for flowing water bodies

ActiveCN109655315AAvoid affecting test resultsAutomatic disengagementWithdrawing sample devicesImpellerMotor drive

The invention relates to a sampling device for flowing water bodies, the device effectively solves the problems that manual sampling is inconvenient, automatic sampling cannot fully reflect the actualsituation of the water bodies and sampling is not accurate enough. The technical scheme includes driving an impeller to rotate through river water; driving, by the impeller, a first winding wheel tocollect a rope, and releasing, by a second winding wheel, the rope, so as to enable the time interval for collecting samples to be proportional to the flow rate of the river water; controlling the starting and stopping of a motor by a signal transmitted by a Hall sensor; when the motor drives a second rotary shaft to rotate, collecting a sample; collecting, by the second winding wheel, the rope, and releasing, by the first winding wheel, the rope, so as to enable the impeller to rotate in the reverse direction. According to the above technical scheme, the nearby river water is stirred to prevent the river water from stratification, and floating objects wound on the impeller are automatically separated from the impeller.

Owner:江门新财富环境管家技术有限公司

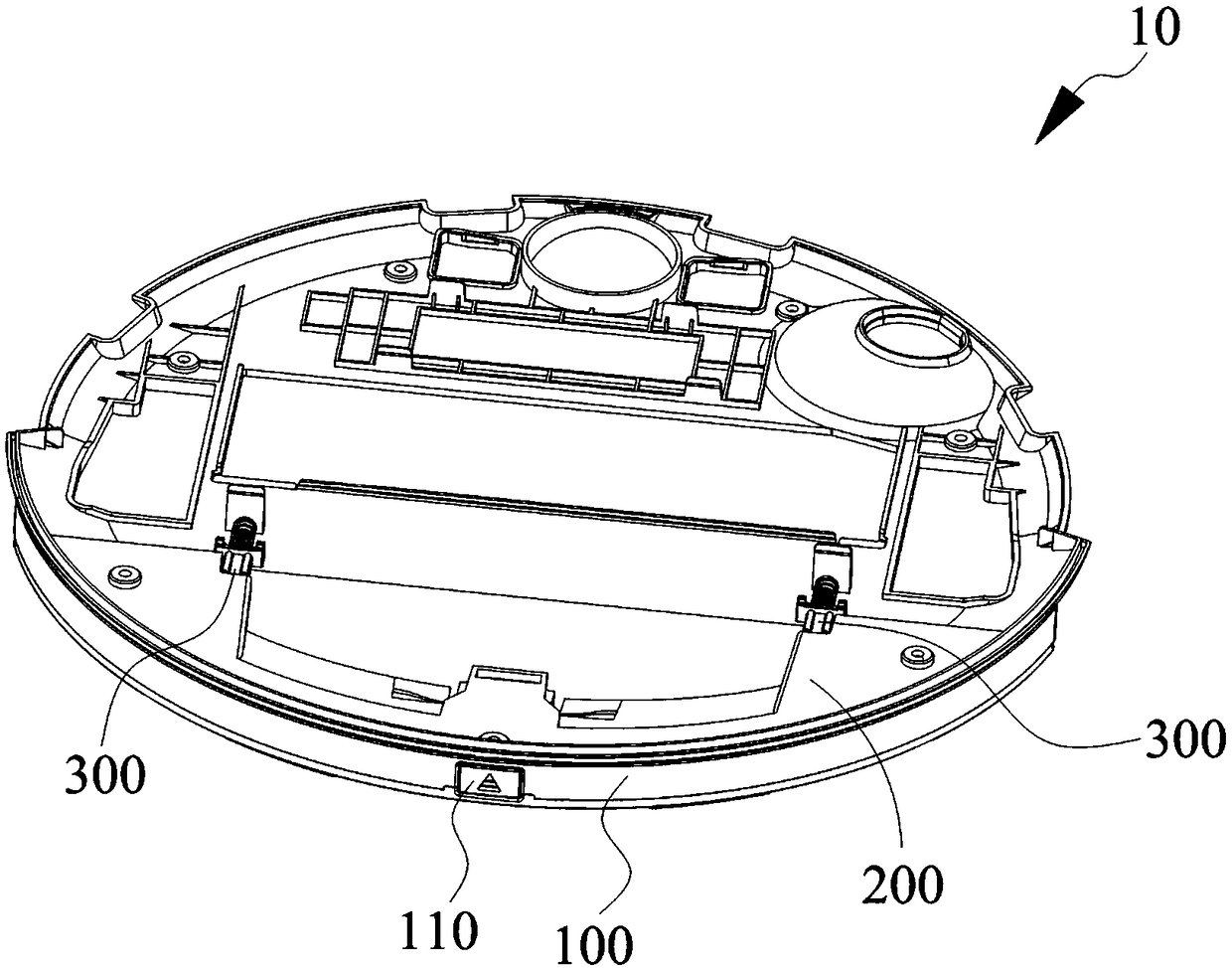

Cleaning robot

InactiveCN109452906AAutomatic disengagementEasy to take outCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a cleaning robot, which comprises a main body, a bearing piece and an ejection structure. The main body is provided with a card slot, and the bearing piece is provided with a switch assembly matched with the card slot. The detachable connection between the bearing piece and the main body is realized through the buckling or separation between the switch assembly and the cardslot. The ejection structure is elastically connected between the main body and the bearing piece. The ejection structure compresses and elastically supports the main body and the bearing piece whenthe switch assembly and the card slot are buckled. When the switch assembly and the card slot are separated, the ejection structure is ejected to eject the bearing piece from one side of the main body.

Owner:深圳飞科机器人有限公司

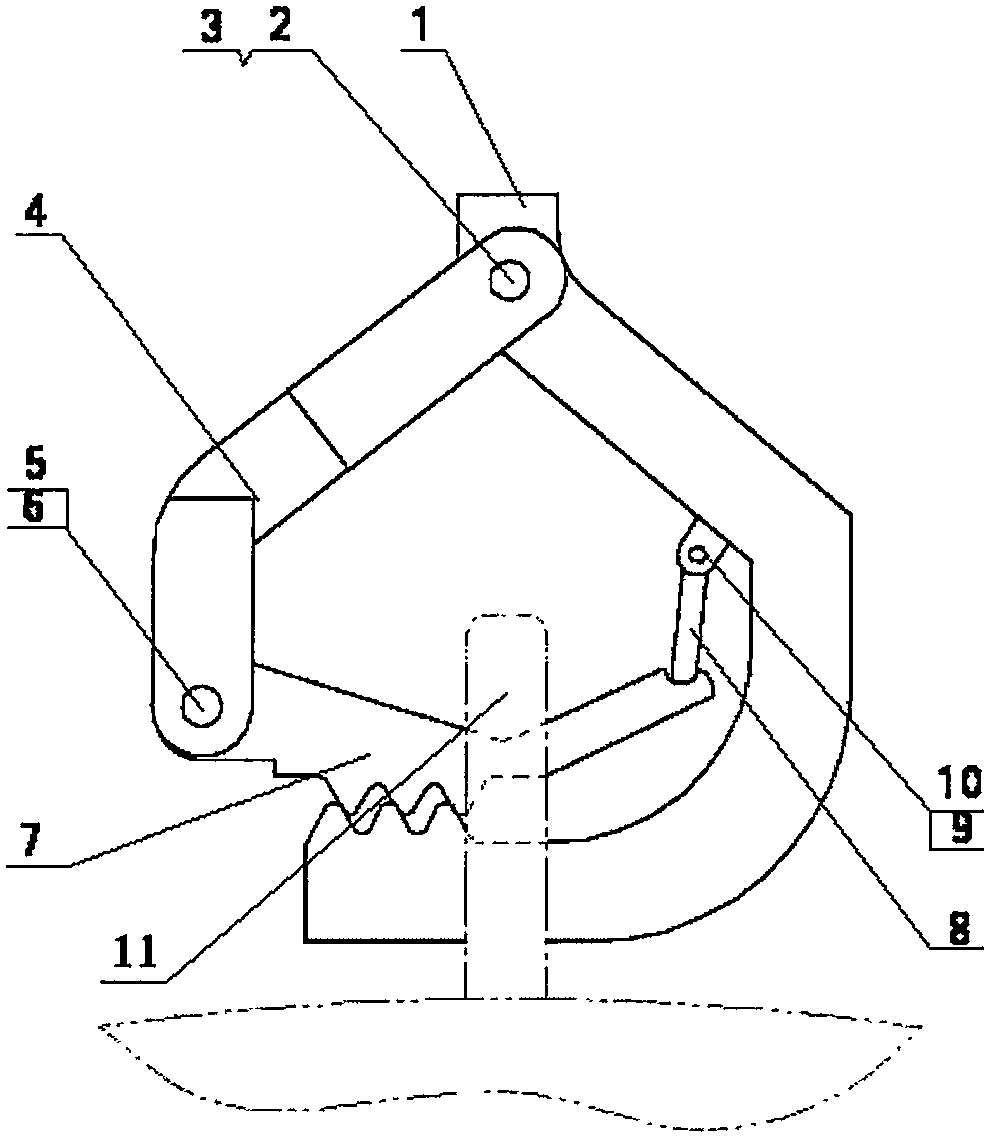

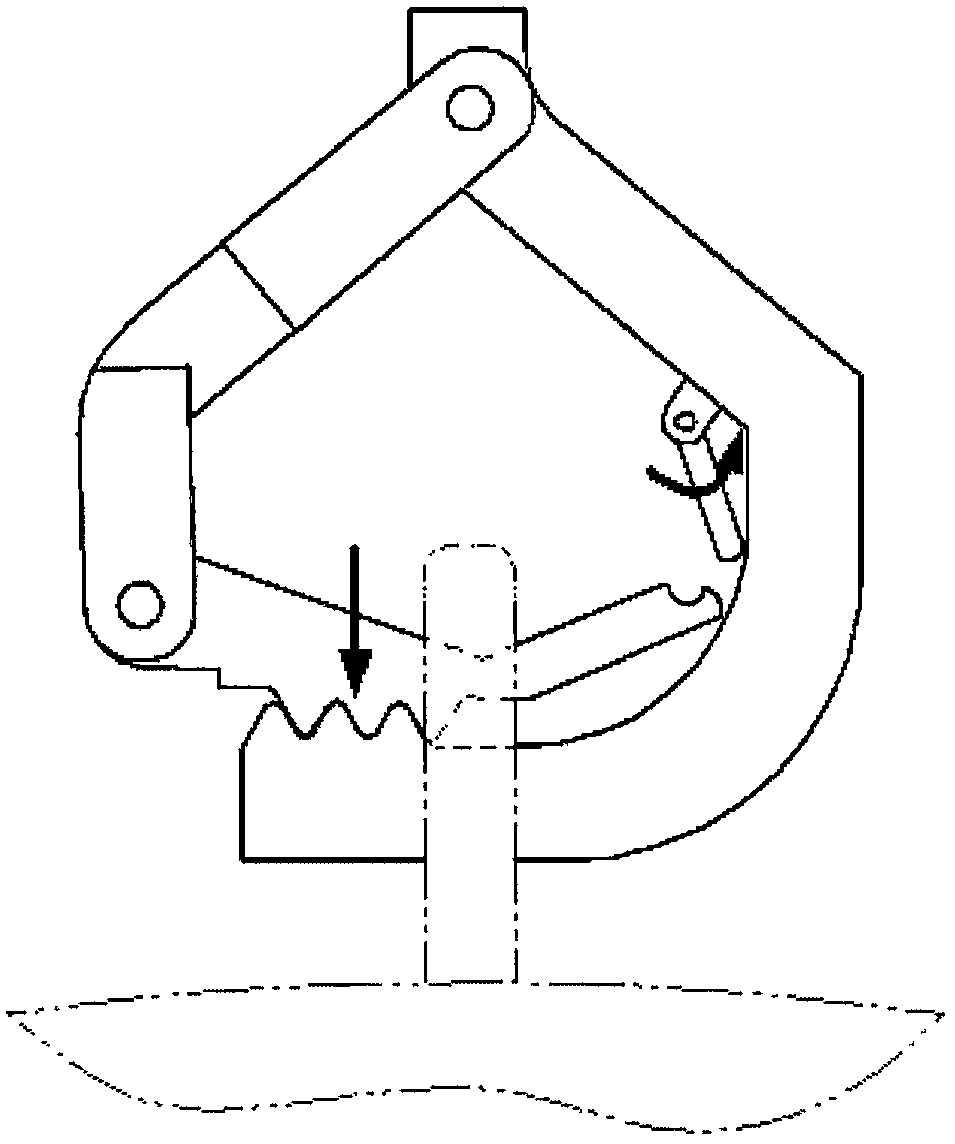

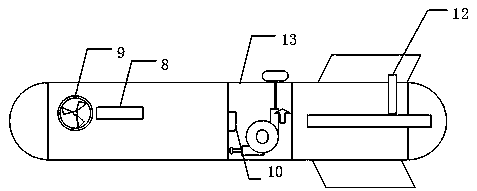

Automatic releasing lifting hook structure and using method thereof

InactiveCN108249279AAchieve the purpose of automatic releaseImprove lifting release efficiencyLoad-engaging elementsPull forceUnderwater

The invention discloses an automatic releasing lifting hook structure and using method thereof for lifting and realizing of an underwater or water surface navigation device. The automatic releasing lifting hook structure includes a right hook claw, a first rotating shaft, a first torsion spring, a first left hook claw, a second rotating shaft, a second torsion spring, a second left hook claw, a baffle, a third rotating shaft and a third torsion spring. By using the self-locking function of a tooth structure between the left hook claw and the right hook claw, so that when a lifting hook is notforced, the lifting hook is closed and self-locked; when the hook is pulled downwards, the baffle loses the limiting function for the left hook claw; and when the lifting hook is not forced again, thelifting hook is automatically opened, the lifting hook is separated automatically after the underwater or water surface navigation device enters water. The automatic releasing lifting hook structurehas the advantages that after the underwater or water surface navigation device is lifted and enters the water, the lifting hook is separated from a lifting point automatically, and the purpose that the navigation device is released automatically is achieved; and divers do not need to carry on operation in water, manpower and physical consumption is reduced, and the lifting and releasing efficiency of the navigation device is improved.

Owner:中国船舶重工集团公司第七〇五研究所昆明分部

Ocean monitoring robot capable of avoiding stormy waves on the own

ActiveCN110641659AAutomatic disengagementReal-time monitoring of surface wind and wavesUnderwater equipmentTransceiverAutomatic control

The invention discloses an ocean monitoring robot capable of avoiding stormy waves on the own. The ocean monitoring robot comprises a waterproof shell, a propulsion motor, an internal control unit, apower supply, a necessary alarm sensor, a signal cable releasing and collecting device, a floating air bag and a signal cable, wherein the floating air bag comprises a stormy wave detection and signaltransceiver and a sensor with a specific function; and the floating air bag and the signal cable are in closed connection. The ocean monitoring robot has the advantages that ocean information is monitored and stormy waves are automatically avoided. In addition, a telescoping signal cable structure can monitor ocean surface information and receives and emits external information in real time undera severe environment of heavy stormy waves, a robot body can be guaranteed to automatically float to the ocean surface to continuously work after the stormy waves finish, a situation that the robot body is damaged by heavy stormy waves is avoided, and the ocean monitoring robot supports intelligent automatic control, remote control and manual control.

Owner:JIANGSU UNIV OF SCI & TECH

Crab pot hook and automatic unhooking and recovery device

ActiveCN108967372AAutomatic disengagementAchieve recyclingFishing netsPisciculture and aquariaEngineering

The invention relates to a crab pot hook and an automatic unhooking and recovery device. The hook comprises a crab hook assembly and a support transverse board. The crab hook assembly comprises a middle ring and a bottom ring, a movable rod connected with the middle ring and a hook rod connected with the bottom ring. The middle ring and the bottom ring are connected. The end part, away from the bottom ring, of the hook rod is equipped with a hook ring in a winding manner. The end part, away from the middle ring, of the movable rod is inserted into the hook ring. The movable rod penetrates through the support transverse board. Additionally, the movable rod is inserted into the part of the support transverse board and fixedly connected with the support transverse board.

Owner:ZHEJIANG OCEAN UNIV

Composite welding rod

InactiveCN104889606AAvoid residueImprove electrical conductivityWelding/cutting media/materialsSoldering mediaBrown iron oxideIron based alloy

The invention discloses a composite welding rod and a manufacture method thereof. The composite welding rod comprises a metal core and a coating, wherein the metal core comprises a work portion and a clamp portion which are fixedly connected, the coating coats the outer surface of the work portion, the work portion is made of iron-base alloy, the clamp portion is made of aluminum-base alloy, and the coating contains following compositions of, by weight percentage, 2.5-3.0% of carbon, 2.75-5.0% of nickel, 0.5-1.2% of molybdenum, 3.0-4.5% of manganese, and the balance iron oxide. The manufacture method of the composite welding rod includes: coating the work portion and the clamp portion with the coating after friction welding is performed on the work portion and the clamp portion. The composite welding rod and the manufacture method thereof prevent welding rod stub residues from being left on weld joints after the welding is completed.

Owner:赵兰

Trans-road paying-off high-altitude support

ActiveCN104836163ACable detachmentAutomatic disengagementApparatus for overhead lines/cablesEngineeringConnection control

Owner:国网山东省电力公司昌邑市供电公司 +1

Steel wire rope overload automatic falling-off lifting sling

The invention provides a steel wire rope overload automatic falling-off lifting sling. The situation that when heavy objects exceed the load carrying capacity of the steel wire rope, the lifting slingcan automatically make the heavy objects be separated is better achieved, and the risk that the heavy objects fall after being lifted is avoided. According to the technical scheme, the steel wire rope overload automatic falling-off lifting sling comprises a clamping device, and the clamping device is composed of two clamping blocks; each clamping block comprises a semicircular arc-shaped block, and horizontal plate clamping devices are connected to the exterior of each clamping block; a first connecting rod and a first pin shaft are arranged below each horizontal plate clamping device, the first connecting rods are arranged on the first pin shafts in a sleeving mode, a strong spring is connected between each first connecting rod and a corresponding baffle, and a supporting frame is internally provided with a limiting step; a second pin shaft is arranged below each clamping device, a sliding block is attached to the inner side of each baffle, and a second connecting rod is hinged to the inner side of each sliding block; transverse through grooves are formed in a bottom plate, and the sliding blocks are located above the transverse through grooves; and adjusting screw rods are fixedto the two sides of a supporting frame, and the end, placed in the supporting frame, of each adjusting screw rod is in threaded connection with a vertical plate. The steel wire rope overload automatic falling-off lifting sling is novel in conception and ingenious in structure.

Owner:HENAN DAFANG HEAVY MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com