Patents

Literature

31results about How to "Uniform wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

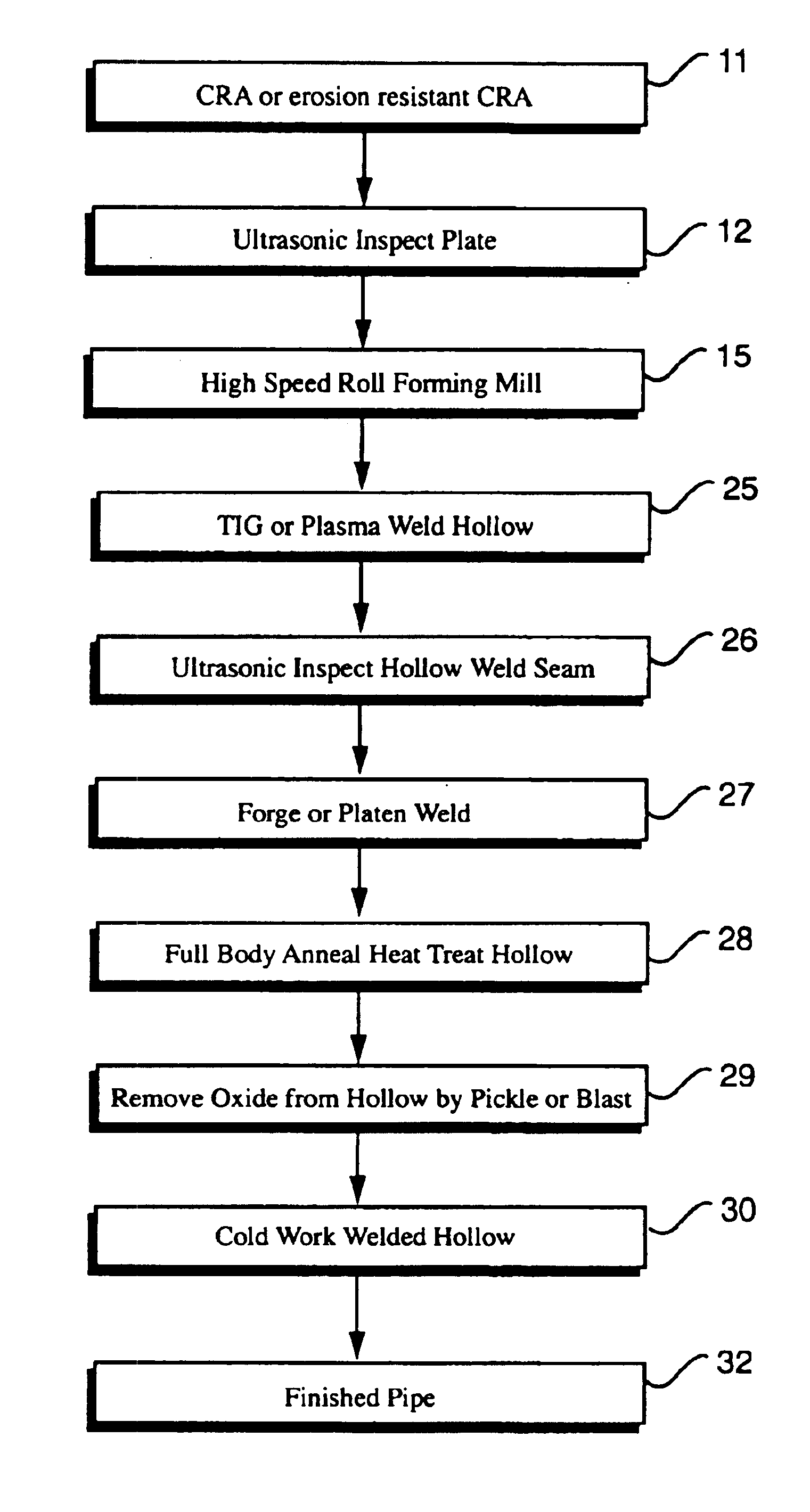

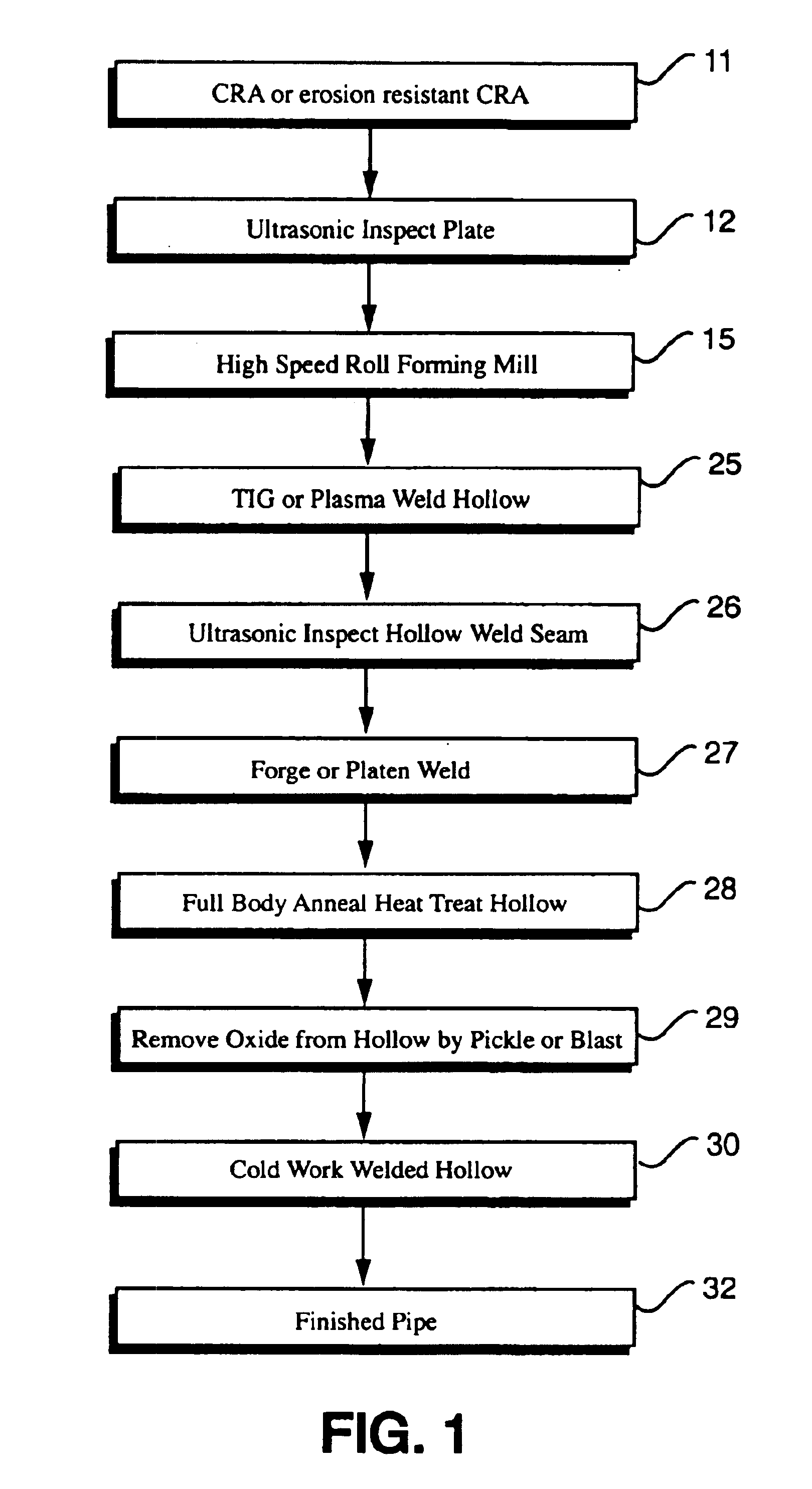

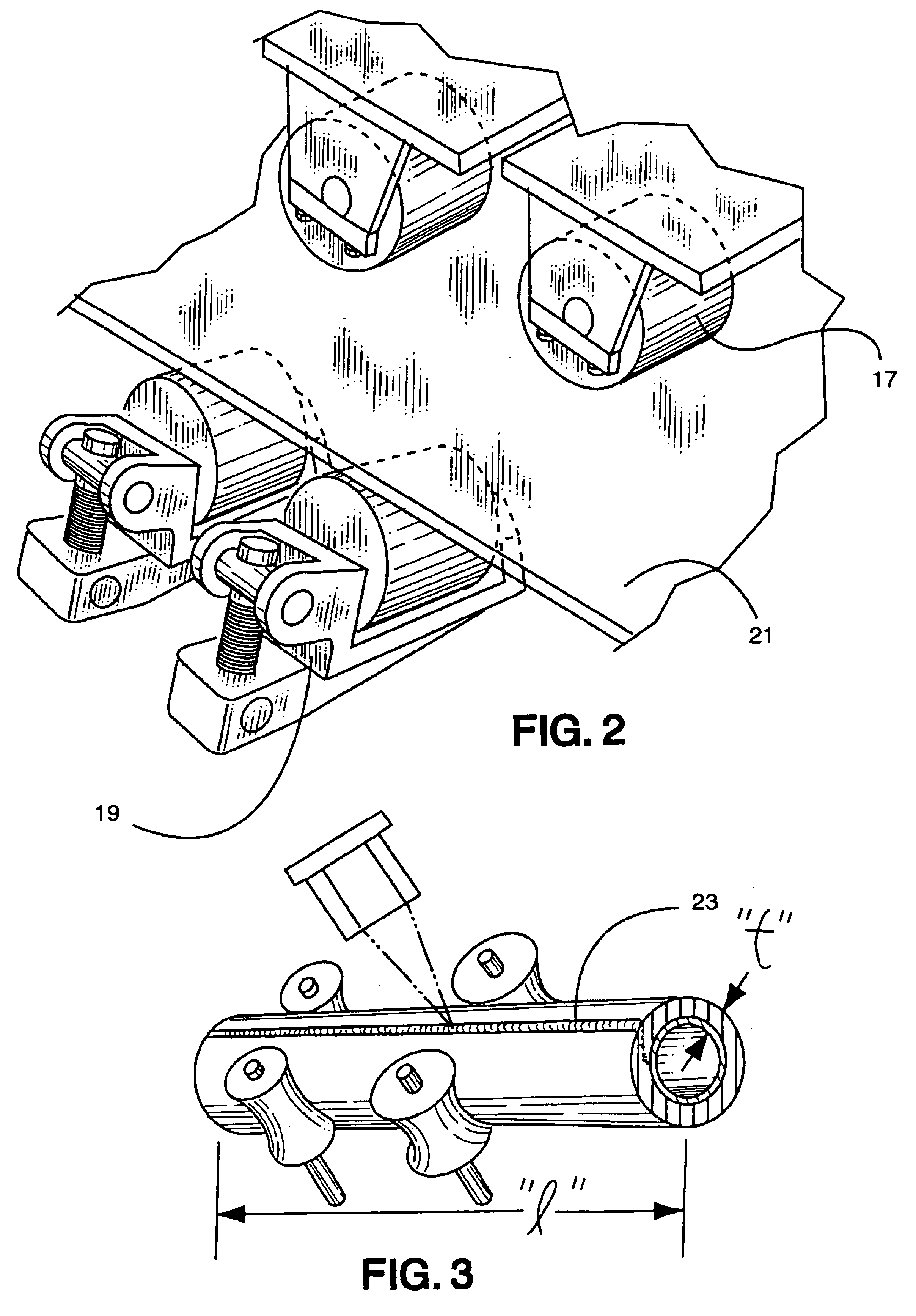

Method of manufacturing cold worked, high strength seamless CRA PIPE

InactiveUS6880220B2High tensile strengthHigh yield strengthSoldering apparatusArc welding apparatusRoll formingCorrosion

A process produces a welded seamless PIPE having good yield strength and excellent corrosion and / or erosion resistance. Up to a maximum outside diameter corrosion and / or erosion resistant CRA PIPE is cold worked from a welded hollow, rather than using the traditional seamless pierced hollow method. A high-speed roll-forming mill is also utilized, rather than using the slow traditional break press to form the welded hollow. Welded hollow dimensions can be achieved which comply with the method of cold working's capability to produce the yield strengths and dimensional tolerances required to meet the service criteria of the PIPE's intended application.

Owner:CORROSION RESISTANT ALLOYS

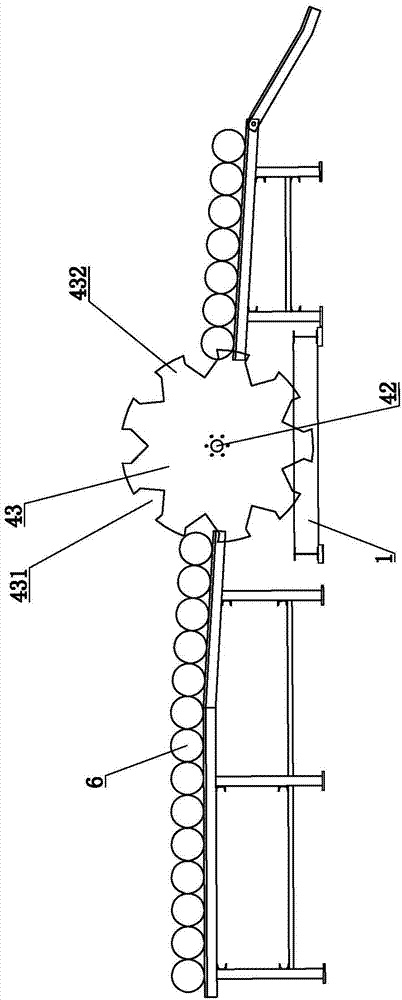

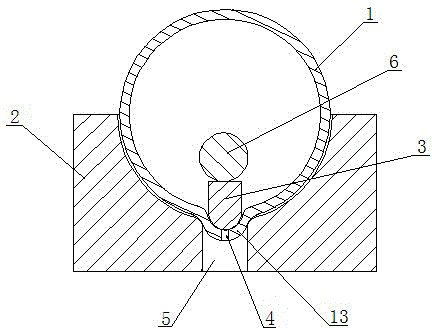

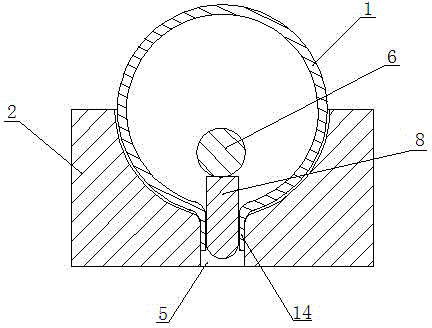

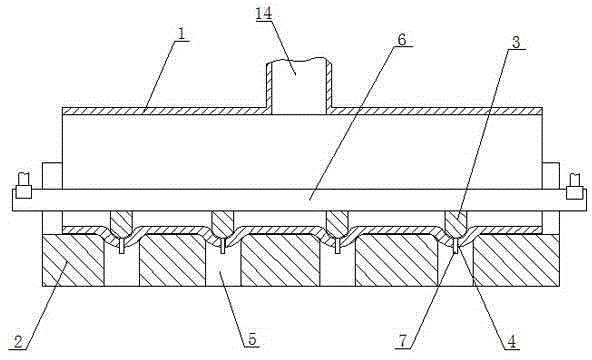

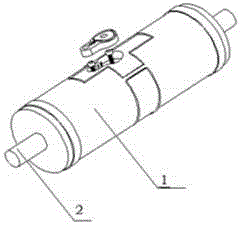

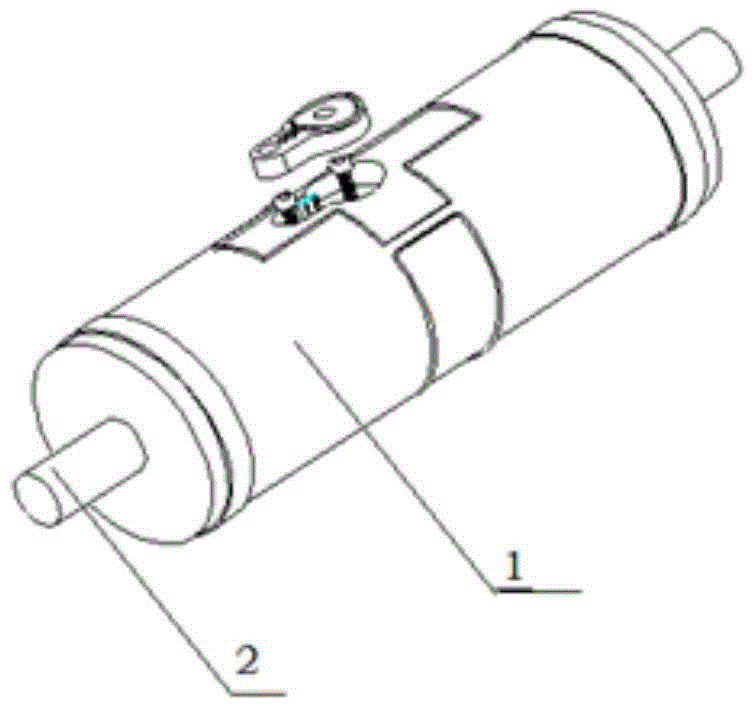

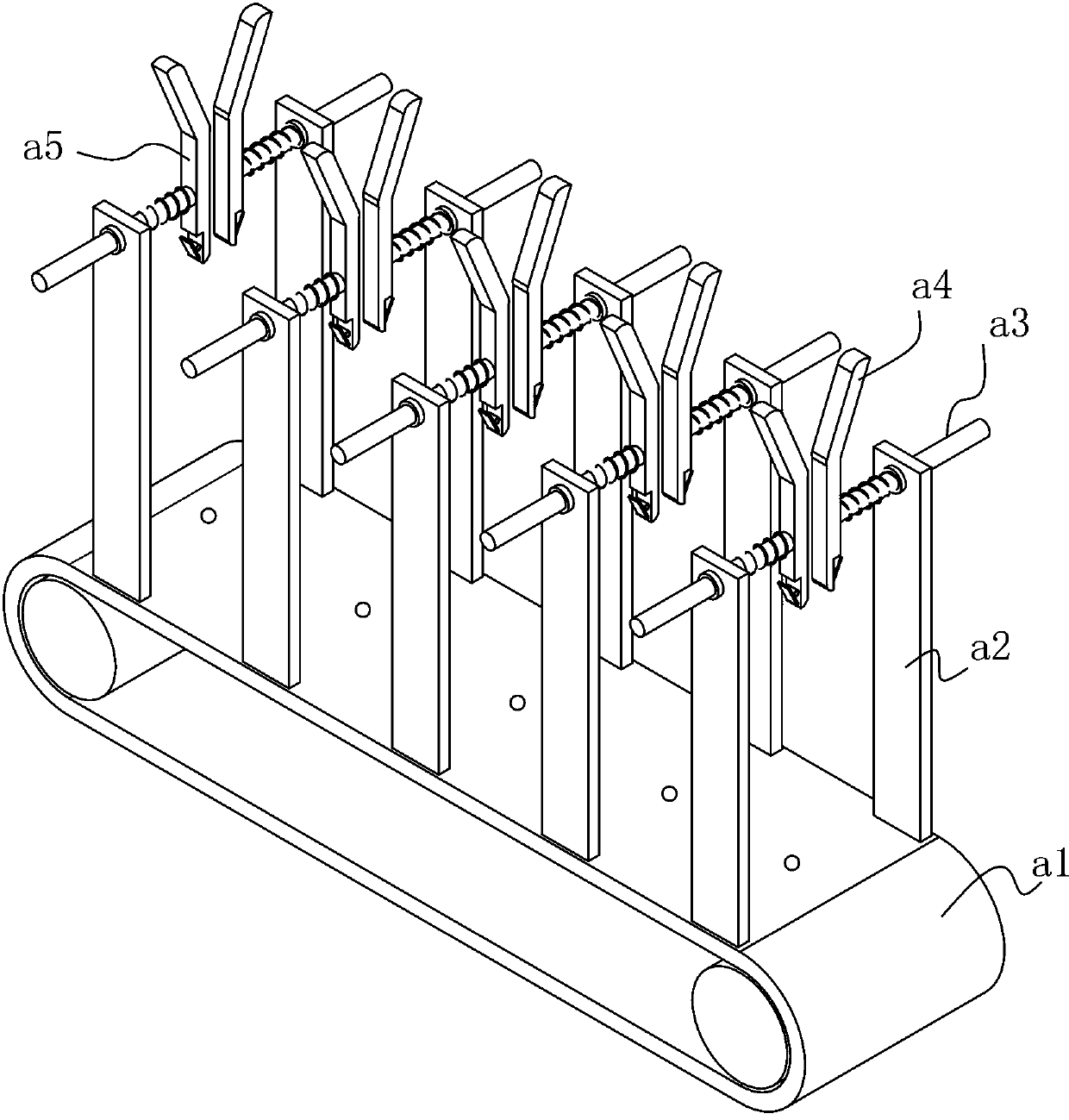

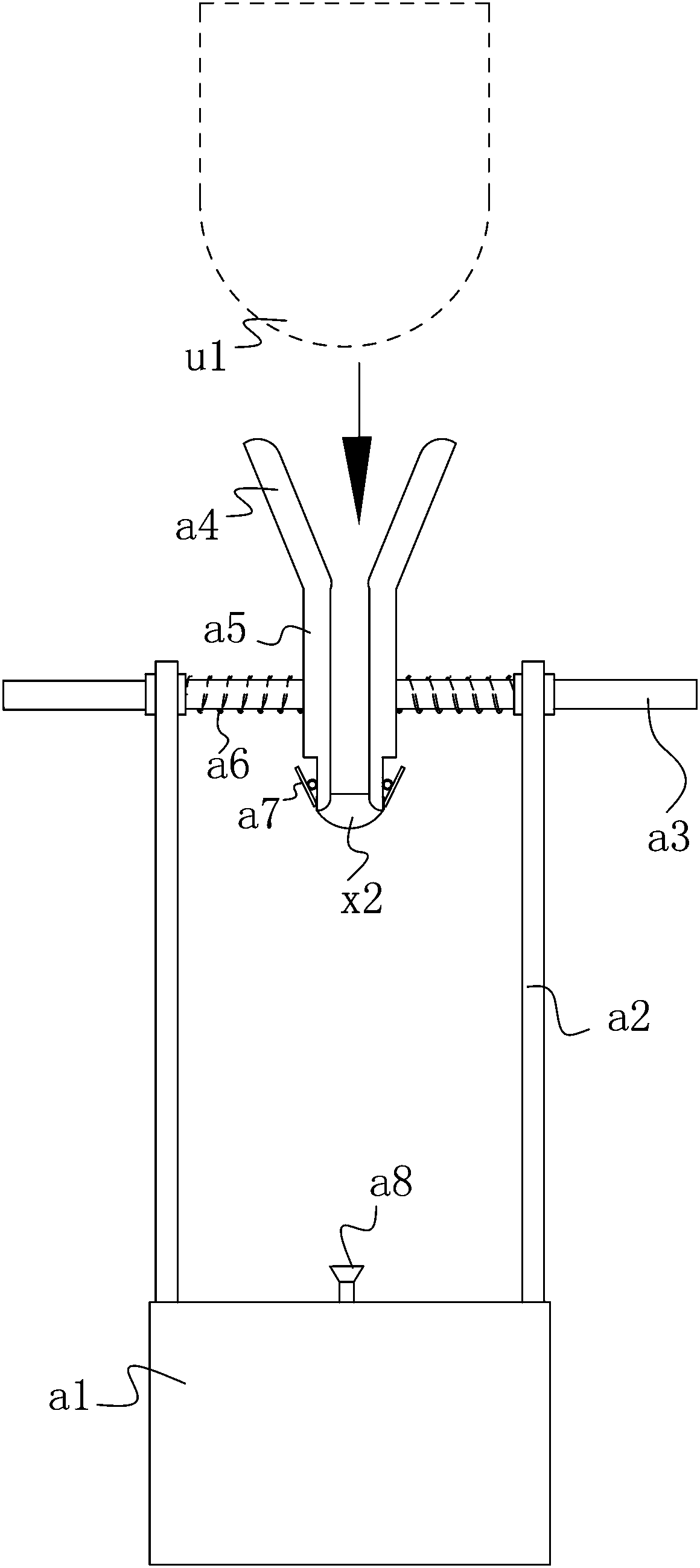

Reamer

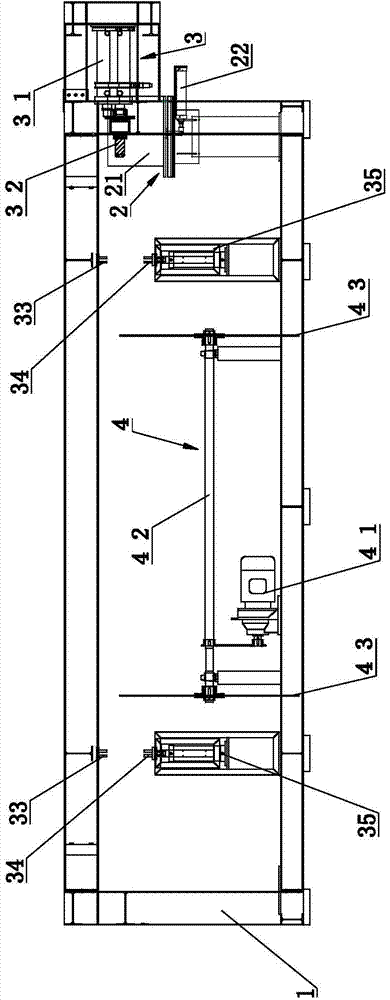

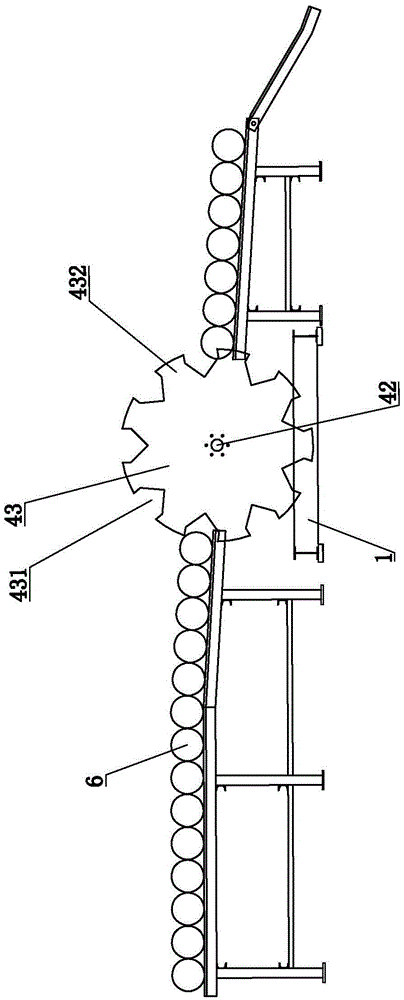

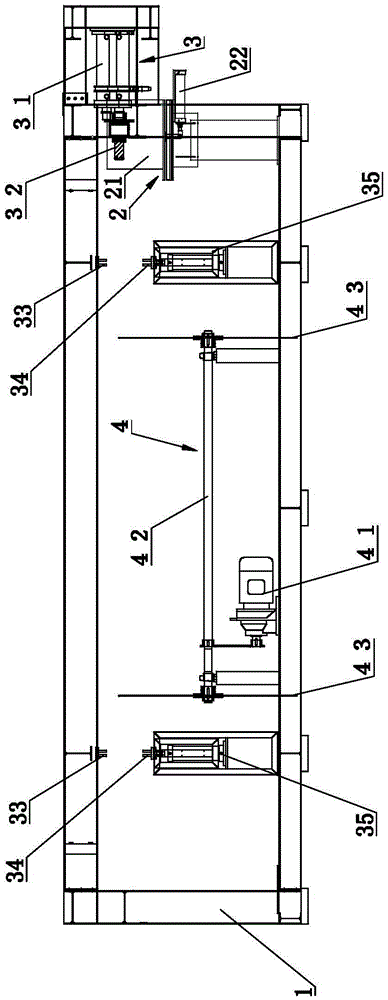

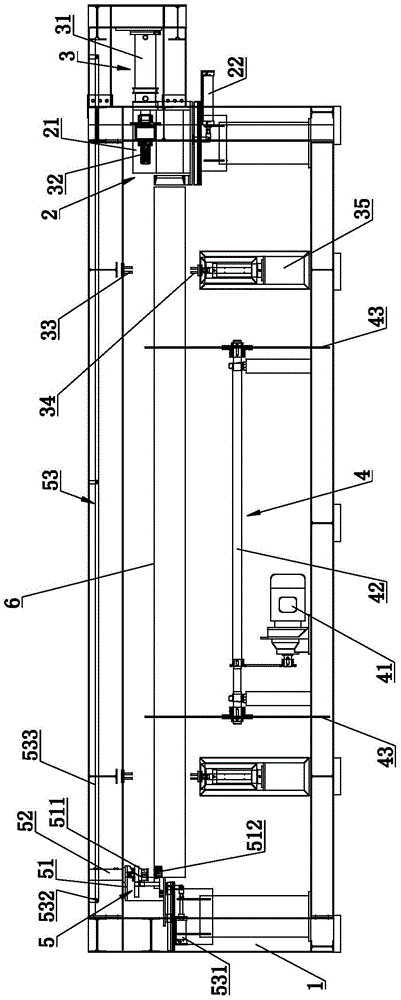

ActiveCN104492988AIncrease productivitySave energyShaping toolsMetal-working feeding devicesReamerSmall footprint

The invention discloses a reamer. The reamer comprises a rack, wherein the rack is provided with an electromagnetic heating device and a reaming device which are arranged from front to back in sequence; the electromagnetic heating device comprises an electromagnetic heating coil; the reaming device comprises a reaming hole driven by a first power device; the rack is provided with a poking plate feeding device; the poking plate feeding device comprises a rotating shaft connected with a second power device; the rotating shaft is transversely arranged on the rack; the two ends of the rotating shaft are fixedly provided with circular poking plates; the peripheral parts of the poking plates are provided with at least three feeding fork entries for conveying metal pipes; poking plates are formed between adjacent feeding fork entries and can rotate to the positions, corresponding to the electromagnetic heating coil and a reaming head, on every two adjacent feeding fork entries respectively. The reamer has the advantages of high production efficiency, small floor area and low power consumption.

Owner:高密天一机械科技有限公司

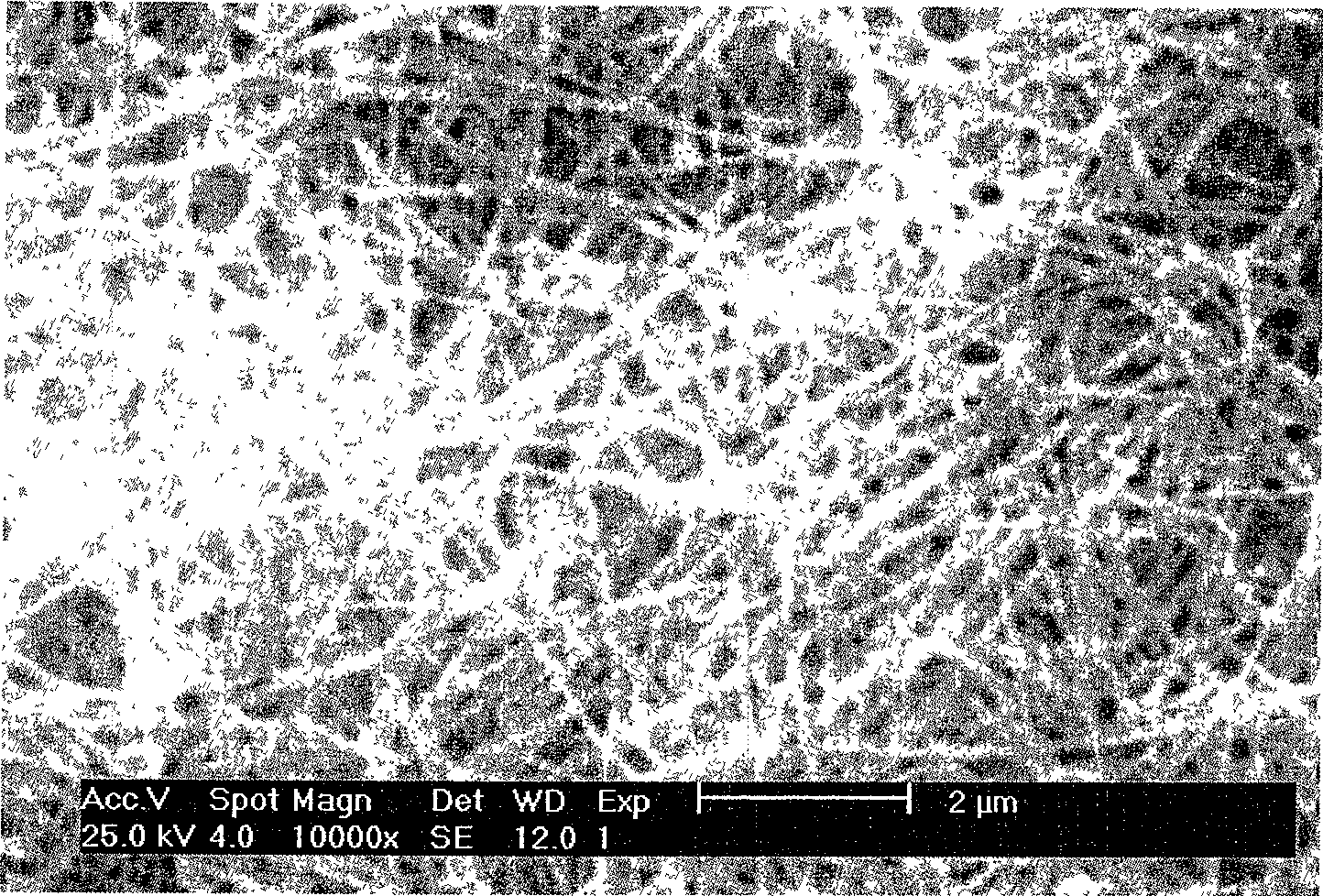

Method for preparing Nano tube of zirconium dioxide

InactiveCN101049964ASimple processEasy to operateNanostructure manufactureZirconium oxidesSolventZirconium dioxide

This invention relates to a method for preparing ZrO2 nanotubes by anodic oxidation. The method comprises: mixing formamide and alcohol solvent at a volume ratio of (1-3):1 to obtain a mixed solvent, preparing 0.5-1.5 wt.% fluoride solution, introducing the fluoride solution into a reactor with Zr plate as the anode and Pt plate or graphite plate as the cathode, performing anodic oxidation under 10-90 V DC at room temperature to generate ZrO2 nanotubes on the Zr plate, falling off during the reaction, separating precipitated to the bottom of the reactor, washing with water, and drying at 105 deg.C to obtain ZrO2 nanotubes. The distance between the anode and the cathode is 1.5 cm. The method has such advantages as simple process, low cost, no pollution and uniform wall thickness of ZrO2 nanotubes.

Owner:HEBEI UNIV OF TECH

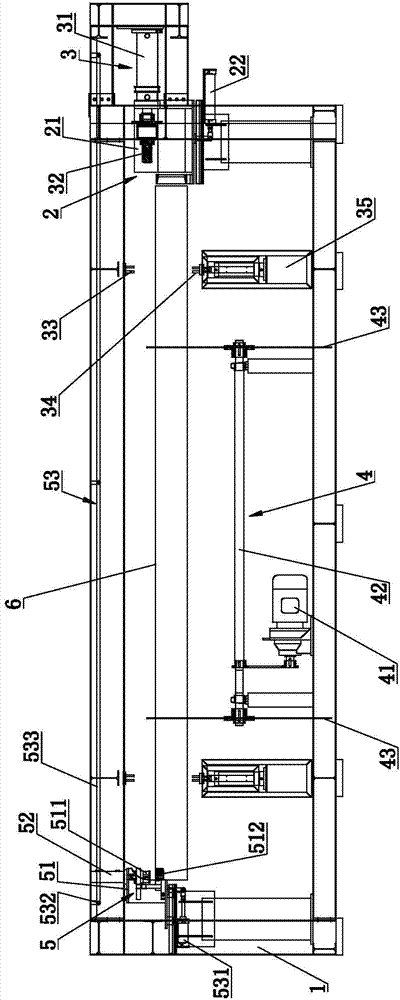

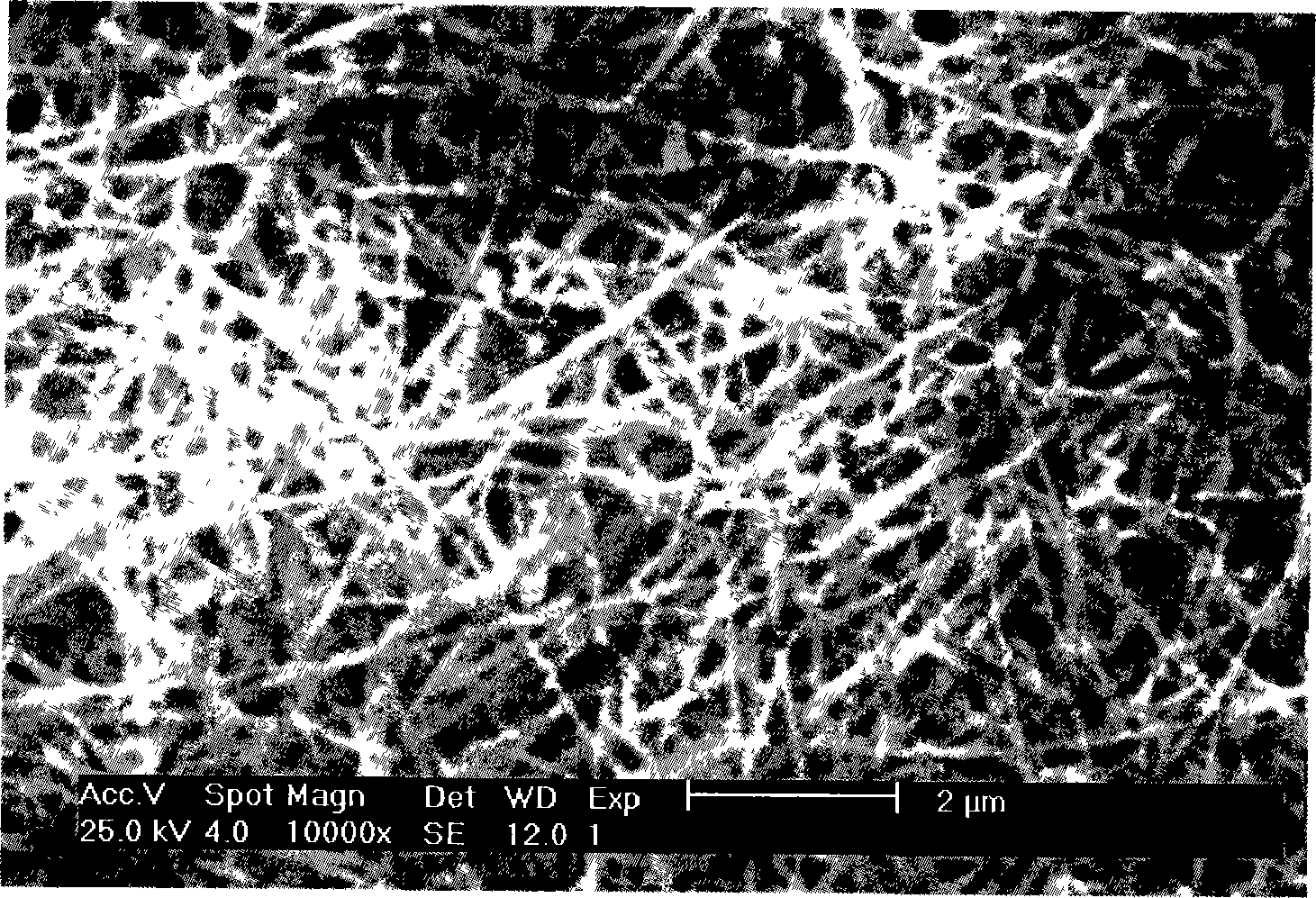

Calcining process of synthesizing hollow silica alumina ball

The calcining process of synthesizing hollow silica-alumina ball includes the steps of crushing sawdust, mixing with water and adhesive, making wet ball kernel, turning the wet ball kernel in ball forming machine in proper rotation speed while throwing proper amount of refractory silica-alumina powder for coating the ball kernel, and calcining at high temperature to produce the hollow silica-alumina ball. The hollow silica-alumina ball has low bulk density, low production cost and other advantages, and is used as the material for producing high grade refractory material. The present invention makes it possible to producing light refractory material with bulk density smaller than 0.6 g / cu cm.

Owner:平顶山新型耐材股份有限公司

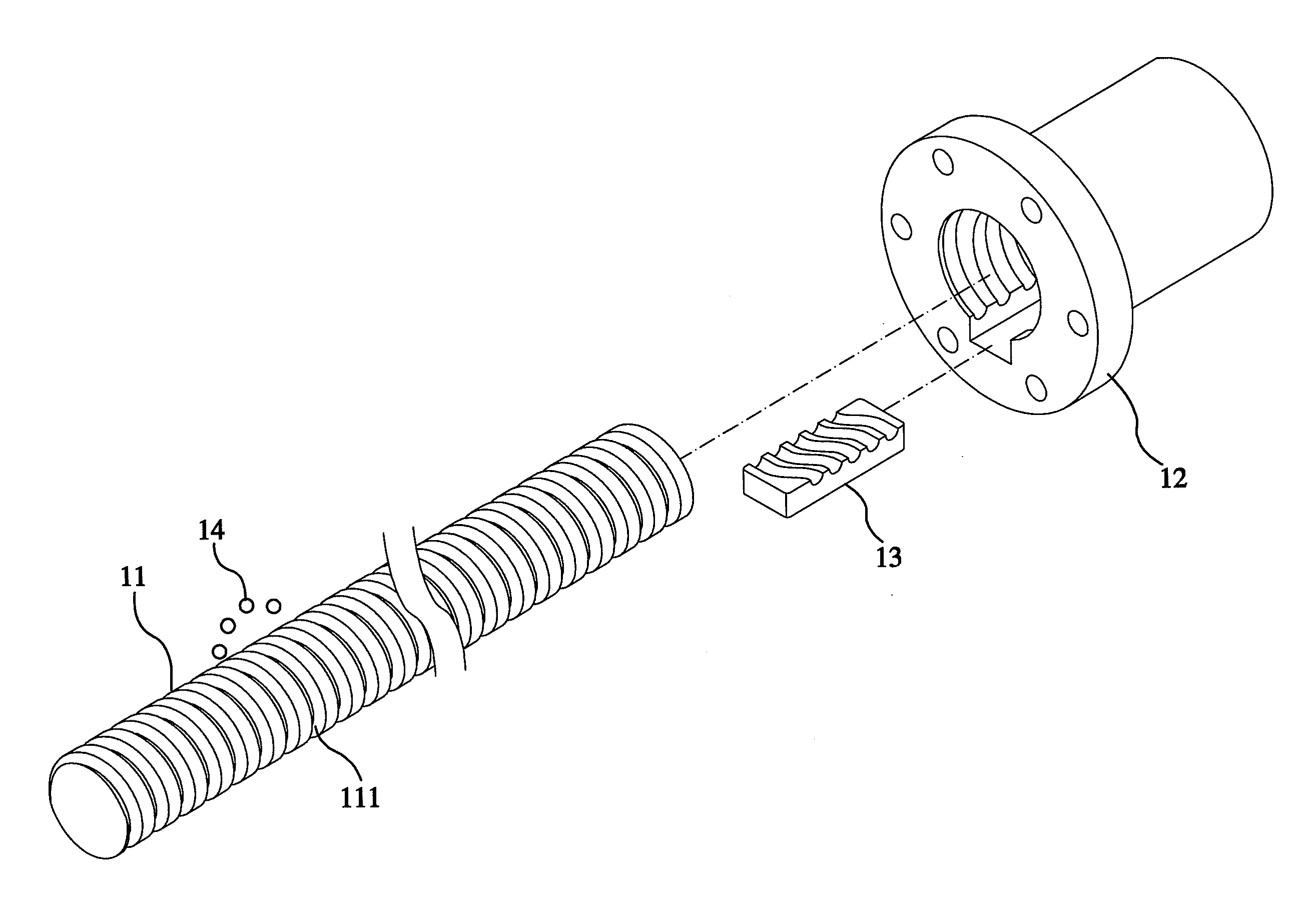

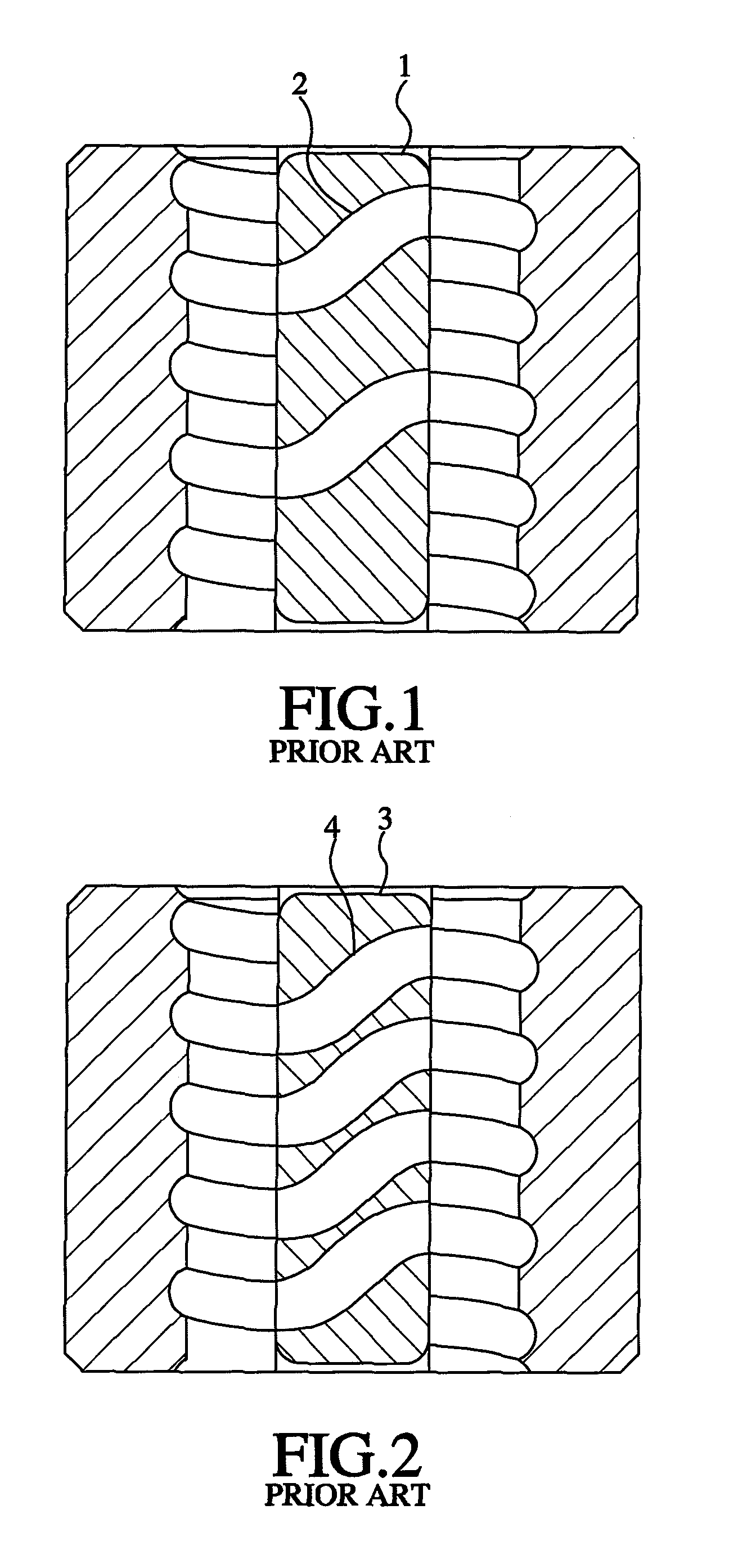

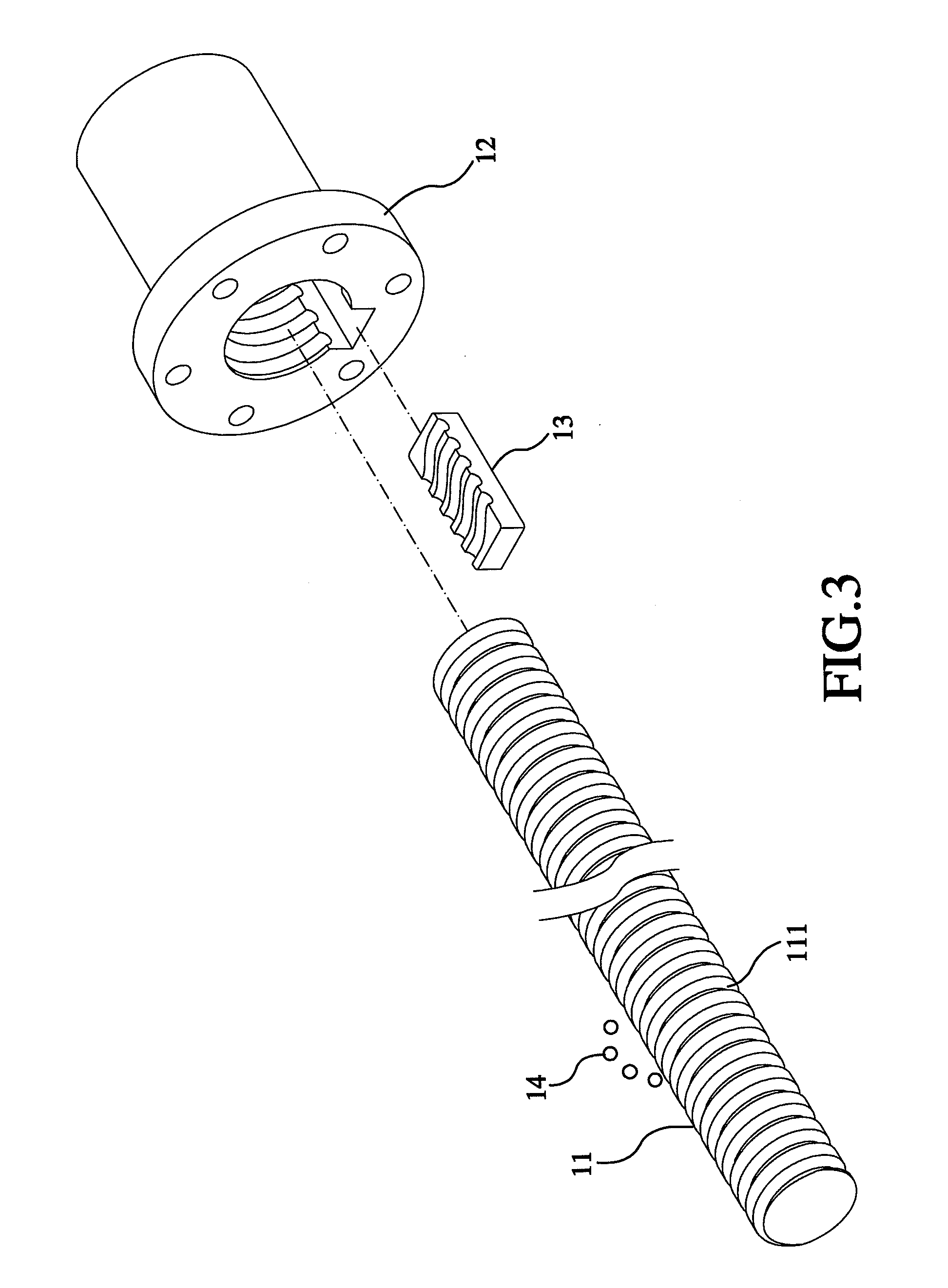

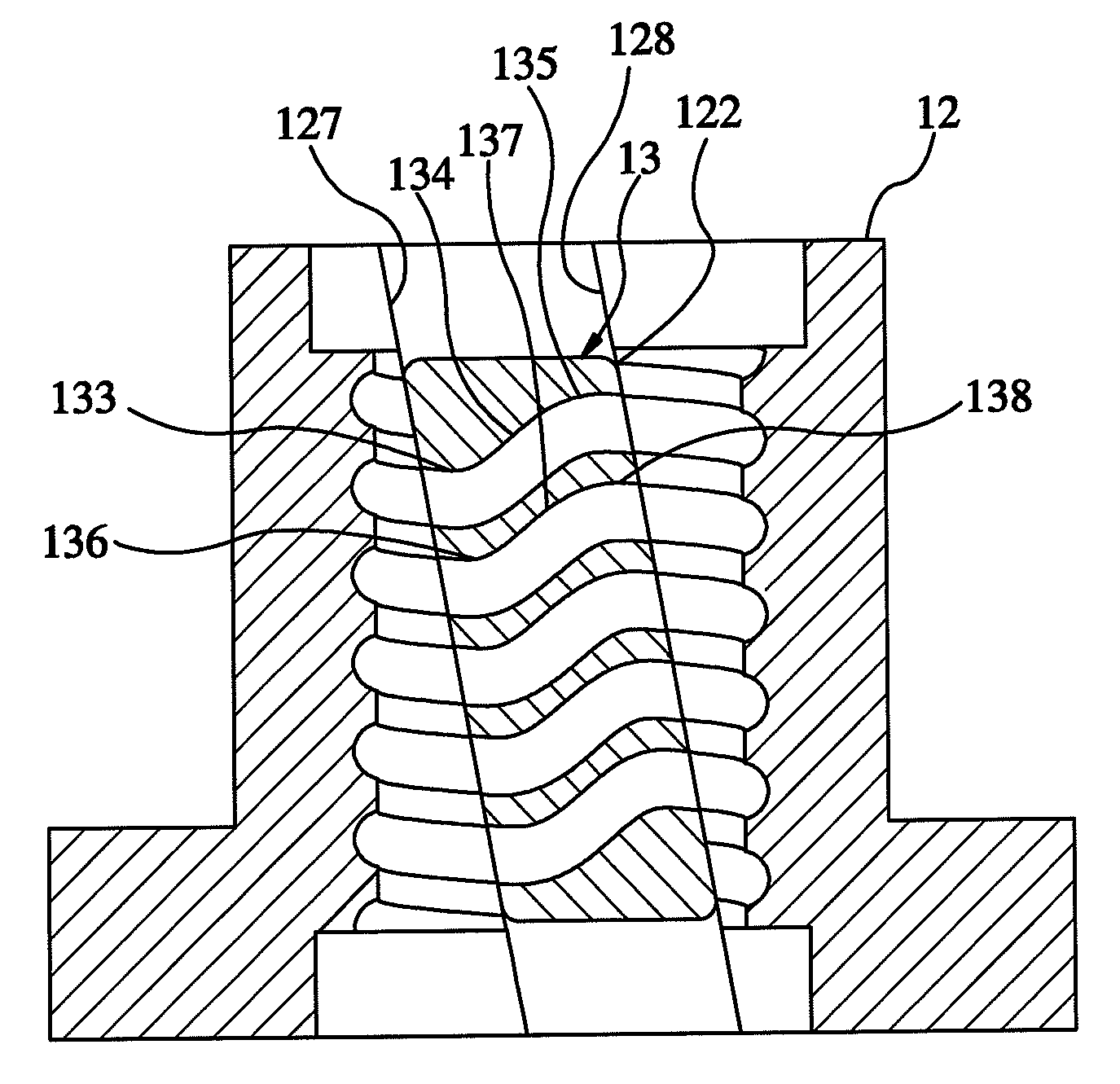

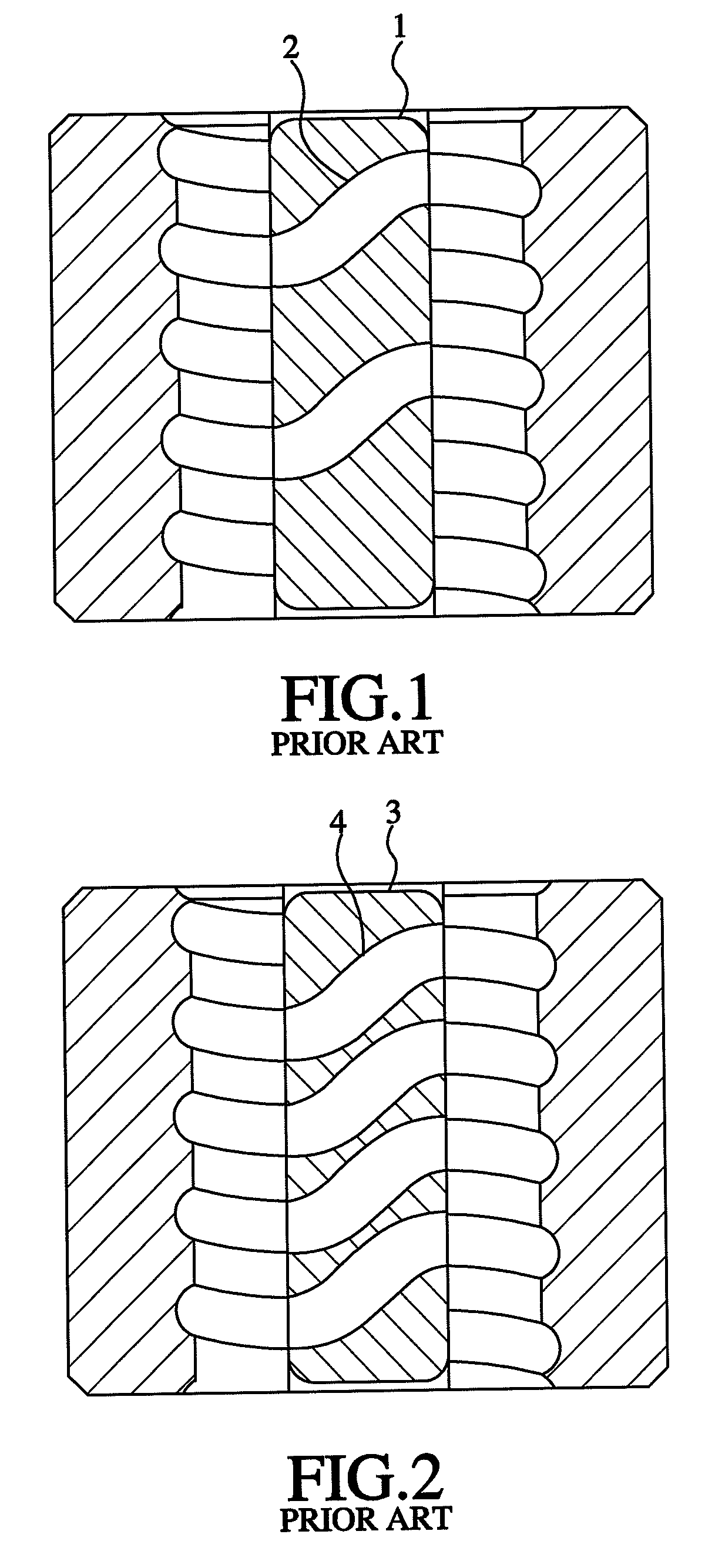

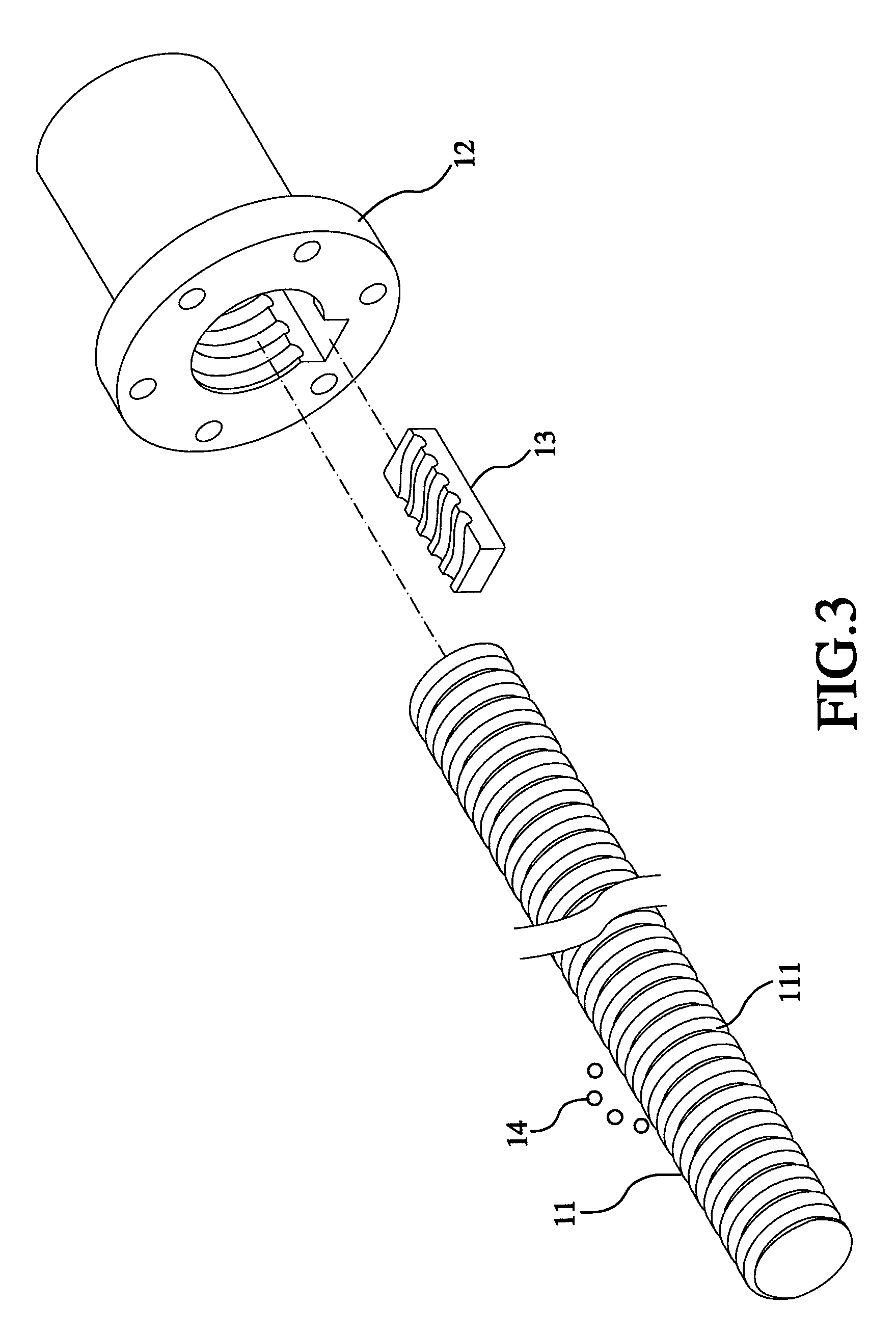

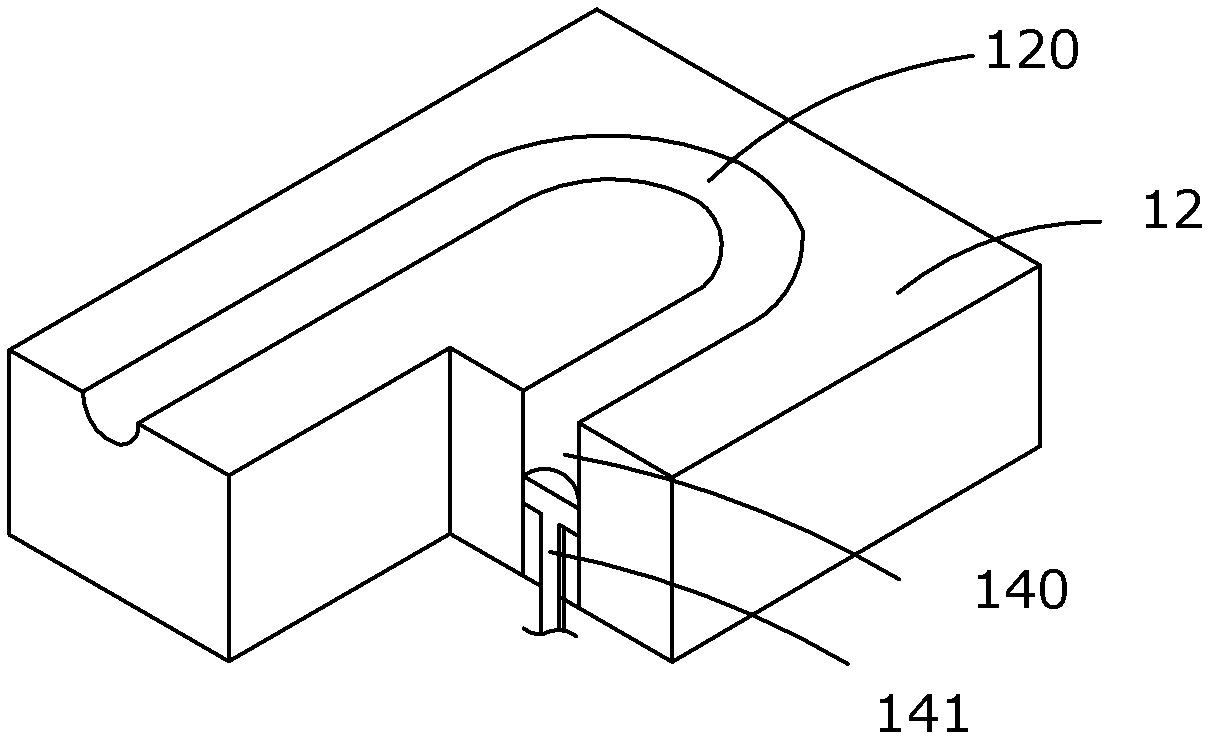

Internal circulation ball screw

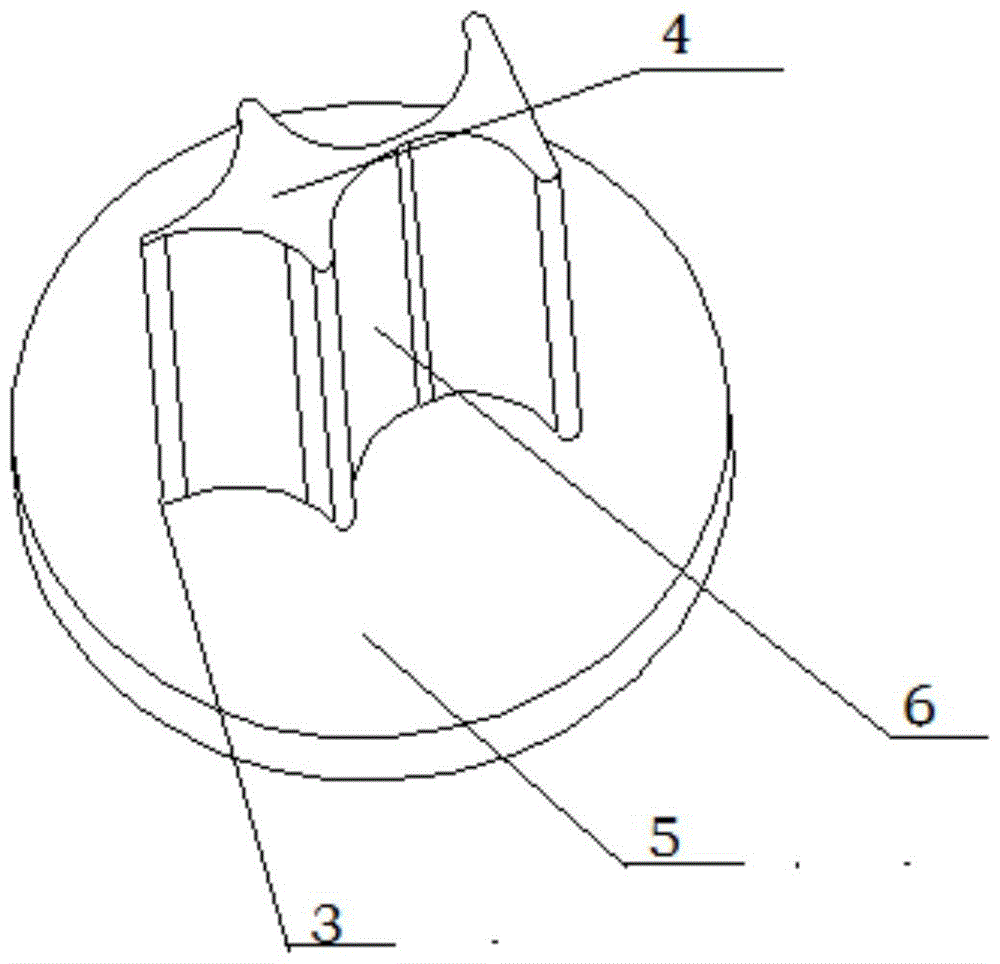

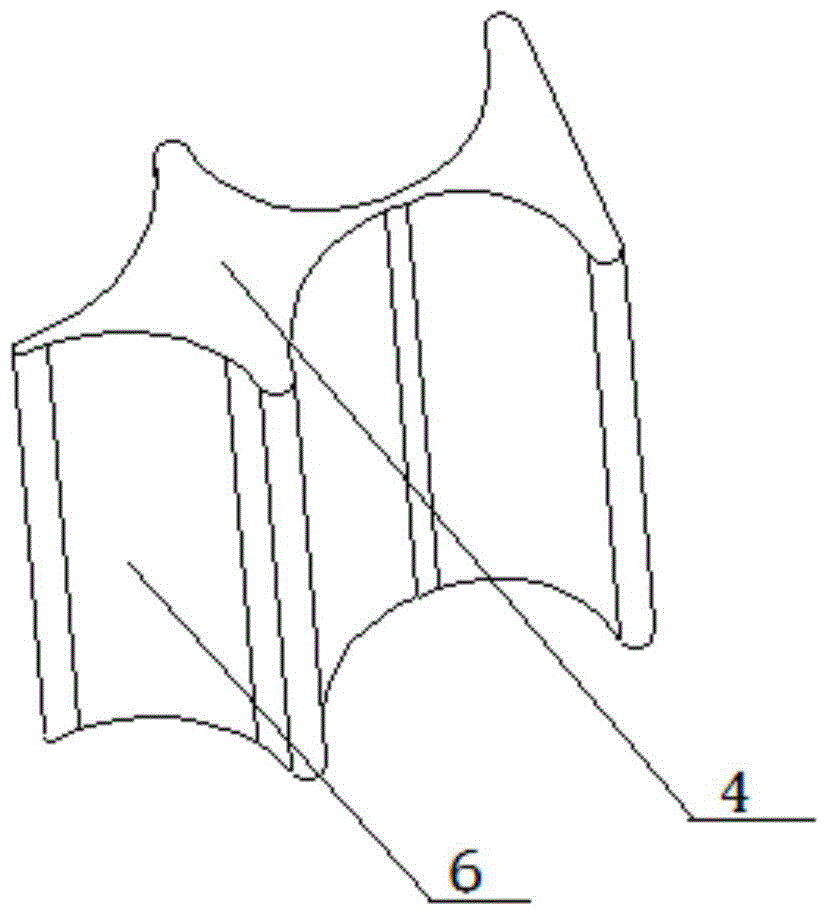

ActiveUS20130133453A1Uniform wallIncreased durabilityPortable liftingToothed gearingsBall screwEngineering

An internal circulation ball screw includes a threaded shaft, a nut having a receiving space, a circulation member mounted to the receiving space and having a first circulation groove and a second circulation groove, and a plurality of rolling members running between the threaded shaft and the nut. The first circulation groove defines a first front section, a first rear section, and a first curved section communicating with the first front section and the first rear section separately. The second circulation groove defines a second front section, a second rear section, and a second curved section communicating with the second front section and the second rear section separately. The first and second curved sections define a predetermined included angle with respect to the threaded shaft radially. Therefore, the wall between the circulation channels is uniform to enhance the durability of the ball screw.

Owner:HIWIN TECH

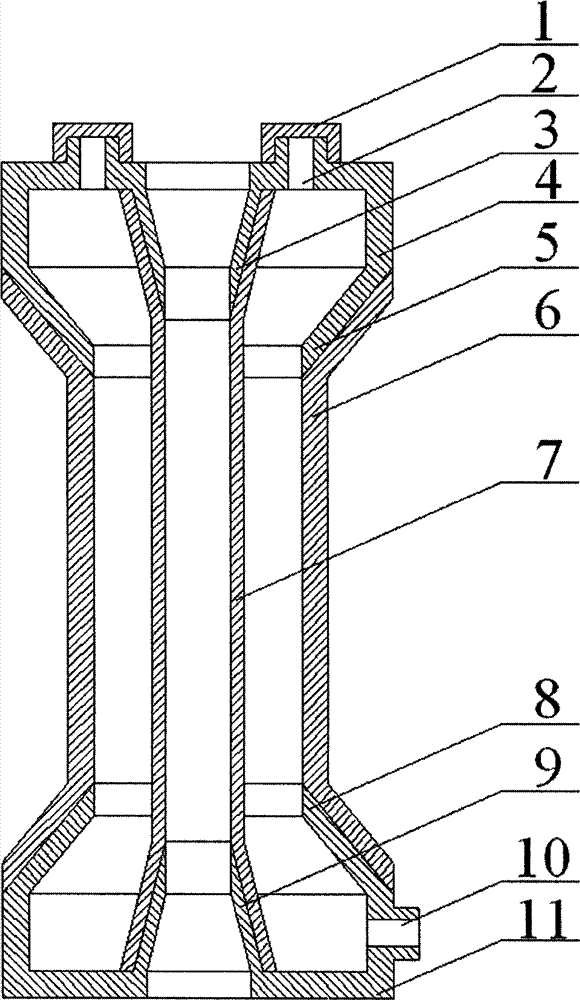

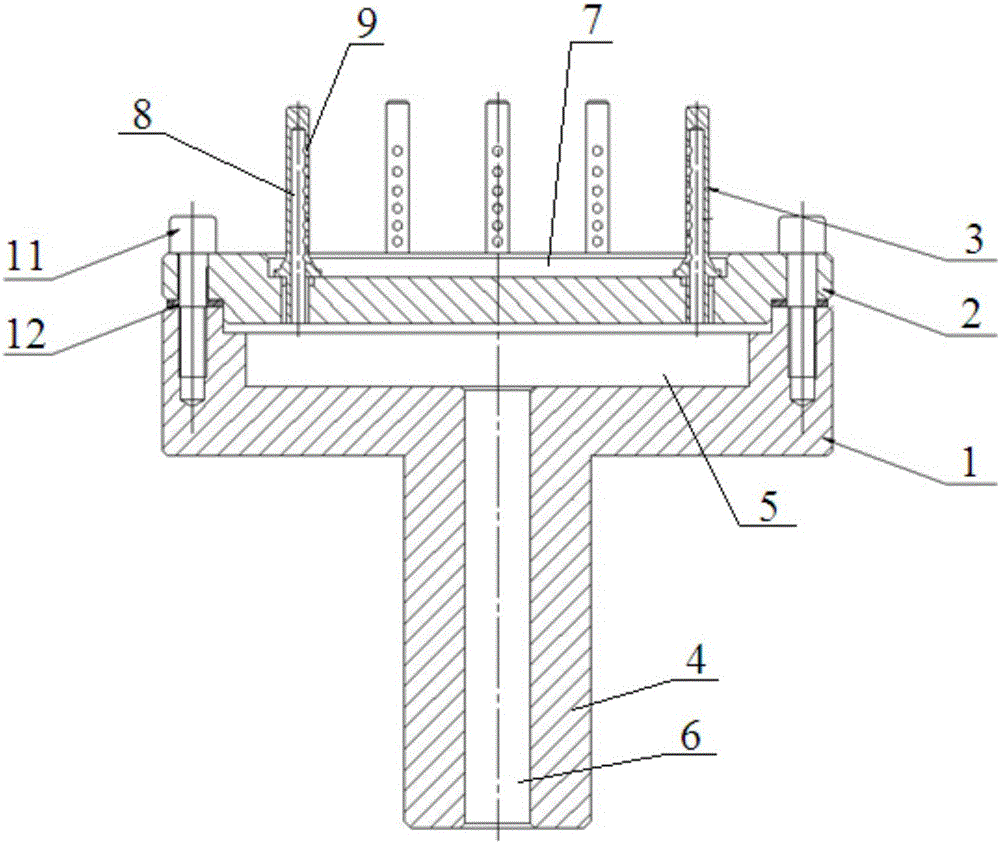

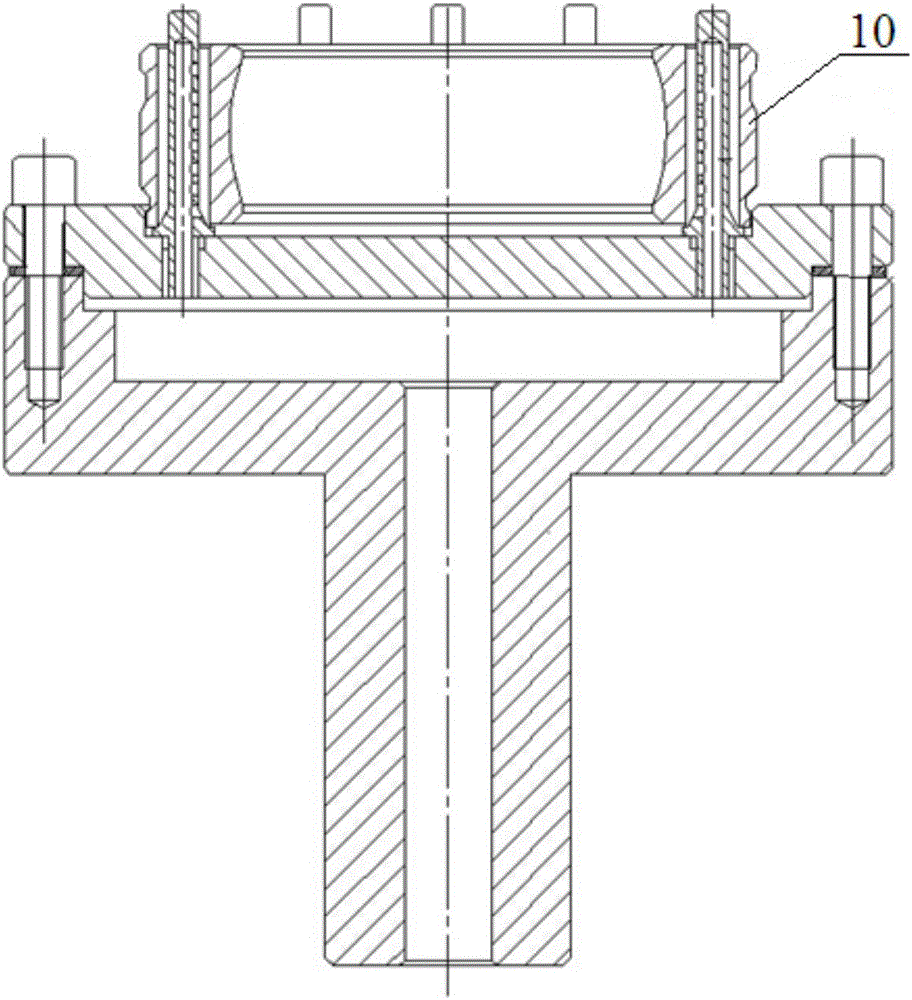

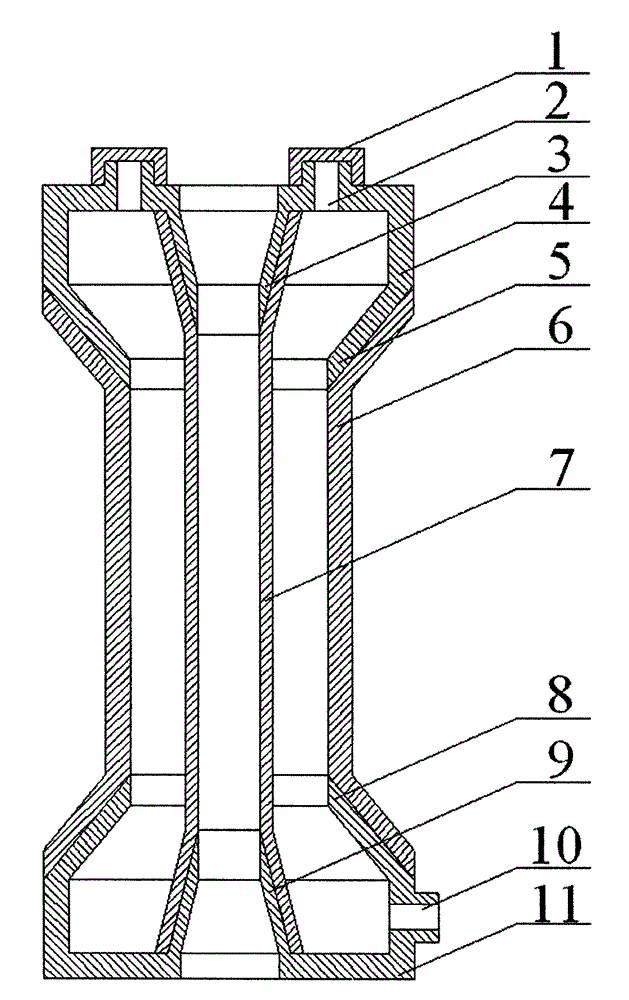

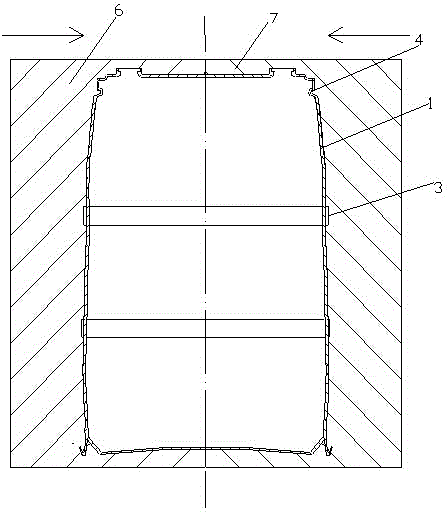

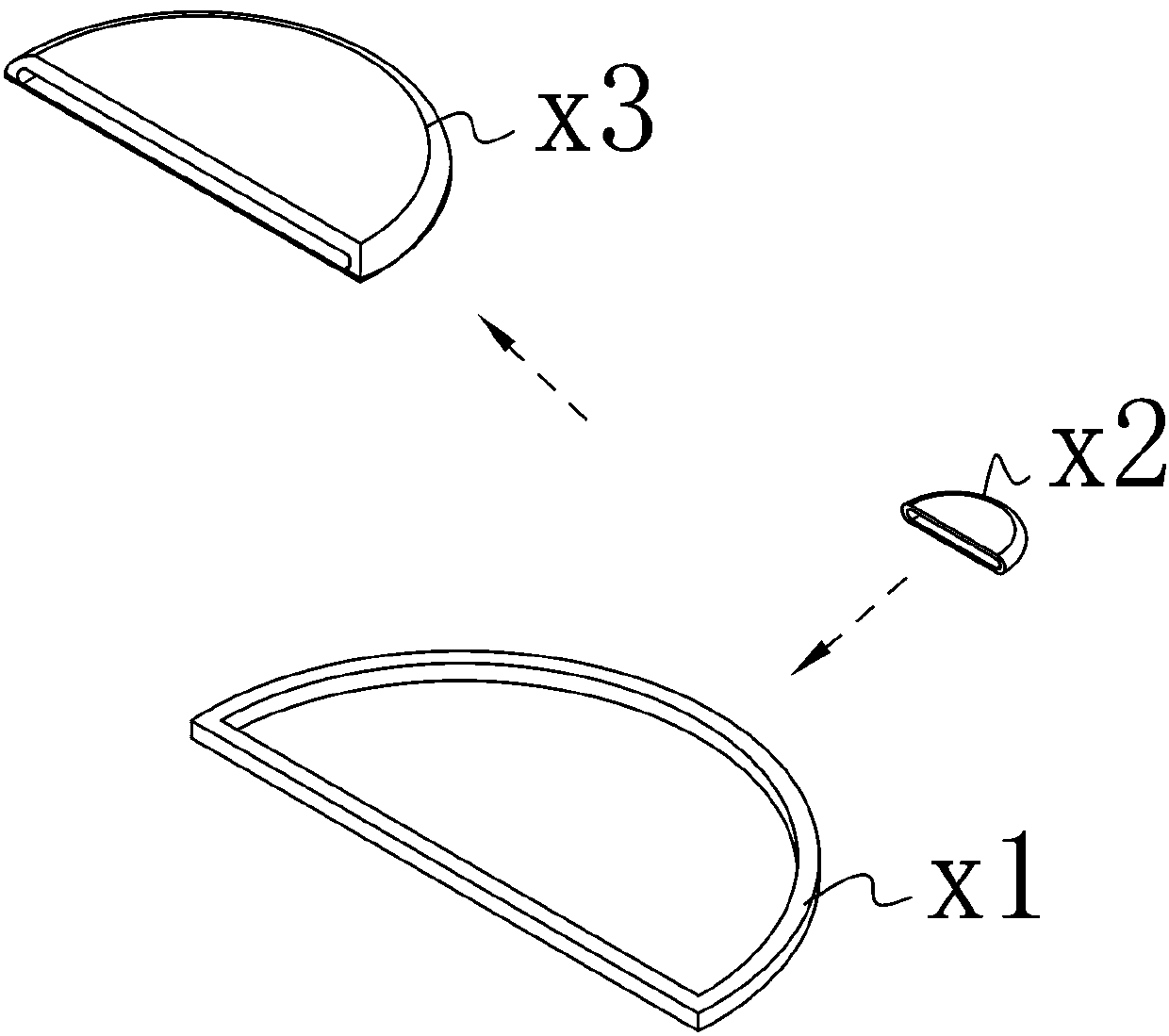

Artificial blood vessel preparing device

The invention relates to an artificial blood vessel preparing device and belongs to the biomedical engineering field. The preparing device is formed by connecting a combined upper cover, an outer mold tube, an inner mold tube, and a combined lower cover in a combined mode. The inner wall of the top of the combined upper cover is provided with an upper inner mold tube connector. An upper outer mold tube connector is arranged at the lower end of the combined upper cover. The inner wall of the bottom of the combined lower cover is provided with a lower inner mold tube connector. A lower outer mold tube connector is arranged at the upper end of the combined lower cover. The side wall of the combined lower cover is provided with an air pumping hole. The upper outer mold tube connector and the upper inner mold tube connector in the combined upper cover are respectively connected with one end of the outer mold tube and one end of the inner mold tube, and the lower outer mold tube connector and the lower inner mold tube connector in the combined lower cover are respectively connected with the other end of the outer mold tube and the other end of the inner mold tube. The artificial blood vessel preparing device changes the current situations that a large number of complicated devices are needed to prepare artificial blood vessels at present, and vessel walls of the artificial blood vessels are uneven, and has the advantages of being reasonable in structure, convenient to install, and simple to operate and use.

Owner:WUHAN TEXTILE UNIV

Medicinal plastic bottle and manufacturing method thereof

InactiveCN102070818AWell mixedUniform wallPharmaceutical containersMedical packagingEngineeringPolypropylene

The invention discloses a medicinal plastic bottle and a manufacturing method thereof, and belongs to the technical field of medicinal plastic bottle processing. The medicinal plastic bottle is characterized by being manufactured by the following raw materials in part by weight: 95 parts of polyethylene, 5 parts of polypropylene and 4 parts of color concentrate. The manufacturing method is characterized by comprising the following steps of: 1) adding the polyethylene, the polypropylene and the color concentrate into a mixer; (2) uniformly mixing the materials in the mixer to obtain a mixture; (3) molding the mixture into a blank by injection; (4) molding the blank by blowing; and (5) de-bottling. dhpe / pp raw materials are adopted and the raw materials are fully and uniformly blended, so the bottle wall is uniform, the permeability resistance is high, the shelf storage period of filled medicaments is long, materials are saved and the cost is reduced. The manufacturing method has the advantages of high production efficiency and short period; and compared with a two-station 'pouring-blowing' process, the manufacturing method can realize fully automatic counting and packaging.

Owner:SHANDONG PHARMA GLASS

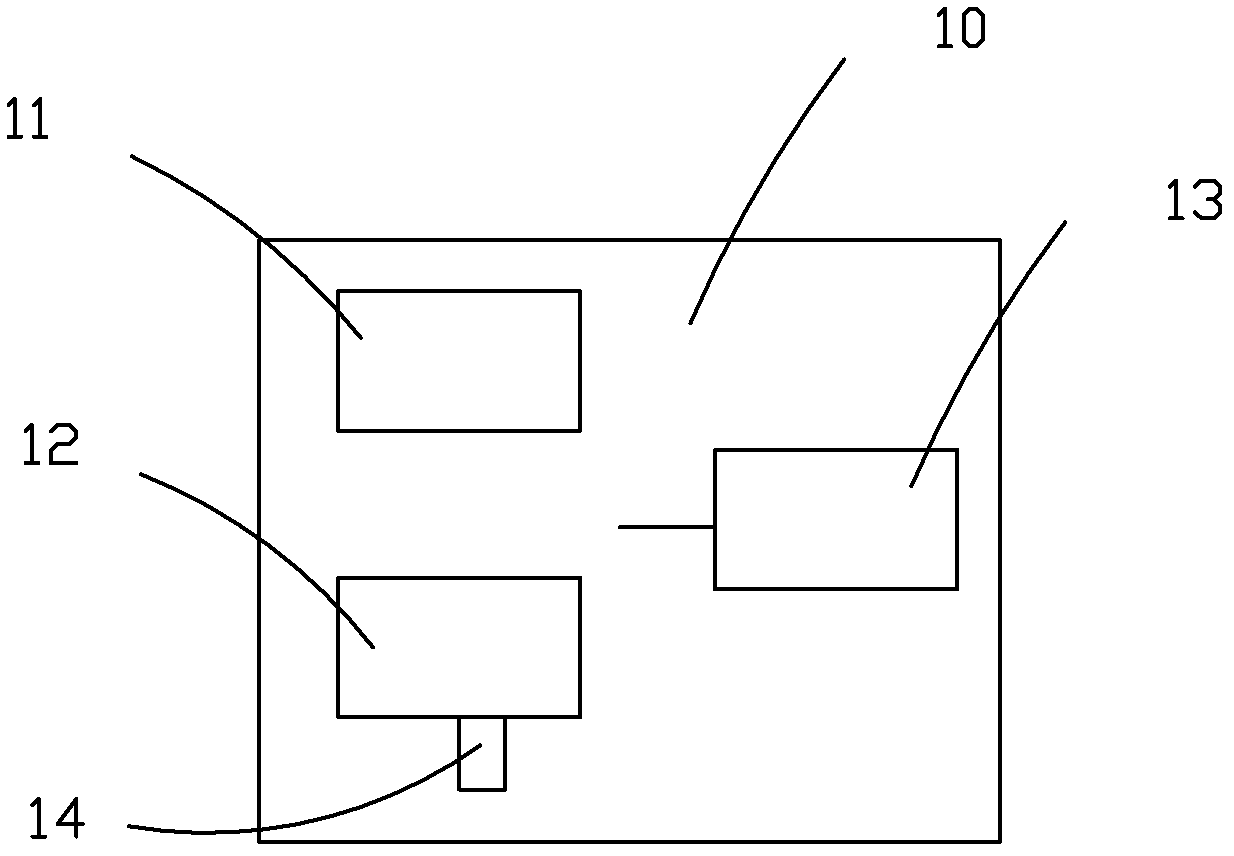

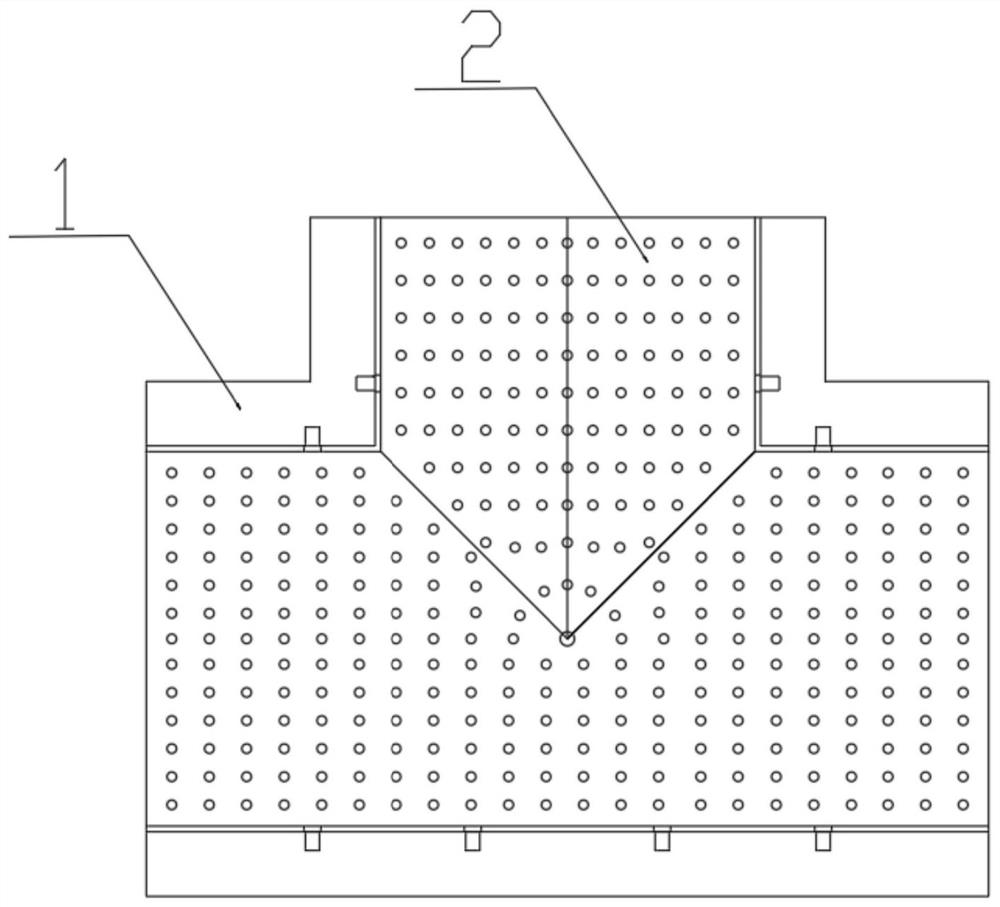

Method for forming connected filter chambers and channels by butt joint of water purifier dual-row filter cartridges and engine bases

InactiveCN103801140AFirmly connectedImprove manufacturing qualityMultistage water/sewage treatmentFiltration separationButt jointFiltration

The invention discloses relates to the water treatment industry, particularly relates to the filtration of drinking water, and discloses a method for forming connected filter chambers and channels by butt joint of water purifier dual-row filter cartridges and engine bases. The connected filter chambers and channels comprise injection molding cartridge bodies with movable covers and seal elements and injection molding engine bases with water passing pipelines; the injection molding cylinder bodies, in which built-in filtering containers are arranged, are of structures bigger in upper part and smaller in lower part; the sealed butt joint parts arranged on the injection molding engine bases are corresponding to the bottom parts of dual-row multi-cavity injection molding cartridge bodies; connected filter cartridges, which are formed by butt joint in a sealed mode by a plastic welding connection technology or a bonding agent bonding technology, are bigger in upper part and smaller in lower part and are connected with the engine base; the connected filter cartridges and the movable covers as well as the seal elements form a plurality of connected seal cavities bigger in upper part and smaller in lower part; a space is reserved in the periphery of the lower part of each cartridge body; each water passing pipeline of the injection molding bases is connected with each filter cartridge in series by correspondingly arranged sealed chamber water passing interfaces so as to form filter channels which are respectively connected with a water inlet and a water outlet of each internally arranged filter cartridge in series, wherein at least one water passing interface is positioned in the sealed butt joint parts of the engine bases and is in butt joint in a sealed mode with water openings with seal elements on the lower end surfaces of the internally arranged filter containers.

Owner:杜也兵

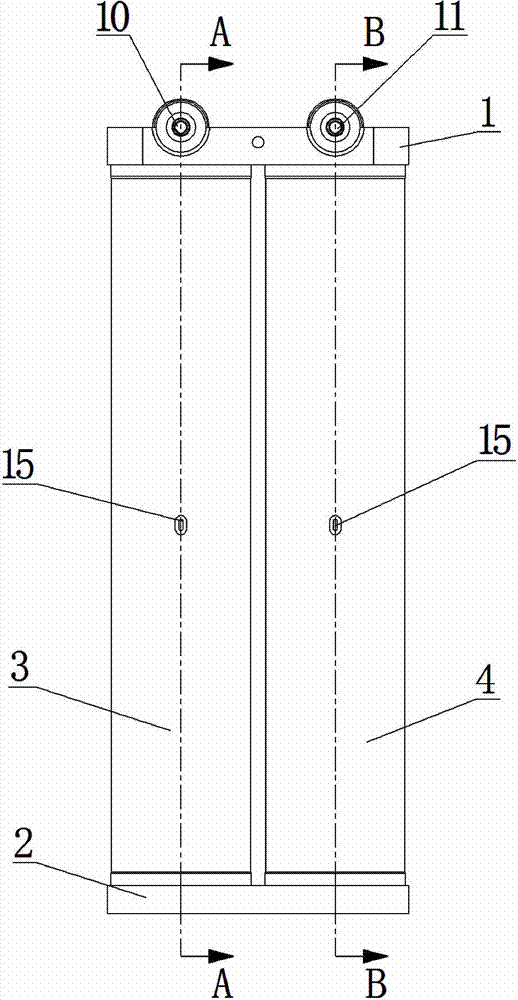

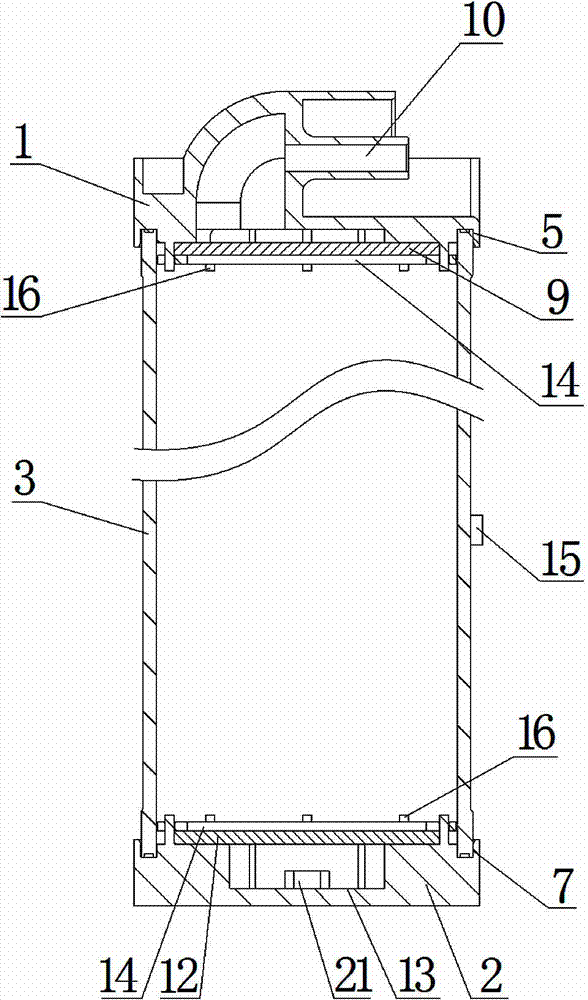

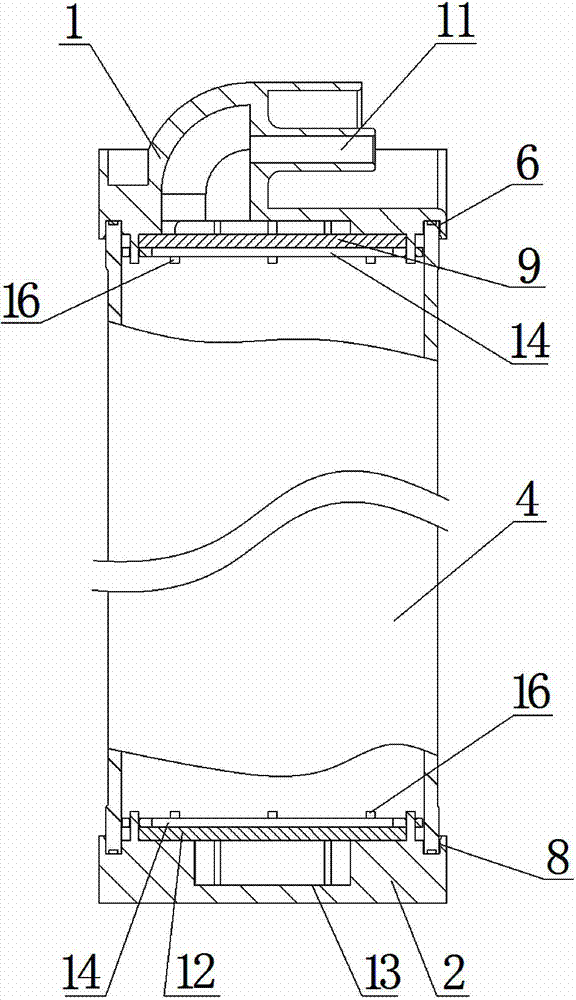

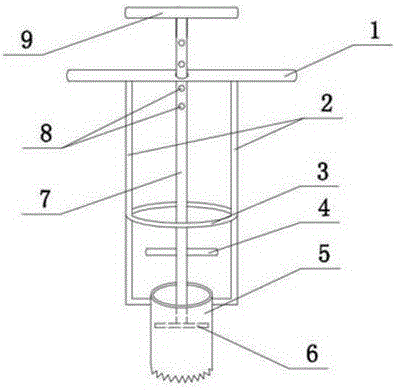

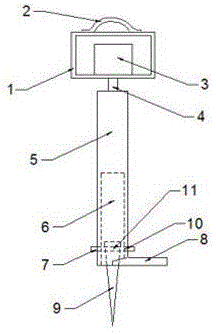

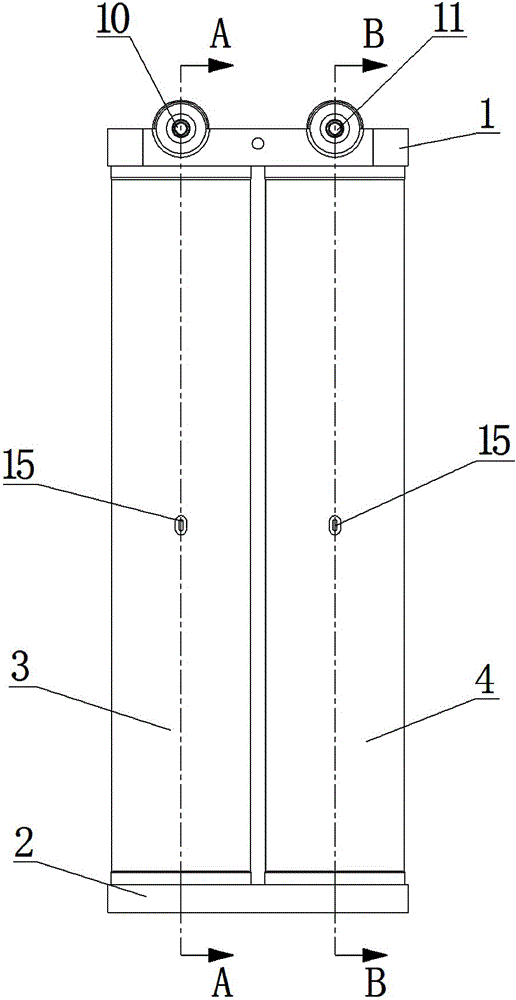

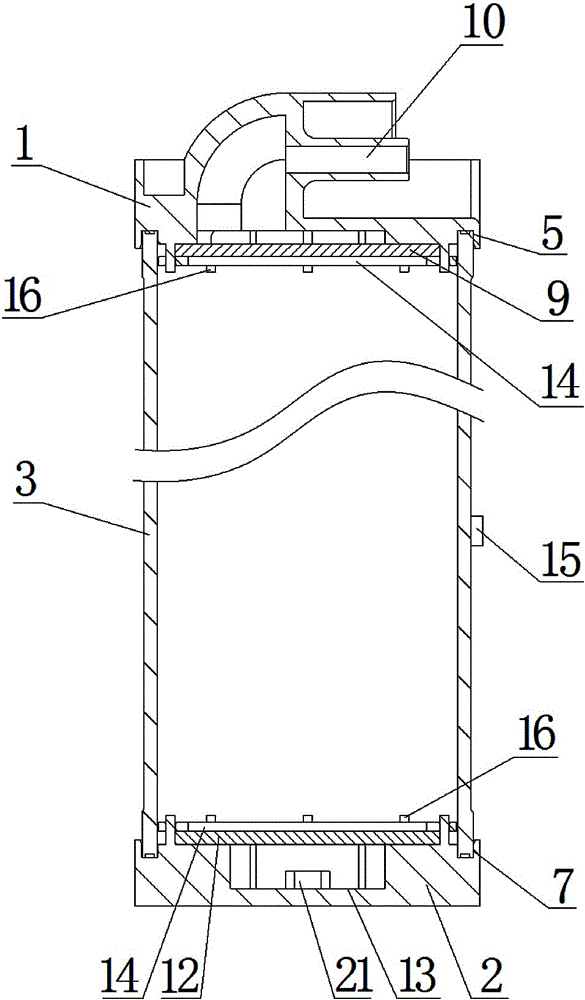

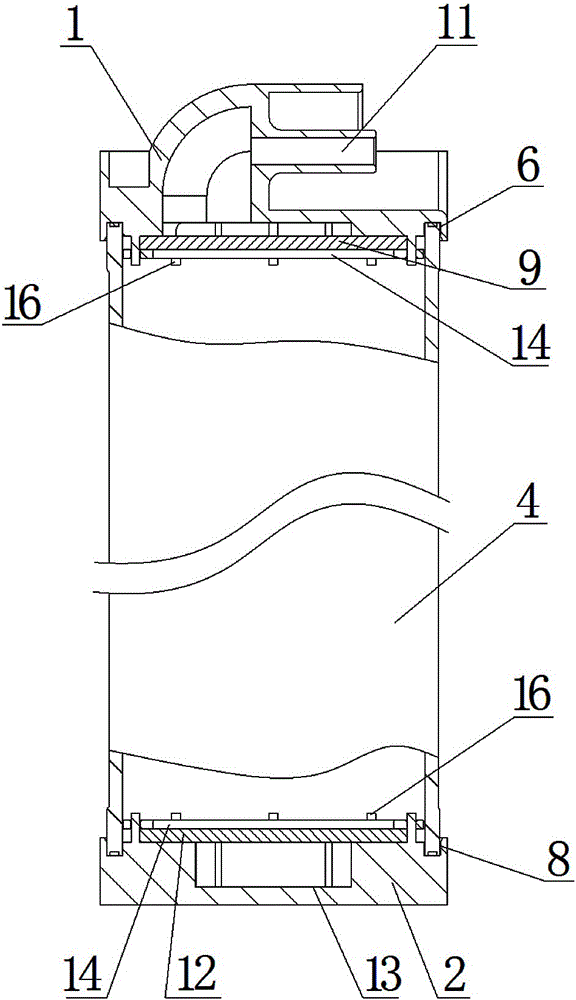

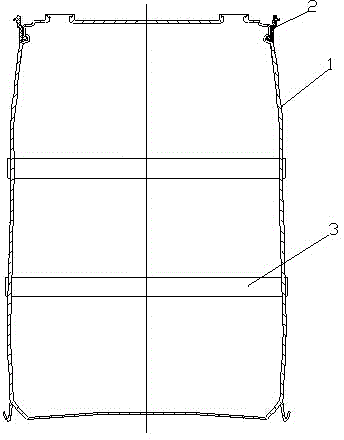

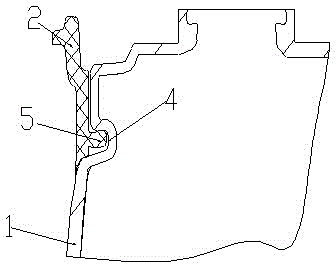

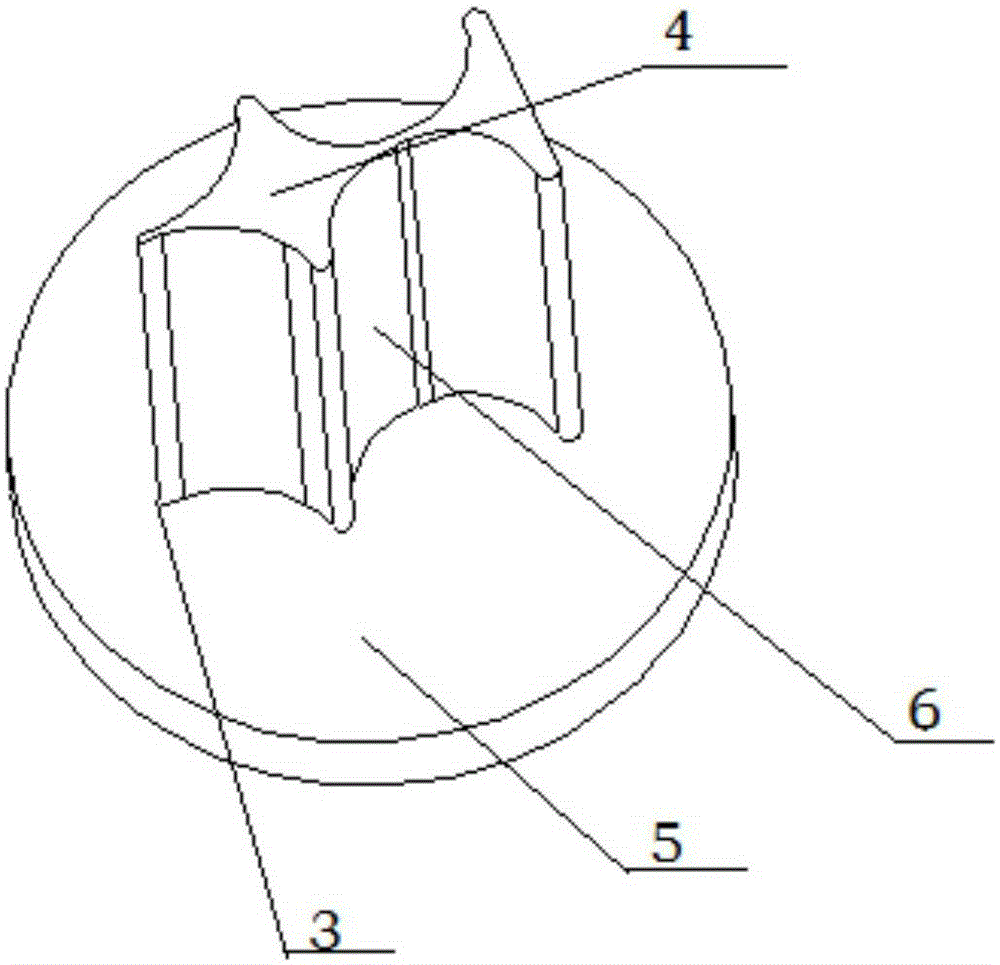

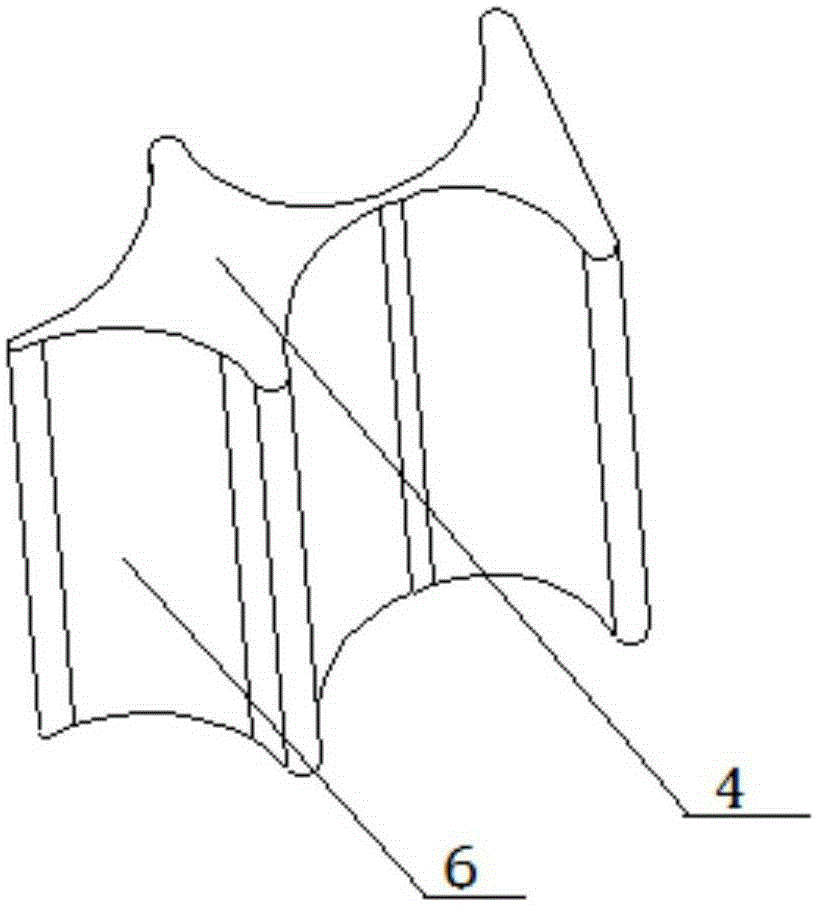

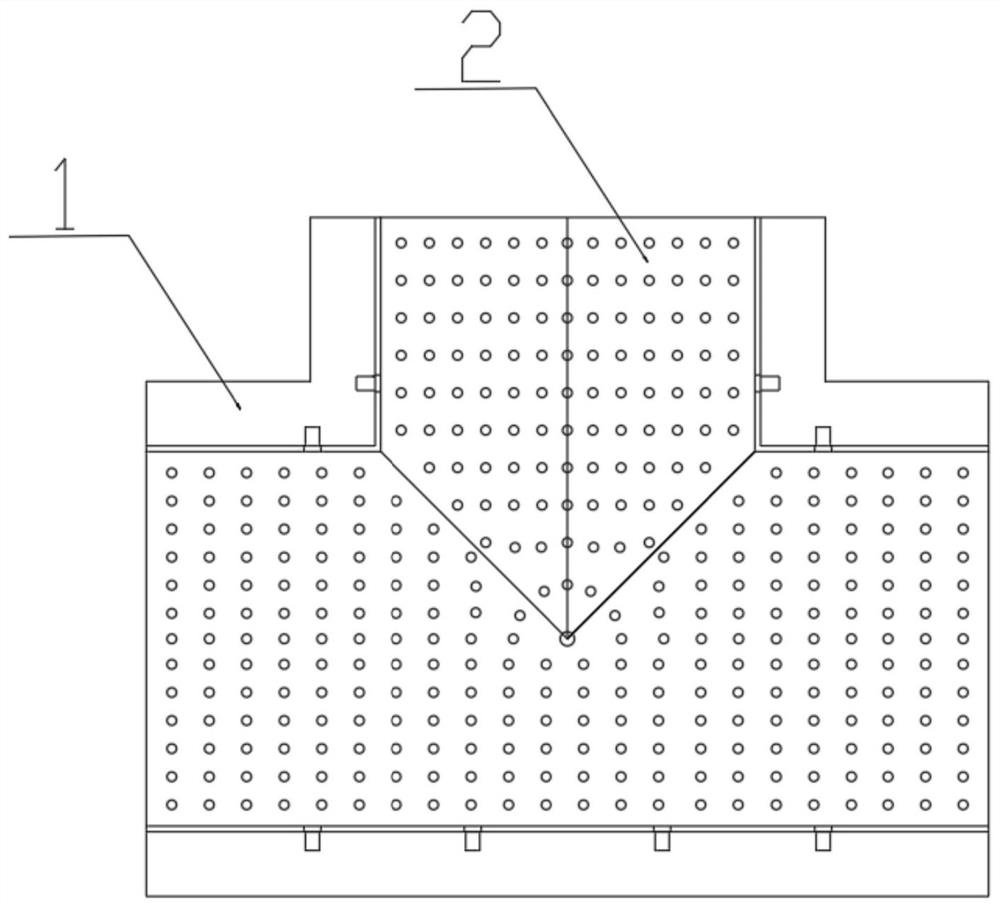

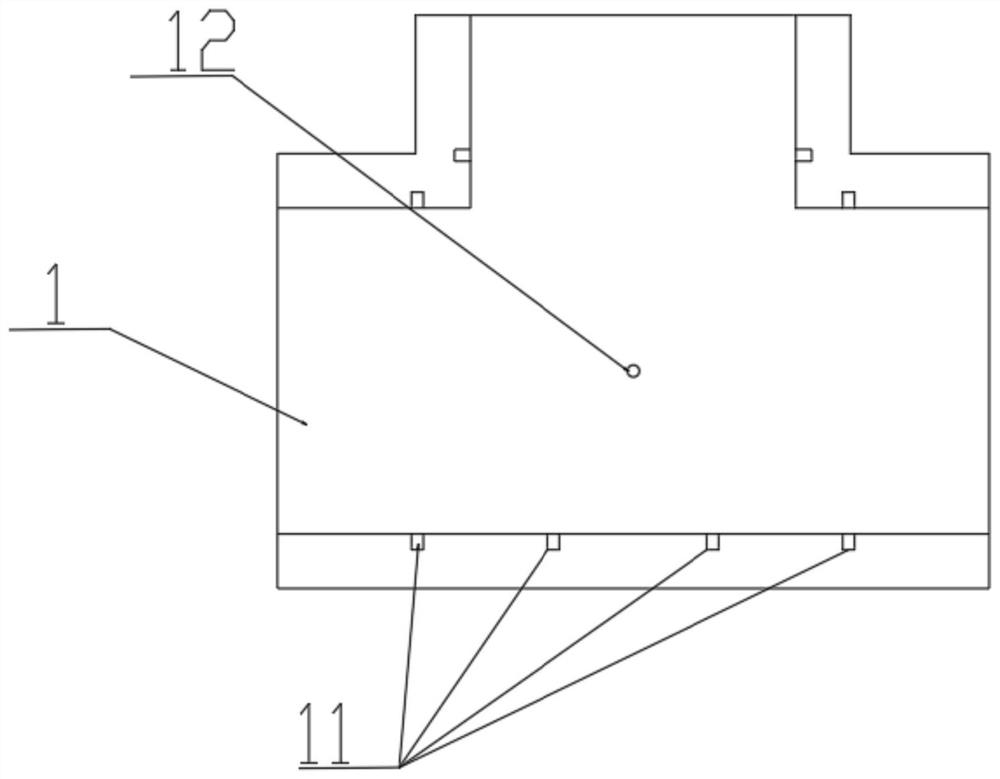

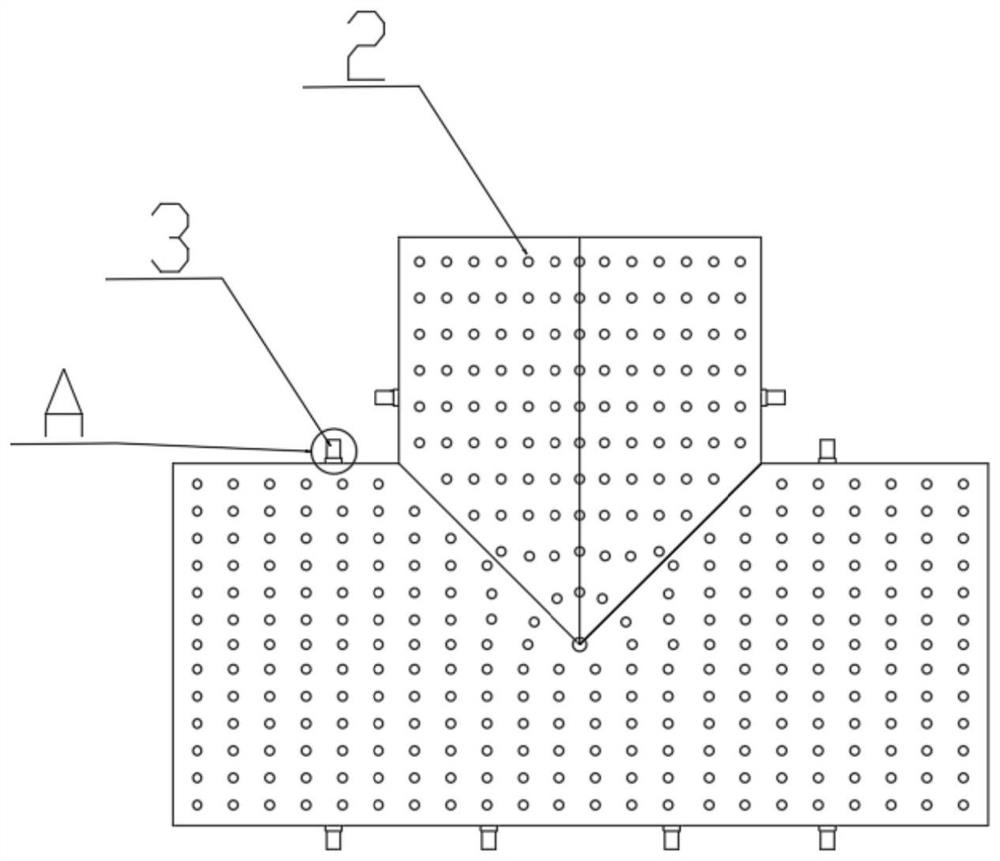

Super purification column for laboratory water purifier

ActiveCN104843907AEasy transferUniform wallMultistage water/sewage treatmentNon-contaminated water treatmentFilter effectLaboratory facility

The invention discloses a super purification column for a laboratory water purifier. The super purification column comprises an upper end cover (1), a lower end cover (2), a purification column body A (3) and a purification column body B (4), wherein the top end and bottom end of the purification column body B (4) are respectively welded in an annular groove b (6) and an annular groove d (8); micro-porous filters I (9) positioned in an annular groove a (5) and the annular groove b (6) are formed in the bottom surface of the upper end cover (1); a water inlet joint (10) communicated with the purification column body A (3) and a water outlet joint (11) communicated with the purification column body B (4) are formed in the upper end cover (1); and a water through hole (21) communicated with two cavities (13) is formed in the lower end cover (2). The super purification column disclosed by the invention has the beneficial effects that the purification column is compact in structure and convenient and rapid to mount, resin scrap leakage is avoided, and the filtering effect is good.

Owner:SICHUAN ULUPURE ULTRAPURE TECH

Internal circulation ball screw

ActiveUS9010210B2Increased durabilityUniform wallToothed gearingsPortable liftingBall screwScrew thread

An internal circulation ball screw includes a threaded shaft, a nut having a receiving space, a circulation member mounted to the receiving space and having a first circulation groove and a second circulation groove, and a plurality of rolling members running between the threaded shaft and the nut. The first circulation groove defines a first front section, a first rear section, and a first curved section communicating with the first front section and the first rear section separately. The second circulation groove defines a second front section, a second rear section, and a second curved section communicating with the second front section and the second rear section separately. The first and second curved sections define a predetermined included angle with respect to the threaded shaft radially. Therefore, the wall between the circulation channels is uniform to enhance the durability of the ball screw.

Owner:HIWIN TECH

Induction hardening tooling for outer shell of disc six-hole type cage constant velocity universal joint

InactiveCN105838850AReduce the temperatureUniform wallFurnace typesIncreasing energy efficiencyConstant-velocity jointConstant velocity

The invention discloses an induction hardening tooling for an outer shell of a disc six-hole type cage constant velocity universal joint. The induction hardening tooling comprises a base and a seal disc, wherein a straight shank is arranged at the bottom of the base; the seal disc is fixedly mounted on the base; a cavity is formed in the position, below the seal disc, of the base; a through hole is formed inside the straight shank; a counter bore is formed in the seal disc; a plurality of water spraying pillars are fixedly connected around the counter bore; blind holes are formed inside the plurality of water spraying pillars; and water spraying holes are formed in the inner side walls of the plurality of water spraying pillars. According to the induction hardening tooling, the purposes that the hole walls of six holes of a workpiece are effectively cooled, and the temperature is reduced are achieved; the edges of the six holes of the workpiece are prevented from generating cracks due to the high temperature penetrating actions of the inner cavity and six grooves when the workpiece is subjected to medium-frequency induction hardening; depths of hardening layers of the inner cavity and the six grooves of the workpiece are guaranteed to reach an effective range; the uniformity of clearances between the hole walls of the six holes and the water spraying pillars can be guaranteed through self centering; and the cooling water pressure and quantity received by the six holes of the workpiece can be guaranteed to be uniform.

Owner:芜湖佳先传动轴有限公司

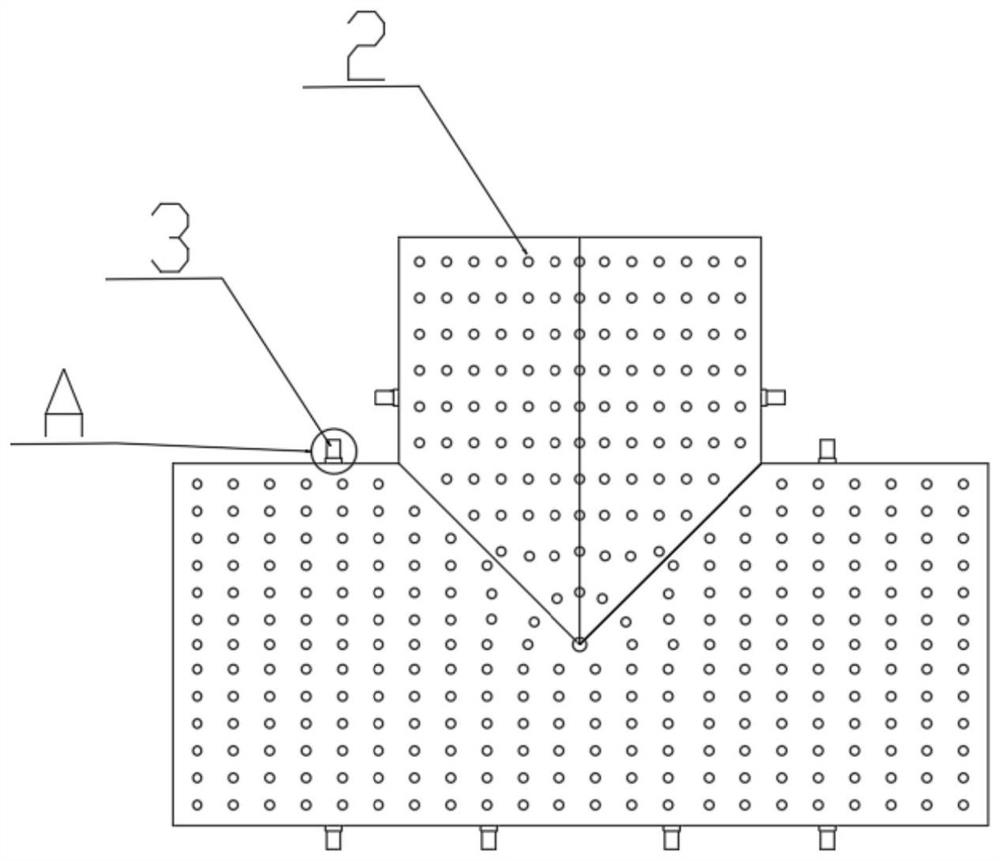

Tee extrusion method

The invention discloses a tee extrusion method. The tee extrusion method includes: clamping a tee workpiece in a main tube cavity enclosed by an upper die and a lower die, and using a support cylinder to push a support bar inside a tee branch-tube cavity into the tube wall of a branch tube open end of the tee workpiece; using a lateral cylinder to push an ejector pin into a main tube opening, and using a water injection system to inject normal pressure water into the tee workpiece through a liquid delivery tube cavity; continuing to insert the ejector pin into an inner cavity a main tube of the tee workpiece, using the water injection system to inject high pressure water into the tee workpiece before the copper tee main tube slightly deforms under water pressure, continuing using the lateral cylinder to push an ejector pin step to extrude in the tee direction so as to coordinate with the high pressure water in the tee workpiece to forcedly extend copper material of the tee main tube towards cavities of branch tubes, pulling back the support bar inside a support cavity till the branch tubes are formed; and stopping the water injection system from injecting the high pressure water, returning the ejector pin, and returning the upper tide to complete branch tube forming. By the tee extrusion method, finished tees are higher in forming quality and good in consistence, and yield of the finished tees is increased.

Owner:佛山市顺德区炖煌五金塑料实业有限公司

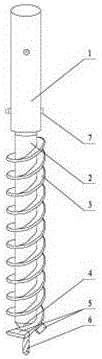

Soil drilling tool

The invention relates to the field of agricultural tools, in particular to a soil drilling tool, which includes a cylindrical cylinder, the end of which is a cone structure, and two Semicircular steel blades, the angle between the two semicircular steel blades is between 30-90°, and the angle between the two semicircular steel blades and the axis of the cylinder is consistent, the two semicircular steel blades There is no staggered area in the projection of the shaped steel blades on the horizontal plane; a handle is arranged horizontally on the top of the cylinder. The obtained soil drilling tool of the present invention, when drilling soil holes, rotate the handle on the tool and give a certain pressure, pull out the tool vertically after rotating two or three times, discard and stick on two semicircular steel blades of soil and continue to repeat the process. This process is especially suitable for drilling soils with high water content or paddy fields. Application of the invention provides a punching tool, and the walls of the drilled soil holes are smooth and uniform.

Owner:ZHEJIANG JIAXING AGRI SCI ACADEMY INST +1

An artificial blood vessel preparation device

Owner:WUHAN TEXTILE UNIV

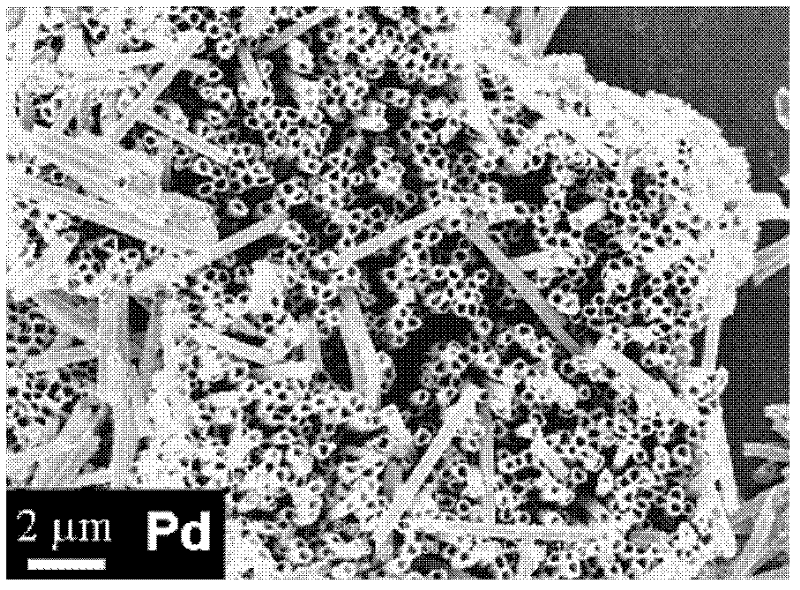

Preparation method of tubular metal catalyst

InactiveCN102407106APromote formationSlow down the spreadCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsElectrochemical windowSolvent

The invention discloses a preparation method of tubular metal catalyst comprising dissolving metal salt and sodium nitrate in dimethyl sulfoxide to obtain mixed solution; taking aluminum oxide porous template with nano path as template, conducting electrochemical deposition of the mixed solution at the nano path, and removing the template to obtain the tubular metal catalyst. The invention takes polar aprotic solvent dimethyl sulfoxide (DMSO) as solvent and electrolyte, since DMSO contains S group with weak absorption effect to metal surface, when metal is reduced to particles, DMSO moleculeswill absorb on the particle surface to inhibit the particle from growing large to make the prepared tubular metal catalyst wall thin and to increase the activated area. Furthermore, DMSO with relatively wide electrochemical window, high dielectric constant and high viscosity can ensure the prepared tubular metal catalyst wall is thin and made of particles, the length diameter ratio is high and the wall is uniform.

Owner:UNIV OF SCI & TECH OF CHINA

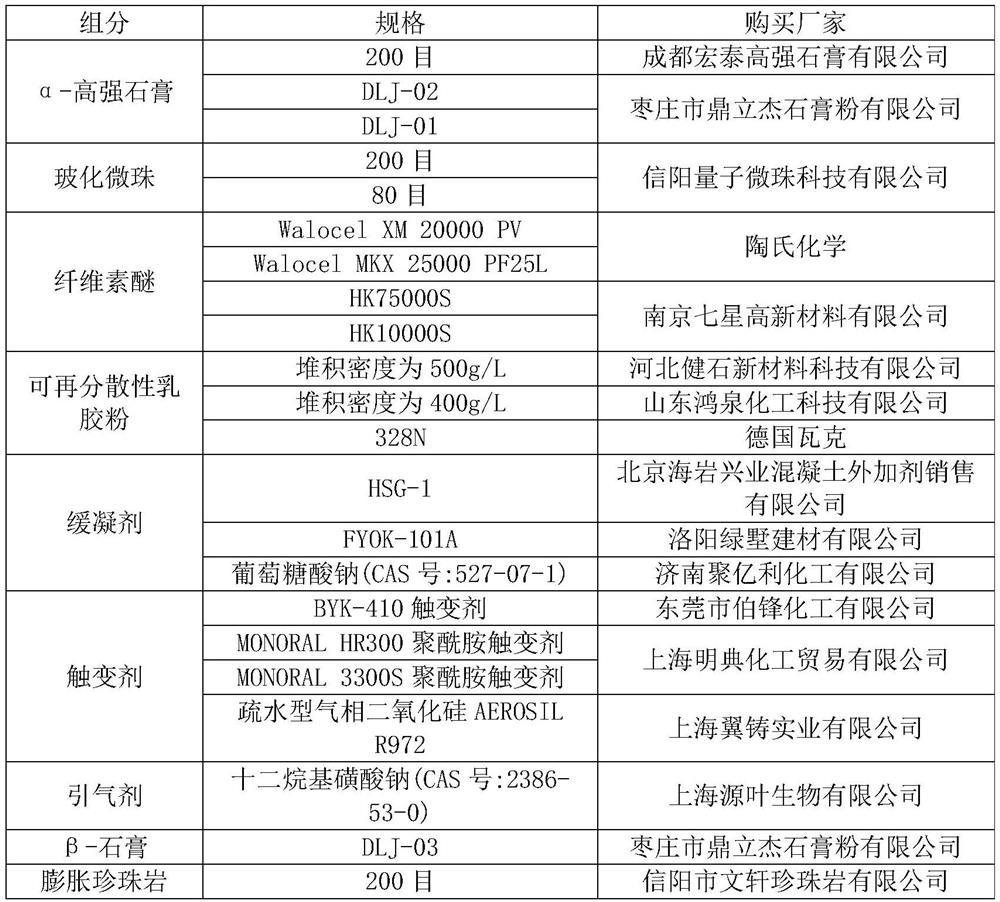

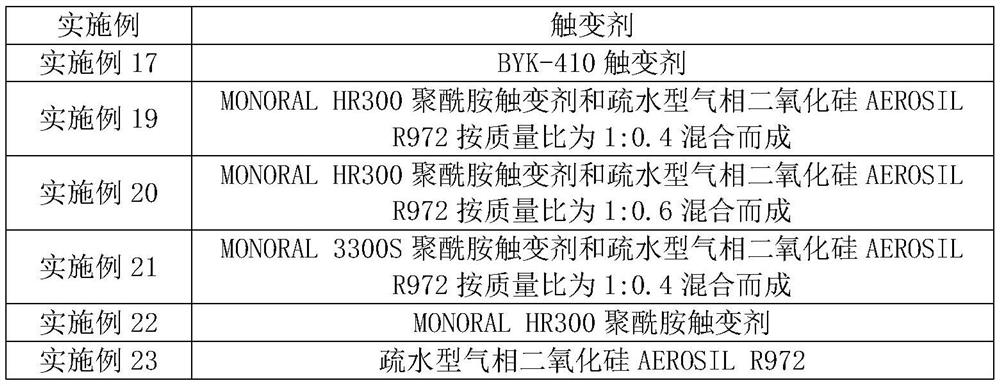

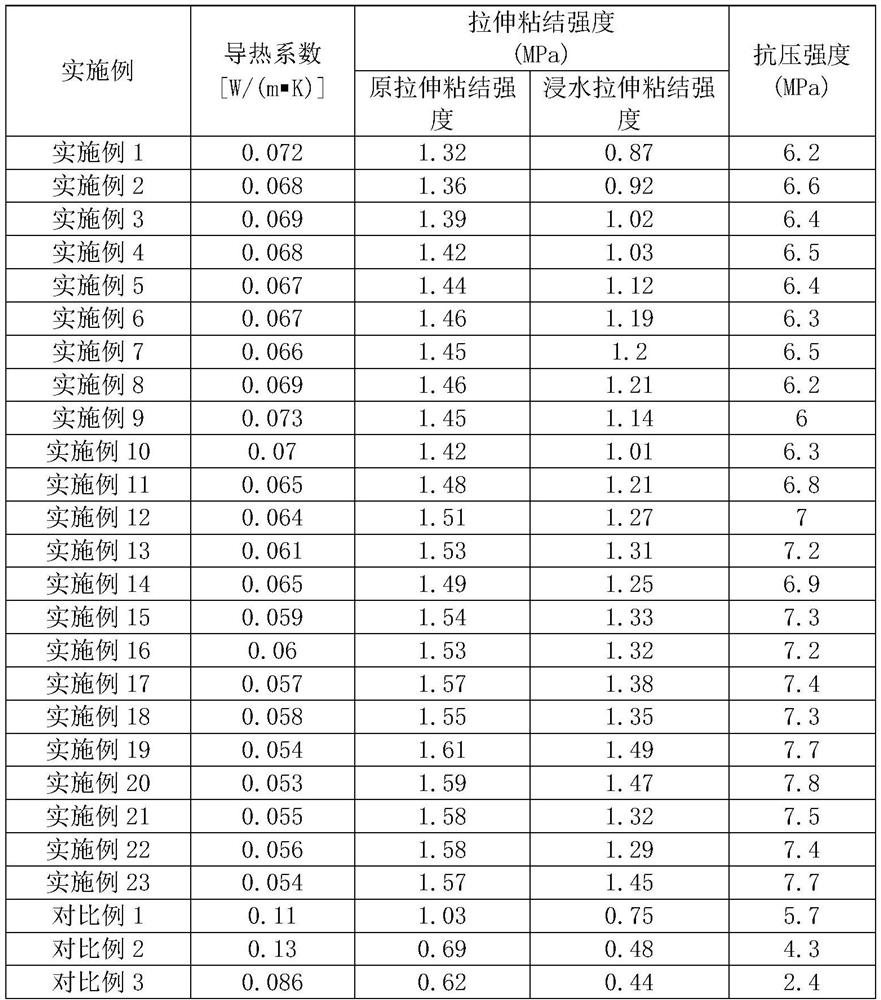

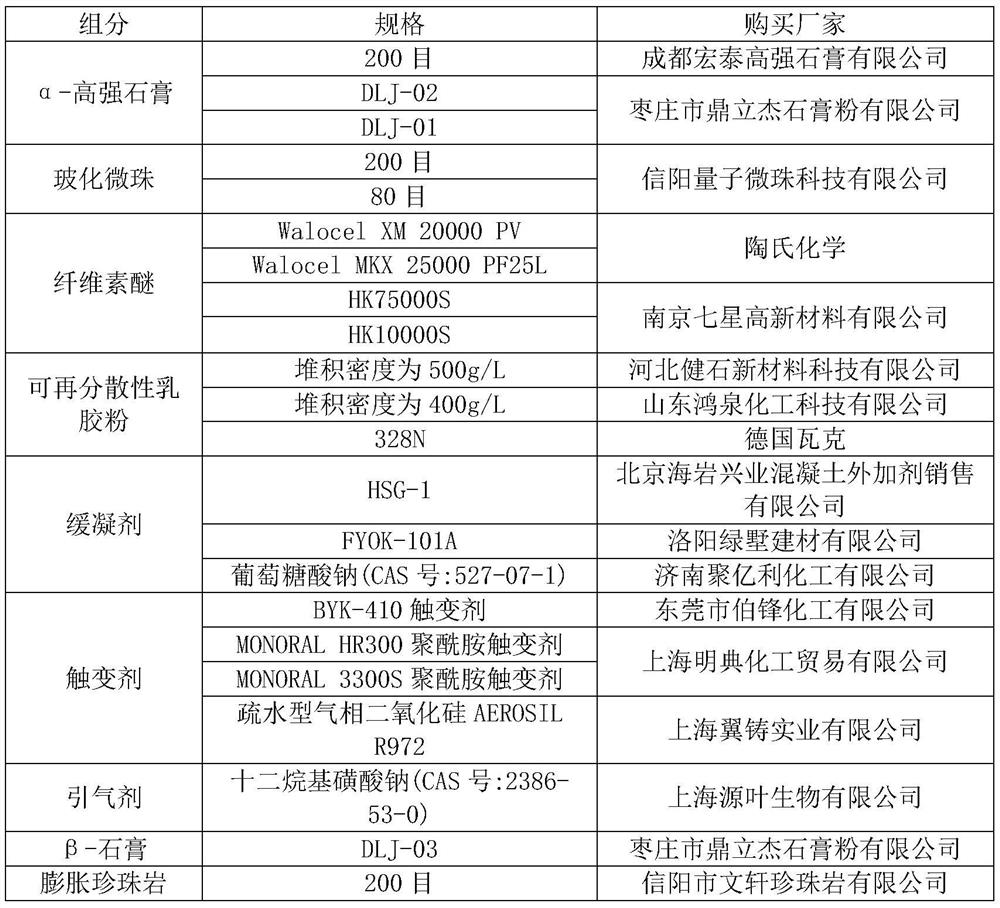

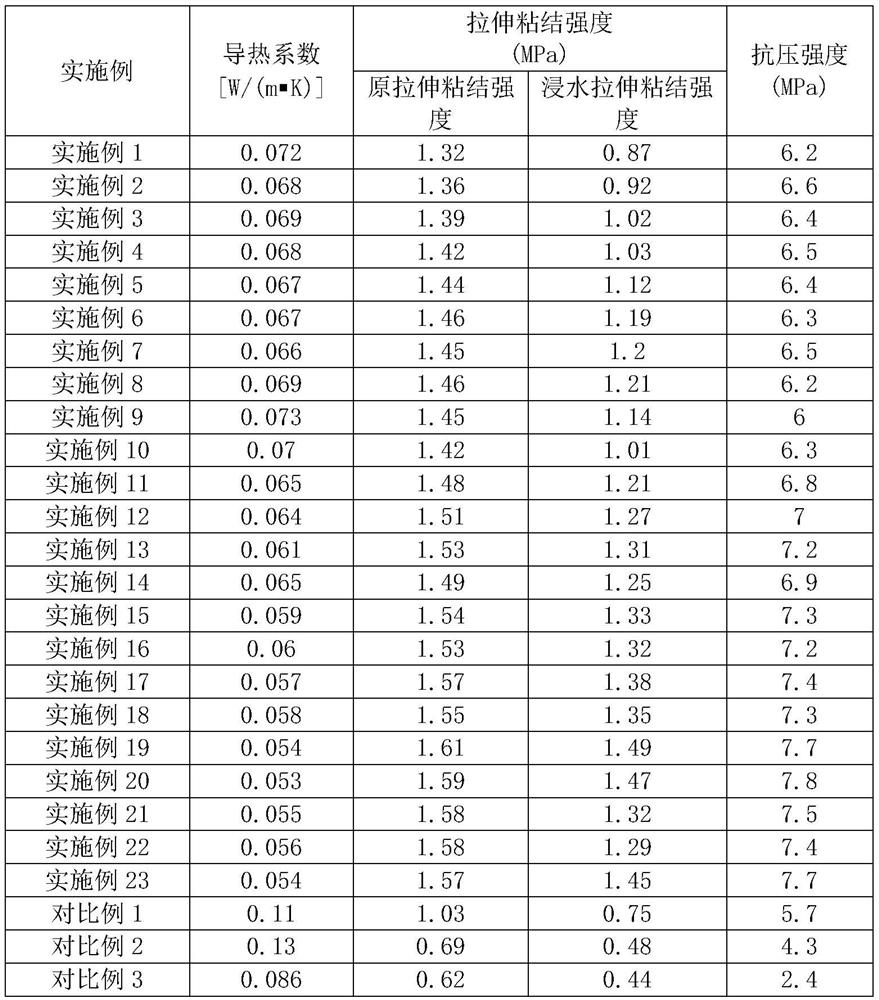

Novel high-strength gypsum thermal insulation putty and preparation method thereof

ActiveCN112646409AReduce construction proceduresGuarantee smooth constructionFilling pastesPolymer scienceThermal insulation

The invention relates to the field of wall decoration materials, in particular to novel high-strength gypsum thermal insulation putty and a preparation method thereof. The novel high-strength gypsum thermal insulation putty is prepared from the following raw materials in parts by weight: 50 to 70 parts of alpha-high-strength gypsum, 7 to 10 parts of vitrified micro beads, 0.1 to 0.3 part of cellulose ether, 1 to 2 parts of redispersible latex powder, 0.1 to 0.5 part of a retarder, 0.1 to 0.5 part of a thixotropic agent and 0.01 to 0.05 part of an air entraining agent, wherein the particle size of the vitrified micro beads is 180-200 meshes; and the cellulose ether comprises 2wt% of modified cellulose ether with the viscosity being 18000-22000mPa.s at the temperature of 20 DEG C. The novel high-strength gypsum thermal insulation putty can be used as gypsum thermal insulation mortar and can also be used as gypsum putty for leveling, additional gypsum putty leveling is not needed after construction, and the one-time construction thickness can reach 30 mm, so that construction procedures are reduced, construction is smooth, the constructed wall surface is uniform, scraping is fine and smooth, no color difference exists, and the novel high-strength gypsum thermal insulation putty has an excellent decoration effect; and the later-period heat preservation performance is not reduced, and the hollowing and cracking phenomena are avoided.

Owner:苏州大乘环保新材有限公司

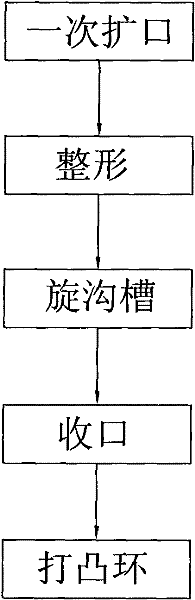

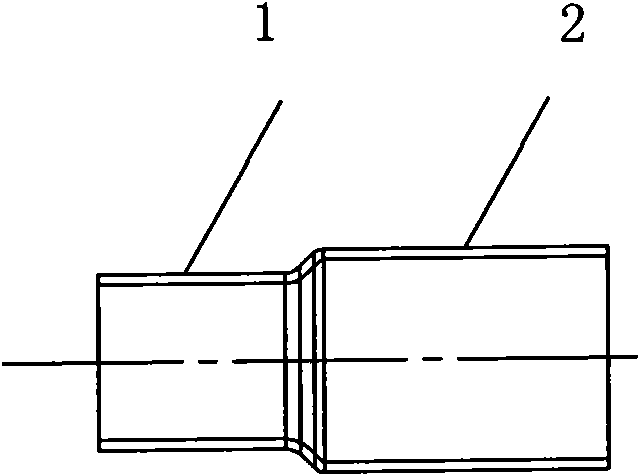

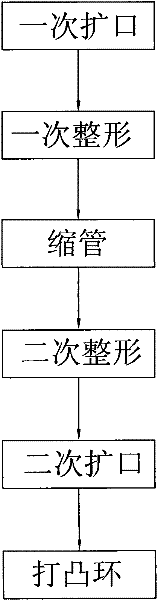

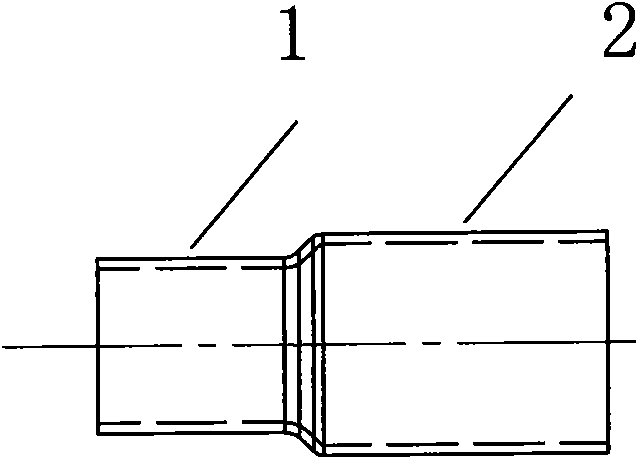

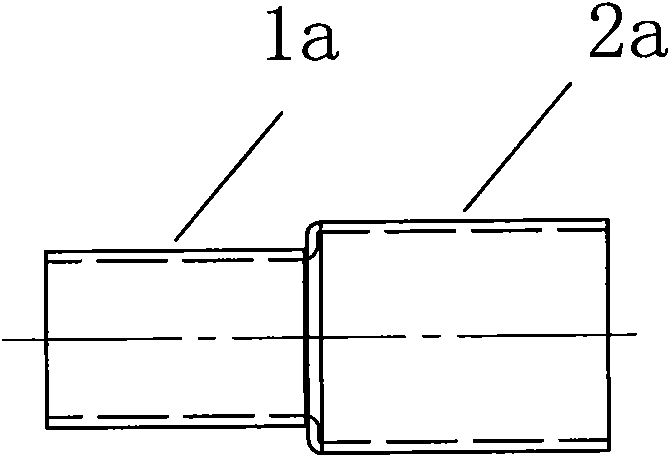

Production process of quick connecting pipe

The invention belongs to the technical field of connecting pipes and in particular relates to a production process of a quick connecting pipe; the production process comprises the following steps: 1) once flaring; 2) reshaping; 3) flute spinning; 4) binding off; 5) flange ring making; the product adopts an integral structure, the sealing surface is smooth, the sealing reliability is high, the appearance is artistic, the cost is low, the usage is convenient and reliable, and the service life is long; the quick connecting pipe is suitable for heaters and water heating pipe fittings.

Owner:ZHEJIANG GUANGTAO HEALTHY KITCHEN UTENSILS CO LTD

Molding process of header body

ActiveCN102773675BUniform sizeQuality improvementBoiler drums/headersFluid heatersIngotHeating furnace

The invention provides a molding process of a header body, comprising the following steps of manufacturing a circular pipe by using a steel ingot, adding into a heating furnace to be treated and carrying out turning machining to form a header main body pipe; determining the position of each branch pipe connector on the header main body pipe, and drilling a positioning hole; sending into the heating furnace to be heated and taking out; upwards putting a semicircular surface provided with a positioning hole and downwards putting the semicircular surface into water for cooling; then placing on a die and ejecting a convex bag at the position of the positioning hole in the pipe wall of the header main body pipe; drawing the convex bag by utilizing a chambering die core to form a pipe wall blank of the branch pipe connector, and finishing to form a connector pipe of the branch pipe connector; and carrying out annealing treatment on the header body, detecting, brushing paint and leaving from a factory. The pipe connector and the header body are connected to form an integral structure and are connected in a seamless manner so that the tightness is good; and with the adoption of a process for cooling one surface after heating, the header main body pipe does not deform and the whole size of a machined header body is uniform.

Owner:河南光大管业有限公司

An ultra-purification column of a laboratory water purifier

ActiveCN104843907BEasy transferUniform wallMultistage water/sewage treatmentNon-contaminated water treatmentFilter effectLaboratory facility

The invention discloses a super purification column for a laboratory water purifier. The super purification column comprises an upper end cover (1), a lower end cover (2), a purification column body A (3) and a purification column body B (4), wherein the top end and bottom end of the purification column body B (4) are respectively welded in an annular groove b (6) and an annular groove d (8); micro-porous filters I (9) positioned in an annular groove a (5) and the annular groove b (6) are formed in the bottom surface of the upper end cover (1); a water inlet joint (10) communicated with the purification column body A (3) and a water outlet joint (11) communicated with the purification column body B (4) are formed in the upper end cover (1); and a water through hole (21) communicated with two cavities (13) is formed in the lower end cover (2). The super purification column disclosed by the invention has the beneficial effects that the purification column is compact in structure and convenient and rapid to mount, resin scrap leakage is avoided, and the filtering effect is good.

Owner:SICHUAN ULUPURE ULTRAPURE TECH

Plastic vessel and preparation process thereof

The invention relates to a plastic vessel and a preparation process thereof. The plastic vessel comprises a barrel body, wherein the external circumference of the top surface of the barrel body is provided with a supporting conveying ring; the circumference of the barrel body is provided with two annular ribs. The plastic vessel is characterized in that the supporting conveying ring and the barrel body are of a split structure; the barrel body is formed by stretching the supporting conveying ring in a hot state and combining and tightening the supporting conveying ring with the top surface of the barrel body; the external circumference in the top surface area of the barrel body is provided with an annular groove; correspondingly, the internal circumference of the supporting conveying ring is provided with an annular convex body which is matched with the annular groove; the supporting conveying ring is inlaid and tightened at the external circumference of the top surface of the barrel body. The plastic vessel and preparation process has the advantages that the supporting conveying ring and the barrel body of the plastic vessel are of the split structure, the barrel wall of the barrel body is uniform, the material consumption is low and the material cost is reduced; furthermore, the preparation process of the plastic vessel is simple, so that the equipment investment cost and the material cost are lowered.

Owner:南通市华洋包装容器厂如皋分厂

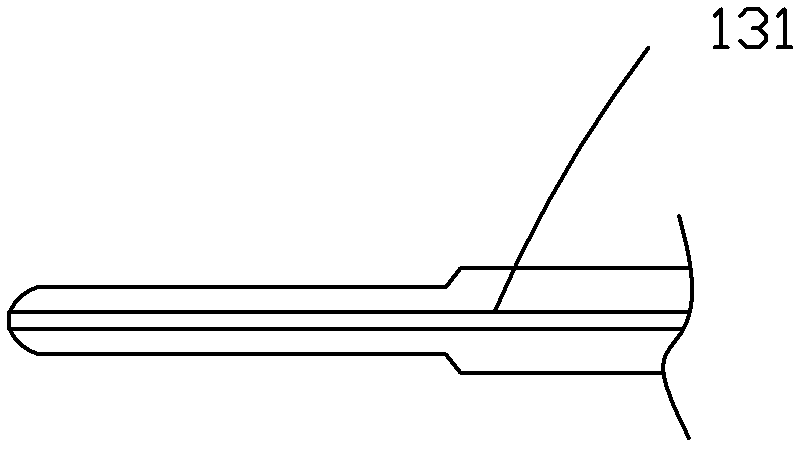

Waste discharging device for knife roll of rotary die-cutting machine

The invention discloses a waste discharging device for a knife roll of a rotary die-cutting machine. The waste discharging device comprises a cutting die and movable shaft shoulders arranged at the ends of the cutting die. An inner cavity of the cutting die is hollow, the cavity wall of the cutting die is uniform, and the inner cavity of the cutting die is filled with an elastic component. A special-shaped ejector pin is arranged on the upper portion of the elastic component. The special-shaped ejector pin makes direct contact with the elastic component. The special-shaped ejector pin is composed of two parts which are a pin body and a base. The pin body is fixedly connected to the upper portion of the base. One part of the pin body stretches out of the surface of the cutting die, and the other part of the pin body stretches into the inner cavity of the cutting die. The pin body is provided with a plurality of arc surfaces, and every two arc surfaces are symmetric. The base is round. An indentation is formed in the base. The shape of the indentation is matched with the shape of the lower portion of the pin body. The waste discharging device for the knife roll of the rotary die-cutting machine is simple in structure, convenient to use, high in practicality, suitable for various products with small shapes and small gaps, and capable of discharging waste completely, improving production efficiency and reducing production cost.

Owner:坂崎雕刻模具(昆山)有限公司

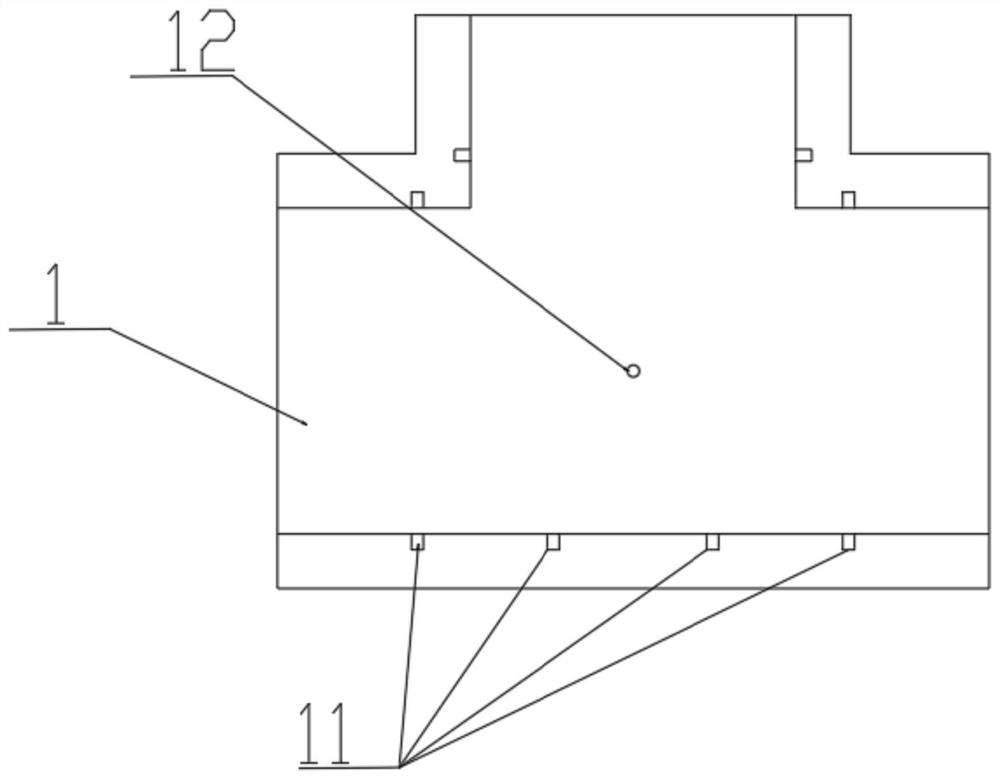

Steel-plastic composite pipe framework positioning device and method without secondary machining

ActiveCN112238567APrecise positioningNo risk of leakageTubular articlesPipe fittingStructural engineering

The invention discloses a steel-plastic composite pipe framework positioning device and method without secondary machining. The steel-plastic composite pipe framework positioning device comprises a mold, a framework body and plastic positioning nails; the mold is detachably divided into an upper part and a lower part, and a mold cavity matched with the containing framework body is formed in the mold; placing grooves are formed in the periphery of the mold cavity; support nuts are fixedly arranged on the surface of the framework body; and the plastic positioning nails are fixed on the support nuts. When the framework body is placed in the mold cavity, the plastic positioning nails are inserted into the placing grooves to realize positioning of the framework body, and the framework body is jacked up through the support nuts, so that the framework body is suspended relative to the mold, and the uniform distance between the framework body and the mold cavity wall of the mold is ensured. Bymeans of the device, a steel framework can be effectively positioned, meanwhile, when the steel-plastic composite pipe is completed, only redundant plastic positioning nails need to be cut off, secondary plugging machining is not needed, and it is guaranteed that the risk of leakage of the pipe due to plugging quality is avoided.

Owner:安源管道实业股份有限公司

A rotary die cutting machine knife roller waste discharge device

The invention discloses a waste discharging device for a knife roll of a rotary die-cutting machine. The waste discharging device comprises a cutting die and movable shaft shoulders arranged at the ends of the cutting die. An inner cavity of the cutting die is hollow, the cavity wall of the cutting die is uniform, and the inner cavity of the cutting die is filled with an elastic component. A special-shaped ejector pin is arranged on the upper portion of the elastic component. The special-shaped ejector pin makes direct contact with the elastic component. The special-shaped ejector pin is composed of two parts which are a pin body and a base. The pin body is fixedly connected to the upper portion of the base. One part of the pin body stretches out of the surface of the cutting die, and the other part of the pin body stretches into the inner cavity of the cutting die. The pin body is provided with a plurality of arc surfaces, and every two arc surfaces are symmetric. The base is round. An indentation is formed in the base. The shape of the indentation is matched with the shape of the lower portion of the pin body. The waste discharging device for the knife roll of the rotary die-cutting machine is simple in structure, convenient to use, high in practicality, suitable for various products with small shapes and small gaps, and capable of discharging waste completely, improving production efficiency and reducing production cost.

Owner:坂崎雕刻模具(昆山)有限公司

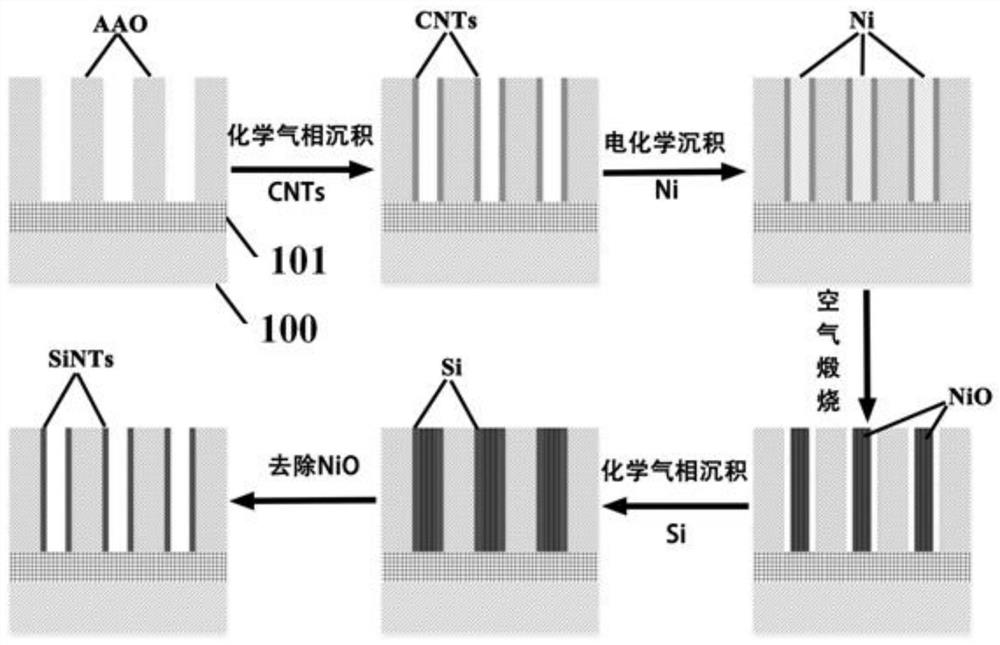

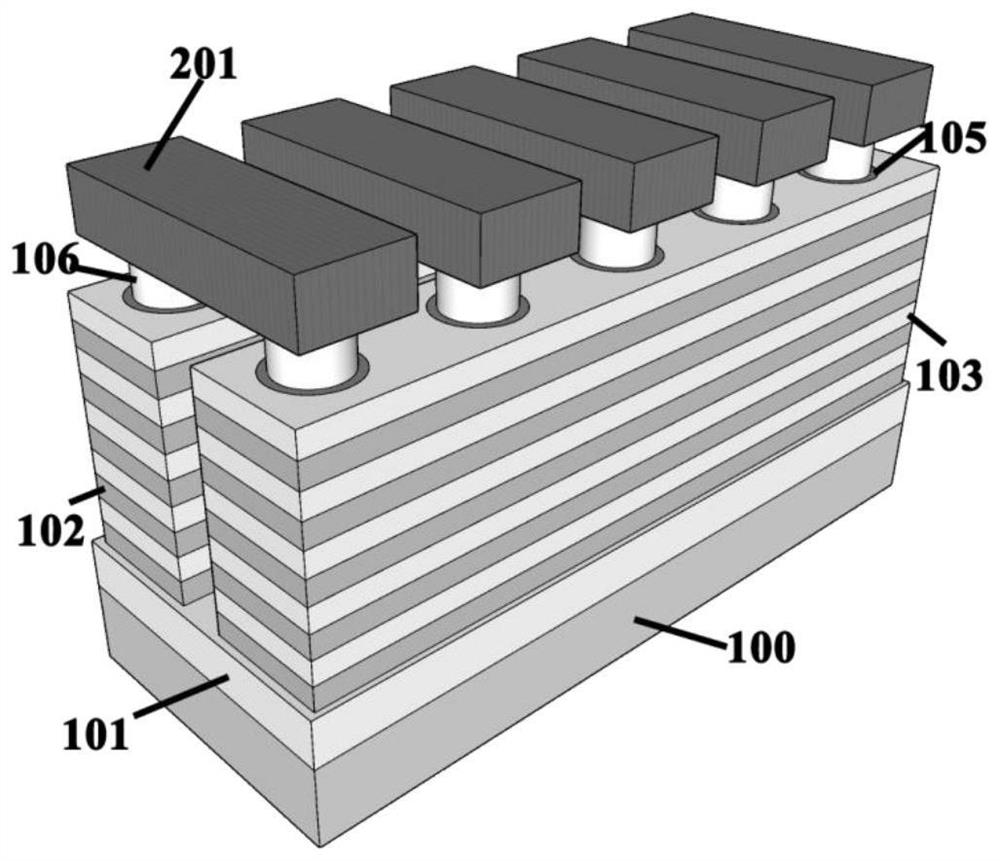

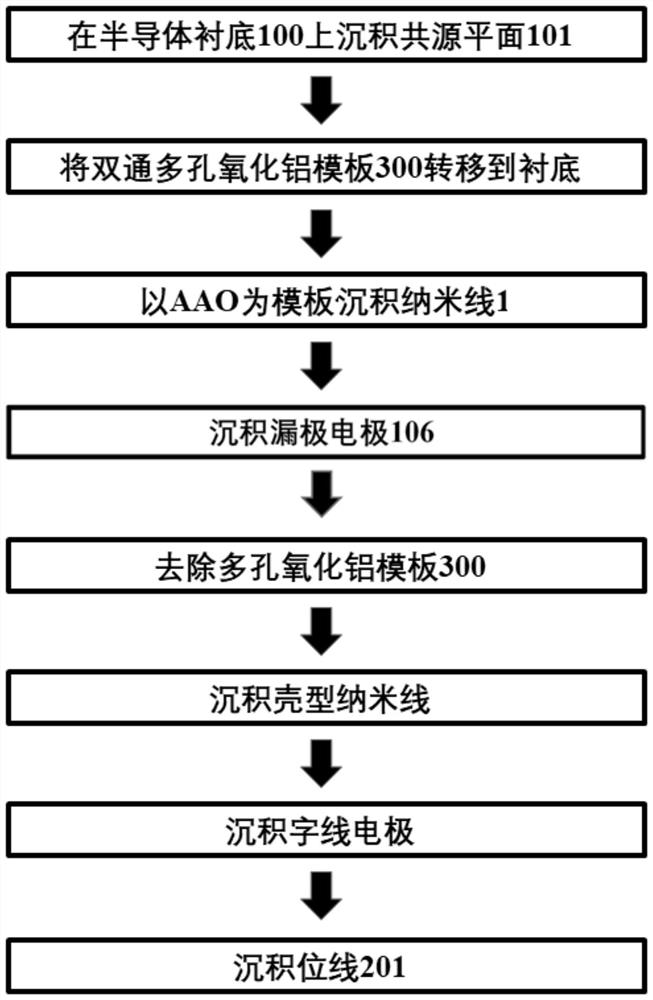

3d NAND flash memory device and its preparation method of coated silicon nanotube

ActiveCN110197829BReduce productionSimple processSolid-state devicesNanotechnologyManufacturing cost reductionNanowire

The invention discloses a 3D NAND flash memory device and a method for preparing the coated silicon nanotube, belonging to the field of 3D NAND flash memory. The preparation method of the coated silicon nanotube The storage device uses carbon nanotubes as templates, deposits a Ni layer in the inner cavity of the carbon nanotubes, then calcines the carbon nanotubes to remove the Ni layer and oxidizes the Ni layer to obtain NiO nanowires, and then uses chemical Vapor deposition deposits a Si layer outside the NiO nanowires, and finally removes the NiO nanowires to obtain coated silicon nanotubes. The 3D NAND flash memory device is composed of coated nanotubes as NAND strings, which can effectively simplify the device structure, reduce the complex manufacturing process steps in the original device manufacturing process, simplify the preparation process, and have a positive effect on reducing manufacturing costs. At the same time, the use of the multi-step template replication method makes the diameter and wall of the prepared nanotube more uniform, and the thickness of the tube wall is more controllable.

Owner:HUAZHONG UNIV OF SCI & TECH

A small cotton bag clamping mechanism

Owner:台州市洺祥纺织股份有限公司

Method for preparing Nano tube of zirconium dioxide

InactiveCN100500576CSimple processEasy to operateNanostructure manufactureZirconium oxidesSolventZirconium dioxide

Owner:HEBEI UNIV OF TECH

A steel-plastic composite pipe skeleton positioning device and method without secondary processing

The invention discloses a steel-plastic composite pipe frame positioning device and method without secondary processing, including a mold, a frame body, and plastic positioning nails; the detachable mold is divided into upper and lower parts; The mold cavity that is suitable for the body; there is a placement groove around the mold cavity; the support nut is fixed on the surface of the skeleton body; the plastic positioning nail is fixed on the support nut; when the skeleton body is placed in the mold cavity, the plastic positioning nail is inserted and placed The groove realizes the positioning of the skeleton body, and the skeleton body is lifted up by the support nut, so that the skeleton body is suspended relative to the mold, so as to ensure that the distance between the skeleton body and the cavity wall of the mold is even. The device provided by the invention can realize the effective positioning of the steel skeleton, and at the same time, when the steel-plastic composite pipe is completed, only the redundant plastic positioning nails need to be cut off, and no secondary sealing process is required, which ensures that the pipe fittings will not be blocked due to Risk of leakage due to blockage.

Owner:安源管道实业股份有限公司

a hole reaming machine

ActiveCN104492988BSave energyIncrease productivityShaping toolsMetal-working feeding devicesEngineeringSmall footprint

The invention discloses a reamer. The reamer comprises a rack, wherein the rack is provided with an electromagnetic heating device and a reaming device which are arranged from front to back in sequence; the electromagnetic heating device comprises an electromagnetic heating coil; the reaming device comprises a reaming hole driven by a first power device; the rack is provided with a poking plate feeding device; the poking plate feeding device comprises a rotating shaft connected with a second power device; the rotating shaft is transversely arranged on the rack; the two ends of the rotating shaft are fixedly provided with circular poking plates; the peripheral parts of the poking plates are provided with at least three feeding fork entries for conveying metal pipes; poking plates are formed between adjacent feeding fork entries and can rotate to the positions, corresponding to the electromagnetic heating coil and a reaming head, on every two adjacent feeding fork entries respectively. The reamer has the advantages of high production efficiency, small floor area and low power consumption.

Owner:高密天一机械科技有限公司

Production technology for quick coupling tube

Owner:ZHEJIANG GUANGTAO HEALTHY KITCHEN UTENSILS CO LTD

A kind of high-strength gypsum thermal insulation putty and its preparation method

ActiveCN112646409BReduce construction proceduresGuarantee smooth constructionFilling pastesPolymer scienceThermal insulation

The application relates to the field of wall decoration materials, in particular to a novel high-strength gypsum thermal insulation putty and a preparation method thereof. A new type of high-strength gypsum thermal insulation putty, which includes the following preparation raw materials in parts by weight: 50-70 parts of α-high-strength gypsum, 7-10 parts of vitrified microbeads, 0.1-0.3 parts of cellulose ether, and 1 part of redispersible latex powder -2 parts, 0.1-0.5 parts of retarder, 0.1-0.5 parts of thixotropic agent, 0.01-0.05 parts of air-entraining agent; the particle size of the vitrified microbeads is 180-200 mesh; the cellulose ether includes 2wt %, Modified cellulose ether with a viscosity of 18000-22000mPa.s at 20°C. The new high-strength gypsum thermal insulation putty provided by this application can be used as gypsum thermal insulation mortar, and can also be used as gypsum putty for leveling. After construction, no additional gypsum putty is required for leveling. The thickness of one construction can reach 30mm, which reduces the construction process and smooth construction. Uniform, fine batch scraping, no color difference, excellent decorative effect, and no loss of thermal insulation performance in the later stage, no hollowing and cracking.

Owner:苏州大乘环保新材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com